#3dcadmodelling

Explore tagged Tumblr posts

Text

3D CAD Modeling Services | Precision Design Solutions by Designx5

Designx5: Your Trusted Partner for 3D CAD Modeling Services

In today’s digital age, businesses and individuals require cutting-edge 3D CAD modeling services to bring their ideas to life. At Designx5, we specialize in providing top-notch 3D CAD modeling services tailored to meet the diverse needs of industries such as architecture, engineering, product design, and manufacturing. Our commitment to excellence and attention to detail make us a preferred choice for businesses looking for precise and efficient CAD solutions.

What Are 3D CAD Modeling Services?

3D CAD modeling services involve the creation of detailed three-dimensional representations of objects, structures, or products using specialized computer-aided design (CAD) software. These models help in visualization, prototyping, and manufacturing, ensuring that every aspect of the design is accurate before production. At Designx5, we offer a comprehensive range of 3D CAD modeling services that cater to various industries, ensuring accuracy, efficiency, and cost-effectiveness.

Why Choose Designx5 for 3D CAD Modeling Services?

At Designx5, we pride ourselves on delivering high-quality 3D CAD modeling services that help businesses streamline their design and production processes. Here’s why our clients trust us:

Expertise and Experience: Our team consists of highly skilled CAD designers with years of experience in providing 3D CAD modeling services across different industries.

Advanced Technology: We use the latest CAD software, including AutoCAD, SolidWorks, and CATIA, to provide accurate and detailed models.

Customized Solutions: Every project is unique, and we tailor our 3D CAD modeling services to meet the specific requirements of our clients.

Cost-Effective Services: We offer competitive pricing without compromising on quality, making Designx5 a cost-effective solution for 3D CAD modeling services.

Quick Turnaround Time: We understand the importance of deadlines and ensure that our 3D CAD modeling services are delivered on time.

Industries That Benefit from 3D CAD Modeling Services

Designx5 provides 3D CAD modeling services to a wide range of industries, including:

Architecture and Construction: We create detailed architectural models that help in planning, visualization, and construction.

Manufacturing: Our 3D CAD modeling services assist manufacturers in designing precise components and assemblies.

Automotive: We offer 3D CAD modeling services for vehicle design, ensuring efficiency and performance.

Aerospace: Our expertise in 3D CAD modeling services helps aerospace companies develop complex components.

Medical Devices: We design intricate medical devices with high precision using our 3D CAD modeling services.

Consumer Products: From concept to production, our 3D CAD modeling services help businesses bring innovative products to market.

Our 3D CAD Modeling Process

At Designx5, our 3D CAD modeling services follow a structured process to ensure quality and accuracy:

Requirement Analysis: We discuss your project requirements and understand your goals.

Conceptual Design: Our team creates initial sketches and concepts based on your ideas.

3D CAD Modeling: Using advanced software, we develop detailed 3D CAD models.

Review and Modifications: We review the models with you and make necessary adjustments.

Final Delivery: Once approved, we provide the final 3D CAD models in the required format.

Benefits of 3D CAD Modeling Services by Designx5

Our 3D CAD modeling services offer numerous advantages, including:

Enhanced Visualization: Get a realistic view of your design before manufacturing.

Improved Accuracy: Reduce errors and design flaws with precise 3D CAD modeling.

Time and Cost Savings: Streamline the design process and reduce production costs.

Easy Modifications: Make design changes quickly without starting from scratch.

Better Communication: Share accurate models with stakeholders for better collaboration.

Our Commitment to Quality

At Designx5, we are committed to delivering high-quality 3D CAD modeling services that exceed client expectations. Our stringent quality control measures ensure that every 3D CAD model meets industry standards and specifications. Whether you need a simple prototype or a complex industrial design, our 3D CAD modeling services guarantee precision and excellence.

Get Started with Designx5

Are you looking for professional 3D CAD modeling services? Designx5 is here to help! Our team of experts is ready to transform your ideas into detailed 3D CAD models that enhance your project’s success. Contact us today to learn more about our 3D CAD modeling services and how we can assist you in achieving your design goals.

With Designx5, you can trust that your project is in capable hands. Our dedication to providing top-tier 3D CAD modeling services ensures that your designs are accurate, functional, and ready for production. Partner with Designx5 and experience the best in 3D CAD modeling services today!

Follow Us:

Contact No.: +91 9909580337

Email: [email protected]

Website: https://www.designx5.com/

#3DCADModeling#CADDesign#3DCADServices#EngineeringDesign#ProductDesign#ManufacturingDesign#AutoCAD#SolidWorks#3DModeling#CADSolutions#AerospaceDesign#MechanicalDesign#ArchitecturalCAD#PrototypeDesign#IndustrialDesign

1 note

·

View note

Text

3D CAD Modeling Services: Transforming Ideas into Reality

In today's competitive design world, 3D CAD modeling is essential. Shalin Designs offers best 3D CAD modeling services in the UK which help you create amazing designs and turn your ideas into reality.

Superiority of 3D CAD Modeling over 2D Drawings:

Realistic Testing: 3D models enable the simulation of real-world conditions, ensuring your design performs flawlessly in its intended environment.

Enhanced Visualization: 2D CAD drawing and 3D Modeling complement each other, where 3D models provide a photorealistic representation of your design, allowing for a more comprehensive understanding of form, function, and aesthetics.

Improved Prototyping: 3D models can be readily used to create prototypes, facilitating design testing and refinement before physical production commences.

Streamlined Collaboration: 3D models foster seamless collaboration between designers, engineers, and clients, guaranteeing everyone is on the same page.

Benefits of Shalin Designs’s 3D CAD Modeling Services:

Experienced Professionals: Our team comprises highly skilled and experienced 3D CAD modelers who are proficient in using cutting-edge design software.

Industry Expertise: We cater to a broad spectrum of industries, including engineering, architecture, product design, and more.

Precision and Accuracy: We deliver high-quality, detail-oriented 3D models that meet your exact specifications.

Efficient Communication: We maintain clear and consistent communication throughout the project lifecycle, ensuring your requirements are understood and implemented.

Shalin Designs - Your Partner in Design Innovation

By leveraging our 3D CAD modeling expertise, you can streamline your design process, reduce development costs, and create exceptional products that stand out from the competition. Contact Shalin Designs today to discuss your project requirements and unlock the potential of 3D CAD modeling for your designs.

1 note

·

View note

Text

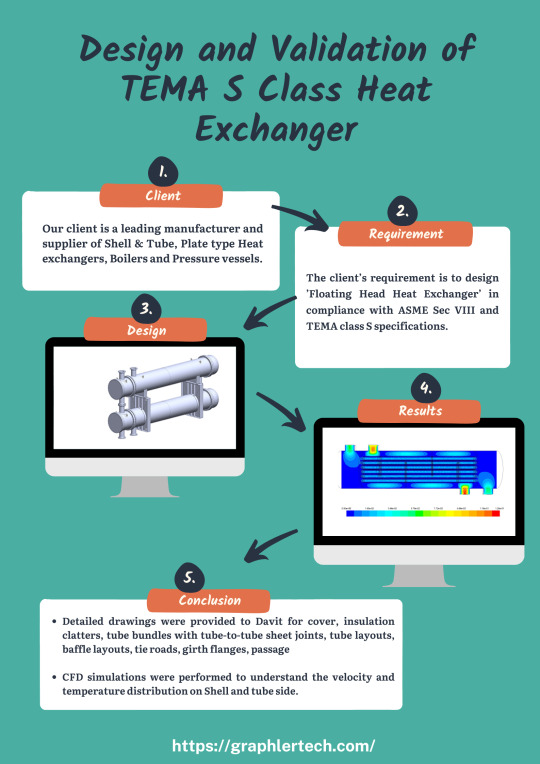

Design and Validation of TEMA S Class Heat Exchanger

Designing and validating TEMA S-Class heat exchangers. Get expert tips and insights!

You can come up with new routes by teaming up with a leading Stress Analysis Services Partner or Product Design Companies with a good reputation.

0 notes

Text

Model Based Definition

By using the MBD 3D CAD model, the data is kept digitally, making it simpler to reuse by outside design departments on factory floors and quality control areas.

It can also be used in different ways throughout an organization, which brings the second concept, Model-Based Enterprise (MBE). Roadmap ERP system offers a direct integration with MBD-based 3D CAD software application.

Roadmap ERP system offers a direct integration with MBD-based 3D CAD software application.

#MBD#ModelBasedDefinition#CAD#productdevelopment#productmanufacturing#production#productmanufacturinginformation#manufacturing#paperlessdrawings#ProductLifecycle#3DCADmodels#roadmaperp#erpsoftware#digital#design#autocad#wordoftheweek#erp

1 note

·

View note

Link

We deliver top quality CAD Conversion services to our global clientele based out of the USA, UK, Canada, Australia, Europe, Singapore, Norway, Ireland UAE region.

1 note

·

View note

Text

Five Reasons to Use an Automatic Liquid Filling Machine

Automation in the packaging process benefits the packaging business substantially. The automatic liquid filler distributes product from a holding tank to waiting bottles or other containers during each fill cycle without requiring operator interaction. By automating the filling process, a corporation can anticipate to improve the packaging operation in a number of ways, including but not limited to the following.

1. Consistent and Reliable Fills

The use of an automatic filler simplifies the filling process. Whether searching for a level fill, a highly precise volumetric fill, or any other specified condition, the automatic machine ensures that each cycle is carried out in the same way. You can attain uniformity and reliability that you can't get by filling bottles or containers by hand using the right machine for each operation.

2. Speed

When a product's demand exceeds a certain threshold, engaging manual labour to fill each bottle becomes impracticable. The ability to increase speeds is likely the most obvious benefit of using automated packing equipment. Production may be operated not only faster, but also constantly, with the use of power conveyors and multiple fill heads, as well as the proper filling principle.

3. Versatility

For a single product, many businesses use several bottles. Multiple items are also offered by a lot of businesses. In most circumstances, single liquid filler may be designed to fill all of a company's bottles and products. Some machines can switch from one bottle or product to another with a few easy modifications, while others may take a little longer if the bottle size or viscosity of the substance differs significantly.

4. Ease of Use

Almost all automatic filling equipment will have a PLC and an intuitive operator interface. The operator inputs the various times and quantities required to finish each cycle using a touchscreen interface. After you've entered your numbers, a recipe screen will allow you to save them. Eventually, the operator will only need to enter the recipe number into the interface, make any necessary physical modifications (conveyor rails, fill head height, etc.), and then watch the machine work.

5. Growth Potential

Automatic packing equipment may and should be built for the long term. To put it another way, the machine should not be built to reach maximum capacity right away. We create our equipment at LPS with the expectation of seeing our customers grow! Filling machine upgrades, such as additional fill heads, allow the equipment to scale with the business.

While there are other advantages to automating the filling process from project to project, a packager can always count on receiving the above benefits. Contact our team today to learn more about how automating packaging operations might help your project.

#3dcadmodelling#3dcadmodellingsoftware#Automationoffoodindustry#Automating Food Production#Manufacturing Engineering Consulting Services#Food Processing Equipment

0 notes

Photo

The EPIC McLaren MP4-30 2015 Steering Wheel by @nachete_2016 is taking shape and already looks amazing. The main body is printed in @fiberthree PA CF Pro on the Prusa i3 MK3S+ by @josefprusa and look at those beautiful top layer infill patterns. It almost looks like the real deal. Can't wait to finish this one. #3dprinting #3dprintingindustry #3dprinter #3dprint #3dp #3dmodel #3dcadmodel #3d #prusa #prusa3d #prusaprinters #prusai3mk3s #prusalive #mmu2s #fiberthree #carbonfilled #f1 #mclaren #mp430 #steeringwheel #makermovement #maker #tech #technology #innovation #de3dprintman (at Leiderdorp) https://www.instagram.com/p/CSCF3WKDeeq/?utm_medium=tumblr

#3dprinting#3dprintingindustry#3dprinter#3dprint#3dp#3dmodel#3dcadmodel#3d#prusa#prusa3d#prusaprinters#prusai3mk3s#prusalive#mmu2s#fiberthree#carbonfilled#f1#mclaren#mp430#steeringwheel#makermovement#maker#tech#technology#innovation#de3dprintman

3 notes

·

View notes

Link

Various benefits of Solidworks which makes easy and smooth communication and collaboration with team members. Which help the manufacturing, fabrication and product development industries for better growth and transforming the concepts to reality through 3D CAD models.

Look at the primary benefits which completely required for CAD engineers to Manufacturer.

1 note

·

View note

Photo

Silicon Engineering Consultants Limited, is an eminent Scan To BIM Service provider globally with strong roots in #Auckland, #Newzealand.

bit.ly/469NQuy

#BIMServices#ScanToBIMServices#3DCADModel#BuildingInformationModeling#CADDrafting#ArchitecturalBIMServices#ScanToBIMSolution#ScanToBIMOutsourcingServices#RevitBIMService#3DBIMLaserScanning

1 note

·

View note

Text

Do you sell a products ?

Product Photography is an old trends, It's time to create 3D Model. We are Best Model Maker in USA, UK, Canada and India .

#3dmodel#3dmodeling#3dmodels#3dmodelling#3dmodelingshowcase#architecturalmodel#3dwarehouse#architecturalmodeling#architecturalmodelling#productmodel#productmodels#productmodeling#3dcaddesign#3dcadmodeling#3dcad#interiordesignstudio#interiordesignservices#3danimation#2d animation#animation#graphic design#architecture#2d animated movie#industrial animation#youtube

1 note

·

View note

Text

Looking for professional 3D CAD modeling services? Designx5 offers precise, cost-effective, and industry-leading CAD solutions for architecture, engineering, manufacturing, and more. Get expert 3D models today!

#3DCADModeling#CADDesign#3DCADServices#EngineeringDesign#ProductDesign#Designx5#ManufacturingDesign#AutoCAD#SolidWorks#3DModeling#CADSolutions#AerospaceDesign#MechanicalDesign#ArchitecturalCAD#PrototypeDesign#IndustrialDesign

1 note

·

View note

Text

Boost Your Design Process with Expert 3D CAD Modeling Services Take your designs to the next level with ShalinDesigns' 3D CAD modeling and design services. Visualize your creations from all angles, create prototypes, and test products virtually. Boost your design process and bring your ideas to life efficiently.

1 note

·

View note

Text

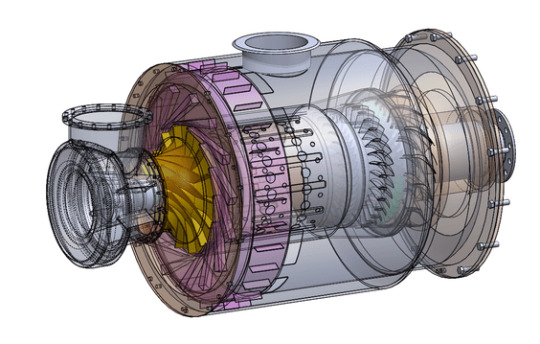

Design and Validation of TEMA S Class Heat Exchanger

Our client is a leading manufacturer and supplier of Shell & Tube, Plate type Heat exchangers, Boilers and Pressure vessels. The client’s requirement is to design ’Floating Head Heat Exchanger’ in compliance with ASME Sec VIII and TEMA class S specifications.

What we Delivered:

3D CAD Model as per Client’s requirement/specifications

General Arrangement Drawings

Fabrication drawings

Machine drawings of various components

Parts drawings of various components

Detailed Bill of materials

CFD simulations to ensure customer’s design criteria is met

FE simulations to ensure structural integrity during lifting, transportation.

Design Specifications:

The Floating Head Heat Exchanger is designed for:

Pressure rating: Shell side: 38 kg/sq. cm, and Tube side: 30 kg/sq. cm

Temperature rating: Shell side: 150 °C and Tube side: 110 °C

Fluid capacity, Shell side: 2.8 cu.m., and Tube side: 1.8 cu.m

No. of passes: shell side (cross flow) and tube side (10).

Design wind reluctance: 50 m/s as per IS 875 Part 3

Seismic design code: IS: 1893-2005

Insulation thickness is 15/50 mm.

Gross weight of Heat exchanger (empty): 13 tons

Through simulations, we were able to provide nozzle loads, wind seismic data, bolt torque and forces, and welding stresses and forces.

Detailed drawings were provided to Davit for cover, insulation clatters, tube bundles with tube-to-tube sheet joints, tube layouts, baffle layouts, tie roads, girth flanges, passage partitions, gaskets, hold points, name plates, etc.

Finally, all design information, like native 3D CAD data, drawings and simulation reports, was submitted to the customer.

CFD Analysis validation:

CFD simulations were performed to understand the velocity and temperature distribution on Shell and tube side. The heat exchanger was simulated with operating temperature and pressure. The intensity of turbulence, heat transfer rate was studied and the results are reported to ensure that the design is in compliance with requirement and efficiency of the system is achieved.

The best way to obtain the accurate information is to consult an experienced CFD Consulting Services or Structural Analysis Services provider.

0 notes

Text

3D Architectural Modeling Services | 3D Revit BIM Modeling Services

Chudasama Outsourcing provides a range of Architectural 3D Modeling services to support the design, planning and visualization phase of various projects. Chudasama Outsourcing uses the most modern 3D architectural illustration techniques to create 3D CAD models. Our architectural 3D modeling & rendering of any product or project has the highest geometrical symmetry and image quality and other details such as the technical detailing are finely Our entire range of architectural 3D modeling services can be tailored to fit your needs. Know More Details at https://bit.ly/3ixlmlf

Contact us: Email: [email protected] Phone : +61 2 8324 6519 Phone : +1-209-565-8512 Phone : +91-9979238180

#Architectural3DModeling#3DModelingServices#ArchitecturalModelingServices#3DExteriorModeling#3D InteriorModeling#3DFurnitureModeling#2Dto3DTransformationModeling#3DCADModeling#RevitModeling#SketchUpModeling#FloorPlanModeling

0 notes

Text

Ways to Improving Engineering Design Process

Many engineering projects can be classified as architecture, which refers to devices, or systems that were designed by humans and are not pre-existing or superior to existing devices or systems. Designs and innovations might arise out of nowhere. It is the consequence of merging technology in order to suit the needs of people or solve problems. Design is sometimes the outcome of someone attempting to do a task fast or successfully. The design process takes time and necessitates a step-by-step approach.

Problem-solving activity for rebuilding problems frequently employs the five-step process. Because design problems are routinely complex and have numerous possible solutions, the procedure may need to be repeated. Solving a design challenge is a potentially lengthy process, and the solution is prone to unforeseen issues and modifications as the project progresses. The Wright brothers were ignorant of the obstacles and problems they would have in handling a strong aircraft until they built and tested their first gliders. The following are the five steps used to overcome design problems.

Define the problem:

Engineers’ design and construction work is constantly motivated by human requirements. You must first determine the requirement for a new product, software, or machine before you can establish a design definition for a design challenge. Engineers are frequently involved in presenting the problem, although they are not always the first to see the necessity. Market power frequently triggers the need for new development in the private sector. The company’s survival is depending on developing a product that people will buy, as well as one that can be manufactured and sold profitably. Consumers establish a need when they buy and use a product that they believe fits their needs for comfort, health, recreation, travel, lodging, and so on. Citizens also decide whether they require safe drinking water, roads, highways, libraries, schools, and fire protection, among other things.

Gather relevant information

You must first acquire all accessible information regarding the problem before proceeding with the design process. Novice designers will rapidly skip this stage and go on to developing new ideas. Gathering relevant data can expose facts about the situation, resulting in a problem that is redefined. Other designers’ mistakes and false start-ups can be found.

Generate multiple solutions

According to a psychological study, there is no link between intelligence and art. People build in need to think and act correctly. Innovation is a skill that everyone possesses. The first step in the creation process is to determine to take risks. A handful of the qualities of creative persons are listed below. These aren’t hard and fast rules to follow if you want to gain wisdom. Engineering solutions aren’t created out of thin air. New ideas develop when people are free to take chances and make mistakes. Evaluating this step is a group effort, with people from many walks of life contributing to a range of solutions to the problem.

Analyse and select a solution

Before choosing which design solution to use, you must first evaluate each option. Perform a wide range of evaluations for each design. Every design problem is different, requires different approach to analysis. In engineering, ergonomic, or the study of how humans interact with machines, is a human thing. A wide variety of products have to interact with users in some way. By living in or around the design, humans can contribute energy, control, or act as a planned sensor.

Test and implement the solution

The implementation phase of the design process focuses on the testing, improvement, and production of a design solution. Generating a product type – the first fully functional product of an entire construction solution – is the first phase of testing and developing a new product, defined as prototyping. Many models have still not been thoroughly tested and may not work as expected. The model’s goal is to put the construction test to the test in real-world scenarios. Traditional construction methods are sequential or sequential in nature: each phase of the process is done in order or only after the preceding ones have been finished. After creating a model or a model from engineering drawings, the design is put into action. Writing your work and clearly conveying the solution to your design problem so that others can comprehend what you’ve made is one of the most important duties in building. When a client wants a last-minute adjustment or change, the engineering construction process becomes time-consuming and daunting. Product designers believe that advancements in 3D CAD technology will help to mitigate resource depletion in order to address this issue. Engineers, producers, and customers have all taken notice of rapid prototyping at this point. Because it allows for quick assembly of scattered body pieces into a model, the RP’s prospective features have transformed the manufacturing sector’s entire process. The finished product’s composition is almost identical to the composition of the anticipated finished product. In contrast to the low-reliability model, where there is a considerable difference between the type and the final product, it is known to as the high-reliability type. This technique is being used by product designers to produce components that represent specific models rapidly. Before mass production, this can assist with identification, composition, and evolution of the production process. Engineering is usually completed in its entirety. It combines judgement, data, modelling, and other people’s opinions, among other things. The engineer makes design decisions in the intention of improving the product. That is precisely what some engineers do. When there is a lot of diversity to deal with for many different purposes and challenges, however, this form of knowledge-based application may fall short of identifying the best design. The interaction is extremely complex, and the degree of flexibility is far too great for a smart design to intuitively determine. The algorithms’ efficiency can be significant. It helps the designer in bringing together all the mass design. Designers, on either side, must be aware of a number of facts, which include: 1.The engineering model must be validated properly and carefully by the designer. The best and most misleading and time-wasting light is the effectiveness of an incorrect model. Algorithm modifications routinely make use of the model’s defects, if any present.

2.Algorithms help the designer with integrating a particular design concept. Algorithms are no longer able to suggest that a different concept would be more appropriate. Choosing the right idea and executing things in excess are key to achieving perfect righteousness.

3.Many engineering designs show a level of consistency between conflicting goals. In order to gain insight and understanding in the design space, a designer will sometimes want to investigate different meanings of different problems. Countless factors sometimes can drive the formation in profoundly significant ways. Almost every design in the “real” world is changing. Variations in industrial processes, visual structures, changing operating conditions, and the environment are only a few examples. Variety almost always has negative effects. Variations in product sizes may result in minimal or no assembly, or may cause the product to malfunction. Product failure, poor performance, and customer unhappiness can all result from failing to seek for differences. Prepared designs are extremely susceptible to alteration. Because well-designed designs frequently include functional or binding components, this is true. Such rights are at risk of being infringed upon. The setting may fail due to minor differences in problem parameters.

0 notes

Photo

YES! Five days and too many toolchanges to count but it's finished. I had one layer shift near the end because the purge block came loose. A tiny bulb material accumulated on the block and got tipped over. This also resulted in a tiny layer shift near the top and I had to McGyver the purge block back in place. But just wow it looks magnificent already. Painted in PrusaSlicer and printed on the Prusa i3 MK3S with MMU2S by @josefprusa. Now for the fun part. All that support needs to be removed. 🙈 #3dprinting #3dprinted #3dprinten #3dprint #3dp #3dmodel #3dcadmodel #prusa #prusa3d #prusaresearch #prusai3mk3s #prusalive #prusament #prusaprinters #halloween #multimaterial #multicolor3dprinting #makers #technology #tech #3dsculpting #de3dprintman (at Leiderdorp) https://www.instagram.com/p/CVm2kwarfqv/?utm_medium=tumblr

#3dprinting#3dprinted#3dprinten#3dprint#3dp#3dmodel#3dcadmodel#prusa#prusa3d#prusaresearch#prusai3mk3s#prusalive#prusament#prusaprinters#halloween#multimaterial#multicolor3dprinting#makers#technology#tech#3dsculpting#de3dprintman

1 note

·

View note