#electronics manufacturing service

Text

Embracing the Future: The Cutting-Edge of Electronics Manufacturing with Avalontec

In today's fast-paced technological landscape, the electronics manufacturing industry is undergoing a remarkable transformation. Companies like Avalontec are at the forefront, shaping the future of Electronic Manufacturing Services (EMS) with innovative solutions that cater to diverse sector's

The Evolution of Electronics Manufacturing

From the early days of vacuum tubes to the revolutionary impact of transistors and integrated circuits, electronics manufacturing has seen significant milestones. Avalontec embodies this evolution, leveraging advanced technologies to deliver high-quality manufacturing solutions that meet the demands of modern consumers.

Key Trends Driving the EMS Industry

Automation and Industry 4.0: Automation is reshaping manufacturing processes, enabling real-time monitoring and optimization. The integration of IoT, AI, and machine learning enhances efficiency and reduces downtime.

Sustainability: As environmental concerns grow, manufacturers are prioritizing eco-friendly practices. Avalontec is committed to utilizing recyclable materials and energy-efficient processes to minimize its environmental impact.

Flexible and Printed Electronics: The rise of flexible electronics opens new avenues for innovative product designs, allowing for lightweight, bendable devices that cater to diverse applications, including healthcare and wearables.

Advanced Materials: The exploration of materials like graphene and nanomaterials pushes the boundaries of electronic device capabilities, enabling the creation of smaller, more efficient devices.

The Role of Collaboration

In this rapidly evolving landscape, collaboration is key. Avalontec emphasizes partnerships with suppliers, technology providers, and research institutions to drive innovation and tackle common challenges. By fostering a collaborative ecosystem, the company enhances its competitive advantage and accelerates technological advancement's

Looking Ahead

The future of electronics manufacturing is bright, characterized by endless possibilities. As consumer preferences evolve, manufacturers must remain agile and responsive, focusing on customization and sustainability. Avalontec is well-positioned to navigate these changes, ensuring it meets the demands of a dynamic market while driving innovation forwards

Leading Clean Energy & EMS industry India | Avalon (avalontec.com)

Conclusions

As we embrace the future of electronics manufacturing, companies like Avalontec lead the way with cutting-edge solutions and a commitment to excellence. By staying informed about industry trends and fostering collaboration, we can all contribute to a more innovative and sustainable future in electronics manufacturing.

#ElectronicsManufacturing#Avalontec#Innovation#Sustainability#Automation#Industry4_0#FlexibleElectronics#AdvancedMaterials#TechTrends#FutureOfManufacturing#EcoFriendly#Collaboration#SmartManufacturing#ConsumerTrends#ManufacturingExcellence#electronics manufacturing service#electronic manufacturing company#manufacturing services company#ems manufacturing services#aerospace metal fabrication#todaynews#USA#Blog#Post#wednesday#Trendynew#Trendy blog

1 note

·

View note

Link

Get the best SMT and SMD Reflow Services in Gandhinagar and Ahmedabad, India. Our experienced team delivers fast, efficient, and high-quality results. Contact us now to get started!

Our services play a crucial role in the production of process control instruments for industrial and commercial applications, such as temperature, pressure, and flow control solutions.

#smd reflow#surface mountain device#smt#electronics manufacturing service#pcb contract manufacturing#pcb assembly#pcb soldering#pcb wave-soldering in ahmedabad#gandhinagar#ahmedabad#electronics industry#electronics in gandhinagar

0 notes

Text

The Benefits of Ordering Printed Circuit Boards Online: A Guide to Choosing the Right PCB Manufacturer

In today's rapidly advancing technological landscape, printed circuit boards (PCBs) play a crucial role in various electronic devices, from smartphones to industrial machinery. As demand for these essential components grows, businesses and hobbyists alike seek efficient and cost-effective solutions for obtaining high-quality PCBs. One of the most convenient methods is to order printed circuit boards online. In this article, we will explore the advantages of ordering PCBs online and provide insights into selecting a reputable PCB manufacturer.

Why Order Printed Circuit Boards Online?

Ordering printed circuit boards online offers several benefits, making it an attractive option for many businesses and individuals:

Convenience: The ability to order PCBs from the comfort of your home or office eliminates the need for in-person visits to manufacturers or suppliers. This convenience saves time and effort, allowing you to focus on your projects or business operations.

Wide Range of Options: Online PCB manufacturers offer a variety of options in terms of materials, layer counts, finishes, and more. This flexibility allows you to customize your PCBs according to your specific requirements and budget.

Cost-Effectiveness: Many online PCB manufacturers provide competitive pricing, especially for bulk orders. Additionally, you can easily compare prices and services from different providers, ensuring you get the best value for your money.

Quick Turnaround Times: Online ordering often comes with expedited production and shipping options, allowing you to receive your PCBs faster. This is particularly beneficial for projects with tight deadlines or when you need quick prototypes.

Access to Advanced Technologies: Many online PCB manufacturers offer advanced technologies such as high-frequency PCBs, flexible PCBs, and more. This access to cutting-edge technology ensures your designs are compatible with the latest industry standards.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer is crucial to ensuring the quality and reliability of your printed circuit boards. Here are some key factors to consider when choosing a PCB manufacturer:

Experience and Reputation: Look for a manufacturer with a solid track record and positive reviews from previous customers. Experienced manufacturers are more likely to produce high-quality PCBs and provide reliable service.

Quality Assurance: Ensure the manufacturer follows strict quality control measures, such as ISO certification and regular testing. High-quality PCBs are essential for the proper functioning and longevity of your electronic devices.

Customer Support: Good customer support is vital, especially if you encounter issues during the ordering process or with the final product. Choose a manufacturer that offers responsive and helpful customer service.

Manufacturing Capabilities: Check the manufacturer’s capabilities, including the types of PCBs they can produce, their layer count capacity, and the materials they use. Make sure they can meet your specific design requirements.

Lead Times and Shipping: Consider the manufacturer’s production lead times and shipping options. Quick turnaround times are crucial for meeting project deadlines, so choose a manufacturer that can deliver within your required timeframe.

Pricing and Payment Terms: While cost is an important factor, it should not be the sole consideration. Ensure the manufacturer offers transparent pricing and flexible payment terms that suit your budget.

Conclusion

Ordering printed circuit boards online is a convenient and cost-effective way to obtain high-quality PCBs for your projects. By choosing a reputable PCB manufacturer, you can ensure the reliability and performance of your electronic devices. Whether you are a business looking to streamline your supply chain or a hobbyist working on a personal project, ordering PCBs online provides a seamless and efficient solution.

For those ready to place a printed circuit board order online, consider the factors outlined above to select the right PCB manufacturer for your needs. With the right partner, you can bring your electronic designs to life with precision and quality.

#printed circuit board#pcb manufacturer#pcb supplier#printed circuit board order online#pcb design & manufacturing services#pcb circuit manufacturer in ahmedabad#electronic circuit design company

2 notes

·

View notes

Text

Electronic Manufacturing Services provider in Gujarat

Looking for a reliable Electronic Manufacturing Services provider in Gujarat? Discover our top-notch electronic manufacturing services, tailored to your specific needs.

#electronic Manufacturing Services provider in Gujarat#pcb assembly service provider#pcb assembly service provider in gujarat#pcb assembly service provider in india#ems solution provides#electronic manufacturing services provider in gujarat

5 notes

·

View notes

Text

#hardware design#hardware design services#pcb assembly#pcb design#pcb manufacturer#pcba#pcbassembly#electronics design#automotive electronics

2 notes

·

View notes

Text

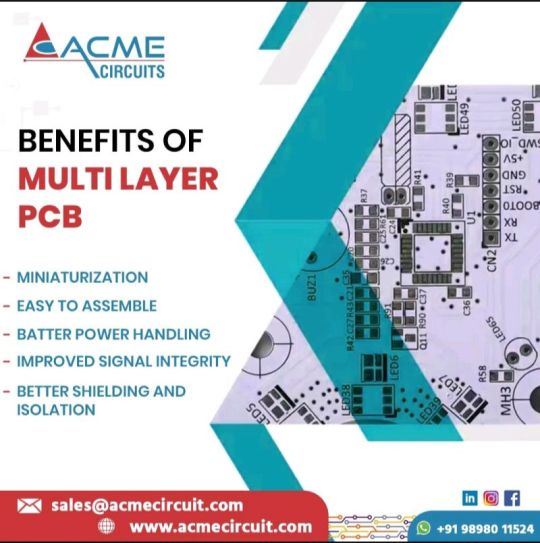

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

Online shopping: Benefits and Drawbacks

I. Introduction

Definition of electronic components

Electronic components are basic building blocks of electronic devices and systems. They are physical parts or elements that can be connected together to create a functioning electronic circuit.

Some common electronic components include resistors, capacitors, diodes, transistors, integrated circuits, and sensors. Each electronic component has its own set of characteristics, including resistance, capacitance, voltage, and current capacity, which are used to design and build circuits for various applications such as computers, telecommunications, medical devices, and consumer electronics.

II. Advantages of Buying Components Online

Buying components online offers several benefits, including:

Convenience: Online shopping allows you to purchase components from the comfort of your own home or office, without having to travel to a physical store. This saves time and effort, especially if you live in an area where component stores are scarce.

Wide selection: Online stores offer a wider selection of components than brick-and-mortar stores. This means you have access to more options and can compare prices and specifications more easily.

Lower prices: Online stores often have lower prices than physical stores. This is because they don't have to pay for rent, utilities, and other expenses associated with running a physical store. Additionally, online retailers can take advantage of economies of scale and offer bulk discounts.

Product reviews: Online stores usually have customer reviews and ratings, which can help you make an informed purchasing decision. You can read about other people's experiences with a particular product and decide if it's right for you.

Easy comparison: Online stores allow you to compare prices, features, and specifications of components from different brands and manufacturers. This makes it easier to find the best product for your needs and budget.

Time-saving: Online shopping saves time by eliminating the need to travel to a physical store and wait in lines. Plus, online stores are open 24/7, so you can shop whenever it's convenient for you.

Overall, buying components online offers many benefits that make it a convenient and cost-effective option for consumers.

III. Disadvantages of Buying Components Online

While there are many benefits to buying components online, such as convenience and a wider selection of products, there are also several disadvantages to consider. Here are some of the disadvantages of buying components online:

Shipping Costs: Many online retailers charge shipping fees for components. This can add up quickly, especially if you need multiple items.

Shipping Delays: Sometimes, components can take longer to arrive than anticipated. This can be frustrating if you need the components urgently.

Quality Concerns: When you buy components online, you cannot physically inspect the components before purchasing them. This can lead to quality concerns, as you may receive components that are defective or of lower quality than you expected.

Fraud and Scams: Buying components online carries a risk of fraud and scams, especially if you are purchasing from an unknown retailer. You may receive counterfeit components.

IV. Conclusion

Recommendation for Shopping Online

Shopping online can be convenient and cost-effective, but it's important to take precautions to ensure that your shopping experience is safe and secure.

Stick to well-known and established websites when shopping for electronic components online, as they are more likely to have secure payment systems and customer service policies in place. For online websites, you can try Robu, Flipkart, amazon, electronics comp, and many more.

Before making a purchase, read product reviews from other customers who have bought the same item. This can help you make an informed decision about whether or not to buy the product.

Look for secure payment options: Always use a secure payment method, such as a credit card or PayPal. These payment methods offer more protection against fraud and unauthorized charges.

By following these recommendations, you can have a safe and enjoyable online shopping experience.

2 notes

·

View notes

Text

Electronic Circuit Assembly

What has always seemed like a riddle to you? What makes your laptop or smartphone work seamlessly? Why does the temperature change exactly when your smart thermostat knows it should?

These common technical wonders are achieved thanks to electronic circuit assembly. It is an interesting and complex process that gives life to various gadgets. But what is it all about? Let’s find out.

#electronics contract manufacturing#east west manufacturing austin#electronics manufacturers#electronics manufacturing services#defense electronics manufacturing#aerospace and defense manufacturing#aftermarket services#east west electronics#integration system

0 notes

Text

Leading Plastic Molding Manufacturer for Custom Solutions

Partner with a trusted Plastic Molding Manufacturer for high-quality, custom plastic parts. Our advanced molding technologies and experienced team ensure precision and consistency in every project. Serving various industries, we provide tailored solutions that meet your exact specifications, from concept to production. Rely on us for durable, efficient, and cost-effective plastic molding services.

#plastic injection molding supplier#electronics manufacturing services#automotive mold manufacturers#aluminium die casting

0 notes

Text

Clean Energy Design and Manufacturing

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#best Ems companies in India#EMS#industry#cleanenergy#manufacturing#quality#renewableenergy#technology

2 notes

·

View notes

Link

Get high-grade PCB Soldering Services in India for superior Electronic Assembly and Electronics Manufacturing Service. Techno Advance System also providing EMS in Ahmedabad, Gandhinagar.

#PCB Soldering Services in India#PCB Soldering Service in Ahmedabad#PCB Soldering Services in Gandhinagar#EMS in Ahmedabad#Electronics Manufacturing Service

1 note

·

View note

Text

Top Service Providers for the Electronics Sector in 2024

When searching for the best Electronics Manufacturing Services, Bwtech should be your first stop. For every phase of your electrical production requirements, we can offer specialized solutions. The use of state-of-the-art technology and an emphasis on quality are only two of the numerous advantages that Bwtech provides. The business provides a broad range of services, such as prototyping, PCB installation, testing, and other associated work. The experience of our team ensures that your ideas are generated effectively and submitted on schedule. No matter how much experience you have in this field, Bwtech can accurately and efficiently meet your specific needs.

0 notes

Text

Printed Circuit Board Basics

Most of us are using Printed Circuit Board in our daily life. Printed Circuit Boards are used in almost all the Electronic products, from consumer gadgets such as PCs, tablets, smartphones, and gaming consoles to industrial and even high tech products in strategic and medical electronics domains.

Here, we have some statistics for you that shows how many electronic devices connect worldwide from 2015 to 2025. This statistic shows an increase in the use of a number of PCB in people daily life. Hence, CircuitWala took this opportunity to provide a basic knowledge about PCB via this article.

There are so many books available online which teach about Printed Circuit Board design and hardware part. There are few links available online which shows only a few basic fundamentals of PCB and few are there for Basics of Printed Circuit Board (PCB) Design. Few which gives good know knowledge on Printed Circuit Board terminology. But in the end for the hobbyist, there is no such material available which make their work easy.

Now days there few online designing websites available which allow hobbyist and students to create their design and Printed Circuit Board fabrication part. These websites provide limited features and charge high for the full edition. We, @CircuitWala are in try to provide one platform which provides plenty of Printed Circuit Board knowledge digitally to make your work simple and easy.

Alternatives of PCB include wire wrap and point-to-point construction. Creating a layout of PCB is a little bit time-consuming method as compared to its alternative solution but manufacturing of PCB is cheaper and faster then other wiring methods as electronic components are mounted and wired with one single part.

Let’s start with some basics of Printed Circuit Board with this article. Here in this article we will discuss about history of PCB to understand the emerge of PCB, Types of PCB to make your complex PCB a very simple using different types, Usage of PCB to provide you an idea to create more Printed Circuit Board projects, Advantages and Disadvantages, Possible Future to know about new technological change in Printed Circuit Board manufacturing and also about how to destroy and manage your PCB’s e-waste? We know you are eager to know all the stuff in details but before that let’s make a simple definition of Printed Circuit Board.

What is Printed Circuit Board?Printed Circuit Board is an electronic device made of conductive material(FR-4) like copper which connects components mounted on it to to get desired output by providing an input on another end.

When the board has not mounted with any of the components is called as Printed Circuit Board or Printed Wired Board. Mounting of an electronic component on Printed Circuit Board is called as PCB assembly.

History of Printed Circuit BoardThe invention of Printed Circuit Board was by Austrian engineer Paul Eisler as part of a radio set while working in England around 1936.

In early days before Printed Circuit Board became common in use, Point-to-Point construction was used. This meant some bulky and unreliable design that required plenty of sockets and regular replacement of it. Most of this issue directly address when PCB went into regular production.

Originally, every electronic component had wire leads, and the PCB had holes drilled for each wire of each component. The components’ leads were then passed through the holes and soldered to the PCB trace. This method of assembly is called Through-Hole construction. There is one other method to mount component is called as Surface Mount.

Type of Printed Circuit BoardPCBs are produced from the different types of material and on the basis of that material PCBs are divided mainly into two parts: Rigid PCB and Flexible PCB. Nowadays, a combination of Rigid and flexible PCB is also possible and that is called as Flexi-Rigid PCBs.

Most of the PCBs are built in layers. The inner layer is the base material called as a substrate. Rigid PCBs are mainly made of material like epoxy materials and Flexible PCBs are made of plastic material that can withstand high temperatures.

Rigid PCBs are generally, hard materials that hold the component in a better way. The motherboard in the tower of a computer is the best example of Rigid PCBs. Flexible PCBs fundamental material allows PCB to fit into forms that Rigid PCBs can not. Flexible PCBs can turn round without harmful the circuit on PCB.

All Rigid and Flexible PCBs can come in three formats by layers: Single Layer, Double Layer, and Multi-Layer.

1. Single Layer PCBSingle Layer PCBs have been around since the late 1950s and still dominate the world market in sheer piece volume. Single Sided PCBs contain only one layer of conductive material and are best suited for low-density designs. Single-sided PCBs are easy to design and quick to manufacture. They serve as the most lucrative platform in the industry.

2. Double Layer PCBDouble Layered printed circuit board technology is conceivably the most popular type of PCB in the industry. Double Sided PCB (also known as Double-Sided Plated Thru or DSPT) circuits are the gateway to advanced technology applications. They allow for a closer (and perhaps more) routing traces by alternating between top and bottom layers using vias.

3. Multi Layer PCB

Multilayer PCB is a circuit board that has more than two layers. Unlike a Double-Sided PCB which only has two conductive layers of material, all multilayer PCBs must have at least three layers of conductive material which are buried in the center of the material.

Usage of Printed Circuit BoardBy reading this article till this point, we hope that you are now able to get about printed circuit boards. Now, we will make you understand about different applications of printed Circuit Board.

In this digital world, Printed Circuit Board is in almost all our daily life electronic devices and in our industrial electronics as well. Below are the industries where PCBs are used:

Possible FutureNowadays, most of the circuits are replaced to produce Printed Circuit Board from the old methods. Revolution in technology made many of the processes automated and hence it is easy to manufacture PCB. But still, these processes are a bit expensive to hire, involve toxic waste and use high temperatures and acids. With technological advances we have seen in the past years, it is not hard to imagine PCB will soon be revolutionized. Not only that but research institutes predict a more ‘green’ future for PCBs; PCBs being made of paper.

Electronic Waste (e-waste)Electronic Waste or e-waste is described as discarded electrical or electronic devices. Informal processing of e-waste in developing countries can lead to adverse human health effects and environmental pollution.

Electronic scrap components contain a hazardous substance such as lead, cadmium, beryllium, or brominated flame retardants. Recycling and disposal of e-waste may involve significant risk to health of workers and communities in developed countries and great care must be taken to avoid unsafe exposure in recycling operations

Nowadays, developing countries are encouraging electronic users to take care while recycling the e-waste or submit them to the organization who are involved in such activities.

SummaryIn this blog, we have learned the basics of Printed Circuit Board. CircuitWala is planning to write as many blogs to provide more and more knowledge of Printed Circuit Board. Either it is basics or manufacturing or usages or advantages and disadvantages of PCBs. We will also try to make our users/customers up to date for the new technology innovations, including past histories and revolution of the PCB industries.

In the next blog, we will look at more briefly about the different types of Printed Circuit Board. We also understand the process to make it and different usage and application for the same.

#electronic circuit design company#pcb circuit manufacturer in ahmedabad#pcb design & manufacturing services#printed circuit board companies#printed circuit board order online#PCB manufacturer#Printed Circuited Board#double layer PCB#PCB Quality Control

2 notes

·

View notes

Text

I look forward to meeting people who are destined, whether at work or in life.

https://www.linkedin.com/in/keria-chen-integrated-circuits-agents-distributors-market-manager-17abb7305?utm_source=share&utm_campaign=share_via&utm_content=profile&utm_medium=ios_app

#marketing#electronic components#Electronic research and development#hardware development#PCBaA#pcb assembly#Printed circuit board#printed circuit board manufacturers#printed circuit board assembly#Circuit assembly#circuit#electronic component#electronic#Active components#Passive components#sales#Agency brand#agent certificates#distributor#Trade provider#Procurement service provider#stock market#Spot stock#warehouse inventory management

1 note

·

View note

Text

#pcb#electronics#pcbassembly#pcbmanufacturer#circuit#investing#manufacturer#manufacturing#marketing#top pcb manufacture#pcb design services#pcb manufacturer in ahmedabad#pcb stencil material#pcb fabrication near me#pcb assembly#pcb manufacturer in Gandhinagar#pcb manufacturer in surat#how to cut pcb circuit board#printed circuit board manufacturers near me

0 notes

Text

Get the best electronics manufacturing services in India?

The electronics manufacturing industry has seen good growth in recent years and has become an important member of the global electronic industry. With the government's push like ‘Make in India’ and growing foreign investments, the industry has observed enhancements in both technology and infrastructure. This growth has seen fertile ground for electronics manufacturing services in India (EMS) with many companies from across the world investing in the country.

The strong growth of the Indian electronics sector has enhanced its global importance in terms of expansion. As per the latest statistics, it is forecast that the industry will hit $400 billion by 2025 due to domestic consumption as well as export sales. This growth is driven mainly by the necessity of electronics using devices like smart phones, laptops and IoT gadgets for modern life and business.

The government’s push for a digital economy has only served to grow the sector even more. Programs such as Digital India for enhancing usage and connections to the internet have further strengthened the need for electronic products hence fueling growth for electronics manufacturing services in India.

Key statistics are useful to point to this upward trend. For example, the electronics manufacturing industry in India rose to 23% in 2021 from 2020, with exports worth $11. 4 billion. The country is now among the five leading producers of mobile phones in the world, which underlines its aptitude for mass manufacturing and development.

What involves EMS?

EMS signifies a range of services that extend from the development to the manufacturing, testing and supply of electronic parts and systems.

Design

EMS providers work closely with clients to come up with comprehensive designs based on certain criteria. Schematics are designed and employments are made of the components including the printed circuit boards (PCBs).

Production

After the final decision on the design, there comes the production stage. This involves acquiring materials used to make PCBs and all other components, mounting and soldering these PCBs and finally installing all parts onto the circuit board. The production process involves the use of technology and automation to achieve accuracy and effectiveness.

Test

Various test methodologies are performed to ensure that the electronic assemblies are functional and reliable. This involves circuit testing, functional testing, and environmental testing to help detect any flaws that may be present.

Support

Good post production support is crucial in ensuring that the quality of the product and the satisfaction of the consumers are kept at an optimum level. To that end, EMS providers provide services like repairs, upgrades, and support logistics so that the products remain functional and satisfactory to end-users.

Epsilon Electronics provides end-to-end electronics manufacturing services in India that address the specific requirements of every customer. Epsilon Electronics has only one mission, deliver outstanding electronics manufacturing services that surpass client’s expectations. So don’t miss out on the opportunity to collaborate with the best EMS provider. Visit Epsilon Electronics to fulfill all your electronics manufacturing needs.

#electronics manufacturing services in India#electronics manufacturing services#electronics manufacturing service provider#ems solution provides

0 notes