#virtual reality 3D modeling

Explore tagged Tumblr posts

Text

The Impact of 3D Modeling for 3D Printing on Custom Manufacturing

Impact of 3D Modeling for 3D Printing

In today's fast-paced and hyper-personalized world, businesses and consumers increasingly seek custom-made products tailored to their unique needs. At the core of this shift lies the powerful combination of 3D modeling for 3D printing and custom manufacturing. This pairing transforms traditional production processes and drives innovation across various industries—from medical devices and consumer products to aerospace and architecture.

What is 3D Modeling for 3D Printing?

3D modeling for 3D printing involves creating a digital representation of a physical object that can be directly converted into a printable format, usually an STL or OBJ file. These models are created using professional 3D Modeling Services and are designed with precision to meet the functional, aesthetic, and mechanical requirements of the final product.

By leveraging 3D product modeling services, manufacturers can develop complex geometries, internal structures, and intricate details that would be impossible or too expensive to achieve through traditional methods.

The Rise of Custom Manufacturing

Thanks to 3D Modeling for 3D Printing, companies can now create prototypes, test ideas, and manufacture small batches of custom products with speed and accuracy.

How 3D Modeling Empowers Customization

1. Rapid Prototyping

One of the most significant impacts of 3D Model Augmented Reality is in rapid prototyping. A 3D model maker for a 3D printer can quickly convert a concept into a tangible prototype. This enables designers and engineers to identify flaws early, make necessary adjustments, and improve product quality without incurring high tooling costs.

2. Personalization at Scale

With the help of 3D modeling services, manufacturers can offer customized products at scale. Whether it’s personalized dental aligners, custom phone cases, or ergonomically designed handles, 3D product modeling services make it possible to adapt each product to the specific measurements or preferences of an individual customer.

3. Enhanced Product Complexity

However, 3D Modeling for 3D Printing removes these limitations. Designers can now create highly complex and lightweight structures—such as lattice supports or internal channels—without additional production steps.

Integration with AR and VR Technologies

The impact of 3D modeling extends beyond physical products. Emerging technologies like 3D Model Augmented Reality (AR) and virtual reality (VR) are redefining how models are visualized, tested, and even marketed.

AR 3D Modeling for Visualization

AR 3D Modeling enables businesses to visualize digital objects in the real world before they’re manufactured. This helps clients understand product dimensions, placement, and aesthetics with greater clarity. For instance, using AR Product Visualization, a furniture manufacturer can show how a custom-made table would look in a customer’s living room before it is printed.

VR 3D Modeling for Simulation

On the other hand, VR 3D Modeling allows designers to immerse themselves in a virtual environment to test their designs. Whether it’s evaluating the usability of a custom vehicle dashboard or the ergonomics of a tool handle, Virtual Reality 3D Modeling provides a hands-on approach to refining product designs before printing.

Applications of 3D Modeling for 3D Printing in Custom Manufacturing

1. Healthcare & Medical Devices

From prosthetics to dental implants, the healthcare sector has embraced 3D modeling for 3D printing to provide customized solutions for patients. Using advanced 3D product modeling services, prosthetic limbs can be tailored to an individual's anatomy, ensuring better comfort and functionality.

2. Automotive & Aerospace

High-performance industries like automotive and aerospace rely on 3D Model Maker for 3D Printer to create lightweight yet durable parts. This includes everything from custom brackets and housings to functional interior parts designed for specific models or pilots.

3. Consumer Products

In fashion, jewelry, and home decor, 3D Modeling Services empower designers to offer one-of-a-kind products. AR features also enhance the shopping experience. For example, AR Product Visualization allows customers to virtually “try on” glasses or see how a custom ring would look on their hand.

4. Industrial Manufacturing

In industrial settings, custom jigs, fixtures, and machine parts can be designed using 3D modeling services to match specific production lines or machinery.

3D Modeling for 3D Printing

Cost Efficiency

Instead of investing in expensive molds, they can directly print parts as needed, even in small quantities.

Speed to Market

The design-to-production cycle is significantly shortened. Changes can be made instantly in the 3D model and printed on the same day, ensuring faster product development and launch.

Sustainability

Custom manufacturing using 3D product modeling services produces less waste compared to traditional subtractive methods. Materials are only used where needed, and designs can be optimized for minimal environmental impact.

Design Flexibility

3D Modeling Services offer unprecedented design freedom. Whether for organic shapes, custom engravings, or complex moving parts, the possibilities are virtually limitless.

The Role of Professional 3D Modeling Services

While 3D printing hardware is more accessible than ever, the quality of output still depends on the quality of the digital model. That's why professional 3D modeling services play a vital role in custom manufacturing. These services ensure models are designed with the appropriate tolerances, wall thickness, and structural integrity needed for specific materials and 3D printing methods.

Whether you need a 3D Model Maker for 3D Printer, an expert in AR 3D Modeling, or a specialist in VR 3D Modeling, partnering with a skilled team can dramatically improve the performance, accuracy, and marketability of your custom product.

Future Outlook

As 3D product modeling services continue to evolve and integrate AI-driven automation, the process of turning ideas into personalized products will become faster, cheaper, and more intelligent.

We are also seeing growth in cloud-based platforms where users can design, visualize, and order custom products from the comfort of their homes. With real-time AR Product Visualization and Virtual Reality 3D Modeling, the entire production lifecycle—from design to delivery—is being redefined.

Conclusion

3D Modeling for 3D Printing is not just a technological trend—it is a foundational element driving the future of custom manufacturing. From rapid prototyping and personalized medical devices to immersive AR/VR product visualization, the impact of this digital-to-physical workflow is profound and far-reaching.

Businesses looking to stay ahead in a competitive marketplace must embrace 3D Modeling Services, explore AR 3D Modeling for consumer engagement, and tap into 3D product modeling services for tailored production. Whether you're a startup, a global manufacturer, or a creative entrepreneur, the fusion of 3D modeling and 3D printing offers a gateway to limitless customization.

#3D Modeling Services#AR 3D Modeling#3D product modeling services#3D Model Augmented Reality#AR Product Visualization#VR 3D Modeling#Virtual Reality 3D Modeling#3D Modeling for 3D Printing#3D Model Maker for 3D Printer

0 notes

Text

How Virtual Reality is Revolutionizing Product Design

In today’s rapidly evolving tech landscape, Virtual Reality (VR) is not just a futuristic concept—it’s a game-changer for industries across the board, especially product design. From concept to creation, VR tools are empowering designers to visualize, modify, and perfect their ideas like never before.

Gone are the days of static sketches and basic prototypes. With virtual reality 3D modeling, designers can step into their creations, inspect details from every angle, and identify potential design flaws in real-time. This immersive experience accelerates the development process, improves accuracy, and reduces production costs.

VR also bridges the gap between clients and designers. Instead of trying to interpret a 2D sketch, clients can now experience the product before it's made, leading to faster approvals and better collaboration. Whether it's automotive, furniture, or tech gadgets, VR enables stakeholders to make informed decisions at every stage.

Moreover, combining VR with 3D product visualisation enhances product marketing, giving customers an interactive, engaging preview. This not only improves customer experience but also boosts conversion rates in e-commerce settings.

As technology continues to evolve, virtual reality 3D modeling will undoubtedly become the standard in modern product design—enabling smarter, faster, and more creative solutions.

About Us: At Baked Moon Studios, we specialize in AR/VR-enabled 3D modeling solutions that help businesses visualize, market, and innovate their products with precision. Visit us to explore how we can bring your vision to life.

0 notes

Text

Create Despite

finally back to more regular personal art after a very long physical therapy break :,)

#art#3d art#video#art video#artists on tumblr#digital art#3d model#deer#furry#ar#augmented reality#vr#virtual reality#figmin xr#tilt brush#i have a ton of pics to post of this as well#but that will happen tomorrow !#anyways i started this almost a year ago i think.... crazy#it means a lot to me and i'm glad i didn't give up on it

285 notes

·

View notes

Text

A less exciting video, but I tried my hand at uploading an avatar to #resonite. Video below the break~ https://www.youtube.com/watch?v=qFRVJP-6CU4

youtube

#resonite#vr#novabeast#3d modeling#virtual reality#furry#video#my video#tumblr compressed the hell out of that video above wow

39 notes

·

View notes

Text

Welcome to activitude!

12 notes

·

View notes

Text

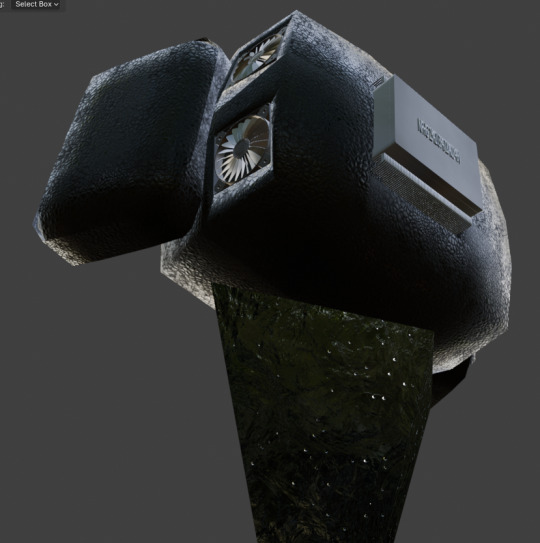

Some test renders for a college project I'm doing

#3d art#3d model#3d design#3d modling#3d modelling#texturing#vr games#vrchat#virtual reality#college#college posting#college project#coding#code game#coding game

2 notes

·

View notes

Text

Creating Interactive VR 3D Models Experiences

VR 3D Models Experiences

In today's digital era, interactive 3D models are becoming the backbone of immersive virtual reality (VR) experiences. Whether it's for gaming, education, product visualization, or architectural walkthroughs, VR has revolutionized the way we interact with digital content. At the heart of these experiences lies a complex and creative process—Virtual Reality 3D Modeling. This blog will walk you through the essentials of creating interactive 3D models tailored for VR, including the tools, techniques, and the role of cutting-edge 3D Modeling Services.

Why 3D Models Are Crucial for VR

To make this possible, environments and objects must respond dynamically to user actions. Interactive 3D models make this immersion possible. They can be manipulated, navigated, and interacted with in real-time, offering a sense of presence and realism that flat, 2D interfaces cannot match.

This is where VR 3D Modeling comes into play. It focuses on building assets that perform well in virtual environments, balancing visual fidelity with performance.

Step-by-Step Process for Creating VR-Ready 3D Models

1. Conceptualization and Planning

Is it for AR Product Visualization, a VR game, or a training simulator? Understanding the end-use helps guide the level of detail, interactivity, and optimization needed.

Here, many businesses turn to 3D Modeling Services for their expertise in translating ideas into digital formats. Professionals bring the skill set necessary to create high-quality models that are both interactive and platform-friendly.

2. 3D Modeling

If the end goal is to support 3D Model Augmented Reality as well as VR, models need to be lightweight and adaptable to various platforms.

Organic Modeling for characters and natural environments

For product-related projects, businesses often opt for 3D product modeling services, which specialize in accurately depicting real-world products for immersive applications.

3. Texturing and UV Mapping

Realism is essential for VR, and textures play a significant role in achieving that. The better the texture quality, the more engaging the Virtual Reality 3D Modeling experience becomes.

PBR (Physically Based Rendering) materials are commonly used in VR and AR 3D Modeling to simulate real-world lighting and material effects.

4. Rigging and Animation (If Applicable)

If the 3D model includes movement, like a door opening, a character walking, or a product disassembling, rigging and animation are essential.

For instance, a 3D model for augmented reality furniture app might allow users to rotate, resize, or open parts of a cabinet in a virtual showroom.

5. Optimization for Real-Time Rendering

VR applications require high frame rates to prevent motion sickness and ensure smooth interaction. Therefore, polygon counts must be optimized without sacrificing visual quality. This is particularly critical in VR 3D Modeling, where every frame counts.

Optimization techniques include:

Reducing poly count

Efficient UV layouts

Baking, lighting and shadows

6. Integration into VR Platforms

After the model is finalized, it’s imported into VR development platforms like Unity or Unreal Engine. This is where interactivity is programmed.

Applications of Interactive 3D Models in VR

1. Gaming and Entertainment

From characters to weapons to fully fleshed-out environments, each asset plays a crucial role in immersing the player.

2. E-Commerce and Product Demos

With the rise ofAR Product Visualization, businesses are increasingly using VR to create virtual showrooms. Customers can explore 3D product models from every angle, interact with components, and make informed purchase decisions.

3. Architecture and Real Estate

Using 3D modeling services, architects create VR walkthroughs of buildings long before construction begins.

4. Healthcare and Training

In fields like medicine, interactive virtual reality 3D modeling is used to simulate surgeries or anatomical studies.

5. Manufacturing and 3D Printing

Before sending designs to a printer, many engineers use 3D Modeling for 3D Printing to test and visualize their creations in VR.

Bridging AR and VR with Unified 3D Assets

In many cases, assets created for VR can also be repurposed for AR. This trend is particularly popular in retail and marketing, where 3D Model Augmented Reality and VR are used side-by-side to enhance customer engagement.

For example, a 3D Model Maker for 3D Printer might create a model that works in both a VR store environment and an AR mobile app.

Choosing the Right 3D Modeling Service

When outsourcing, choose a 3D modeling service that understands both AR and VR requirements. Look for portfolios that showcase:

Experience with VR 3D Modeling

Knowledge of platform-specific optimization

Interactive design capabilities

Also, if your project involves 3D Modeling for 3D Printing, ensure they understand tolerances, support structures, and export formats like STL or OBJ. A skilled 3D Model Maker for 3D Printer can help bridge the gap between virtual design and physical output.

Future of Interactive VR Modeling

As devices get more powerful and accessible, demand for Virtual Reality 3D Modeling will continue to grow across industries.

Another growing trend is the integration of AR 3D Modeling and VR in hybrid platforms, creating seamless transitions between physical and digital worlds. Whether it's a car showroom, a factory floor, or an educational module, the power of interactive 3D models is only just beginning to be realized.

Conclusion

Creating interactive 3D models for VR is both an art and a science. From concept to optimization, each step plays a vital role in crafting immersive experiences. Whether you're a developer, marketer, or business owner, investing in professional 3D Modeling Services can elevate your project and expand your reach into AR and VR platforms.

As 3D model augmented reality, VR 3D Modeling, and 3D Modeling for 3D Printing continue to evolve, the need for high-quality, interactive, and optimized assets is more critical than ever. With the right tools and talent, you can transform your ideas into powerful, engaging digital realities.

#3D Modeling Services#AR 3D Modeling#3D product modeling services#3D Model Augmented Reality#AR Product Visualization#VR 3D Modeling#Virtual Reality 3D Modeling#3D Modeling for 3D Printing#3D Model Maker for 3D Printer

0 notes

Text

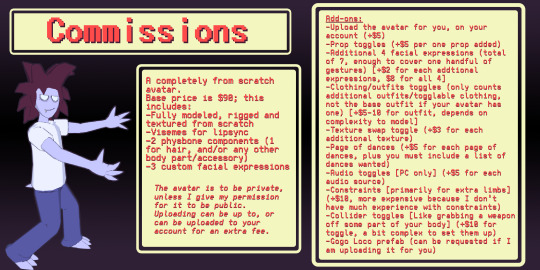

I am on Ko-fi now!

I know I don't personally post my stuff as much as I should on here, but due to recent events, and for ease of myself and anyone interested in my work, I have made a Ko-fi page.

You can keep up with my work there and support me to help keep making stuff! I plan to post updates, behind the scene WIPs, and even polls for avatars!

I have monthly memberships but also allow for one time donations if you cant commit to that. It is basically pay what you want, so absolutely any amount helps support me!

Members get access to things such as: -Invite to my Discord and a "Member" role -WIP screenshots and details of stuff I am currently working on -First ones to get access to any new VRC content I upload before I post about it publicly -Occasional polls to help me decide on what to make next -Invited to my VRC Group -Friend me on VRC -Avatar Commissions! (if currently available) Commission prices (members only):

You can find me on Ko-fi here!

#you dont have to support me but if you can I really appreciate it!#vrchat#vrchat avatar#vrc avatar#virtual reality#avatar commissions#undertale#deltarune#3d modeling#blender 3d#indie#small creator#ko fi support#digital art#artist on kofi#kofi commission

2 notes

·

View notes

Text

#furry nsft#vr games#vtubesona#vtube model#vtuber#virtual reality#vrc shenanigans#gaming#meta quest#3d

3 notes

·

View notes

Text

VRC password sharing to do “uploads” is NOT SAFE!! It is never safe to share a password!

While they have access to the password they can:

Log into your account on browser and edit your username, bio, friends, groups, access your VRC+ info, change your password and email, etc

Have access to your upload options via their Unity and browser

And even if you change that password later it may not log them out of Unity, in Unity they:

Can upload the avatar you agreed upon to receive, but also;

Could upload other things or change the agreed upon avatar

Have access to view your other uploaded avatars and delete them

Have access to the unique codes for the other uploaded avatars, and can use that to replace them with different avatars

None of that is safe!!

I saw a kid recently get their VRC account stolen because of doing password sharing for an “upload.” Just because a lot of people do it doesn’t make it smart or safe. Don’t trust strangers!

#VRchat#VRC#internet safety#vr#virtual reality#3D#3d modeling#I don’t care if you don’t know how to use Unity to upload your own…#playing in a new avatar in VRC is not worth getting your account stolen or messed with#even password sharing with a friend could backfire after a fallout#as a teen I shared one password with a ‘friend’ and a few years later when we split apart he used it to get me banned#don’t password share!

4 notes

·

View notes

Text

Remember that time I made a whole 3D sculpted model in vr of my character Moth, and forgot to post it anywhere? Just me? Yeah...

-MӨƬΉ

2 notes

·

View notes

Text

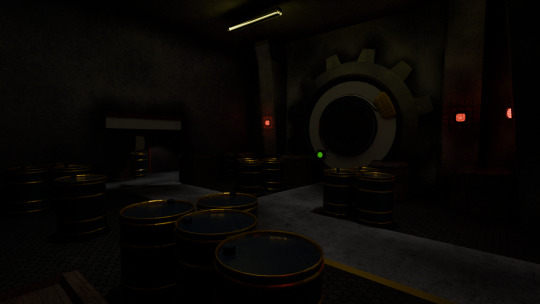

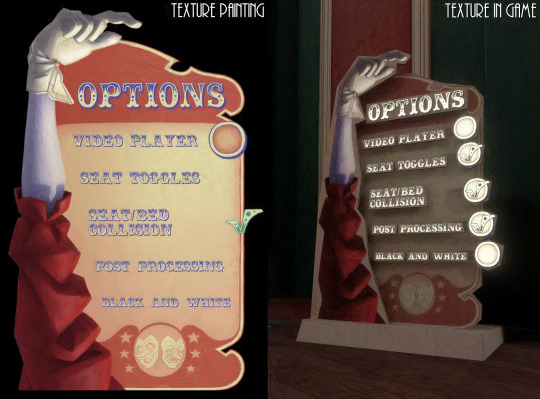

A world I created for the game VR Chat, inspired by the Electric Notting Hill Cinema in London, combining it’s old colours with its post renovation furnishing.

Included are not only the screenshots of the world itself, but the digital paintings I did for the game's textures.

Link to world here https://vrchat.com/home/launch?worldId=wrld_ef910aeb-ee17-4d34-b8bc-6991b1c08710

#vrchat#vrchat world#unity3d#unity#cinema#theatre#environment#3dart#3d model#virtual reality#vintage#theatre mask

3 notes

·

View notes

Text

3D Modeling for 3D Printing: Avoiding Common Design Mistakes

Avoiding Common Design Mistakes

In today's era of rapid prototyping and custom manufacturing, 3D Modeling for 3D Printing has become a cornerstone of product development, architecture, healthcare, and even fashion. While powerful 3D printers and cutting-edge 3D Modeling Services make fabrication more accessible, one small design flaw in the digital model can result in a failed print, wasted resources, and project delays.

To ensure seamless output, it’s essential to create accurate, printer-friendly models from the start.

Why Precision Matters in 3D Product Modeling Services

Before diving into the design pitfalls, let’s understand why accuracy is vital in 3D product modeling services.

Whether you are building a prototype for a startup or a replacement part for a machine, the digital model becomes the blueprint for the physical product. Unlike screen-based uses such as AR Product Visualization or Virtual Reality 3D Modeling, 3D printing involves real-world material constraints such as gravity, strength, and support. A minor modeling error can cause layer shifting, warping, or structural weakness.

That’s why choosing experienced 3D Model Maker for 3D Printer and understanding key design principles are essential.

Mistakes in 3D Modeling for 3D Printing

1. Ignoring Minimum Wall Thickness

One of the most frequent errors in 3D Modeling for 3D Printing is designing walls that are too thin. Each printing material has a recommended minimum wall thickness

Solution: Always check the minimum wall thickness supported by your chosen material and printer. Use wall-thickness analysis tools in your modeling software.

2. Overlooking File Format Compatibility

3D printers rely on specific file types like STL, OBJ, or 3MF. Choosing the wrong file format or incorrectly exporting your model can lead to printing errors or loss of detail.

Solution: Consult with your 3D Modeling Services provider to determine the correct file format. Make sure to check for and repair non-manifold edges, inverted normals, or overlapping faces before exporting.

3. Inadequate Support Structures

Designs with overhangs exceeding 45 degrees or intricate geometries often need support structures to print successfully. Failing to include or optimize these structures can lead to sagging, poor surface finish, or broken parts.

Solution: Use slicer software to preview and automatically generate support structures. Modify your model in advance to reduce the need for excessive supports.

4. Non-Watertight Models

Open meshes confuse the printer’s slicing software, often leading to missing layers or a corrupted print.

Solution: Run mesh integrity checks using tools like Netfabb or Meshmixer to ensure your model is solid and printable.

5. Scaling Issues

Many times, users unknowingly design models in the wrong scale or measurement units, leading to prints that are too small, too large, or dimensionally inaccurate.

Solution: Always work in millimeters unless otherwise required. Cross-check dimensions in your modeling software and slicer before exporting for print.

6. Overcomplicating Geometry

While it’s tempting to design complex features, excessive detail can result in jagged or broken prints, especially on low-resolution printers.

Solution: Simplify your geometry without compromising functionality. Use 3D product modeling services that specialize in optimizing high-poly models for printability.

Leveraging AR and VR

AR 3D Modeling for Prototyping

AR 3D Modeling isn’t just for games and marketing—it can also be an invaluable tool during the design phase of 3D printed products. Visualizing your model in real-world environments helps spot scale issues and ergonomic flaws before printing.

Example: Imagine placing your 3D model of a chair into a living room scene via AR Product Visualization to check for spatial fit and aesthetics.

VR 3D Modeling for Immersive Editing

Using VR 3D Modeling software like Gravity Sketch or Oculus Medium allows designers to sculpt, view, and manipulate models in a virtual 3D space. This can significantly improve accuracy and creativity during the design phase, especially for organic forms.

Bonus: With Virtual Reality 3D Modeling, teams can collaboratively review complex geometries before investing in physical production.

How 3D Model Augmented Reality Enhances Client Approval

When clients can’t physically interact with prototypes, 3D Model Augmented Reality bridges the gap. Instead of sending multiple iterations through print, use AR to present the model in context. This shortens approval cycles and reduces rework.

Tips for Effective 3D Modeling for Printing

Start with the End in Mind:

Understand what the final product should do and where it will be used.

Know Your Printer and Material:

Different machines and materials have different tolerances.

Design for Assembly:

For larger prints, break your model into parts that fit within printer constraints and are easy to assemble.

Use Boolean Operations Sparingly:

Boolean unions and subtractions can cause mesh errors—double-check for non-manifold edges.

Iterate with Prototypes:

Start with scaled-down or low-resolution prints to catch issues early.

Final Thoughts

3D Modeling for 3D Printing is a nuanced process that goes beyond just beautiful design—it’s about functionality, manufacturability, and real-world performance. By avoiding common mistakes like ignoring wall thickness, forgetting support structures, or exporting incorrect file types, you save valuable time and resources.

Whether you're a designer, manufacturer, or business owner, investing in reliable 3D Modeling Services and expert 3D product modeling services ensures that your printed models are not just prototypes, but powerful, functional innovations.

#3D Modeling Services#AR 3D Modeling#3D product modeling services#3D Model Augmented Reality#AR Product Visualization#VR 3D Modeling#Virtual Reality 3D Modeling#3D Modeling for 3D Printing#3D Model Maker for 3D Printer

0 notes

Text

EU_LOGY @ SUBSYSTEM >_SERVER ROOM #22

this is definitely one of my favorite venues. the lighting in here is incredibly dynamic and it was nice to pop in to listen to a friend's set :)) people at this venue are always dancing to the max and with no shame. expect heavy hitting, intense, hard industrial music when coming to this venue.

4 notes

·

View notes

Text

BIM Careers: Building Your Future in the Digital AEC Arena

The construction industry is undergoing a digital revolution, and BIM (Building Information Modeling) is at the forefront. It's no longer just a fancy 3D modeling tool; BIM is a collaborative platform that integrates data-rich models with workflows across the entire building lifecycle. This translates to exciting career opportunities for those who can harness the power of BIM.

Are you ready to step into the octagon of the digital construction arena? (Yes, we're keeping the fighting metaphor alive!) Here's a breakdown of the in-demand skills, salary ranges, and future prospects for BIM professionals:

The In-Demand Skillset: Your BIM Arsenal

Think of your BIM skills as your tools in the digital construction toolbox. Here are the top weapons you'll need:

BIM Software Proficiency: Mastering software like Revit, ArchiCAD, or Navisworks is crucial. Understanding their functionalities allows you to create, manipulate, and analyze BIM models.

Building Science Fundamentals: A solid grasp of architectural, structural, and MEP (mechanical, electrical, and plumbing) principles is essential for creating BIM models that reflect real-world construction realities.

Collaboration & Communication: BIM thrives on teamwork. The ability to collaborate effectively with architects, engineers, and other stakeholders is paramount.

Data Management & Analysis: BIM models are data-rich. Being adept at data extraction, analysis, and interpretation unlocks the true potential of BIM for informed decision-making.

Problem-Solving & Critical Thinking: BIM projects are complex. The ability to identify and solve problems creatively, while thinking critically about the design and construction process, is invaluable.

Salary Showdown: The BIM Payday Punch

Now, let's talk about the real knock-out factor – salaries! According to Indeed, BIM professionals in the US can expect an average annual salary of around $85,000. This number can vary depending on experience, location, and specific BIM expertise. Entry-level BIM roles might start around $60,000, while BIM Managers and BIM Specialists with extensive experience can command salaries exceeding $100,000.

Future Forecast: A Bright BIM Horizon

The future of BIM is bright. The global BIM market is projected to reach a staggering $8.8 billion by 2025 (Grand View Research). This translates to a continuous rise in demand for skilled BIM professionals. Here are some exciting trends shaping the future of BIM careers:

BIM for Specialty Trades: BIM is no longer just for architects and engineers. We'll see increased adoption by specialty trades like HVAC technicians and fire protection specialists.

Integration with AI and Machine Learning: Imagine BIM models that can predict potential issues or suggest optimal design solutions. AI and machine learning will revolutionize BIM capabilities.

VR and AR for Enhanced Collaboration: Virtual Reality (VR) and Augmented Reality (AR) will allow for immersive BIM model walkthroughs, facilitating better collaboration and design communication.

Ready to Join the BIM Revolution?

The BIM landscape offers a dynamic and rewarding career path for those with the right skills. If you're passionate about technology, construction, and shaping the future of the built environment, then BIM might be your perfect career match. So, hone your skills, embrace the digital revolution, and step into the exciting world of BIM with Capstone Engineering!

#tumblr blogs#bim#careers#buildings#bim consulting services#bim consultants#construction#aec#architecture#3d modeling#bim coordination#consulting#3d model#bimclashdetectionservices#engineering#MEP engineers#building information modeling#oil and gas#manufacturing#virtual reality#collaboration#bim services#uaejobs

2 notes

·

View notes

Text

Just a silly lil guy dancing to a Mixamo dance!

#furry art#furry#furry fandom#furry character#dance#dancehall#mixamo#blender#3d render#3d model#3d animation#3d art#cute#cute animals#vrchat#resonite#virtual reality#Spotify

8 notes

·

View notes