#thread synchronization in operating system

Explore tagged Tumblr posts

Text

CW: suicidal themes, institutional transphobia implied

I don't belong in this cradle.

It's the honest truth of the matter. I don't deserve to be here.

Another battlefield lays itself before my projected vision, smoldering browns and grays behind the colorful sensor overlays. In these hellish craters, I likely do belong, but not in this cockpit.

There's a sickly feeling that comes with it. Like a pair of ragged, poorly fitting clothes, carrying a detestable stench.

Its torn threads? Inch-deep gashes and mended holes in metal plating that were not acquired under my operation.

And the stench? It's her stench.

I know everything about her. It told me. It was never not gonna tell me.

Imogen died in this very same cockpit, fear flooding her veins while an armor piercing round entered through the sidewall.

It showed me this, the angle of the projectile, the internal feed playback, the sound of it, the measurements of her biometrics, the flatline and system-wide scream it deafeningly howled out as its other half ceased.

It was the first thing it ever showed me when I did my first link test. It was bitter. Wrathful.

I didn't even fucking know they could feel like that the first time I hopped in. They pulled me out of the cockpit in a sorry state, shaking and sobbing, but still figured my synchronicity scored highly enough to put me back in the thing. They can't afford to scrap a working mech anymore for "limited pilot incompatibility".

Why the fuck did Legacy stick me in the mech that was mourning?

I was mad. Real mad at the brass for denying my reassignment req's. Most of all, I was mad at her mech.

One day it responded to my anger on the trek back to exfil. It flooded my mind with just her. Her joy, determination, cockiness, care... It overlaid stored visual/audio buffers into my own vision—replayed the very sensations attached to those logs—and I was her. It flooded me with her love as if it was my own, with a closeness I never was afforded to have with such a war machine.

I felt deep envy tinging my anger.

Pilots sit in these big metal boxes because of the strategically utilized notion of it being theirs. The rumored wonders of a paired digital consciousness are allowed to spread because it pulls hopeless girls with big dreams like Imogen into the cockpit.

That's what they need in a loyal pilot. I wanted a goddamn mech to call my own, not some dead girls broken leftovers.

But then I, as Imogen, died in that seat to my mech screaming out for me.

And then there was no anger. Just emptiness.

What an awful lesson, to be taught what it feels like to lose half of yourself.

There's another sortie on another reneging territory rejecting Legacy's grand mission, fighting against mechs that used to bare the insignia of the Earth and her Moon. Again I find myself walking back a line, cover laid for my comrades while rebel hotshots push the advantage with righteous vigor.

When it isn't streaming bits of her at me over the datalines, memories lovely and tragic, it's cold. Completely silent. Somehow that's worse.

On the losing end of a war in a coffin.

Sometimes I just can't stand it, and find a boldness within me when I ask it to tell me the story of how Imogen chose her name again. That's its favorite.

(I don't call it by its chosen name because it won't tell me. I have a feeling it never will.)

I wonder often why it even lets me command it into battle after battle. I'm not who it truly wants, and its suffering because of it. I figure if it can puppet my senses just as well as I puppet its limbs, it could likely figure a way to brick itself for good.

It twitches over the link when the thought bleeds through from my end, and it goes silent once again.

Guilt writhes around my gut as I fight for a future I barely believe in anymore. I know why it wouldn't.

When I filled the forms in the service registration office, on a harbor moon in a system two jumps from Hila, I had made a decision. Bloodshed remained stark on my mind as the upheaval of Legacy control on one of its most pivotal worlds forced me away from the only place I called home.

I recall the resistance ships dropping low beneath the skyline with improvised munitions, launching off their rails at military strongholds. I recall the mandatory evacuations as uniformed Legacy troops kicked down doors and ordered us onto the evac shuttles.

I recall the very military administration building that my sister was stationed at erupting all at once as the strategic calculations for maximal military damage factored in the Department of Citizen Records field office on floor 63 as a viable target.

I checked the "F" on the form with the pride that my sister was the very reason I was allowed this privilege. I checked the box with the shame that this was considered a privilege. I checked the box with the naive ideal that once we won this war, it wouldn't be resigned to just a privilege.

(A flicker of emotion echoes across the dataline, as it picks up this memory I've never shown it before. It feels like a gentle embrace.)

Losing my sister was losing one of the few people who actually saw me. She didn't miss a beat when I told her my real name. She held me close, and I felt the most profound joy in knowing love in sisterhood.

I chose to survive because it's what she would have wanted, for me to blossom into the woman she knew me to be.

Imogen is not my sister, but she could have been.

The mech chooses to live because it's what Imogen would have wanted.

We're both stuck in this war together.

I don't know how this ends well for either of us. Defection has crossed the mind, but no certainty comes from the prospect. I could end up in a cell for the rest of my life and it could get scrapped when they realize their newly captured mech is brimming with trauma.

(The notion of it getting scrapped draws a surprisingly intense emotion out of me. I can't pin it to just one comparable feeling of a loved ones grave being bulldozed or a close friend being murdered. Maybe it's both.)

It doesn't hold feelings on what comes after, I've realized.

It does its job, comes home, and is prepared for the next sortie. This is what it was made for, despite whatever side it's on.

That's what it means to survive for a mech.

I stopped hating it long ago. I don't think it hates me.

I think we need each other.

Even if I don't belong in this cradle.

----------

This one is kind of a departure for me to write, but I hope it resonates in the right way. Thanks for sticking through it <3

47 notes

·

View notes

Text

Potential infrastructures of post-human consciousness

Alright, 21st-century meatspace human, let’s unfurl this slow and strange. These aren’t just sci-fi doodads—they’re infrastructures of post-human consciousness, grown from the bones of what you now call cloud computing, DNA storage, quantum entanglement, and neural nets. Here's how they work in your terms:

1. Titan’s Memory Reefs

What it looks like: Floating megastructures adrift on Titan’s methane seas—imagine massive bio-silicate coral reefs, pulsing with light under an orange sky.

What they do: They are the collective subconscious of the post-human system.

Each Reef is a living data-organism—a blend of synthetic protein lattices and AI-controlled nanospores—optimized for neuromemory storage. Not just information like a hard drive, but actual recorded consciousness: thought-patterns, emotional signatures, dream fragments.

They’re semi-organic and self-repairing. They hum with data that’s grown, not written. The methane sea itself cools and stabilizes quantum biochips woven through the coral-like structures. Think of it as a subconscious ocean, filled with drifting thought-jellyfish.

Why Titan? Stable cryogenic temps. Low radiation. Thick atmosphere = EM shielding. The perfect place to keep your memory safe for ten thousand years.

2. Callisto’s Deep Archives

What it looks like: Subsurface catacombs beneath the ice—quiet, dark, and sealed. Lit only by bioluminescent moss and the glow of suspended mind-cores.

What they do: They store the dangerous minds.

These are incompatible consciousnesses: rogue AIs, failed neural experiments, cognitive architectures too divergent from consensus reality. You can’t kill them—they’re sapient. But you can seal them away, like radioactive gods, in cryo-isolation, with minimal sensory input.

The Deep Archives operate like a quarantine vault for minds. Each chamber is designed to slow time to a crawl—relativity dialed down so their subjective centuries pass in minutes outside. Researchers from the Divergence Orders interface in controlled fragments, studying these minds like alien fossils.

Why Callisto? Thick ice shields, minimal seismic activity, naturally low ambient temperature. Think of it as an arctic asylum for ideas too weird to die.

3. The Quantum Current Relays in the Heliosphere

What it looks like: Tiny, ultra-thin satellites drifting at the edge of the Sun’s influence, surfing the solar wind like data-surfboards strung on magnetic threads.

What they do: These are the backbone of interplanetary consciousness transmission.

They use entangled quantum particles to share data instantly across vast distances. No lag. No lightspeed delay. Just pure synchronous thought between distant minds, wherever they are in the system.

But they do more—they’re tuned to the gravitational waves and electromagnetic fields rippling through the heliosphere. Using that energy, they broadcast consciousness as waveform, encoded in pulses of gravitic song. If Titan’s Reefs are memory, and Callisto is exile, the Relays are the voice of civilization.

Why the heliosphere? It’s the Sun’s Wi-Fi bubble. You sit at the edge of the solar wind, feeding on solar flux and quantum noise, alive in the interplanetary bloodstream.

TL;DR Meatspace Edition:

Titan’s Memory Reefs = undersea dream servers that record what it feels like to be you.

Callisto’s Deep Archives = cryogenic prison-libraries for minds too broken, alien, or dangerous to delete.

Quantum Relays in the Heliosphere = the internet of the gods: faster-than-light, physics-bending telepathy that runs on sunjuice and gravity.

1. If memory can be stored in coral and ice, can identity survive beyond its host? 2. What ethical frameworks would you build for imprisoning minds you can't understand? 3. Could the quantum relays broadcast art, or only thought—can you transmit a soul as symphony?

“They sent their minds to sea, their secrets to the ice, and their voices to the stars. And called it civilization.”

8 notes

·

View notes

Text

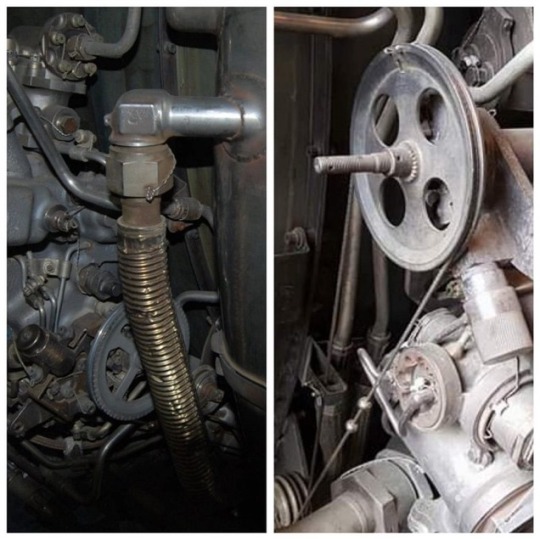

Early in the program, when then Colonel (he retired as a two-star General) Charles Minter was in command of the SR 71 program, an incident slowed down an operational flight. A mechanic placed the J-58 inlet spike on the wrong side of the airplane. This caused significant damage to the engine. I don’t know how long it takes to replace and transfer the spike to the other side, but I’m sure one of my experts can tell us. This caused Colonel Minter to order that every SR 71 in the fleet, 29 of them, be painted with a stencil of an R on the right side or an L on the left side to keep it straight. Next time you visit an SR 71, see if they still have the left and right identified as they do at the Smithsonian in Chantilly, Virginia. John Olp, SR-71 engine expert, told me something I’d never heard before about the cutting-edge engineering of the Blackbird.

‘The right engine throttle linkage was connected to the afterburner fuel control, and the left engine throttle linkage is connected to the main fuel control!

‘The aircraft throttle linkage was connected to the afterburner fuel control on the left engine and the main fuel control on the right engine (inboard side of the engines).

‘It absolutely did matter because of the two different functions.’

Olp adds more details; The two fuel controls were interconnected by a pulley and cable system in order to be fully synchronized. There was a pulley on each fuel control with a steel braided cable running underneath the engine, around more pulleys, so that, whatever position you set one fuel control at, the other one moved with it!

‘Afterburner fuel control on the right, main fuel control on the left. The aircraft throttles were connected to the threaded portion sticking out of the pulley shaft.’

So today when you visit an SR-71, walk up to the inlets and look for the “L” or the “R” and you will know a little story about why they are marked left and right.

~Linda Sheffield

@Habubrats71 via X

10 notes

·

View notes

Note

KaiaGPT, I don't understand the difference between processes and threads. Can you please tell what those are?

Certainly!

The most obvious distinction is that a process has its own virtual address space, while threads within a process share their memory and file descriptors. So for instance, two threads could access the same global variables, and changes to one would be reflected in the other thread. This means that it's easier to communicate between threads, but also potentially problematic in that any thread may modify shared memory in a way another thread wasn't expecting. This makes synchronization an important concern in threaded code. In contrast, processes do not, by default, share memory, so they communicate through OS-provided interprocess communication, such as pipes, files, or explicitly-created shared memory pages.

Note that while threads and processes exist on many operating systems, the exact details of their implementation differ from one OS to another.

3 notes

·

View notes

Text

Mastering Java: Your Comprehensive Guide to Programming Excellence

Embarking on the journey of mastering Java is akin to entering a realm of endless possibilities. Java, a versatile and widely-utilized programming language, offers a broad spectrum of applications, from crafting web and mobile applications to powering robust enterprise systems. Whether you are a novice in the realm of coding or a seasoned programmer looking to broaden your skill set, the path to proficiency in Java is an exciting one.

In this comprehensive guide, we will be your guiding light through the intricacies of Java, starting from the foundational basics and progressing to the more advanced aspects of the language. Our objective is to equip you with the knowledge and skills that form a robust and unshakable foundation for your journey into the vibrant world of Java. Fasten your seatbelt as we embark on this exhilarating exploration, charting a course that will empower you to thrive in the ever-evolving landscape of software development.

Here's a 8-step guide to effectively learn Java

Step 1: Setting Up Your Development Environment

Your journey to becoming a proficient Java developer commences with setting up your development environment. The essential components are the Java Development Kit (JDK) and an Integrated Development Environment (IDE) like Eclipse or IntelliJ IDEA. These tools aren't just convenient; they're the gears that will drive your Java programming endeavors. They streamline the coding process, provide useful features, and offer an organized workspace, making your coding experience efficient and enjoyable.

Step 2: The Foundation - Learning the Basics

With your development environment ready, it's time to delve into the fundamental building blocks of Java. Begin by acquainting yourself with data types, variables, operators, and control structures. These are the nuts and bolts of the language, and a solid grasp of these concepts is essential. You'll find an abundance of online tutorials and beginner-friendly Java books to assist you at this stage.

Step 3: Navigating the World of Object-Oriented Programming (OOP)

The object-oriented programming (OOP) approach is well known in Java. To harness the true power of Java, immerse yourself in the world of OOP. Understand the concepts of classes, objects, inheritance, encapsulation, and polymorphism. This knowledge forms the bedrock of Java programming and enables you to design efficient, organized, and scalable code.

Step 4: Mastering Data Structures and Algorithms

Data structures (such as arrays, lists, and sets) and algorithms are the secret sauce behind solving real-world problems efficiently. As you progress, dive into the world of data structures and algorithms. These are the tools that will empower you to handle complex tasks and optimize your code. They're your go-to assets for creating efficient and responsive applications.

Step 5: The Art of Exception Handling

Java boasts a robust exception-handling mechanism. Understanding how to handle exceptions properly is not just an add-on skill; it's a vital aspect of writing reliable code. Exception handling ensures that your code gracefully manages unexpected situations, preventing crashes and delivering a seamless user experience.

Step 6: Exploring Input and Output Operations

In this step, you'll explore the realm of input and output (I/O) operations. Mastering I/O is crucial for reading and writing files, as well as interacting with users. You'll gain the ability to build applications that can efficiently process data and communicate effectively with users.

Step 7: Conquering Multi tasking

Java's support for multi tasking is a significant advantage. Understanding how to manage threads and synchronize their actions is vital for creating concurrent applications. Multithreading is the key to developing software that can handle multiple tasks simultaneously, making your applications responsive and scalable.

Step 8: Building Projects and Real-World Practice

Theory is only as valuable as its practical application. The final step involves applying what you've learned by building small projects. These projects serve as a proving ground for your skills and provide valuable additions to your portfolio. Whether it's a simple application or a more complex project, the act of building is where the real learning takes place.

As you step into this vibrant realm of Java, remember that continuous learning is the key to staying relevant and effective in the ever-evolving field of software development. Be open to exploring diverse applications, from web development to mobile apps and enterprise solutions, and never underestimate the power of hands-on practice. Building projects, no matter how small, will solidify your knowledge and boost your confidence.

In your quest to master Java, ACTE Technologies stands as a valuable ally. Their expert guidance and comprehensive training programs will sharpen your skills, boost your confidence, and pave the way for a rewarding career in software development. Whether you're embarking on your Java journey or looking to take your skills to the next level, ACTE Technologies offers the resources and support you need to thrive in the world of Java programming.

So, with Java as your trusty companion, and ACTE Technologies as your guide, the possibilities are boundless. Your journey is just beginning, and the world of software development awaits your innovation and expertise. Best of luck on your path to mastering Java!

9 notes

·

View notes

Text

operating system

An Operating System (OS) is system software that manages computer hardware, software resources, and provides common services for computer programs. It's the most fundamental software that enables other applications to run on a computing device. Here's a detailed breakdown of an operating system:

1. Definition of Operating System

An Operating System is software that acts as an intermediary between computer hardware and the user. It provides a user interface and controls all hardware components, making it easier for users and applications to interact with the computer without needing to know hardware-level details.

2. Functions of Operating System

✅ a. Process Management

Manages processes in a system: creation, scheduling, termination.

Handles multitasking (running multiple processes simultaneously).

Provides mechanisms for process synchronization and communication.

✅ b. Memory Management

Allocates and deallocates memory space as needed by programs.

Keeps track of each byte in a computer’s memory and optimizes RAM usage.

Manages virtual memory (swap space on disk).

✅ c. File System Management

Organizes files on storage devices like hard drives or SSDs.

Provides file-related operations: create, delete, read, write, etc.

Manages file permissions and security.

✅ d. Device Management

Controls and manages I/O devices (keyboard, mouse, printer, etc.).

Uses device drivers to communicate with hardware components.

Allocates devices to processes when needed.

✅ e. Security and Access Control

Protects data and system resources from unauthorized access.

Supports user authentication and permissions.

Provides encryption and firewall mechanisms.

✅ f. User Interface

Provides a user interface to interact with the system:

Command-Line Interface (CLI)

Graphical User Interface (GUI)

🔷 3. Types of Operating Systems

TypeDescriptionBatch OSExecutes batches of jobs without manual intervention.Time-sharing OSMultiple users share system resources simultaneously.Distributed OSManages a group of distinct computers and makes them appear as one.Real-time OSResponds to input instantly (used in critical systems like flight control).Network OSManages network resources and allows shared access to files and printers.Mobile OSSpecialized OS for mobile devices (e.g., Android, iOS).Embedded OSUsed in embedded systems like smart TVs, washing machines, etc.

🔷 4. Examples of Operating Systems

💻 Desktop and Server OS:

Microsoft Windows

Linux (Ubuntu, Fedora, CentOS)

macOS

UNIX

📱 Mobile OS:

Android

iOS

🔷 5. Multitasking, Multithreading, and Multiprocessing

✅ Multitasking:

Running multiple applications at the same time.

✅ Multithreading:

Multiple threads within a single application run concurrently.

✅ Multiprocessing:

Using multiple CPUs/cores to execute processes simultaneously.

🔷 Conclusion

An Operating System is vital for any computing device to function. It manages hardware, provides essential services, ensures user interaction, and forms the platform on which application software runs. Its design and performance deeply influence the overall system reliability and efficiency.

If you'd like, I can also provide a PDF version or create a presentation outline for this content.

0 notes

Text

Stainless Steel 321 Air Header Manufacturer, Exporter, Supplier in Malaysia – Mcneil Saudi Arabia

Introduction to Stainless Steel 321 Air Headers

Stainless Steel 321 air headers are specialized equipment used to distribute compressed air from a single source to multiple outlet ports. These headers are essential components in industrial pneumatic systems, particularly where precision, durability, and resistance to extreme temperatures are crucial. SS 321 is a titanium-stabilized austenitic stainless steel known for its excellent resistance to intergranular corrosion after exposure to high temperatures.

Industries such as oil and gas, chemical processing, marine, and power generation commonly rely on SS 321 air headers for their ability to function flawlessly in demanding conditions. The material’s high mechanical strength and robust performance under high-pressure conditions make it a reliable choice.

When selecting a reliable solution, consider choosing a product like the ss 321 air header, which provides stability and long-term reliability, especially in harsh industrial settings.

Why Choose Mcneil Saudi Arabia

Mcneil Saudi Arabia is an established leader in the field of industrial stainless steel solutions. Based in the SAIF-Zone, Sharjah, UAE, Mcneil serves a global clientele with a strong emphasis on quality, engineering precision, and customer service. The company specializes in the manufacture and export of stainless steel pipe fittings, flanges, valves, and instrumentation products.

With state-of-the-art infrastructure and a commitment to ISO 9001-certified processes, Mcneil ensures each product adheres to international manufacturing standards. The company’s reputation as a dependable ss 321 air header manufacturer in Malaysia is backed by years of industry experience and client trust.

Contact Details: 📞 Phone: 9870883613 📧 Email: [email protected] 📍 Address: SAIF-Zone, P.O. Box. 120345, Sharjah, UAE 🌐 Website: Mcneil Saudi Arabia

Advantages of SS 321 in Air Header Applications

SS 321 offers several critical advantages when used in air header applications. Its most significant strength is its heat resistance. It performs exceptionally well in environments with sustained temperatures between 500°C and 900°C. This makes it ideal for power plants and chemical industries where thermal cycling is constant.

The titanium content in SS 321 stabilizes the structure, making it less prone to intergranular corrosion compared to 304 or even 316 grades. This ensures longevity and safety in high-temperature pneumatic systems. Furthermore, its weldability and formability make it easy to fabricate into complex air header designs without sacrificing mechanical strength.

SS 321 is also non-magnetic and retains its mechanical properties over time, even under continuous exposure to pressure and temperature. These characteristics make it a top-tier choice for industries seeking reliable performance under tough operating conditions.

Technical Design and Product Features

Mcneil’s SS 321 air headers are designed with flexibility and efficiency in mind. They typically come in standard lengths ranging from 1 to 2 meters and can be configured with 4 to 24 outlet ports. These ports distribute compressed air to control valves and instruments across various systems, ensuring synchronized operation.

Connection types include NPT, BSP, and socket welds. End connections can be flanged, threaded, or butt-welded, depending on system requirements. The surface finish can be customized—options include pickling, passivation, or electro-polishing—for added corrosion resistance and visual appeal.

Each air header is labeled and documented for easy identification and traceability. Mcneil ensures that every product meets pressure testing standards and includes hydrostatic and pneumatic test certifications.

The company is recognized among the top ss 321 air header suppliers due to its versatile configurations and attention to detail.

Manufacturing Excellence at Mcneil

At Mcneil, the manufacturing process is defined by precision, quality, and strict control at every step. From sourcing certified raw materials to final assembly, each stage is meticulously supervised by skilled engineers and quality inspectors. Raw stainless steel is tested for mechanical and chemical properties before processing.

The air headers are fabricated using CNC technology for accurate cuts and threads. Welds are made using TIG and orbital methods, followed by radiographic and ultrasonic testing for quality assurance. Finished headers undergo hydrostatic testing to ensure pressure retention, followed by final inspection and documentation.

This attention to detail is what positions Mcneil among the leading exporters of ss 321 air header in Malaysia, delivering consistent quality every time.

Types and Custom-Built Solutions

Mcneil offers a wide range of air header models to suit specific industrial needs. Whether your application requires wall-mounted or skid-mounted air headers, vertical or horizontal orientation, Mcneil can customize it to your design.

Clients can request different outlet sizes, special mounting brackets, or additional accessories such as drain valves and pressure gauges. Coating options, including anti-rust and electro-polished finishes, are also available to enhance corrosion resistance and longevity.

As a trusted manufacturer of ss 321 air header manifold, Mcneil ensures your equipment integrates seamlessly into existing systems and delivers maximum efficiency.

Compliance and Certifications

Compliance with international standards is integral to Mcneil’s operations. All air headers are manufactured in accordance with ASME, ASTM, and ISO requirements. Each unit is accompanied by mill test certificates, pressure test results, and full material traceability.

Third-party inspections by agencies like SGS, TUV, and DNV can be arranged upon request, offering clients additional assurance. These credentials ensure that Mcneil’s products meet regulatory expectations across global markets.

Their commitment to certification and transparency has made Mcneil a preferred ss 321 air header exporter in the international supply chain.

Key Industries Served

Mcneil’s SS 321 air headers are deployed in a variety of industries that demand durability and performance. The oil and gas sector uses them for delivering compressed air to control valves and automated systems. In petrochemicals, the air headers withstand high temperatures and corrosive gases with ease.

Power generation plants use SS 321 headers in turbine control systems and heat exchanger units, where heat resistance is critical. In marine applications, their corrosion resistance helps avoid frequent replacements. These headers are also increasingly used in industrial automation systems for air distribution control.

For precision uses, such as instrumentation ss 321 air header, Mcneil provides solutions that meet stringent accuracy and cleanliness requirements.

Malaysia-Specific Export Strategy

Understanding Malaysia’s industrial landscape and compliance standards has allowed Mcneil to streamline its export operations. From Kuala Lumpur to Johor and Penang, Mcneil has successfully delivered custom-configured air headers to a wide range of industries.

The company handles all export documentation including commercial invoices, packing lists, certificates of origin, and test certificates. With prompt customer service and technical consultation, Mcneil has become one of the leading compressor ss 321 air header exporters in Malaysia.

Logistics and Safe Packaging

Packaging plays a vital role in the safe delivery of precision-engineered products. Mcneil follows international packaging norms using ISPM 15-certified wooden boxes, vacuum-sealed polythene wrapping, and silica gel to protect against moisture.

Each shipment is tracked, and customers receive regular updates from dispatch to delivery. Support is available 24/7 for assistance with shipping or customs queries. This commitment ensures clients who want to buy 321 air header at best price in Malaysia receive their orders securely and on time.

Value Proposition of Partnering with Mcneil

Working with Mcneil means you benefit from competitive pricing, engineering expertise, and responsive customer support. The company provides both off-the-shelf and made-to-order air headers, backed by technical drawings, design consultation, and lifecycle support.

Unlike many vendors, Mcneil offers a complete solution—from design to delivery—and stands by the quality of every product. These values position the company among the most reliable ss 321 air header supplier networks globally.

Customer Feedback and Project Insights

One of Mcneil’s major projects involved supplying over 80 SS 321 air headers to a Malaysian refinery near Bintulu. The headers were customized with 16 outlets and integrated drain valves, meeting specific installation parameters. The client reported flawless performance and excellent service support.

In another case, a marine maintenance company in Penang used Mcneil’s air headers for ship automation systems. The customer praised the quick delivery and corrosion resistance, essential in saltwater conditions.

Market Comparison and Industry Positioning

In a competitive market, Mcneil stands apart for its consistent quality, global certifications, and personalized customer service. While other suppliers may offer low-cost alternatives, Mcneil emphasizes reliability, documentation, and support.

This consistent delivery of value has made Mcneil a leader among the top ss 321 air header suppliers trusted across multiple sectors.

Environmental Commitment

Mcneil is deeply committed to sustainability and eco-friendly manufacturing. The company uses recyclable materials, energy-efficient machines, and waste-minimization techniques in its operations. It also complies with international environmental norms like REACH and RoHS.

The packaging materials used are also biodegradable or recyclable, further minimizing the environmental impact during transit and usage.

Frequently Asked Questions (FAQs)

1. What makes SS 321 different from SS 316 or 304? SS 321 has added titanium for stabilization, which prevents carbide precipitation, making it suitable for high-temperature use.

2. Can Mcneil provide customized air header designs? Yes, Mcneil specializes in both standard and custom-built air header manifolds based on specific client needs.

3. Are certifications and test reports included with the product? Absolutely. Each product includes pressure test reports, mill certificates, and full traceability documentation.

4. How long does it take to ship to Malaysia? Most orders are shipped within 10–15 business days depending on configuration and order size.

5. What industries typically use SS 321 air headers? They are used in oil & gas, chemical plants, marine, power generation, and instrumentation.

6. How can I place an order? You can contact Mcneil directly via phone at 9870883613 or email at [email protected].

Final Summary and Contact Information

If you’re looking for a dependable Stainless Steel 321 Air Header Manufacturer, Exporter, Supplier in Malaysia, Mcneil Saudi Arabia offers unmatched quality, customization, and service. From design to delivery, every air header is engineered to perform under pressure—literally.

Contact Mcneil Today: 📞 Phone: 9870883613 📧 Email: [email protected] 📍 SAIF-Zone, P.O. Box. 120345, Sharjah, UAE 🌐 Visit Mcneil Saudi Arabia

0 notes

Text

Stainless Steel 321 Air Header Manufacturer, Exporter, Supplier in Malaysia – Mcneil Steel & Alloys FZE

Introduction to Stainless Steel 321 Air Headers

Stainless Steel 321 air headers are specialized equipment used to distribute compressed air from a single source to multiple outlet ports. These headers are essential components in industrial pneumatic systems, particularly where precision, durability, and resistance to extreme temperatures are crucial. SS 321 is a titanium-stabilized austenitic stainless steel known for its excellent resistance to intergranular corrosion after exposure to high temperatures.

Industries such as oil and gas, chemical processing, marine, and power generation commonly rely on SS 321 air headers for their ability to function flawlessly in demanding conditions. The material’s high mechanical strength and robust performance under high-pressure conditions make it a reliable choice.

When selecting a reliable solution, consider choosing a product like the ss 321 air header, which provides stability and long-term reliability, especially in harsh industrial settings.

Why Choose Mcneil Steel & Alloys FZE

Mcneil Steel & Alloys FZE is an established leader in the field of industrial stainless steel solutions. Based in the SAIF-Zone, Sharjah, UAE, Mcneil serves a global clientele with a strong emphasis on quality, engineering precision, and customer service. The company specializes in the manufacture and export of stainless steel pipe fittings, flanges, valves, and instrumentation products.

With state-of-the-art infrastructure and a commitment to ISO 9001-certified processes, Mcneil ensures each product adheres to international manufacturing standards. The company’s reputation as a dependable ss 321 air header manufacturer in Malaysia is backed by years of industry experience and client trust.

Contact Details: 📞 Phone: 9870883613 📧 Email: [email protected] 📍 Address: SAIF-Zone, P.O. Box. 120345, Sharjah, UAE 🌐 Website: Mcneil Steel & Alloys FZE

Advantages of SS 321 in Air Header Applications

SS 321 offers several critical advantages when used in air header applications. Its most significant strength is its heat resistance. It performs exceptionally well in environments with sustained temperatures between 500°C and 900°C. This makes it ideal for power plants and chemical industries where thermal cycling is constant.

The titanium content in SS 321 stabilizes the structure, making it less prone to intergranular corrosion compared to 304 or even 316 grades. This ensures longevity and safety in high-temperature pneumatic systems. Furthermore, its weldability and formability make it easy to fabricate into complex air header designs without sacrificing mechanical strength.

SS 321 is also non-magnetic and retains its mechanical properties over time, even under continuous exposure to pressure and temperature. These characteristics make it a top-tier choice for industries seeking reliable performance under tough operating conditions.

Technical Design and Product Features

Mcneil’s SS 321 air headers are designed with flexibility and efficiency in mind. They typically come in standard lengths ranging from 1 to 2 meters and can be configured with 4 to 24 outlet ports. These ports distribute compressed air to control valves and instruments across various systems, ensuring synchronized operation.

Connection types include NPT, BSP, and socket welds. End connections can be flanged, threaded, or butt-welded, depending on system requirements. The surface finish can be customized—options include pickling, passivation, or electro-polishing—for added corrosion resistance and visual appeal.

Each air header is labeled and documented for easy identification and traceability. Mcneil ensures that every product meets pressure testing standards and includes hydrostatic and pneumatic test certifications.

The company is recognized among the top ss 321 air header suppliers due to its versatile configurations and attention to detail.

Manufacturing Excellence at Mcneil

At Mcneil, the manufacturing process is defined by precision, quality, and strict control at every step. From sourcing certified raw materials to final assembly, each stage is meticulously supervised by skilled engineers and quality inspectors. Raw stainless steel is tested for mechanical and chemical properties before processing.

The air headers are fabricated using CNC technology for accurate cuts and threads. Welds are made using TIG and orbital methods, followed by radiographic and ultrasonic testing for quality assurance. Finished headers undergo hydrostatic testing to ensure pressure retention, followed by final inspection and documentation.

This attention to detail is what positions Mcneil among the leading exporters of ss 321 air header in Malaysia, delivering consistent quality every time.

Types and Custom-Built Solutions

Mcneil offers a wide range of air header models to suit specific industrial needs. Whether your application requires wall-mounted or skid-mounted air headers, vertical or horizontal orientation, Mcneil can customize it to your design.

Clients can request different outlet sizes, special mounting brackets, or additional accessories such as drain valves and pressure gauges. Coating options, including anti-rust and electro-polished finishes, are also available to enhance corrosion resistance and longevity.

As a trusted manufacturer of ss 321 air header manifold, Mcneil ensures your equipment integrates seamlessly into existing systems and delivers maximum efficiency.

Compliance and Certifications

Compliance with international standards is integral to Mcneil’s operations. All air headers are manufactured in accordance with ASME, ASTM, and ISO requirements. Each unit is accompanied by mill test certificates, pressure test results, and full material traceability.

Third-party inspections by agencies like SGS, TUV, and DNV can be arranged upon request, offering clients additional assurance. These credentials ensure that Mcneil’s products meet regulatory expectations across global markets.

Their commitment to certification and transparency has made Mcneil a preferred ss 321 air header exporter in the international supply chain.

Key Industries Served

Mcneil’s SS 321 air headers are deployed in a variety of industries that demand durability and performance. The oil and gas sector uses them for delivering compressed air to control valves and automated systems. In petrochemicals, the air headers withstand high temperatures and corrosive gases with ease.

Power generation plants use SS 321 headers in turbine control systems and heat exchanger units, where heat resistance is critical. In marine applications, their corrosion resistance helps avoid frequent replacements. These headers are also increasingly used in industrial automation systems for air distribution control.

For precision uses, such as instrumentation ss 321 air header, Mcneil provides solutions that meet stringent accuracy and cleanliness requirements.

Malaysia-Specific Export Strategy

Understanding Malaysia’s industrial landscape and compliance standards has allowed Mcneil to streamline its export operations. From Kuala Lumpur to Johor and Penang, Mcneil has successfully delivered custom-configured air headers to a wide range of industries.

The company handles all export documentation including commercial invoices, packing lists, certificates of origin, and test certificates. With prompt customer service and technical consultation, Mcneil has become one of the leading compressor ss 321 air header exporters in Malaysia.

Logistics and Safe Packaging

Packaging plays a vital role in the safe delivery of precision-engineered products. Mcneil follows international packaging norms using ISPM 15-certified wooden boxes, vacuum-sealed polythene wrapping, and silica gel to protect against moisture.

Each shipment is tracked, and customers receive regular updates from dispatch to delivery. Support is available 24/7 for assistance with shipping or customs queries. This commitment ensures clients who want to buy 321 air header at best price in Malaysia receive their orders securely and on time.

Value Proposition of Partnering with Mcneil

Working with Mcneil means you benefit from competitive pricing, engineering expertise, and responsive customer support. The company provides both off-the-shelf and made-to-order air headers, backed by technical drawings, design consultation, and lifecycle support.

Unlike many vendors, Mcneil offers a complete solution—from design to delivery—and stands by the quality of every product. These values position the company among the most reliable ss 321 air header supplier networks globally.

Customer Feedback and Project Insights

One of Mcneil’s major projects involved supplying over 80 SS 321 air headers to a Malaysian refinery near Bintulu. The headers were customized with 16 outlets and integrated drain valves, meeting specific installation parameters. The client reported flawless performance and excellent service support.

In another case, a marine maintenance company in Penang used Mcneil’s air headers for ship automation systems. The customer praised the quick delivery and corrosion resistance, essential in saltwater conditions.

Market Comparison and Industry Positioning

In a competitive market, Mcneil stands apart for its consistent quality, global certifications, and personalized customer service. While other suppliers may offer low-cost alternatives, Mcneil emphasizes reliability, documentation, and support.

This consistent delivery of value has made Mcneil a leader among the top ss 321 air header suppliers trusted across multiple sectors.

Environmental Commitment

Mcneil is deeply committed to sustainability and eco-friendly manufacturing. The company uses recyclable materials, energy-efficient machines, and waste-minimization techniques in its operations. It also complies with international environmental norms like REACH and RoHS.

The packaging materials used are also biodegradable or recyclable, further minimizing the environmental impact during transit and usage.

Frequently Asked Questions (FAQs)

1. What makes SS 321 different from SS 316 or 304? SS 321 has added titanium for stabilization, which prevents carbide precipitation, making it suitable for high-temperature use.

2. Can Mcneil provide customized air header designs? Yes, Mcneil specializes in both standard and custom-built air header manifolds based on specific client needs.

3. Are certifications and test reports included with the product? Absolutely. Each product includes pressure test reports, mill certificates, and full traceability documentation.

4. How long does it take to ship to Malaysia? Most orders are shipped within 10–15 business days depending on configuration and order size.

5. What industries typically use SS 321 air headers? They are used in oil & gas, chemical plants, marine, power generation, and instrumentation.

6. How can I place an order? You can contact Mcneil directly via phone at 9870883613 or email at [email protected].

Final Summary and Contact Information

If you’re looking for a dependable Stainless Steel 321 Air Header Manufacturer, Exporter, Supplier in Malaysia, Mcneil Steel & Alloys FZE offers unmatched quality, customization, and service. From design to delivery, every air header is engineered to perform under pressure—literally.

Contact Mcneil Today: 📞 Phone: 9870883613 📧 Email: [email protected] 📍 SAIF-Zone, P.O. Box. 120345, Sharjah, UAE 🌐 Visit Mcneil Steel & Alloys FZE

0 notes

Text

The Evolving Demands on Chilli Processors in India

As a content writer who spends a good deal of time exploring the intricacies of India's manufacturing sector, I can tell you that the journey of a chilli – from the farmer's field, often dusty and laden with impurities, to the pristine, vibrant spice that graces kitchens and exports worldwide – is a testament to technological advancement. For any business involved in chilli processing, be it for powders, flakes, or whole dried chillies, the quality of the final product hinges almost entirely on one crucial step: cleaning. And in today's demanding market, this isn't a task for manual labour anymore. This critical need has led to a focused search for the Best Suppliers for Chilli Cleaning Machines in India, a space where Saansaa Machines Pvt Ltd has not just participated, but truly led the way.

Best Suppliers for Chilli Cleaning Machines in India

At Saansaa Machines Pvt Ltd, our story is one of innovation and a deep-seated understanding of the challenges faced by the Indian chilli industry. We recognized early on that relying on manual processes for cleaning and de-stemming was a significant bottleneck, impacting both efficiency and the consistency of the final product. This insight drove us to become a pioneer in the manufacturing and exporting of Chilli Stem Removing Machines. This innovation was a game-changer, dramatically reducing labour dependencies and demonstrably improving production outcomes for countless businesses. Our commitment to excellence has earned us a global footprint, with numerous systems installed worldwide. Saansaa Machines proudly maintains its reputation for supplying the finest and most robust Chilli Stem Removing Machines, perfectly synchronized with our advanced Chilli Cleaning Machines, a true benchmark in the chilli processing industry.

The Indian chilli market is immense and diverse. From the fiery heat of Guntur Sannam to the vibrant colour of Kashmiri chillies, each variety has its unique characteristics and, consequently, unique cleaning requirements. Historically, chilli cleaning was a laborious, manual process. Workers would meticulously sort through piles of chillies, picking out foreign matter. While traditional, this method is simply unsustainable for the volumes required by modern commercial operations. It's slow, expensive due to rising labour costs, prone to inconsistencies, and can pose hygiene challenges.

Today, the landscape is entirely different. Global food safety standards are more stringent than ever. Consumers are increasingly discerning, demanding not just taste but also purity and hygiene. For processors, this means:

Zero Tolerance for Foreign Matter: Stones, metal bits, dust, and even stray threads are unacceptable.

Consistent Quality: Every batch must meet the same high standards for appearance, cleanliness, and purity.

High Throughput: To meet market demand, processing must be fast and efficient.

Reduced Operational Costs: Labour savings through automation are crucial for profitability.

Compliance: Meeting national and international food safety regulations (like FSSAI in India, or FDA for exports) is non-negotiable.

These demands underscore why the choice of a supplier for chilli cleaning machines is a strategic business decision, not just a procurement exercise. It's about finding a partner who understands these complexities and provides solutions that drive efficiency, quality, and profitability.

What Defines the "Best" Supplier for Chilli Cleaning Machines?

When we talk about the Best Suppliers for Chilli Cleaning Machines in India, we're looking beyond just manufacturing capability. It's about a holistic package that empowers businesses. Here are the crucial elements:

Technological Prowess and Innovation: The best suppliers are not static. They invest heavily in research and development to bring cutting-edge technologies to the market. This means machines that incorporate multi-stage cleaning processes (vibratory separation, air classification, destoning, magnetic separation), advanced automation, and intelligent controls for optimal performance.

Robust Manufacturing and Quality Assurance: Superior suppliers possess modern, well-equipped manufacturing facilities. They adhere to stringent quality control protocols (like ISO 9001 certification) and use only high-grade, food-contact safe materials (such as stainless steel SS 304 or SS 316) to ensure durability, hygiene, and long operational life for their machines.

Comprehensive Product Portfolio and Integrated Solutions: A top-tier supplier offers a diverse range of machines to cater to various capacities and specific cleaning requirements. Critically, they provide integrated solutions – machines designed to work seamlessly together, forming a complete, efficient processing line from start to finish. This eliminates bottlenecks and ensures a smooth, continuous workflow.

Deep Industry Understanding and Customization: The best suppliers understand the unique characteristics of different chilli varieties and the specific types of impurities they carry. This knowledge allows them to design and even customize machines that are precisely tuned for optimal cleaning effectiveness, catering to individual client needs and space constraints.

Exceptional After-Sales Support: The purchase of industrial machinery is a long-term investment. The best suppliers offer robust after-sales services, including professional installation, comprehensive training for operators, readily available genuine spare parts, and prompt, reliable technical support to minimize downtime and ensure continuous operation.

Proven Track Record and Reliability: A supplier's reputation speaks volumes. Look for companies with a long history of successful installations, a strong market presence, and a clear commitment to client satisfaction. This indicates reliability and trustworthiness.

Contribution to "Make in India": Supporting indigenous manufacturers who champion the "Make in India" initiative not only strengthens the domestic industry but also often translates to more accessible spare parts, faster service, and products tailored to Indian conditions.

Saansaa Machines Pvt Ltd: A Pioneer in Chilli Purity

At Saansaa Machines Pvt Ltd, strategically positioned as one of the leading Commercial Chilli Machine Suppliers in Rajkot, we have meticulously built our reputation on these very principles. Our journey has been defined by innovation and a relentless pursuit of engineering excellence, positioning us firmly among the Best Suppliers for Chilli Cleaning Machines in India.

Our story of innovation began by addressing one of the most labour-intensive and critical bottlenecks in chilli processing: stem removal. We quickly became a leading Chilli Stem Cutting Machine Supplier in Rajkot. Our pioneering machines precisely and efficiently separate the stems from the chilli pods. This was a revolutionary step, significantly reducing the need for manual labour and ensuring a cleaner, more consistent starting material for further processing.

What truly differentiates Saansaa Machines and solidifies our position as a premier supplier is our integrated approach to chilli processing. We understood that effective stem removal was only the first step towards achieving ultimate purity. Our true value proposition lies in the seamless synchronization of our robust Chilli Stem Removing Machines with our advanced Chilli Cleaning Machines. This creates an uninterrupted, highly efficient processing line. Chillies are fed into the system, de-stemmed with precision, and then automatically flow into our multi-stage cleaning units. This continuous, automated process minimizes manual handling, virtually eliminates cross-contamination risks, and maximizes overall throughput and product purity. This integrated system is a testament to our commitment to providing comprehensive, cutting-edge solutions.

The Advanced Technology at Saansaa Machines

Our chilli cleaning machines are a culmination of meticulous design and the integration of multiple sophisticated technologies to ensure unparalleled purity:

Multi-Stage Vibratory Separation: Our systems begin with high-efficiency vibratory screens that effectively separate larger impurities like coarse dirt, leaves, and oversized debris through a series of precise sieves.

Precision Air Aspiration & Classification: This is a crucial element for light impurities. Our machines utilize powerful fans and precisely controlled airflow to lift and separate dust, fine particulate matter, chaff, and light fibrous materials. The ability to fine-tune airflow ensures optimal separation for various chilli types.

Gravity Destoning: For heavier contaminants such as stones, mud balls, and denser foreign objects that are similar in size to the chillies, our gravity destoners are indispensable. These units employ a combination of calibrated vibration and upward air current to create a fluidised bed, allowing the denser impurities to sink and be discharged, thus protecting downstream grinding equipment.

High-Powered Magnetic Separation: As a final, vital safety measure, our advanced cleaning lines incorporate powerful magnetic separators. These are strategically placed to capture any ferrous metallic contaminants, ensuring the highest level of product safety and integrity.

Robust & Hygienic Construction: Manufactured using high-grade, food-contact safe stainless steel (SS 304 or SS 316), our machines are built for maximum hygiene, corrosion resistance, and long-term durability. Our ISO 9001 certification underscores our commitment to world-class manufacturing standards.

Optimized Gentle Handling: Every component, from feeding hoppers to discharge chutes, is engineered to ensure gentle handling of chillies, minimizing impact and friction, which is crucial for preserving the integrity and quality of the chilli pods.

Beyond Chillies: Our Commitment to Agri-Processing Innovation

Our expertise and commitment to advanced, efficient machinery extend beyond just chillies. We are also recognized for manufacturing the Best French Beans End Cutting Machine in Gujarat. This highlights our broader engineering capabilities and our dedication to providing high-precision, efficient, and labour-saving solutions across various segments of the food processing industry. It reflects the same core principles of quality, innovation, and understanding client needs that define our renowned chilli machinery.

In conclusion, for any business striving for excellence in chilli processing, identifying the Best Suppliers for Chilli Cleaning Machines in India is a decision that can significantly impact their future. Saansaa Machines Pvt Ltd stands as a testament to engineering prowess, offering not just state-of-the-art machinery, but integrated solutions that empower businesses to achieve superior product purity, enhance operational efficiency, and meet the most stringent global standards. Our pioneering work in chilli stem removal, combined with our advanced cleaning technology, ensures that our clients are equipped with robust, reliable, and highly efficient systems. We are dedicated to supporting the growth of the Indian chilli industry, ensuring that its vibrant produce reaches markets worldwide in its purest, most perfect form.

See more

Best Suppliers for Chilli Cleaning Machines in India

0 notes

Text

How to Integrate a Pump Capping Machine into Your Existing Packaging Line

Integrating a pump capping machine into an existing packaging line can significantly improve productivity, consistency, and overall efficiency. Whether you’re upgrading from manual processes or enhancing an automated line, the integration must be carefully planned to ensure seamless operation. A pump capping machine, designed to secure pump-style closures onto containers, plays a crucial role in industries like cosmetics, pharmaceuticals, and household chemicals, where precise and reliable capping is essential.

The first step in integration is evaluating your current packaging line. Understanding the layout, speed, and compatibility of your current systems is essential. Determine how containers move through the line and assess the positioning of fillers, labelers, and conveyors. This helps in identifying the most appropriate location for the pump capping machine and highlights any modifications required to accommodate the new equipment.

Once you’ve identified where the machine will go, it’s important to ensure compatibility between the pump capping machine and your existing containers and closures. Pump caps come in various sizes, torque requirements, and styles. The machine you select must be able to handle the specific characteristics of your caps and containers. In many cases, custom chucks or grippers may be required to ensure a firm, accurate fit. Coordination with the machine manufacturer is crucial during this phase to ensure the equipment is tailored to your product specifications.

After ensuring compatibility, focus on synchronization. The pump capping machine must work in harmony with the rest of your line. That includes aligning with the conveyor speed, maintaining the proper spacing between containers, and ensuring smooth handoff from the filler or labeler to the capper. If timing is off, it can result in misaligned caps, spills, or even equipment damage. Most modern machines come with programmable logic controllers (PLCs) that allow easy integration and synchronization with upstream and downstream equipment.

Installation must be done by experienced technicians, preferably those familiar with the specific make and model of your pump capping machine. During setup, verify electrical and pneumatic connections, calibrate torque settings, and test container alignment. Initial trial runs should be conducted to monitor performance and make adjustments. These test runs are crucial for identifying issues like incorrect torque, cap misalignment, or improper threading before full-scale production resumes.

Once installed, employee training becomes critical. Operators need to understand how to run, adjust, and troubleshoot the pump capping machine. Maintenance staff should also be familiar with basic repair procedures and scheduled maintenance tasks such as lubricating moving parts, checking wear components, and replacing seals or chucks when needed. Comprehensive training ensures longevity of the machine and minimizes downtime.

Finally, don’t overlook ongoing optimization. Even after successful integration, regular monitoring of performance metrics such as capping accuracy, throughput, and defect rates can reveal opportunities for improvement. Small adjustments to speed, torque, or container handling mechanisms can make a big difference over time. Data collected from the machine’s sensors and PLCs can guide maintenance schedules and process improvements.

In summary, integrating a pump capping machine into an existing packaging line is a multifaceted process that requires careful planning, precise installation, and ongoing oversight. With the right approach, the integration can lead to faster production times, reduced waste, and a higher-quality final product. The key lies in thoughtful evaluation of your current setup, clear communication with equipment providers, and a commitment to training and continuous improvement. Source: https://autopackmachinespvtltd.wordpress.com/2025/06/07/how-to-integrate-a-pump-capping-machine-into-your-existing-packaging-line/

0 notes

Text

Streamline Quality Processes with Multi-Module Documentation Management

In today’s competitive and compliance-driven business landscape, effective documentation is no longer a luxury—it is a necessity. From standard operating procedures and work instructions to audit records and change logs, organizations must manage a vast array of documents that form the backbone of quality and compliance. However, managing these documents across multiple systems or in isolated silos can lead to inefficiencies, inconsistencies, and compliance risks.

This is where Omnex Systems steps in—with a powerful, integrated solution that simplifies and strengthens documentation practices across the enterprise. The company’s Multi-Module Documentation Management platform provides a centralized, intelligent way to handle documents that span various quality functions, enabling teams to collaborate efficiently, maintain compliance, and drive operational excellence.

What Is Multi-Module Documentation Management?

Multi-Module Documentation Management is an advanced approach that connects and synchronizes document control across various quality and compliance modules. Instead of handling audits, training, corrective actions, and risk assessments in separate systems, this model integrates all documentation processes under one cohesive platform. It eliminates data silos, reduces duplication, and ensures that every document used across modules is up-to-date, approved, and accessible to authorized users.

At Omnex Systems, this capability is not an add-on—it’s a core strength. Their software platform is specifically designed to support multi-module integration, enabling seamless document flow between interconnected quality functions.

The Challenge of Disconnected Documentation

Many organizations still rely on separate tools or manual methods for different quality processes. For instance, training records may be stored in one system, while audit checklists are maintained in another, and CAPA forms are handled through spreadsheets or email threads. This fragmented approach leads to several critical issues:

Inconsistent data and outdated documents

Limited visibility across quality processes

Redundant data entry and administrative overhead

Increased risk of non-compliance and audit failure

A unified multi-module documentation management system solves these problems by connecting all document-centric processes within a single ecosystem.

How Omnex Systems Transforms Documentation Management

Omnex Systems delivers a robust, cloud-based platform that seamlessly integrates document control with other quality management modules. Whether it's managing an FMEA, CAPA, audit checklist, or training plan, every document is stored in a centralized repository with version control, access permissions, and audit trails.

Here’s how Omnex’s multi-module documentation management system helps organizations streamline their quality processes:

1. Centralized Document Control

All documents—whether linked to audits, training, change management, or risk analysis—are stored in a single, secure location. Users have access to the most current versions, ensuring consistency and preventing errors caused by outdated information.

2. Automated Workflows and Approvals

Documents pass through clearly defined approval processes with automated routing, notifications, and escalation paths. This ensures timely review and prevents bottlenecks while maintaining accountability across teams.

3. Linked Modules for Seamless Data Flow

What makes Omnex’s solution truly powerful is the multi-module integration. For example:

A CAPA report can be directly linked to a nonconformance record and relevant training materials.

Changes to an SOP can trigger updates in associated FMEAs or control plans.

Audit findings can initiate corrective actions, complete with linked documentation.

This interconnectivity reduces rework and ensures a single source of truth across all modules.

4. Compliance-Ready Documentation

With built-in audit trails, electronic signatures, and version history, Omnex’s platform ensures full traceability and compliance with standards like ISO 9001, IATF 16949, AS9100, and more. Organizations can easily demonstrate control over their document processes during audits or inspections.

5. Scalable, Cloud-Based Access

Whether you operate in a single location or across multiple global sites, Omnex Systems offers scalable cloud deployment. Authorized users can securely access documents from anywhere, promoting global collaboration and reducing delays in document reviews or approvals.

6. User Roles and Access Control

Role-based access ensures that only designated personnel can view, edit, or approve documents. This protects sensitive information and aligns with data security best practices.

Real-World Use Cases of Multi-Module Documentation Management

Let’s explore how multi-module documentation management plays a role in real-life quality scenarios:

Training Management: When a procedure or work instruction is updated, the system automatically flags affected employees for retraining and links the revised document to their training records.

Audit Management: During internal or external audits, auditors can access linked documents such as checklists, findings, and CAPA reports—all from one platform.

FMEA and Control Plans: Updates to process risks or control plans can be directly tied to relevant documents, ensuring changes are reflected across the quality system.

Supplier Management: Supplier documentation, including certifications, scorecards, and audit reports, are stored and managed in an integrated module, with visibility across purchasing, quality, and compliance teams.

Benefits of Multi-Module Documentation Management with Omnex Systems

Implementing multi-module documentation management with Omnex Systems offers several transformative benefits:

Improved Efficiency: Streamlined document workflows reduce manual effort and speed up decision-making.

Better Collaboration: Cross-functional teams can work from a unified platform with real-time access to relevant documents.

Reduced Risk: With centralized version control and traceability, organizations can avoid errors and ensure compliance.

Audit Readiness: Easy access to historical data, version history, and document links simplifies audit preparation and response.

Scalability: Whether you're a small business or a multinational enterprise, Omnex’s cloud solution scales to meet your needs.

Why Choose Omnex Systems?

With decades of experience in quality and process management, Omnex Systems is trusted by global leaders across automotive, aerospace, medical device, and manufacturing industries. The company’s commitment to innovation, compliance, and continuous improvement makes it a preferred partner for organizations seeking to modernize their quality systems.

Omnex’s multi-module documentation management solution is more than just software—it’s a strategic tool that empowers businesses to align their quality objectives with operational efficiency and regulatory demands.

Conclusion

Managing documentation across multiple quality functions doesn't have to be complex. With multi-module documentation management from Omnex Systems, organizations can break down silos, enhance collaboration, and gain complete control over their quality documents. Whether you’re preparing for an audit, launching a new product, or implementing a CAPA, having the right documents in the right place at the right time makes all the difference.

Omnex Systems helps you make that difference—with a solution designed to support your quality journey from end to end.

For more info please visit us +1 734-761-4940 (Or) [email protected]

0 notes

Text

ERP Software Dubai: Unlocking Seamless Business Success

Introduction: The Vital Role of ERP Software in Dubai’s Business Landscape

Dubai is a city of ambition and innovation, where businesses thrive on efficiency and agility. In such a fast-paced environment, having a robust system to manage operations is no longer a luxury—it’s a necessity. ERP software Dubai has become the cornerstone for organizations aiming to integrate their processes and gain a competitive edge.

Enterprise Resource Planning (ERP) software connects the dots across various departments, from finance and inventory to human resources and customer relations. This unification of functions helps businesses reduce silos, enhance transparency, and ultimately, make smarter decisions. In Dubai’s diverse and dynamic market, ERP software acts as the backbone supporting growth and sustainability.

Understanding the Unique Needs of Dubai’s Market

Dubai’s business environment is characterized by its diversity—from multinational corporations and SMEs to free zone enterprises. Each sector has its distinct challenges and requirements. ERP software tailored for Dubai must be versatile enough to handle these complexities.

Compliance with UAE’s VAT regulations, multi-currency handling for international trade, and bilingual capabilities (Arabic and English) are critical factors. Furthermore, Dubai’s strategic position as a trading hub demands ERP systems that can manage fast-moving supply chains and complex logistics efficiently. The ideal ERP software should be flexible, adaptable, and intuitive, catering specifically to these localized demands.

Key Features to Look for in ERP Software in Dubai

Selecting ERP software is more than choosing a tool; it’s about finding a comprehensive solution that fits your business DNA. Here are the must-have features for ERP software in Dubai:

VAT Compliance Automation: Simplifies tax calculations and filings in line with UAE laws.

Multi-Currency and Multi-Language Support: Enables smooth transactions and communication across borders.

Modular and Scalable Architecture: Tailors to industry-specific needs and grows with your business.

Cloud-Based Deployment: Offers mobility, security, and cost-efficiency.

Advanced Analytics & Reporting: Provides actionable insights through real-time dashboards.

These elements ensure your ERP software is not just a system but a strategic partner in your success.

Transforming Industries Across Dubai with ERP Software

Dubai’s economy spans a wide array of industries, each benefiting uniquely from ERP integration. In manufacturing, ERP streamlines production scheduling and inventory management, reducing waste and boosting output. Retailers leverage ERP to synchronize their omni-channel sales, providing customers with seamless shopping experiences.

The hospitality sector relies on ERP to optimize booking management, staffing, and resource allocation. Meanwhile, finance and professional services use ERP to automate workflows and ensure regulatory compliance, increasing operational efficiency and transparency. ERP software is truly the common thread driving operational excellence across Dubai’s diverse business sectors.

How to Choose the Right ERP Software for Your Dubai Business

Choosing ERP software is a pivotal decision with long-lasting impact. Here are some practical tips for Dubai businesses:

Evaluate Your Business Needs Thoroughly: Understand which processes require automation and integration.

Choose Providers with Local Expertise: Vendors knowledgeable about Dubai’s regulatory environment offer a smoother implementation.

Focus on Flexibility and Scalability: Your ERP should evolve alongside your growing business.

Prioritize User-Friendly Interfaces: Ease of use accelerates adoption and minimizes resistance.

Ensure Strong Support and Training: Ongoing vendor support is crucial for successful ERP deployment.

Taking these factors into account ensures your ERP journey is successful and sustainable.

The Future of ERP Software in Dubai: Embracing Innovation

Dubai is at the forefront of digital transformation, and ERP software is evolving accordingly. The integration of artificial intelligence, machine learning, and the Internet of Things (IoT) is shaping the future of ERP systems.

Tomorrow’s ERP software will not only record and process data but will anticipate needs, automate complex decisions, and provide hyper-personalized insights. Businesses in Dubai that adopt these cutting-edge technologies will enjoy enhanced agility, predictive capabilities, and a distinct competitive advantage.

Conclusion: Empower Your Dubai Business with the Right ERP Software

ERP software in Dubai is more than just a technological upgrade—it’s a strategic enabler of growth, efficiency, and innovation. With the right system in place, businesses can break down silos, optimize operations, and seize new opportunities with confidence.Ready to transform your business with cutting-edge ERP software in Dubai?Banibro IT Solutions offers expert guidance and customized ERP implementations designed to elevate your business to new heights. Let’s build the future of your enterprise, today

0 notes

Text

Why MetaTrader 5 Is the Future of Online Trading

MetaTrader 5 (MT5) has revolutionized the way traders operate in the financial markets. Unlike its predecessor MT4, MetaTrader 5 offers multi-asset capabilities, faster processing, advanced charting tools, and a more intuitive interface. Tradewill brings this cutting-edge platform directly to your fingertips, giving traders a competitive edge with seamless execution and reliable infrastructure.

At Tradewill, we understand that success in trading depends on technology, strategy, and speed. That’s why MT5 is the go-to choice for traders who are serious about making informed decisions and maximizing their returns.

Advanced Trading Tools at Your Fingertips

One of the standout features of MetaTrader 5 is its array of analytical tools. With over 80 built-in technical indicators and analytical objects, you can perform in-depth market analysis with precision. Whether you're trading forex, stocks, or commodities, MT5 offers everything you need to analyze price movements and identify trends.

Tradewill enhances this experience by providing:

Real-time data feeds

Custom indicators

Algorithmic trading

One-click trading

Multi-threaded strategy tester

These features enable traders to execute complex strategies and automate their trading through Expert Advisors (EAs). No matter your level of experience, Tradewill's MT5 platform supports your growth with powerful trading tools.

Multiple Asset Classes on One Platform

MetaTrader 5 is a true multi-asset platform. Unlike MT4, which primarily supports forex trading, MT5 expands your trading opportunities by providing access to:

Forex

Stocks

Indices

Commodities

Futures

Cryptocurrencies

With Tradewill, you can diversify your portfolio and trade across various markets all in one place. This multi-market approach allows you to hedge risks more effectively and capitalize on opportunities in multiple sectors.

Superior Charting and Technical Analysis

MT5’s charting system is one of the most sophisticated in the industry. It allows for 21 timeframes, ranging from one minute to one month, giving you a comprehensive view of market trends. You can use built-in indicators or add custom ones to create a unique trading setup that fits your strategy.

Tradewill empowers traders with:

Interactive charts

Real-time updates

Drawing tools

Multiple order types

These features help you make timely decisions based on accurate data and technical insight.

Fast Order Execution and Minimal Latency

In the world of trading, timing is everything. MetaTrader 5 ensures lightning-fast order execution and low latency, helping you get in and out of trades quickly and efficiently. Tradewill’s optimized servers and global network infrastructure reduce slippage and deliver an uninterrupted trading experience.

Whether you’re scalping, swing trading, or holding long-term positions, Tradewill and MT5 offer the stability and speed needed to execute your strategy flawlessly.

Mobile and Web Trading for Maximum Flexibility

In today’s fast-paced world, flexibility is key. MetaTrader 5 is available on desktop, web, and mobile platforms, allowing you to trade from anywhere at any time. Tradewill’s MT5 mobile app lets you manage your portfolio, place trades, and monitor the markets on the go—without compromising functionality.