#3D CAD design

Explore tagged Tumblr posts

Text

How 3D CAD Helps Engineers Perform Thermal Analysis for Spacecraft

The extreme conditions of space pose significant challenges for spacecraft design, particularly in thermal management. Spacecraft experience fluctuating temperatures, intense solar radiation, and the vacuum of space, all of which can impact performance. Thermal analysis is a critical step in spacecraft engineering, ensuring that systems remain operational under these harsh conditions. One of the most transformative tools in this process is 3D CAD (Computer-Aided Design). By integrating CAD with thermal analysis software, engineers can efficiently simulate, analyze, and optimize spacecraft designs.

The Role of Thermal Analysis in Spacecraft Design

Thermal analysis involves predicting how a spacecraft will behave thermally under various conditions. Engineers use simulations to evaluate heat transfer mechanisms such as conduction, convection (if applicable), and radiation. This process ensures that components stay within their operational temperature limits and identifies the need for heaters, radiators, or insulation layers to maintain thermal balance.

Spacecraft thermal analysis typically includes:

Modeling energy exchange factors: Calculating absorbed energy from orbital sources like the Sun and reflected planetary radiation.

Simulating heat dissipation: Predicting how internal components generate and transfer heat during operation.

Designing control systems: Determining heater power requirements and radiator sizing to regulate temperatures.

How 3D CAD Enhances Thermal Analysis

3D CAD tools revolutionize thermal analysis by enabling engineers to create detailed models of spacecraft geometry. These models serve as the foundation for simulations and allow engineers to visualize complex systems under varying environmental conditions. Here’s how 3D CAD contributes to thermal analysis:

1. Accurate Geometry Representation

Spacecraft designs often involve intricate geometries with multiple subsystems. 3D CAD software allows engineers to create highly detailed models that account for every component's size, shape, and orientation. Tools like NX Space Systems Thermal simplify the modeling of large assemblies without requiring manual geometry conversions. This level of detail ensures accurate predictions during simulations.

2. Integration with Thermal Analysis Software

Modern CAD tools are seamlessly integrated with thermal analysis software such as Thermal Desktop or Simcenter 3D Space Systems Thermal. These integrations enable engineers to import CAD models directly into simulation environments without losing fidelity. For example:

Thermal Desktop uses AutoCAD-based models to compute radiative exchange factors and orbital heating via Monte Carlo methods.

Simcenter 3D synchronizes CAD data automatically, reducing errors and improving efficiency during iterative design processes.

3. Material Property Assignment

Thermal performance depends heavily on material properties like conductivity, emissivity, and specific heat capacity. CAD-based tools often include databases of thermophysical properties, allowing engineers to assign realistic materials to spacecraft components. This capability ensures that simulations reflect real-world behavior.

4. Visualization and Post-Processing

Engineers can use CAD-integrated tools to visualize temperature distributions across spacecraft surfaces in 3D. Features like contour plots or scatter plots make it easier to identify hotspots or areas requiring additional thermal control measures. Visualization enhances collaboration among teams by presenting complex data in an intuitive format.

Applications of 3D CAD in Spacecraft Thermal Analysis

Orbital Simulations

Orbital mechanics significantly influence a spacecraft's thermal environment due to changing positions relative to the Sun and Earth. Engineers use 3D CAD models to simulate these dynamics and predict temperature fluctuations over time. For instance, NX Space Systems Thermal enables orbital simulations with synchronized geometry updates for evolving designs

Component-Level Analysis

Thermal analysis extends beyond the spacecraft as a whole—it includes evaluating individual subsystems like electronics or propulsion units. Tools like Solaria Thermal specialize in finite element analysis (FEA) for detailed component-level simulations. Engineers can model copper layers in PCBs or heat dissipation from rocket engines using these tools.

Iterative Design Optimization

Thermal analysis is an iterative process involving multiple design revisions. With CAD-integrated software, engineers can quickly update models based on simulation results without starting from scratch. This agility accelerates development timelines while improving accuracy.

Benefits of Using 3D CAD for Thermal Analysis

The integration of 3D CAD with thermal analysis software offers several advantages:

Efficiency: Automated synchronization between CAD models and simulation tools reduces manual effort.

Accuracy: Detailed geometry and material property assignments result in more reliable predictions.

Cost Savings: Virtual testing minimizes the need for expensive physical prototypes.

Collaboration: Intuitive visualizations enhance communication among engineering teams.

Conclusion

In the realm of spacecraft engineering, thermal analysis is indispensable for ensuring mission success under extreme conditions. The integration of 3D CAD tools with advanced simulation software has streamlined this process, enabling engineers to design more robust systems efficiently. From orbital simulations to component-level evaluations, these tools provide unparalleled accuracy and visualization capabilities.

As space exploration continues to push boundaries, the role of 3D CAD design services in thermal analysis will only grow more critical, empowering engineers to tackle increasingly complex challenges with confidence. Whether designing satellites for Earth's orbit or interplanetary missions, leveraging these technologies ensures that every spacecraft is prepared for its journey into the unknown.

#Thermal Analysis in Spacecraft Design#Spacecraft Design#Thermal Analysis#3D CAD Design#3D CAD Design Services#3d app development services#3d application development#3d mobile app development#3d desktop application development#3d desktop application#3d desktop application development companies#best 3d application development company#3d engineering application development services#3D application development for engineering#3D development tools for engineering applications#3d web application development services#3d mobile application development

0 notes

Video

youtube

Introduction to CATIA V5: Solid Modeling

0 notes

Text

Transforming Product Design with 3D CAD Services

In today’s competitive market, product designers must innovate quickly and efficiently to bring exceptional products to life. Achieving this requires creativity, vision, and powerful tools to turn ideas into reality. 3D computer-aided design (CAD) services have become vital for product designers, offering unparalleled efficiency and precision in creating, iterating, and refining designs.

Shalin Designs, a leader in 3D CAD design services, understands the unique challenges faced by product designers. Our comprehensive suite of services can revolutionize your design approach, from conceptualization to manufacturing. Here's how 3D CAD services empower product designers:

1. Enhanced Visualization and Communication

Gone are the days of relying on 2D sketches and hand-built prototypes to convey design intent. 3D CAD software enables designers to create realistic 3D models that accurately represent a product’s form, function, and assembly. This allows designers to:

Visualize Concepts in Detail: 3D models provide a clear understanding of a product’s size, shape, and spatial relationships between components. Designers can explore different iterations virtually, identify potential issues early on, and refine their ideas before investing in physical prototypes.

Improve Communication: 3D models are powerful tools for communicating ideas. Designers can effectively share their concepts with stakeholders, including engineers, manufacturers, and investors. Realistic renderings and animations showcase the product’s functionality and user experience, fostering better collaboration and reducing misunderstandings.

By leveraging these services, companies can accelerate product development cycles and achieve higher precision and innovation in their designs. For more information, read our detailed article on the industries benefiting from 3D product design services and their advantages.

2. Increased Design Efficiency and Iteration

The traditional design process often involves a lengthy cycle of creating physical prototypes, testing, and making modifications. 3D CAD streamlines this process significantly, allowing designers to:

Rapidly Iterate on Designs: Changes to the 3D model can be made quickly and easily, enabling designers to explore various options and find optimal solutions faster, reducing design cycles and time-to-market.

Identify and Address Design Flaws Early: 3D CAD software includes design rule checking and collision detection features. These tools help identify potential assembly, fit, and functionality issues before a physical prototype is built, saving time and resources.

3. Advanced Design Capabilities and Optimization

3D CAD software offers advanced capabilities that empower designers to create complex and innovative products:

Parametric Modeling: This feature allows designers to define relationships and rules within the model. Changes to one aspect of the design automatically update other relevant features, ensuring consistency and reducing the risk of errors.

Engineering Analysis: Advanced 3D CAD software integrates with engineering analysis tools, allowing designers to perform simulations to assess stress, heat transfer, and fluid flow. These insights can optimize product designs for performance, durability, and manufacturability.

4. Streamlined Collaboration and Manufacturing

3D CAD models are the foundation for a collaborative design and manufacturing process, enabling:

Seamless Integration with Manufacturing: 3D models can be directly exported to computer-aided manufacturing (CAM) software, generating toolpaths for CNC machines and other equipment. This reduces errors and streamlines the transition from design to production.

Improved Stakeholder Communication: 3D models serve as a universal language, facilitating clear communication between designers, engineers, and manufacturers. This ensures everyone works from the same data set, minimizing errors and rework.

Conclusion

By leveraging 3D CAD services, product designers can unlock new levels of creativity, efficiency, and innovation. Shalin Designs experienced professionals can help you harness the power of 3D CAD to bring your product ideas to life. We offer a customized approach tailored to your specific needs and project requirements.

Call to Action

Ready to transform your product design process? Contact Shalin Designs today for a free consultation and learn how our 3D CAD design services can empower you to create exceptional products. Let’s turn your vision into reality, together.

0 notes

Text

Submit your jewelry ideas and I will model and render them!

#for freeeee#3d cad modeling#3d cad#cad cam#custom jewelry#silversmith#goldsmith#jewelry#graphic design#3d design

4 notes

·

View notes

Text

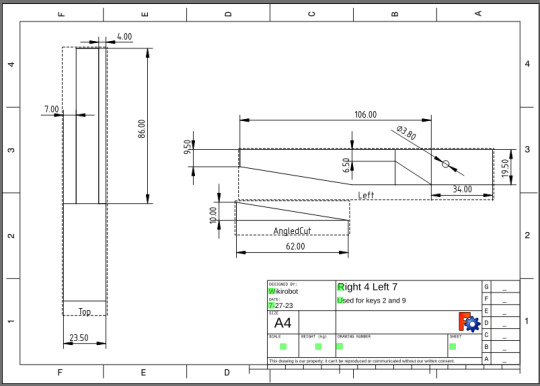

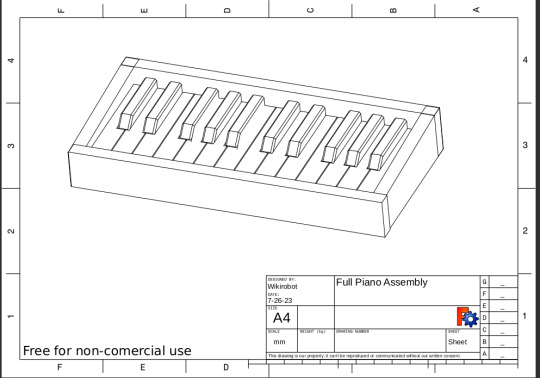

Want to build your own Piano Coat Rack?

I put together some plans for the Piano Coat Rack so that if anyone else wants to try to make one they have a starting point. I ended up putting them on itch.io for free since tumblr doesn't really like PDFs or zip files. The plans are free for non-commercial use. I also have a section describing some of the process to hopefully make it fairly easy to replicate.

I put these plans together in FreeCad, so along with a PDF version of the technical drawings there are also full 3D models that you can use to get a better understanding of how it goes together. If you notice any oddities or mistakes or have any question please just me up!

Also if you make one please tag me, I would love to see it!

Some Samples:

#woodworking#crafts#art#design#3d model#CAD#handtools#furniture#woodworking plans#technical drawings#piano#piano coat rack#sharing#free#hand tools#wood carving#plans#guides#finishing#maker#diy#freecad

62 notes

·

View notes

Text

I’ve stared producing my own Balls. Made in Fusion360 and then 3D printed, these eye models come in connected and separate varieties, both half and whole spheres; the separate having a bracket to keep the eyes stationed in place without them wobbling all over. They screw in to anchor them in place and can be removed for repair or cleaning. They’re made to match a 40mm ping pong ball and are only slightly heavier at 5% infill.

These particular fellers used up the last of my white which is why the tops are yellow. They’re gunna all get sanded and sprayed over with matte white primer anyways though.

5 notes

·

View notes

Text

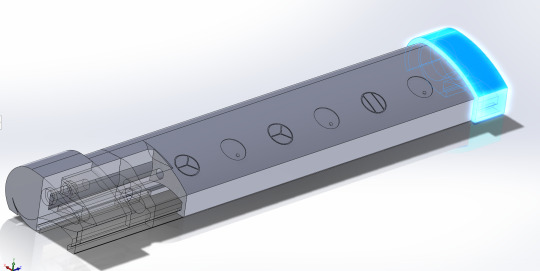

Friend bought this fan with UV reactive ink on it, but it didn't have UV lights to make it glow all the time. So we added some.

Designed the battery compartment to be printed and slide onto the handle, and did the wiring/battery design. Used dryer sheets to reflect the light back to the front, it worked super well.

I forgot to get a picture before she went to Dinolands and it got given away there, so no picture, but yeah.

I really want to make a rave mask, but I'm busy and haven't made progress on it yet.

25 notes

·

View notes

Text

MCR Interior Design (Solo Project Task) - 2010

#MCR#mcr tour#empower#promote#service#marketing#branding#presentation#3d cad modeling#3d render#design#digital art#portfolio#artist#automotive design#concept#umarali#khokhar#bristol#umi3-nous design#technology#futuristic#ideas#innovation#artwork#UK#tech skills#self taught designer

3 notes

·

View notes

Text

I’m back in school and also back to working on projects, I have lots of ideas I want to start of but what I’ve done in the first week is this, I got fabricated the new design for the driving mechanism and got it working!

This version needs some adjustment as the side walls have their dimensions all wrong so the parts don’t fit together right. This is mostly because I also changed how the structural struts are fitted. Now instead of using screws the plan is to have a tension fit. Then to get the spacing right I’ll have the laser cutter etch on to the ends of the struts, making them a bit thinner and able to fit into the holes

I’ve also got a whole new assembly model now, now made on the updated version of FreeCAD, it was fairly hard to make as FreeCAD doesn’t support assemblies by default, because I don’t need this one to move just putting the parts in the right spaces is enough

I’m a bit sick right now but I’m going to keep going this semester and hopefully get back up to speeds with making new things!

#engineering#design#mechanism#cad#robotics#biotech#bugs#robot#leg#machinery#lasercutting#wood#3d printing

3 notes

·

View notes

Text

JF17 Fighter Jet Concept - Advanced 3D CAD & Visualisation 2010

#fighter jet#aircraft#aviation#design#digital art#3d cad modeling#portfolio#artist#project#automotive design#concept vehicle#umar ali#khokhar#bristol#umi3-nous design#2008 to 2014#technology#futuristic#ideas#innovation#artwork

2 notes

·

View notes

Text

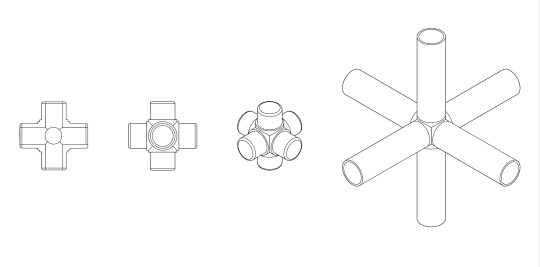

Technical Drawings of the connectors. From left to right: - Cross-section - Top-view - Isometric view - Connector with aluminium pipes

5 notes

·

View notes

Text

Seamlessly Export Your SolidWorks Models to GLTF Format

Are you having difficulty showcasing your SolidWorks model in 3D design to impress your clients with polished and professional 3D presentations? Don't worry, ProtoTech Solutions is here to help you. 🚀

🌐 Presenting your SolidWorks creations in 3D has never been easier. ProtoTech's GLTF Exporter is the key to unlocking a world of possibilities for your designs.

💡 Why ProtoTech's GLTF Exporter? ✅ Seamlessly export your SolidWorks models to GLTF format ✅ Preserve intricate details and textures ✅ Showcase your designs in immersive 3D environments ✅ Impress your clients, colleagues, and friends with professional presentations ✅ Elevate your presentations and WOW your audience

Ready to revolutionize your design presentations? 🚀 Elevate your creations with ProtoTech's GLTF Exporter for SolidWorks.

Get a FREE Trial Today - https://prototechsolutions.com/3d-products/solidworks/gltf-exporter/

#ProtoTech#ProtoTech Solutions#ProtoTech GLTF Exporter#Free Trial#SolidWorks#GLTF Exporter#3D CAD Design#3D Modeling#Design Revolution#Design In 3D#SolidWorks Magic#CAD Plugin Development

0 notes

Text

I think the fun part about being lonely is that you only really notice it at 4:00 am at your cousin's house when you're having a metaphorical conversation with her unborn daughter...

#listen engineer has fucked up my brain#and so has 3d design#littraly this is an electronic class why is 50% of out final grad based on cad design??#delete later

5 notes

·

View notes

Text

Shalin Designs: 3D CAD Design and Modeling Services

Shalin Designs is a leading provider of 3D CAD design and modeling services. They offer a wide range of services, including 3D CAD design, 3D rendering, product prototyping, and reverse engineering. Shalin Designs is committed to quality, innovation, and client satisfaction. They have a proven track record of success and offer competitive pricing.

#3D CAD design#CAD modeling#Shalin Designs#digital design#engineering blog#product design tips#CAD software insights#industrial design trends#3D rendering techniques#design process guide

0 notes

Text

W.I.P.

Row boat under development.

3 notes

·

View notes

Text

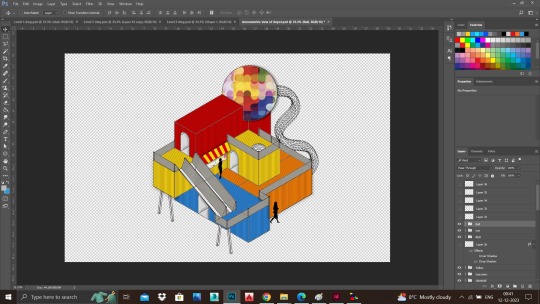

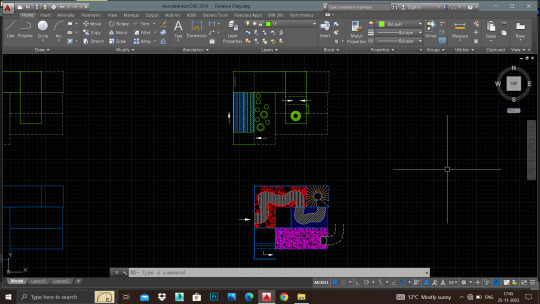

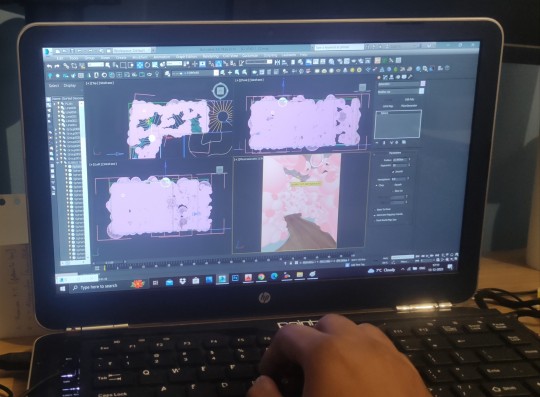

Sharing out some of my design process..... Work in Progress!

After the physical model-making part, it is time to complete the other process of design. I have used softwares like:-

AutoCAD - 2D drawing and drafting 3Dsmax with Vray- 3D Visualisation Photoshop- To give life to the design 🥰 Editing

Moving forward with the final stage of designing!

#work in progress#work#design#interior design#visualisation#drawing#architectural drafting services#cad design#cad drawing#autocad#3dsmax#3d modeling#photoshop#edit#editing#architecture#blog post#go with the flow#trust the process

5 notes

·

View notes