#Components of Turbocharger

Explore tagged Tumblr posts

Text

Upgrade your 2001-2004 6.6L LB7 Duramax turbocharger with top-of-the-line compressor wheels and housings from ProSource Diesel. Enhance performance and reliability with our premium selection.

0 notes

Note

if i say idk what the turbo or crankshaft is will u laugh

don't worry i would never laugh at people asking questions because i rarely laugh in the first place

the current major components of the pu (and their allowable allocations per season) are:

the internal combustion engine (currently the v6) -> 4

the motor generator unit-kinetic (mgu-k) -> 4

the motor generator unit-heat (mgu-h) -> 4

the turbocharger (tc) -> 4

the energy store (es) (aka the battery) -> 2

the control electronics (ce) -> 2

the exhaust (ex) -> 8 per set

i will go through them one by one. i'm not going to list every single component connected to them because that would take way too long and honestly isn't necessary... i'm just listing the most relevant things, if you look up an actual f1 car there will be more going on than what i'm saying here.

the ice is the primary source of power. it turns fuel into kinetic energy. combustion engines are very common but can get quite complex, especially one that operates at such high efficiency like f1's... but the basic idea here is that it operates in a four-step cycle where air is taken in, compressed, mixed with fuel, then ignited. this creates a force which pushes a series of pistons, and finally this force travels through a few other components until it reaches the rear wheels to accelerate the car. the crankshaft is one of these; it takes the pressure from the pistons and uses it to drive a rotational force which is then used by the succeeding components.

the mgu-k is attached to the crankshaft and electronically to the es (battery). during braking, it harvests energy from the rear that would otherwise be released as heat to put into the battery. (it cannot harvest energy from the front) when accelerating, it can then redirect energy from either the battery or the mgu-h into the crankshaft to add extra torque. there is a strict limitation on how much power the mgu-k can contribute, but the 2026 regulations are increasing this massively (like 3x the amount). also the mgu-k is why f1 cars can self-start when stalled mid-race, as even if the engine is off it can still power the crankshaft so long as there is energy in the battery.

the turbocharger is attached to the ice's exhaust manifolds and is composed of a turbine and a compressor. the exhaust gas from the ice rotates the turbine which activates the compressor. the compressor compresses incoming air before it enters the engine for combustion, allowing for more air to be taken in overall. basically it makes the engine more efficient without it becoming too heavy or large.

the mgu-h is mechanically attached to the turbo's central shaft and electrically connected to the battery. it harvests otherwise unused heat from the exhaust gases and sends it to either the mgu-k or the battery. back in the old days before the mgu-h existed and turbos were far less efficient, drivers would need to sit on the throttle to keep the it running. nowadays the mgu-h is used for this, as it can use energy from the battery to control the turbo's speed, including when at low revs. the mgu-h is the component being ditched for 2026 and is the reason why the mgu-k's capacity is being beefed up (to compensate for its loss).

the energy store is the battery. energy harvested by the motors is stored here until deployment. the battery (and the ce) are comparatively small, flat, and very efficient because they need to rapidly charge and discharge energy according to the driver's inputs. when people refer to f1 pus as being hybrid, they're referring to the mixture of power from the ice and the electrical energy from the mgu units that is stored in the battery.

the control electronics that's being referred to here is what converts the energy from the motors into an energy format that can be stored in the battery and vice-versa. this is not the same as the ecu, which is a standardized controller for the electronics of the car (such as the braking system), despite the confusing names.

the exhausts are attached to the engine's exhaust ports. they are divided into sets, with three on either side of the engine and then a connection to the turbo.

as i said i didn't talk about every component that powers the car here because that would be effectively every single one... but let me know if you have any questions. i deleted like 1k words from this because i realised i was going off topic 😭

60 notes

·

View notes

Text

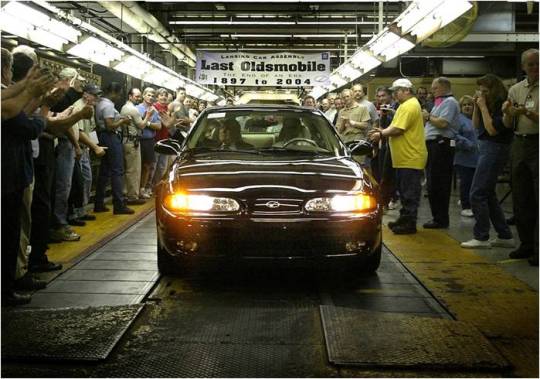

Oldsmobile

April 29'th 2004. The last Oldsmobile rolls off the line. You may be surprised to learn, that for a long time Oldsmobile meant innovation. Here are just a few of the Automotive technologies Olds pioneered in it's 100+ years in business:

1898: Olds Motor Vehicle Company exports the first American car, a steam-powered automobile, to Mumbai, India.

1901: The first speedometer offered on a production car was on an Oldsmobile Curved Dash.

1901: Oldsmobile was the first to procure parts from third-party suppliers.

1901: Olds produces 635 cars, becoming the first high-volume gasoline automobile producer.

1901: Oldsmobile becomes the first manufacturer to publicly promote their vehicles.

1902: The Oldsmobile Curved Dash is the first mass-produced vehicle in America.

1903: Oldsmobile builds the first purpose-built mail truck.

1908: Oldsmobile rebadges the Buick Model B as the Oldsmobile Model 20, possibly creating the first badge-engineered car.

1915: First standard windshield introduced by Oldsmobile.

1926: Oldsmobile is the first to use chrome plating on trim.

1929: Oldsmobile creates the first Monobloc V8 engine in its Viking Sister brand.

1932: Oldsmobile introduces the first automatic choke.

1935: Oldsmobile offers the first all-steel roof on an automobile.

1940: Oldsmobile introduces the Hydra-Matic, the first fully automatic transmission.

1948: Oldsmobile offers one-piece curved windshields, along with Buick and Cadillac.

1949: Oldsmobile introduces the Rocket, the first high-compression OHV V8 engine.

1952: Oldsmobile introduces the "Autronic Eye," the first automatic headlight dimming system.

1953: Oldsmobile switches its lineup to the 12v charging system.

1962: Oldsmobile creates the first production turbocharged car, the F-85 Jetfire.

1962: Oldsmobile also creates the first production car with water injection, the F-85 Jetfire.

1966: The Oldsmobile Toronado is the first mass-produced front-wheel-drive American car.

1969: First use of chromed ABS plastic exterior trim on the 1969 Oldsmobile Toronado.

1969: First electric grid window defogger on an American car, the 1969 Oldsmobile Toronado.

1971: The Oldsmobile Toronado is one of the first cars to feature a high-mounted brake light.

1974: The Toronado is the first American car to offer a driver-side airbag.

1977: The Toronado is the first American car with a microprocessor to run engine controls.

1982: First use of high-impact molded plastic body components on the 1982 Oldsmobile Omega.

1986: Oldsmobile introduces the Delco VIC touchscreen interface on the Toronado, shared with Buick Riviera.

1988: The first production heads-up display system is introduced on the 1988 Oldsmobile Cutlass Supreme Indy Pace Car.

1988: Oldsmobile breaks a world speed record with the Oldsmobile Aerotech at 267 mph, driven by A.J. Foyt.

1990: Oldsmobile updates the color touchscreen interface with a built-in cellular phone on the 1990 Toronado Trofeo.

1995: Oldsmobile introduces Guidestar, the first onboard navigation system on a U.S. production car.

1997: Oldsmobile becomes the first American car company to turn 100 years old.

2001: The redesigned 2002 Oldsmobile Bravada becomes the first truck to pace the Indianapolis 500.

95 notes

·

View notes

Note

*boops nose*

How's your research going?

what was that?

Anyways, I started my rocket research by modding the hell out of a car turbocharger, but Im hitting a stupid number of brick walls trying to decipher these papers with brute force. The first problem was with the oscillating component of the firing pressure. I managed to get the intermediate frequency oscillatory combustion error down to 7% by running a computer simulation. Theres no way Im doing that on my potato of a PC, though. Net even in ten billion years.

10 notes

·

View notes

Text

How Do F1 Cars Work?: Power, Transmit, Suspend

Alright part 2 everyone. Let's go.

1.Power Units

You have probably heard lots of yammering about power unit components before. Things like 'they took on too many and now have a grid penalty' are common to hear. But what is the power unit, and what does that mean?

So the power unit refers to the engine system that helps power the car. The modern F1 car is a hybrid, a mix between a typical Internal Combustion Engine (ICE) and Energy Recover Systems (ERS). The modern F1 ICE is a 1.6 liter V6 turbocharged engine and can rev up to 15,000 RPM. It uses gasoline and generates a majority of the power. I've explained how it works in an older post, but briefly it compresses air and fuel and ignites it to create combustion which generates energy. The turbocharger is a part of the ICE that helps condense air more, in turn forcing the engine to create more energy.

The ERS has two components. The first is Motor Generator Unit-Kinetic (MGU-K), which recovers energy from braking, stores it in the battery (which stores energy from the two units), and can be used as a boost to power. The second is Motor Generator Unit- Heat (MGU-H). This unit recovers heat energy from the turbocharger and converts it to electrical energy. It can either charge the battery directly or assist the ICE.

When teams get in trouble taking too many power units it essentially means they have replaced something like the MGU-H too many times. There is a cap for how many times you can replace a power unit component, but with the addition of more races every year the FIA is under pressure to increase this limit. Almost every single car takes the penalty at some point.

2. Transmission

The transmission is the semi-automatic gear box inside of F1 cars, which for them is 8-speed. It is located at the rear of the car and connects to the power unit. This is a part of the car that is famous for having issues, and often when a drivers car retires it is due to a gear box failure. With paddle shifters located under the steering wheel, drivers can change the gear in which they are driving. Different gears effect the traction, grip, fuel economy, and speed of the car and are used strategically throughout the race. Part of the transmission is the differential. The differential distributes power between the rear wheels when cornering, allowing the inside tire to rotate slower than the outside tire. The final majorly important part of the transmission is the clutch. In F1 the clutch, which is a device that connects the engine and transmission to the car is automated and controlled by electronics. It is usually used when starting the race or leaving the pit lane.

Grip levels, cornering speeds, and straight-line speeds all play a crucial role in gear ratio calculations. The teams have to find the perfect balance between acceleration, top speed, and adaptability. The team’s engineers use advanced simulations and data analysis to calculate the optimal ratios for each gear. They also take into account factors like tire wear and fuel consumption to fine-tune their calculations. All of this information can be gathered from electronic data gatherers inside of the car, running simulations, and also the drivers reporting themselves. Its why radio communication is so important in F1. This decision can make or break a race, and we have seen drivers lose due to an incorrect gear decision.

3. Suspension

The suspension system works to keep the tires in contact with the road and helps absorb the shocks F1 cars experience. This is created through a variety of springs, shock absorbers, sway bars, etc. Without the suspension, the chassis would be experiencing the full extent of the shaking and pressure, which would do damage to the car and be very painful for the driver. Anytime you see a driver shaking like crazy in the car, it usually means there is something off with the suspension. Suspension also allows the force of the bumps and the kinetic energy to be stored by a spring, which is then compressed, absorbing the energy transferred by that bump in the road and allowing all four tires to grip the road. The biggest difference between street car suspension and F1 suspension is that in an F1 car each tire is independently sprung, which means that they move on their own, useful around corners.

In F1 cars they have a pushrod or pullrod suspension. These systems transfer pressure from the wheels to the suspension dampers and springs. In a push-rod system, the rocker arms are placed at the highest point in the car. As such, the rod is under pressure as it transfers compression forces upwards into the rocker arms. In a pull-rod system however, the rocker arms are located between the upper and lower control arms, at the center of the car This means every time it hits a bump or curb, the wheel pulls on the spring which causes the pull-rod to go up and outwards from the chassis. Both are regularly used suspension types.

Teams regularly change how their suspension is functioning, and it is by far one of the most tweaked systems on the car. Truly, a weak suspension can make any car one of the slowest cars on the grid. So next time you hear a. driver complain about how slow they are on the straights, or how much their back hurts, it usually means their suspension is not where it should be.

That's all for this post, next one should be about braking, the various electronics/sensors, cooling systems, and wrap up of how everything works together.

Cheers,

-B

19 notes

·

View notes

Text

10/12/2023: Minor Overhaul

Off the back of the turbo removal, I took it upon myself not only to replenish the fasteners and gaskets but to replace the injector looms along with breather pipes etc etc… why? Well why not. I know most will argue if it’s not broke, why you fixing (replacing) it. Preventive maintenance and mitigating further components failure. Here’s the list of parts replaced.

Injector Wiring Harness - TD5: AMR6103G

Gasket-Turbocharger: PNT100030

Exhaust Gasket and Nuts - TD5: PM303

Washer-Sealing: ADU6847L

Screw: FS106167L

Gasket: ERR6768G

Cam Cover Gasket - TD5 (LATE): LVP000020LR

Isolator: ERR7266

Screw Flanged: FS106307L

Hose-Breather-Cam Cvr Tube: LLH500180LR

Valve: LLN100140LG

Nut - (Flanged): LR019197LR

Screw-Flanged Head M6 X 12: FS106127L

Front Camshaft Oil Seal - TD5: LDI100030

Plastic clip: PRC3180

Annoyingly it started to rain, and I didn’t fancy waiting another day for the sake of a drizzle even if that drizzle felt like -5 degs C, anyway all parts that required swapping out were straight forward. When replacing the front cam cover gasket, take care removing it, avoid using screw drivers to pry it out. I have seen on the internet pesky cowboy mechanics silicone’ing the cap in place to stop the leak instead of spending £5-15 (brand depending).

At some point I’d like to swap out the injector seals and check clearances. The 90 is a tad tappier than the 110. Be interested to know the condition of the hydraulic lifters.

Anyway if I post nothing further this month, Merry Christmas y’all!

10 notes

·

View notes

Text

The first Lublin-BelAZs were actually copies of the Lublin, then in 1997 the plant began to receive components for the new Daewoo Lublin 2. The base engine was the Polish Andoria, a diesel, water-cooled, with a volume of 2417 cm3 and a power of 70 hp. Since 1996, some Lublin trucks began to be equipped with a turbocharged Andoria 4CT90 engine, of the same volume, but with a power of 90 hp.

5 notes

·

View notes

Video

youtube

2025 Chevrolet Corvette ZR1 - Full Tech Specs and Performance

The 2025 Chevrolet Corvette ZR1 marks a new benchmark in American supercar engineering, combining advanced aerodynamics, powertrain innovation, and motorsport-derived performance.

At its core is the LT7 engine, a 5.5-liter twin-turbocharged V8 with a flat-plane crankshaft. This engine produces 1,064 HPr at 7,000 rpm and 825 pound-feet of torque at 6,000 rpm, making it the most powerful V8 engine ever by GM.

The LT7 is a significant evolution of the naturally aspirated LT6 found in the Corvette Z06. Key changes include forged aluminum pistons, strengthened connecting rods, and twin 76 mm ball-bearing turbochargers integrated into the exhaust manifolds. The engine also features an anti-lag system that maintains boost pressure during throttle lift-off, ensuring immediate power delivery when re-engaged.

Power is delivered to the rear wheels via a dual-clutch 8-speed transmission that has been reinforced to handle the increased torque. Chevrolet estimates 0 to 60 mph in 2.3 seconds, with a top speed exceeding 215 mph. In private testing, the 2025 Corvette ZR1 has achieved verified runs over 230 mph, including a peak of 233.

Standard models of the 2025 Corvette ZR1 feature a front splitter, underbody strakes, and an active rear spoiler. With the available ZTK package, the ZR1 gains a large fixed rear wing, dive planes, and additional carbon-fiber components. Combined, these upgrades provide over 1,200 pounds of downforce.

Chassis tuning includes Magnetic Ride Control 4.0 and a track-optimized suspension geometry. The ZR1 is equipped with Michelin tires—20 inches at the front and 21 inches at the rear. Braking is handled by carbon-ceramic rotors, measuring 15.7 inches in front and 15.4 inches in the rear, with electronic brake boost providing consistent stopping power.

Cooling performance has been enhanced through several functional design elements. A center-mounted intercooler evacuates heat through a vented hood, while additional ducts in the front fascia and rear quarter panels direct airflow to critical systems. Roof and rear window have been optimized for thermal management.

2025 Chevrolet Corvette ZR1 – Technical Specifications

General Informations Model: 2025 Chevrolet Corvette ZR1 Body style: 2-door coupe, mid-engine layout Platform: GM Y2 (C8 architecture) Drive type: Rear-wheel drive Production location: Bowling Green, Kentucky, USA

Powertrain Engine code: LT7 Configuration: 5.5-liter V8, twin-turbocharged, dual overhead cam, flat-plane crankshaft Displacement: 5500 cc Induction: Twin 76 millimeter ball-bearing turbochargers integrated into exhaust manifolds Maximum horsepower: 1064 horsepower at 7000 rpm Maximum torque: 825 pound-feet at 6000 rpm Redline: 8000 rpm Fuel delivery: Direct injection Cooling system: Intercooler with hood vent, front and side intake ducts, roof-integrated airflow, and rear-quarter cooling channels Special features: Anti-lag system, forged aluminum pistons, reinforced connecting rods, dry sump oiling system

Transmission Type: 8-speed dual-clutch automatic Final drive: Strengthened limited-slip differential

Performance Estimates 0 to 60 miles per hour: 2.3 seconds Quarter mile: Estimated 9.5 seconds with ZTK package Top speed: Electronically confirmed runs over 230 mph, with a recorded maximum of 233 mph

Chassis and Suspension Front suspension: Short/long arm configuration with Magnetic Ride Control version 4.0 Rear suspension: Multilink setup with Magnetic Ride Control version 4.0 Braking system: Carbon-ceramic rotors, 15.7 inches front and 15.4 inches rear, with electronic brake boost Steering: Electric power steering with variable ratio

Wheels and Tires Front tires: 275/30 ZR20 Rear tires: 345/25 ZR21 Tire options: Michelin Pilot Sport 4S standard, Michelin Pilot Sport Cup 2 R optional with ZTK package Wheel sizes: 20 inches by 10 inches front, 21 inches by 13 inches rear Construction: Lightweight forged aluminum

Aerodynamics Standard aero: Front splitter, underbody strakes, active rear spoiler Optional ZTK package: Fixed carbon fiber rear wing, front dive planes, additional carbon fiber components Downforce: Exceeds 1200 pounds with ZTK configuration

Dimensions (estimated) Overall length: 182.3 inches Overall width: 79.7 inches Overall height: 48.6 inches Wheelbase: 107.2 inches Curb weight: 3750 to 3800 pounds depending on configuration

Interior and Technology Driver interface: Digital instrument cluster, performance data recorder Seating options: GT2 and Competition Sport seats Infotainment: Chevrolet Infotainment 3 Premium with 8" touchscreen Audio system: Bose sound system Driver aids: Launch control, performance traction management, customizable drive modes

Optional Packages ZTK Track Performance Package includes track-optimized suspension, Cup 2 R tires, and high downforce aerodynamic components Carbon Fiber Package: carbon trim elements on exterior and interior

MSRP Starting price above 185,000 US dollars

5 notes

·

View notes

Note

OMG I'm such a dumbass I knew you did one on the GR Yaris before too, and I love her ALSO, but I actually meant the GR Supra 😳🫣 (slip of the tongue)

Gotcha.

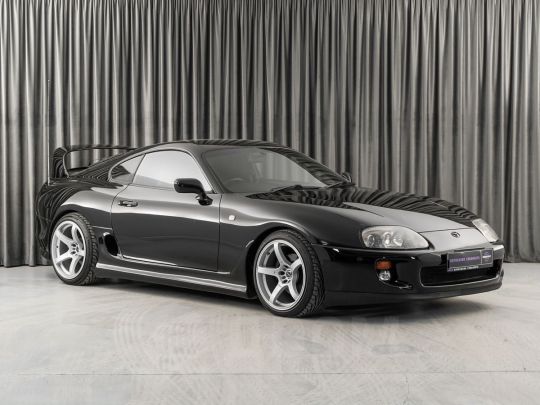

Since I managed to take some two weeks to answer this (got distracted both by real life obligations and other posts that were meant to be very quick to make. Meant to.) y'all may have forgotten, but our dear friend of the blog had asked for opinions on the GR Yaris, hinting to its controversial status. Turns out the GR Supra is what that request, and thus that hint, was actually about - so let's talk about the car and the controversy that engulfs it.

In 1993, Toyota launched the fourth generation of its rear wheel drive sportscar (well, arguably a bit of a Grand Tourer, i.e. something more oriented to cruising than a sportscar) the Supra - which was born a quarter century earlier as a more upmarket, six cylinder version of the Celica, graduating from Celica Supra to its own dignified name with the third generation I talked about that one time I forgot to check what blog I was reblogging with.

But this time, things would be different. Most notably because the inline six the Mk4 Supra came out with was an absolute MONSTER.

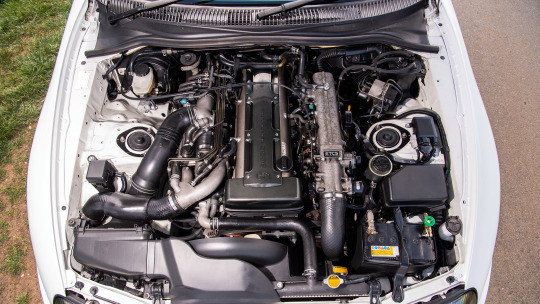

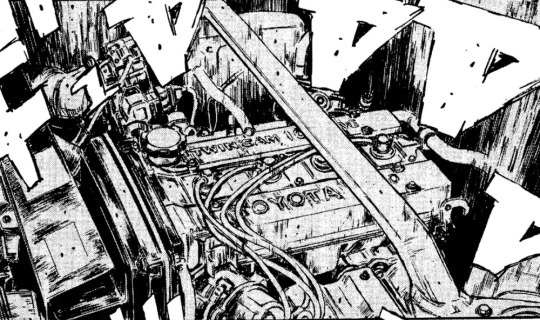

Remember how I talked about the GT-R's RB26 engine being one of the greatest, most coveted production engines to ever come out of Japan? Well, the 2JZ-GTE is the other.

It was larger at 3 liters, no less powerful, and to reduce turbocharger lag it used two of them sequentially: first air goes in the smaller, more responsive turbo, then gradually some of it gets sent to the bigger turbo to make it start spinning, then when it gets going the two are finally used in conjunction. (Imagine the big turbo as a hung husband that takes a while to get it up and the small turbo as an eager stepson ready to take over until the hung one can join in for a spitroast. Or something. I don't watch porn with real people, but from what I gather the plots seem to resemble how sequential turbos work.) It even at one point got Variable Valve Timing, i.e. the ability to vary the time in which the valves open depending on engine speed, which allows to optimize tuning for performance and efficiency! (Cool thing to go over in detail if y'all want me to.) And also, the kind of things that engine is able to take make me wish I hadn't used up my porn analogy quota.

See, to chop off eons of nuance, an engine is just a big block of metal with a lot of bits attached, and the two main measures of an engine's potential are the slope of the line in the Bits Fiddled With / Power Output graph and how far up (It's up, right? The second axis you specify is the vertical one, right?) you can take it before the block becomes the weakest link - with another important point being when you need to start messing with internals, i.e. the components inside the engine, e.g. pistons (the things the boom pushes down), camshaft (the thing the pistons spin) and connecting rods (you can guess).

So for instance, just to make the point that an engine can be beloved without having much overall tuning potential, in one of Toyota's most beloved engines, the 4A-GE four cylinder illustrated above (yes, the one from that white and black car in all the eurobeat videos), some pin the block's limit as low as 250hp. The 2JZ, tho? It can take 800hp without even messing with the internals, and once you get your grubby hands on those you can keep pushing the line to some 2000hp. That is two Bugattis. That is 40 times my car. That is well above the power level where "tires that will at any point grip" and "tires that are in any way road legal" stop intersecting.

I am not in the slightest exaggerating when I say that this and the Skyline GT-R are widely regarded as the top of Japan's 20th century automotive production. The Messi & Ronaldo of the Japanese Domestic Market. It is absolutely no coincidence this was the hero car in The Fast And The Furious.

And then in 2002, as all things, its production ended, and given the abysmal sales and catastrophic recession, Toyota decided that would be that.

And then, years later, The Teasening began.

I want to stress, almost half of my conscious life (I choose to believe the stretch from birth to kindergarten is just run-up) the world was in some state of getting teased with talk of a new Supra. The trademark on the name was renewed in 2010. In 2014 they dropped the FT-1 concept, and of course that became speculation about what the production version would look like.

Because come the fuck on, it's not gonna look like that.

Or was it?

Only five entire years and much more teasing later would we officially get an answer, when after seventeen years, the Toyota GR Supra (and for those wondering what GR means, y'all should've clicked the Yaris link >:C) hit the streets.

You know what, good enough.

Good enough to earn itself a sea of words of praise, Jason Cammisa's "The most punch-above-its-weight sportscar ever made" just some among them.

It did have its share of problems at the start, like its power being 335hp and not 382, a lack of manual transmission, and the inability to spec it with a less powerful 4 cylinder engine - well, I don't know who considered that last one a problem, but Toyota's updates solved that one too.

The Supra has a much bigger problem than those though, one no little update can solve. That red car in the background.

See, the new Supra is actually a joint venture with BMW, who made a new model of its Z4 roadster out of the platform. And unlike with the other joint-venture sportscar Toyota sells, people are big mad about that. Why?

See, the interior is engulfed in BMW switchgear and the drivetrain is all BMW (the manual gearbox took until this year to come out because BMW did not have one for that engine so Toyota had to modify another BMW transmission to fit), giving people the impression that this was less of a joint venture and more of a BMW project that Toyota tacked its design on top of, which is a problem whether true or not.

See, a range-topping sportscar is supposed to represent what the brand is capable of - having it done by someone else (or so the criticism goes) is a bit like performing Hallelujah in playback.

Actually, a better musical analogy: You know "I'm back bitch" singles? When a humongous artist drops a new record with a humongous lead single about absolutely nothing but reaffirming they're the biggest fucking deal in the universe? Without Me, Bad, Gimme More, so on. Well, think of SexyBack - one of the most monumental phenomenons of its decade, most incontrovertibly proving Justin Timberlake sat atop the goddamn world. Now, imagine if, after all the years that went by between that record and the next, when he finally came out with Suit And Tie all the verses were Jay-Z. Going from a humongous statement about having the power to reach the top of the game and stay there to having to get absolutely carried by what in this logic is essentially a competitor. Basically, that's the critics' complaint: the supra went from 2JZ to too much Jay-Z.

And therein lies the other problem of the Supra: the Supra.

See, any time you evaluate something, you do so relative to its context - and when you give it a nameplate, you make that context include where else that nameplate has been. An undeserved name may not just be stupid, but even outright kill the car in some's eyes, see the case of the Dodge Dart, or get me to talk about the Ford Capri prototype recently spotted if you want to find out what I'm like when I lose my cool. (I'd liken this phenomenon to undeserved Grammies but I already used my music analogy quota too.) So the Toyota Supra does not just need to be good, it needs to deserve the name. And some argue it doesn't. But why? This thing is no less powerful, no slower, hell it's not even any bigger or heavier and we've gone over how rare that is these days! So is it the lack of backseats and a targa version? No, no one gives a crap about those. It's something deeper.

Sometimes, the problem with a revival is people base their expectation not on what the original was like in the context of its time but what it's like in the context of today (for example, I've heard people call the latest GT-R "too computerized, too assisted, far from the pure driving experience of its predecessors", when its predecessors had some of the most technologically advanced driving assists of their time and could only be called "pure" and "analog" by comparison with cars decades newer). But of course, that'll only be some people - so if what the original car looks like to modern eyes and what the original car represented at its time are two different enough concepts, any revival will receive some criticism for not being one of the two.

But for the Supra, this compounds with another problem: the original Supra (as in the previous generation, since no one gives a crap about the first three), to modern eyes, looks like a thousand-horsepower flame-spitting beast, because that's what all Supras have been turned into, and that's why you know of Supras in the first place (it sure isn't because people bought it!), and that, consciously or not, exacerbates the problem of misplaced expectations to a level akin to hearing an NBA player is about to have a brother and expecting the baby to be a 6'4" three-shooter.

But I wasn't asked about the controversies, I was asked about my take. And my take is: no realistic expectation of what a Supra would look like today was disappointed - at least not by where the car stands today. Well, unless the expectation involved backseats.

"But it was made by BMW" and so? This is a new Supra, and a good one - what does it matter how it got here? Especially when this is an upgrade over the Z4 in every way - looks way better, drives better, and now has a manual that the Z4 doesn't.

Okay, almost every way: the Supra's roof won't get out of the way. If only though, if only. Could you imagine a Toyota product that looks this good, sounds this good, goes this fast, and has a drop top? ...and maybe backseats?

Well, I can.

Yes, the badge and core concept may have some people consider it from midlife crisis mobile to old man's car. (though we know it's not a car bought by old men because if that was the case someone would be buying these). But just try to imagine sitting in this thing.

Take a couple of seconds to take in that picture and truly immerse yourself. You're in a Lexus LC500 Convertible, with a V8 at your right foot's command, its spectacular sound ready to battle the perfect sound system serenading you with your fanciest CD, because of course Lexuses still come with CD players.

Are you immersed? Okay: Someone just called your Lexus a midlife crisis car. See? You don't give a shit either, do ya.

Automatic only though. The pain. Oh, and it kind of costs as much as two Supras. But, you know, neither of those Supras will be convertibles!

Links in blue are posts of mine about the topic in question - if you liked this post, you might like those!

52 notes

·

View notes

Text

AMG S63 E PERFORMANCE „The Boss“.

Mercedes-AMG S63 E PERFORMANCE (combined fuel consumption, weighted: 4.4 l/100 km; combined CO2 emissions, weighted: 100 g/km; combined power consumption, weighted: 21.4 kWh/100 km)[1] with AMG hybrid technology once again sets the benchmark in the segment. The E PERFORMANCE model combines the AMG 4.0-litre V8 biturbo engine with the AMG-specific hybrid powertrain and a new expansion stage of the AMG high-performance battery.

The focus of the powertrain, however, is less on electric range and more on best-in-class performance. With 590kW (802hp) of system output and 1430Nm of system torque, the saloon sets new standards in the segment. The acceleration of 3.3 seconds to 100km/h and the optional top speed of 290km/h underline the superior, dynamic driving performance. Systems such as the AMG RIDE CONTROL+ suspension, AMG ACTIVE RIDE CONTROL roll stabilisation and rear-axle steering as standard ensure a wide spread between driving dynamics and comfort.

A central component of the P3 hybrid powertrain is the AMG 4.0 V8 biturbo engine, in this case producing 450kW (612hp). It provides a maximum torque of 900Nm, which is available over a wide speed range. The engine’s most important design features include the two twin-scroll turbochargers, which are located in the hot inner-V. The position between the two cylinder banks shortens the paths of the exhaust gases to the turbocharger and the compressed fresh air to the combustion chamber.

The result is a very immediate response. Another important feature is the belt-driven starter-generator (RSG), which is integrated into the 400-volt electrical system. This combines the starter and alternator into one unit, and has sufficient power to always start the V8 at once.

Mercedes-AMG One man, one engine Handcrafted by Michael Kübler @f1mike28 in Germany Affalterbach. Driving Performance is our Passion!

Mercedes-AMG the Performance and Sports Car Brand from Mercedes-Benz. Mercedes-AMG Handcrafted by Racers.

#amg#sclass#s63#s63amg#s63amgeperformance#s63eperformance#eperformance#mercedesamg#mercedes#mercedesbenz#affalterbach#onemanoneengine#pagani

8 notes

·

View notes

Text

Achieving a goal is the beginning of a new challenge. To run really fast, HKS thinks.

A drag race scene where people compete for 0.001 seconds over a distance of about 400 meters in just a few seconds. '91 is a drag field that demands quick response and power from the engine, clutch, suspension, and even a single drop of oil or gasoline, as well as durability and transmission ability to handle instantaneous high power. -In '95-'96, the ``HKS R32 DRAG GT-R'' won the series championship in the RRC Drag Race Championship for three consecutive years. The following year, in 1997, the ``HKS DRAG 180SX'' in the BERC Drag Race Championship Pro Stock class and the ``HKS R33 DRAG GT-R'' in the Pro GT-R class achieved the Avec Championship. Having achieved one goal in 1997, what we aimed for in 1998 is:

Quarter mile time in 9 seconds with FF base vehicle. They then talked about their know-how from drag racing to date, and ``HKS FF DRAG CELICA'' made its debut. The first goal was achieved on October 9, 1998 at Sendai Highlands with a time of 9.886 seconds. He further improved his time to 9.727 seconds, and in 1999 he set a goal of breaking the quarter mile in the 6-second range, and has already begun a new challenge. "Achieving a goal is the beginning of a new challenge" - HKS' never-ending battle continues

HKS

■Company overview

●Name HKS Co., Ltd. Established October 31, 1971

●Capital 607,475/Kawa Representative Director and President Naruyuki Hasegawa

●Location Head Office 2266 Kamiogawa, Kunikami City, 418-0192

●Business details

Development, design, and product sales of automobile parts, racing engines, turbocharger-related parts, and automotive components and systems Design, development, and manufacturing of original mufflers, suspensions, and engine parts Development of complete cars, development of aircraft engines

●Number of employees: 407 (333%, 74 women)

●Equipment overview

Experiment building: Dynamometer (1,000/800/600~300/200/PS) Chassis dynamo, exhaust gas analyzer

Old experimental building: Dynamometer (600/600-500-200/PS)

Manufacturing factory: 10ft machining center, 5 NC lathes, 41 cam polishing machines, 21 biston narai, 11 turning centers, 21 crank Kenjoshi, Monzen Kendanmei, 21 surface grinders, 1 gun drill machine.

Muffler factory: Pipe bender, robot welding machine, 1 laser machine, shell machine, multi-spot welding machine 11, 100T press, TIG welding machine, CO2 welding machine multi-stage

Muffler 2nd factory: Pipe bender / shirring / Yasuda machining center 1 piece

Suspension factory: Cold solid coiling machine, continuous coiling machine, surface grinding machine, shot peening machine, automatic setting machine, automatic load testing machine, etc.

●Affiliated companies

HKS Aviation Co., Ltd. HKS Service Center (Tokyo/West/Kyu)

HKS USA, INC (USA)

HKS EUROPE()

25 notes

·

View notes

Text

Hamilton Set For Azerbaijan GP Pit Lane Start After Engine Change

Lewis Hamilton will start Formula 1's 2024 Azerbaijan Grand Prix from the pit lane after Mercedes chose to change several components of his power unit. Hamilton, who had been set to start seventh for the Baku race, has now taken his fifth engine of the season, one more than the permitted allocation. Mercedes has also swapped the turbocharger, MGU-H and MGU-K components on his car. The move was one Mercedes had long been expecting to make, as Hamilton's engine failure retirement from the Australian GP back at the beginning of the season meant he was on the limit for getting through the year without taking a further engine from that point onwards. The issue with Hamilton's Australian engine was later traced to an unexplained bottom-end failure. Motorsport.com understands that Mercedes had been assessing which race would be best to make the change and incur the grid penalty, given the overtaking challenge at various tracks left on the 2024 calendar. The Baku event, with its track's long straights and the tyre management requirements of Sunday's race, meant Mercedes decided to take the penalty hit here after its disappointing qualifying on Saturday in Azerbaijan. Hamilton qualified seventh after failing to get his tyres working well at the start of his final lap in Q3, after being told to slow down late in his warm-up tour due to Alex Albon's Williams being temporarily stuck at the pitlane exit with its cooling fan still attached to its airbox. The delay in pushing on to start his final flier meant Hamilton's tyres "wouldn't work," something Mercedes team boss Toto Wolff said also impacted George Russell in the other W15, given the younger Briton was running just ahead of his teammate. Mercedes is confident that Hamilton can recover up the order to at least get back towards the position he should have started in.

#lewis hamilton#f1#formula 1#baku gp 2024#fic ref#fic ref 2024#baku#baku 2024#baku 2024 saturday#baku 2024 sunday#with george

7 notes

·

View notes

Text

Why are so many cars designed to make it almost impossible to replace the headlight bulbs? Even LEDs do not last forever.

The difficult headlight bulb replacement in modern cars stems from several deliberate design trade-offs – prioritizing other factors over serviceability. Here's why engineers often sacrifice accessibility:

Aerodynamics & Styling Demands:

Low, Sloping Hoods: Aggressive aerodynamic profiles minimize the space under the hood, pushing components (including the headlight assemblies) closer to the radiator, engine, and structural elements.

Seamless Body Lines: Sleek headlight designs with complex contours often require integrated bezels and trim pieces that physically block access points. Removing bumpers or entire assemblies becomes necessary to preserve the desired visual lines.

Thin Headlight Profiles: Modern lights are shallow and wrap tightly around body panels, leaving minimal clearance behind the bulb socket.

Overcrowded Engine Bays:

Packing in Tech: Modern engine compartments are packed with turbochargers, intercoolers, complex intake systems, emission control devices, coolant reservoirs, air ducts, battery boxes, fuseboxes, and wiring harnesses.

Prioritized Placement: Engineers give prime, accessible space to critical components like the air filter, oil dipstick, coolant reservoir, and brake fluid. Headlight bulbs become an afterthought, relegated to the cramped spaces left behind.

Complex Headlight Assemblies (Especially for LEDs):

Sealed Units: Most modern LED headlights are not designed with replaceable "bulbs" like halogens. The LEDs are tiny chips soldered onto circuit boards, integrated with heatsinks, lenses, projectors, and complex electronic drivers.

Thermal Management: LED units require effective heat dissipation, often involving large heatsinks and fans inside the sealed assembly. Making them easily serviceable would compromise the thermal seal and design integrity. They are designed as a single, sealed module.

Alignment & Calibration: Modern adaptive headlights (swiveling cornering beams, auto-leveling) require extremely precise optical alignment and electronic calibration from the factory. Replacing an internal LED chip would likely disrupt this precision far more than swapping a simple halogen bulb. Replacing the whole sealed unit ensures this calibration remains intact (it's locked into the housing).

Moisture Seal: Creating a user-serviceable opening for LED chips without compromising the hermetic seal against moisture (which would rapidly destroy the electronics) is extremely difficult.

Safety and Regulatory Concerns:

Accurate Beam Pattern: Headlights must be perfectly aligned to avoid blinding oncoming traffic. A complex mounting system helps ensure the entire headlight assembly remains stable and doesn't get knocked out of alignment easily. Making bulbs "toolless" might compromise this stability.

Electrical Integrity: Complex connectors and wiring harnesses are designed for reliability over the life of the vehicle, not for frequent disconnection/reconnection by owners. Easier access might increase the risk of moisture ingress or connector damage.

Manufacturing Cost, Efficiency & Profit:

Simplified Assembly Line: Designing for easy post-assembly service adds complexity during manufacturing. Mounting the headlight assembly deep within the front end might be faster/easier on the line than leaving room for hand access later.

Dealer Service Profit: While often overstated as the primary reason, manufacturers know difficult repairs increase the likelihood owners will use dealer service departments, where labor rates are high. Making bulbs easy to swap yourself costs them potential revenue.

Reduced Parts Inventory: Designing around sealed LED modules reduces the number of individual parts needed (bulb types, sockets) and simplifies inventory logistics, even though the module itself is more expensive.

Longevity Focus (Even with LEDs):

Perceived Permanence: While LEDs don't last forever, their projected lifespan (often 10,000-15,000 hours+) significantly exceeds the average ownership period of a vehicle (around 8 years). Manufacturers design knowing that most owners won't need to replace them during their ownership, reducing the incentive to prioritize access.

Electronics vs. Filament: Halogen bulbs fail frequently due to fragile filaments. LED modules are solid-state electronics. While the LEDs themselves are long-lasting, drivers/fans/corrosion can cause the entire module to fail before the individual LEDs burn out. It's simpler/necessary to replace the complex module rather than diagnose and repair individual electronic components embedded within it.

In Summary: Engineers are solving a complex puzzle: maximizing aerodynamics, fitting more technology, meeting strict safety regulations, achieving aggressive styling, managing thermal loads (LEDs), ensuring long-term reliability/sealing, and minimizing manufacturing costs/ease. Prioritizing your ability to quickly replace a bulb is rarely high on that list, especially with LEDs designed as long-life, sealed units for performance and reliability reasons. While frustrating for DIY mechanics, the trade-offs made sense to the designers for the other priorities.

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#led light bulbs#led strip lights#car rental#cars#electric cars#classic cars#car#carlos sainz#truck#porsche#sabrina carpenter#suv#lamborghini#bmw#autonomous vehicle headlights#overtake another vehicle#older vehicles#very pretty#vehicle#automatic headlights

2 notes

·

View notes

Note

when people talk about the new rules for 2026 i hear them say it’s gonna be an “engine formula” a lot. what does this mean?

FORMULA EXPLAINED - Part One Engine Formula

When referencing the FIA's new set of rules & regulations for the 2026 season, you may hear people talking about something called "engine formula".

Engine Formula is all the parts that are put together to make the engine work like components and batteries.

The 2026 engine is to be a 50/50 split between internal combustion engine and electrical power, dropping the MGU-H (which i'll cover soon) and massively upping the MGU-K (which will also be covered soon) to a power output of 350kW or around 469bnp.

The current hybrid (engine) set-up includes the energy store, the V6 engine, the turbocharger, and two other components.

Said components are the MGU-H and the MGU-K. Let's start by focusing on:

What they are

What their purpose is

MGU-H Motor Generation Unit - Heat The MGU-H is a compound of the hybrid-electric internal combustion engine. (this is literally just the name of the engine) Its job is to convert heat energy from exhaust gas into electrical energy. - Acts as an anti-lag system for the turbocharger.

MGU-K Motor Generation Unit - Kinetic The MGU-K is a kinetic energy recovery system connected to the crankshaft with the main task of converting kinetic energy into electrical energy. Much like the MGU-H but different. - Kinetic energy is the energy an object has because of its motion. - The crankshaft is another engine component. It is a piston that converts the linear motion generated by the engine into rotational motion. (in simpler words, it converts the vertical movement of the pistons into horizontal rotational movement which drives the wheels via the gearbox.)

For 2026 they plan on completely dropping the MGU-H system and upping the MGU-K system to have a significantly larger power output (as stated above). Removing the MGU-H is the most significant change being made to the engine as they are literally removing a whole component.

They are making this drastic change as they deemed it "too complex, with too little road relevance for manufacturers." - essentially, a bit too difficult for manufacturers (the people that make it) to understand completely how to make it, as they are more used to working on engines build for the roads. Hence "road relevance".

------------------------------------------------------------------------------

That's a wrap for part one of "FORMULA EXPLAINED" by copythat!

Thanks for your read! If you're new here, have a quick read at my intro post for this series.

*all feedback and constructive criticism is welcome!*

also, if you'd like to - follow my Instagram! @/copythatblogs

#f1#motorsports#driving#formula racing#sports#formula 1#journalism#sports journalism#engineering#electric#vehicle#circuit#electric vehicles#cars#fast cars#research#engine formula#2026#fia#rules#regulations#formula one#f1 2024#f1blr#FORMULA EXPLAINED#copythatblogs#copythat FORMULA EXPLAINED

16 notes

·

View notes

Text

Japanese Engineering Superiority: Exploring the Globe of JDM Components

Introduction

Japanese design has long been celebrated for its unmatched premium, impressive design, and also performance-oriented services. The automotive industry is an archetype of this excellence, specifically when it comes to the world of Eastern Residential Market (JDM) components. Fanatics and also racers identical have discovered that JDM parts not merely enrich the efficiency of lorries however additionally give special aesthetic upgrades that specify all of them in addition to standard models. Within this extensive write-up, our experts will definitely explore the appeal of JDM parts, their impact on automobile efficiency, and exactly how they stand for Asia's engineering prowess.

What Are actually JDM Parts?

Japanese Engineering Quality: Checking Out the Planet of JDM Parts

JDM means Eastern Residential Market, pertaining to motor vehicles and components primarily made for sale in Japan. This market is actually renowned for making high-performance parts that typically go beyond the requirements discovered in various other areas. From Honda Civics to Toyota Supras and Nissan GT-Rs, JDM components are associated with high quality and also precision.

youtube

Why Decide on JDM Parts? Performance Enhancements

When it involves performance improvements, nothing at all fairly matches up to authentic JDM parts. These components are crafted to work effortlessly with specific motor vehicles, ensuring ideal efficiency and integrity. As an example:

Engine Components: Upgrading your motor with DOHC (Twin Overhead Camshaft) units enriches horse power as well as torque. Suspension Systems: Efficiency revocation packages strengthen taking care of and flight comfort. Exhaust Systems: Updated exhaust bodies enable far better air movement, strengthening engine efficiency.

By finding JDM components, you're certainly not merely selecting any sort of aftermarket device; you are actually purchasing components designed primarily for your vehicle's needs.

Quality Assurance

One considerable advantage of buying JDM parts is actually the affirmation of top quality. Cars made in Asia undergo thorough screening requirements before they struck the marketplace. With brand names like Honda as well as Toyota leading the charge in technology and dependability, you may depend on that each component sticks to rigorous top quality controls.

Understanding the Types of JDM Parts Engine Components

Performance fanatics acknowledge that the heart of any kind of vehicle lies in its own engine. Listed hdwerks.net below's a more detailed look at some preferred engine-related JDM parts:

Turbochargers: Designed to boost motor performance forcibly even more air in to ignition chambers. ECU Tunes: Custom-made adjusting options permit chauffeurs to improve their automobile's performance characteristics. Intake Systems: Upgraded air intake bodies boost airflow into the engine, boosting overall energy output. Suspension Upgrades

A well-tuned suspension system significantly improves managing qualities:

Coilovers: Changeable coilover packages supply flexibility in adventure height and stiffness. Sway Bars: These parts minimize bod

2 notes

·

View notes

Text

A General History of F1: Turbo Titans

The 1970s saw lots of changes for Formula 1. Many of the early legends were gone, either to retirement or tragic death. The sport was also expanding massively and starting to gain recognition in non-European countries. The biggest changes, however, were to the cars themselves. New turbocharged engines meant that the cars had more power in them, and enhanced competition.

But what is a turbocharged engine? Well, in Formula 1 cars an internal combustion engine (ICE) was used to run the car. This is a heat based engine, were the combustion of fuel and usually air create pressure and heat. This heat and pressure applies force to an internal component, usually pistons or turbine blades (depending on the engine type). All of this, to put it simply, makes the car go.

The turbocharger gave the car a little kick. This is a forced induction device (used to increase air density) powered by the flow of exhaust gases. Essentially the energy taken from this compresses the intake air, forcing more air into the engine, which in turn produces more power in the engine. Like caffeine for cars.

With the faster and more complicated cars, F1 was ramped up another level. As the sport got bigger and bigger, and new hungry drivers started to come onto the seem, it started to morph into what we know today. Legends that came out of this time period include Jackie Stewart, Emerson Fittipaldi, James Hunt, and Niki Lauda. The last two drivers on that list also increased the hype around driveer rivalries. While they had existed before, the Lauda-Hunt rivalry took on a life of its own, and it famously memorialized in the movie Rush.

The 1980s were similar to the 70s, but showed that teams who took advantage of new turbochargers and worked hard for innovative development would be on top. Mclaren and William ruled the roost as 'Turbo Titans', and rivalry even more seemed to be at the core of F1. Technical skills became paramount, and drivers like Alain Prost (along with Lauda) became legends for their intelligence and understanding of the cars they drove. These drivers on the 70s and 80s were the second generation of legends, and they were even more intense than their predecessors.

The 1980s also introduced Ayrton Senna to the F1 world. He would go on to become one of the most legendary drivers of all times, mostly due to his magical talent, intense rivalry with Alain Prost, and his tragic death.

Next part will be on Senna.

Cheers,

-B

4 notes

·

View notes