#3D Metal Printing and CNC Machining

Explore tagged Tumblr posts

Text

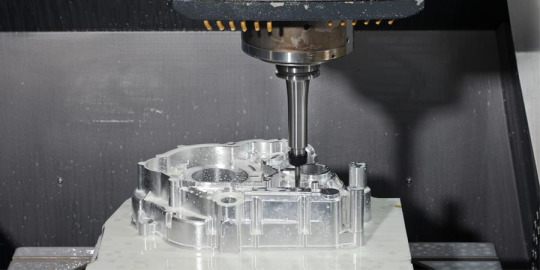

The Perfect Blend: 3D Metal Printing and CNC Machining

In modern manufacturing, innovation constantly pushes the boundaries of what’s possible. Two technologies at the forefront of this revolution are 3D printing and CNC machining. While traditionally, they have been seen as competing methods, a growing trend is to combine these processes to realize the best of both worlds.

0 notes

Text

Maintenance Tips for Your CNC Turning Machine by MechPlus China

As a leading CNC turning machine manufacturing, MechPlus China understands the importance of proper maintenance to ensure precision and efficiency. Regular upkeep not only extends the machine's lifespan but also maximizes productivity and quality. Here are essential maintenance tips from MechPlus China to keep your CNC turning machine running smoothly and efficiently.

Keeping your CNC turning machine in top condition is crucial for optimal performance. Regular maintenance not only extends the machine's lifespan but also ensures precision and efficiency in your operations. Here are essential maintenance tips to keep your CNC turning machine running smoothly.

Daily Inspection and Cleaning

Start each day with a thorough inspection of your CNC turning machine. Check for any signs of wear and tear, and ensure all components are in good working order. Clean the machine daily to remove any debris, chips, and coolant residue. This prevents buildup that can affect performance and accuracy.

Lubrication

Proper lubrication is vital for the smooth operation of your CNC turning machine. Lubricate all moving parts as recommended by the manufacturer. This includes the spindle, guideways, and ball screws. Regular lubrication reduces friction, prevents wear, and extends the machine’s life.

Coolant Maintenance

Maintaining the coolant system is essential for the longevity of your CNC machine. Regularly check the coolant level and concentration. Replace or refill the coolant as needed. Also, clean the coolant tank and filters to avoid contamination that can damage the machine and workpieces.

Alignment and Calibration

Ensure that your CNC turning machine is properly aligned and calibrated. Misalignment can lead to inaccuracies in your machining processes. Regularly check and adjust the machine’s alignment and calibration according to the manufacturer’s guidelines. This ensures precision in your operations.

Check Electrical Components

Inspect the electrical components of your CNC turning machine regularly. Look for any loose connections, worn-out wires, or faulty switches. Address any electrical issues immediately to prevent machine downtime and potential safety hazards.

Monitor Machine Vibration

Excessive vibration can lead to poor machining quality and damage to your CNC turning machine. Monitor the machine for any unusual vibrations or noises during operation. Identify and address the source of the vibration to maintain optimal performance.

Regular Software Updates

Keep your CNC machine’s software up to date. Manufacturers often release updates that improve functionality and fix bugs. Regularly updating the software ensures your machine operates efficiently and takes advantage of the latest technological advancements.

Tool Maintenance

Regularly inspect and maintain the cutting tools used in your CNC turning machine. Sharp and well-maintained tools are crucial for high-quality machining. Replace worn or damaged tools promptly to ensure precise and efficient operation.

Preventive Maintenance Schedule

Implement a preventive maintenance schedule for your quick response machining tool. Follow the manufacturer’s recommended maintenance intervals for all components. Regular preventive maintenance helps identify potential issues before they become major problems, reducing downtime and repair costs.

Training and Safety

Ensure that all operators are properly trained in the maintenance and operation of the CNC turning machine. Regular training updates and adherence to safety protocols are crucial for preventing accidents and ensuring smooth operations.

Document Maintenance Activities

Keep detailed records of all maintenance activities performed on your CNC turning machine. Documenting maintenance helps track the machine’s condition over time and provides valuable information for troubleshooting and repairs with all types of customized machining parts.

In conclusion, regular maintenance of your CNC turning machine is essential for its longevity and performance. By following these tips, you can ensure your machine operates efficiently, reducing downtime and improving the quality of your machining processes. Implement these maintenance practices to keep your CNC turning machine in optimal condition.

#Prototyping solutions#SLA Rapid Prototyping manufacturing#SLS Rapid machining manufacturing#5 Axis CNC machining manufacturing#3D metal printing manufacturing

2 notes

·

View notes

Text

Implementing a Just-in-Time (JIT) Manufacturing System in On-Demand Manufacturing (ODM)

Discover how implementing a Just-In-Time (JIT) manufacturing system can revolutionize your On-Demand Manufacturing (ODM) process. This insightful article by Mechkonnect explores how JIT minimizes inventory waste, enhances production speed, and streamlines supply chain efficiency—crucial for manufacturers adapting to real-time customer demands.

Whether you're a growing startup or an established manufacturer, embracing JIT can lead to better resource utilization, reduced overheads, and a more agile production cycle.

For expert consultation and implementation support, contact Mechkonnect at +91 9819030700. Read More:

#parts of a cnc milling machine#applications of cnc machine#aluminium metal casting#3d printing machines#sheet metal process in manufacturing#electronics manufacturing service#custom manufacturing services#machine milling process

0 notes

Text

Rapid Prototyping in Prototype

Rapid prototyping refers to one or several prototypes made first according to the product appearance drawings or structure drawings for checking the appearance or structure reasonableness without opening the mould. With the development of technology, the definition and use of the handpiece has expanded, and it is now more often used to test and validate products, optimize product design, and even used directly as a finished product.

Historical Background and Definition Rapid prototyping technology originated in the 1980s, initially to solve the problems in traditional manufacturing methods, such as high cost and long cycle time. With the development of technology, rapid prototyping has gradually matured and has been widely used in various fields. It is not only suitable for product development, but also has a wide range of applications in software applications, architectural design and other fields.

Process Rapid prototyping processes include a variety of technologies such as Stereolithography (SLA), Fusion Deposition Modeling (FDM) and others. SLA technology initiates the polymerisation of photosensitive resins by means of a light source of a specific wavelength to form polymers, while FDM technology involves the extrusion of melted material in layers. In addition, traditional moulding methods such as vacuum infusion, low pressure casting and CNC machining are also widely used in the production of handmade boards. 1.3D printing: Prototypes are created using a 3D printer by adding material layer by layer. This method allows for fast, low-cost prototyping of products with complex structures. 2.CNC machining: Cutting and engraving of materials by means of computer numerically controlled machines, suitable for prototypes requiring high precision and complex shapes. 3.Vacuum casting: Liquid material is injected into the mould using a mould and then cured into shape, suitable for validation prior to mass production. 4.Rapid tooling: Creation of moulds by means of rapid tooling technology, followed by series production. 5.Injection molding: Mass reproduction using injection moulding machines for situations where mass production is required.

Material There is also a wide selection of materials for rapid prototyping, with common ones such as photosensitive resin and nylon. For small batch production, vacuum casting process can be used, using materials such as ABS and PMMA for replication, followed by subsequent processing such as sanding and spraying with oil. For metal parts, the machining services are mostly used.

Advantages 1.Rapid outputs: Compared to traditional manufacturing methods, rapid prototyping can complete prototyping in a short period of time, greatly reducing product development cycles which suitable for low volume manufacturing. 2.Low cost: 3D printing technology, in particular, allows for the low-cost production of complex structural prototypes and small batches. 3.High flexibility: Can be prototyped using a wide range of materials and techniques, adapting to different design needs. 4.High precision: The ability to accurately replicate the structure, detail and texture of a prototype provides a surface quality. 5.Variety of materials: Polyurethane materials with different properties such as rigid, elastic, transparent or various coloured materials can be selected according to requirements.

Applications 1.Manufacturing and Industrial Applications Rapid prototyping technology enables the rapid production of complex and accurate prototypes, helping designers and engineers to validate design concepts, perform functional testing and evaluate appearance. For parts that need to be produced in small quantities, it offers a cost-effective and flexible solution. 2.Automobile industry Automakers use rapid prototyping technology to rapidly develop prototype automotive parts for performance testing and validation.In addition, it enables the manufacture of personalised automotive parts, such as dashboard panels and door handles, and is used for production tooling. 3.Medical field Rapid prototyping technology enables personalized medical devices, implants and prosthetics to be tailored to a patient's body structure, providing better fit and comfort.In the field of bioprinting, it is used for research in tissue engineering and organ transplantation. 4.Others Rapid prototyping also plays an important role in a number of industries, including aerospace, consumer electronics, and artwork creation, and its applications will become more widespread as technology advances and costs are reduced.

Rapid Prototyping is the process of creating a simple model of a product or project in the early stages of development so that it can be used to validate and test design concepts, features and interfaces. It is a method of rapidly building physical prototypes and iterating on a design with few changes to improve the design.

#design#business#prototyping#autos#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#3d printing services#3d printing#metal 3d printing#3d printed#cnc machining service#vacuum casting#rapid tooling#rapid prototype

1 note

·

View note

Video

youtube

We specialize in rapid, professional prototyping services, utilizing advanced technologies to deliver high-quality results. Whether you're looking for functional prototypes or appearance samples, we can meet your needs with precision.

Simply upload your 2D and 3D drawings, specify the materials, surface finishes, and quantities, and we will promptly provide you with a free quote.

Contact us today—we look forward to your inquiry!

📞 Contact us: [email protected] 🌐 Visit our website: www.kd-cncmachining.com

#youtube#Prototype parts manufacturing#Rapid prototyping#Functional prototypes#Appearance prototypes#CNC prototyping services#3D printing prototypes#Prototype machining#Custom prototype parts#Prototype development#Low-volume production#Precision prototyping#Prototype design and fabrication#Plastic prototype parts#Metal prototype parts#2D/3D CAD prototypes#Surface finish prototyping#Prototype assembly#Prototype testing#Free prototype quote

0 notes

Text

Website: https://www.justway.com/?link2

Justway Express Solution For All Custom Metal And Plastic Parts. CNC Machining\Sheet Metal\3D Printing\Vacuum Casting\Injection Molding

1 note

·

View note

Text

We offer Metal 3D Printing Service and Parts, SLA 3D Printing Service, High Precision Customized CNC Machining and Die Casting Parts

Get Free 3D Print, CNC and Die Casting Samples, Enjoy Lifetime Warranty and Lifetime Technical Support services.

Learn More https://xy-global.com

0 notes

Text

1 note

·

View note

Text

I need $378 in 9 hours and idk what to do

I'm trying to find my car title so I can get a title loan but I can't find it ANYWHERE, which is weird because I keep all of my paperwork in one area - except for this one piece, apparently.

I need to pay my phone bill or I get shut off at midnight tonight! If I can get $400 I can buy a copy of my title online and then get a title loan and pay someone back. We would actually pay you back when Raven gets paid at the end of the month.

(I would ideally like to make some more money than that - Raven's birthday is today, and their party is this weekend, and I'd like to be able to get food and a cake.)

I've been applying to jobs left, right, and center - so I need the phone for that - but no one has been responding. They're all jobs I'm qualified for, but my job history of being unable to hold down a job long-term because of my executive dysfunction is NOT HELPING ME.

If you can help in any way, even just a few bucks, my Cashapp, PayPal, Ko-Fi, Chime? All $NovasPrime. Let me know if you need to be paid back and I will do so as soon as we get paid.

÷÷÷÷÷÷÷÷÷÷÷÷

I'm also down to barter my skills for money! I can do 3D rendering for manufacture, and I have a 3D printer! Raven is also a very talented miniature painter, so if you need wargaming minis or D&D figurines designed, printed, painted, and shipped? Cat-Thulu Productions has your back!

~~~~~~~~~~~~~~~

I can also help polish a resume, I can write collegiate papers, I can tutor in English language (especially for writing for college), and I am pretty good at tutoring in sociology, machine/construction math, any kind of stagecraft stuff (behind the scenes stuff like wardrobe and set building - I am not an actor, although I can read scenes OK with you if you need practice).

I am a former journalist and can help format and write press releases, do page layout for print or online publishing (PDF format unless otherwise specified), and minor graphic design.

I CAN do metal stuffs, like writing code for CNC machines, but I don't have access to a full machine to test it out.

I have the stuff to make proxies for card games!

I want to earn money, but I can't find an employer who can accommodate my executive dysfunction, which is, frankly, understandable. So instead, get yourself a cool shiny, or help that you need!

So please, if you can help by commissioning me, or Raven, or both of us, please do! If you can help until we can get a title loan, let me know!

If not, please consider signal boosting. I can't lose my phone right now.

34 notes

·

View notes

Text

it's absolutely insane what you can do these days as a hobbyist....

JLC for machining, 3d printing, pcbs

Sendcutsend for sheet metal fabrication

dozens and dozens of pcb shops

a huge number of suppliers of cheap parts and middle men to get components in consumer quantities from bulk suppliers.

all of this with a few days turn around if you're willing to pay for it.

not to mention at home equipment is easier to get and better than ever. 3d printers, cnc, cheap machine tools.

when I started making things as a kid (not that long ago... 15 or so years) i had to scavenge components and structural parts. ordering things was an ordering was an ordeal, expensive and slow. that is if a supplier would even talk to you, most would only sell if you were buying industrial quantities, they didn't have time to sell a kid two units for a pocket change. if radio shack didn't have it you were out of luck, and in 2010 radioshack was slowly dying and the online maker supply scene hadn't caught up.

it's wild how different things are and I love it, it's never been a better time to make something.

3 notes

·

View notes

Text

Techniques and craftmanship methods require for Jewelry making

Jewelry making involves a wide range of techniques and craftsmanship methods, each requiring specific skills, tools, and materials. Here are some of the most common techniques used in jewelry making, whether for handmade artisanal pieces or mass-produced collections:

Hand Fabrication

Sawing: Using a jeweler’s saw to cut metal sheets into desired shapes.

Filing & Sanding: Smoothing and refining metal surfaces or edges after cutting.

Soldering: Using heat to melt solder (a metal alloy) to join pieces of metal, such as attaching clasps, links, or settings.

Forging: Shaping metal by hammering it to create texture, thin it out, or curve it.

Polishing: Using buffing machines, wheels, or cloth to achieve a high-shine finish on the metal.

Casting

Lost Wax Casting: A mold is created from a wax model, which is then melted and replaced with molten metal. This is one of the oldest techniques used for making detailed metal jewelry pieces.

Centrifugal & Vacuum Casting: Used to ensure the molten metal flows evenly into the mold, minimizing air bubbles and imperfections.

Stone Setting

Prong Setting: Small metal prongs are used to hold a gemstone in place. Common for engagement rings.

Bezel Setting: A metal rim encircles the gemstone to hold it securely.

Pavé Setting: Multiple small gemstones are set closely together, often giving the illusion of a continuous surface of stones.

Channel Setting: Gemstones are set between two strips of metal, allowing for a seamless, smooth look.

Flush Setting: The gemstone is set flush with the metal surface, offering a sleek and modern aesthetic.

Gypsy Setting: Similar to flush setting but usually involves a hammered finish around the gemstone, used for bold, simple designs.

Engraving & Embellishment

Hand Engraving: Using sharp tools to carve intricate patterns or designs into metal surfaces.

Laser Engraving: A modern technique that uses lasers to create detailed engravings or inscriptions, often used for personalization.

Etching: Using acid or other chemicals to corrode the surface of the metal in specific patterns, creating a textured or detailed design.

Filigree

Wire Work: Fine wires of gold or silver are twisted and shaped into intricate designs, often with lace-like appearances. This technique requires high precision and is often used in traditional jewelry.

Enameling

Cloisonné: Small cells or compartments are created with metal wire, which are then filled with enamel (colored glass powder) and fired to create vibrant patterns.

Champlevé: Enamel is applied into recessed areas of metal, then fired to create a colored design.

Plique-à-Jour: A transparent enamel technique that allows light to shine through, giving a stained-glass effect.

Hammering & Texturing

Chasing: A technique where the surface of the metal is hammered from the front to create patterns or designs.

Repoussé: The reverse of chasing, where the metal is hammered from the back to create a raised design.

Texturing: Using different hammers, stamps, or other tools to create a variety of surface textures, such as hammered, brushed, or matte finishes.

Wirework

Wire Wrapping: Jewelry made from twisting and wrapping wire into shapes and loops, often around gemstones, beads, or crystals.

Weaving & Knotting: Using wire or string to weave intricate patterns, often incorporating beads or small stones.

Beadwork

Stringing: Threading beads, pearls, or gemstones onto a string or wire to create necklaces or bracelets.

Knotting: Tying knots between beads (commonly pearls) to ensure they don’t rub against each other and for added strength.

Loom Beading: Using a loom to weave tiny seed beads into patterns for bracelets, necklaces, or other accessories.

Electroforming

Metal Coating: This is a process where a base material (such as a wax or organic object) is coated with a metal layer through electroplating. It’s commonly used for creating lightweight, hollow jewelry pieces.

CNC & 3D Printing

CNC Machining: This computerized technique is used to carve precise patterns and designs into metal or wax, enabling intricate designs that are difficult to achieve by hand.

3D Printing: Used for prototyping or creating complex designs, 3D printing involves creating a wax or resin model layer by layer, which can then be cast in metal using traditional techniques.

Inlay & Marquetry

Stone Inlay: Stones, such as turquoise or lapis lazuli, are cut into thin pieces and inserted into metal grooves to create decorative designs.

Wood or Shell Inlay: Wood, shell, or other non-metal materials are inlaid into metal surfaces to create intricate designs or mosaics.

Embossing & Stamping

Stamping: Using metal stamps or dies to create patterns or letters on the surface of a piece.

Embossing: Using pressure to raise designs on metal surfaces, creating a three-dimensional effect.

Granulation

Beading Technique: Small metal beads or granules are applied to the surface of a piece and soldered to create intricate designs, often used in ancient and traditional jewelry styles.

Soldering & Welding

Soldering: Used to join metal pieces together with the help of solder and heat.

Laser Welding: A modern technique using laser technology to weld small or delicate pieces of metal together, often for intricate repairs.

Pearl & Bead Setting

Knotting: Hand-knotting is used in pearl necklaces to separate each pearl and add durability.

Glue Setting: Some beads and pearls are set using adhesives, especially in designs where drilling holes isn't practical.

By mastering these techniques and methods, jewelry makers can produce pieces ranging from simple, minimalist designs to complex, ornate creations. The choice of technique depends on the desired aesthetic, materials used, and the skill level of the jeweler.

5 notes

·

View notes

Text

How Plastic Fabrication Can Benefit Your Business

Plastic fabrication is a process that turns raw plastic materials into useful products for various industries. Whether it’s for prototyping, custom designs, or creating complex components, plastic fabrication offers a wide range of benefits to businesses of all sizes. This article will explore how this versatile method can help elevate your business operations.

Streamlined Production and Customization

One of the most significant advantages of plastic fabrication is its ability to streamline production. With advanced technologies such as CNC machining, laser cutting, and 3D printing, businesses can manufacture precise and complex plastic parts with minimal effort. This reduces the need for additional labor or lengthy production timelines.

Customization is also a key benefit of plastic fabrication. Unlike traditional mass production methods, plastic fabrication allows companies to create customized products that meet their specific needs. Whether you’re creating unique prototypes or designing parts for specific machinery, the ability to customize products ensures your business stands out in a competitive market.

For instance, industries like automotive, aerospace, and healthcare often rely on tailored plastic components to fit specific equipment requirements. By working with a reliable plastic fabrication company, you can ensure that your custom needs are met with high precision and quality.

Cost-Effective Manufacturing

Another benefit of plastic fabrication is its cost-effectiveness, especially for small to medium-sized businesses. Traditional manufacturing methods, such as metal fabrication, can be expensive due to the high costs of raw materials and production processes. In contrast, plastic materials tend to be more affordable and versatile, making it a great choice for businesses looking to save money while still producing high-quality products.

Additionally, plastic fabrication offers long-term savings due to the durability and longevity of the materials used. Many plastic materials are resistant to corrosion, weathering, and wear, ensuring that your products will last longer, reducing the need for frequent replacements.

Versatility Across Industries

Plastic fabrication is incredibly versatile and can be used across numerous industries. Whether you’re in the medical, electronics, packaging, or construction industries, plastic parts and components are essential to your business operations.

For example, in the medical field, plastic fabrication is used to create sterile surgical instruments, medical devices, and protective barriers. In electronics, plastic enclosures are often used to protect sensitive equipment from environmental damage. In packaging, plastic containers and wraps are designed to securely hold products for transportation and sale.

This adaptability makes plastic fabrication an invaluable tool for various businesses. No matter the sector, the ability to produce customized and durable plastic components will always offer a significant competitive edge.

Finding the Right Plastic Fabrication Partner

Finding the right plastic fabrication company is crucial to ensuring that your products meet high standards of quality and precision. Partnering with an experienced and reliable fabricator can make the difference between a successful project and costly errors. To locate the right professional for your needs, it’s essential to consider their experience, reputation, and ability to work with your desired materials.

If you’re looking for a plastic fabrication company near me, you’ll likely find many local professionals who can meet your requirements. Make sure to check reviews and ask for samples of previous work to ensure they can deliver the quality and service you expect. A trusted local fabricator can help you avoid the logistical challenges of long-distance shipping and offer faster turnaround times for your projects.

Plastic fabrication offers numerous benefits for businesses, including cost savings, customization, versatility, and efficiency. By partnering with a professional plastic fabrication company, you can enhance your product development process and ensure your business stays competitive in the marketplace. Whether you’re looking for precision parts, durable products, or customized designs, plastic fabrication is a smart choice for any growing business.

2 notes

·

View notes

Text

Advantages & Applications of Metal 3D Printing

Metal 3D printing is an additive manufacturing technology that creates three-dimensional objects by stacking metal powders layer by layer. In metal 3D printing, metal powders such as titanium, aluminium and stainless steel are usually used as raw materials, which are melted and shaped by a laser or other high-energy beam stream.

With the continuous development of 3D printing technology, metal 3D printing is gaining attention as an important manufacturing process in industry. It allows the direct conversion of digitized models into metal parts. Metal 3D printing technology has many advantages over traditional manufacturing techniques.

1.Advantages of Metal 3D Printing ①High Manufacturing Efficiency Metal 3D printing technology can produce complex metal parts in a short period of time. Compared to traditional manufacturing techniques, it does not require additional machining steps and therefore significantly reduce the production cycle time. At the same time, product development from design to printing rarely requires human intervention due to the use of digital design processes, it is important for the design verification of new products, as well as small batch production, which can greatly shorten the time-to-market and improve competitiveness.

②Reduced Production Costs Metal 3D printing technology can reduce costs by saving materials and reducing labour intervention. Compared to traditional manufacturing techniques, metal 3D printing technology can make better use of materials and avoid wastage. It can also reduce costs by reducing manual intervention and links on mechanical processing and assembly among others as it can be designed and manufactured through a digital process. It can accurately control the use of materials according to actual needs, avoiding the waste of large amounts of material in traditional cutting processing, improving material utilisation and reducing costs.

③Customized Production Metal 3D printing can be customized to produce parts or products with specific shapes, specifications and properties to meet the needs of different fields. Compared to traditional manufacturing techniques, it does not require additional moulds and equipment, and can significantly increase production efficiency, while also meeting the individual needs of customers.

④Increased Design Diversity Metal 3D printing technology has made it possible to significantly reduce design constraints in the manufacturing process. It enables more complex, precise and detailed structures than traditional manufacturing methods, such as openwork, curved surfaces, and porous structures, which can dramatically improve the performance and longevity of materials. It allows the use of a wide range of metal materials, including titanium alloys, aluminium alloys, stainless steel, cobalt-chromium alloys and more, providing greater design freedom and application flexibility.

⑤Excellent Mechanical Properties Metal 3D printing technology makes the internal organisation of the formed part uniform and dense through the rapid solidification process, with excellent mechanical properties and corrosion resistance, and is able to increase strength without loss of plasticity. Compared to traditional manufacturing techniques, metal 3D printing technology provides better control over product quality and reduces the rate of product defects.

2.Applications of Metal 3D Printing ①Manufacturing Industry Metal 3D printing technology is widely used in the manufacturing industry. It can be used to produce automotive parts, aircraft parts, and a variety of mechanical parts, among others. In addition, it can also be used to manufacture some complex structural parts, such as gears, reducers and so on.

②Medical Industry Metal 3D printing technology also has a wide range of applications in the medical industry. It can be used to create prosthetics, teeth, implants, etc. Metal 3D printing technology can be better adapted to the individual needs of patients than traditional production methods.

③Aerospace Industry Metal 3D printing technology is also widely used in the aerospace industry. It can be used to manufacture a number of complex structural parts, fuel nozzles and turbine blades, among others. Compared with the traditional manufacturing technology, metal 3D printing technology can better control the quality of the products and improve the accuracy of the products.

④Construction Industry Metal 3D printing technology has a wide range of applications in the construction industry as well. It can be used to manufacture building structural parts, doors and windows, etc. Compared with traditional manufacturing methods, metal 3D printing technology can better meet the individual needs of customers and can significantly reduce the production cycle.

Metal 3D printing technology has significant advantages in terms of high manufacturing efficiency, rapid prototyping, customized production, material utilization and sustainability, but it also suffers from drawbacks such as slow manufacturing speeds and difficulties in subsequent processing. In practical application, it is necessary to comprehensively consider its advantages and disadvantages and select suitable applications to maximize its advantages.

#design#business#prototyping#prototype#prototype machining#cnc machining#rapid prototyping#precision machining#3d printed#3d printing#3d printing services#3d printing plastics market#metal 3d printing#rapid prototype

1 note

·

View note

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

#lasercutting #cncprocessing #cnc #cncservices

#cnc milling service#cnc car parts#online cnc machining services#sheet metal fabrication#sheet metal processing services#custom sheet metal fabrication#cnc turning services#cnc machining services#online cnc precision machining

2 notes

·

View notes

Text

GD prototyping is a Prototypes&low volume manufacturer, provide (3&4&5axis)CNC machining, 3d printing, sheet metal, vacuum casting rapid tooling and surface finish. https://www.gd-prototyping.com/

2 notes

·

View notes