#structural steel pipe

Explore tagged Tumblr posts

Text

India’s largest structural steel tubes & pipes manufacturing company. Redefining the landscape of construction in India since 1986! We are India’s largest producer of structural steel tubes and steel pipes to cater to all tubular steel building solutions.

#Rectangular Hollow Sections#structural steel pipe#apl apollo#ms pipe manufacturers#apl apollo tubes

0 notes

Text

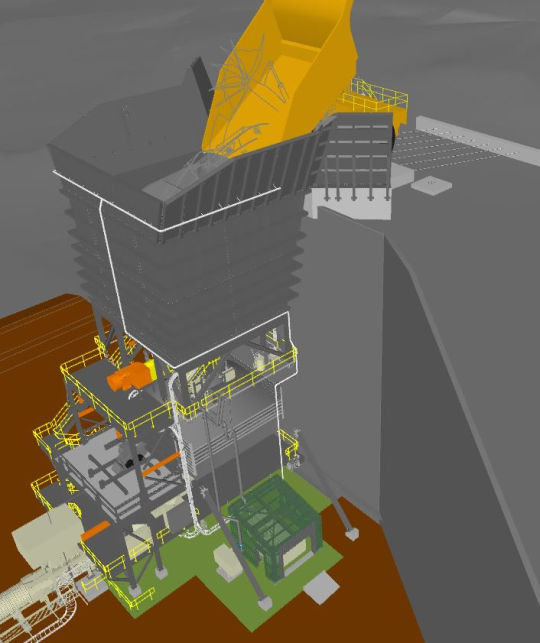

Methods India: Bulk Material Handling Equipment Manufacturers in Bangalore | Chennai | India

Looking for reliable bulk material handling equipment manufacturers in Bangalore, Chennai, Hyderabad, Mumbai, and across India? Methods India offers high-performance conveyors, silos, hoppers & more—custom-engineered to boost industrial efficiency. Trusted by top industries. Get a free quote today!

For more info, visit: https://methodsindia.com/methods-india-leading-structural-design-fabrication-bulk-material-handling-company/

#bulkmaterialhandling#bulkmaterialhandlingsystems#bulkmaterialmanufacturersinindia#methodsindia#structural steel fabrication#pipe conveyors#belt conveyors#bulkmaterialhandlingequipmentmanufacturersinindia#bulkmaterialhandlingequipmentmanufacturersinchennai#bulkmaterialhandlingequipmentmanufacturersinbangalore

0 notes

Text

CASTING and ENGINEERING

#Casting and Engineering#Metal Castings#Metal Forgings#steel fabrication#steel pipe fabrication#steel plate#steel structure#manufacturing#precisionengineering#manganese

1 note

·

View note

Text

Types of Hot Dip Galvanized Solar Structures : GI Square Pipes, GI Base Plates, GI Slotted Angles and more

Solar energy is a backbone of sustainable development, and robust infrastructure is required to harness it efficiently. Among the main components of a solar installation are the solar structures that support and stabilize the panels. At Parco Engineers, we specialize in high-quality, hot dip galvanized (HDG) solar structures designed for durability and performance. This blog explores the various types of galvanized solar structures, their uses, and the advantages they bring to solar installations.

Why Hot Dip Galvanized Solar Structures?

Hot dip galvanization is a process where steel is coated with zinc to prevent corrosion, making it ideal for solar structures exposed to harsh weather conditions. A solar panel structure endures years of environmental wear and tear, and galvanization ensures longevity and minimal maintenance.

Key Types of Hot Dip Galvanized Solar Structures

1. GI Square Pipes

Corrosion resistance due to the zinc coating.

High tensile strength to withstand strong winds and other environmental conditions.

Versatile design for both ground-mounted and rooftop solar panel structures.

At Parco Engineers, our GI square pipes come in various dimensions to meet the unique requirements of different solar projects.

Features and Benefits:

Galvanized square steel pipes are a fundamental component in solar mounting structures. These pipes provide exceptional strength and stability, making them ideal for framing and supporting structural solar panels.

2. GI Base Plates

Enhanced load-bearing capacity.

Corrosion-resistant surface for long-term use.

Easy installation and compatibility with various solar mounting designs.

Our steel base plates are precision-engineered for reliability and durability, ensuring your solar setup stands the test of time.

Advantages:

A base plate serves as the foundation for securing solar structures to the ground or rooftops. Made from high-quality galvanized steel, base plates ensure the stability of the entire installation.

3. GI Slotted Angles

Supporting smaller solar panel structures.

Creating flexible mounting configurations.

Securing additional components like inverters or batteries.

Their flexibility and ease of use make slotted angles a favorite choice among solar engineers and installers.

Applications:

GI slotted angles are another versatile component used in solar installations. They allow for adjustable connections and are commonly used in framing and mounting systems.

4. GI Round Bars

Superior corrosion resistance.

High strength-to-weight ratio.

Long lifespan, even in extreme weather conditions.

Why Choose GI Round Bars?

GI round bars, also known as galvanized round bars, are widely used for structural and reinforcement purposes in solar projects. These bars add strength and stability to the overall design.

5. Strut Channels and Unistrut Channels

The strut channels are otherwise known as unistrut channels, which provide essential mounting support to the solar panels. The strut channels can bear heavy loads and are quite flexible for mounting purposes.

Important Features:

Modular structure that allows for easy assembly

High corrosion resistance to withstand outdoor environments

Easy to fit in mounting brackets and other fittings.

Strut channels are particularly useful for commercial and industrial solar installations where adaptability is essential.

6. Custom Components

We also offer bespoke components at Parco Engineers:

Steel base plates for one-off mounting requirements

Specialty galvanized round bars for reinforcement

Customized solar panel structures that are dimensionally designed for your project

Benefits of Hot Dip Galvanized Solar Structures

Hot Dip Galvanized solar structures offer numerous benefits when incorporated into your solar installation:

Resistance to corrosion: through the application of zinc, making the structure resistant to rust, and therefore increasing the life expectancy of your solar mounting structure

Strength and Durability: HDG components can withstand extreme weather conditions, ensuring stable performance over decades.

Sustainability: Galvanized steel is recyclable, making it an eco-friendly choice for renewable energy projects.Versatility: Components like GI square pipes, strut channels, and base plates can be tailored to suit different project requirements.

Applications of Hot Dip Galvanized Solar Structures

Residential Solar Systems:

Homeowners rely on compact, durable GI structures for solar panels to maximize rooftop efficiency.

Commercial and Industrial Solar Projects:

For large-sized installation, a solid solar mounting structure is needed. It may comprise galvanized square steel or unistrut channels.

Open-Field Solar Farms

It demands heavy-duty frames, GI pipes, and reinforced steel base plates to support the firm installation of a solar farm.

Why Parco Engineers?

We are an experienced manufacturing company that produces GI structures for the installation of solar panels. We Facilitates tailormade to individual project specifications.

We provide competitive pricing and timely delivery. We deliver uncompromised commitment to quality and sustainability.

When it comes to building durable, reliable, and efficient solar panel structures, hot dip galvanized components are the gold standard. Whether you need GI square pipes, steel base plates, or strut channels, Parco Engineers has the expertise and products to power your renewable energy projects.

Invest in the future of energy with Parco Engineers, your partner for sustainable infrastructure. Contact us today to learn more about our complete range of solar structures and solutions.

#solar panel structure#structural solar panels#solar mounting structure#gi structure for solar panels#galvanized square steel#gi square pipe#gi pipe manufacturers#round bar#gi round bar#galvanized round bar#unistrut channel#base plate

0 notes

Text

Oxygen Plant in 15 Days: APL Apollo's Rapid Solution Unveiled

Discover APL Apollo Columns, India's trusted leader in structural steel tubes, ideal for diverse construction needs. Visit us for more details!

#steel-sheet#steel-tube#steel-pipe#steel-pipes#structural-steel-buildings#structural-steel-pipes#structural-steel-tubes#apl-apollo

0 notes

Text

Enhancing Sustainability with Structural Steel Fabrication

Structural steel fabrication is transforming sustainable construction by reducing material waste, energy consumption, and emissions. Using precision engineering and recyclable materials, it minimizes environmental impact while ensuring durability. Prefabrication speeds up construction, reducing on-site energy use and machinery emissions. Advanced coatings enhance longevity and cut maintenance costs. With a high recyclability rate, steel supports circular economy goals and long-term sustainability. Discover how structural steel fabrication is key to creating cost-effective, energy-efficient, and environmentally responsible industrial and commercial infrastructure.

0 notes

Text

#Casting and Engineering#Metal Castings#Metal Forgings#Steel Fabrication#steel structure#Steel Pipe Fabrication#precision machining#Sand Castings#Investment Castings#Die Castings#miningequipment#Manganese Castings#Chrome Castings#cnc machining#manufacturer#manufacturing#stainless steel#steel plate#steel pipe

1 note

·

View note

Text

Automotive Component Manufacturing Experts | Metalman Auto Ltd.

Metalman Auto Ltd. stands as a Best Automotive Component Manufacturing Experts, delivering precision-engineered solutions to Original Equipment Manufacturers (OEMs) across the automotive industry. With over three decades of experience, we specialize in producing high-quality components for two-wheelers, three-wheelers, passenger vehicles, commercial vehicles, and off-highway vehicles, meeting the exacting standards of performance, reliability, and durability.

Our advanced manufacturing facilities are equipped with cutting-edge technologies, including CNC machining, metal stamping, tubular fabrication, and metal finishing. This allows us to offer a wide range of automotive components, from chassis parts to engine components and body panels. Each product is meticulously crafted to meet the specific needs of our OEM partners, ensuring seamless integration and optimal performance in their vehicles.

At Metalman Auto Ltd., quality is embedded in every step of our manufacturing process. We adhere to ISO-certified quality management systems and employ rigorous testing and inspection procedures to ensure that every component we produce meets or exceeds industry standards. Our commitment to excellence has earned us a reputation as a trusted partner for some of the most renowned names in the automotive industry.

Innovation is at the core of our operations. We continuously invest in research and development to stay ahead of industry trends and provide our clients with the most advanced automotive component solutions. Our team of skilled engineers and technicians works closely with OEMs to develop customized components that meet the unique challenges of today’s automotive market, from electric vehicles (EVs) to autonomous driving technologies.

Partner with Metalman Auto Ltd. to experience the expertise and reliability. best automotive component manufacturing experts. Explore our comprehensive range of services and discover how we can help you drive success in your automotive projects.

#OEM metal fabrication services#Custom metal parts manufacturer for OEMs#Bespoke metal fabrication for automotive industry#Custom metalwork for vehicle manufacturers#Precision metal fabrication for OEMs#Specialized metal fabrication for automotive parts#Tailored metal fabrication solutions for OEMs#Custom steel fabrication for automotive OEMs#Metal parts supplier for automotive industry#OEM metal components manufacturer#Automotive metal fabrication services#Steel and aluminum components for vehicles#Automotive metal body parts supplier#Precision metal parts for automotive applications#Automotive structural components manufacturer#OEM automotive metal components provider#Tube fabrication for automotive applications#Precision tube bending services#Tubular components manufacturer for OEMs#Automotive tubular parts fabrication#Custom tube fabrication for vehicles#Metal tube fabrication for automotive industry#Precision pipe fabrication services#Tubular assembly solutions for automotive OEMs#automotive tools#automotive industry#automotive innovation#automobile#automotive#crack in the chassis

1 note

·

View note

Text

Stainless Steel Sheet & Plates by Emirerri Steel

Emirerri Steel is a leading manufacturer and supplier of high-quality stainless-steel sheets and plates, designed to meet the diverse needs of various industries. Our extensive range of products includes specialized plates for shipbuilding, wear-resistant applications, high-strength structural purposes, and pressure vessels. Each product is crafted with precision to ensure maximum durability, strength, and performance.

Ship Building Steel Plate

Our Ship Building Steel Plates are engineered to provide superior strength and toughness to withstand harsh marine environments. These plates are essential for constructing the hulls of ships, offering excellent weldability and resistance to seawater corrosion. Available in various grades and thicknesses, our shipbuilding steel plates ensure the safety and longevity of maritime structures.

Wear Resistant Steel

For applications that demand exceptional durability, our Wear Resistant Steel plates are the ideal choice. These plates are specifically designed to resist abrasion and wear, making them suitable for use in industries such as mining, construction, and material handling. With a high hardness and toughness, our wear-resistant steel plates extend the service life of equipment and reduce maintenance costs.

High Strength Structural Steel

Emirerri Steel's High Strength Structural Steel plates are designed to provide exceptional load-bearing capacity without compromising on flexibility. These plates are perfect for constructing high-rise buildings, bridges, and other infrastructures requiring robust support. Our high-strength structural steel is characterized by its high yield strength and excellent tensile properties, ensuring stability and safety in construction projects.

Pressure Vessel Steel

Our Pressure Vessel Steel plates are tailored to meet the stringent requirements of the pressure vessel industry. These plates are capable of withstanding high pressures and temperatures, making them ideal for use in boilers, heat exchangers, and other pressure-containing applications. With superior toughness and resistance to cracking, our pressure vessel steel plates ensure the integrity and reliability of critical equipment.

Why Choose Emirerri Steel?

At Emirerri Steel, we prioritize quality and customer satisfaction. Our stainless steel sheets and plates are manufactured using advanced technologies and rigorous quality control measures to meet international standards. Whether you need plates for shipbuilding, wear-resistant applications, high-strength structural purposes, or pressure vessels, you can trust Emirerri Steel to deliver products that exceed your expectations.

Explore our wide range of stainless steel sheets and plates and discover the perfect solution for your industrial needs. Contact us today to learn more about our products and services. www.emirerristeel.com

#steel manufacturing#success#marketing#steel manufacturer#pipe fittings#stainless-steel sheets and plates#stainless-steel#sheets and plates#sheets#plates#Ship Building Steel Plate#Wear Resistant Steel Plate#High Strength Structural Steel Plate#Pressure Vessel Steel Plate

0 notes

Text

Build Your Dream Commercial Spaces with Apollo Structural

Discover APL Apollo, India's leading maker of structural steel pipes, tubes, and hollow sections with advanced tech and top-notch standards. Learn more!

#steel-sheet#steel-tube#steel-pipe#steel-pipes#structural-steel-buildings#structural-steel-pipes#structural-steel-tubes#apl-apollo

0 notes

Text

Conveyor Idlers by Methods India: Durable Solutions for Bulk Material Handling

Ensure reliability and efficiency in your material handling processes with Methods India’s Conveyor Idlers. Crafted to handle the most demanding conditions, our idlers consistently support conveyor belts, ensuring smooth operation and reduced wear. Industries like mining, construction, and power generation trust Methods India for our innovative designs and long-lasting performance. Partner with us for high-quality Conveyor Idlers that improve system efficiency and lower operational costs. Experience the difference with Methods India today! For more information visit: https://methodsindia.com/the-role-of-structural-steel-fabrication-in-modern-industrial-construction

0 notes

Text

Why Super Rings Are Key to Enhancing the Durability of TMT Steel

Steel Pipe Company stands at the vanguard of innovation in construction substances, in particular within the improvement of high-overall performance TMT metal reinforcement bars. Among the many technological advancements that have revolutionized the steel industry, the combination of Super Rings into TMT steel production strategies has emerged as a game-changing component for structural sturdiness and toughness.

The Revolutionary Impact of Super Ring Technology

TMT steel has turned out to be the spine of modern construction; however, not all TMT merchandise delivers the same overall performance. The distinction frequently lies in the microscopic information—particularly in the formation of Super Rings for the duration of the quenching and tempering system. These Super Rings create a distinct metallurgical shape that drastically enhances the bodily homes of reinforcement bars.

How Super Rings Transform Ordinary TMT Steel

The sturdiness of TMT metal depends in large part on its capability to resist each tensile and compressive force concurrently. Super Rings contribute to this functionality through several mechanisms:

Enhanced Core-Rim Structure: The formation of super Rings creates great stability between a ductile core and a hardened rim. This twin-nature shape enables TMT steel to flex without breaking, even while preserving marvelous load-bearing capacity.

Improved Corrosion Resistance: The particular association of Super Rings in TMT steel creates herbal obstacles against corrosive elements. This protection extends the lifespan of strengthened concrete systems, particularly in coastal or chemically aggressive environments.

Superior Weldability and Bendability: Steel Pipe Company's TMT metal with Super Ring era continues terrific workability regardless of its expanded electricity. Construction teams respect the benefit of manipulation without sacrificing structural overall performance.

The Science Behind Super Ring Formation

The introduction of Super Rings isn't always accidental but the result of an exactly controlled thermomechanical remedy. During production, TMT metallic undergoes fast floor quenching followed by means of self-tempering from the residual heat of the middle. This process creates a one-of-a-kind martensitic rim with a ferrite-pearlite internal shape.

What makes Super Rings first rate is their perfect arrangement inside this twin structure. As warm metallic enters the quenching chamber, speedy cooling of the floor creates thermal gradients that force the formation of those concentric jewelry.

Real-World Implications for Construction Projects

The presence of Super Rings in TMT steel translates to tangible advantages for construction initiatives:

Extended Structural Lifespan: Buildings reinforced with Super Ring-more desirable TMT metallic continuously outperform the ones built with conventional reinforcement bars, often including a long time to their purposeful lifespan.

Earthquake Resistance: The specific ductility provided via Super Rings allows structures to absorb seismic power without catastrophic failure. This feature has demonstrated priceless in earthquake-inclined areas.

Cost Efficiency: While top-rated TMT metallic may additionally represent better initial funding, the extended durability and reduced renovation requirements supply sizable long-term savings for property proprietors and developers.

Making the Right Choice for Your Construction Needs

When choosing reinforcement materials for construction initiatives, examining the microstructure for Super Rings needs to be a concern. High-pleasant TMT steel offering those formations gives you super performance throughout all important parameters: tensile power, yield energy, elongation, and bend check consequences. Steel Pipe Company's advanced production approaches make certain regular Super Ring formation for the duration of their TMT metallic products.

Conclusion: The Definitive Edge in Construction Quality

The inclusion of super rings in TMT metal represents one of the most massive improvements in substance generation. These microscopic systems supply macroscopic benefits, remodeling everyday reinforcement bars into amazing building additives that stand the test of time.

For creation professionals committed to building structures that ultimate generations, choosing TMT metal with properly fashioned Super Rings isn't only a desire—it's a necessity. Steel Pipe Company keeps to steer this technological frontier, making sure that contemporary structures enjoy the complete ability of advanced metallurgical science.

#Steel Pipe Company#Super Rings#TMT Steel#durable steel#reinforced bars#steel strength#construction steel#high-strength steel#corrosion-resistant#steel durability#TMT bars#structural steel#earthquake-resistant#steel reinforcement#building materials#advanced steel#steel technology#metallurgical steel#steel manufacturing#steel industry.

0 notes

Text

Little P.Eng. Engineering: Leading the Way in Bulk Material Transport Design across North America

In industries where massive volumes of materials are processed, the importance of efficient and safe bulk material transport cannot be overstated. Little P.Eng. Engineering stands as a beacon of excellence in this niche, offering top-tier structural and mechanical designs for a variety of equipment across Canada and the USA.

The Genesis of Bulk Material Transport

Bulk material transport is an integral cog in the machine of large-scale industries. Be it mining, manufacturing, or agriculture, the ability to move vast amounts of raw or processed materials efficiently ensures seamless operations and reduced downtimes. This task's complexity demands innovative solutions tailored to specific needs and geographic conditions.

Decoding Little P.Eng. Engineering's Portfolio

Apron Feeders:

Role: Essential in mining and heavy industry, they deliver a steady feed of materials to other machines.

Little P.Eng. Precision: Custom designs account for rugged conditions, ensuring robustness, minimal wear-tear, and efficient feeding speeds.

Belt Conveyors:

Role: The backbone of many industries, they transport materials over short to long distances.

Little P.Eng.'s Approach: Focus on load-bearing capacity, adaptive designs for different terrains, and durability in varied climatic conditions.

Belt Feeders:

Role: Controlled feeding of bulk materials, often used in coordination with other systems.

Little P.Eng.'s Vision: Precision-engineered for accurate delivery rates and volumes, ensuring no overloading or wastage.

Mobile Conveyor Bridges:

Role: Vital for large mining operations, they offer flexibility in transporting materials across significant distances.

Little P.Eng.'s Craft: Mobility and stability converge, ensuring these bridges can be relocated effortlessly without compromising safety.

Mobile Transfer Conveyors:

Role: As the name suggests, these conveyors are mobile and are often used in tandem with other stationary equipment.

Little P.Eng. Insight: Prioritizing easy maneuverability, these conveyors also spotlight on energy efficiency and fast material transfer.

Tube Conveyors:

Role: They provide enclosed transport, often used for grains, powders, or any material susceptible to external contamination or spillage.

Little P.Eng.'s Touch: Airtight sealing, efficient transport mechanism, and designs that reduce maintenance downtimes.

In-plant Conveyor Systems:

Role: Within factories or processing plants, they link various stages of production or processing.

Little P.Eng. Expertise: Modular designs that fit seamlessly into existing infrastructures, ensuring no workflow disruption.

Pipe Conveyor Systems:

Role: Offering enclosed transport, they are often used for materials like coal, ensuring no spillage or dust emissions.

Little P.Eng.'s Specialty: Enhanced curvature ability, ensuring a smaller footprint and efficient transport even in space-constrained areas.

Steel Belt Conveyors:

Role: Handling materials at high temperatures or those that might be abrasive or cut regular belts.

Little P.Eng. Mastery: Heat-resilient designs, ensuring prolonged lifespans even under intense conditions.

The North American Landscape: Challenges and Innovations

From the icy terrains of Northern Canada to the industrious heartlands of the USA, each region poses its unique challenges. Whether it's dealing with permafrost or ensuring equipment can withstand desert heat, Little P.Eng. Engineering's designs embody adaptability, ensuring machinery performs at its peak regardless of external conditions.

Moreover, with both countries emphasizing sustainable operations, the engineering firm ensures eco-friendly designs, minimizing energy consumption and environmental impact.

Conclusion

In an age where efficiency can dictate market standings, Little P.Eng. Engineering's contribution to the bulk material transport sector across Canada and the USA is undeniable. Through an intricate understanding of mechanics, topography, and industrial needs, the firm crafts solutions that don't just move materials but advance industries.

Read more:

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Tags:

Little P.Eng. Engineering

Structural design

Mechanical design

Mining equipment

Tailored equipment design

Bulk material transport

Modular design

Apron feeders

Belt conveyors

Belt feeders

Mobile conveyor bridges

Mobile transfer conveyors

Tube conveyor systems

In-plant conveyor systems

Pipe conveyor systems

Steel belt conveyors

North American industry

Sustainable operations

Material movement solutions

Efficient material transport

Custom machinery design

Industrial innovations

Canada industrial machinery

USA industrial machinery

Adaptability in design

Eco-friendly machinery

High-temperature material handling

Enclosed transport systems

Production workflow

Advanced material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Mechanical design#Mining equipment#Tailored equipment design#Bulk material transport#Modular design#Apron feeders#Belt conveyors#Belt feeders#Mobile conveyor bridges#Mobile transfer conveyors#Tube conveyor systems#In-plant conveyor systems#Pipe conveyor systems#Steel belt conveyors#North American industry#Sustainable operations#Material movement solutions#Efficient material transport#Custom machinery design#Industrial innovations#Canada industrial machinery#USA industrial machinery#Adaptability in design#Eco-friendly machinery#High-temperature material handling#Enclosed transport systems#Production workflow#Advanced material handling

0 notes