#304 and 316 Stainless Steel pipes

Text

Kitchen Plumbing Fittings: Essential Components for a Functional Kitchen

When it comes to setting up a kitchen, plumbing fittings play a crucial role in ensuring functionality, efficiency, and safety. Primegold International Limited, a leading manufacturer and distributor of construction-related products, offers a wide range of high-quality kitchen plumbing fittings designed to meet various needs and preferences. In this blog, we will explore the importance of kitchen plumbing fittings, their types, and tips for choosing the best ones for your kitchen.

Understanding Kitchen Plumbing Fittings

Kitchen plumbing fittings are essential components that connect various plumbing fixtures and ensure the smooth flow of water and waste. They include pipes, faucets, sinks, valves, and connectors, among others. High-quality fittings are crucial for preventing leaks, maintaining water pressure, and ensuring the longevity of your kitchen plumbing system.

Types of Kitchen Plumbing Fittings

1. Faucets

Faucets are one of the most used plumbing fittings in a kitchen. They come in various styles, including single-handle, double-handle, pull-out, and touchless faucets. Choosing the right faucet depends on your kitchen’s design, your cooking habits, and the ease of use you desire.

2. Sinks

Kitchen sinks come in different materials such as stainless steel, porcelain, granite, and composite. Stainless steel sinks are popular due to their durability and ease of cleaning. The number of basins (single or double) should be chosen based on your cooking and cleaning needs.

3. Pipes and Tubes

Pipes and tubes are the backbone of any kitchen plumbing system. They are responsible for carrying water to and from your kitchen fixtures. Common materials include copper, PVC, and PEX. Copper is known for its durability, while PVC and PEX are appreciated for their flexibility and ease of installation.

4. Valves

Valves control the flow of water in your kitchen plumbing system. They are essential for isolating water supply during repairs or maintenance. Common types include gate valves, ball valves, and globe valves.

5. Traps and Drains

Traps and drains are vital for waste management in the kitchen. The P-trap is a commonly used component that prevents sewer gases from entering your kitchen. Ensuring that your drains and traps are of high quality can prevent clogs and leaks.

6. Connectors and Adapters

Connectors and adapters are used to join different plumbing fittings. They come in various shapes and sizes to accommodate different types of pipes and fixtures. Choosing the right connectors ensures a secure and leak-proof connection.

Tips for Choosing the Best Kitchen Plumbing Fittings

1. Quality and Material

Opt for high-quality materials that are durable and resistant to corrosion. Stainless steel, brass, and copper are excellent choices for kitchen plumbing fittings due to their longevity and reliability.

2. Compatibility

Ensure that the fittings you choose are compatible with your existing plumbing system. This includes checking the size and type of pipes and connectors used in your kitchen.

3. Ease of Installation

Choose fittings that are easy to install and maintain. Some modern fittings come with quick-connect features that make installation hassle-free.

4. Water Efficiency

Look for water-efficient fixtures, such as low-flow faucets, to reduce water consumption and save on utility bills. Many high-quality fittings are designed to provide excellent performance while conserving water.

5. Aesthetics

While functionality is crucial, aesthetics also play a significant role in kitchen design. Choose fittings that complement your kitchen's style and décor. Modern designs offer a range of options, from sleek and minimalistic to traditional and ornate.

6. Warranty and Support

Opt for products that come with a warranty and reliable customer support. This ensures that you can get assistance and replacements if needed.

Conclusion

Kitchen plumbing fittings are the unsung heroes of a functional and efficient kitchen. Primegold International Limited offers a comprehensive range of high-quality fittings designed to meet diverse needs and preferences. By understanding the types of fittings available and considering factors such as quality, compatibility, and water efficiency, you can make informed decisions that enhance your kitchen's performance and longevity.

Investing in the right kitchen plumbing fittings not only ensures the smooth operation of your kitchen but also adds value to your home. Whether you are renovating your kitchen or setting up a new one, choosing the best fittings is a crucial step towards creating a space that is both functional and beautiful. Trust Primegold International Limited for all your kitchen plumbing needs and experience the difference that quality and expertise can make.

#Best Plumbing Pipe Fittings#Kitchen Plumbing Fittings#Bathroom Pipes and Fittings#Best Stainless Steel Plumbing Fittings#Best plumbing pipes#304 and 316 stainless steel pipes

0 notes

Text

Outstanding Quality Stainless Steel Pipe in India

Pearl Pipe India is a market-leading Stainless Steel Pipe Manufacturer in India and Stainless Steel 202 Pipe Manufacturer in India. Stainless steel pipes are commonly used in industrial settings for the transportation of liquids, gases, and chemicals. Their ability to withstand high temperatures and corrosive environments renders them indispensable in manufacturing processes. We are also the leading Stainless Steel Pipe Manufacturers in Chennai and Stainless Steel Pipe Manufacturers in Bangalore.

Contact us

Phone: +91 91723 33437

Website: https://pearlpipeindia.com

Product Source: SS Pipe Manufacturer in India and Jindal Stainless Steel Pipe Price List PDF

Also visit: Stainless Steel 316 Pipe Manufacturer in India and Stainless Steel 304 Pipe Manufacturer in India

#Stainless Steel 316 Pipe Manufacturer in India#Stainless Steel 304 Pipe Manufacturer in India#Stainless Steel Pipe Manufacturer in India#SS Pipe Manufacturer in India#Stainless Steel Pipe Manufacturer#Jindal Stainless Steel Pipe Price List PDF

0 notes

Text

Om Steel is a leading stainless steel manufacturer, specializing in the production of high-quality stainless steel grades such as austenitic, ferritic, and duplex. Our expertise lies in providing customized solutions for diverse applications, offering exceptional corrosion resistance and hygienic properties. With a focus on strength, durability, and precision, we supply stainless steel for industrial sectors including defense, aerospace, oil/gas, and specialty valves. Explore our range of stainless steel products, including sheets, plates, pipes, tubes, round bars, and forged fittings, delivering reliable performance across various industries worldwide.

#Stainless steel manufacturer#Austenitic stainless steel#Duplex stainless steel#Corrosion-resistant steel#Customized stainless steel solutions#Hygienic stainless steel#304 stainless steel#316 stainless steel#430 stainless steel#2205 stainless steel#Stainless steel properties#Industrial stainless steel applications#Stainless steel sheets#Stainless steel plates#Stainless steel pipes#Stainless steel tubes#Stainless steel round bars#Stainless steel forged fittings#Defense & Aerospace stainless steel#Oil/Gas stainless steel

0 notes

Text

Stainless Steel Round Bar, Strip, Sheet, Plate and Fitting Exports & Supplier

Jay Steel Corporation is a globally recognized leader, manufacturing, supplying, and exporting premium stainless steel products like Round Bars, Strips, Sheets & Plates, Wire Mesh, Pipes, Tubes, and more. Specializing in sought-after items such as Stainless Steel 304/304L/304H Round Bars, 316/316L/316Ti Round Bars, 304H and 316/316L/316Ti Plates, and 304/304L/304H Tubes & Pipes, we maintain an unwavering commitment to quality. With a significant presence in Germany, Thailand, Russia, France, Saudi Arabia, Kuwait, Qatar, Egypt, Turkey, Oman, and Jordan, Jay Steel Corporation combines global reach with a solid reputation for delivering excellence through continual technological advancements. Choose us for top-tier stainless steel solutions with a focus on quality and innovation.

#Stainless Steel 304/304L/304H Round Bar#Stainless Steel 904L Round Bar#Stainless Steel 316/316L/316Ti Tube & Pipe#Stainless Steel 904L plate

0 notes

Text

Seamless Pipe Uses and Applications - Shree Impex Alloys

What is a seamless stainless steel pipe defined as?

As there is no weld on the surface of the steel pipe and it is perforated from a single round piece of steel, the steel pipe is known as seamless steel pipe. In order to create a hollow tube or shell, the solid steel used to make seamless pipes is heated and shaped into solid circular shapes called "billets" before being cast on a mould resembling a piercing rod. Reliability and Maintenance of Existing Pipelines.

One of India's top manufacturers and suppliers of stainless steel seamless pipe is Shree Impex Alloys. We provide premium stainless steel seamless pipes to numerous sectors across the world.

We are one of the largest Stainless Steel Seamless Pipe Manufacturers in India. Manufacturers of seamless pipes adhere to both Indian and foreign standards such as ASME, AISI, ASTM, ANSI, DIN, BS, IS, and JIS. We are Leading Stainless Steel Seamless Tube Manufacturer and Stainless Steel welded Pipes.

Specifications for Stainless Steel Seamless Pipe

SS Seamless Pipe Types: SS Seamless Pipe, ERW Seamless Pipe, Welded Seamless Pipe, Fabricated Seamless Pipe, LSAW Seamless Pipe, Box Seamless Pipe.

Standard: JIS, AISI, ASME, ASTM, AMS, GB, DIN, EN, GOST.

Thickness: SCH.5, 10, 40/S, 80/S, 160

Schedules: ASTM A-312, EN 10216-5 & Its Equivalent ASME, DIN & EN Standard.

Seamless steel pipes are widely used

With the highest output, conventional carbon structural steel, low-alloy structural steel, or alloy structural steel are used to roll general-purpose seamless steel pipes. These pipes are mostly utilised as pipelines or structural components for moving fluids. Boiler, chemical, and electric power seamless pipes, steel seamless pipes for geology, and petroleum seamless pipes are only a few examples of special-purpose seamless pipes.

What Are the Advantages of Using Stainless Steel Seamless Pipe

In industrial applications, seamless stainless steel pipe has a number of benefits over welded tubing. Here are a few of the main advantages:

Enhanced Strength: Because there are no weld seams, which are frequently the weak places in the pipe, seamless stainless steel pipe is stronger than welded stainless steel pipe.

Improved Corrosion Resistance: Because seamless stainless steel pipe has a strong resistance to oxidation and corrosion, it is perfect for use in corrosive and hostile situations.

Better Hygiene: Because seamless stainless steel tubing is simple to maintain and clean, it is frequently used in the pharmaceutical industry, the food and beverage industry, and other industries where cleanliness is essential.

Why Choose Shree Impex Alloys?

By calling the number or sending an email to the address provided, you can now make your enquiry and ask any questions you may have about Stainless Steel Seamless Pipe. We are dedicated to maintaining high standards for quality and timely product delivery. All of our items are offered at factory prices in large or small quantities.

Our knowledgeable crew checks the product for quality before it is shipped. Call +91 91679 63226 or contact [email protected] if you require a specific size, thickness, or coating for stainless steel seamless pipe, and our sales professionals will provide you with the precise sizes that are currently in stock and confirm the delivery schedule to your nearest port.

#Stainless Steel 304 Seamless Pipe Stockist#Stainless Steel Seamless Pipes Manufacturer Stainless Steel 316 Seamless Pipe Exporter#Stainless Steel Seamless Pipe Supplier in India

0 notes

Photo

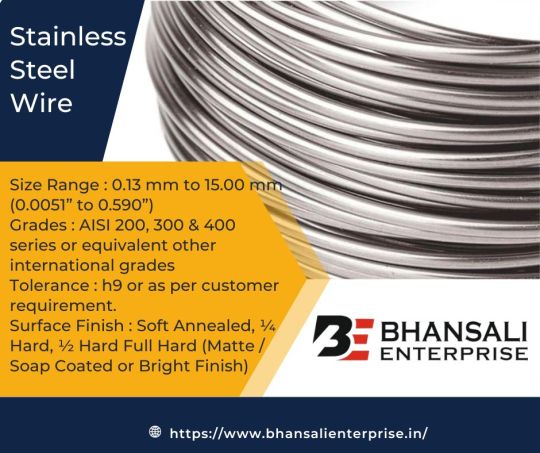

"Manufacturer of Stainless Steel In India."

The highly state-of-the-art infrastructure facility at Bhansali Enterprise undergoes regular update, for reasons of attaining a repudiated and dynamic position in the industry and to maintain high production capacity so that we can cater large quantity demands in limited time. Laced with all the machines and equipment needed, we have been able to develop the offered products as per the modern market developments. In order to attain streamlined and hassle free management of the firm’s operations, the facility has been parted into several functional units. Its superior strength, optimum performance, and longer service life are owed to the best grade raw materials and latest machines used, in line with the norms and guidelines defined by the industry. Apart from this, the offered collection is provided in the market at the most economical price possible. To cater the diverse demands of our clients, we are offering these products in various configurations.

#stainless steel round bar#stainless steel wire#stainless steel wire manufacturers in india#ss 316 chemical composition#stainless steel 316l#stainless steel 304#manufacturer of stainless steel in india#uns s32750#stainless steel 201 cu wire manufactures in mumbai#wire manufacturers#stainless steel round bar manufacturer in india#titanium grade 5#forging of steel#titanium pipes#duplex 2205 stainless steel

0 notes

Text

Main characteristics of stainless steel

weldability

Stainless steel sculpture

Product use of different welding performance requirements are also different. A kind of tableware generally does not require welding performance, even including some pot enterprises. But the vast majority of products need good welding performance of raw materials, such as second class tableware, thermos cup, steel pipe, water heater, water dispenser and so on.

Corrosion resistance

The vast majority of stainless steel products for corrosion resistant performance is good, like a, 2 kinds of tableware, kitchen utensils and appliances, water heaters, water dispensers, etc., some foreign businessmen on corrosion resistance of products also do experiment: in NACL aqueous solution heated to boiling, after a period of time out solution, wash and drying, weight loss, to determine the degree of corrosion (note: When polishing the product, due to the content of Fe in emery cloth or sandpaper, it will lead to rust spots on the surface of the test.

Polishing performance

In today's society, stainless steel products are generally polished in the production of this process, only a few products such as water heater, water dispenser tank do not need polishing. Therefore, the polishing performance of raw materials is very good. The main factors affecting the polishing performance are as follows:

① Surface defects of raw materials. Such as scratches, pitting, pickling and so on.

② Raw material problems. The hardness is too low, it is not easy to shine when polishing (BQ is not good), and the hardness is too low, the surface is easy to appear orange peel phenomenon when deep stretching, thus affecting the BQ. The BQ with high hardness is relatively good.

③ For deeply stretched products, small black spots and RIDGING will appear on the surface of the area with great deformation, which will affect the BQ property.

Heat resistant performance

Heat resistance refers to the high temperature stainless steel can still maintain its excellent physical and mechanical properties.

Influence of carbon: Carbon is an element that strongly forms and stabilizes austenite and enlarges austenite zone in austenitic stainless steel. The ability of carbon to form austenite is about 30 times that of nickel. Carbon is an interstitial element, and the strength of austenitic stainless steel can be significantly improved by solution strengthening. Carbon can also improve the stress and corrosion resistance of austenitic stainless steel in high concentration chloride, such as 42%MgCl2 boiling solution.

But, in the austenitic stainless steel, carbon is often seen as the harmful elements, this is mainly due to the corrosion of stainless steel used in some conditions, such as welding or heating by 450 ~ 850 ℃), carbon steel with chromium in forming high chromium Cr23C6 type carbon compounds which can lead to local chromium depletion, make steel corrosion resistance especially resistant to intergranular corrosion performance degradation. So. Since the 60 s of the development of new cr-ni austenitic stainless steel is mostly carbon content less than 0.03% or 0.02% of the ultra-low carbon type, you can know as the carbon content is reduced, the steel intergranular corrosion sensitivity is reduced, when carbon content less than 0.02% is one of the most obvious effect, some experiments also pointed out that the carbon will also increase the chromium austenitic stainless steel corrosion tendency. Due to the harmful effect of carbon, not only in the process of austenitic stainless steel smelting should be controlled as low as possible carbon content, but also in the subsequent hot, cold processing and heat treatment process to prevent stainless steel surface carburization, to avoid chromium carbide precipitation.

When the number of chromium atoms in the steel is not less than 12.5%, the electrode potential of the steel can be changed from negative to positive. Prevent electrochemical corrosion.

#stainless#304 stainless steel prices#stainless steel 304#ss 304 scrap#stainless steel sheet 304#stainless steel 316#304 ss pipe

1 note

·

View note

Text

Monel K500 Blind Flanges Exporters

Monel Blind Flanges are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types. A Blind flange is round plate which has all of the relevant boltholes but no center hole, and because of this feature this flange is used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened.

However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure temperature applications.

Monel Blind Flanges are used for testing the flow of gas or liquid through a pipeline or vessel. It helps to close the end of piping systems or vessel openings. It allows easy access to the pipeline when there is a requirement to work done inside the line. They are used in high pressure applications available in all grades, materials, size and specifications. Blind pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind pipe flanges, the standard height is 1/16" for blind pipe flanges under 400 ( 2.4360)#. For blind pipe flanges of 400 ( 2.4360)# and up, the standard blind pipe flange raised face height is 1/4".

B16.5 ASTM A182 Blind Flange, Fusion Bonded Epoxy Coating, EN 1092-2 PN16 Blind Flange, ASME B16.5 Dual Monel Alloy Blind Flange, ANSI B16.5 Class 150 Flat Face Blind Flange, Monel Alloy Reducing Blind Flange Stockiest.

Standards Specification:

Size : 1/2" to 48"

Specifications : ASTM A182

Rating: 150#, 300#, 600 (2.4640)#, 900#, 1500#, 2500#,

Material & Grade :

Stainless Steel :Grade: 304 (1.4301), 304L (1.4307), 304H (1.4948), 309 (1.4828), 309S, 310, 310S (1.4845) , 316 ( 1.4401), 316H, 316L( 1.4404 /1.4432) , 317, 317L (1.4438), 321 (1.4541), 321 H(1.4878), 347 (1.4550), 347H (1.4961), 904L (1.4539)

Duplex Steel:Grade: 2205 (1.4507)

Super Duplex Steel:Grade: 2507 (UNS S32750) (1.4410) (UNS S32750)

Inconel :Grade: Inconel 600 (2.4640), Inconel 601 (2.4851), Inconel 625 (2.4856), Inconel 718(2.4668)

Incoloy :Grade: Incoloy 800 (2.4958), Incoloy 800H, Incoloy 800HT

Nickel :Grade: Nickel 200, Nickel 201

Titanium :Grade: Gr.1 (3.7025) , Gr.2 (3.7035) , Gr.3:(3.7055) , Gr.5(3.7164/65), Gr. 7(3.7235) , Gr. 11 (3.7225)

Hastalloy :Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X.

For More Information

Visit Our Website - http://www.kobsindia.in/monel-blind-flange.html

Contact Us -9819523999

Email Id - [email protected]

4 notes

·

View notes

Text

Stainless Steel Seamless Pipes, commonly known as SS seamless pipes, are a vital component in various industrial applications. Renowned for their strength, durability, and superior corrosion resistance, these pipes are manufactured without any welds or seams, ensuring a uniform structure that can withstand high pressure and extreme temperatures. At Udhhyog, a leading SS seamless pipe supplier, we provide top-quality seamless pipes, including SS 304 seamless pipes and SS 316 seamless pipes, tailored to meet the diverse needs of our clients across various industries.

#SSERWPipe#ERWPipe#LowestPrice#SteelPipes#AffordablePipes#IndustrialPipes#ERWPipesDeal#Udhhyog#PipeSupplier#BuyNow

1 note

·

View note

Text

Exploring the Best Stainless Steel Plumbing Fittings: A Comprehensive Guide

When it comes to plumbing fittings, durability, reliability, and corrosion resistance are paramount. In the realm of stainless steel plumbing fittings, Primegold International Limited stands out as a trusted name synonymous with quality and innovation. In this blog, we delve into the world of stainless steel plumbing fittings, exploring their benefits, applications, and why Primegold's offerings reign supreme.

Understanding Stainless Steel Plumbing Fittings

Stainless steel plumbing fittings are essential components in residential, commercial, and industrial plumbing systems. Known for their exceptional corrosion resistance, strength, and longevity, stainless steel fittings offer numerous advantages over traditional materials like brass or copper. These fittings are available in various shapes, sizes, and configurations to suit diverse plumbing requirements.

The Benefits of Stainless Steel Plumbing Fittings

1. Corrosion Resistance

Stainless steel fittings are highly resistant to corrosion, making them ideal for use in environments where exposure to moisture, chemicals, or harsh conditions is a concern. Unlike other materials that may rust or corrode over time, stainless steel fittings maintain their integrity and appearance for years to come.

2. Strength and Durability

Stainless steel is renowned for its strength and durability, ensuring that plumbing systems remain robust and reliable even under high-pressure conditions. Whether it's residential plumbing fixtures or industrial piping systems, stainless steel fittings provide long-lasting performance and peace of mind to users.

3. Hygienic Properties

Stainless steel is inherently hygienic, making it an excellent choice for plumbing fittings in applications where cleanliness is essential, such as food processing facilities, hospitals, and laboratories. The smooth surface of stainless steel fittings discourages bacterial growth and facilitates easy cleaning and maintenance.

4. Aesthetic Appeal

In addition to their functional benefits, stainless steel fittings offer aesthetic appeal, enhancing the visual appeal of plumbing installations. With their sleek and modern appearance, stainless steel fittings complement a wide range of architectural styles and interior designs, adding a touch of sophistication to any space.

Primegold's Stainless Steel Plumbing Fittings: Unmatched Quality and Performance

As a leading manufacturer and distributor of construction-related products, Primegold International Limited prides itself on delivering top-quality stainless steel plumbing fittings that exceed industry standards. Here's why Primegold's offerings stand out:

1. Superior Material Quality

Primegold's stainless steel plumbing fittings are crafted from high-grade stainless steel alloys that meet stringent quality specifications. Each fitting undergoes rigorous testing and inspection to ensure exceptional performance and longevity in real-world applications.

2. Extensive Product Range

From pipe fittings and couplings to valves and connectors, Primegold offers an extensive range of stainless steel plumbing fittings to cater to diverse plumbing needs. Whether you're working on a residential renovation project or a large-scale commercial development, Primegold has the fittings you need.

3. Commitment to Customer Satisfaction

Primegold is committed to providing unparalleled customer satisfaction, offering prompt service, technical support, and after-sales assistance to customers worldwide. With a focus on reliability, integrity, and innovation, Primegold continues to set the benchmark for excellence in the industry.

Conclusion

In conclusion, stainless steel plumbing fittings offered by Primegold International Limited represent the pinnacle of quality, durability, and performance in the plumbing industry. With their corrosion resistance, strength, and aesthetic appeal, these fittings provide unmatched value to customers across residential, commercial, and industrial sectors. Whether you're upgrading your home's plumbing system or specifying fittings for a large-scale construction project, Primegold's stainless steel plumbing fittings are the ideal choice for lasting reliability and peace of mind.

#Best Plumbing Pipe Fittings#Best Bath Pipe Fittings#Stainless Steel Pipes#PVC Pipes and Fittings#304 and 316 Stainless Steel pipes#Kitchen Plumbing Fittings#Bathroom Pipes and Fittings#Best Stainless Steel Plumbing Fittings

0 notes

Text

Best-Quality Stainless Steel Pipe in India

Pearl Pipe India is a market-leading Stainless Steel Pipe Manufacturer in India and Stainless Steel 202 Pipe Manufacturer in India. Stainless steel pipes are commonly used in industrial settings for the transportation of liquids, gases, and chemicals. Their ability to withstand high temperatures and corrosive environments renders them indispensable in manufacturing processes. We are also the leading Stainless Steel Pipe Manufacturers in Chennai and Stainless Steel Pipe Manufacturers in Bangalore.

Contact us

Phone: +91 91723 33437

Website: https://pearlpipeindia.com

Product Source: SS Pipe Manufacturer in India and Jindal Stainless Steel Pipe Price List PDF

Also visit: Stainless Steel 316 Pipe Manufacturer in India and Stainless Steel 304 Pipe Manufacturer in India

#Stainless Steel 316 Pipe Manufacturer in India#Stainless Steel 304 Pipe Manufacturer in India#Stainless Steel Pipe Manufacturer in India#SS Pipe Manufacturer in India#Stainless Steel Pipe Manufacturer#Jindal Stainless Steel Pipe Price List PDF

0 notes

Text

Supplier of Stainless Steel Hexagonal Bar in Odisha

Arisa Impex is a Top Supplier of Stainless Steel Hexagonal Bar in Odisha.

Our manufacturing unit is located in Ahmedabad, Gujarat, India.

Arisa Impex is a Manufacturer, Exporter, and Supplier of Stainless Steel Products, including Stainless Steel Round Bars, Wires, Rods, Sheets, Coils, Pipes, Flat Bars, Square Bars, Hexagonal Bars, Angles, Flanges, and Alloy Steel.

We offer a premium range of high-grade quality series, including 200, 300, 400, and 600.

Stainless Steel Hexagonal bar is a solid piece of stainless steel shaped into a hexagonal cross-section.

This type of bar is known for its excellent corrosion resistance, strength, and versatility, making it ideal for various industrial and commercial applications.

Why Choose Us?

Effective Service: Our dedicated team ensures timely support and assistance to meet all customer needs efficiently.

Wide Product Range: We provide an extensive selection of products to cater to diverse industry requirements and applications.

Customization: Tailored solutions are available to meet specific client needs, ensuring optimal performance and satisfaction.

Cost Effective: We design our products and services to deliver high quality at competitive prices, maximizing value.

Specification:

SS Hexagonal Bar Grades: 201, 202, 301, 302, 303, 304, 304H, 304L, 316, 316H, 316L, 309, 309S, 310, 310S, 316Ti, 317, 317L, 347, 321, 321H, 410, 416, 420, 430, 430F, 431, 440C, 630, 17-4PH, F51, ASTM A276, ASTM A484

Size: 16mm to 55mm

Length: 4 to 6meters, or as customer’s requirements

Tolerances: K11, K10, K12, H8, H10, K9, H9, H11, H13, H12

Packing: Standard packing

Specifications: EN 10272, EN 10088-3 Grade 1.4301 (304), 1.4306 (304L), 1.4401 (316), 1.4404 (316L)

Finish: Black, Peeled, Polished, Smooth Turned, Rough Turned, Centreless Ground, Grinding, Cold Drawn Turned, Bright Drawn, Bright, Annealed

Usage in

Manufacturing and Fabrication

Automotive and Aerospace

Construction and Architecture

Marine and Coastal Applications

Arisa Impex is a Top Supplier of Stainless Steel Hexagonal Bar in Odisha including locations like Bhubaneswar, Cuttack, Rourkela, Berhampur, Sambalpur, Puri, Balasore, Bhadrak, Baripada.

For more information and inquiries, feel free to contact us.

View Product: Click Here

Read the full article

#andAlloySteel#Angles#Annealed#ArisaImpex#Balasore#Baripada#Berhampur#Bhadrak#Bhubaneswar#Black#Bright#BrightDrawn#CentrelessGround#Coils#ColdDrawnTurned#Cuttack#Exporter#Flanges#FlatBars#Grinding#Gujarat#HexagonalBars#India#Manufacturer#manufacturingunitislocatedinAhmedabad#Odisha#Peeled#Pipes#Polished#Puri

0 notes

Text

Jay Steel Corporation leading Manufacturer and Supplier of Stainless Steel

Jay Steel Corporation is the largest Manufacturer, Supplier and Exports of Stainless Steel Round Bar Strip, Sheet & Plate, Wire Mesh, Pipes, Tubes, Pipe Fittings, Flanges, Welding Rod, Fasteners, Process Equipment and other steel product supplier in France, Turkey, Saudi Arabia, Tunisia, Qatar and UAE.

#Stainless Steel 304/304L/304H Round Bar#Stainless Steel 316/316L/316Ti Round Bar#Stainless Steel 904L Round Bar#Tube & Pipe#Stainless Steel 304H plate

0 notes

Text

Learn About Stainless Steel Seamless Pipe Types

What is Stainless Steel Seamless Pipe ?

Stainless steel seamless pipe is a type of pipe made from stainless steel that is manufactured without any welding or joining seams. It is produced through a process called seamless pipe manufacturing, where a solid steel billet is heated and then pierced to form a hollow tube. The seamless process allows for a smooth and uniform finish, with no weld beads or joints, which makes it highly resistant to corrosion and heat.

Stainless steel seamless pipes are commonly used in industries such as oil and gas, chemical, petrochemical, pharmaceutical, food and beverage, and marine, where high-pressure, high-temperature, or corrosive environments require pipes that can withstand extreme conditions.

They are available in a range of sizes and thicknesses, and can be manufactured in various grades of stainless steel, such as 304, 310, and 316.Inox Steel India is the Leading Stainless Steel Seamless Pipe Manufacturers in India.

Types Of stainless steel seamless pipe

There are several types of stainless steel seamless pipes available, each with its unique characteristics and properties. Some of the most common types of stainless steel seamless pipes are:

Stainless Steel 304 Seamless Pipe

Stainless Steel 304 seamless pipe is typically used in applications where corrosion resistance is critical, such as in the food and beverage industry, chemical processing, and pharmaceuticals. It can also be used in architectural applications, such as for handrails and balustrades.

Stainless Steel 310 Seamless Pipe

Stainless Steel 310 seamless pipe is typically used in high-temperature applications, such as in furnaces, kilns, and other heat treatment equipment. It is also commonly used in the chemical and petrochemical industries for applications that require resistance to corrosive environments and high-temperature gases.

Stainless Steel 316 Seamless Pipe

Stainless Steel 316 seamless pipe is also known for its high strength and excellent weldability, making it ideal for applications that require both corrosion resistance and structural integrity.It is known for its excellent corrosion resistance, particularly in chloride environments, and is commonly used in industries such as marine, chemical processing, and pharmaceuticals.

For More Detail Visit:Seamless Pipe Manufacturers in India

#Stainless steel seamless pipe#seamless pipe manufacturers in india#ss seamless pipe manufacturers in india#stainless steel seamless pipe manufacturers in india#Stainless Steel 304 Seamless Pipe#Stainless Steel 310 Seamless Pipe#Stainless Steel 316 Seamless Pipe

0 notes

Text

How To Select A Good Stainless Steel Round Bar Using Weight Chart

Stainless steel round bars are commonly used in the industrial sector in conditions involving high as well as low pressure work. They are either made seamless or in welded nature. The material used in manufacturing these pipes has to go through different procedures like melting, casting and hot rolling. Following is a detailed explanation of this procedure:

Melting: the stainless steel material is composed of iron, chromium, nickel, etc and it is melted in Electric Arc Furnace (EAF) for further steps.

Casting: the molten steel is then emptied into a cast to form billets or large slabs which will be used to make the round bars.

Hot rolling: this process involves passing the billets obtained in the casting process through rollers to achieve round bars. The diameter and the thickness of the bars is also decided in this stage.

After this, the bars are given cold drawing or heat treatment to provide enhanced strength or to relieve stress.

These bars are either seamless or welded. The seamless round bars are made by piercing a heated billet, thereby leaving no weak areas on the surface, while welded round bars are made by joining two ends of a steel plate by performing welding on it.

There are at least 5 different grades of stainless steel round bar namely austenitic, ferritic, martensitic, duplex and Precipitation-Hardening grades.

It becomes very hard for someone to select a good stainless steel round bar which fit into their specific preference and requirement due to availability of so many grades.

Hence following are some pointers one should remember while selecting a round bar using a weight chart:

Knowing the specification requirement:

Stainless steel round bars have a variety of grades like austenitic, ferritic, duplex, etc while contain more standard specifications like 304, 316, 310, etc, which are used in demanding environments. Hence, before selecting a material, one should know the requirements of the machinery like corrosion resistance, durability, weldability, etc. this helps in proper functioning of the machinery.

Selecting based on requirement:

One should be familiar with the conditions of the working environment, this helps in selection process regarding the material grade. many factories have extreme heat zones, high pressure work, high exposure to corrosion or low temperature zone as well. Hence because of this, there are different standard specified grades available in the market and one should carefully examine them as per the need before selecting.

Use of weight chart:

The weight chart contains very valuable information of the material related to its size, dimensions and weight.

The size of rod is an important variable as the rod should be able to cover the required area without falling short.

The dimensions are an important aspect as well because the diameter or thickness of different materials should be compatible otherwise it may lead to accident.

The weight of the material is directly proportional to its capability to handle pressure while maintaining its stability hence, one should calculate the weight requirement of the project and select the bar accordingly.

0 notes

Text

Stainless Steel Plates in Bihar

Meghmani Metal Industries is a Manufacturer and Supplier of Stainless Steel Plates in Bihar, India.

We established our company in 2011 in Ahmedabad, Gujarat, India.

Stainless Steel (SS) Plates are renowned for their exceptional strength, durability, and corrosion resistance, making them indispensable in various industries.

These plates, made from high-quality stainless steel alloys, offer a broad range of applications due to their robust nature and the ability to withstand extreme conditions.

Technical Specifications:

Material: Stainless Steel (SS) 304, 316, 410, etc.

Thickness: 0.5mm to 50mm.

Size: 4' x 8', 5' x 10', custom sizes.

Finish: Polished, brushed, mirror, and more.

Standard: ASTM A240, ASME SA240.

Features of SS Plates:

Corrosion Resistance: Withstands harsh environments and chemicals.

High Strength: Excellent tensile strength and load-bearing capacity.

Low Maintenance: Easy to clean and maintain.

Hygienic: Ideal for food processing and pharmaceutical applications.

Aesthetically Pleasing: Polished or brushed finishes available.

Applications and Industries:

Food Processing: Equipment, containers, and storage.

Pharmaceutical: Machinery, equipment, and packaging.

Chemical: Reactors, tanks, and piping.

Construction: Handrails, decorative features, and cladding.

Automotive: Exhaust systems, engine components, and trim.

Meghmani Metal Industries is a Manufacturer and Supplier of Stainless Steel Plates in Bihar, India Including Araria, Arwal, Aurangabad, Banka, Begusarai, Bhagalpur, Bhojpur, Buxar, Darbhanga, East Champaran, Gaya, Gopalganj, Jamui, Jehanabad, Khagaria, Kishanganj, Kaimur, Katihar, Lakhi-sarai, Madhubani, Munger, Madhepura, Muzaffarpur, Nalanda, Nawada, Patna, Purnia, Rohtas, Saharsa, Samastipur, Sheohar, Sheikhpura, Saran, Sitamarhi, Supaul, Siwan, Vaishali, West Champaran.

Feel free to contact us for more information and inquiries.

View Product: Click Here

Read the full article

0 notes