#semi-crystalline materials

Text

Causes and countermeasures for deformation of injection molded parts - 4

Serial No. 4 (Friends who are interested can follow Gud Mold and check out previous series.)

4. Factors affecting deformation

1. Plastic raw materials

Characteristics of plastic raw materials have a huge impact on deformation of molded products. Different raw materials have different molecular structures and intermolecular forces, which manifest themselves in different fluidity, orientation…

View On WordPress

#amorphous plastics#Causes and countermeasures for deformation of injection molded parts#crystalline materials#crystalline plastics#Deformation of Injection Molded Parts#injection molded parts#injection molding factories#injection molding production#mechanical transmission products#mold factories#molded products#pressure-holding#semi-crystalline materials#semi-crystalline plastics#thermosetting plastics

0 notes

Text

Loved the Annihilation book, just saw the 2018 movie, and thoughts on the ending. Heavily spoilers, partial ending explanation.

The first moment in the movie I stopped and said “Wait, that makes no sense” is the ending when Lena walks on the beach with the glass trees. Up until this moment I followed with a ‘eldritch cosmic horror being unreality” mindset, but this moment stopped me.

Because it made no sense to me that there could be any sort of mutation that results in clear, crystalline forms. This movie hammers in that biology is being disfigured, but not non organic forms; we see the old buildings, the boats are practically untouched, old weaponry is usable. So why now with these trees? Minerals don’t have dna to mutate.

But THEN the movies goes on, and Lena is replicated with a green being. And we see the inside of the lighthouse, the underneath with that shimmer black moving WHATEVER, and the creature itself, which is an iridescent green. Then it all makes sense.

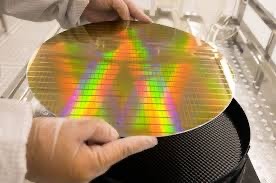

Sand is the largest source of silicon in the world, and silicon is the second most abundant element on earth. Sand is also a primary ingredient in glass. Silicon -> Sand -> Glass -> Glass trees.

This is the best photo I could get of the being underneath the lighthouse, if you’ve seen the movie you know it’s more shimmery, almost liquid, looking identical to the material on the right, which is solid silicon.

Silicon is also used in making computer chips and wafers.

Silicon wafers have a holding, greenish iridescent shimmer as well, much like the being that tries to relocate Lena at the climax.

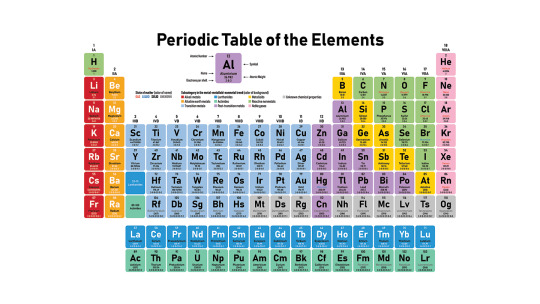

Here’s the thing about Silicons atomic properties. Silicon has 4 valence electrons, and if you remember grade school chemistry, an unreactive, stable atom has 8. So silicon is semi stable, but would really like to bond with other atoms to achieve 8 valence electrons. This basic concept is what makes it a good semiconductor, or a material that easily allows electrons to move through it. There’s a lot more technical science that has to do with it I’ll cut out, but some elements are ‘injected’ into silicon to manipulate these properties, creating a system that allows electrons/electricity/energy to very very easily run through it. A very popular choice is phosphorous.

I couldn’t get photos of the scene, but Oscar Isaac’s human character self immolates with a PHOSPHORUS grenade. When he destroys himself, it’s a contained, rapid fire that does not spread to his surrounding and dies out fairly quickly. But when the creature is then trapped in a phosphorous blast, it doesn’t dissolve, but continuously burns. The burn doesn’t spread to the regular stone of the lighthouse, but absolutely rips through the underground area and being growing on the side of the lighthouse that the movie has us believe is a living creature, apart of the clone, or obviously at least the same substance that one (aka me) might say is silicon.

Here’s one last thing about silicone properties. The material most related to silicon on the periodic table is carbon.

All known organic life is made of carbon. Period. If it’s alive it’s carbon. Many traits responsible for why carbon makes life possible is shared with other Group 16 elements. Silicon is the closest Group 16 element to carbon. Therefore, it is hypothesized that any non-carbon based life would have to be made of silicon. Many theories and sci-fi stories play with the idea of an alien life being made of silicon is more environments that can accommodate that.

So back to my initial confusion. I was confused as to why the creature, or the shimmer, or whatever force that is responsible for the movie could make clear, crystalline, glass like trees. It’s ability was clearly stated to genetically mutate living things. But I’m arguing that somehow through sci-fi movie reasons, the creature is silicon based life, or become silicon based upon hitting the sand at the beach, then perhaps adapted into carbon based life.

After this scene, when Lena is being interrogated, she is asked ‘Was it carbon based?’ Imma say that is a very, very relevant question, and maybe the entire point of this line of questions. So cool thing the movie did, it all still makes sense.

End credits: the reason we don’t see silicon based life is it would theoretically require an insane amount of energy to sustain. Doesn’t react with this theory but yo it’s a movie they gotta make it work somehow.

#annihilation#annihilation 2018#southern reach trilogy#area x#natalie portman#jeff vandermeer#alex garland#movie theory#chemistry#movie details#idk man hope anyone cares#almost discussed that on Reddit but I do not like talking to those people

438 notes

·

View notes

Photo

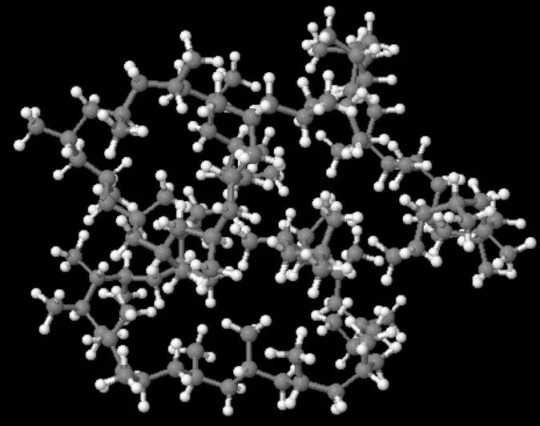

Polymers: Polyetheretherketone

Polyetheretherketone, or PEEK, is considered to be a high performance polymer, capable of being used in applications that require a broad range of temperatures. It is a thermoplastic material in the family of polyaryletherketone (PEAK) polymers with a melting point of ~334°C, allowing it to be used in applications up to around 300°C in the short term and 250°C in the long term.

In particular, PEEK is known for its wear and abrasion resistance and is typically at least semi-crystalline, manufactured through step-growth polymerization. It also has excellent mechanical properties, including fatigue resistance, and is relatively stable when it comes to chemical and corrosion resistance. One of the main downsides of PEEK is its relatively cost, but it can be easy to process. PEEK polymer products can even be produced with 3D printing technologies.

As PEEK is also biocompatible, the main industry that uses the material is the medical industry, where it is used in implants and drug delivery systems. Other applications include the aerospace and automotive industries as well as electrical insulation. It is also considered to be fully recyclable.

Sources/Further reading: ( 1 - images 1, 3, and 4 ) ( 2 - image 2 ) ( 3 - image 5 ) ( 4 )

16 notes

·

View notes

Text

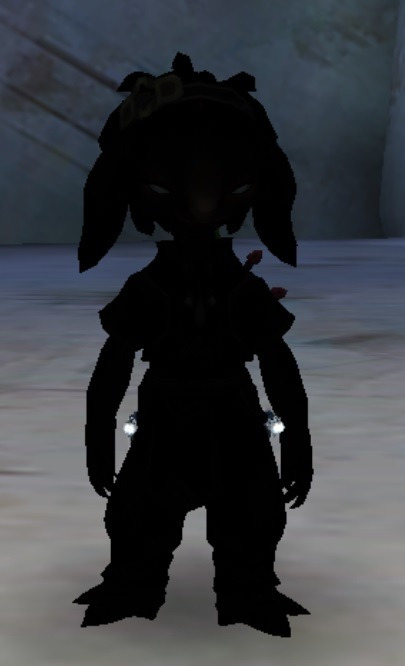

Time for Asura Appreciation Week, as organized by the @asura-appreciation-corner! More pictures/images at the bottom of all the text!

Day 1: Talk About One Of Your Asura OCs

My main is my Daredevil Thief, Infiltrator Cixxe! Cixxe (pronounced like the number 6) is an odd case.

Cixxe was found as an infant by a small family of skritt in the ruins of a recently destroyed Asura research lab in Metrica Province. The remains of the lab was marked only with the number 6, which the skritt took to be her name (albeit with a little spelling flair), and adopted the little shadow. Now Cixxe has strong pseudomelanism, only her eyes and the small patch on her nose denoting that she's not truly melanistic, and her coloration helped her excel at stealth and thievery scavenging. Also her being not actually a skritt meant that she was the only member of the family with the ability to focus on more complex tasks and goals when split from the rest of the family.

Then, one day while the family was travelling between Scratches (skritt towns), a dangerous enough endeavor for a group of skritt, they were attacked by some asura who were trying to drive them away from their material storage. Cixxe was split from her family, and captured in the panic. Confused by this strange asura child, the researchers brought her back to Rata Sum where she was given instructors in an attempt to re-educate her back into proper asura civilization.

It didn't take.

Cixxe was a problem for every teacher and krewe she was assigned to, and eventually was given up on altogether. She was labeled a lost cause and ultimately, when she was a pre-teen/early teen, they gave up trying. Instead, she was given a warehouse/lab to live in and left much to her own devices as long as she didn't cause too much ruckus in the city. She began the slow work of tracking and rejoining her scattered family of skritt, housing them in her home lab where they could finally be safe and well cared for.

Not long after that she was scouted by the Order of Whispers due to her stealth skills, and while on some jobs for the Pact she met and was semi-adopted by a charr named Amara @drakeheart (who she refers to as 'mom' just as much as she does for her adopted skritt mother, Korri'kee).

Cixxe likes crystals and collecting junk, and has a particularly morbid fascination with the Brand and the crystalline formations of it.

5 notes

·

View notes

Text

PBT prices surge in Ahmedabad

The Ahmedabad polymer market experienced a notable shift in the prices of Polybutylene Terephthalate (PBT), grade Imported as per the sources from Indian Petrochem. The price has moved up by Rs 2/kg on September 20, 2024 from Rs 144/kg on September 19, 2024. Polybutylene Terephthalate (PBT) is a semi-crystalline engineering thermoplastic material. It has similar properties and composition to polyethylene terephthalate (PBT). It is a member of the polyester family of polymers. PBT has gained commercial interest due to its wide range of applications. Indian PBT Prices, PBT Prices In India, Indian Prices PBT, Indianpetrochem.

0 notes

Text

Unleash the Natural Beauty of Your Home with Stone Slabs

These are a unique and exquisite option for enhancing the aesthetic appeal of interiors and exteriors. Gemstone Slabs , crafted from semi-precious stones, offer a blend of natural beauty and exceptional durability, making them a popular choice for high-end architectural and interior design projects. Subh Gemstones, a renowned name in the gemstone industry, is at the forefront of providing top-quality gemstone that cater to the discerning tastes of their clientele.

What Are Gemstone

Gemstone is large pieces of semi-precious stones that have been cut and polished to create a smooth, flat surface. These slabs can be used in various applications, including countertops, wall cladding, flooring, and decorative pieces. The process of creating gemstone involves selecting high-quality rough stones, cutting them into slabs, and then polishing them to reveal their natural beauty and intricate patterns.

The Allure of Gemstone

The primary allure of gemstone lies in their unique and striking appearance. Each slab is a work of art, showcasing the natural patterns, colors, and textures of the stone. No two slabs are exactly alike, ensuring that any installation using these materials is truly one-of-a-kind. Some popular types of gemstone include:

Agate Slabs: Known for their vibrant colors and intricate banding, agate slabs can create a stunning focal point in any space.

Amethyst Slabs: These purple-hued slabs are highly sought after for their regal appearance and are often used in luxurious interiors.

Quartz Slabs: Quartz is known for its durability and beautiful crystalline structure, making it a popular choice for countertops and flooring.

Lapis Lazuli Slabs: With their deep blue color and gold flecks, lapis lazuli slabs add a touch of opulence to any setting.

Applications of Gemstone

Gemstone are incredibly versatile and can be used in a variety of applications:

Countertops: Gemstone make for stunning countertops in kitchens, bathrooms, and bars. Their durability and resistance to heat and scratches make them a practical choice, while their beauty adds a touch of luxury.

Wall Cladding: Using gemstone for wall cladding can create a dramatic and eye-catching feature in any room. They can be used to create accent walls, fireplace surrounds, or even entire walls in living spaces and commercial settings.

Flooring: Gemstone can be used as flooring material to create a luxurious and unique surface. Their natural patterns and colors can transform any space into an elegant and sophisticated area.

Decorative Pieces: Smaller gemstone can be used to create a variety of decorative pieces, such as tabletops, backsplashes, and even custom art installations.

Leaders in Gemstone

Subh Gemstones is a leading provider of high-quality slabs, renowned for their commitment to excellence and customer satisfaction. With years of experience in the gemstone industry, Gemstones has built a reputation for sourcing the finest semi-precious stones and transforming them into exquisite slabs that meet the highest standards of quality and craftsmanship.

Why Choose Subh Gemstones?

Quality Assurance: Subh Gemstones ensures that every slab meets rigorous quality standards. From the selection of raw stones to the final polishing process, each step is meticulously monitored to guarantee the best possible product.

Wide Selection: Subh Gemstones offers a diverse range of gemstone, catering to various tastes and preferences. Whether you are looking for the vibrant hues of agate, the deep blues of lapis lazuli, or the crystalline beauty of quartz, it has the perfect slab for you.

Customization: Understanding that each project is unique, it offers customization options to meet specific design requirements. Their team of skilled artisans can create bespoke slabs that perfectly fit the vision of any project.

Sustainability: it is committed to sustainable practices, ensuring that their operations have minimal impact on the environment. They adhere to ethical sourcing practices and use eco-friendly processes in the creation of their gemstone.

Conclusion

Gemstone are an exceptional choice for those looking to add a touch of natural beauty and luxury to their spaces. With their unique patterns and colors, these slabs can transform any area into a sophisticated and elegant setting. Subh, with their dedication to quality and craftsmanship, is the perfect partner for sourcing the finest gemstone. Whether for countertops, wall cladding, flooring, or decorative pieces, Shubh Gemstones provides products that are both stunning and enduring.

0 notes

Text

Injection Molded Plastics Market Is on Track To Hitting USD 409.2 Billion by 2030

The word "injection molding" covers a wide range of processes, including the molding of metals, ceramics, polymers, and several other substances. Plastics and injection molding are frequently used together. Plastics can also be formed using a variety of different methods, such as extrusion and blow molding. But the most used method of forming plastics worldwide is injection molding.

It is predicted that the need for injection molded plastics would be driven by the rising demand for plastic components from a variety of end-use sectors, including consumer goods and electronics, packaging, and automotive and medical devices.

In addition, injection molding developments are also being focused on by businesses to reduce the rate of defective manufacturing, which has had a substantial effect on the demand for injection-molded plastic components globally. Thus, the injection molded plastics market is set to reach USD 409.2 billion by 2030, according to P&S Intelligence.

Application in Packaging Contributes Majority of Revenue

With a market share of 30% across all applications, packaging will continue to rule the market; as a result, the expansion of the packaging industry will be a major market driver.

The gradual transition away from glass and metals in the consumer packaging market in favor of polymers is driven by the latter's reduced space need, decreasing weight, durability, adaptability, and cost-effectiveness.

Moreover, polypropylene holds the majority of the market share, at about 40%, as a result of its lightweight properties, moisture resistance, shock resistance, cheap cost, high molding capacity, and outstanding compatibility with food applications, particularly in terms of package safety.

Furthermore, it may be used in injection molding to create components and goods of all different sizes and forms. Due to its semi-crystalline structure and strong flexural strength, polypropylene also has this property.

Demand for Polymers Is Growing in Automotive Applications

One of the end markets for injection-molded plastics with the quickest growth is the automobile sector. The need for such materials would be boosted throughout the projected period by the expansion of the Asian automotive market, notably in China and India.

Thermoplastic elastomers and other injection-molded polymers are discovering new uses in the vehicle sector because of technological advancements in the production of automotive components. The majority of car parts up until recently were composed of steel. To lighten the total weight of cars, plastic is now quickly replacing steel.

In addition, as automotive manufacturing methods continue to advance, high-performance materials—such as thermoplastic elastomers, which combine the properties of rubber and plastic while also being lighter than steel and other polymeric materials—are replacing traditional polymers in an expanding number of applications.

APAC Is a Major Consumer of Injection Molded Plastics

With a 40% revenue share, APAC now holds the top spot in the market for polymers used in injection molding and will continue to do so until the year 2030. Demand for injection-molded plastics is anticipated to rise in the Asia-Pacific area as a result of rising infrastructure investment and rising vehicle sales in Indonesia, India, China, and Malaysia.

Due to its low cost of producing a variety of goods, China has the greatest revenue in the area, which will increase at a CAGR of over 5%. The important drivers driving the market's growth are China's vast population and its quick urbanization.

Source: P&S Intelligence

#Injection Molded Plastics Market Share#Injection Molded Plastics Market Size#Injection Molded Plastics Market Growth#Injection Molded Plastics Market Applications#Injection Molded Plastics Market Trends

1 note

·

View note

Text

Polyphthalamide (PPA) Market to Scale New Heights as Market Players Focus on Innovations 2024 – 2030

Polyphthalamide (PPA) Is An Aromatic And Semi-Crystalline Polyamide. It Is Stronger, Stiffer, Less Sensitive To Moisture, And Has Higher Thermal Capabilities When Compared With Nylon 6/6. It Has Substantial Chemical Fatigue And Creep Resistance. These Resins Are Suitable For A Wide Range Of Applications Because Of Their Outstanding Physical, Thermal And Electrical Properties. Unlike Many Other Resins, They Can Resist Infrared Soldering Environments. The Addition of Other Polyamides to Polyphthalamide (PPA)) Lowers the Melting Point and Glass Transition Temperature, Which Potentially Makes Polyphthalamide Blends Easier To Process When Compared To Higher Melting/Softening Polyphthalamide

Free Sample Report + All Related Graphs & Charts @: https://www.advancemarketanalytics.com/sample-report/123757-global-polyphthalamide-ppa-market?utm_source=Organic&utm_medium=Vinay

Latest released the research study on Global Polyphthalamide (PPA) Market, offers a detailed overview of the factors influencing the global business scope. Polyphthalamide (PPA) Market research report shows the latest market insights, current situation analysis with upcoming trends and breakdown of the products and services. The report provides key statistics on the market status, size, share, growth factors of the Polyphthalamide (PPA) The study covers emerging player’s data, including: competitive landscape, sales, revenue and global market share of top manufacturers are BASF (Germany), Dupont (United States), Solvay S.A. (Belgium), EMS Chemie (Switzerland), Evonik Industries (Germany), Arkema S.A. (France), SABIC (Saudi Arabia), Eurotec (Turkey), Propolymers Inc. (United States), Akro Plastics GMBH (Germany), Korea Engineering Plastics Co., Ltd (South Korea), Zhejiang NHU Special Materials Co. Ltd. (China),

Thanks for reading this article; you can also get individual chapter wise section or region wise report version like North America, Europe or Southeast Asia.

Contact Us:

Craig Francis (PR & Marketing Manager)

AMA Research & Media LLP

Unit No. 429, Parsonage Road Edison, NJ

New Jersey USA – 08837

0 notes

Text

Exploring Thebaine: An Important Opium Alkaloid

Thebaine was first isolated from opium in 1833 by the German pharmacist Friedrich Sertürner. The early history of this is closely related to the development of morphine as a medicine. During isolation attempts to obtain pure morphine, Sertürner observed that opium contained an additional alkaloid that he initially called "paramorphine". In the late 1830s, the French chemist Pelletier determined its correct empirical formula and established it as a separate alkaloid, naming it this due to its presence in opium harvested from Papaver bracteatum, which is native to the district of Thebes in Greece. While initially considered a minor constituent, further research revealed this to possess important pharmacological activities of its own.

Chemical Properties and Structure of Thebaine

This is a pale yellow, crystalline powder that is weakly alkaline and sparingly soluble in water and acid solutions. Chemically, it is an opium alkaloid derived from the glutamic acid pathway, with the chemical formula C19H21NO3. This contains a bicyclic octahydroisoquinoline skeleton with a phenanthrene group. It closely resembles both codeine and oripavine in structure, differing mainly by substitution of various methyl and hydroxyl groups around the phenanthrene core. This lacks the methoxy group in position C6 that gives codeine its agonist effects, but contains the 3-hydroxy group found in oripavine derivatives. Due to its unique structure, this serves as a key biochemical intermediate in the biosynthesis of several important opioids.

Uses of Thebaine

While this itself has only weak opioid activity, it represents an important starting material in the semi-synthetic production of several potent analgesic drugs. Oxycodone, oxymorphone, nalbuphine, naloxone and naltrexone are all synthesized from this. In particular, this is essential for the commercial manufacture of oxycodone, one of the most widely prescribed opioid painkillers. The US pharmaceutical industry consumes approximately 80 metric tons of this annually for this purpose. Its extraction from natural opium is not economically viable, so it is instead obtained from cultivated Papaver bracteatum or Papaver somniferum varieties that are selectively bred to accumulate higher levels over morphine. Southeast Asian countries are major legal producers and suppliers of this to drug makers globally.

Thebaine and Regulation

Given its strategic role in the synthesis of potent controlled prescription opioids, its production and trade are tightly regulated. It is specifically named along with morphine, codeine and other opiates in international drug control agreements like the Single Convention on Narcotic Drugs. However, as a precursor its legal status is somewhat less restrictive than finished drugs. While subject to import/export authorizations between countries, commercial firms can acquire this if they hold valid processing licenses from drug authorities. Its regulated availability is critical for the opioid pharmaceutical sector. Nonetheless, diversion remains a concern and there have been reports of this being misused for illicit opioid synthesis in clandestine labs, posing new safety and law enforcement challenges.

0 notes

Text

PEEK Plastic: A High-Performance Material for Diverse Applications

PEEK Plastic: A High-Performance Material for Diverse Applications

Polyetheretherketone (PEEK) is a remarkable thermoplastic known for its exceptional properties. Let’s delve into what makes PEEK stand out and explore its various applications.Get more news about PEEK Magnet wire,you can vist our website!

What is PEEK Plastic?

PEEK is a semi-crystalline thermoplastic with outstanding environmental resistance, dimensional stability, and mechanical strength. Key features include:

High Temperature Suitability: PEEK can withstand temperatures up to 250°C (483°F) and even higher in steam or high-pressure environments.

Biocompatibility: It is autoclavable, making it suitable for medical applications.

Low Toxicity: PEEK emits minimal gas when exposed to flames, enhancing safety in high-heat environments.

Chemical Resistance: PEEK resists chemicals, solvents, hydrolysis, and seawater.

Mechanical Strength: It is incredibly strong, stiff, and shatter-resistant.

Long Lifespan: PEEK parts outlast materials like stainless steel, bronze, and ceramics due to their corrosion resistance.

Applications of PEEK

Medical Devices: PEEK is used in medical prostheses, dental implants, and surgical instruments. Its biocompatibility and durability make it ideal for implantable applications1.

Aerospace: PEEK components find their way into aircraft engines, bearings, and structural parts due to their high-temperature performance and lightweight nature.

Industrial Bearings: PEEK bearings offer low friction, reducing wear and energy consumption.

Ultra-High Vacuum Pumps: PEEK’s chemical resistance and low outgassing make it suitable for vacuum systems.

Electrical Insulation: PEEK insulators are used in electrical connectors and switches.

Oil and Gas Industry: PEEK withstands harsh environments, including corrosive chemicals and high pressures.

Automotive: PEEK contributes to lightweighting and improved fuel efficiency.

Consumer Goods: From gaming chairs to office furniture, PEEK’s strength and rigidity enhance product performance.

Conclusion

PEEK plastic continues to revolutionize industries, offering longevity, reliability, and versatility. As technology advances, we can expect even broader applications for this remarkable material.

0 notes

Text

Advanced Waterproofing Technologies in Construction: Ensuring Durability in Masonry North York

The integration of waterproofing technology within the construction sector marks a significant advancement, particularly in regions such as masonry North York, where buildings are regularly subjected to varied climatic conditions. This discourse delves into how contemporary waterproofing techniques are reshaping the construction landscape by providing robust protection and enhancing the overall structural integrity of edifices.

Critical Importance of Waterproofing in Construction

Waterproofing is indispensable in construction, serving not merely as a preventive measure but as a fundamental necessity. It averts water infiltration that can lead to severe damages, including mold proliferation, deterioration of concrete, and corrosion of metallic components. Specifically in masonry North York, where precipitation is common, effective waterproofing ensures that structures remain intact and durable. Furthermore, it preserves the aesthetic quality of construction materials, preventing unsightly water stains and leakages.

Materials Employed in Waterproofing

The selection of materials for waterproof technologies varies, depending on the specific requirements of the application and environmental conditions. Prominent materials include:

Bituminous Membrane: Typically used on roofs, this material forms a sticky, impermeable layer highly effective against water penetration.

Cementitious Waterproofing: This technique involves a rigid or semi-rigid type of waterproof barrier applied to surfaces such as interior basement walls.

Liquid Waterproofing Membrane: Consisting of a thin coating applied via spray, roller, or trowel, it provides a flexible seal against moisture.

Methods of Waterproofing

The efficacy of waterproofing is achieved through various methods tailored to distinct parts of a building:

Torch-On Membrane: Applied using a torch and commonly used on flat roofs, this method is favored in commercial constructions throughout Masonry North York.

Integral Waterproofing: This strategy involves mixing additives directly with concrete to imbue the concrete itself with waterproof properties.

Crystalline Waterproofing: Utilizing a crystalline compound that reacts with water and concrete, this method effectively blocks pores within the concrete to prevent water ingress.

Challenges and Solutions in Waterproofing

Despite its numerous advantages, waterproofing presents several challenges:

Complex Application: Certain waterproofing applications are intricate and necessitate skilled execution to guarantee effectiveness.

Cost Considerations: Premium waterproof materials can be expensive, though they represent a prudent investment for ensuring long-term durability.

Maintenance Requirements: Sustained maintenance is critical to prolong the effectiveness of waterproof treatments, particularly in regions like Masonry North York, which are prone to extreme weather conditions.

Innovations in Waterproof Technology

The domain of waterproof technology is continuously progressing. Noteworthy innovations include:

Eco-friendly Materials: Recent developments have introduced materials that are not only effective but also environmentally benign, thereby reducing the ecological footprint of construction projects.

Smart Sensing Technology: Advanced systems are now capable of detecting leaks and autonomously activating waterproofing treatments, ensuring perpetual protection.

Conclusion

The significance of incorporating advanced waterproofing technologies in construction projects in masonry North York cannot be overstated. These technologies not only fortify the structural integrity of buildings but also ensure their longevity against the rigors of Canadian weather conditions. As the construction industry evolves, embracing sophisticated and efficient waterproofing methods will become crucial to achieving sustainable and resilient construction practices. By investing in high-quality waterproofing solutions, property owners in Masonry North York can secure their assets and enhance the quality of residential and commercial environments.

0 notes

Text

PBT prices drop in Ahmedabad

The Ahmedabad polymer market today witnessed a price drop in Polybutylene Terephthalate (PBT) prices, grade Imported. The price dropped by Rs 2/kg on September 16, 2024 from Rs 146/kg on September 14,2024 according to a recent update from Indian Petrochem. Polybutylene Terephthalate (PBT) is a semi-crystalline engineering thermoplastic material. It has similar properties and composition to polyethylene terephthalate (PET). It is a member of the polyester family of polymers. PBT has gained commercial interest due to its wide range of applications, Indian PET Prices, PET Prices In India, Indian Prices PET, Indianpetrochem.

0 notes

Text

What Temperatures can PEEK Withstand?

In the world of plastic materials, PEEK (polyetheretherketone) has attracted much attention for its excellent performance and wide range of applications. Today, we’ll take a closer look at PEEK’s ability to withstand temperature and how this property plays a key role in a variety of applications.

1. Introduction to PEEK materials

PEEK, or polyetheretherketone, is a semi-crystalline,…

View On WordPress

0 notes

Text

Diving into Linear Low Density Polyethylene (LLDPE): Understanding Its Properties and Manufacturing (2023-2034)

In the world of plastics, LLDPE stands tall for its remarkable toughness, enabling the creation of thinner yet robust films. Not to be confused with its cousin LDPE, or Low Density Polyethylene, LLDPE boasts a unique structure with numerous short branches. This structural advantage allows its chains to glide smoothly during stretching, preventing entanglement—a common issue with LDPE due to its long branching chains. The result? LLDPE offers superior tensile strength, along with heightened impact and puncture resistance compared to LDPE. So, when it comes to durability and performance, LLDPE takes the lead, making it a top choice for various applications where strength and resilience are paramount.

Introduction

LLDPE or Low-Density Polyethylene is a lightweight, flexible plastic. LLDPE stands out among polyethylene variants due to its semi-crystalline nature, featuring linear molecular chains with short branches. Unlike LDPE and HDPE, these linear molecules exhibit slower tangling. LLDPE is synthesized using one of three alpha-olefin co-monomers, namely octene, hexene, or butene, each influencing its properties differently. Octene contributes long branch chains, offering superior performance. Hexene strikes a balance between octene and butene, providing a cost-effective way. Butene, the most commonly utilized co-monomer for commodity plastics due to its affordability, features the shortest branch chains. Moreover, LLDPE properties can be further tailored by blending it with other co-monomers, with combinations of butene and hexene being particularly prevalent in practice.

LLDPE’s properties include:

Puncture-resistant: making it highly resilient against sharp objects or external forces that could cause punctures or tears.

Good flexibility: its ability to adapt to different shapes or movements without losing its structural integrity.

Resistant to oxidation: LLDPE has the capability to withstand oxidation, which is a chemical reaction involving oxygen that can degrade or weaken materials over time. Resistance to oxidation ensures the material's durability and longevity.

Excellent barrier properties: LLDPE has the ability to prevent the passage of gases, liquids, or other substances through it. Materials with excellent barrier properties are effective in containing or isolating substances, protecting them from external factors.

High impact strength: LLDPE can withstand sudden or intense impacts without breaking or shattering, indicating its resilience to mechanical forces or collisions.

Good environmental stress cracking resistance: LLDPE is resistant to cracking or fracturing when subjected to stress from environmental factors such as temperature variations, chemical exposure, or mechanical loading. Low Water Absorption: With its low water absorption rate, LDPE remains unaffected by moisture, making it suitable for applications where exposure to water or humidity is common.

Low Cost: Perhaps one of its most appealing attributes is its affordability. LDPE offers a cost-effective solution without compromising on performance, making it a preferred choice for a wide range of applications across industries.

LLDPE exhibits distinctive melt flow characteristics, making it suitable for processes like blow molding, film extrusion, and injection molding. Film extrusion, particularly, dominates LLDPE processing. It's worth noting that LLDPE's semi-crystalline nature contributes to its high shrinkage rate, whereby the material occupies more volume in its molten state than when solid. Overall, LLDPE's versatile production methods and unique properties make it a go-to material for various applications in industries ranging from packaging to automotive and beyond.

Manufacturing Process

The manufacturing process consists of four primary phases:

(1) Polymerization

(2) Devolatilization

(3) Distillation

(4) Finishing

Polymerization:

Ethylene and 1-octene initially undergo treatment in fixed-bed adsorption systems to remove water, oxygen, and other polar impurities that could potentially hinder the catalyst. After purification, the monomers are mixed with a polymerization solvent comprising a blend of C8-C9 paraffins. This mixture then enters the first of two consecutive continuous stirred tank reactors (CSTR), where polymerization occurs.

The polymerization process happens adiabatically in the liquid phase, with hydrogen acting as a molecular weight regulator. These steps ensure impurity removal and create ideal conditions for controlled and efficient polymer production in the liquid-phase reactors.

Devolatilization & Pelletizing:

The polymer solution exiting the second reactor enters an adiabatic flash vessel, where pressure reduction causes volatile elements, mainly unreacted ethylene, to vaporize. The concentrated polymer solution then undergoes devolatilization to remove residual monomers. The separated volatile components are cooled and sent for distillation, while the polymer proceeds to finishing. The devolatilized polymer is fed into an extruder to incorporate additives and pelletize the polymer, resulting in the final product being transferred to blending and storage.

Raw Materials Recovery:

The volatile effluents from devolatilization, containing unreacted monomers and solvents, undergo purification through distillation columns to recover these components and eliminate impurities, refining the final product.

The manufacturing process of LLDPE (linear low-density polyethylene) by Dow Chemicals involves a combination of polymerization techniques. Here is the brief overview of the LLDPE production process:

Monomer Preparation:

The first step in LLDPE production is getting the building blocks ready, called monomers. Unlike LDPE which uses only ethylene, LLDPE is made by combining ethylene with another molecule called a comonomer. Common comonomers include 1-butene, 1-hexene, or 1-octene. Adding this comonomer creates branches in the LLDPE structure, which give it special properties different from LDPE.

Polymerization:

Dow uses various polymerization techniques to produce LLDPE.

Solution Polymerization

Monomers and a catalyst system dissolved in a solvent, it's all stirred together in a reactor under carefully controlled temperature, pressure, and mixing. This controlled environment triggers a chemical reaction called polymerization, with catalysts, which often are Ziegler-Natta or metallocene catalysts.

Gas-Phase Polymerization

For gas-phase production, the reaction happens in a special reactor with a constantly moving bed of particles. These particles may hold the catalyst system (like a supported catalyst or a metallocene one). The mixture of monomers and catalyst is fed into the reactor, along with precise controls on temperature, pressure, and how long the ingredients stay inside (residence time). The heat from the reaction itself helps keep the process going.

Product Finishing:

After the LLDPE is polymerized completely, it's time to collect it from the reactor. This raw material, called resin, might go through some finishing touches to get the exact properties needed. This involves removing any trapped gas (degassing), shaping it into pellets (pelletization), and additive incorporation.

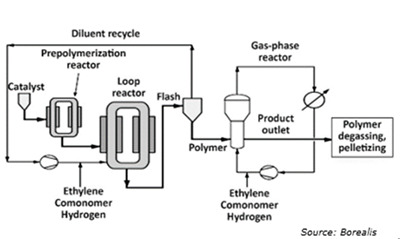

Borstar, a pioneering multi-modal patented technology employed by Borealis for PE and PP production, represents a significant advancement in process technology. Borealis is actively commercializing the latest iteration of Borstar, including Borstar PE 3G, and continues to innovate within the Borstar framework. These advancements enable flexible polymer design, ranging from bi-modal to multi-modal PE/PP resins, and contribute to the development of a diverse range of new plastics.

The Borstar polyethylene (PE) method enables the production of a wide range of bimodal and unimodal LLDPE, MDPE, and HDPE products. This method combines a loop reactor and a gas phase reactor to form Borstar PE. PE with densities ranging from 918 to 970 kg/m3 and melt flows from 0.1 to 100 can be manufactured using this process. While single-site catalysts will be utilized for PE processing in the future, Ziegler-Natta catalysts are currently employed.

A mixture of propane diluent and catalyst is injected into a small pre-polymerization reactor, where pre-polymerization takes place. The resulting slurry is then fed into the loop reactor, operating under supercritical conditions at temperatures of 75–100 °C and pressures of 55–65 bar, to produce higher density and lower molecular weight components of bimodal polymers. Afterward, diluent and unreacted materials are removed from the polymer in a flash tank.

The loop reactor and gas phase reactor operate independently, allowing for easy regulation of reactor conditions and flexibility in processing various products. In the fluidized bed gas phase reactor, polymerization continues, producing a homogeneous polymer on the same catalyst particles. Operating at temperatures between 75 and 100 °C and pressures of 20 bar, this reactor introduces fresh hydrogen, ethylene, and comonomer to form high molecular weight components and broaden the molecular weight distribution (MWD), enhancing the polymer's strength.

The production rate ratio between the reactors can be adjusted to achieve desired product qualities. Finally, hydrocarbon residues are removed, and the polymer powder is extruded to obtain the final product.

NOVA Chemicals use the SCLAIRTECH method on the other hand. The SCLAIRTECH technology method produces a wide spectrum of linear polyethylene (PE) products, including linear low, medium, and high-density grades with narrow to broad molecular weight distribution. The most effective PE swing method enables cost-effective production throughout the whole range of PE grades from a single train.

The process utilizes a reactor fed with a solution containing ethylene and a co-monomer, such as butene-1, octene-1, or even a combination of both. The short residence time (under 2 minutes) allows for a highly flexible system in the solution phase. This translates to quick transitions between producing different grades of the final product, making it adaptable to diverse market needs.

High conversion rates within the reactor maximize output and prevent uncontrolled reactions. A hydrocarbon solvent keeps the reaction mixture in solution while facilitating heat removal. This solvent is then efficiently recycled back into the reactor. Finally, the molten polymer exits the system and is shaped into pellets using a conventional extruder and pelletizer.

The Spherilene method, developed by LyondellBasell, employs a gas-phase reactor in its proprietary technology. The LyondellBasell Spherilene process encompasses a fluidized-bed, gas-phase approach for manufacturing polyethylene (PE) products across all densities, spanning from linear low density (LLDPE) to medium density (MDPE) and high density (HDPE). This technology's versatility, demonstrated by its extensive range of grades, empowers licensees to effectively navigate the continually evolving polyethylene markets well into the future.

The core of the Spherilene technology lies in its simple design with just one reactor and a recirculation system. This setup is surprisingly versatile, capable of producing a wide range of polyethylene (PE) products with melt indices between 0.01 and 100 g/10 min and densities spanning 0.918 to 0.965 g/cm3. This technology, using Avant Z Ziegler and Avant C Chromium catalysts, can create various single-modal (monomodal) products like LLDPE film, HDPE for injection molding, and MDPE for rotomolding and textiles.

Spherilene stands out for its operational stability, leading to high reliability when paired with the consistent performance of Avant catalysts. A unique reactor outlet mechanism efficiently extracts product with minimal gas contamination. Unlike competing technologies, Spherilene allows for start-up with Avant Z catalysts without needing a pre-existing polymer seed bed.

Applications of Linear Low Density Polyethylene (LLDPE)

Packaging

When storing multi-pack beverages for future use, the shrink wraps typically used to encase plastic bottles is often composed of LLDPE. Similarly, the durable plastic can rings utilized to hold together multi-pack canned beverages are also crafted from LLDPE material due to its robustness. It can be used in the form of stretch wraps.

Tubing

Beyond packaging, LLDPE finds use in tubes. LLDPE pipes for safe and reliable delivery of water to livestock.

Consumer Goods

Rigid LLDPE's affordability and ease of shaping make it a go-to material for everyday items like lids, buckets, bottles, and containers.

Market Outlook:

The global Linear Low Density Polyethylene (LLDPE) market stood at roughly 38 million tonnes in 2023 and is likely to grow at a CAGR of 4.80% by the year 2034. The rising need for low-density polyethylene (LLDPE) in packaging, fueled by its exceptional toughness and diverse applications in film production, especially in both food and non-food packaging sectors, is a significant factor driving market growth. The shift from rigid containers to flexible packaging further boosts this growth trend. Moreover, the growing demand for high-performance linear low-density polyethylene (LLDPE) with remarkable attributes such as superior strength and resistance to organic solvents significantly contributes to various applications. Importantly, the increasing utilization of LLDPE in injection molding, a crucial aspect of manufacturing technology, presents promising opportunities for market expansion.

Linear Low Density Polyethylene (LLDPE) Major Manufacturers

Significant companies in the Global Linear Low Density Polyethylene (LLDPE) market are ExxonMobil, ExxonMobil and SABIC JV, Nova Chemicals, Shell, DowDuPont, Chevron Phillips Chemical, Formosa Plastics, Lyondell Basell (Louisiana Integrated Polyethylene JV LLC), Sasol, Borealis GmbH, and Others.

Linear Low Density Polyethylene (LLDPE) Market Challenges

Linear Low Density Polyethylene (LLDPE) market has a few restraints as well that hinder its market growth trajectory. The emergence of cost-effective alternatives like linear low-density polyethylene (LLDPE), polyethylene terephthalate (PET), acrylonitrile butadiene styrene (ABS), and high-density polyethylene (HDPE) is hindering market growth. Additionally, the environmental impact of waste plastic bags, which pollute land and water, poses a significant threat to wildlife. As a result, many countries have implemented plastic bans, prohibiting the use of single-use plastic in various sectors, which could potentially impact the growth of the Low-Density Polyethylene Market.

Conclusion:

The rising need for Linear Low Density Polyethylene (LLDPE) to produce thin films for flexible packaging across diverse industries is projected to fuel the growth of the global LLDPE market. The unique properties of LLDPE like puncture resistance, resistance to corrosion, low water absorption, and tough nature makes it useful for packaging applications. Rising technological developments and product development is likely to aid the LLDPE market expansion. With increasing emphasis on cleanliness and long-lasting products, LLDPE is poised to become even more popular. Its reliability makes it a go-to material for a wide range of consumer products like buckets and bottles.

1 note

·

View note

Text

Polyphthalamide Resin Market was Dominated by the APAC Region

The polyphthalamide resin market is USD 1,522.3 million in 2023, and it will power at a rate of 6.4% during 2024–2030, to touch USD 2,320.6 million by 2030.

The growth is because of the increasing use of PPA resin as a substitute to metals in automobiles and the mushrooming R&D investments. The material has numerous beneficial properties, for example advanced thermal and electrical mechanical possessions of this material contain opacity, semi-crystalline structure, and resistance to moisture.

The glass-fiber-reinforced category has the largest share as this option is nonflammable, compressive, and resilient to humidity and temperature and doesn’t bend easily.

Moreover, it is easily obtainable, and the electronics and automotive sectors are extensively using it. Furthermore, it bids decent value for money and owns chemical resistance, which will, propel the market growth in this category.

Electrical and electronics applications will have the highest rate, of 7%, in the years to come, since PPA resin recollects its structure and size under variable ecological conditions, owns surface-mount capability, and electrical components, for example LEDs, switches, circuit breakers, sockets, and connectors.

The important assistances that make it perfect for these applications, along with e- cars, are good electrical properties and flame retardance.

North America is second in terms of revenue, with a value of USD 0.3 billion in 2023. This is because of the increasing acceptance of e- vehicles and of cutting-edge materials in numerous applications.

In North Americapolyphthalamide resin market, the U.S. is the leader because of the government initiatives for decreasing emissions, the most projecting of which is the execution of strict regulations on aircraft, industries, and automobiles.

APAC is the major revenue contributor as a result of the increasing sales of vehicles, which is supplementing vehicle manufacturing. Across India, China, and Japan, the existence of numerous automobile manufacturing centers increases the growth of the industry.

As a result of the obtainability of monetary incentives and the low cost of manufacturing vehicles, the automotive sector is growing reliably in China, Thailand, Indonesia, and India.

The automotive sector is mounting because of the increase in income. With this, the passenger car sales continue to increase in developing and developed countries. Moreover, recently the industry has seen a massive uptake of cutting-edge technologies because of the increasing competition amongst manufacturers.

Besides, the requirement for e-vehicles is growing with the increasing concerns for the environment and the numerous steps governments globally are enabling a low-emission transport system.

It is because of the increase in the use of PPA resin in vehicles, the demand for the same is on the rise. What’s more, this trend will continue in the years to come as well.

Source: P&S Intelligence

#Polyphthalamide Resin Market Share#Polyphthalamide Resin Market Size#Polyphthalamide Resin Market Growth#Polyphthalamide Resin Market Applications#Polyphthalamide Resin Market Trends

1 note

·

View note

Text

Navigating the Thriving Landscape of the Polyetheretherketone (PEEK) Market

Welcome to the forefront of high-performance polymers, where innovation meets versatility – the Polyetheretherketone (PEEK) market. PEEK, a semi-crystalline thermoplastic renowned for its exceptional mechanical, thermal, and chemical properties, has emerged as a key player across diverse industries. In this exploration, we unravel the intricacies of the PEEK market, shedding light on its growth drivers, applications, and the dynamic landscape that positions it as a frontrunner in advanced materials.

Understanding the PEEK Advantage: What Sets it Apart?

Polyetheretherketone, or PEEK, has earned its reputation as a premium engineering thermoplastic due to its unique combination of properties:

High Temperature Resistance: PEEK excels in high-temperature environments, with a melting point reaching up to 343°C (649°F). This attribute makes it an ideal choice for applications demanding thermal stability.

Exceptional Mechanical Strength: With a tensile strength comparable to metals, PEEK offers outstanding mechanical properties, ensuring durability and reliability in demanding conditions.

Chemical Resistance: PEEK is highly resistant to a wide range of chemicals, acids, and solvents, making it suitable for applications in aggressive industrial environments.

Biocompatibility: Widely used in medical applications, PEEK is biocompatible and meets stringent regulatory requirements, making it a preferred choice for medical implants and devices.

Diverse Applications Driving Market Growth:

Aerospace Innovations: PEEK's lightweight nature, combined with its high strength and resistance to extreme temperatures, has positioned it as a material of choice in aerospace applications. From structural components to interior elements, PEEK contributes to the efficiency and performance of modern aircraft.

Medical Advancements: PEEK has gained prominence in the medical sector for its biocompatibility and radiolucency. It finds applications in orthopedic implants, dental devices, and medical instruments, contributing to the advancement of healthcare technologies.

Automotive Solutions: In the automotive industry, PEEK is utilized for components that demand exceptional mechanical performance and resistance to harsh operating conditions. Applications range from engine components to electrical systems.

Oil and Gas Exploration: PEEK's resistance to aggressive chemicals and high temperatures makes it a valuable material for components used in oil and gas exploration, such as seals, gaskets, and connectors.

Market Trends and Future Outlook:

Rapid Technological Advancements: Ongoing research and development activities are focused on enhancing PEEK formulations, introducing variants with improved properties, and expanding its range of applications.

Increasing Global Adoption: The PEEK market is witnessing global expansion, with a growing demand in regions like Asia-Pacific due to industrialization and infrastructure development.

Sustainable Initiatives: Sustainability is becoming a focal point in material development. PEEK manufacturers are exploring eco-friendly formulations and recyclability to align with environmental considerations.

Conclusion:

As we navigate the dynamic landscape of the Polyetheretherketone (PEEK) market, it's evident that this high-performance polymer is at the forefront of transformative innovations. From aerospace to healthcare, PEEK continues to redefine industry standards by providing solutions to complex challenges. As technology advances and industries seek materials that deliver on multiple fronts, the PEEK market stands as a beacon of versatility and resilience, driving progress and shaping the future of advanced materials. Stay tuned for more insights into the ever-evolving world of PEEK, where possibilities are as limitless as its exceptional properties.

0 notes