#Automotive PCB Market Demand

Text

Automotive PCB Market 2024 Size Predicted to Increase at a Positive CAGR

Global Automotive PCB Market research report published by Exactitude Constancy reveals the current outlook of the global and key regions from the following perspectives: Key players, countries, product types, and end industries. The report studies the top companies in the global market and divides the market into several parameters. This Automotive PCB Market research report pinpoints the industry's competitive landscape to understand the international competition. This report study explains the expected growth of the global market for the upcoming years from 2024 to 2030. This research report is accumulated based on static and dynamic perspectives on business.

The global automotive PCB market is expected to grow at a 6.34% CAGR from 2022 to 2029. It is expected to reach above USD 12.4 billion by 2029 from USD 7.13 billion in 2023.

Browse Complete Summary and Table of Content @ https://exactitudeconsultancy.com/ja/reports/11379/automotive-pcb-market/

#Automotive PCB Industry#Automotive PCB Market 2024#Automotive PCB Market Analysis#Automotive PCB Market Research Report#Automotive PCB Market Demand#Automotive PCB Market Growth#Automotive PCB Market Insights#Automotive PCB Market Revenue#Automotive PCB Market Share#Automotive PCB Market Size#Automotive PCB Market Trends

0 notes

Text

Printed Circuit Boards (PCBs) Market Analysis, Key Players, Share Dynamic Demand and Consumption to 2032

The printed circuit boards (PCBs) market refers to the industry involved in the design, production, and sale of PCBs, which are essential components in electronic devices. PCBs provide a platform for interconnecting and supporting various electronic components, such as integrated circuits (ICs), resistors, capacitors, and connectors.

printed circuit board market size is expected to increase USD 3.60 billion by 2032 and Growth Rate from 2023 CAGR of 3.9% Forecast Period 2023 To 2032

Here are some key points about the PCBs market:

Market Size and Growth: The PCBs market has experienced significant growth in recent years. Factors driving this growth include the increasing demand for consumer electronics, telecommunications equipment, automotive electronics, industrial automation, and healthcare devices. The proliferation of smart devices, Internet of Things (IoT) applications, and advancements in technologies like 5G and artificial intelligence also contribute to the expanding PCBs market.

Types of PCBs: PCBs come in different types, including single-sided, double-sided, multi-layered, rigid, flexible, and rigid-flex PCBs. Each type has its specific applications and advantages. For instance, flexible PCBs are used in wearable devices and applications where flexibility and compactness are essential, while multi-layered PCBs are commonly found in complex electronic systems like smartphones and computers.

Manufacturing Process: PCB manufacturing involves several steps, including design, substrate selection, copper etching, solder mask application, and component assembly. The industry has seen advancements in manufacturing techniques such as surface-mount technology (SMT) and advanced packaging, enabling smaller and more complex PCB designs.

Market Players: The PCBs market is highly competitive, with numerous manufacturers operating globally. Some of the key players in the industry include Nippon Mektron Ltd., Unimicron Technology Corp., Zhen Ding Technology Holding Limited, Tripod Technology Corporation, Samsung Electro-Mechanics Co., Ltd., and TTM Technologies, Inc. These companies offer a wide range of PCB products and services to cater to different industries and customer requirements.

Regional Market: Asia-Pacific dominates the global PCBs market, primarily due to the presence of major electronics manufacturing hubs in countries like China, Japan, South Korea, and Taiwan. These countries are known for their strong electronics industry, which drives the demand for PCBs. North America and Europe also contribute significantly to the market due to their established electronics and automotive sectors.

Emerging Trends: The PCBs market is influenced by several emerging trends. These include the miniaturization of electronic devices, the adoption of advanced materials and technologies for higher performance and reliability, the shift towards environmentally friendly and lead-free PCBs, and the growing demand for high-speed and high-frequency PCBs to support advanced applications.

It's worth noting that the PCBs market is subject to various factors, including technological advancements, regulatory requirements, supply chain dynamics, and customer demand. To obtain the most accurate and up-to-date information on the market, it's advisable to refer to industry reports, market research studies, and publications specific to the PCBs market.

I recommend referring to our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into the humidity sensors market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to the humidity sensors market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in the market.

Remember to look for recent reports to ensure you have the most current and relevant information.

Click Here, To Get Free Sample Report : https://stringentdatalytics.com/reports/printed-circuit-boards-(pcbs)-market/901/

Market Segmentations:

Global Printed Circuit Boards (PCBs) Market: By Company

• AT&S

• Nippon Mektron

• Unimicron

• Samsung

• Dynamic Electronics

• Daeduck Electronics

• CMK Corporation

• Nan Ya PCB Co.

• TTM Technologies

• Shenzhen Kinwong Electronic

Global Printed Circuit Boards (PCBs) Market: By Type

• Single-sided

• Double-sided

• Multi-layer

Global Printed Circuit Boards (PCBs) Market: By Application

• Consumer Electronics

• Aerospace and Defense

• Automotive

• Healthcare

• Others

Global Printed Circuit Boards (PCBs) Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Printed Circuit Boards (PCBs) market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/printed-circuit-boards-(pcbs)-market/901/

Reasons to Purchase Printed Circuit Boards (PCBs) Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organization’s useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy development, and business planning.

Click Here, To Buy Premium Report: https://stringentdatalytics.com/purchase/printed-circuit-boards-(pcbs)-market/901/?license=single

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - 91-9763384149

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Printed Circuit Boards (PCBs) Market Analysis#Key Players#Share Dynamic Demand and Consumption to 2032#The printed circuit boards (PCBs) market refers to the industry involved in the design#production#and sale of PCBs#which are essential components in electronic devices. PCBs provide a platform for interconnecting and supporting various electronic compone#such as integrated circuits (ICs)#resistors#capacitors#and connectors.#printed circuit board market size is expected to increase USD 3.60 billion by 2032 and Growth Rate from 2023 CAGR of 3.9% Forecast Period#Here are some key points about the PCBs market:#1.#Market Size and Growth: The PCBs market has experienced significant growth in recent years. Factors driving this growth include the increas#telecommunications equipment#automotive electronics#industrial automation#and healthcare devices. The proliferation of smart devices#Internet of Things (IoT) applications#and advancements in technologies like 5G and artificial intelligence also contribute to the expanding PCBs market.#2.#Types of PCBs: PCBs come in different types#including single-sided#double-sided#multi-layered#rigid#flexible#and rigid-flex PCBs. Each type has its specific applications and advantages. For instance#flexible PCBs are used in wearable devices and applications where flexibility and compactness are essential

0 notes

Text

The report "Conformal Coating Market by Type (Acrylic, Silicone, Epoxy, Urethane, and Parylene), End-Use (Consumer Electronics, Automotive, Aerospace & Defense, Industrial and Telecommunication), and Region - Global Forecast to 2025" The Conformal coatings market is estimated to be USD 807 million in 2020 and is expected to reach USD 1,081 million by 2025 at CAGR of 6.0%. The growth of the conformal coatings market is attributed to the increasing number PCB manufacturers and demand from high end applications that require conformal coatings.

The automotive industry has grown at a fast pace in the last decade, which led to the rapid evolution and increased consumption of electronics used in the vehicles. Currently, an average mid-range vehicle is loaded with technological features such as lane sensors, adaptive cruise control, in-car entertainment, and navigation. Also, the emergence of electric vehicle (EV), connected cars, and autonomous vehicles have resulted in a rapid surge in the advancement of electronics installed in these vehicles. From the industry point of view, the challenge is to protect these huge volumes PCBs and ICs used in the electronics system over a long period while meeting the specifications required by the automotive industry. This creates an attractive opportunity for conformal coatings manufacturers in the automotive and transportation industry. It is also the go-to-market for PCB manufacturers.

APAC is the largest market of conformal coatings, and this dominance is expected to continue till 2025. China is the key market in the region, consuming more than half of the demand for conformal coatings, followed by Taiwan, South Korea, and Japan. These countries are expected to witness a steady increase in consumption from 2020 to 2025. The region contributes close to 90% of PCB production in the world, and market is mainly driven by the presence of a large number of leading global electronics companies. PCB industry is quite fragmented as there are more than 100 companies that constitute close to 90% of overall PCB revenues and most of them belong to APAC, more so in China & Taiwan. Recent years have seen a lot of PCB manufacturing shifts to APAC due to cost-effectiveness and closer access to customers in the region, hence the increase in consumption of conformal coatings.

The key companies in the conformal coatings are Henkel (Germany), Illinois Tool Work (US), Shin-Etsu Chemical (Japan), Dow (US), H.B. Fuller (US), Chase Corporation (US), Electrolube (UK), Dymax Corporation (US), MG Chemical (Canada) and Specialty Coating System (US).

#Conformal Coatings Market#Conformal Coatings#Global Conformal Coatings Market#Conformal Coatings Industry#COVID-19 impact on automotive conformal coatings market#Conformal Coatings Market Size#Conformal Coatings Market Trends#Conformal Coatings Market Forecast#Conformal Coatings Demand#Conformal Coatings Sales#Conformal Coatings Market for PCBs#Conformal Coatings Market Opportunity

0 notes

Text

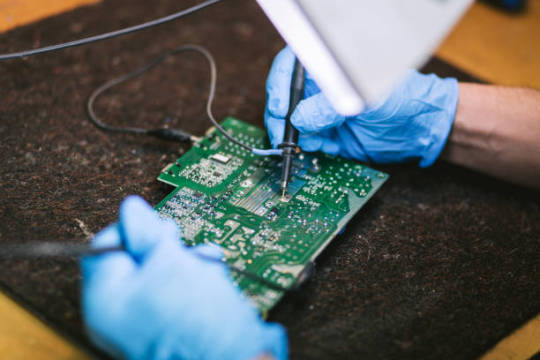

Note the Various Benefits of Clone PCB

A clone PCB is a replicated version of an existing printed circuit board (PCB), designed to mimic the layout, components, and functionality of the original PCB. It serves purposes such as backup, legacy support, cost reduction, customization, or reverse engineering. However, creating clone PCBs must be done while considering legal and ethical considerations regarding intellectual property rights.

Sometimes, clone PCBs are created through reverse engineering processes to replicate the functionality of an existing PCB without access to its original design files or documentation. PCB (Printed Circuit Board) reverse engineering is the process of deconstructing and analyzing the design and functionality of a printed circuit board to understand its schematics, layout, and operation.

There are multifaceted benefits of clone PCBs:

Continuity and redundancy - Clone PCBs provide a safety net for businesses by ensuring continuity in production processes. In case the original PCB design becomes unavailable due to damage, loss, or obsolescence, having clone PCBs allows manufacturing to continue without disruptions. This redundancy is crucial for industries where downtime can result in substantial financial losses.

Legacy support and maintenance - Many industries rely on equipment or devices with legacy PCB designs that may no longer be supported by the original manufacturer. Clone PCBs enable the continued operation, maintenance, and repair of such equipment, extending its lifespan and maximizing return on investment. This is particularly important in sectors like aerospace, defense, automotive, and industrial manufacturing, where equipment longevity is paramount.

Cost optimization - Clone PCBs offer opportunities for cost optimization in several ways. By replicating the original PCB design using more readily available or cost-effective components, manufacturers can reduce production costs without sacrificing quality or performance. Additionally, economies of scale can be leveraged when producing clone PCBs in bulk, further driving down per-unit costs.

Flexibility and customization - Clone PCBs can be tailored to meet specific requirements or to incorporate improvements over the original design. Manufacturers can modify aspects such as component selection, layout, or functionality to optimize performance, enhance reliability, or adapt to evolving technological standards. This flexibility enables businesses to stay competitive and responsive to changing market demands.

Reverse engineering and innovation - Clone PCBs support innovation by facilitating reverse engineering efforts. Analyzing and replicating existing PCB designs allows engineers to gain insights into complex electronic systems, identify best practices, and develop new products or technologies based on proven designs. This process fosters creativity, knowledge transfer, and continuous improvement within the industry.

Intellectual property protection - While not directly a benefit, clone PCBs can also help protect intellectual property (IP) by offering a legal and authorized means for manufacturers to reproduce their own designs. This ensures that valuable innovations are safeguarded against unauthorized replication or counterfeiting, preserving the competitive advantage of original equipment manufacturers.

0 notes

Text

Advanced Materials for Electronics is Projected to Grow at a 7.4% CAGR between 2022 and 2031

The Advanced Materials for Electronics Market is predicted to reach US$ 57.8 billion by 2031. According to market forecasts, the market is expected to grow at a CAGR of 7.4% through 2031.

Electronics that are printed and flexible continue to grow at a fast rate. Along the value chain, energy and resource efficiency can be significantly increased through new technological approaches to both production and product design.

Electronics are undergoing constant reorganization to meet changing consumer demands, which results in continuously evolving technologies, materials, and business models. Innovations in the technology industry have been stimulated by the growing need for miniaturized and improved capacity computers and networks, faster data transmission speeds, and most importantly, sustainable technologies.

For instance, a new high-speed broadband standard protocol for digital subscriber lines (DSL) was approved by the International Telecommunication Union (ITU) in December 2014. It is referred to as Gaits for local loops under 500 meters that support uploads and downloads at 150 Mb/s to 2 Gb/s. A local loop's length determines how fast Gaits can transmit data. It is mandatory in Gaits to have an asymmetry ratio of 90/10 to 50/50 between downstream and upstream

Download Sample Copy with Graphs & List of Figures: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=85652

Market Segmentation

The advanced materials for electronics market can be segmented by service type, sourcing type, application, industry vertical, and region.

By Service Type

Design and Consulting

Integration and Implementation

Maintenance and Support

By Sourcing Type

In-house

Outsourced

By Application

Semiconductor Devices

Printed Circuit Boards (PCBs)

Display Panels

Batteries and Energy Storage

By Industry Vertical

Consumer Electronics

Automotive

Telecommunications

Healthcare

Energy and Power

By Region

North America

Europe

Asia-Pacific

Latin America

Middle East and Africa

Regional Analysis

North America: Dominates the market due to the presence of major semiconductor companies and substantial investments in R&D.

Europe: Shows significant growth driven by the automotive sector, particularly in EVs.

Asia-Pacific: Expected to witness the fastest growth owing to the large consumer electronics market and manufacturing hub in countries like China, Japan, and South Korea.

Latin America and Middle East & Africa: Emerging markets with growing investments in technology infrastructure and renewable energy projects.

Market Drivers and Challenges

Drivers:

Technological Advancements: Innovations in semiconductor and nanotechnology drive the demand for advanced materials.

Growing Consumer Electronics Market: Increased adoption of smartphones, tablets, and wearable devices.

Electric Vehicles and Renewable Energy: Rising demand for EVs and renewable energy solutions, which require advanced battery materials and energy storage systems.

Challenges:

High Production Costs: The advanced materials often require complex and costly manufacturing processes.

Supply Chain Issues: Dependency on specific raw materials which might be geographically concentrated or scarce.

Regulatory Hurdles: Stringent environmental regulations regarding material production and disposal.

Market Trends

Miniaturization of Electronic Devices: Increasing demand for smaller, lighter, and more efficient electronic components.

Development of Flexible and Wearable Electronics: Surge in demand for materials that are flexible and can be integrated into wearable technology.

Sustainability: Focus on environmentally friendly materials and sustainable manufacturing processes.

Future Outlook

The future of the advanced materials for electronics market looks promising with continuous innovations and increasing integration of these materials in various high-tech applications. The push towards 5G technology, AI, and IoT will further amplify the demand for advanced electronic materials. Additionally, the evolution of the EV market and renewable energy solutions will continue to create substantial growth opportunities.

Key Market Study Points

Detailed analysis of market size and growth projections.

Comprehensive segmentation analysis to understand market dynamics.

Regional performance and growth prospects.

Identification of key market drivers, challenges, and trends.

Future outlook and strategic recommendations for market participants.

Competitive Landscape

The market is characterized by intense competition with several key players investing heavily in R&D to gain a competitive edge. Major companies include BASF SE, DowDuPont Inc., Samsung SDI, LG Chem, and 3M. These players focus on strategic partnerships, mergers, acquisitions, and new product developments to expand their market presence.

Buy this Premium Research Report | Immediate Delivery Available: https://www.transparencymarketresearch.com/checkout.php?rep_id=85652<ype=S

Recent Developments

BASF SE recently announced the development of a new line of conductive polymers for flexible electronics.

Samsung SDI expanded its production capacity for advanced battery materials to meet the growing demand from the EV market.

3M launched a new range of high-temperature resistant adhesives for semiconductor applications.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Comprehensive Exploration of Copper-Based PCBs: Innovations and Applications

Introduction

Printed Circuit Boards (PCBs) serve as the intricate scaffolding of modern electronic systems, facilitating the interconnection of electronic components. Among the diverse array of PCB types, copper-based PCBs, characterized by their utilization of copper cores, stand at the forefront due to their unparalleled thermal conductivity and electrical performance. This comprehensive guide delves into the intricacies of copper-based PCBs, elucidating their composition, applications, manufacturing processes, and the pivotal role they play in driving technological advancements across various industries.

Definition and Composition

Copper-based PCBs represent a specialized subset within the realm of metal core PCBs, where copper, distinguished for its exceptional electrical and thermal conductivity properties, serves as the core material instead of aluminum or other metals. The utilization of copper cores not only enhances electrical performance but also significantly augments heat dissipation capabilities, rendering copper-based PCBs indispensable for applications necessitating optimal thermal management.

Comparative Analysis: Copper vs. Aluminum

While aluminum-based PCBs hold sway in industries characterized by stringent cost considerations, such as LED manufacturing, copper-based counterparts reign supreme in domains where thermal management and electrical performance are paramount. The inherent superiority of copper in thermal conductivity (approximately 400 W/(m·K) compared to aluminum's approximately 200 W/(m·K)) renders copper-based PCBs the preferred choice for applications requiring intricate circuitry, high current densities, and impeccable signal integrity.

Optimal Applications for Copper-Based PCBs

Cost-Performance Dynamics

Despite commanding a premium in the market, the advanced features and unparalleled performance characteristics of copper-based PCBs justify their adoption for mission-critical applications. The decision to opt for copper-based PCBs necessitates a meticulous evaluation of the cost-performance trade-off, with due consideration given to the unique requirements of each project.

Thermal Management Superiority

In environments characterized by continuous operation or the deployment of high-power electronic components, the superior thermal conductivity of copper emerges as a decisive factor in preserving circuit performance and longevity. The enhanced thermal management capabilities afforded by copper-based PCBs ensure sustained operational efficiency even in the face of demanding operating conditions.

Multilayer and High-Frequency Applications

The inherent design flexibility of copper-based PCBs renders them ideally suited for applications necessitating the integration of multiple circuit layers. Moreover, their adeptness at managing heat without necessitating a thick core enables the seamless incorporation of additional layers, thereby bolstering functionality without compromising thermal performance. In scenarios wherein high-frequency circuit designs demand uncompromising signal integrity and minimal electromagnetic interference, copper-based PCBs emerge as the preeminent choice, underpinning the seamless integration and compatibility of electronic devices.

Manufacturing Process of Copper-Based PCBs

Intrinsic Challenges

The manufacturing of copper-based PCBs necessitates meticulous attention to detail owing to the distinctive material characteristics of copper, including its hardness and thermal properties. These inherent challenges impart a heightened level of complexity to the manufacturing process, exerting a discernible influence on both cost and production timelines.

Innovations in Thermal Management

Advanced techniques such as thermoelectric separation are leveraged to enhance thermal conductivities, catering to the diverse and evolving needs of industries spanning new energy automotive lighting, high-power LED systems, and other high-technology sectors.

Comprehensive Testing and Quality Assurance

Each copper-based PCB is subjected to a battery of stringent tests meticulously designed to ascertain compliance with the exacting thermal and electrical specifications stipulated by clients. This rigorous testing regimen underscores the unwavering commitment to delivering copper-based PCBs of unparalleled reliability and efficiency.

Conclusion

Copper-based PCBs epitomize a paradigm shift within the PCB industry, offering a confluence of unrivaled thermal management capabilities and superior electrical conductivity. Despite commanding a premium, their manifold benefits in high-stakes applications yield substantial returns on investment, heralding a new era of electronic innovation characterized by enhanced performance and reliability. As the technological landscape continues to evolve, the indispensability of copper-based PCBs in underpinning the next generation of electronic advancements is irrefutable.

0 notes

Text

Industrial Controls Market – Trends Forecast Till 2030

Industrial Controls Market analysis report figures out market landscape, brand awareness, latest trends, possible future issues, industry trends and customer behaviour so that the business can stand high in the crowd. It includes extensive research on the current conditions of the industry, potential of the market in the present and the future prospects from various angles. This Industrial Controls Market report comprises of data that can be pretty essential when it comes to dominating the market or making a mark in the Semiconductors & Electronics industry as a new emergent. To bestow clients with the best results, Industrial Controls Market research report is produced by using integrated approaches and latest technology.

Download Free Sample Report at: https://www.delvens.com/get-free-sample/industrial-controls-market

Industrial Controls Market by Type (Distributed Control System, Supervisory Control & Data Acquisition System, Manufacturing Execution System, Programmable Logic Controller (PLC), Product Lifecycle Management (PLM), Enterprise Resource Planning (ERP), Human Machine Interface (HMI) and Others), Component (Modular Terminal Blocks, Relays & Optocouplers, Surge Protectors, Marking Systems, Printing, Ferulles Cable Lugs, Handtools, Testers, Enclosure Products, PCB Connectors & Terminals, Heavy Duty Connectors, Analog Signal Conditioner, Electronic Housings, Power Supplies, Industrial Ethernet, and Remote IO), Application and End User (Automotive, Utility, Electronics & Semiconductors, Oil and Gas, Chemical and Petrochemical, Power, Life Sciences, Food and Beverage and Mining), and region (North America, Europe, Asia-Pacific, Middle East and Africa and South America), global opportunity analysis and Industry Forecast, 2023-2030. The global Industrial Controls market size was estimated at USD 140 billion in 2023 and is projected to reach USD 239.9354 billion in 2030 at a CAGR of 8% during the forecast period 2023-2030.

Industrial Controls Market Competitive Landscape:

ABB Ltd.

Emerson Electric Corporation

Honeywell International Incorporation

Kawasaki Robotics control system

Mitsubishi Electric Factory Automation

Omron Corporation

Rockwell Automation Inc.

Siemens AG

Schneider Electric SA

Yokogawa Electric Corporation

Endress+Hauser AG

General Electric

GLC Controls Inc.

Industrial Controls Market Recent Developments:

In July 2022, IBM acquired Databand.ai, a leading provider of data observability software that helps organizations fix issues with their data, including errors, pipeline failures, and poor quality, before it impacts their bottom line.

In July 2022, Sap acquired Askdata to strengthen its ability to help organizations take better-informed decisions by leveraging AI-driven natural language searches. Users are empowered to search, interact, and collaborate on live data to maximize business insights.

Make an Inquiry Before Buying at: https://www.delvens.com/Inquire-before-buying/industrial-controls-market

Industrial controls systems refer to various automation devices, machines and equipment used in industry. They are developed to better control and monitor industrial processes and automate tasks to increase efficiency and reliability while improving quality. These systems include a variety of controls systems such as supervisory control and data acquisition or SCADA, programmable logic controllers or PLCs, and distributed controls systems or DCS.

They can help automate processes, critical infrastructure or remote monitoring and management. They also help collect data from remote devices, monitor the operation of distributed factories, and perform automated electromechanical processes. Rapid adoption of cloud-based services and growing automation trends in industry are important factors for the global industry. Market dominance. Automation helps industries achieve better accuracy and quality while reducing costs.

Growth is driven by the demand for intelligent controls systems and automation in various industries, mass production in industry and the adoption of industrial controls systems in various end-uses such as automotive and mining, as well as increasing R&D investments. in the industrial control market. However, increasing cyber-attacks, lack of authentication procedures, lack of experienced professionals and awareness of industrial security solutions are restraining the growth of the industrial controls market. In addition, the deployment of a smart grid to protect critical infrastructure against cyber-attacks and cloud computing for industrial controls systems creates lucrative opportunities for the industrial surveillance market.

Scope of the Industrial Controls Market Report:

The Industrial Controls Market is segmented into various segments such as type, component, End user and region:

Based on type

Distributed control system (DCS)

Supervisory control & data acquisition system (SCADA)

Manufacturing execution system (MES)

Programmable Logic Controller (PLC)

Product Lifecycle Management (PLM)

Enterprise Resource Planning (ERP)

Human Machine Interface (HMI)

Others

Based on the component

Modular terminal blocks

Relays & optocouplers

Surge protectors

Marking systems

Printing

Ferulles cable lugs

Handtools

Testers

Enclosure products

PCB connectors and terminals

Heavy duty connectors

Analog signal conditioner

Electronic housings

Power supplies

Industrial ethernet

Remote IO

Based on the End user

Automotive

Utility

Electronics & semiconductors

Mining

Oil and Gas

Chemical and Petrochemical

Power

Life Sciences

Food and Beverage

Others

Based on Application

Automotive

Pharmaceutical

Oil & Gas

Electrical Power

Others

Based on Network

Fieldbus

Communication Router

Firewall

MODEMS

Remote Access Points

Based on region

Asia Pacific

North America

Europe

South America

Middle East & Africa

Industrial Controls Market Regional Analysis:

North America to Dominate the Market

North America is on the brink of the fourth industrial revolution. The data generated is used for high-volume production, while the data is integrated into various production systems throughout the supply chain. The region is also one of the world's largest automotive markets, with more than 13 major automotive manufacturers operating. The automobile industry was one of the largest income generators in the region. Due to significant adoption of industrial control systems and automation technologies in the automotive industry, the region offers a huge opportunity for market growth.

Several key vendors operating in the country are launching new upgrades to support the growth of smart factories along with the development of industrial control systems. Such technological development indicates regional growth in the studied market.

Direct Purchase of the Industrial Controls Market Research Report at: https://www.delvens.com/checkout/industrial-controls-market

Browse Related Reports:

12V Lithium-Ion Battery Market

Pressure Sensor Market

Industrial Valves Market

About Us:

Delvens is a strategic advisory and consulting company headquartered in New Delhi, India. The company holds expertise in providing syndicated research reports, customized research reports and consulting services. Delvens qualitative and quantitative data is highly utilized by each level from niche to major markets, serving more than 1K prominent companies by assuring to provide the information on country, regional and global business environment. We have a database for more than 45 industries in more than 115+ major countries globally.

Delvens database assists the clients by providing in-depth information in crucial business decisions. Delvens offers significant facts and figures across various industries namely Healthcare, IT & Telecom, Chemicals & Materials, Semiconductor & Electronics, Energy, Pharmaceutical, Consumer Goods & Services, Food & Beverages. Our company provides an exhaustive and comprehensive understanding of the business environment.

Contact Us:

UNIT NO. 2126, TOWER B,

21ST FLOOR ALPHATHUM

SECTOR 90 NOIDA 201305, IN

+44-20-3290-6466

#consulting company#strategic advisory firm#best market reports#trending reports#market analysis reports#syndicated reports#Industrial Controls Market#Industrial Controls

0 notes

Text

Choosing the Right High and Low Temperature Shock Test Chamber for Your Testing Needs

High and Low Temperature Thermal Shock Chamber are used in electronic and electrical components, automation components, communication components, automotive parts, metals, chemical materials, plastics and other industries, as well as in the physical changes of national defense industry, aerospace, military industry, BGA, PCB base plates, electronic chip ICs, semiconductor ceramics, and polymer materials,

Testing the repeated tensile force of its materials against high and low temperatures and the chemical change or physical damage produced by the thermal expansion of the product can confirm the quality of the product. It can be used from precision IC to heavy machinery components, and is an indispensable test chamber for product testing in various fields.

The High and Low Temperature Shock Test Chamber for Your Testing Needs simulates the alternating changes of high and low temperature environments, exposing products to problems in harsh environments. It is a very important testing equipment in multiple industrial manufacturing fields.

How to choose a suitable high and low temperature shock test chamber?

The selection of equipment is not as expensive as possible, but rather to choose products that are suitable for oneself. The manufacturer of the High and Low Temperature Shock Test Chamber will tell you how to choose the equipment reasonably:

1. Two chamber vs. three chamber

The two chamber shock only has high and low temperature shocks, while the three chamber shock has a room temperature transition in the middle. For products, there is no transition at room temperature, which is more destructive and imposes stricter requirements on the product.

2. Water cooled vs. air cooled

Normally, a temperature of -40~+150 ℃ for 50L-100L is sufficient for air cooling. A larger capacity and a lower temperature (100L/-70 ℃) for water cooling provide more stable performance.

3. Material and inward dimensions

The cold and hot shock chamber usually has two materials: stainless steel and baking paint, which can be customized according to needs. The stainless steel material is beautiful and easy to care. The baking paint color can be selected by yourself, and can be matched with other equipment colors.

The thickness of the board has an impact on the quality of the equipment, because the thickness of the board is too thin, and the equipment is prone to deformation when the bearing weight is too large or the temperature is too high. Most equipment suppliers choose qualified sheet materials.

The board of conventional equipment is generally 1.0mm or 1.2mm, so the thickness of the material is important for the quality of the equipment. When selecting equipment, it is important to have a clear understanding.

From the perspective of internal chamber size, the specification requires that the product must be placed inside the testing area. Some

The manufacturer places the product inside the air duct, although it is only 10cm away from the testing area, this energy difference is quite significant. And it cannot truly reflect the temperature changes on the surface of the test object. So choose the appropriate inner box size.

On the market, the conventional capacity of the cold and hot shock test chamber is 50L, 80L, 100L, 150L, 225L, 408L, 800L, 1000L, etc. It is recommended that you choose the capacity based on the long-term test demand.

4. Impact temperature

Pay attention to the large range of temperatures that can actually be reached in the testing area. Note that it is not the limit temperature for preheating and precooling chambers. The test load directly affects how many test items can be placed. Generally speaking, the larger the weight, the better.

Select appropriate temperature impact range of cold and hot impact test chamber according to relevant test standards of product materials (national standard/military standard/European and American standard), generally - 40 ℃~+150 ℃- 55℃~+150℃;- 70 ℃~+150 ℃, of course, different impact ranges can also be selected for different products.

High and Low Temperature Thermal Shock Chamber can be used in the temperature shock test and fast-changing temperature test in a wide range such as aviation, air space, electronic components and material research.

HLST-500D has two separate chambers: high temperature chamber and low temperature chamber.

HLST-500T has three separate chambers: high temperature chamber, low temperature chamber and test chamber.

Lisun Instruments Limited was found by LISUN GROUP in 2003. LISUN quality system has been strictly certified by ISO9001:2015. As a CIE Membership, LISUN products are designed based on CIE, IEC and other international or national standards. All products passed CE certificate and authenticated by the third party lab.

Our main products are Goniophotometer, Integrating Sphere, Spectroradiometer, Surge Generator, ESD Simulator Guns, EMI Receiver, EMC Test Equipment, Electrical Safety Tester, Environmental Chamber, Temperature Chamber, Climate Chamber, Thermal Chamber, Salt Spray Test, Dust Test Chamber, Waterproof Test, RoHS Test (EDXRF), Glow Wire Test and Needle Flame Test.

Please feel free to contact us if you need any support.

Tech Dep: [email protected], Cell/WhatsApp:+8615317907381

Sales Dep: [email protected], Cell/WhatsApp:+8618117273997

Read the full article

0 notes

Text

Reactive Adhesives Market Report: Trends, Analysis, and Projections

Reactive adhesives are gaining prominence in various industries due to their exceptional bonding strength, durability, and versatility in bonding different materials. This blog delves into the dynamics of the global reactive adhesives market, analyzing key drivers, applications across industries, emerging trends, and future growth prospects.

Understanding the Reactive Adhesives Market:

Reactive adhesives are adhesive formulations that require a chemical reaction to achieve bonding. They include epoxy, polyurethane, silicone, and cyanoacrylate adhesives, among others, each offering unique properties suitable for specific applications.

Market Dynamics:

Construction and Building Materials: Reactive adhesives are extensively used in construction for bonding structural elements, composites, flooring, and insulation materials due to their high strength, weather resistance, and bonding versatility.

Automotive and Aerospace: In the automotive and aerospace industries, reactive adhesives play a critical role in bonding components, lightweight materials, composite structures, and interior assemblies, contributing to weight reduction and improved performance.

Electronics and Electrical Industry: Reactive adhesives are utilized for bonding electronic components, PCBs, displays, and encapsulation of sensitive devices due to their thermal stability, electrical insulation properties, and protection against environmental factors.

Packaging and Consumer Goods: Reactive adhesives find applications in packaging, assembly of consumer goods, furniture manufacturing, and product bonding where high bond strength, durability, and aesthetics are essential.

Applications Across Industries:

Construction: Structural bonding, flooring, insulation.

Automotive and Aerospace: Lightweight materials, composites, assemblies.

Electronics: PCB bonding, encapsulation, component assembly.

Packaging and Consumer Goods: Product assembly, furniture bonding, packaging.

Market Trends:

High-Performance Formulations: Demand for reactive adhesives with superior bond strength, impact resistance, temperature resistance, and chemical resistance drives innovation in formulation technologies and adhesive additives.

Customized Solutions: Increasing focus on tailored adhesive solutions for specific substrates, surface conditions, environmental requirements, and application methods to optimize bonding performance and efficiency.

Green and Sustainable Adhesives: Growing emphasis on eco-friendly adhesives with low VOC emissions, recyclability, and bio-based raw materials aligns with sustainability goals and regulatory standards, driving market demand for green adhesives.

Future Prospects:

The global reactive adhesives market is poised for significant growth, driven by advancements in material science, increasing adoption in critical industries, and demand for high-performance bonding solutions. Investments in R&D, customization capabilities, and sustainability initiatives will shape the market's trajectory and competitiveness.

Conclusion:

Reactive adhesives offer robust bonding solutions across diverse industries, meeting stringent performance requirements and contributing to product innovation and efficiency. Understanding market trends, technological advancements, and customer needs is crucial for stakeholders in the reactive adhesives market to capitalize on growth opportunities and address evolving industry demands effectively. With a focus on performance, customization, and sustainability, the reactive adhesives market presents promising prospects for innovation and market expansion globally.

0 notes

Text

High-Speed Connector Market: Transforming Networks & Connectivity

The demand for digital services, and consequently data transmission, has witnessed explosive growth. As per IEA, since 2010, global internet traffic has expanded twenty-five-fold. This surge underpins the escalating need for high speed cable connectors, crucial for efficient data handling and transmission across various sectors. This growth is a direct response to the increasing need for robust connectivity solutions that can keep pace with the exponential growth of data generation and transmission. According to our report, the Global High Speed Connector Market is expected to grow significantly, driven by a CAGR of over 9.15% over 2024-2032.

High speed connectors also address compatibility issues with legacy systems, providing seamless integration that is essential for modernizing existing technology infrastructures. This capability is not only enhancing operational efficiencies but is also projected to boost market growth substantially in the near future.

Explore in detail about this market in our FREE sample

High Speed Connector Market: Spotlight on Key Products

Board-to-Cable Connectors

Among the various products, board-to-cable connectors witness significant traction due to their critical role in ensuring continuous and reliable connectivity in complex electronic assemblies. These connectors are particularly favored for their flexibility and durability, which are essential for applications involving frequent disconnection and reconnection.

Latest developments in board-to-cable connectors have showcased several innovations, particularly in terms of performance and application adaptability. Notably, in October 2023, Molex introduced the KickStart Connector System that combines low transmission loss and a compact design, making it the first Open Compute Project (OCP)-compliant solution of its kind.

Board-to-Board Connectors

Board-to-board connectors are also gaining prominence as they are vital for creating secure and efficient connections between printed circuit boards (PCBs) within a single device. This is increasingly important in compact electronic devices such as smartphones and tablets.

New innovations in board-to-board connectors have been noteworthy. For instance, in Market 2023, Hirose Electric introduced the IT14 Series, designed for telecommunications, supporting high-speed data transmission up to 112Gbps using PAM4 technology.

In the field of advanced automotive, board-to-board connectors play a crucial role. These connectors are essential for connecting multiple electronic control units (ECUs) within vehicles, which are central to the functionality of ADAS.

Connect with our experts for a simplified analysis!

USB Type-C: A Catalyst for High Speed Connector Evolution

The adoption of USB Type-C connectors has been a game-changer in the field of high-speed connectivity. Known for their reversibility and high-speed data transfer capabilities, USB Type-C connectors are becoming a standard in new devices, fueling further development and innovation in the high-speed connector market. Their versatility across various platforms and devices underscores the shift towards more universal, efficient connection solutions in technology hardware.

Trends and Investment Opportunities Ahead

Advancements in the high-speed connector market are focused on enhancing connector design to reduce electromagnetic interference and improve signal integrity. Innovations such as connectors supporting up to 400 Gbps are transforming data center operations with faster, more reliable cloud services.

Looking ahead, further developments are expected in nanotechnology and advanced materials science, promising more efficient connectivity solutions. This makes sectors like cloud computing and artificial intelligence particularly ripe for investment. Hence, monitoring these technological shifts is essential for businesses and investors to invest in high speed cable connect solutions.

Explore Our Latest Release for the 2024-2032 Market Analysis

FAQs

Q1) What advantages do high-speed connectors provide over traditional connectors?

High-speed connectors offer superior performance in terms of data transmission speed and reliability, which is critical for modern digital applications.

Q2) Can high-speed connectors be used with any device?

While high-speed connectors are versatile, compatibility with specific devices depends on the connector type and device specifications.

Q3) What are the future trends in the high-speed connector market?

Future trends include the development of connectors with higher speed capacities, enhanced durability, and improved EMI resistance, all crucial for the next generation of digital devices.

0 notes

Text

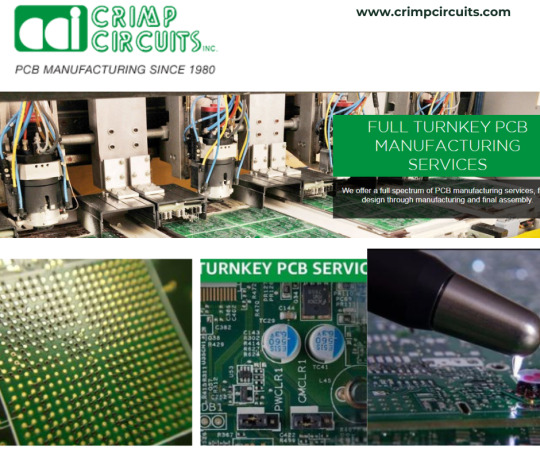

Powering Innovation: The Role of PCB Manufacturers in Canad

Introduction: In the fast-paced world of electronics manufacturing, printed circuit boards (PCBs) are the backbone of countless devices and systems. From smartphones and automotive electronics to medical devices and aerospace technology, PCBs are essential components that enable the functionality of modern technology. In Canada, a select group of PCB manufacturers are leading the charge in delivering high-quality, innovative solutions to meet the demands of diverse industries. At Crimp Circuits, we're proud to be among the top PCB manufacturers in Canada, dedicated to powering innovation and driving technological advancements. In this blog, we'll explore the pivotal role of PCB manufacturers in Canada and highlight how Crimp Circuits is making its mark in the industry.

The Significance of PCB Manufacturers: PCB manufacturers play a crucial role in the electronics supply chain, serving as the bridge between design concepts and tangible products. These manufacturers are responsible for translating design specifications into physical PCBs that meet the unique requirements of various applications. With advancements in technology and increasing demands for smaller, more complex devices, the role of PCB manufacturers has become more critical than ever.

Crimp Circuits: A Beacon of Excellence in PCB Manufacturing: As a leading PCB manufacturer in Canada, Crimp Circuits has established itself as a beacon of excellence and innovation in the industry. With over four decades of experience, we have honed our expertise and built a reputation for delivering high-quality PCB solutions tailored to the specific needs of our clients. Our commitment to quality, reliability, and customer satisfaction sets us apart as a trusted partner for businesses across diverse sectors.

Comprehensive PCB Solutions: At Crimp Circuits, we offer a comprehensive range of PCB solutions to address the evolving needs of our clients. From single-layer to multi-layer PCBs, we have the capabilities to produce a wide variety of PCB types to accommodate different design requirements. Our services include PCB design, prototyping, manufacturing, assembly, and testing, ensuring that we can support our clients throughout every stage of the production process.

Quality Assurance and Compliance: Quality is at the core of everything we do at Crimp Circuits. We adhere to stringent quality control measures and industry standards to ensure that every PCB we manufacture meets the highest levels of reliability and performance. Our commitment to quality is further underscored by our adherence to environmental regulations and sustainability practices, ensuring that our operations have a minimal impact on the environment.

Driving Innovation and Advancement: Innovation is the driving force behind our success at Crimp Circuits. We continuously invest in research and development to stay at the forefront of emerging technologies and manufacturing techniques. By embracing innovation and collaboration, we empower our clients to bring their most ambitious projects to fruition and stay ahead of the competition in an ever-evolving market.

Conclusion: In conclusion, PCB manufacturers play a pivotal role in driving innovation and technological advancement across various industries. As a leading PCB manufacturer in Canada, Crimp Circuits is committed to delivering high-quality, innovative PCB solutions that meet the unique needs of our clients. With our expertise, dedication, and relentless pursuit of excellence, we're proud to be a trusted partner for businesses seeking reliable PCB manufacturing services in Canada and beyond. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

0 notes

Text

Exploring the Dynamics of the X-ray Inspection System Market: Trends, Innovations, and Future Prospects

In today's rapidly evolving industrial landscape, quality control and assurance have become paramount. Manufacturers across various sectors are constantly seeking advanced solutions to ensure the integrity and safety of their products. Among these solutions, X-ray inspection systems have emerged as indispensable tools for non-destructive testing and quality assessment. The X-ray inspection system market is witnessing significant growth, driven by technological advancements, stringent regulatory requirements, and the increasing demand for high-quality products.

One of the key drivers propelling the growth of the X-ray inspection system market is the rising emphasis on product quality and safety. In industries such as automotive, electronics, aerospace, and food processing, the need to detect defects, contaminants, and irregularities in products has never been greater. X-ray inspection systems offer a non-invasive method of inspecting internal structures, ensuring that even the smallest defects are identified with precision. As a result, manufacturers can maintain compliance with industry standards and regulations while safeguarding their reputation and brand integrity.

Moreover, technological advancements have led to the development of more sophisticated X-ray inspection systems with enhanced capabilities. Modern systems are equipped with advanced imaging techniques, such as computed tomography (CT), which provide three-dimensional insights into the internal structures of objects. This enables manufacturers to detect defects hidden within complex assemblies and materials, thereby improving the overall quality and reliability of their products. Additionally, the integration of artificial intelligence and machine learning algorithms has further enhanced the efficiency and accuracy of X-ray inspection systems, allowing for real-time defect detection and analysis.

The X-ray inspection system market is also benefiting from the growing adoption of Industry 4.0 principles in manufacturing processes. As industries embrace automation, connectivity, and data analytics, X-ray inspection systems are being seamlessly integrated into smart production lines. These systems can be networked with other manufacturing equipment, allowing for seamless data exchange and process optimization. Furthermore, the incorporation of IoT-enabled sensors enables remote monitoring and predictive maintenance of X-ray inspection systems, minimizing downtime and maximizing productivity.

In terms of application, the X-ray inspection system market spans a wide range of industries and sectors. In the automotive industry, these systems are used for inspecting welds, castings, and assemblies to ensure structural integrity and safety compliance. In electronics manufacturing, X-ray inspection systems are employed to detect defects such as voids, cracks, and solder joint irregularities in printed circuit boards (PCBs) and semiconductor devices. Similarly, in the food and pharmaceutical industries, these systems play a crucial role in detecting contaminants, foreign objects, and packaging defects, thereby ensuring product safety and regulatory compliance.

Looking ahead, the future of the X-ray inspection system market looks promising, driven by ongoing technological innovations and the increasing adoption of quality control measures across industries. With the continuous evolution of imaging techniques, software algorithms, and hardware components, X-ray inspection systems are expected to become more efficient, reliable, and versatile. Additionally, as industries continue to prioritize sustainability and environmental responsibility, there is a growing demand for X-ray inspection systems that are energy-efficient and eco-friendly.

In conclusion, the X-ray inspection system market is experiencing robust growth driven by the need for advanced quality control solutions across various industries. Technological advancements, regulatory requirements, and the shift towards Industry 4.0 are key factors shaping the market dynamics. As manufacturers strive to maintain high standards of quality and safety, X-ray inspection systems are poised to play a central role in ensuring product integrity and reliability in the years to come.

#X-ray inspection#inspection systems#industrial technology#quality control#non-destructive testing#manufacturing#market trends

0 notes

Text

Exploring the Top PCB Manufacturing Companies in Delhi: Shree Ram Electronics

In the vibrant landscape of Delhi's electronics industry, the quest for reliable PCB manufacturing companies is paramount. As technology evolves, the demand for quality printed circuit boards (PCBs) continues to rise, necessitating a closer look at the key players in the market. Amidst the myriad options, one name shines brightly.

PCB manufacturing companies in Delhi cater to a diverse clientele, from budding startups to established enterprises. However, discerning customers prioritize certain factors: quality, reliability, and innovation. We embodie our qualitie, emerging as a frontrunner in the competitive realm of PCB manufacturing.

Founded as a testament to women entrepreneurship, Shree Ram Electronics epitomizes the spirit of empowerment and innovation. With a firm commitment to the Make in India initiative, this organization has carved a niche for itself, delivering superior PCB solutions to clients across various industries.

We stand out for its unwavering dedication to quality. Each PCB undergoes rigorous testing procedures, ensuring adherence to international standards. From single-layer to multi-layer boards, the company offers a comprehensive range of products tailored to meet diverse specifications.

In the bustling metropolis of Delhi, where competition is fierce, we set itself apart through its relentless pursuit of excellence. The company's state-of-the-art manufacturing facilities leverage cutting-edge technology to deliver unmatched precision and performance.

Whether it's automotive, aerospace, or consumer electronics, we cater to a broad spectrum of industries. With a customer-centric approach, the company strives to exceed expectations, forging long-lasting partnerships built on trust and reliability.

In the dynamic landscape of PCB manufacturing, innovation is key. We embrace this ethos wholeheartedly, constantly pushing the boundaries of possibility. Through continuous research and development, the company remains at the forefront of technological advancements, offering solutions that drive progress and innovation.

As the demand for PCBs continues to escalate, choosing the right manufacturing partner is paramount. PCB manufacturing companies in Delhi abound, but none quite match the caliber of Shree Ram Electronics. With a legacy of excellence and a commitment to customer satisfaction, this organization stands tall as a beacon of quality and reliability in the bustling capital city.

#PCB manufacturing companies in Delhi#pcb manufacturers in Delhi#pcb design and fabrication in Delhi

0 notes

Text

Conformal Coatings Market for PCBs to Reach USD 5.3 billion, Growing 5.5% CAGR

The global conformal coatings market for PCBs is estimated to flourish at a CAGR of 5.5% from 2023 to 2031. Transparency Market Research projects that the overall sales revenue conformal coatings market for PCBs is estimated to reach US$ 5.3 billion by the end of 2031.

The increasing adoption of PCBs in medical devices necessitates conformal coatings that meet stringent regulatory requirements for biocompatibility, sterilization, and long-term reliability in harsh medical environments. The proliferation of renewable energy technologies such as solar panels and wind turbines requires PCBs with durable conformal coatings to withstand outdoor exposure to UV radiation, moisture, and temperature fluctuations.

The expansion of telecommunications infrastructure, including 5G networks and satellite communication systems, drives demand for high-performance PCBs with conformal coatings optimized for reliability and longevity in demanding outdoor environments. The growing interest in space exploration and satellite technology necessitates PCBs equipped with conformal coatings capable of withstanding extreme temperature variations, vacuum conditions, and radiation exposure in space environments.

Download Sample Copy of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=44288

Market Segmentation

By Service Type: Segmented into coating application services, consulting, and customization services catering to diverse industry needs.

By Sourcing Type: Includes acrylics, silicones, urethanes, perylene, and other material variants, reflecting different performance characteristics and application requirements.

By Application: Covers PCB protection, automotive electronics, aerospace components, industrial equipment, medical devices, and consumer electronics.

By Industry Vertical: Encompasses electronics manufacturing, automotive, aerospace & defense, healthcare, industrial machinery, and telecommunications.

By Region: Analysis based on geographical regions such as North America, Europe, Asia Pacific, Latin America, and Middle East & Africa, considering regional demand dynamics and regulatory frameworks.

Regional Analysis

North America: Technological advancements in electronics, automotive innovations, and aerospace developments drive significant demand for conformal coatings in the region.

Europe: Strict regulatory standards for electronic devices and automotive components boost adoption of high-performance conformal coatings.

Asia Pacific: Dominant region in electronics manufacturing, automotive production, and consumer electronics, fueling market growth for conformal coatings.

Latin America, Middle East & Africa: Emerging markets witnessing increased industrialization and infrastructure development contribute to market opportunities for conformal coatings.

Market Drivers and Challenges

Drivers:

Electronic Device Miniaturization: Shrinking electronic components require advanced protection against environmental factors, driving demand for conformal coatings.

Automotive and Aerospace Innovations: Complex electronic systems in vehicles and aircraft demand reliable protection solutions, boosting coating market growth.

Stringent Quality Standards: Compliance with industry standards and regulations mandates the use of reliable conformal coatings for critical applications.

Challenges:

Technological Complexity: Evolving electronics and materials require continuous innovation in coating formulations and application methods.

Environmental Concerns: Proper handling, disposal, and recycling of coating materials pose sustainability challenges for the industry.

Cost Pressures: Balancing performance requirements with cost-effectiveness remains a challenge for coating manufacturers and end-users.

Market Trends

Emergence of Nano-coatings: Development of nano-scale conformal coatings for enhanced protection, moisture resistance, and electrical insulation.

Environmentally Friendly Formulations: Adoption of eco-friendly materials, solvent-free coatings, and recycling initiatives to address sustainability concerns.

Smart Coatings: Integration of functional properties such as self-healing, anti-corrosion, and antimicrobial features in conformal coatings for specialized applications.

Future Outlook

The conformal coatings market is poised for continued growth driven by technological advancements, expanding applications across industries, and regulatory imperatives for product reliability and performance. Market players focusing on innovation, sustainability, and strategic partnerships will be well-positioned to capitalize on emerging opportunities and address evolving customer needs.

Key Market Study Points

Market size and growth projections for conformal coatings

Segmentation analysis based on service type, sourcing type, application, industry vertical, and region

Regional dynamics, regulatory landscapes, and market trends

Drivers, challenges, and opportunities shaping the market landscape

Future outlook and growth strategies for stakeholders

Conformal Coatings Market for PCBs: Competitive Landscape

The Conformal Coatings Market for PCBs is fiercely competitive, characterized by key players like Henkel AG & Co. KGaA, Dow Chemical Company, and Chase Corporation. These industry giants dominate with extensive product portfolios and global presence. Emerging players such as MG Chemicals and Electrolube are rapidly gaining traction, offering innovative formulations and tailored solutions to meet specific customer needs.

Buy this Premium Research Report @ https://www.transparencymarketresearch.com/checkout.php?rep_id=44288<ype=S

Competition is driven by factors like product performance, environmental regulations, and technological advancements. As electronics become more pervasive across industries, the demand for high-quality conformal coatings continues to rise, intensifying competition and spurring innovation in the market. Some prominent players are as follows:

Henkel AG & Co. KGaA

Dow

Chase Corporation

Electrolube

Shin-Etsu Chemical Co. Ltd.

Europlasma N.V.

B. Fuller Company

MG Chemicals

Al Technology Inc.

Chemtronics

Aalpha Conformal Coatings

KISCO Ltd.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Introduction to Audio Amplifier PCBs

The initial section would set the stage by outlining the critical role of PCBs in audio amplification, emphasizing their impact on sound quality and system reliability. It would introduce the reader to the basic types of audio amplifier PCBs, such as Class A, Class B, Class AB, and Class D, each offering distinct advantages and suited for different applications.

Detailed Analysis of PCB Components and Design

A thorough exploration of the components that make up an audio amplifier PCB would follow. This would include an in-depth look at resistors, capacitors, inductors, and the various semiconductor devices such as transistors and integrated circuits. The discussion would extend to design considerations like PCB layout, signal integrity, noise reduction, and thermal management, crucial for optimizing performance and durability.

Material Science and Innovation

This section would delve into the materials used in PCB construction, comparing traditional materials like FR4 with more advanced options like metal-core boards, particularly focusing on their thermal conductivity and durability under high-power conditions. Innovations such as flexible PCBs for more compact and versatile designs would also be highlighted.

Manufacturing Processes and Quality Assurance

The manufacturing process for audio amplifier PCBs would be examined, from etching and drilling to plating and final assembly. Quality assurance processes, including testing methods like Automated Optical Inspection (AOI), In-Circuit Testing (ICT), and functional testing, would be detailed to emphasize their importance in ensuring product reliability.

Applications and Case Studies

Real-world applications of audio amplifier PCBs in various industries would be presented. This would include their use in consumer electronics, automotive audio systems, professional audio equipment, and even in military applications. Case studies from leading manufacturers and designers would illustrate how innovative PCB design has solved specific audio challenges or enhanced performance.

Regulatory and Environmental Considerations

Compliance with international standards such as the IPC (Institute for Printed Circuits) standards, and environmental regulations like RoHS (Restriction of Hazardous Substances) and REACH (Registration, Evaluation, Authorization, and Restriction of Chemicals) would be covered. This section would discuss how these regulations impact the design and disposal of audio amplifier PCBs and what steps manufacturers are taking to reduce environmental impact.

The Future of Audio Amplifier PCBs

Exploring future trends and technologies, this section would speculate on the advancements in PCB design and materials, such as the integration of AI for smart diagnostics and the use of graphene and other nanomaterials for enhanced performance. It would also consider the impact of emerging markets and technologies on the demand and design of audio amplifier PCBs.

Conclusion

The final part of the guide would summarize the critical points discussed, reinforcing the importance of innovative, well-designed audio amplifier PCBs in the advancement of audio technology. It would also encourage ongoing research and development efforts within the field to meet the evolving demands of the industry.

This extensive guide would not only serve as an educational tool but also as a reference for designing next-generation audio amplifier PCBs, combining theoretical knowledge with practical insights to push the boundaries of audio technology.

0 notes

Text

SMD Thick Film Resistor, Global Market Size Forecast, Top 14 Players Rank and Market Share

SMD Thick Film Resistor Market Summary

Surface Mount Device (SMD) thick film resistors are electronic components used in circuitry to control the flow of electric current. These resistors are made using a thick film deposition process, where a resistive paste is printed onto a ceramic substrate and then baked to form the resistive element. SMD thick film resistors are designed for surface mounting onto printed circuit boards (PCBs), offering advantages like space efficiency, ease of automated assembly, and good stability under various operating conditions. They come in various sizes and power ratings, catering to different application needs. The "thick film" aspect refers to the thicker layer of resistive material compared to thin film resistors, providing different electrical and thermal properties.

Figure. SMD Thick Film Resistors Product Picture

Source: Secondary Sources and QYResearch, 2024

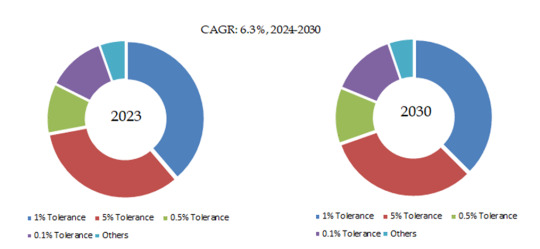

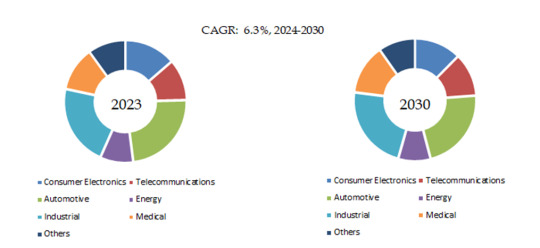

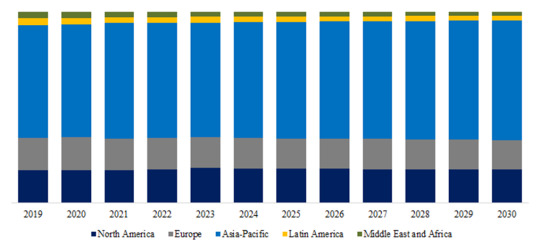

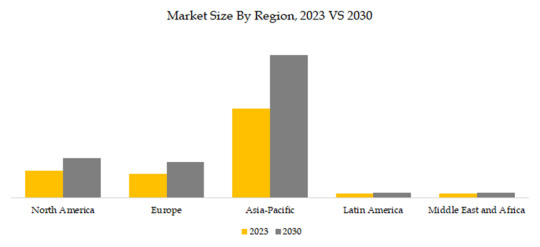

According to the new market research report “Global SMD Thick Film Resistor Market Report 2023-2030”, published by QYResearch, the global SMD Thick Film Resistor market size is projected to reach USD 2.55 billion by 2030, at a CAGR of 6.3% during the forecast period.

Figure. Global SMD Thick Film Resistor Market Size (US$ Million), 2019-2030

Above data is based on report from QYResearch: Global SMD Thick Film Resistor Market Report 2023-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

Figure. Global SMD Thick Film Resistor Top 14 Players Ranking and Market Share (Ranking is based on the revenue of 2023, continually updated)

Above data is based on report from QYResearch: Global SMD Thick Film Resistor Market Report 2023-2030 (published in 2024). If you need the latest data, plaese contact QYResearch.

According to QYResearch Top Players Research Center, the global key manufacturers of SMD Thick Film Resistor include Yageo, KOA, Walsin Technology, Vishay, Fenghua Advanced Technology, Ta-I Technology, Panasonic, Samsung Electro-Mechanics, Rohm, UniOhm, etc. In 2023, the global top 10 players had a share approximately 84.0% in terms of revenue.

Figure. SMD Thick Film Resistor, Global Market Size, Split by Product Segment

Based on or includes research from QYResearch: Global SMD Thick Film Resistor Market Report 2023-2030.

In terms of product type, 1% Tolerance is the largest segment, hold a share of 38.7%,

Figure. SMD Thick Film Resistor, Global Market Size, Split by Application Segment

Based on or includes research from QYResearch: Global SMD Thick Film Resistor Market Report 2023-2030.

In terms of product application, Automotive is the largest application, hold a share of 23.4%,

Figure. SMD Thick Film Resistor, Global Market Size, Split by Region

Based on or includes research from QYResearch: Global SMD Thick Film Resistor Market Report 2023-2030.

Market Drivers:

D1: Consumer Electronics Boom: The continuous growth in consumer electronics, including smart devices, home appliances, and entertainment systems, has contributed to the demand for SMD Thick Film Resistors in various applications.

D2: There is a stable demand for SMD thick film resistors in the automotive, industrial, medical, Telecommunication, energy and other fields of various countries.

D3: Growth in Demand in Emerging Economies such as China, India, Southeast Asia, Brazil etc.

Restraint:

R1: Price Volatility: Fluctuations in raw material prices used in SMD Thick Film Resistors, can affect production costs and subsequently impact pricing strategies.