#mold factories

Text

Causes and Countermeasures for Deformation of Injection Molded Parts - 7

Serial No. 7 (Friends who are interested can follow Gud Mould to view previous series in historical news)

3) Mold inlay design

Usually when moldmakers consider inlay design, their starting points are: ease of processing, lower material costs, reduce tendency of mold core deformation, and improve exhaust. However, few mold designers can proactively consider mold core inlays from perspective of…

View On WordPress

#Causes and countermeasures for deformation of injection molded parts#clamping force#cooling design#Deformation of Injection Molded Parts#design of exhaust#Exhaust system design#injection molded parts#injection molding production#injection pressure#Mold designer#Mold ejection design#mold factories#Mold inlay design#mold manufacturing#product design#Strength of mold structure

0 notes

Text

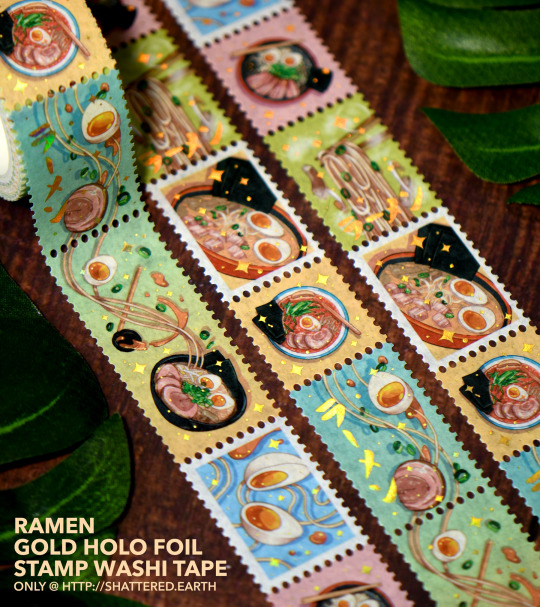

Some of my favorite in tape designs!!!!!! (That I designed.. lol)

They are all "stamp" type tape, i even paid the factory extra to get custom molds for these because I love the differing lengths and shapes of real stamps as well as amore delicate line of circles vs the default molds with huge circles.

There was a little drama at some point because the factory was letting people use my mold that I paid for but I cleared it up @_@;;

Anyway I don't go to cons anymore so I will probably have to stop selling washi tape cause they don't do so hot online especially for the price we have to sell them at to make it worth it for these complex designs + foil etc. No regretti tho, to see them in person is worth it.

All my washi tape (there's more than this too lol) are buy 4 get 1 free~

#washi tape#store#finished art#ghibli#squiggle cat#ramen#wait tea in the tags#i was so fucking pissed off at that factory like what the fuck#u made us pay like#SEVEN HUNDRED DOLLARS#to get a custom mold#that took forever for ME TO DESIGN#CIRCLE BY CIRCLE#the circles between stamps are actually OVALS to facilitate better ripping#that's how in depth i made this mold myself#and these mfers had the gall to let other people use it!!!!#it's not those artist's fault they had no idea but it just pissed me off u know#anyway i was so nice to fucking make them a NEW MOLD#with slight modifications#and now artists can have tiny holes too because of me when they use this factory#they just don't have the one ultra long stamp

264 notes

·

View notes

Text

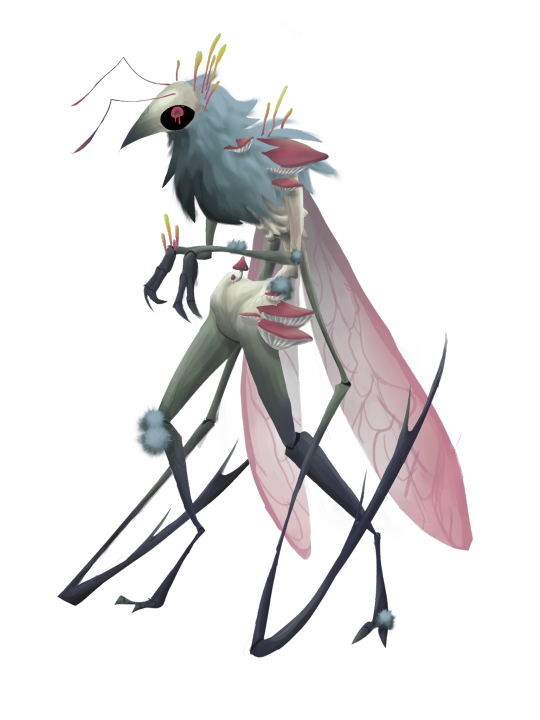

#tma oc#tw body horror#tw fungi#tw mold#the corruption#tma#the magnus archives#she’s a living spore factory that infects anyone who comes near#due to the nature of the au I made her for; she gets a cool monster appearance#the rot#oc#fandom oc#art#don’t know the credit for the image I used as a background#so if you see this and you took that photo#and you would like me not to use it or give credit#I will do so

22 notes

·

View notes

Text

The making of a vinyl record from electrodecksdaily on tiktok!

#stimboard#moodboard#stim#stimblr#stim gifs#gifset#gif#vinyl#record#vinyl record#rolling#molding#squishing#pink#blue#teal#aqua#machine#friday the 13th#factory#white#hands#gloves#visual stim

10 notes

·

View notes

Text

whenever i see an amateur investigator going into an old house or building for a ghost video, not once are they checking the air quality in case there no oxygen or a gas leak. or wearing a mask to protect them from asbestos or other harmful refractory particles or harmful mold particles. like i get that they are goofing for youtube views for ghosts but guys, i am worried about your long term health and a lot of old buildings aren't safe to be in, especially abandoned buildings that are no longer maintained

#i swear i am like worried for these ppl#like going into old hospitals or factories#even houses#like the rot in the wood and the just general asbestos and lead and mold#you can get a respiratory disease#or just die of anoxia in a confined space#i feel that is not really talked about in the ghost investigation vids and shows

56 notes

·

View notes

Text

Material expansion: At present, the types of materials for 3D printing are relatively limited. In the future, more types of materials can be explored, including new polymer materials, metal materials, ceramic materials, etc., to meet the needs of different fields.

Technological progress: At present, the speed, accuracy and quality of 3D printing technology still need to be improved. In the future, new printing technologies can be developed to increase printing speed, reduce printing errors and improve printing quality.

Diversified applications: At present, the application fields of 3D printing technology are still relatively limited. In the future, applications in more fields can be explored, such as applications in construction, medical, aerospace, automobile manufacturing and other fields, and its unique technical advantages can be exerted.

Intelligent development: In the future, artificial intelligence, machine learning and other technologies can be combined with 3D printing technology to realize intelligent design, optimization and production, and improve production efficiency and product quality.

Green development: At present, the waste and environmental protection problems generated by 3D printing technology still need to be solved. In the future, we can explore the path of green development, such as developing recyclable materials, reducing waste generation, etc., while paying attention to the impact on human body and environment .

Interdisciplinary cooperation: In the future, cooperation and innovation between different disciplines can be promoted, such as combining biology, chemistry, physics and other disciplines with material science, mechanical engineering, electronic information and other disciplines to jointly promote the development and application of 3D printing technology .

Cost reduction: At present, the cost of 3D printing technology is still relatively high. In the future, technological progress and large-scale production can be used to reduce costs and increase the penetration rate and application range.

2 notes

·

View notes

Text

Legit so mad ab the rainbow high mold thing bc I found a 5 pack for only $60 and I was gonna get it the next day but ofc that same night I saw the mold thing 😩 come oooon

#i mean i guess i dont need to start an actual collection of rh but still :/#and like sure i could chance it but what if they were made in the same factory as the mold ones and the mold spores are just too small#/sparse that they havent built any visible colonies but theyre still THERE yknow?#i dont need to risk that shit with my health#marquilla

3 notes

·

View notes

Text

I'm going to start a figure production company devoted entirely to selling figures of podcast characters

#podcasts#you see the joke is that podcasts are a visual medium#and yet I will be visualizing them#you see how it's funny#ha ha ha amiright??#yea you get it#this is my new dream though. not podcast characters specifically but I bet I could manage a figure company#I watched one single video just now on how they design nendoroids and I'm pretty sure I could do all that singlehandedly in half the time#I just need a warehouse or an office or perhaps a small shack or dilapidated barn to work out of#and for someone to email a production factory for me to create the metal molds and mass produce the figures bc emails are scary 🥺#or maybe I'll open a production facility under a different name and operate from my own facility for tax benefits#illegally of course#this is a good idea#fluffle talks

5 notes

·

View notes

Text

Ensuring Product The Quality Control System of a Mold Parts Factory

In the realm of manufacturing, especially within the intricate domain of mold parts factory production, ensuring product quality is paramount. A robust quality control system is the cornerstone upon which the reputation and success of a mold parts factory are built. In this article, we delve into the intricacies of how the mold parts factory establishes and maintains its quality control systems to uphold standards across its product lines.

At the heart of any mold parts factory's quality control system lies a comprehensive set of processes and procedures designed to monitor and evaluate every stage of production. From the initial design phase to the final product inspection, each step is meticulously scrutinized to identify and address any potential issues that may compromise product quality.

One of the primary components of a quality control system is the establishment of clear quality standards and specifications for each type of mold part produced. These standards serve as benchmarks against which all products are evaluated, ensuring consistency and uniformity across the production line. Additionally, these standards may align with industry-specific regulations or customer requirements to meet specific needs.

To enforce these quality standards effectively, the mold parts factory employs a range of inspection techniques and testing methodologies throughout the production process. Advanced inspection equipment, such as coordinate measuring machines (CMMs) and optical comparators, allows for precise measurement and evaluation of critical dimensions and tolerances. In-process inspections are conducted at key stages of production to detect any deviations from the established standards and take corrective action promptly.

Furthermore, quality control extends beyond the production floor to encompass the selection and qualification of raw materials and components. Suppliers are carefully vetted to ensure they meet stringent quality criteria, and incoming materials undergo rigorous inspection upon arrival at the factory. By maintaining strict control over the quality of inputs, the mold parts factory can reduce variability and ensure the consistency of finished products.

Another vital aspect of a quality control system is the implementation of corrective and preventive actions to address any issues that arise during production. In the event of non-conforming products or process deviations, root cause analysis techniques, such as the 5 Whys or Fishbone diagrams, are employed to identify the underlying causes. Corrective actions are then implemented to address these root causes and prevent recurrence in the future.

In addition to internal quality control measures, the mold parts factory often engages in external quality audits and certifications to validate the effectiveness of its quality management systems. Third-party auditors assess adherence to established standards and regulations, providing an independent validation of the factory's commitment to quality. Achieving certifications such as ISO 9001 or industry-specific standards demonstrates a mold parts factory's dedication to maintaining high levels of product quality and customer satisfaction.

Moreover, continuous improvement is a core principle of any effective quality control system. The mold parts factory regularly reviews and analyzes performance data to identify opportunities for optimization and enhancement. This may involve implementing new technologies, refining processes, or providing additional personnel training to ensure ongoing product quality and manufacturing efficiency.

In conclusion, the quality control system of a mold parts factory serves as the linchpin of its operations, ensuring that every product that leaves the facility meets high standards of excellence. Through meticulous attention to detail, rigorous inspection protocols, and a commitment to continuous improvement, mold parts factories uphold their reputation for quality and reliability in the competitive manufacturing landscape. As guardians of precision and performance, mold parts factories exemplify the importance of unwavering dedication to product quality in the pursuit of customer satisfaction and industry leadership.

0 notes

Text

Causes and Countermeasures for Deformation of Injection Molded Parts - 6

Serial No. 6 (Friends who are interested can follow Gud Mould and view serials 1, 2, 3, 4, and 5 in historical news.)

This paragraph focuses on influence of mold runner gate design and cooling system design on deformation, which can be used as a guiding ideology for design of pouring system and cooling system.

3. Mold design

In terms of mold design, factors that have a greater impact on…

View On WordPress

#Causes and countermeasures for deformation of injection molded parts#cooling design of mold#cooling system design#Deformation of Injection Molded Parts#design of pouring system#Fan-shaped gate#injection mold#injection molded parts#injection molding#Mechanical function design of mold#mold design#Mold designer#mold factories#mold runner gate design#Mold temperature#Molding Defects#multi-cavity molds#Rheological functional design of mold#Rheological properties of plastics#thermoplastic injection mold

0 notes

Text

the american school system is a wide-scale industrial cult. send tweet.

#ness thoughts#cult mention#thinking about our school trauma and how much we have in common with others.#school is a terrifying and torturous experience if you are not a white cishet neurotypical male.#even if you're a child#the factory wishes to mold someone into the “perfect” human being. if you are not perfect then you are sentenced to punishment.#and if you do survive then you have to pay more to suffer more.

0 notes

Video

youtube

greedaikin precision mold (tiktok)

#youtube#Because GDM believes that every customer has visited different mold factories we consider the entire visit process from the customer's persp#When customers come to GDM to visit the factory they can deeply understand GDM's rigorous attitude towards the entire production process and

0 notes

Text

The making of a vinyl record from peaktechno on tiktok!

#stimboard#moodboard#stim#stimblr#stim gifs#gifset#gif#vinyl#record#vinyl record#white#red#machine#factory#music#rolling#molding#squishing#hands#visual stim#gloves

9 notes

·

View notes

Text

Form and Function: Basket Molds

Versatility in Design with Basket Molds

One of the key advantages of basket mold factories is their versatility in design. These molds can create various shapes and sizes, from small storage baskets to large industrial containers. The ability to customize basket molds allows manufacturers to meet the specific requirements of their products, whether it's a specific pattern, size, or structural strength. This versatility is a significant reason why basket molds are widely used in different industries.

Efficiency in Plastic Processing with Basket Molds

Basket molds factory are designed for efficient plastic processing, enabling manufacturers to produce high-quality products quickly. The mold's intricate design allows for even distribution of molten plastic, ensuring consistent wall thickness and structural integrity. This efficiency leads to reduced cycle times, allowing manufacturers to produce more units in less time. For industries that rely on mass production, such as consumer goods and packaging, basket molds are a valuable asset.

0 notes

Note

Honestly docs (and all non-custom leather boots) just take a lot of time wearing to bend and adjust to the shape of your foot. If they don’t fit snugly and are moving around creating pain, I recommend lambs wool or cut up tissues to fill gaps.

If it’s more like ball of foot or heel pain, I recommend switching the sole out for a better one (the factory ones ain’t the best) and honestly, wearing thick socks and wearing them a lot to get them used to the shape of your foot. It sucks for a bit, but what I always did was like wear them inside the house and just walk around in circles for a while to break them in…. Good luck!

Other Anon:

hey! Fellow doc wearer here - tbh my latest pair took like three or four weeks to get comfortable, what I did to get them better is just wear them around the house 10-20 minutes a day with thick socks (or like until they hurt) and they broke in that way

THANK U GUYS FOR THE ADVICE ACTUALLY THIS MAKES ME SO HAPPY 😭😭 the verdict seems to be to just wear them more often with thick socks and maybe find a better insole to help things a little bit 🫡 will do!

#el-mail#i wore them to anirevo all day and my feet were so numbbbb so that kinda scared me off of wearing them but ive been massaging it#and i found out theres a factory insole in it and it fits a lot better now and the massaging did help reduce blisters😭#i had a spare insole that protects my heel its jus the ball of my foot thats the remaining issue rn and i think its time for me to start#wearing them fr to get it all molded to my feet

1 note

·

View note

Text

Plastic Injection Molding Factory

A plastic injection molding factory is a specialized facility equipped with machinery for mass-producing plastic parts through injection molding processes. These factories utilize molds to shape molten plastic into desired forms, catering to diverse industries such as automotive, electronics, and consumer goods. From prototyping to full-scale production, these facilities ensure precision, efficiency, and consistency in manufacturing plastic components.

0 notes