#semi-crystalline plastics

Text

Causes and countermeasures for deformation of injection molded parts - 4

Serial No. 4 (Friends who are interested can follow Gud Mold and check out previous series.)

4. Factors affecting deformation

1. Plastic raw materials

Characteristics of plastic raw materials have a huge impact on deformation of molded products. Different raw materials have different molecular structures and intermolecular forces, which manifest themselves in different fluidity, orientation…

View On WordPress

#amorphous plastics#Causes and countermeasures for deformation of injection molded parts#crystalline materials#crystalline plastics#Deformation of Injection Molded Parts#injection molded parts#injection molding factories#injection molding production#mechanical transmission products#mold factories#molded products#pressure-holding#semi-crystalline materials#semi-crystalline plastics#thermosetting plastics

0 notes

Text

Simulacrum

Jace looked at his handwork.

Hours upon hours spent learning the deep fundamentals of biotech. Three full years of diligent academia and artistic work, all purpose to this final life changing goal.

A body was laid out before him. It shown in the warm light of his basement. The place had initially been dark and damp, then bright and clinical when Jace had first started this little hobby of his. At some point mad scientist wasn’t the right vibe though and the lab had shifted to what it was today.

He hadn’t actually been working with anything organic, so cold steel and easily cleaned tile had been replaced with soft carpet and colorful wallpaper. Jace sat in an old comfy couch, perched in a strange way that he personally found very comfortable.

Jace knew he was a crazy person, but he would prefer to be a cozy crazy person.

His work was just about done, the last pieces of sleek interchangeable parts slotted in. Each had been designed by Jace, replicating perfectly the motions and physics of the human body. Every piece easy to remove and edit, down to the precious orb sat snug in the cranium.

That piece had ironically been the easiest for him to create. It was the central operating computer of the simulacrum, an exact duplicate of a brain. It was crystalline and bright, its electrochemistry identical in form to that of its flesh counterpart.

Memory replication had been a widespread technology for years. It was the cornerstone of modern entertainment as well as modern education. It had been what had gotten Jace to an education level that would’ve taken decades just 30 years ago. Information recorded directly from a brain and transferred to anyone with an implant.

It was definitely dystopian, that strange tech. It had been abused for ages, corroding personality with very foreign thought. Jace had only gotten his implant recently, disturbed by news stories of celebrities’ memories having superimposed personality traits into the minds of their loving fans. Stories of billionaires trying to download their minds into employees, with a horrifying amount of success. Now though, with numerous studies and societal changes revolving around such things, Jace had taken to his fixation. Had downloaded years of academic knowledge directly into his skull and had only ever picked up the lightest tastes and preferences from his “professors”.

Now he liked tea instead of coffee. Sipping it now though was nice, calming his nerves as he checked and double checked his various prototyped parts. A joint had a minor malfunction and he had set his printer to quickly create another. It would’ve caused nearly a smallest fraction of improper articulation, but the process was easy and fast to replace it. A minute was nothing even as his nerves rose waiting. Plus he’d hate to wake up with a cramp.

The crystalline orb pulsed, connected to his implant. Devouring his experiences and recording them in its semi-metal quartz.

Jace wondered if his obsessing over the thing was less so about his perfectionism rather than that nagging existential fear. He’d gone into this project with so much excitement, yet that fear joined him on every step.

He’d need to record his entire soul into this thing, down to the last split second. He didn’t want to the one fucked over when it came down to it.

Jace had spent every moment ensuring that he would avoid abuse in this situation. Every part had been memorized and adapted to be built on a non-specialized printer. Each piece was easily replaceable without anything more complex than a screwdriver.

As Jace clicked the replacement joint back into place, his heart raced. All systems a go.

The body wasn’t much to look at.

It was humanoid, built in equal part of plasticine metal and metallic plastic. Sciency bullshit that was cheap and top of the line. It followed the form of a person, yet it was clearly not a person. Internal metallic “organs” were exposed and there was only a vaguely human outer shell.

It still resembled Jace. It had the same shape of his face, although now clade in a dull flexible metal. Across it glowed tiny dots, beginning to flare up as he set the machine to activate.

These dots scattered across the whole of the simulacrum, flecked like freckles across what could barely pass as skin. To be fair though, it wasn’t meant to be skin.

Jace tapped the final button and the lights seemed to multiply, swarming like flies across the body. Weaving together in every color before they arranged themselves into a clear coating across the body. Blues, yellows and reds merging and melding into a tan actually frecked skin.

It flowed across the entire body until Jace could finally recognise it. Various scars and moles placed at the exact places he remembered in the mirror. His tattoos placed in their proper places and replicated properly. That was especially important, that art held a place in his identity that was beyond important.

It was bizarre seeing the things he’d spent painful hours and money on be so simply recreated. It was more bizarre to feel so in awe of it, a feeling that was likely very narcissistic considering he was in awe of his own work. These patterns and images that were indicative of his soul now shared with this other body.

He noted that it was probably healthy to feel good about it considering what was inevitably coming. He’d have to be fine with sharing such things past this point.

The orb gave one last flash before the solid light projections finally covered it, replacing the dull metal in Jace’s face. Jace closed his eyes as it happened, trying to still his thoughts even as he felt his implant still whirring away in his mind. It rose with palpable last minute scans, tearing through his thoughts over and over due to the thousand in-built checks that Jace had thought were so necessary weeks ago.

Jace wondered if he would open his eyes and still be in this body or if he’d wake up on the table. His heart pounded with fear and excitement, half hoping for either. The adrenaline was addicting as he challenged every notion of scifi horror to try to accept being the clone if that was the way the coin flipped. He was doing a solid attempt, although the anticipation didn’t help.

He waited for what felt like minutes before the firing stopped and a mental beep rang through his head. DONE

His fingers creesed around his shirt, still feeling the same fabric he had been clenching. He could still feel the ground under his boots, standing as he braced himself. He heard himself breath out the breath he’d been holding, shaky and relieved.

He heard another breath in turn, this one breathing in. It was hoarse and shaky, underlying with a tint of anxious energy.

Jace opened his eyes to see their counterparts staring back. Bright green reflecting his own face back at him, pupils dilated with simulated adrenaline. The program having replicated the exact way that his hair fell onto the simulacrum face, ginger strands lazily standing back with product. The same beard that he had kept for ages, short and well trimmed.

A smile across his duplicate’s face that he couldn’t resist returning, even as his heart pounded.

“Guess I’m the copy huh” his twin joked, his tone fusing elation and dread into one impossible mix. He pulled himself up from his position on the table, proppig himself to face his original self in all his naked glory.

Jace tried not to stare at their quite brillant package, sitting down on the armchair.

“Seems like it” he replied, shrugging. “Feel weird?”

“Obviously”, his twin already feeling out his hands. The hard light composing his outer body perfectly simulated Jace’s muscles, the sinew bending and warping just like it should. Individual hairs on his arms reacting to the motion as if they were real, glinting in the light and shifting as the simulacrum man passed his hands over them.

The android flexed his arm a few times before looking back at Jace. “All systems appear operational, running at 100% optimum”. He paused before laughing. “I guess I had ensured that before I downloaded myself didn’t I”

Jace laughed too, worry for the other quelled as the android seemed to enjoy tensing and untensing his new body. “Yup, seems like you like it”

“I feel weirdly normal” his android said, even as he practiced turning on and off the hard light of his hand. It would flash and there would be his internal skeleton, metallic fingers and joints showing every true mechanic working of the motion. It would flash again and the warm skin would appear again, as if the hand had always been human. Jace was transfixed.

The android went on. “Kind of an ego boost feeling how identical this is to the old works, we did a bangup job”. He motioned to Jace “Does the meat suit still feel good, didn’t fry your brain?”

“Feels fine I think, might be getting a migraine” He admitted, rubbing his temple. It hadn’t hurt, but those scans felt like they’d pickled his brain. Maybe he’d put too many backup checks in.

His twin frowned, shifting to move closer to Jace as if to inspect him. It unfortunately moved his very naked body closer to him, Jace unable to avert his gaze from the dick now flopped up in front of him. It was big and Jace knew that. Hell he had been proud of that since he was younger, pleasing many boys and girls he’d brought home.

It shouldn’t be making his thoughts turn to even more putty. He’d seen it his whole life, jacked off and fucked a million times using it. Now though as his android self moved his head downwards to look at his implant’s external connection, he was forced to look down at it.

He felt his own dick harden awkwardly under his jeans staing at it. The insidious want that this had all been for playing over and over in his head as the android prodded at the implant.

The simulacrum asked him a question and he murmured an affirmative, extremely distracted. Jace had always wondered what he felt like. Well, he’d more so imagined over and over in his head scenarios in which he could feel his cock. Tasting it on his throat and feeling the way it grew and grew.

His brain was filled with enough dirty shit that even the slight migraine faded away. His android self would mutter something and he would resist the need to rub away the growing pressure in his jeans

“Are you even listening to me?” his duplicate finally said, clearly annoyed.

He clooked up at the simulated face over him. He was about to fake a reason about his migraine before that intelligent gaze shifted over the bulge in his jeans. There was an understanding in his eyes, some fire behind them.

The android slowly pushed his head down on top of his growing dick, forcing Jace to switch from his fantasies right to sucking his twin’s dick. It felt real, his tongue already beginning to work in practiced motions as he felt it.

His twin moaned and before long they were stripping off Jace’s clothes as he continued to fight to finish his duplicate. It felt like a challenge, Jace resisting his duplicate from removing his shirt in between watching the double resist peaking over that final edge. Every now and then the duplicate’s eyes would roll and he’d still as Jace made another step to the finish line.

“You piece of shit” his duplicate moaned as he gave up on pushing Jace’s jeans off with his feet, trying to get a view of Jace’s own identical cock. Jace punished him by increasing the motion of the blowjob, the simulacrum tensing his own body as he tried with every fiber of his being to stay on the ride.

He failed, to Jace’s satisfaction. The synthetic dick burst with holographic cum, warm and wet inside his mouth for a few seconds before fizzing away. It felt like static in his mouth as some sli down his mouth before popping out of existence.

Jace eased his mouth off of the pole with a sassy grin. “Just needed to check if you are actually working as intended”

“I’m just your glorified sexbot” his twin said, looking down at him with a very satisfied smirk.

“Just the first” Jace smirked back. “Now that I know the prototype is perfect”

His twin rolled his eyes, before pushing away. He left his original to sit there unrelieved with his jeans still half on. Jace sat there dazed as the android typed away at their printer.

Jace sent a confused look at the android as he finished his task and parked his body back down before him. The android with his hands finally free pushed his jeans off hgis body, one of his hands clasping his dick firmly. He looked up into Jace’s eyes, an equal competitive edge alive and violent in them.

He stroked Jace’s cock and motioned with his head towards the printer. It was already active, lacing metal and plastic into an object. A foot was already forming after just a minute of printing.

“Think you can hold off on cumming before the second comes around” his twin challenged, before pushing him down.

“Bet” he snarled, already in motion. Enjoying the way his motions were mimicked, and knowing he could hold out longer.

It would be more fun with another person anyways.

——————————————————————————

Jace 4 was produced upon the third round of fucking a few hours ago. He had all of the original Jace’s memories up to that point, feeling like he’d just been fucked to an inch of his life before being inserted into a completely fresh body to continue having sex. That's actually how he sort of came to be, the original Jace having wanted to both pass out from exhaustion and keep going.

Jace 4 had come into the world fucking and then had fell into simulated sleep. They’d all woken up at about the same times, four identical men pushing off of the bed that was stained with only the original Jace’s fluids. One of them would have to clean that.

They’d dressed themselves, picking from the many identical sets of clothing. Jace had prepared for this situation, and so Jace four got fresh new boots and clothes just like the ones he typically wore. Or at least he should’ve, but he’d taken Jace’s old clothes.

They were his clothes, to be fair. Jace prime had just jokingly whined then bragged about his new clothes, mockingly showing off his new boots to the other’s who wore the exact same outfit. They all gave identical compliments.

The Jaces found themselves hilarious. They all held themselves back from falling back into the same cycle of lust. The original Jace ate breakfast, his implant cycling the feeling to all of them. Jace 4 could feel the way the eggs and bacon tasted, a part of him frustrated he hadn’t used such a synchrony feature before. The original Jace picked up on his frustrated selves’ realization and laughed.

“Guess we’ll use that tonight” he said between bites of potato, the flavor coating all of their tongues. “Didn’t think the connection would properly hold”

They hadn’t. It was meant to relay a lifetime’s worth of knowledge to an unrestrained computer. It had been likely to stop relaying once the pesky hardlight had activated, the substance muffling and impermeable.

Jace 4 tested a suspicion and rubbed his cock as the man swallowed another bite. He smiled when the man choked, feeling Jace 4’s fingers.

The other Jaces shot him a glance as they too mved their hands to their dicks, stroking it. Jace four could feel them all paradoxically on his cock even as he palmed it himself. The original groaned, pretending to be annoyed by their collective horniness even as he totally wanted it too. Jace 4 knew because Jace 4 was him.

It wasn’t long before they’d given their loving original a wet spot on his jeans, chuckling amongst each other over the perks of their self cleaning.

The printer stood there tauntingly. Each Jace thinking to themselves on how they could next abuse it. The original Jace knowing they’d probably have to break it eventually, lest the house get completely overrun.

There’d be time between then and now though. Jace had prepared a lot for this moment. The house could comfortably handle a LOT of people.

It was bound to be an exciting week.

#copy#identical#clones#android#my writing#First time using mage space#Don’t look too close at the pic

14 notes

·

View notes

Text

POM Sheets Manufacturers in Mumbai

POM Sheets plastic is a semi-crystalline thermoplastic with high mechanical strength and rigidity. Polyacetal/Delrin rods offer a unique combination of properties not available with metals or other plastics. Due to its low moisture absorption rate, Acetal's physical properties remain constant in every environment.

0 notes

Text

Injection Molded Plastics Market Is on Track To Hitting USD 409.2 Billion by 2030

The word "injection molding" covers a wide range of processes, including the molding of metals, ceramics, polymers, and several other substances. Plastics and injection molding are frequently used together. Plastics can also be formed using a variety of different methods, such as extrusion and blow molding. But the most used method of forming plastics worldwide is injection molding.

It is predicted that the need for injection molded plastics would be driven by the rising demand for plastic components from a variety of end-use sectors, including consumer goods and electronics, packaging, and automotive and medical devices.

In addition, injection molding developments are also being focused on by businesses to reduce the rate of defective manufacturing, which has had a substantial effect on the demand for injection-molded plastic components globally. Thus, the injection molded plastics market is set to reach USD 409.2 billion by 2030, according to P&S Intelligence.

Application in Packaging Contributes Majority of Revenue

With a market share of 30% across all applications, packaging will continue to rule the market; as a result, the expansion of the packaging industry will be a major market driver.

The gradual transition away from glass and metals in the consumer packaging market in favor of polymers is driven by the latter's reduced space need, decreasing weight, durability, adaptability, and cost-effectiveness.

Moreover, polypropylene holds the majority of the market share, at about 40%, as a result of its lightweight properties, moisture resistance, shock resistance, cheap cost, high molding capacity, and outstanding compatibility with food applications, particularly in terms of package safety.

Furthermore, it may be used in injection molding to create components and goods of all different sizes and forms. Due to its semi-crystalline structure and strong flexural strength, polypropylene also has this property.

Demand for Polymers Is Growing in Automotive Applications

One of the end markets for injection-molded plastics with the quickest growth is the automobile sector. The need for such materials would be boosted throughout the projected period by the expansion of the Asian automotive market, notably in China and India.

Thermoplastic elastomers and other injection-molded polymers are discovering new uses in the vehicle sector because of technological advancements in the production of automotive components. The majority of car parts up until recently were composed of steel. To lighten the total weight of cars, plastic is now quickly replacing steel.

In addition, as automotive manufacturing methods continue to advance, high-performance materials—such as thermoplastic elastomers, which combine the properties of rubber and plastic while also being lighter than steel and other polymeric materials—are replacing traditional polymers in an expanding number of applications.

APAC Is a Major Consumer of Injection Molded Plastics

With a 40% revenue share, APAC now holds the top spot in the market for polymers used in injection molding and will continue to do so until the year 2030. Demand for injection-molded plastics is anticipated to rise in the Asia-Pacific area as a result of rising infrastructure investment and rising vehicle sales in Indonesia, India, China, and Malaysia.

Due to its low cost of producing a variety of goods, China has the greatest revenue in the area, which will increase at a CAGR of over 5%. The important drivers driving the market's growth are China's vast population and its quick urbanization.

Source: P&S Intelligence

#Injection Molded Plastics Market Share#Injection Molded Plastics Market Size#Injection Molded Plastics Market Growth#Injection Molded Plastics Market Applications#Injection Molded Plastics Market Trends

1 note

·

View note

Text

Polyphthalamide (PPA) Market to Scale New Heights as Market Players Focus on Innovations 2024 – 2030

Polyphthalamide (PPA) Is An Aromatic And Semi-Crystalline Polyamide. It Is Stronger, Stiffer, Less Sensitive To Moisture, And Has Higher Thermal Capabilities When Compared With Nylon 6/6. It Has Substantial Chemical Fatigue And Creep Resistance. These Resins Are Suitable For A Wide Range Of Applications Because Of Their Outstanding Physical, Thermal And Electrical Properties. Unlike Many Other Resins, They Can Resist Infrared Soldering Environments. The Addition of Other Polyamides to Polyphthalamide (PPA)) Lowers the Melting Point and Glass Transition Temperature, Which Potentially Makes Polyphthalamide Blends Easier To Process When Compared To Higher Melting/Softening Polyphthalamide

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/123757-global-polyphthalamide-ppa-market?utm_source=Organic&utm_medium=Vinay

Latest released the research study on Global Polyphthalamide (PPA) Market, offers a detailed overview of the factors influencing the global business scope. Polyphthalamide (PPA) Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Polyphthalamide (PPA) The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are BASF (Germany), Dupont (United States), Solvay S.A. (Belgium), EMS Chemie (Switzerland), Evonik Industries (Germany), Arkema S.A. (France), SABIC (Saudi Arabia), Eurotec (Turkey), Propolymers Inc. (United States), Akro Plastics GMBH (Germany), Korea Engineering Plastics Co., Ltd (South Korea), Zhejiang NHU Special Materials Co. Ltd. (China),

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

Contact Us:

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

0 notes

Text

PEEK Plastic: A High-Performance Material for Diverse Applications

PEEK Plastic: A High-Performance Material for Diverse Applications

Polyetheretherketone (PEEK) is a remarkable thermoplastic known for its exceptional properties. Let’s delve into what makes PEEK stand out and explore its various applications.Get more news about PEEK Magnet wire,you can vist our website!

What is PEEK Plastic?

PEEK is a semi-crystalline thermoplastic with outstanding environmental resistance, dimensional stability, and mechanical strength. Key features include:

High Temperature Suitability: PEEK can withstand temperatures up to 250°C (483°F) and even higher in steam or high-pressure environments.

Biocompatibility: It is autoclavable, making it suitable for medical applications.

Low Toxicity: PEEK emits minimal gas when exposed to flames, enhancing safety in high-heat environments.

Chemical Resistance: PEEK resists chemicals, solvents, hydrolysis, and seawater.

Mechanical Strength: It is incredibly strong, stiff, and shatter-resistant.

Long Lifespan: PEEK parts outlast materials like stainless steel, bronze, and ceramics due to their corrosion resistance.

Applications of PEEK

Medical Devices: PEEK is used in medical prostheses, dental implants, and surgical instruments. Its biocompatibility and durability make it ideal for implantable applications1.

Aerospace: PEEK components find their way into aircraft engines, bearings, and structural parts due to their high-temperature performance and lightweight nature.

Industrial Bearings: PEEK bearings offer low friction, reducing wear and energy consumption.

Ultra-High Vacuum Pumps: PEEK’s chemical resistance and low outgassing make it suitable for vacuum systems.

Electrical Insulation: PEEK insulators are used in electrical connectors and switches.

Oil and Gas Industry: PEEK withstands harsh environments, including corrosive chemicals and high pressures.

Automotive: PEEK contributes to lightweighting and improved fuel efficiency.

Consumer Goods: From gaming chairs to office furniture, PEEK’s strength and rigidity enhance product performance.

Conclusion

PEEK plastic continues to revolutionize industries, offering longevity, reliability, and versatility. As technology advances, we can expect even broader applications for this remarkable material.

0 notes

Text

Is PEEK Tube Flexible?

In the field of high-performance plastics, PEEK (polyetheretherketone) has attracted much attention due to its unique physical and chemical properties. As a semi-crystalline high-temperature thermoplastic, PEEK not only has excellent chemical resistance, temperature resistance and electrical properties, but is also widely used in many high-tech industrial fields. So, is PEEK tube flexible? This…

View On WordPress

0 notes

Text

Diving into Linear Low Density Polyethylene (LLDPE): Understanding Its Properties and Manufacturing (2023-2034)

In the world of plastics, LLDPE stands tall for its remarkable toughness, enabling the creation of thinner yet robust films. Not to be confused with its cousin LDPE, or Low Density Polyethylene, LLDPE boasts a unique structure with numerous short branches. This structural advantage allows its chains to glide smoothly during stretching, preventing entanglement—a common issue with LDPE due to its long branching chains. The result? LLDPE offers superior tensile strength, along with heightened impact and puncture resistance compared to LDPE. So, when it comes to durability and performance, LLDPE takes the lead, making it a top choice for various applications where strength and resilience are paramount.

Introduction

LLDPE or Low-Density Polyethylene is a lightweight, flexible plastic. LLDPE stands out among polyethylene variants due to its semi-crystalline nature, featuring linear molecular chains with short branches. Unlike LDPE and HDPE, these linear molecules exhibit slower tangling. LLDPE is synthesized using one of three alpha-olefin co-monomers, namely octene, hexene, or butene, each influencing its properties differently. Octene contributes long branch chains, offering superior performance. Hexene strikes a balance between octene and butene, providing a cost-effective way. Butene, the most commonly utilized co-monomer for commodity plastics due to its affordability, features the shortest branch chains. Moreover, LLDPE properties can be further tailored by blending it with other co-monomers, with combinations of butene and hexene being particularly prevalent in practice.

LLDPE’s properties include:

Puncture-resistant: making it highly resilient against sharp objects or external forces that could cause punctures or tears.

Good flexibility: its ability to adapt to different shapes or movements without losing its structural integrity.

Resistant to oxidation: LLDPE has the capability to withstand oxidation, which is a chemical reaction involving oxygen that can degrade or weaken materials over time. Resistance to oxidation ensures the material's durability and longevity.

Excellent barrier properties: LLDPE has the ability to prevent the passage of gases, liquids, or other substances through it. Materials with excellent barrier properties are effective in containing or isolating substances, protecting them from external factors.

High impact strength: LLDPE can withstand sudden or intense impacts without breaking or shattering, indicating its resilience to mechanical forces or collisions.

Good environmental stress cracking resistance: LLDPE is resistant to cracking or fracturing when subjected to stress from environmental factors such as temperature variations, chemical exposure, or mechanical loading. Low Water Absorption: With its low water absorption rate, LDPE remains unaffected by moisture, making it suitable for applications where exposure to water or humidity is common.

Low Cost: Perhaps one of its most appealing attributes is its affordability. LDPE offers a cost-effective solution without compromising on performance, making it a preferred choice for a wide range of applications across industries.

LLDPE exhibits distinctive melt flow characteristics, making it suitable for processes like blow molding, film extrusion, and injection molding. Film extrusion, particularly, dominates LLDPE processing. It's worth noting that LLDPE's semi-crystalline nature contributes to its high shrinkage rate, whereby the material occupies more volume in its molten state than when solid. Overall, LLDPE's versatile production methods and unique properties make it a go-to material for various applications in industries ranging from packaging to automotive and beyond.

Manufacturing Process

The manufacturing process consists of four primary phases:

(1) Polymerization

(2) Devolatilization

(3) Distillation

(4) Finishing

Polymerization:

Ethylene and 1-octene initially undergo treatment in fixed-bed adsorption systems to remove water, oxygen, and other polar impurities that could potentially hinder the catalyst. After purification, the monomers are mixed with a polymerization solvent comprising a blend of C8-C9 paraffins. This mixture then enters the first of two consecutive continuous stirred tank reactors (CSTR), where polymerization occurs.

The polymerization process happens adiabatically in the liquid phase, with hydrogen acting as a molecular weight regulator. These steps ensure impurity removal and create ideal conditions for controlled and efficient polymer production in the liquid-phase reactors.

Devolatilization & Pelletizing:

The polymer solution exiting the second reactor enters an adiabatic flash vessel, where pressure reduction causes volatile elements, mainly unreacted ethylene, to vaporize. The concentrated polymer solution then undergoes devolatilization to remove residual monomers. The separated volatile components are cooled and sent for distillation, while the polymer proceeds to finishing. The devolatilized polymer is fed into an extruder to incorporate additives and pelletize the polymer, resulting in the final product being transferred to blending and storage.

Raw Materials Recovery:

The volatile effluents from devolatilization, containing unreacted monomers and solvents, undergo purification through distillation columns to recover these components and eliminate impurities, refining the final product.

The manufacturing process of LLDPE (linear low-density polyethylene) by Dow Chemicals involves a combination of polymerization techniques. Here is the brief overview of the LLDPE production process:

Monomer Preparation:

The first step in LLDPE production is getting the building blocks ready, called monomers. Unlike LDPE which uses only ethylene, LLDPE is made by combining ethylene with another molecule called a comonomer. Common comonomers include 1-butene, 1-hexene, or 1-octene. Adding this comonomer creates branches in the LLDPE structure, which give it special properties different from LDPE.

Polymerization:

Dow uses various polymerization techniques to produce LLDPE.

Solution Polymerization

Monomers and a catalyst system dissolved in a solvent, it's all stirred together in a reactor under carefully controlled temperature, pressure, and mixing. This controlled environment triggers a chemical reaction called polymerization, with catalysts, which often are Ziegler-Natta or metallocene catalysts.

Gas-Phase Polymerization

For gas-phase production, the reaction happens in a special reactor with a constantly moving bed of particles. These particles may hold the catalyst system (like a supported catalyst or a metallocene one). The mixture of monomers and catalyst is fed into the reactor, along with precise controls on temperature, pressure, and how long the ingredients stay inside (residence time). The heat from the reaction itself helps keep the process going.

Product Finishing:

After the LLDPE is polymerized completely, it's time to collect it from the reactor. This raw material, called resin, might go through some finishing touches to get the exact properties needed. This involves removing any trapped gas (degassing), shaping it into pellets (pelletization), and additive incorporation.

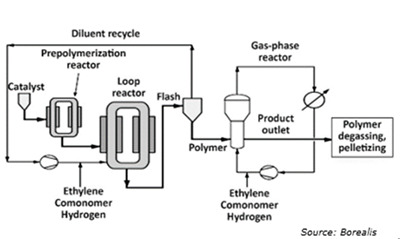

Borstar, a pioneering multi-modal patented technology employed by Borealis for PE and PP production, represents a significant advancement in process technology. Borealis is actively commercializing the latest iteration of Borstar, including Borstar PE 3G, and continues to innovate within the Borstar framework. These advancements enable flexible polymer design, ranging from bi-modal to multi-modal PE/PP resins, and contribute to the development of a diverse range of new plastics.

The Borstar polyethylene (PE) method enables the production of a wide range of bimodal and unimodal LLDPE, MDPE, and HDPE products. This method combines a loop reactor and a gas phase reactor to form Borstar PE. PE with densities ranging from 918 to 970 kg/m3 and melt flows from 0.1 to 100 can be manufactured using this process. While single-site catalysts will be utilized for PE processing in the future, Ziegler-Natta catalysts are currently employed.

A mixture of propane diluent and catalyst is injected into a small pre-polymerization reactor, where pre-polymerization takes place. The resulting slurry is then fed into the loop reactor, operating under supercritical conditions at temperatures of 75–100 °C and pressures of 55–65 bar, to produce higher density and lower molecular weight components of bimodal polymers. Afterward, diluent and unreacted materials are removed from the polymer in a flash tank.

The loop reactor and gas phase reactor operate independently, allowing for easy regulation of reactor conditions and flexibility in processing various products. In the fluidized bed gas phase reactor, polymerization continues, producing a homogeneous polymer on the same catalyst particles. Operating at temperatures between 75 and 100 °C and pressures of 20 bar, this reactor introduces fresh hydrogen, ethylene, and comonomer to form high molecular weight components and broaden the molecular weight distribution (MWD), enhancing the polymer's strength.

The production rate ratio between the reactors can be adjusted to achieve desired product qualities. Finally, hydrocarbon residues are removed, and the polymer powder is extruded to obtain the final product.

NOVA Chemicals use the SCLAIRTECH method on the other hand. The SCLAIRTECH technology method produces a wide spectrum of linear polyethylene (PE) products, including linear low, medium, and high-density grades with narrow to broad molecular weight distribution. The most effective PE swing method enables cost-effective production throughout the whole range of PE grades from a single train.

The process utilizes a reactor fed with a solution containing ethylene and a co-monomer, such as butene-1, octene-1, or even a combination of both. The short residence time (under 2 minutes) allows for a highly flexible system in the solution phase. This translates to quick transitions between producing different grades of the final product, making it adaptable to diverse market needs.

High conversion rates within the reactor maximize output and prevent uncontrolled reactions. A hydrocarbon solvent keeps the reaction mixture in solution while facilitating heat removal. This solvent is then efficiently recycled back into the reactor. Finally, the molten polymer exits the system and is shaped into pellets using a conventional extruder and pelletizer.

The Spherilene method, developed by LyondellBasell, employs a gas-phase reactor in its proprietary technology. The LyondellBasell Spherilene process encompasses a fluidized-bed, gas-phase approach for manufacturing polyethylene (PE) products across all densities, spanning from linear low density (LLDPE) to medium density (MDPE) and high density (HDPE). This technology's versatility, demonstrated by its extensive range of grades, empowers licensees to effectively navigate the continually evolving polyethylene markets well into the future.

The core of the Spherilene technology lies in its simple design with just one reactor and a recirculation system. This setup is surprisingly versatile, capable of producing a wide range of polyethylene (PE) products with melt indices between 0.01 and 100 g/10 min and densities spanning 0.918 to 0.965 g/cm3. This technology, using Avant Z Ziegler and Avant C Chromium catalysts, can create various single-modal (monomodal) products like LLDPE film, HDPE for injection molding, and MDPE for rotomolding and textiles.

Spherilene stands out for its operational stability, leading to high reliability when paired with the consistent performance of Avant catalysts. A unique reactor outlet mechanism efficiently extracts product with minimal gas contamination. Unlike competing technologies, Spherilene allows for start-up with Avant Z catalysts without needing a pre-existing polymer seed bed.

Applications of Linear Low Density Polyethylene (LLDPE)

Packaging

When storing multi-pack beverages for future use, the shrink wraps typically used to encase plastic bottles is often composed of LLDPE. Similarly, the durable plastic can rings utilized to hold together multi-pack canned beverages are also crafted from LLDPE material due to its robustness. It can be used in the form of stretch wraps.

Tubing

Beyond packaging, LLDPE finds use in tubes. LLDPE pipes for safe and reliable delivery of water to livestock.

Consumer Goods

Rigid LLDPE's affordability and ease of shaping make it a go-to material for everyday items like lids, buckets, bottles, and containers.

Market Outlook:

The global Linear Low Density Polyethylene (LLDPE) market stood at roughly 38 million tonnes in 2023 and is likely to grow at a CAGR of 4.80% by the year 2034. The rising need for low-density polyethylene (LLDPE) in packaging, fueled by its exceptional toughness and diverse applications in film production, especially in both food and non-food packaging sectors, is a significant factor driving market growth. The shift from rigid containers to flexible packaging further boosts this growth trend. Moreover, the growing demand for high-performance linear low-density polyethylene (LLDPE) with remarkable attributes such as superior strength and resistance to organic solvents significantly contributes to various applications. Importantly, the increasing utilization of LLDPE in injection molding, a crucial aspect of manufacturing technology, presents promising opportunities for market expansion.

Linear Low Density Polyethylene (LLDPE) Major Manufacturers

Significant companies in the Global Linear Low Density Polyethylene (LLDPE) market are ExxonMobil, ExxonMobil and SABIC JV, Nova Chemicals, Shell, DowDuPont, Chevron Phillips Chemical, Formosa Plastics, Lyondell Basell (Louisiana Integrated Polyethylene JV LLC), Sasol, Borealis GmbH, and Others.

Linear Low Density Polyethylene (LLDPE) Market Challenges

Linear Low Density Polyethylene (LLDPE) market has a few restraints as well that hinder its market growth trajectory. The emergence of cost-effective alternatives like linear low-density polyethylene (LLDPE), polyethylene terephthalate (PET), acrylonitrile butadiene styrene (ABS), and high-density polyethylene (HDPE) is hindering market growth. Additionally, the environmental impact of waste plastic bags, which pollute land and water, poses a significant threat to wildlife. As a result, many countries have implemented plastic bans, prohibiting the use of single-use plastic in various sectors, which could potentially impact the growth of the Low-Density Polyethylene Market.

Conclusion:

The rising need for Linear Low Density Polyethylene (LLDPE) to produce thin films for flexible packaging across diverse industries is projected to fuel the growth of the global LLDPE market. The unique properties of LLDPE like puncture resistance, resistance to corrosion, low water absorption, and tough nature makes it useful for packaging applications. Rising technological developments and product development is likely to aid the LLDPE market expansion. With increasing emphasis on cleanliness and long-lasting products, LLDPE is poised to become even more popular. Its reliability makes it a go-to material for a wide range of consumer products like buckets and bottles.

1 note

·

View note

Text

Causes and Countermeasures of Deformation of Injection Molded Parts - 3

Serial 3 (Readers who are interested can follow Gud Mould to view previous serials 1 and 2)We understand characteristics of earthworms, then we use earthworm theory to describe molding process. This will help us understand what happens to earthworms, so we can understand why plastics deform.Countless small earthworm particles (each particle contains countless frozen and inactive earthworms) are…

View On WordPress

#amorphous plastic#Causes and Countermeasures of Deformation of Injection Molded Parts#crystalline plastics#Deformation of Injection Molded Parts#deformation of product#earthworm theory#injection molded part#injection molded parts#injection molded product#mold design#mold processing#mold structure#molding process#plastic product#plastic products#pressure holding#product structure#semi-crystalline plastic

0 notes

Note

y'know what? we made a hahafunni googledoc of a researcher trying to figure out how an absurd fantasy species works so have this:

Observations and hypotheses about It

Immortality and Invincibility greater than scp 682 (and 682 can return from even zero atoms left!) is due to the fact that “each member of its species has a single ‘true’, but still not really vulnerable form in a single universe where said ‘true’ form is the only thing that exists, and the visible form i see of it is a projection that its species considers more important and the actual form. These universes can not be accessed by anyone except the ‘true’ form”. As for the “projection”, Its cells can somehow contain stupid amounts of a ton of chemicals to use for digestion, toxin neutralization, and More. don't ask how, or what the more means. On the topic of cells, they also kinda do like sea sponges where they can rearrange any organ and can just trigger cells to become stem cells and then make those cells do/become whatever.

Also due to the above, very atypical way of gleaning energy. Special receptors on surface of the material that could be considered skin-analogous by a stretch so absurd it almost breaks and has torn in quite a few places, sense what it is, take it into the body, and utilize aforementioned chemicals to convert it into whatever. Also note that it can somehow produce excess of its own cells enough to sustain itself if wanted/needed.

The texture of it, despite resembling different common materials (porcelain, plastic, and precious metals for main body, eye tissue, feathers and fur for rest) can spring and rebound even bullets if hit… due to the cell chemicals as well?

The crystalline stingers on its fluffy tails and fangs are filled with lethal toxins worse than anything previously known and become consistently more hazardous to anything that is not part of its species…

Is it made of all the same substance? Who the f— knows?! Certainly not this tired researcher…

On a similar note, why the hell is that fire-esque semi smoke-like, seemingly gas/plasma state substance that coats its wings and mimics hair something it can change at will (due to similar mechanisms as the rest of the cells) while staying the same shade of iridescent ? What liquids are its clear arms filled with, and what are the cute charm-like objects inside said liquid..?

The other day, it showed me that it can make any its tissues into vocal cords and i have no idea how to react.

It has told me that its species does not reproduce or mate in any way, and are all grossed out by that idea due to how foreign it is. Apparently, they must either evolved so that this generation is now all thats left, or were created. Either way is simultaneously beautiful and cursed.

I think the rest of the system, considering we are all repulsed aces who laugh in the face of maslows hierarchy of needs, can relate. I particularly envy the fact that they have never given birth and just must have reproduced/would reproduce asexually (while somehow maintaining genetic diversity too!). I dont know how though, it did say it was “born from a rock”... whatever that means.

It has spoken of being able to perceive all radiation wavelengths and dimensionalities. Perhaps that explains some of its quirks? Though i still cant see how that could give it control over the universe that overshadows anything from any media, and it has no pupils or marks on its iris…

Its magic seems to function similar to the system from wundersmith, complete with markings identical to what is described in the book, but on a much more powerful scale.

Now to figure out how it jumps/controls universes so well…

It said that though it can generate a cursed vocal cord structure anywhere it wants, it generally prefers to use strigulation to speak and preform mimicry and a thought leaked that was along the lines of “he doesn't need to know why?!”

Dear. (nontheistic) God.

(edit: a couple minutes later another thought leak was revealed: “he wouldn’t get it”

…W. T. F.

(it should be noted that its response to this was to giggle and say “don’t worry little one”...)

my cpu overheating

0 notes

Text

What You Need to Know About Solar Installation

Solar Installation is the process of installing a home’s solar energy system. This typically involves mounting panels on a roof and running wiring to connect them to the grid.

The upfront investment is typically recouped in six to 30 years by electricity savings. It’s also possible to lease panels instead of purchasing them outright.

Solar Panels

Taking the sun’s energy and turning it into usable electricity is what Solar Installation panels do. They’re built on a frame and housed in a glass, metal or plastic casing. They’re semi-permanent and can be quite expensive to remove, so they’re often added into buildings at the design stage rather than being retrofitted later on.

Solar panels contain photovoltaic (PV) cells that are made from crystalline silicon with p-type or n-type semiconductors to create current. Narrow slits in the cells funnel sunlight to generate power, and all PV modules are tested under Standard Test Conditions (STC) before entering production to ensure that they meet their projected output and efficiency levels.

Domestic solar systems can be grid-tied to pull in electricity from the utility company when their production isn’t enough, or homeowners can go off-grid with a large enough system and battery bank. They can also be used to offset peak demand charges from the utility company during summer and winter periods.

Inverters

The inverter converts the direct current from your solar panels to the alternating current used by household appliances. It’s installed between the batteries and power controller. The battery bank stores electricity for use when the sun isn’t shining. Batteries are wired in series to essentially create one big battery.

The charge controller automatically sends electrical current to where it’s needed. The system monitors the solar panel output, battery levels and metering. The system can be sized for your household needs, for producing enough energy to sell back to the grid or anywhere in between.

It’s important to understand your household’s current and future power demands when shopping for a solar installation. The size of your system will determine how long it takes to break even on the initial investment, and also impact how much you save over time. Other factors, including your location and incentives, influence total costs. Be sure to comparison shop solar providers and review their customer reviews, certifications, Better Business Bureau profiles and other information available online.

Batteries

Batteries store the electricity collected by solar panels and provide instant backup power. They can be used in grid-tie solar systems or off-grid homes and businesses. Batteries are the most expensive part of a solar energy system and there are many different options to choose from.

The type of battery used depends on your specific energy needs. The most common are lead acid batteries, which are deep-cycle and inexpensive, but require regular maintenance. Other options are lithium, nickel cadmium and flow batteries.

Solar batteries use chemical reactions to store surplus solar energy as potential electricity. This energy can be accessed anytime, even during non-sunny periods. Battery capacity is another important consideration when choosing a solar battery. This is based on the amount of charge cycles the battery can go through before it loses its capacity. The depth of discharge is also an important factor to consider. Most manufacturers recommend a maximum discharge of 45%, as discharging deeper than this can shorten the lifespan of the battery.

Wiring

Electrical wiring is the lifeline of any Solar Installation Brisbane energy system, enabling its reliable operation. Properly sized wires reduce voltage drop and overheating, while effective wire management prevents mechanical stress and provides protection from the elements. Routine maintenance and inspections allow for identifying problems before they become serious, and abiding by electrical standards safeguards against safety risks.

When stringing solar panels in series, the positive terminals of each panel are connected to the negative terminal of the next. The addition of each new panel increases the current (amperage) of the string, but the voltage remains unchanged. This allows each panel to continue generating electricity if it becomes heavily shaded or damaged.

Wire types differ in conductor material and insulation, and selecting the appropriate one for a solar installation is crucial. Copper offers superior conductivity, while aluminum is an economical option. Stranded wires are also preferred, as they offer greater flexibility and durability. The correct wire type is determined by evaluating the wattage and voltage requirements of the system.

0 notes

Text

Why people choose Acetal Copolymer Rod

Are you looking for a synthetic polymer that is known for its excellent dimensional stability, chemical resistance, and strength? Look no further! Acetal copolymer just might be the perfect material for your project needs. This Ultimate Guide to Acetal Copolymer Properties and Applications will break down what makes this thermoplastic so great, and help you make the right decision for your next project. We'll look at the differences between copolymer and homopolymer acetal, as well as discuss various types of grades, processing conditions and more. So if you're looking to learn more about why acetal copolymer might be the right choice for your next project, buckle up and let's dive into the ultimate guide to properties and applications of this wildly popular thermoplastic.

Acetal Copolymer, also known as copolymer of formaldehyde, is a semi-crystalline thermoplastic material formed from the polymerization of two monomers, namely formaldehyde and a vinyl ether. This material exhibits numerous advantageous properties – including excellent mechanical strength, dimensional stability and chemical resistance – making it an attractive material for a variety of applications.

When compared to other plastics on the market, Acetal Copolymer is especially attractive for its high crystallinity and low coefficient of friction. Its low thermal expansion and good fatigue resistance make it particularly suitable for use in precision parts that are subjected to severe stress and rapid wear during operation. Additionally, it has good electrical dielectric properties, chemical stability, low water absorption rate and superior machinability.

However, Acetal Copolymer has some drawbacks too. It is relatively expensive compared to other engineering plastics and forms dangerous hydrogen gas when heated or burned leading to potential safety issues. Despite these drawbacks it still remains a popular choice because of its desirable properties.

Acetal Copolymer is a tough yet flexible amorphous thermoplastic that exhibits greater modulus of elasticity, fatigue strength and wear resistance compared to many other thermoplastics. It also has excellent chemical resistance, high tensile strength and good thermal stability up to 180° F (82ºC).

Overall, acetal copolymer combines an excellent fusion of physical properties that make it useful across multiple industries. With this knowledge in mind, we look next at the numerous applications of acetal copolymer and how it’s applied in real life situations. Next we will discuss the applications of acetal copolymer and how they are utilized in today's world.

0 notes

Text

Preparing for Injection Molding Resin Selection

Manufacturers employ a diverse range of plastics for shaping components integrated into products, progressively replacing materials such as bronze, stainless steel, aluminium, and ceramics. This shift toward plastics is driven by several compelling factors, including extended part lifespan, reduced wear on other product components, enhanced production line efficiency, resistance to corrosion, and weight reduction. To ensure the successful production of a part, it is essential to collaborate closely with your best injection molding company when selecting the most suitable resin during the design for manufacturability phase. A good starting point is gaining a fundamental understanding of the two primary resin types: amorphous and semi-crystalline.

Amorphous

Amorphous resins encompass a variety of transparent plastics, including polycarbonate, acrylic, PETG, ABS, and polysulfone. This group of high-temperature resins can often serve as interchangeable substitutes within the same injection molds, as their linear shrinkage tendencies fall within a similar range.

Semi-crystalline

Semi-crystalline resins exhibit a highly organized molecular structure and do not undergo softening with increasing temperature; instead, they possess a well-defined and narrow melting point. Typically, their melting point surpasses the upper limit of amorphous thermoplastics. Nylon and Acetal are among the most frequently encountered semi-crystalline plastics.

Part Appearance and Geometry

The overall look and structure of a component have a significant influence on both the molding feasibility and the appropriate choice of resin. Aspects of part design, such as its dimensions, configuration, and wall thickness, can render it susceptible to imperfections. Additionally, features like snaps, undercuts, bosses, ribs, and more can introduce complexity into the molding process.

Recognizing the potential risks associated with part defects prior to commencing the manufacturing process represents a crucial step in injection molding. It is essential for plastic injection molding manufacturer to leverage cutting-edge technology to perform simulations that validate the design and resin selection before finalising the project for production.

Part Strength and Flexibility

The choice of materials plays a pivotal role in determining the strength and flexibility of your molded part. Achieving the optimal functionality of a part hinges on striking a balance between characteristics like stiffness, durability, toughness, and others. Additionally, it is crucial to comprehend the key distinctions among some of the more commonly employed resins.

ABS (acrylonitrile butadiene styrene) stands as a frequently used material for injection molding, readily available and moldable at a reasonable cost. It is a robust and sturdy material that offers commendable impact resistance, ease of machining, and meets various aesthetic demands. However, it is not suitable for applications involving sustained high temperatures, as it tends to warp or melt around 200 degrees Fahrenheit.

Polycarbonates belong to the high-grade category of thermoplastics, easily moldable and known for enhancing shatter resistance. With natural transparency, polycarbonate is ideal for applications requiring glass-like strength, such as safety goggles and medical lab equipment. Nonetheless, it may not be the best choice when flexibility or coloured aesthetics are paramount.

Glass-filled nylon is a reinforced thermoplastic, with added glass fibres to the base nylon resin to boost strength and heat resistance. This resin is also more electrically non-conductive compared to many others but is susceptible to burning despite its high melting point.

Polypropylene is a flexible thermoplastic suitable for both industrial and consumer applications. It is recognized for its high pliability, allowing it to be shaped in various ways without losing its original form. Polypropylene also offers resistance to solvents, chemicals, and UV rays.

Acetal is renowned for its excellent friction resistance and high rigidity. It can be easily coloured and dyed during the molding process, although it does not provide exceptional heat resistance.

Chemical and Environmental Factors

Many resins are susceptible to degradation when subjected to radiant and ultraviolet energy, which can lead to material breakdown. Extreme temperatures, humidity levels, radiation exposure, and other environmental variables, including potential requirements for fire resistance, all warrant consideration.

Regulatory Requirements

The plastic injection molding solutions and resin selection process can present unique challenges when it comes to meeting regulatory requirements. These criteria may encompass compliance with standards such as ASTM, ANSI, OSHA, FDA, EPA, and others.

Utilising Additives

The inclusion of additives can reinforce the materials, imparting strength and stiffness that can help minimise warping and shrinkage. Additives like glass or carbon fibres can be employed to elevate part performance and improve flow, ejection, and dispersion. This list should encompass essential considerations such as cost targets and resin availability, as resin availability can carry its own set of risks, necessitating the consideration of backup resin options. Factors like the array of available resins, part appearance, part strength, environmental considerations, regulatory demands, and the potential need for additives should all be meticulously evaluated before embarking on an injection molding project. Moreover, reviewing specifications for generic polymer variants is advisable, as these materials' characteristics may align well with your application.

If you are commencing a project that requires the expertise of an experienced plastic plastic injection mould manufacturer, discover how Moulding Injection aims to be your top-tier supplier and a reliable partner you can depend on.

#plastic moulding manufacturers#plastic injection mold design#plastic chocolate molds#injection molding maker#injection molding solutions#plastic injection molding manufacturer

0 notes

Text

Thermoplastic Polyester Engineering Resins Market is Led by APAC

The thermoplastic polyester engineering resins market was USD 3,912.2 million in 2022, and it will touch USD 5,896.6 million, advancing at a 5.4% compound annual growth rate, by 2030.

The growth of the industry is attributed to the increasing utilization of these resins for various nonstructural applications as they can be utilized without filters and are usually tougher and more ductile than thermoset resins. Furthermore, they are extensively accessible to meet domestic requirements and are easy to recycle. The rising need from the automobile and electronic sectors is also propelling the advancement of the industry.

The polybutylene terephthalate category will advance at a steady rate in the years to come. This is because of the growing requirement for PBT in the electrical and automobile sectors. PBT has unique features, including heat resistance, semi-crystalline, and lightweight, because of which conventional materials including bronze, ceramics, and cast iron in the automotive sector are getting replaced.

In 2022, the automotive category, based on application, led the thermoplastic polyester engineering resins market, with 40% share, and it will remain leading in the years to come. The automotive sector has gained momentum, over the past few years, and key manufacturers of automobiles are utilizing thermoplastic polyester to produce parts of vehicles, which benefits them to lessen the overall weight of the automobiles.

North America is likely to observe significant growth in the years to come. This is primarily because of the mounting need for recycled plastics, the existence of major players, and the growing emphasis on fuel-efficient vehicles, because of which manufacturers are extensively utilizing TPER to make their automobiles lightweight.

With the mounting utilization of such resins for numerous industrial applications, the thermoplastic polyester engineering resins industry will continue to advance in the years to come.

#acetic anhydride market#chemical industry#industrial applications#acetic anhydride production#market analysis#chemical compounds#acetic anhydride uses#pharmaceutical intermediates#chemical synthesis#chemical innovation

0 notes

Text

Hot Runner Mold Design: A Comprehensive Guide

Hot Runner Mold Design: A Comprehensive Guide

Hot runner molds are an essential component in the plastic injection molding industry. They consist of two plates that are heated with a manifold system. The manifold helps maintain a consistent temperature by keeping the molten thermoplastic in the runners at the same temperature as the heating cylinder. The heated runners deliver the molten plastic to nozzles that fill the core mold to form the final part .Get more news about Hot Runner Mold Design,you can vist our website!

The hot runner system should be easy to assemble into the molds without requiring special tolerances or tools. It should be responsive to the controls and able to maintain a stable processing temperature window that is close to the resin manufacturer’s specifications without using special controls or critical settings .

DuPont has published a manual that gives guidance on basic gate design and hot runner selection for the robust molding of semi-crystalline resins 3. The manual provides insights into the design and development of hot runner systems for various applications. It describes the hot runner design requirements for semi-crystalline polymers, such as Delrin® (POM), Zytel® (PA), Minlon® (PA), Zytel® HTN (PPA), Rynite® (PET), Crastin® (PBT), Sorona® (PTT), and some Hytrel® (TPC-ET) .

Melt Design, Inc. is an established supplier of high-quality, high-precision hot runner systems and components for the plastic injection molding industries. They supply and support Appliance, Automotive, Caps & Closures, Consumer Electronics, Consumer Products, Medical, and Thin Wall Packaging industries. With over 35 years of experience, their custom-built hot runner systems and components bring quality and value no matter how complex the molding process is .

In conclusion, hot runner mold design is a crucial aspect of the plastic injection molding industry. The articles published by DuPont and Melt Design, Inc. provide insights into the design and development of hot runner systems for various applications.

0 notes