#CAD simulation

Explore tagged Tumblr posts

Text

Revolutionizing Product Development: Harnessing AI-Driven CAD Simulation in 2024

In the ever-evolving landscape of product development, innovation reigns supreme. As we navigate through the complexities of design, prototyping, and manufacturing, one technology stands out as a game-changer: AI-driven Computer-Aided Design (CAD) simulation. In 2024, this revolutionary approach is transforming how we conceive, refine, and produce products, optimizing efficiency, reducing costs, and pushing the boundaries of what's possible.

The Evolution of CAD Simulation

CAD simulation has long been a cornerstone of product development, allowing engineers and designers to test concepts virtually before investing time and resources into physical prototypes. However, traditional simulation methods often fall short in accurately predicting real-world behavior due to simplifications and assumptions inherent in their algorithms.

Enter Artificial Intelligence (AI). With advancements in machine learning and computational power, AI-driven CAD simulation has emerged as a disruptive force, enabling engineers to simulate complex scenarios with unprecedented accuracy and efficiency. By learning from vast datasets and iteratively improving models, AI empowers simulations to mimic real-world conditions with remarkable fidelity.

The Power of AI in CAD Simulation

At the heart of AI-driven CAD simulation lies its ability to adapt and evolve. Unlike static simulation models, AI algorithms continuously refine themselves, learning from each iteration to deliver more accurate results. This adaptive approach not only enhances predictive capabilities but also reduces the need for manual intervention, accelerating the design iteration cycle.

Moreover, AI-driven CAD simulation excels in handling complexity. Whether it's simulating fluid dynamics in aerodynamic designs, predicting structural integrity under varying loads, or optimizing thermal management in electronic devices, AI algorithms can tackle multifaceted problems with ease. By simulating intricate interactions between components and subsystems, engineers can uncover insights that would be impossible to glean through traditional methods.

Streamlining Design Iterations

In traditional product development workflows, iterating on design iterations can be a time-consuming and resource-intensive process. Each iteration requires modifications to CAD models, followed by simulation runs to evaluate performance—a cycle that can stretch on for days or even weeks.

AI-driven CAD simulation revolutionizes this process by automating and accelerating design iterations. By leveraging AI to generate and evaluate design alternatives, engineers can explore a vast design space in a fraction of the time. With AI acting as a virtual assistant, suggesting optimizations and highlighting potential pitfalls, designers can focus their expertise on creative problem-solving rather than mundane tasks.

Enhancing Collaboration and Knowledge Sharing

In today's interconnected world, collaboration is key to innovation. AI-driven CAD simulation facilitates collaboration by providing a common platform for engineers, designers, and domain experts to converge and share insights. By centralizing simulation data and results, teams can collaborate in real-time, seamlessly exchanging feedback and ideas to drive the design process forward.

Furthermore, AI-driven CAD simulation democratizes knowledge sharing by capturing and codifying expertise within simulation models. As AI algorithms learn from the collective experience of engineers, they become repositories of domain knowledge, capable of guiding less experienced practitioners through complex design challenges. This democratization of expertise not only accelerates skill development but also fosters a culture of continuous learning and improvement within organizations.

Optimizing Manufacturing Processes

Beyond the design phase, AI-driven CAD simulation plays a crucial role in optimizing manufacturing processes. By simulating manufacturing operations, such as machining, molding, or additive manufacturing, engineers can identify potential bottlenecks, optimize tool paths, and minimize material waste. This holistic approach to product development ensures that designs are not only functional and aesthetically pleasing but also manufacturable at scale.

Moreover, AI-driven CAD simulation enables predictive maintenance, allowing manufacturers to anticipate and address equipment failures before they occur. By analyzing real-time sensor data and historical performance trends, AI algorithms can identify early warning signs of impending failures, enabling proactive maintenance interventions to minimize downtime and maximize productivity.

Overcoming Challenges and Ethical Considerations

While the potential of AI-driven CAD simulation is immense, it's not without its challenges and ethical considerations. Chief among these is the issue of bias in AI algorithms, which can inadvertently perpetuate existing disparities and inequalities. Addressing bias requires a concerted effort to diversify datasets, interrogate algorithmic decision-making processes, and implement safeguards to mitigate potential harms.

Furthermore, the widespread adoption of AI-driven CAD simulation raises questions about data privacy and security. As simulation models become increasingly reliant on proprietary data, safeguarding intellectual property and sensitive information becomes paramount. Robust encryption protocols, access controls, and audit trails are essential components of a comprehensive data security strategy.

Looking Ahead: The Future of Product Development

As we look ahead to the future of product development, the role of AI-driven CAD simulation will only continue to expand. From autonomous vehicles to sustainable infrastructure, AI-powered simulations will drive innovation across industries, unlocking new possibilities and pushing the boundaries of what's achievable.

However, realizing this vision requires a collective effort from stakeholders across academia, industry, and government. By fostering collaboration, investing in research and development, and prioritizing ethical considerations, we can harness the full potential of AI-driven CAD simulation to build a better, more sustainable future for all.

Conclusion

AI-driven CAD simulation represents a paradigm shift in product development, revolutionizing how we conceive, design, and manufacture the products of tomorrow. By leveraging the power of AI to simulate complex scenarios, streamline design iterations, and optimize manufacturing processes, we can unlock new opportunities for innovation and drive positive change on a global scale.

Outsourcing CAD simulation services optimizes product design by tapping into specialized expertise and resources beyond internal capabilities. Skilled professionals conduct simulations, detecting flaws and enhancing performance. This streamlined approach reduces costs and time-to-market by swiftly addressing design issues. Access to cutting-edge tools and diverse perspectives enhances design robustness and efficiency, fostering innovation and competitiveness.

#product development#product design#CAD simulation#Artificial Intelligence (AI)#machine learning#computational power#AI-driven CAD simulation#Outsourcing CAD simulation services

0 notes

Text

CAD/FEA Engineering Services: Optimizing Product Design and Performance with Advanced Simulation

In today's rapidly evolving engineering landscape, Computer-Aided Design (CAD) and Finite Element Analysis (FEA) have become indispensable tools for product development and optimization. These technologies enable engineers to create detailed digital models and simulate real-world conditions, leading to more efficient and reliable designs.

Understanding CAD and FEA

Computer-Aided Design (CAD):

CAD involves the use of software applications to create precise 2D or 3D models of physical components. Tools like AutoCAD, Inventor, SolidWorks, and Creo facilitate the development of detailed geometric representations, allowing for comprehensive visualization and modification of designs before physical prototypes are made.

Finite Element Analysis (FEA):

FEA is a computational technique used to predict how products react to real-world forces, such as heat, vibration, and other physical effects. By breaking down complex structures into smaller elements, FEA software can simulate and analyze the behavior of each component under various conditions, providing insights into potential performance issues.

The Synergy of CAD and FEA in Engineering

Integrating CAD and FEA engineering services allows engineers to design and analyze products within a unified digital environment. This integration streamlines the development process, enabling rapid iterations and refinements based on simulation results. For instance, a design created in CAD can be directly imported into FEA software for stress analysis, facilitating immediate feedback and optimization.

Applications Across Industries

The combined use of CAD and FEA spans various industries, including:

Aerospace: Designing and analyzing flight control systems and structural components to ensure safety and performance.

Automotive: Optimizing vehicle structures for weight reduction while maintaining structural integrity.

Manufacturing: Developing machinery and equipment with enhanced durability and efficiency.

Benefits of CAD/FEA Engineering Services

Engaging specialized CAD/FEA engineering services offers several advantages:

Cost Reduction: By identifying potential design flaws early through simulation, companies can avoid costly physical prototypes and rework.

Improved Performance: Simulations enable the optimization of designs for better performance under specific conditions.

Accelerated Time-to-Market: Streamlined design and analysis processes lead to faster product development cycles.

Servotech Inc.: Expertise in CAD/FEA Design and Analysis

Servotech Inc. specializes in providing comprehensive CAD/FEA design and analysis services. Utilizing advanced software tools, their team designs mechanical systems with 3D solid modeling, ensuring adherence to geometric dimensioning and tolerancing standards. They integrate these designs with FEA software to simulate conditions such as stress, temperature, and fluid dynamics, offering clients precise and efficient engineering solutions.

Conclusion

The integration of CAD and FEA in engineering services by Servotech has revolutionized the way products are designed and analyzed. By leveraging these technologies, companies can achieve optimized designs, reduce costs, and accelerate development timelines. Servotech Inc.'s expertise in this domain exemplifies the benefits of adopting advanced simulation tools in modern engineering practices.

#CAD#FEA#EngineeringDesign#ProductDevelopment#FiniteElementAnalysis#3DModeling#Simulation#StructuralAnalysis#MechanicalEngineering#ServotechInc

0 notes

Text

Menghubungkan Model CAD dengan Simulasi

Dalam dunia rekayasa modern, penggunaan teknologi Computer-Aided Design (CAD) telah menjadi standar dalam proses perancangan produk. Model CAD memungkinkan para insinyur dan desainer untuk membuat representasi digital dari suatu objek dengan tingkat akurasi yang tinggi. Namun, tantangan muncul ketika model CAD ini harus dikonversi ke dalam lingkungan simulasi guna menguji performa dan keandalan desain sebelum diproduksi secara nyata. Proses penghubungan model CAD dengan simulasi bukan sekadar memindahkan file, tetapi juga melibatkan berbagai aspek teknis seperti penyederhanaan geometri, pemilihan parameter material, dan validasi hasil simulasi.

Integrasi yang efektif antara model CAD dan simulasi memberikan banyak manfaat, termasuk penghematan biaya produksi, percepatan siklus pengembangan produk, serta peningkatan kualitas desain. Dengan memanfaatkan simulasi, para insinyur dapat mengidentifikasi potensi kegagalan lebih awal dan mengoptimalkan desain sebelum prototipe fisik dibuat. Oleh karena itu, memahami proses penghubungan model CAD dengan simulasi menjadi hal yang sangat penting dalam dunia industri manufaktur, otomotif, kedirgantaraan, dan berbagai bidang teknik lainnya.

Tantangan dalam Menghubungkan Model CAD dengan Simulasi

Ketika menghubungkan model CAD dengan simulasi, terdapat beberapa tantangan yang perlu diatasi agar proses berjalan dengan lancar dan hasil simulasi tetap akurat. Beberapa tantangan utama meliputi:

Kompleksitas Geometri: Model CAD sering kali memiliki tingkat detail yang sangat tinggi, yang dapat menyebabkan simulasi menjadi lambat atau tidak efisien.

Kompatibilitas Format File: Berbagai perangkat lunak CAD dan simulasi menggunakan format file yang berbeda, sehingga perlu adanya konversi data yang tepat agar informasi tetap utuh.

Definisi Material dan Beban: Model CAD biasanya tidak menyertakan properti material atau kondisi pembebanan, sehingga insinyur harus menambahkannya secara manual dalam perangkat lunak simulasi.

Penyederhanaan Geometri CAD: Proses ini diperlukan untuk menghilangkan detail yang tidak relevan dalam simulasi, seperti fillet kecil, lubang, atau fitur dekoratif yang tidak mempengaruhi performa mekanis.

Langkah-langkah Mengintegrasikan Model CAD dengan Simulasi

Agar integrasi antara model CAD dan simulasi dapat berjalan dengan baik, ada beberapa langkah penting yang harus dilakukan:

Pemilihan Format File yang Tepat

Format file yang digunakan dalam perangkat lunak CAD sering kali berbeda dengan yang digunakan dalam perangkat lunak simulasi. Oleh karena itu, penting untuk memilih format file yang kompatibel, seperti STEP, IGES, atau STL. Format ini memungkinkan pertukaran data yang lebih mudah tanpa kehilangan informasi geometri yang esensial.

Penyederhanaan Geometri CAD

Model CAD sering kali memiliki detail berlebih yang tidak diperlukan dalam simulasi, seperti chamfer kecil atau logo yang hanya menambah beban komputasi. Oleh karena itu, penyederhanaan geometri CAD menjadi langkah penting dalam mempercepat simulasi tanpa mengurangi keakuratan hasilnya.

Definisi Material dan Kondisi Pembebanan

Setelah model CAD disiapkan, langkah selanjutnya adalah menambahkan properti material dan kondisi pembebanan. Properti material mencakup parameter seperti kekuatan tarik, modulus elastisitas, dan kepadatan, yang sangat penting dalam simulasi berbasis elemen hingga (Finite Element Analysis/FEA). Sementara itu, kondisi pembebanan meliputi gaya, tekanan, atau suhu yang akan diterapkan pada model selama simulasi.

Pembuatan Mesh untuk Simulasi

Dalam simulasi berbasis elemen hingga, model CAD harus dikonversi menjadi elemen diskrit yang disebut mesh. Proses meshing sangat penting karena kualitas mesh akan mempengaruhi akurasi dan efisiensi simulasi. Pemilihan ukuran elemen mesh yang optimal menjadi kunci untuk mendapatkan hasil yang akurat dengan waktu komputasi yang wajar.

Validasi dan Interpretasi Hasil Simulasi

Setelah simulasi selesai dijalankan, langkah terakhir adalah memvalidasi dan menginterpretasi hasilnya. Hal ini melibatkan analisis terhadap deformasi, tegangan, atau distribusi suhu pada model yang diuji. Jika hasil simulasi menunjukkan ketidaksesuaian dengan ekspektasi, model CAD dapat diperbaiki dan diuji ulang hingga desain yang optimal ditemukan.

Manfaat Menghubungkan Model CAD dengan Simulasi

Integrasi model CAD dengan simulasi memberikan banyak keuntungan bagi industri teknik dan manufaktur, di antaranya:

Pengurangan Biaya dan Waktu Pengembangan: Dengan melakukan simulasi lebih awal, perusahaan dapat menghindari kesalahan desain yang mahal dan mengurangi jumlah prototipe fisik yang harus dibuat.

Peningkatan Kualitas Produk: Simulasi memungkinkan pengujian berbagai skenario beban dan kondisi lingkungan, sehingga desain dapat dioptimalkan untuk performa terbaik.

Keamanan dan Kepatuhan Standar: Dalam industri seperti otomotif dan kedirgantaraan, simulasi dapat membantu memastikan bahwa produk memenuhi standar keamanan dan regulasi yang ketat.

Inovasi Lebih Cepat: Dengan proses desain yang lebih efisien, perusahaan dapat lebih cepat dalam mengembangkan inovasi baru dan merespons kebutuhan pasar.

Menghubungkan model CAD dengan simulasi adalah langkah penting dalam proses rekayasa modern yang memungkinkan desainer dan insinyur untuk mengevaluasi dan meningkatkan desain sebelum produksi. Tantangan seperti kompatibilitas format file, kompleksitas geometri, dan definisi material dapat diatasi dengan langkah-langkah yang sistematis, termasuk penyederhanaan geometri CAD, pemilihan format file yang tepat, dan pembuatan mesh berkualitas tinggi.

Dengan integrasi yang baik antara CAD dan simulasi, perusahaan dapat menghemat biaya, meningkatkan kualitas produk, dan mempercepat inovasi, menjadikannya strategi yang tak terpisahkan dalam dunia industri masa kini.

0 notes

Text

youtube

Welcome to Episode 7 of the "CAE Simulation using SolidWorks" series! 🎉 In this video, we’ll dive into Fatigue Analysis, exploring how repetitive loading affects the life and durability of materials. Using an S-hook model, we’ll demonstrate the setup, analysis, and interpretation of fatigue life and damage results. Whether you’re analyzing gold ornaments or industrial components, this tutorial will sharpen your simulation skills. 🌟 📌Key Highlights: Why Fatigue Analysis Matters: Real-world applications explained 🔍 Understanding S-N Curves: Predicting material failure under cyclic loads 📊 Types of Loading in SolidWorks: Fully reversed, zero-based, and more ⚙️ Step-by-Step Fatigue Analysis Setup 🛠️ Interpreting results: Damage and Life Predictions

💡 Pro tips for optimizing designs to extend fatigue life 🚀 Check out the episodes of this series here!

https://www.youtube.com/playlist?list=PL9-f9hWLZS61PrvBWiw94i5Kx3xjaFRnx

If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/4fPCi4a

#SolidWorks#FEA#FiniteElementAnalysis#EngineeringSimulation#CAE#SolidWorksTutorial#StressStrain#Meshing#EngineeringDesign#SimulationSoftware#MechanicalEngineering#CAD#LearnSolidWorks#Simulation#skilllync#Youtube

0 notes

Text

Precision and Innovation: Exploring the Role of Engineering Design and CAD Drawing Services

Imagine constructing a skyscraper or designing a complex machine without a detailed plan. This is where Engineering Design Services come into play, transforming abstract ideas into detailed blueprints. These services are essential in laying the groundwork for successful engineering projects, ensuring every aspect is meticulously planned and executed with precision.

Strategic Impact of Engineering Design Services

In the competitive world of engineering, Engineering Design Services provide a significant edge. They refine not only the aesthetic appeal of a project but also its functionality and sustainability. By collaborating with clients and stakeholders, these services ensure that every element of a project aligns with technical specifications and overall vision, setting the stage for successful implementation and long-term success.

The Role of CAD Drawing Services in Modern Engineering

Once the design phase is complete, the focus shifts to detailed visualizations provided by CAD Drawing Services. These services are indispensable in modern engineering, allowing for the creation of precise and detailed drawings. By visualizing every component in three dimensions, engineers and architects can ensure that all parts fit together seamlessly, reducing the risk of errors during the construction phase.

Enhancing Precision with CAD Drawing Services

The advancements in CAD Drawing Services have revolutionized the way engineering projects are visualized and executed. These services allow for the manipulation of intricate 3D models, providing a virtual simulation of the final product. This not only enhances the precision of the design but also allows for modifications to be made easily, ensuring that the final product meets all requirements and standards.

Navigating Future Challenges with Advanced Design Techniques

As technology continues to evolve, the integration of AI and machine learning with Engineering Design Services is becoming increasingly important. These advanced techniques provide predictive insights and automated design adjustments, which are crucial for managing complex projects. Similarly, CAD Drawing Services are evolving to include virtual reality and augmented reality, offering immersive experiences that allow for better design comprehension and client engagement.

Ensuring Compliance and Global Standards

In the evolving landscape of global industries, adhering to international standards and regulations is crucial for success. Engineering Design Services and CAD Drawing Servicesplay a pivotal role in ensuring that projects meet these stringent requirements. By incorporating global best practices and standards into the design and drafting processes, these services help companies expand their reach and maintain competitiveness in international markets. This focus on compliance not only ensures safety and quality but also enhances the credibility and reputation of businesses in the global arena.

Conclusion

In a world where precision and efficiency are paramount, the roles of Engineering Design Services and CAD Drawing Services are more critical than ever. For businesses looking to leverage these advanced services, visitingfeamax.comoffers a gateway to industry-leading expertise and innovative solutions. Whether it’s refining a complex design or ensuring that every component fits perfectly, the right design services can transform potential into reality, driving success in every project.

Blog Source URL :

#Computational Fluid Dynamics Consulting#CFD Consulting Services#Cad Design Services#Computer Aided Design Services#Engineering Design Services#Cad Drawing Services#FEA Consulting Services#Finite Element Analysis Consultants#FEA Simulation Services#Engineering Manufacturing Services#Manufacturing Sourcing Services#Mold Flow Analysis#Moldflow Service#Moldflow And Casting Analysis

0 notes

Text

Maximize Design Efficiency with MSD Facilitators: Premier SolidWorks Solutions Provider

MSD Facilitators, a trusted North Indian reseller of Dassault Systèmes SolidWorks, offers a robust suite of CAD/CAM solutions tailored to meet the needs of modern industries. Their key offerings include:

SolidWorks 3D CAD: Industry-leading software for precise and efficient 3D modeling and design.

SolidWorks Simulation: Powerful tools for validating and optimizing designs through virtual testing.

SolidWorks Electrical: Streamlines electrical system designs with automated workflows.

SolidWorks PDM: Organizes and manages product data to ensure collaboration and version control.

SolidWorks Technical Communication: Simplifies documentation creation for complex designs.

SolidWorks CAM: Facilitates seamless CNC machining with integrated manufacturing tools.

By leveraging these advanced solutions, businesses can enhance product development, reduce time-to-market, and maintain high quality standards. MSD Facilitators also provides training, implementation support, and technical services to ensure their clients make the most of these tools. Their expertise spans across industries, from automotive to consumer electronics, helping organizations thrive in today’s competitive market.

Why Choose MSD Facilitators?

Authorized Reseller: MSD Facilitators is an official SolidWorks partner, ensuring authenticity and excellence in service.

Tailored Solutions: Whether you need design validation, electrical system management, or PDM support, MSD Facilitators customizes solutions for your specific needs.

Training & Support: They offer comprehensive training, ensuring teams can effectively use SolidWorks software.

Industry Expertise: Backed by years of experience, they serve multiple industries, improving product development workflows for companies large and small.

Driving Innovation Through SolidWorks

From conceptualization to final production, SolidWorks’ integrated platform helps businesses innovate. By using advanced simulation tools, engineers can test product durability and performance without costly physical prototypes. SolidWorks Electrical ensures flawless integration of electrical systems with mechanical components, while SolidWorks CAM allows for precise manufacturing with CNC capabilities. These tools help reduce development time, lower production costs, and increase product quality, providing a significant competitive edge.

For businesses in North India looking to optimize their product design processes, MSD Facilitators offers unmatched service and expertise in SolidWorks solutions. From CAD design to PDM integration, they empower industries to stay ahead in the fast-evolving market.

For more information, visit MSD Facilitators.

1 note

·

View note

Text

Stainless Steel Rod Simulation in SolidWorks

0 notes

Text

Engineering DNA offers custom engineering solutions including 3D printing, reverse engineering, drafting, and simulations. Specializing in production engineering, product design, and CFD simulation, we deliver accuracy and excellence. Contact us today for innovative mechanical design and FEA Analysis services.

#3D Printing Design#Reverse Engineering Services#Drafting Services#3D Simulation#Interior design 3D Modeling#CFD Simulation#Product Design Engineering#3D Modeling for 3D Printing#Manufacturing Engineering#Finite Element Analysis Services#Design and Drafting Services#3D CAD Services#Manufacturing Engineering Services#3D Modeling Services#3D Design Services

0 notes

Text

Computer-Aided Design and which Design is Best.

As products become more complex they become more fragile. It is necessary to focus on product robustness by making products less complex. This may be accomplished by using OntoNet™, our QCM Engine. OntoNet™ allows users to: Measure the robustness of a design/component Measure the complexity of a design/component Identify the drivers of design robustness and complexity Perform…

View On WordPress

#CAD#CAE#Complexity#Computer Aided Design#Computer Aided Engineering#fragility#Monte Carlo Simulation#Ontonet#resilience

0 notes

Text

Wing-chair by Range Murata Fa Documenta - 001+002 Collection Catalouge

"This item was the first challenge in the furniture genre. It was designed using CAD drawings and CG simulations and even involved overseas production. Although it is inspired by the wings of an airplane, the integration of wood and iron, as well as the functionality and structure of reclining, are extremely complex. Currently, we are looking for manufacturers capable of solving these challenges."

123 notes

·

View notes

Text

How CAD Role Enhances Accessibility in Aerospace Engineering

In the ever-evolving landscape of aerospace engineering, the importance of accessibility and inclusivity cannot be overstated. As technological advancements push the boundaries of what's possible in flight and space exploration, there's a critical need to ensure that these innovations are accessible to all individuals, regardless of physical abilities or limitations. This is where Computer-Aided Design (CAD) emerges as a pivotal tool in shaping the future of aerospace.

CAD: The Foundation of Aerospace Design

CAD has revolutionized the aerospace industry by providing engineers with powerful tools to create, modify, analyze, and optimize designs with unparalleled precision and efficiency. From the conceptualization phase to the final product, CAD software allows designers to visualize every component and system in three dimensions, enabling them to foresee potential challenges and refine designs before they are physically realized.

Accessibility Challenges in Aerospace Design

Designing aerospace systems and vehicles that are accessible poses unique challenges. Traditional designs often overlook the diverse range of physical abilities among potential users, leading to structures and interfaces that may not accommodate individuals with disabilities. Whether it's the layout of cockpit controls, seating arrangements, or the accessibility of maintenance areas, each aspect must be carefully considered to ensure inclusivity without compromising safety or performance.

How CAD Addresses Accessibility

CAD plays a crucial role in addressing these challenges by facilitating iterative design processes that prioritize accessibility from the outset. Here are key ways CAD contributes to creating accessible aerospace designs:

Virtual Prototyping and Simulation: CAD allows designers to create virtual prototypes that can be tested and modified extensively before physical production begins. This capability is invaluable in identifying accessibility issues early in the design phase and iterating rapidly to find optimal solutions.

Customization and Adaptation: CAD enables the customization of designs to meet specific accessibility requirements. Whether it involves adjusting control interfaces, optimizing cabin layouts for wheelchair accessibility, or designing intuitive user interfaces, CAD tools empower engineers to tailor solutions that cater to diverse user needs.

Collaboration and Stakeholder Engagement: CAD facilitates collaboration among multidisciplinary teams, including accessibility experts and end-users. By incorporating diverse perspectives throughout the design process, engineers can gain valuable insights into how their designs impact accessibility and make informed decisions to enhance inclusivity.

Visualization and Documentation: CAD software produces detailed visualizations and documentation that are crucial for communicating design intentions and specifications. This clarity is essential for ensuring that manufacturing processes adhere to accessibility standards and that maintenance procedures are straightforward and accessible to all technicians.

Innovations and Future Directions

Looking ahead, the integration of CAD with emerging technologies such as virtual reality (VR) and augmented reality (AR) holds promise for further enhancing accessibility in aerospace design. These technologies can provide immersive experiences that allow designers and stakeholders to experience designs firsthand, gaining deeper insights into usability and accessibility considerations.

Moreover, as aerospace companies embrace principles of universal design—designing products and environments to be usable by all people, to the greatest extent possible, without the need for adaptation or specialized design. CAD will continue to play a pivotal role in realizing these aspirations.

Conclusion

In conclusion, the role of CAD in ensuring accessible and inclusive aerospace designs cannot be overstated. By leveraging CAD's capabilities to prioritize accessibility from the outset, aerospace engineers have the power to transform the industry, making space exploration and aviation more inclusive and accessible than ever before. As we continue to push the boundaries of what's possible in aerospace technology, let us also strive to ensure that these advancements benefit all individuals, regardless of their physical abilities or limitations.

By embracing the principles of inclusivity and leveraging the potential of CAD, we can create a future where aerospace innovation knows no bounds and where everyone can participate in and benefit from the wonders of flight and space exploration.

#CAD tools#CAD role#aerospace engineering#accessibility#aerospace products#CAD techniques#aerospace design#design simulation#CAD accessibility#CAD technology#aerospace accessibility#aerospace engineers#sustainable aerospace#engineering#CAD design#CAD drafting#CAD outsourcing#CAD services

0 notes

Text

Finite Element Analysis (FEA) Engineering Services: Enhancing Product Development and Structural Integrity

Finite Element Analysis (FEA) has become an indispensable tool in modern engineering, enabling the simulation and analysis of complex structures and systems under various conditions. By breaking down intricate geometries into smaller, manageable elements, FEA allows engineers to predict how products will react to real-world forces, vibrations, heat, and other physical effects. This article delves into the significance of FEA engineering services, their applications, benefits, and the process involved, with a particular focus on the offerings of Servotech Inc.

Understanding Finite Element Analysis (FEA)

FEA is a computational technique used to approximate the behavior of physical systems. It involves subdividing a complex structure into finite elements—small, simple shapes like triangles or quadrilaterals in 2D, and tetrahedrons or hexahedrons in 3D. By applying known material properties and boundary conditions, engineers can solve the governing equations for each element, thereby predicting the overall behavior of the entire structure.

Applications of FEA Engineering Services

FEA engineering services are utilized across various industries to address a multitude of challenges:

1.Structural Analysis: Assessing stress, strain, and deformation in components to ensure they can withstand operational loads without failure.

2.Thermal Analysis: Evaluating temperature distribution and heat flow within systems to prevent overheating and ensure thermal efficiency.

3.Dynamic Analysis: Studying the response of structures to time-dependent loads, such as vibrations and impacts, to mitigate resonance and fatigue issues.

4.Fluid-Structure Interaction: Analyzing the interaction between fluids and solid structures, crucial in designing efficient aerospace and automotive components.

5.Electromagnetic Analysis: Investigating electromagnetic fields within devices to optimize performance and ensure compliance with regulatory standards.

Benefits of FEA in Engineering

The integration of FEA into the engineering design process offers several advantages:

Cost Reduction: By identifying potential issues early in the design phase, FEA minimizes the need for physical prototypes, thereby reducing material and labor costs.

Enhanced Performance: FEA enables optimization of designs for weight, strength, and durability, leading to superior product performance.

Risk Mitigation: Predicting failure modes and identifying critical stress points help in designing safer products, thereby reducing liability and warranty claims.

Accelerated Development: Virtual testing through FEA shortens the product development cycle, allowing faster time-to-market.

The FEA Process at Servotech Inc.

Servotech Inc. offers comprehensive CAD/FEA design and analysis services, employing a systematic approach to ensure accurate and reliable results:

Pre-Processing:

Geometry Creation: Utilizing CAD software tools such as AutoCAD, Inventor, SolidWorks, and Creo, Servotech designs mechanical systems using 3D solid modeling, adhering to geometric dimensioning and tolerancing standards.

Material Properties: Defining material characteristics, including elasticity, plasticity, thermal conductivity, and density, to accurately simulate real-world behavior.

Loads and Boundary Conditions: Applying external forces, pressures, thermal loads, and constraints to replicate operational environments.

Discretization and Mesh Generation:

Mesh Creation: Dividing the geometry into finite elements, ensuring appropriate element size and shape to balance accuracy and computational efficiency.

Mesh Refinement: Enhancing mesh density in critical areas to capture stress concentrations and intricate details.

Solution:

Physics and Assumptions: Selecting the appropriate analysis type—structural, thermal, fatigue, vibration, or buckling—based on the problem's nature.

Equation Formulation: Generating FEA equations and matrices that represent the physical behavior of the system.

Analysis Execution: Running linear or non-linear analyses, depending on material behavior and load conditions, through interactive or batch processing.

Post-Processing:

Result Evaluation: Interpreting simulation outcomes, such as stress distributions, deformation patterns, temperature gradients, and natural frequencies.

Visualization: Presenting results through contour plots, graphs, and animations to facilitate comprehensive understanding.

Sub-Modeling: Focusing on specific areas of concern within large models to obtain detailed insights.

Servotech Inc.'s Expertise in CAD/FEA Design and Analysis

Servotech Inc. leverages advanced CAD and FEA tools to deliver precise engineering solutions:

Integrated Approach: Combining 3D solid modeling with FEA allows for seamless design iterations and optimization.

Comprehensive Simulations: Conducting simulations to analyze stress, pressure, temperature, and flow velocity distributions over space and time, ensuring designs meet performance criteria.

Hardware-in-the-Loop (HIL) Testing: Integrating FEA models with controllers for HIL testing visualization, enabling real-time validation of control strategies.

Case Study: Hydrostatic Transmission Control

An example of Servotech's application of FEA is the hydrostatic transmission control system

Design and Modeling: Developing a 3D model of the transmission system, incorporating all mechanical components and interfaces.

FEA Simulation: Analyzing stress distribution and deformation under various load conditions to ensure structural integrity and performance.

Optimization: Refining the design based on simulation results to enhance durability and efficiency.

Conclusion

FEA engineering services by servotech play a pivotal role in modern product development, offering insights that drive innovation, safety, and efficiency. Servotech Inc.'s expertise in CAD/FEA design and analysis exemplifies the effective application of these techniques, providing clients with optimized solutions tailored to their specific needs. By embracing FEA, industries can achieve superior

#FEA#FiniteElementAnalysis#EngineeringDesign#StructuralAnalysis#ThermalAnalysis#DynamicAnalysis#CAD#Simulation#StressAnalysis#ProductDevelopment#MechanicalEngineering#AerospaceEngineering#AutomotiveEngineering#IndustrialDesign#ComputationalModeling#DigitalTwin#EngineeringInnovation#MaterialTesting#StructuralIntegrity#ServotechInc

1 note

·

View note

Text

Prototype for our “””simulator””” horse controller for PC. Currently playable with pixel studio engine games. Next prototype will use Pi Pico MCU, two feet pedals and two joystick modules. Controller will use USB HID so no drivers needed and there will be a table mount for the controller. Also, string will be replaced with actual reins(or similar feeling strap). We have been toying with a idea of adding stirrups and saddle but those would be maybe possible in somewhere later versions. (Big maybe). Current setup is suboptimal, we’re using “submarine” controller and DDR dance mat. Time to do some CAD modelling.

#horse games#horse gaming#homebrew gaming setup#horse sim#sso#star stable#star stable online#ssoblr#sta sta#starstable#starshine legacy#Welcome to the horse game hell madness

72 notes

·

View notes

Text

youtube

Welcome to Episode 6 of the "CAE Simulation using SolidWorks" series! 🎉 In this episode, we tackle a buckling analysis challenge for a Cyclone Separator stand. Learn how to model and position a stiffener between the legs, perform buckling analysis, and use Design Studies to find the optimal stiffener position for maximum stability. This video is packed with practical tips to enhance your SolidWorks simulation skills! 💡 📌Key Highlights: How to model and position a stiffener in SolidWorks 🛠️ Setting up and running buckling analysis for structural stability 🔧 Understanding buckling factor of safety 📊 Using Design Studies to optimize stiffener placement and maximize stability ✨ Pro tips for managing parameters and constraints efficiently ⚡ Check out the episodes of this series here! https://www.youtube.com/playlist?list=PL9-f9hWLZS61PrvBWiw94i5Kx3xjaFRnx If you’re interested in speaking with our experts from Scania, Mercedes, and Nissan, and scheduling a personalized career plan, call us at +91-9342691281 or register here: https://bit.ly/4eNKlNJ

#SolidWorks#FEA#FiniteElementAnalysis#EngineeringSimulation#CAE#SolidWorksTutorial#StressStrain#Meshing#EngineeringDesign#SimulationSoftware#MechanicalEngineering#CAD#LearnSolidWorks#Simulation#Youtube

0 notes

Text

Precision and Innovation: Exploring the Role of Engineering Design and CAD Drawing Services

Imagine constructing a skyscraper or designing a complex machine without a detailed plan. This is where Engineering Design Services come into play, transforming abstract ideas into detailed blueprints. These services are essential in laying the groundwork for successful engineering projects, ensuring every aspect is meticulously planned and executed with precision.

Strategic Impact of Engineering Design Services

In the competitive world of engineering, Engineering Design Services provide a significant edge. They refine not only the aesthetic appeal of a project but also its functionality and sustainability. By collaborating with clients and stakeholders, these services ensure that every element of a project aligns with technical specifications and overall vision, setting the stage for successful implementation and long-term success.

The Role of CAD Drawing Services in Modern Engineering

Once the design phase is complete, the focus shifts to detailed visualizations provided by CAD Drawing Services. These services are indispensable in modern engineering, allowing for the creation of precise and detailed drawings. By visualizing every component in three dimensions, engineers and architects can ensure that all parts fit together seamlessly, reducing the risk of errors during the construction phase.

Enhancing Precision with CAD Drawing Services

The advancements in CAD Drawing Services have revolutionized the way engineering projects are visualized and executed. These services allow for the manipulation of intricate 3D models, providing a virtual simulation of the final product. This not only enhances the precision of the design but also allows for modifications to be made easily, ensuring that the final product meets all requirements and standards.

Navigating Future Challenges with Advanced Design Techniques

As technology continues to evolve, the integration of AI and machine learning with Engineering Design Services is becoming increasingly important. These advanced techniques provide predictive insights and automated design adjustments, which are crucial for managing complex projects. Similarly, CAD Drawing Services are evolving to include virtual reality and augmented reality, offering immersive experiences that allow for better design comprehension and client engagement.

Ensuring Compliance and Global Standards

In the evolving landscape of global industries, adhering to international standards and regulations is crucial for success. Engineering Design Services and CAD Drawing Servicesplay a pivotal role in ensuring that projects meet these stringent requirements. By incorporating global best practices and standards into the design and drafting processes, these services help companies expand their reach and maintain competitiveness in international markets. This focus on compliance not only ensures safety and quality but also enhances the credibility and reputation of businesses in the global arena.

Conclusion

In a world where precision and efficiency are paramount, the roles of Engineering Design Services and CAD Drawing Services are more critical than ever. For businesses looking to leverage these advanced services, visitingfeamax.comoffers a gateway to industry-leading expertise and innovative solutions. Whether it’s refining a complex design or ensuring that every component fits perfectly, the right design services can transform potential into reality, driving success in every project.

Blog Source URL :

#Cad Design Services#Computer Aided Design Services#Engineering Design Services#Cad Drawing Services#FEA Consulting Services#Finite Element Analysis Consultants#FEA Simulation Services#Engineering Manufacturing Services#Manufacturing Sourcing Services#Mold Flow Analysis#Moldflow Service#Moldflow And Casting Analysis

0 notes

Text

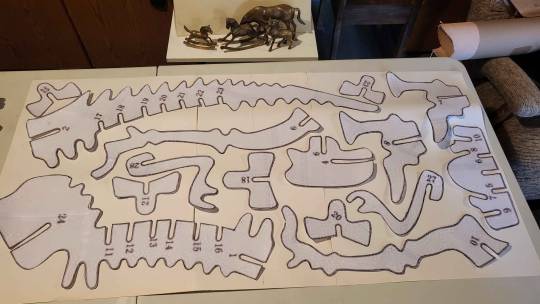

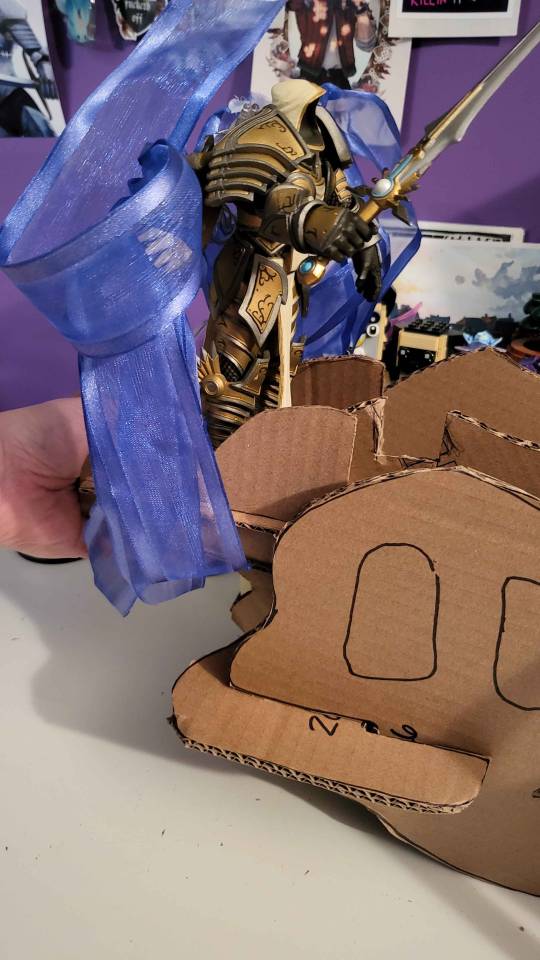

Christmas Dino V1

Part 1

I'm still chugging along so it's time for updates!

Day 2

Found some old newsprint sheets in the craft room. Laid them out in a 2 x 4 foot group for some pattern layouts. The spine and tail weren't going to fit on anything smaller.

Figure 1 - the GIANT table I could have used on day 1 but didn't and now my spine STILL hates me

I then popped a line in to make to 2 x 2 sheets to see if I could get away with smaller boards for the rest of the pattern. The smaller the board is the less wrestling I have to do with the laser engraver.

Success! With a little left over to spare if I need counter weights or anything. I honestly do not know if this thing will be balance properly and I'm not gonna do the maths to find out (or simulate it in a CAD program like I've seen some others do) TRIAL AND ERROR BABY!

One trip to Home Depot later and I've secured my wood! heh

Also some gloves for preventative maintenance on my hands because we all know splinters are a thing and I cannot be trusted not to hurt myself. Next step is remembering to actually use the gloves tho. We'll see how that goes...

Anyway, off to do some fiddling with how Tyreal is gonna fit on this whole thing.

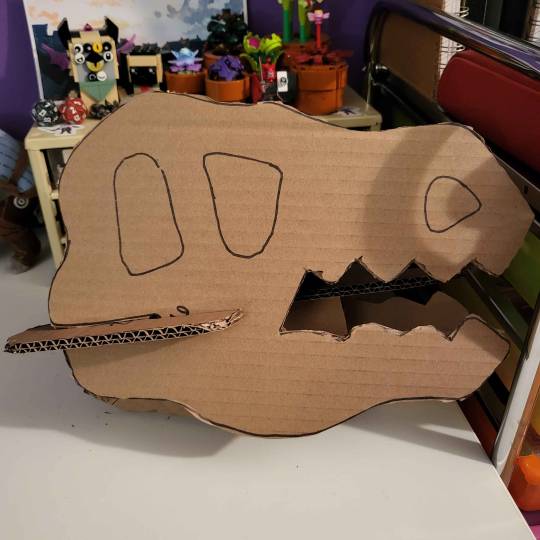

I had to decapitate my poor cardboard boi at this point, because there was just no way I was gonna try to do this with an entire limp skeleton attached.

Okay so I've got one dino skull and one Tyreal. Hmmmm...

So my first thought was just, make it super duper easy. I'll cut a notch in the middle piece and Tyreal can sort of ride it like a horse (with maybe a saddle down the road). Like this:

Okay, not bad.

BUT

sigh He's got the whole tabard of righteousness and it's made of rubber so it's not super flexible. And while it will sort of smush out of the way, it's gonna end up stuck like that and that'll just annoy me to no end.

I could get really fancy and like...cut a slit for the front and back of his tabard but that just feels waaaaaay too fiddly and prone to fucking up.

Thinking.....thinking....

What if...okay so Tyreal has a battery box to make the lights light and I'll need to make some sort of holder for it.

I did kind of want him standing too, you get more visual out of it. So what if I went, like, chariot style? I can get fancy with the sides, and create a double layer base to tuck the battery box in.

Some swearing, a few close encounters with cardboard cuts and volia! (ish)

Okay the basic idea is there but I measured nothing and it shows.

Alright, the concept works let's just try with a little more...effort.

And....

Actual volia!

The battery box fits lovely, the sides aren't too out of proportion and he's still nicely visible! Hurrah!

Tyreal also has the balance of a drunken college kid, so I've traced his feet and I'm going to try to engrave little recessed holes for them in attempt to make him a wee bit more stable.

Additional thoughts that came to me while crafting this:

I can get fancy with cut outs on the chariot sides if I want, which could be fun

Since I want the battery box to be hidden but easily accessible, I'm thinking some kind of leather wrap or tassels around the base of the chariot to obscure it but not make it a pain to get at

Since this is a chariot, he's gonna need some reins. For this year I'll probably do some sort of ribbon dealy BUT this means it's not unreasonable to make a full leather bridle for him next year. And give him a little metal nameplate across the nose band. yes yes yes

This whole contraption might just unbalance the whole t-rex but we'll deal with that later. Maybe. Shush. Bolting him to the table will totally be a reasonable solution.

Okay, that feels productive enough for the day! Now I've really gotta knuckle down and get the original pattern and the new pieces all created in Lightburn....weeeeeeeee -.-

ONWARD!

#nel rambles#nel makes a thing#christmas dino#adhd hyperfocus is holding#for now#I'm thinking Tiberus would be a fun name#think of all the alliteration#so good

9 notes

·

View notes