#stationary asphalt mixing plants

Text

youtube

ZAP-S160 Professional Stationary Asphalt Batch Mix Plant Project Starts Production

ZAP-S160 asphalt batch mixing plant combines with various advantages of western models and adopts modular design, which has compact structure, simple assembly and transport. Components of stationary asphalt mix plant adopt international famous brand, keep pace with the international advanced technology, which can guarantee high reliability and security of the equipment in long operating terms.

Besides, the stationary stype asphalt plant machine has strict trial assembly and test every equipment before delivery, so that guarantee stable quality and high standard of our equipment. Our asphalt batching mixing plant equipment also adopts human-computer interface and PLC control system and perfect human-machine exchange function for easy operating with manual, semi-auto, automatic control function; with remote fault detect and maintenance function,those can solve the problem the first time.

Excellent expansibility of ZAP-S160 asphalt batch mixing plant can be realized by adding RAP, wood fiber adding equipment etc, so that it can satisfy more requirements. Low consumption, high efficiency and environment friendly design is the ideal choice of different kinds of road construction asphalt mixing machines.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#concrete#asphalt plant#heavy equipment#asphaltplant#mobile asphalt drum mix plant#construction#asphalt mix plant#stationary asphalt mixing plant#stationary asphalt mixing plants#stationary asphalt plant#asphalt batch mix plant#asphalt batching mixing plant#asphalt batching plant#Youtube

1 note

·

View note

Text

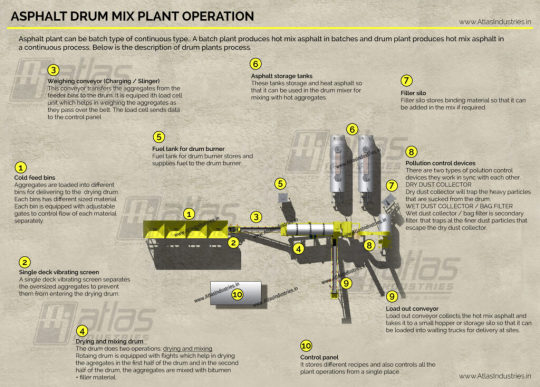

Stationary Asphalt Drum mix Plant Layout - Atlas Industries

A stationary asphalt drum mix plant is the most widely used asphalt mixing plant. It allows operating in less space requirement, the running cost is less and the material produced is of good quality. Visit Us: https://www.atlasindustries.in/blog/asphalt-drum-mix-plant-layout/

0 notes

Text

Asphalt Hot Mix Plant Manufacturer and Suppliers in India

Indian Trade Bird offers a comprehensive solution for road construction projects Asphalt Hot Mix Plants. These robust and efficient plants are designed to produce high-quality asphalt mix, the essential material used for constructing and maintaining roads, highways, and other paved surfaces. Indian Trade Bird's Hot Mix Plants combine various components to seamlessly handle each stage of the asphalt production process. They provide both mobile and stationary plant options, ensuring you have the flexibility to choose the solution that best fits your requirements. As the volume drops through the maximum pressure field, the material is modelled into a solid compact sheet or flakes of ingredients.

For more details clicks here - https://www.indiantradebird.com/product/asphalt-hot-mix-plant

0 notes

Text

Different Types of Asphalt Mixing Plant

Asphalt mixing plant is mainly used for mass production of asphalt, there are various types of asphalt mixing plant, each type has its unique advantages. According to different classification standards, the types and advantages of asphalt mixing plant are as follows:

Classified according to the mixing method:

1, Forced batch asphalt mixing plant:

The main advantage of intermittent asphalt mixing plant is its high flexibility and adaptability. It can adjust the production batch and formula according to the needs of the project and adapt to the production of different types and specifications of asphalt mixture. In addition, batch type asphalt mixing plant usually adopts advanced control system, which can realize precise batching and mixing to ensure product quality. This type of asphalt mixing plant has a mandatory mixing capacity, which can ensure that the asphalt and aggregate are fully mixed to produce high quality asphalt mixture. In addition, its intermittent working mode makes it easier to maintain the equipment, and at the same time, it can adjust the production volume according to the needs, to adapt to the needs of different scale projects.

2, Continuous production asphalt mixing plant:

The continuous asphalt mixing plant is characterized by continuous and stable production, and is capable of producing asphalt mixtures for long periods of time and in large quantities. It is usually equipped with efficient conveying system and mixing system, which can realize continuous supply of raw materials and continuous output of mixture. This type of asphalt mixing plant is suitable for large-scale projects and can significantly improve construction efficiency. Continuous type asphalt mixing plant can produce asphalt mixture continuously and stably, which is suitable for large-scale and continuous engineering projects. Its highly efficient production capacity can significantly shorten the construction period, while reducing production delays caused by equipment downtime.

Classified according to the handling method:

1, Stationary asphalt mixing plant:

Stationary asphalt mixing plant is characterized by large production capacity, high production efficiency and high automation. It is usually equipped with large-capacity storage tanks and efficient mixing system, which can continuously and stably supply high-quality asphalt mixture. Stationary asphalt mixing plant is usually installed in a fixed site with stable production capacity and high efficiency. Due to its fixed nature, it is more convenient to maintain and manage the plant, and at the same time, it can ensure the continuous supply of asphalt mixture to meet the needs of large-scale construction.

2, Semi-fixed and mobile asphalt mixing plant:

This type of asphalt mixing plant has high flexibility and portability, due to its compact design, easy to disassemble and assemble, it can be quickly transferred to different construction sites, and can be quickly transferred and installed according to the needs of the project. It is especially suitable for projects with short construction period and changing locations, which can reduce transportation costs and improve construction efficiency. In addition, mobile asphalt mixing plant usually covers a small area, low requirements for the site environment, can be quickly put into production.

In addition, there are some special types of asphalt mixing plants, such as low-temperature asphalt mixing plant, high-temperature asphalt mixing plant, etc., which are respectively applicable to the construction needs under different climatic conditions, to ensure the quality and stability of asphalt mixture.

In general, all types of asphalt mixing plant has its unique advantages, choose the right type of asphalt mixing plant needs to be based on the specific circumstances of the project, the construction environment, the requirements of the construction period and budget and other factors for comprehensive consideration. Different types of asphalt mixing plants have their own application scenarios, and choosing the right type is important to ensure project quality and improve construction efficiency.

This resource is from http://www.asphalt-mixing-plants.net/industry-news/types-of-asphalt-mixing-plant.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes

Text

Asphalt Plant 60-90 tph - Morocco

Atlas 60-90 tph semi mobile plant installed in Morocco. The feeding unit, drying and mixing drum are fully mobile. The bitumen tank is stationary.

0 notes

Text

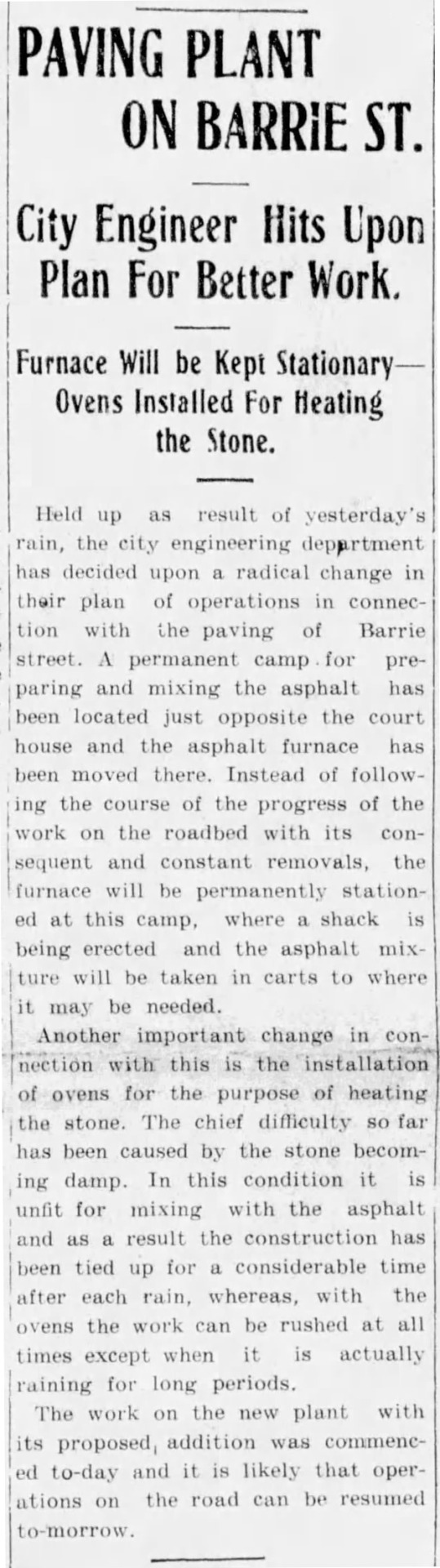

"PAVING PLANT ON BARRIE ST.," Daily Standard (Kingston, Ont.). September 16, 1912. Page 1.

---

City Engineer Hits Upon Plan For Better Work.

---

Furnace Will be Kept Stationary- Ovens Installed For Heating the Stone.

---

Held up as result of yesterday's rain, the city engineering department has decided upon a radical change in their plan of operations in connection with the paving of Barrie street. A permanent camp for preparing and mixing the asphalt has been located just opposite the court house and the asphalt furnace has been moved there. Instead of following the course of the progress of the work on the roadbed with its consequent and constant removals, the furnace will be permanently stationed at this camp, where a shack is being erected and the asphalt mixture will be taken in carts to where it may be needed.

Another important change in connection with this is the installation of ovens for the purpose of heating the stone. The chief difficulty so far has been caused by the stone becoming damp. In this condition it is unfit for mixing with the asphalt and as a result the construction has been tied up for a considerable time after each rain, whereas, with the ovens the work can be rushed at all times except when it is actually raining for long periods.

The work on the new plant with its proposed, addition was commeneed to-day and it is likely that operations on the road can be resumed to-morrow.

#kingston ontario#road workers#road work#street paving#working conditions#1912-1913 kingston street paving#working class struggle#asphalt mixing#work camp#infrastructure construction#road building

0 notes

Text

Finding the Right Concrete Batching Plant Supplier for Your Needs

Concrete batching plants are essential for any construction project that requires large quantities of concrete. These machines mix the raw concrete materials, such as cement, sand, gravel, and water, in precise proportions to create a high-quality product.

When choosing a concrete batching plant supplier, there are a few factors to keep in mind:

Capacity: What is the power of the plant? How much concrete do you need to produce per hour?

Type: There are two main types of concrete batching plants: stationary and mobile. Dormant plants are more expensive but can produce more concrete per hour. Portable plants are less costly and more versatile but have a lower production capacity.

Features: What features are important to you? Some concrete batching plants come with features such as automatic weighing and batching, computerized controls, and environmental protection systems.

Price: How much are you willing to spend? Concrete batching plants can range in price from tens of thousands of dollars to millions of dollars.

Once you have considered these factors, you can start to narrow down your choices. Here are a few tips for finding the right concrete batching plant supplier:

Get quotes from multiple suppliers. This will help you to compare prices and features.

Read reviews from other customers. This can give you an idea of the quality of the supplier’s products and services.

Visit the supplier’s factory in person. This will allow you to see the equipment and talk to the staff.

Choosing the right concrete batching plant supplier is an important decision. By taking the time to consider your needs and research, you can find a supplier that will provide you with a high-quality product at a fair price.

Additional tips:

Look for a supplier with a good reputation and a track record of success.

Ensure the supplier can provide you with the parts and services you need.

Ask about the supplier’s warranty and return policy.

Types of Concrete Batching Plant

Compact concrete batching plant: Compact concrete batching plants are smaller and less expensive than other plants but have a lower production capacity. They are typically used for small to medium-sized construction projects, such as residential buildings and commercial complexes.

Mobile concrete batching plant: Mobile concrete batching plants are mounted on wheels or trailers, efficiently transporting them from one job site to another. They are typically used for projects where the location of the job site is not known in advance or where the job site is remote and difficult to access.

Stationary concrete batching plant: Stationary concrete batching plants are designed to be installed permanently. They are typically more extensive and expensive than mobile plants but can produce more concrete per hour. Stationary plants, such as bridges and highways, are often used for large construction projects.

Cement silo: A cement silo is a large storage tank for cement. It is typically used with a concrete batching plant to ensure a consistent cement supply. Cement silos can be either mobile or stationary.

RMC plant: RMC stands for ready-mix concrete. An RMC plant is a type of concrete batching plant that is specifically designed to produce ready-mix concrete. Ready-mix concrete has been mixed at the plant and transported to the job site in mixer trucks.

WMM plant: WMM stands for wet mix macadam. A WMM plant is a type of concrete batching plant that is specifically designed to produce wet-mix macadam. Wet mix macadam is asphalt mixed with water to create a dense, durable surface.

When choosing a concrete batching plant, it is essential to consider your specific needs. Some of the factors you should consider include the capacity you need, the type of concrete you want to produce, your budget, and the location of the job site. You should also consult with a concrete batching plant supplier to get advice on the best type of plant for your needs.

#cement silo#compact concrete batching plant#concrete batching plant#concrete batching plant supplier#concrete batching plants#mobile concrete batching plant#RMC plant#Stationary Concrete Batching Plant#Wet mix macadam

0 notes

Text

Considerations When Choosing Asphalt Plant On The Market

Asphalt plants are getting to be a vital part road construction and paving projects. Asphalt is among the most generally used paving materials. It is recognized to produce smooth and long-lasting surfaces. In case you are handling a construction project that utilizes asphalt, obtaining your own asphalt plant can significantly benefit your operations.

Obtaining your hot-mix asphalt from the supplier have their fair share of challenges. For instance, you possess no control of the development process, delays due to wait times at the supplier's facility along with the long haul and traffic jams. All of these factors simply cannot only deter your company from realizing its full potential, and in addition affect your reputation as being a reliable and quality construction business.

Investing in your own asphalt plant (Асфальтобетонный завод - абз купить из КИТАЯ в AIMIXGROUP) is now essential in the modern construction industry. However, there are several factors that you should consider before purchasing one. An asphalt plant is really a hefty investment, which isn't a choice that you should take lightly. You should do proper research before settling on a single.

That will help you make a more informed choice, this is a set of factors that you should consider before purchasing an asphalt plant.

i) Measurements of the Plant

Before heading out to the store to acquire an asphalt plant, you first need to understand your daily production requirements. What exactly is your hourly volume target? This can help you determine the proper measurements of asphalt plant that you need. Obviously, the bigger the asphalt plant, the larger the production capacity of the plant.

However, you should also take into account the available space with the construction site. You require to ensure that you have enough space to fir the machine.

The point the following is in order to avoid an asphalt plant that is certainly too large or not big enough for your personal project.

ii) Portability

Another essential factor that you must consider is whether you need a portable or stationary asphalt plant. If you are getting through a large project in the specific area, then you definitely more than likely won't must move the equipment to have an extended time frame. In cases like this, you can think about getting a stationary asphalt plant. However, in case your project requires one to frequently shift the position of the equipment, after that your most suitable choice is really a portable asphalt plant.

iii) Form of Asphalt Plant

The two main main varieties of asphalt plants based on the mode of production Drum Mix Plant and Batch Mix Plant.

Batch Mix Plant: This kind of asphalt plant produces one batch of hot-mix asphalt at the same time. One of the greatest benefits of this sort of plant is that the specification in the product might be adjusted after every batch, thus meeting different client and work requirements.

Drum Mix Asphalt: This kind of asphalt plant is also called continuous type asphalt plant. Simply because unlike the batch plant, it produces asphalt continuously and uninterrupted. The mixing technique of bitumen, filler and aggregate occur in the drying drum uninterrupted toproduce high-quality asphalt.

1 note

·

View note

Text

Asphalt Mixing Plants Industry Analysis, Size, Share, Growth, Trends & Forecast 2022 to 2032

During the forecast period, the worldwide asphalt mixing plants market is expected to generate US$ 8.5 billion while rising at a CAGR of 2.4%. The market is expected to be worth US$ 6.5 billion in 2021 and US$ 6.66 billion in 2022. Increased road construction operations, together with expanding infrastructural development in countries, are expected to drive industry growth.

Increasing asphalt production throughout the world is a key element driving market demand. Countries such as India, Vietnam, and the Philippines will invest extensively in road building and improvements in the future decades in order to improve their rankings.

Over the past few years, tremendous growth in urban centers was witnessed as people moved from the countryside to cities to live and work. Increased disposable incomes will drive up private vehicle ownership, placing greater demands on roads and eventually augmenting road construction projects, particularly in China and India. Portable product type to gain the majority share owing to the increasing necessity for cost-effective and easily transportable construction equipment.

Get a Sample Copy of this Report @

https://www.futuremarketinsights.com/reports/sample/rep-gb-15396

Key Takeaways:

By Product type, the portable product segment of the Asphalt Mixing Plants segment expanded at a ~2% CAGR

Based on Application, the road construction segment of Asphalt Mixing Plants is estimated to record an ~2% CAGR

APAC region is likely to account for the majority share of nearly 3% during the forecast period

Europe region is estimated to gain significant traction in the market for Asphalt Mixing Plants, Germany is likely to hold the majority share.

“Constructers have been investing a lot of time and money in fostering new asphalt plant solutions to cater to important industry requirements, thus in turn, to fuel the market growth of asphalt mixing plants”.

Competitive Landscape

Key players in the global Asphalt Mixing Plants market include Speco Limited, Nikko Co. Ltd., Ammann Group Holding AG, GP Gunter Papenburg AG, Lintec & Linnhoff Germany GmbH.,among others. Recent key developments among players are:

In Aug 2022, Construction Partners, Inc. ROAD (the Company), a vertically integrated civil infrastructure company specializing in the construction and maintenance of roadways across five southeastern states, announced the acquisition of Southern Asphalt, Inc., headquartered in Conway, South Carolina. As a result of the acquisition, the Company added two hot-mix asphalt plants and more than 200 employees in the Myrtle Beach, South Carolina metro area.

In Aug 2021, Berkshire Engineering Supplies (BES) and R&G Cooper (RGC) joined forces to create Bulldog Plant & Equipment Ltd, which is said to be the only business of its kind in Britain and is set to become the number one provider of large-scale production plants in the construction materials, engineering, and energy sectors.

In March 2022, Astec Industriesagreed to acquire MINDS Automation Group (MINDS). The firm is a leader in plant automation control systems and cloud-based data management in the asphalt industry.

More Valuable Insights

Future Market Insights, in its new offering, presents an unbiased analysis of the Global Asphalt Mixing Plants market presenting a historical analysis from 2017 to 2021 and forecast statistics for the period of 2022-2032.

The study reveals essential insights based on Asphalt Mixing Plants Market by Process (Batch, Continuous) by Product (Portable, Stationary) by Application (Road Construction, Others) by Capacity (Below 50T/H, 50-150T/H, 151-300T/H, Above 300T/H) & Region (North America, Europe, East Asia, South Asia, Oceania and Middle East & Africa, and Latin America)

Get Full Information on this Report @

https://www.futuremarketinsights.com/reports/asphalt-mixing-plants-market

Key Segments Covered In The Asphalt Mixing Plants Industry Analysis

Asphalt Mixing Plants Market by Process:

Asphalt Mixing in Batches

Continuous Asphalt Mixing

Asphalt Mixing Plants Market by Product:

Portable Asphalt Mixing Plants

Stationary Asphalt Mixing Plants

Asphalt Mixing Plants Market by Application:

Asphalt Mixing Plants for Road Construction

Others

Asphalt Mixing Plants Market by Capacity:

Below 50T/H Asphalt Mixing Plants

50-150T/H Asphalt Mixing Plants

151-300T/H Asphalt Mixing Plants

Above 300T/H Asphalt Mixing Plants

Asphalt Mixing Plants Market by Region:

North America Asphalt Mixing Plants Market

Latin America Asphalt Mixing Plants Market

Europe Asphalt Mixing Plants Market

East Asia Asphalt Mixing Plants Market

South Asia Asphalt Mixing Plants Market

Oceania Asphalt Mixing Plants Market

Middle East & Africa Asphalt Mixing Plants Market

0 notes

Text

ZAP-S120 Asphalt Mixing Plant Project in Kazakhstan.

Date: 2020.08.27----2020.10.24

Location: Aktobe, KZ(Kazakhstan)

Model and capacity: ZAP-S120, 120T/H

Kazakhstan is a landlocked country in Central Asia and the largest landlocked country in the world. It is also a good neighbor of China.

As an important participant in the Belt and Road Initiative, Kazakhstan has been continuously enhancing the construction and upgrading road infrastructure, attracting more tourists and foreign investment to Kazakhstan, and constantly improving the living standards of local residents.

Our customer finally purchased a set 120T/H asphalt mixing plant from our company to meet the increasing project volume, which was the first large-scale asphalt mixing plant in the area.

This set of asphalt mixing plant is composed of 4 cold feed bins system, drying drum, gas burner (German brand gas valve set), cyclone dust removal + bag house dust collector combined dust removal system, new filler silo with reclaimed filler silo, mixing tower, pneumatic system, thermal oil heating system with bitumen storage tank, automatic computer control system and other parts.In order to ensure the stability of the control system, the electrical components are imported from Siemens and other brands.

#asphalt mixing plant#road construction#bitumen#asphalt drum mix plant#asphalt plant#heavy equipment#concrete#asphaltplant#construction#mobile asphalt drum mix plant#stationary asphalt plant#stationary asphalt mixing plants#asphalt mix plant#stationary asphalt mixing plant#asphalt plant machine#asphalt plant equipment#asphalt paving#asphalt repair

1 note

·

View note

Text

Stationary Asphalt Plant - Atlas Industries

Atlas for sale high quality of asphalt drum mix plant. We are manufacturer of stationary asphalt plants. Available 40 tph to 120 tph capacity of drum mixer.

0 notes

Text

Advantages of Mobile Asphalt Drum Mix Plant - Atlas Technologies

Mobile asphalt plants come with some inherent advantages over their stationary counterpart and size and features like additional portability are not the only ones.With mobile drum mix plants, the components are preassembled on a maximum of three or four chassis.

0 notes

Text

The Environmental Benefits of Using a Mobile Asphalt Batch Mix Plant

In today's era of heightened environmental consciousness, industries across the globe are reevaluating their processes to minimize their ecological footprint. Among these industries, the construction sector stands out for its significant impact on the environment. However, advancements in technology have paved the way for more sustainable practices, and one such innovation is the Mobile Asphalt Batch Mix Plant.

Asphalt, a vital component in road construction, has traditionally been produced in stationary plants, which often consume substantial energy and emit pollutants. However, the advent of mobile asphalt batch mix plants has revolutionized this aspect of construction, offering several environmental benefits that align with the goals of sustainability.

Understanding the Mobile Asphalt Batch Mix Plant

Before delving into its environmental advantages, it's essential to grasp the concept of a mobile asphalt batch mix plant. Unlike stationary plants, mobile asphalt batch mix plants are designed for versatility and mobility. They are compact, modular units that can be easily transported to different job sites, enabling on-site production of asphalt.

Environmental Benefits

1. Reduced Energy Consumption:

Mobile asphalt batch mix plants are engineered for efficiency. They optimize energy consumption by incorporating advanced technologies such as burner systems and insulation techniques, which ensure that energy is utilized judiciously during the asphalt production process. This results in lower fuel consumption per ton of asphalt produced, contributing to reduced carbon emissions.

2. Minimized Transport Costs and Emissions:

The mobility of mobile asphalt batch mix plants significantly reduces the need for transporting raw materials and finished products over long distances. By producing asphalt directly at the construction site, the plant eliminates the environmental impact associated with transporting materials to and from stationary plants. This reduction in transportation requirements translates to lower fuel consumption and greenhouse gas emissions, thus mitigating the ecological strain of construction activities.

3. Enhanced Resource Utilization:

Mobile asphalt batch mix plants offer greater flexibility in resource utilization. They enable construction companies to produce asphalt in precise quantities as per project requirements, thereby minimizing waste and conserving resources. Additionally, these plants can accommodate a variety of raw materials, including recycled asphalt pavement (RAP), promoting sustainable practices by reducing the demand for virgin materials and landfill space.

4. Improved Air Quality:

The implementation of advanced emission control systems in mobile asphalt batch mix plants helps mitigate air pollution. These plants are equipped with state-of-the-art filters and scrubbers that capture particulate matter and harmful emissions before they are released into the atmosphere. As a result, the environmental impact of asphalt production is significantly reduced, contributing to cleaner air and healthier communities.

Conclusion

In conclusion, the adoption of mobile asphalt batch mix plants represents a pivotal step towards achieving sustainable development in the construction industry. By embracing innovative technologies and eco-friendly practices, companies can minimize their environmental footprint while meeting the growing demands for infrastructure development.

At Coninfra Machinery Pvt Ltd, we recognize the importance of environmental stewardship and are committed to providing cutting-edge solutions such as the Mobile Asphalt Batch Mix Plant to promote sustainability in construction projects. Through our dedication to technological excellence and environmental responsibility, we aim to pave the way towards a greener, more sustainable future for generations to come.

For more information about our mobile asphalt batch mix plant and other environmentally friendly construction solutions, please visit our website.

Name: Coninfra Machinery Pvt.Ltd

Address:504, Sahitya Business Park, Nr. Keshav Hero Showroom , S.P Ring Road Nikol, Ahmedabad - 382350, INDIA

Contact No: +91 90999 41311

0 notes

Text

Asphalt Mixing Plants Market In-Depth Analysis with Booming Trends Supporting Growth and Forecast 2022-2032

The global asphalt mixing plants market is anticipated to garner US$ 8.5 Billion while expanding at a CAGR of 2.4% during the forecast period. The market is estimated at US$ 6.5 Billion in 2021 and US$ 6.66 Billion in 2022. The increasing road construction activities coupled with growing infrastructural development in countries are likely to propel industry growth.

Increasing asphalt production across the globe is a prime factor that will drive market demand. Countries, including India, Vietnam, and the Philippines, will be investing heavily in road construction & improvements in the coming decades to enhance their ranking.

Over the past few years, tremendous growth in urban centers was witnessed as people moved from the countryside to cities to live and work. Increased disposable incomes will drive up private vehicle ownership, placing greater demands on roads and eventually augmenting road construction projects, particularly in China and India. Portable product type to gain the majority share owing to the increasing necessity for cost-effective and easily transportable construction equipment.

To Know More@

Key Takeaways:

By Product type, the portable product segment of the Asphalt Mixing Plants segment expanded at a ~2% CAGR

Based on Application, the road construction segment of Asphalt Mixing Plants is estimated to record an ~2% CAGR

APAC region is likely to account for the majority share of nearly 3% during the forecast period

Europe region is estimated to gain significant traction in the market for Asphalt Mixing Plants, Germany is likely to hold the majority share.

“Constructers have been investing a lot of time and money in fostering new asphalt plant solutions to cater to important industry requirements, thus in turn, to fuel the market growth of asphalt mixing plants”.

Competitive Landscape

Key players in the global Asphalt Mixing Plants market include Speco Limited, Nikko Co. Ltd., Ammann Group Holding AG, GP Gunter Papenburg AG, Lintec & Linnhoff Germany GmbH.,among others. Recent key developments among players are:

In Aug 2022, Construction Partners, Inc. ROAD (the Company), a vertically integrated civil infrastructure company specializing in the construction and maintenance of roadways across five southeastern states, announced the acquisition of Southern Asphalt, Inc., headquartered in Conway, South Carolina. As a result of the acquisition, the Company added two hot-mix asphalt plants and more than 200 employees in the Myrtle Beach, South Carolina metro area.

In Aug 2021, Berkshire Engineering Supplies (BES) and R&G Cooper (RGC) joined forces to create Bulldog Plant & Equipment Ltd, which is said to be the only business of its kind in Britain and is set to become the number one provider of large-scale production plants in the construction materials, engineering, and energy sectors.

In March 2022, Astec Industriesagreed to acquire MINDS Automation Group (MINDS). The firm is a leader in plant automation control systems and cloud-based data management in the asphalt industry.

More Valuable Insights

Future Market Insights, in its new offering, presents an unbiased analysis of the Global Asphalt Mixing Plants market presenting a historical analysis from 2017 to 2021 and forecast statistics for the period of 2022-2032.

The study reveals essential insights based on Asphalt Mixing Plants Market by Process (Batch, Continuous) by Product (Portable, Stationary) by Application (Road Construction, Others) by Capacity (Below 50T/H, 50-150T/H, 151-300T/H, Above 300T/H) & Region (North America, Europe, East Asia, South Asia, Oceania and Middle East & Africa, and Latin America)

0 notes

Text

Drum Mix Plant - Installed in Nigeria By Atlas

Photos of 60-90 tph asphalt drum mix plant supplied by Atlas Technologies installed in Nigeria. Asphalt mixer supplied is stationary type.

0 notes

Photo

Mobile Asphalt Plant Manufacturer and Suppliers – Atlas Technologies

Mobile asphalt drum mix plants are in great demand. They are for flexibility and high production in comparison to stationary plants. We are exporter of Mobile Asphalt Plants in countries like Peru, Venezuela and Kenya.

#mobile asphalt plant#Mobile Asphalt Plant Manufacturers#Asphalt plant#construction equipment#construction equipments

0 notes