#FFF/FDM

Explore tagged Tumblr posts

Text

Eklemeli İmalat Teknolojileri: Geleceğin Üretim Yöntemleri

Eklemeli imalat teknolojileri (additive manufacturing technology), 3 boyutlu nesnelerin katman katman oluşturulmasıyla gerçekleşen üretim yöntemlerini ifade eder. Bu süreçlerde, bir dijital model temel alınarak malzeme, katmanlar halinde bir araya getirilir ve istenilen nesne şekli elde edilir. Bazı yaygın eklemeli imalat süreçleri şunlardır: - Erimiş Biriktirme Modelleme (Fused Deposition Modeling -FDM) veya Erimiş Filament İmalatı Filament Fabrication (FFF): 3 boyutlu yazıcılar tarafından kullanılan bir eklemeli imalat teknolojisidir. Bu teknoloji, termoplastik filament adı verilen ince bir malzeme telini kullanarak nesnelerin tabaka tabaka oluşturulmasını sağlar. Bu yöntemde, termoplastik filament (genellikle PLA veya ABS gibi) bir bobinden ısıtılarak ekstrüzyon ucu aracılığıyla tabaka tabaka bir yüzeye çıkarılır ve ardından her katman sertleşir. - Seçici Lazer Sintelreme (Selective Laser Sintering -SLS): Bu yöntemde, bir lazer ışını termoplastik veya metal tozlarını istenilen şekilde eriterek bir tabaka oluşturur. Ardından, platform aşağı iner ve bir sonraki tabaka uygulanır. Her katman bir öncekine bağlanır ve nihayetinde nesne oluşturulur. - Stereolitografi (Stereolithography-SLA): Bu yöntemde, bir UV lazer ışını sıvı bir reçineye odaklanır. Lazerin temas ettiği yerlerde reçine katılaşır ve istenilen katmanın şekli oluşur. Platform daha sonra bir sonraki katmana indirilir ve süreç tekrarlanır. - Elektron Işınıyla Eritme (Electron Beam Melting-EBM): Elektron ışınıyla eritme (Electron Beam Melting - EBM), 3 boyutlu metal baskı veya eklemeli imalat teknolojileri (additive manufacturing) süreçlerinden biridir. Bu yöntem, metallerin katılaştırılarak istenen şekillerde nesneler oluşturulmasını sağlar.EBM'de, bir elektron ışını kullanılarak metallerin toz halindeki formu eritilir ve ardından katılaştırılarak istenilen şekli elde edilir. Bu süreç, metal tozlarını katmanlar halinde bir araya getirerek 3 boyutlu bir nesne oluşturur. Her katman, bir sonraki katmanın üzerine serpilmiş metal tozu tabakasıyla oluşturulur. Elektron ışını, bu tozu istenilen şekilde eritir ve katılaştırır. Bu süreç, çok karmaşık geometrileri olan parçaların üretiminde kullanılır ve yüksek sıcaklıklara dayanıklı parçaların imalatında yaygın olarak tercih edilir. - Doğrudan Metal Lazer Sinterleme (Direct Metal Laser Sintering -DMLS): Bu yöntem, bir lazerin metal tozlarını eriterek katmanlar halinde bir araya getirdiği bir süreçtir. Sonuç olarak, metal parçalar üretilir. Bu eklemeli imalat teknolojileri, endüstride, sağlık sektöründe, havacılıkta ve daha birçok alanda prototip üretimi, özelleştirilmiş parça üretimi ve kompleks geometrili parçaların üretimi gibi birçok uygulamada kullanılmaktadır. Read the full article

#3DBaskı#3Dyazıcılar#Additivemanufacturing#Dijitalimalat#Eklemeliİmalat#ElektronIşınıylaEritme(EBM)#Endüstriyel3Dbaskı#FusedDepositionModeling(FDM)#FusedFilamentFabrication(FFF)#Katmanlıimalat3DyazıcılarSeçiciLazerSinterleme(SLS)#Katmanlıüretim#Malzeme3Dbaskı#Metal3Dbaskı#Nesnelerinfizikselüretimi#Polimer3Dbaskı#Prototipleme#Stereolitografi(SLA)#ÜretimTeknolojileri

0 notes

Text

3Dprintum

Objectum attraction to 3d printers. Including, but not limited to, small, medium, large, plastic filaments printers (FDM/FFF), resin printers (SLA, DLP, MSLA). Yes, even concrete ones

The rainbow line represents ribbon cables/dupont jumper wires that sometimes are exposed, especially on FDM printers, or plastic/resin/other material that it works with. Depends on how you want to see it.

The darker lines are the layers of filament, because FDM printers print in layers, from top to bottom.

And stringing (the light strings that can be visible on almost white line).

Oversimplified explanation of what stringing is👇

What is stringing? Imagine using a hot glue gun to draw lines on paper. If you move the glue gun from one spot to another without stopping the flow, thin strands of glue will stretch between the two points. In 3D printing, the printer’s nozzle melts and extrudes plastic, and if it doesn’t stop properly when moving between different areas, it can leave behind thin, unwanted plastic strands—this is called stringing.

#objectum#techum#3Dprintum#printer#printer objectum#3d printer objectum#3d printer#flag coining#flag making#objectum flag#objectum coining#has id

18 notes

·

View notes

Text

Rev1 Technologies offers the best CreatBot PEEK-300 3D Printer. CreatBot PEEK-300 3D Printer enables high-temp, precision printing of PEEK and advanced materials—engineered for reliable, efficient, and functional part production.

Buy Now: https://rev1tech.com/shop/3d-printing/3d-printers/fff-fdm/peek-300/

#Rev1Technologies#CreatBotPEEK300#PEEK3DPrinter#HighTemp3DPrinting#3DPrintingPEEK#3DPrinterForAerospace

0 notes

Link

0 notes

Text

3D printing technology has been part of the discussion for at least a couple of decades, and about ten years ago the first 3D printer was designed and released. This machines have amazing capabilities and can print almost everything from hardware and toys to food and housing. Today, 3D printers occupy relatively small niches and are mainly used to print product prototypes, custom phone cases, detailed toys and figurines, various cosplay materials, figures for board games (Warhammer 40000, for instance), etc. And after hearing about astonishing 3D printers capacities, you decided to buy one or just planning to use this technology to print some product or simply want to know more about 3D printers, then this article is for you. Today, we unveil the curtain of what stands behind additive manufacturing and introduce you to ten things which are necessary to know before dealing with three-dimensional printing. 1. Different Types Of 3D Printers Use Different Technology Modern market is full of a variety of 3D printers with diverse specifications and requirements that work under different technologies. Let's discuss three the most common approaches to additive manufacturing. Fused Deposition Modeling (FDM) It's the most popular 3D printing process which works on a principle of placing material layer by layer. FDM printers use a thermoplastic or metal spool of filaments and apply heating to release the filament of a material to put down layers that echoing the shape of the model. Fused Filament Fabrication (FFF) is also a widely used term that literally means the very same method of 3D printing and was invented by the RepRap initiative in order to patent and legally used this technology. It's also known as Plastic Jet Printing (PJP). FDM printers are universally available and considered to be relatively not high priced. Stereolithography (SLA) Such printers involve using photosensitive liquid substances as a basic material and work with ultraviolet light in order to release molecules and link them together, forming a solid 3D object. Stereolithography is also called Optical Fabrication or Rapid Prototyping. It's suitable for prototyping, creating models or patterns since SLA is distinguished by the amazing precision of all the details. On the other hand, it allows using a very narrow range of possible materials and is unsuitable for printing organic and metal. Moreover, stereolithography printers are at least twice more expensive than FDM ones and a bit more difficult to found. Selective Laser Sintering (SLS) SLS is slightly different from SLA printing technique in choosing the basic working material which in turn leads to the use of other 3D printing technology. SLS printers engage a laser as a source of power that is focused on a specific place in space according to the 3D model parameters. Such printers work with powder materials, mainly metals, and use a laser to melt the powder and bind its molecules into a solid model. This technology is mainly used to print metal objects. The choice of technology depends on a desirable material and the amount of funds that you are willing to spend on manufacturing. Besides, despite the fact that 3D printing features high details accuracy, some devices in more or less degree do not allow you to print fine details. That's why before choosing a 3D printer for further purchasing or printing, you should consider the points made above. Let's pay a bit more attention to the prices and materials used to print objects. 2. Printers Can Cost As Much As Your House This point will be mainly interesting for the ones who are going to buy a 3D printer or just interested in its pricing policy. Well, the prices of three-dimensional printers depend, for the most part, on a quality of the end-product. Generally, professional and the most expensive ones can produce the higher-quality objects and their price mainly starts from $2,000. However, the price also depends on the type of raw material and the printing technology.

FDM printers are the easiest to find at the market and use at home or in a small office. In general, the lower the price is the more limitations the printer has in terms of the size of final object and materials involved. But, if you don't want to spend a lot of money and prefer to purchase a relatively cheap printer as an introductory device, you can easily find a small printer that will cost you about $100. Nevertheless, the 3D printing technology gains more and more popularity among consumers, and thanks to that prices on 3D printers went down while the printing quality enhances. In addition, do remember that printing devices don't come along with the materials used in a printing process. These components should be purchased or collected separately according to printer and model requirements. 3. There Aren't So Many Materials Fit For 3D Printers Despite the fact that innovators found a way to think-out-of-the-box and print chocolate and pasta, today the devices available for customers have a comparatively narrow range of materials to use. Most popular models involve FDM technology and use different thermoplastics to print solid objects. We would like to examine plastic as an example, so you can see what dangers await you at this step. One of two most popular materials is Poly Lactic Acid (PLA). This material is derived from corn starch and possesses good temperature characteristics (can be cooled or heated quickly). PLA is eco-friendly and presented in solid and translucent colors. This material is perfect for newbies to deal with. However, since it possesses low melting characteristics, the output can contort under high temperatures. Besides, it's not the best options for models that have joints or moving parts. The second material we would like to mention is Acrylonitrile Butadiene Styrene (ABS), a petroleum-based thermoplastic that became popular thanks to its flexibility and durability. Moreover, ABS won't likely be deformed under heat because it's resistant to high temperatures. Furthermore, it can be used to produce a solid object with interlocking parts. On the other hand, at the output, ABS-based models take longer to cool after printing. It's obligatory to know decide on a suitable material before buying a printer or choosing one for future printing. Some printers can work with a range of materials, some, on the other hand, accept only one type. 4 Nozzles Size Is Important When it comes to preferred filament size, it's really up to the printer specifications, 3D model quality, and personal preferences. Most printers go with 1.75 mm filament size, however, 3 mm is also quite common and more tolerant with hardware shortcomings. But you need more force to push 3mm filament into the hot end. The nozzle size affects the horizontal resolution of the print. The most popular nozzle diameters are 0.34 mm and 0.4 mm. Each size is better in some situations. For example, if you need to print the 3D object fast, it's better to choose bigger nozzle since it reduces the overall number of layers thanks to thicker string. Smaller nozzles, on the other hand, ensures the smoother finish of the final prototype. 5 3D Modeling For Different 3D Printers Has Its Peculiarities It's possible to create a 3D model in a wide range of software both free and commercial like Maya, 3ds max or Zbrush. Besides, as you already know the type of raw material is also important and affects the modeling process. When it comes to 3D modeling, you should pay attention to many details and limitations. For instance, take into consideration printer type, printing technology, and physical qualities of the raw material. This also means that you should create a 3D model with physically correct characteristics. If you are not familiar with modeling processes and material guidebooks, you should better entrust this work to professionals who are experienced in 3D modeling for 3D printing. Just provide them with all necessary information about printer type and model,

material that you are going to use while printing and the outlines of the overall idea (sketches, pictures, photos). 6. STL Is A Universal File Format For All Printers The name of .STL file extension does not come from stereolithography printing technique. It stands for Standard Triangle Language and became a worldwide format supported by all 3D printers. Basically, the term 'Standard Triangle Language' means expansion of the modeled object into triangles in three-dimensional coordinates. STL file is required in order to print any 3D model. This file with full information about the model can be uploaded, recognized and proceeded by the printer in a matter of seconds if everything is done according to industry standards. The printer inspects the information received from the STL file and places the pin of the printer which moves along X, Y and Z axes in order to create an object layer by layer to the appropriate point in space according to the model coordinates. In addition, professionals don't recommend to exceed the 100MB file size. 7. You Should Have A Special Software Even if you make everything right with a 3D modeling and compile the correct STL file of the model, you will still need an appropriate software installed. Such programs known as 'slicing software' will explain the printer how to produce the model you uploaded on the language it understands. This software provides exhaustive information about the number of layers, the solid parts of the prototype and hollows, and also the starting position of the print bed. Some companies produce printers that have an inbuilt slicing software or such program come along with the printer. For other printers, you should choose the right software on your own or consult with a community what the best choice is. 8. Different Printers Provide Different Print Quality This point should be noted by the ones who are going to buy a printer or looking for a 3D printing services. Printing quality is one more point that should concern you in three-dimensional printers. To receive a high-quality prototype, you should take into account resolution and printing speed. Print resolution indicates to the level of detail that printer can ensure. The smaller this parameter is, the more detailed object you can create. Print speed refers to the speed of extruder movements. Generally, printers with high print speed characteristics print faster than others. Moreover, there are other factors that may affect the print quality, for instance, slow down the print speed or change the output. These elements can include the material characteristics (some materials cool slower that can cause deformation or blur the details) or default settings when a change of speed is required and printer reacts by acceleration to higher speed and vice verse. Eventually, the best way to judge about the print quality of a specific printer is to carefully examine the final output. If you are going to buy the printer, you should better Google some images and photos of a final product. If you're just looking for the printing services, consult the representatives and look at company portfolio to determine the most suitable printer. 9. 3D Printers Require Careful Care To Prevent Safety Issues Three-dimensional printers as any other manufacturing devices are fraught with specific safety problems to which you should pay special attention. When it comes to working with any 3D printer, precautions must be taken to avoid accidents. For this reason, before purchasing the printer examine all available instructions and possible problems that may arise and follow the rules of operation. We prepared a small brief description about some notable issues. One of the most important things you should pay attention to is high temperatures of materials you are working with. Due to the fact that a majority of 'domestic' printers work with heated plastic, some external parts of the printer can get extremely hot. For instance, print bed, extruders and the plastic itself.

These parts can be a cause of dangerous burns in cases when you aren't careful. Most large printers have an inbuilt protective glass around the print area, however, many small ones have an open area. That's why with that type of 3D printers, you should take extra precautions. Moreover, 3D printers require a well-ventilated space due to the fact that during the printing process some printers accumulate fumes, especially when ABS plastic has been taken as a raw material. There is no much research about the impact of these fumes on general health and there is no final option on that matter. Still, it's better to protect personal health and safety by taking extra precautions. In addition, the plastic you use can be dangerous for your well-being and welfare. Think about it, 3D printing industry has reached the point when three-dimensional printers are used to create many household hardware and kitchenware, in particular. The two most popular thermoplastics mentioned in this article Poly Lactic Acid and Acrylonitrile Butadiene Styrene are considered to be safe, however, it's only in case they are of a good quality. If you buy a substandard plastic no matter on purpose or accidentally, this material can include additives that may be unsafe. Another problem is that most printers work under FDM technology and can produce the items with not smooth enough surface that is a perfect condition for collection of bacteria. In some cases, this problem can be solved by coating an item, however, it's still not completely safe to use printed kitchenware. 10. The Technology Is Everywhere We guess it's not a secret for everyone that 3D printing industry is a field for investment. The world considers three-dimensional printing as the future of manufacturing and even humanity. Thirty years ago people didn't even think about having printed hardware, but now it's everywhere. The majority of 3D printers use plastic or metal material to produce items, but it's also possible to use a generous amount of other primary products, including food. Such devices are capable of creating almost every dish from cookie to pizza. These machines use fresh components that were prepared just before printing. 3D printers is also an area of interest of a Health Care industry. For example, this technology can be used in prosthetics to create custom prostheses that will be individual and fix perfectly for a specific patient and in surgery to conduct operations that now seem impossible. Moreover, humanity organized a housing initiatives in order to provide poor families with relatively cheap houses in countries like China and Netherlands. Besides, in areas where natural disasters have happened, such as a tornado or earthquake, and people lost their homes, such shelters will be a perfect option. In addition, Science and Education are particularly interested in implementation of 3D-printed models and print devices in order to improve educational and research process. 3D printing apps are recommended for children as a part of their study process. Finally, 3D printing can play a significant role in further space exploration, for example in long-term space missions as a part of a spaceship 3D printer can produce and replace the damaged or lost part of the ship according to the design sent from the control center. Although 3D printers aren't very common like PCs, people can observe an express grow in the technology and quantity of devices itself. Many industry experts name 3D printing industry one of the most perspective trends for the upcoming years. While it's easy to predict the areas where 3D printers will become a usual device or a part of a process, some industries are still keeping themselves aloof and probably wait for some kind of a revolution to include 3D printers in their techniques. 3D printers have all chances to revolutionize manufacturing (actually, they have already started doing this) and become one of the most important inventions of a human being. Victor Terekhovskyi is a marketing specialist at Program-Ace.

It is an R&D company that provides a full circle of IT services located in Kharkov, Ukraine. Our team specializes in development of 2D/3D games and apps, custom web solutions and mobile applications. The qualified experts of Program-Ace combine a unique experience in complex web systems and 3D related fields.

0 notes

Photo

3Dプリンターとは3D CADデータを元に3次元の立体造形物を出力(プリント)する装置です。

3Dプリンターには様々な方式があります。

基本的にはどれも1層1層積んでいく仕組みですが、方式によって得意不得意があります。

方式によって、造形物の精度、扱える材料とその物性、造形���能なサイズ、スピード、メンテナンス性など、様々な特徴の差異があります。 また、メーカー各社の独自用語が存在するなど、同じ方式を指していてもそれを表す用語がいくつもあるケースがあり、全体像の把握には、それら表記ゆれに対するケアが必要です。

3Dプリンターの方式はISOで分類が規定されておりますので、その区分を参考にしながら、主要な方式を網羅的にまとめました。

海外では既に3Dプリンターを「実生産」で使うことが当たり前に。 そのノウハウが一足飛びに得られるとしたら?

1つの製品に、何個の部品が使われていますか?会社全体では、何種類の部品がありますか? 多い企業では万単位の部品が存在すると思います。

それらの部品の中から3Dプリンターでの生産に向いている部品を自動で見つけ出し、 続々と生産を効率化していけるシステムがあるとしたら、御社の生産はどう変わるでしょう?

3Dプリンターでの部品実生産ノウハウを御社にインストールするシステム CASTOR 目次 現在主流 FDM方式 最も古い 光造形方式 高精細で表現力が最も高い インクジェット方式 結合剤を噴射する バインダージェット方式 金属3Dプリンターの世界を一変 BMD方式 従来型の金属3Dプリンター パウダーベッド方式 シート積層法 指向性エネルギー堆積法 CIM(Cast in motion)方式 3Dプリンターの仕組み 3Dプリンターは材料を1層1層積み上げていくことで、高さのある造形物を出力します。

様々な方式はありますが、基本的に層を重ねていくことで造形するという点に変わりはありません。 そのように、原理としては非常にシンプルです。

扱える材料も、プラスチック(樹脂)、金属、カーボン等、様々な材料を使って造形することができます。

3Dプリンターとは 3次元造形 現在主流 FDM方式 日本語表記:熱溶解積層方式(Fused Deposition Modeling) ISO分類:材料押出法(Material Extrusion) その他表記:FFF方式(Fused Filament Fabrication) FDM方式の概要 FDM方式とは、3Dプリンター世界シェアNo.1である米国Stratasys社が開発した方式です。 現在3Dプリンターにおいて主流の方式です。

FDM方式による造形 熱で溶かした樹脂をノズルから押し出し、ソフトクリーム製造機のようなイメージで、一筆書きで1層1層積み重ねて造形していきます。 この画期的な方式はストラタシス創設者のスコットクランプがグルーガンを見て想起したという逸話が��っています。

FDM方式 FDM方式の強み 本物の熱可塑性樹脂を使えること、だからこその強度・耐熱が強み 熱可塑性樹脂は射出成形で用いられており、量産する最終製品でよく使われるプラスチック材料です。代表的なものにABS樹脂等があります。

そのため、試作(プロトタイプ)であっても、最終製品に近い物性のリアルで機能的な試験も可能であり、製造業において重宝されています。

他の方式では紫外線硬化樹脂を用いるものが多いため、ABSそのものではなくABSに近い物性を持つ「ABSライク樹脂」が開発されています。

多様な物性の素材が使える FDM方式、特にハイエンド機種では産業界で求められる様々な物性の樹脂に広く対応しています。

エンジニアリングプラスチック、スーパーエンプラまで使えるなら、特殊用途の最終製品まで使えるイメージが沸くのではないでしょうか。

段差も目立ちにくいキメの細かな機種も 初期の頃は層を積み上げた際にできる段差が目立つ傾向がありました。

しかし近年では、材料も装置も進化していることから、従前より段差も目立ちにくくなりました。

FDM方式の弱点 FDM方式は比較的積層痕が目立ちやすいため、物性よりも外観のなめらかさ、プロダクトデザインにおける表現力を重視する用途では、FDM方式よりインクジェット方式の方が適していると言えるでしょう。

また、FDM方式だけでは金属の造形ができません。そのため、金属で造形したい場合は金属専用の3Dプリンターを導入する必要があります。(※FDM方式と組み合わせて金属造形するシステムは存在します。)

どのようなシーンで選ぶべきか? 製造業における試作(ラピッドプロトタイピング)、治具・工具の製作、最終製品の造形をしたい場合で、強度が求められるものはFDM方式を選ぶと良いでしょう。

FDM方式について詳しい解説はこちら

FDM方式の製品一覧はこちら

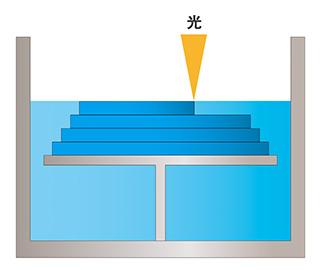

3Dプリンターで何をしたいですか? 最も古い 光造形方式 ISO分類:液槽光重合法(Vat PhotoPolymerization) その他表記:SLA方式(Stereo Lithography Apparatus) 光造形方式はSLA方式とも呼ばれます。 さらにSLAの中には、レーザー光を用いるレーザー方式と、一括面露光をするDLP方式があります。

光造形方式の概要 光造形方式は、最も古い3Dプリンターの方式です。 液体状の光硬化樹脂のプールに光を照射し、1層1層重ねて造形します。

光造形 レーザー方式 レーザー光を照射し、光に触れた箇所が硬化される仕組みです。光造形方式の中でも古くからある方式です。

DLP方式 プロジェクターのように像を作り、一括面露光する仕組みです。

造形物の面積が広い場合はレーザー方式と比較して高速露光できることが強みですが、像を作る際、ピクセル単位で描画することから、照射する範囲を広げると解像度が落ち寸法精度が出にくく、また造形物の表面は水平・垂直の両方向に積層痕(段差)が出てしま��ます。

光造形方式の強み きめの細かな造形物が作りやすいこと、個人向けでは安価なモデルが多数登場していることが挙げられます。 造形速度は比較的速い傾向があります。

光造形方式の一般的な弱点 産業用途の光造形機は高額なものが多く、コストが高くなりがちです。

紫外線硬化樹脂を用いるという性質から、太陽光など光による劣化が起こりやすくなる性質があります。 吊り下げ方式のため大型のモデルの造形に適していなかったり、変形が起こる可能性もあります。 そのため、耐久性を求める用途、最終製品として用いる用途ではベストとは言えません。

また、造形後のアルコールや溶剤での洗浄や二次加工、剥離によるサポート除去など後処理に手間が掛かるものが多いです。

どのようなシーンで選ぶべきか? 歴史的経緯として古くはラピッドプロトタイピングに多く使われてきましたが、3DプリンターのDDM(デジタル・ダイレクト・マニュファクチャリング:最終製品や治工具の製造に3Dプリンターを利用する)が浸透するにつれ、役割は変わりつつあると感じます。

個人向けの3Dプリンターでは良い機種が揃ってきていますので、強度・耐久性を必要としないシーンで小さなサイズのモデルを手軽に造形したい場合にお勧めです。

光造形方式の弱点を克服した機種がStratasysから登場 従来型の光造形方式の3Dプリンターの弱点であった耐久性の弱さや生産性の低さを克服した機種がOrigin Twoです。

Origin Twoは量産でも高精細であり、最終製品のパーツ生産に使用されることを想定しています。

高精細で表現力が最も高い インクジェット方式 ISO分類:材料噴射法(Material Jetting/マテリアルジェッティング) その他表記:PolyJet方式※Stratasys社 インクジェット方式の概要 インクジェット方式という通称もありますが、正式分類では材料噴射法と言います。

その名の通り、材料を噴射し、それに対し光を当てて1層1層積んでいきます。 構造が2Dプリンターでいうインクジェットプリンターに類似していることから、インクジェット方式と呼ばれています。

高精細でリアルな造形物を作ることができる方式です。

インクジェット方式 インクジェット方式の強み 高精細な造形物 第一に、高精細な造形物を作ることができるということが挙げられます。 積層痕の目立たないなめらかな造形物を作りたいなら、まず選択肢にあげると良いでしょう。

機種によってはカラー材料の使用や、フルカラー造形も 紙にカラー印刷できるように、3Dプリンターでもカラー印刷できる機種があります。 その原理は、2Dプリンターが複数カラーのインクを用いてカラー印刷を可能にしているのと同様で、複数のカラー材料を用いることで色を再現します。

後から塗装をする必要がなく、塗装時間の短縮や手間を省く事ができます。

上位機種ではPANTONE®カラー対応のフルカラー造形が可能な機種もあり、色にこだわるプロダクトデザインで、完成物とのイメージ乖離を防ぎます。

透明なクリア材料や、ゴムの質感の再現まで 複数の材料を同時に扱うことができる機種もあります。 アッセンブリ加工が必要なものが、ワンショットで造形できます。

デザイナーが思い浮かべたプロダクトのコンセプトを何もない所から具現化する強力なツールとなるでしょう。

3Dプリンターが描く未来の世界に最も近いものがこ��インクジェット方式の3Dプリンターかもしれません。尚、この分野はストラタシス社がかなりリードしています。

布や皮革の生地に対して直接3Dプリントできる機種も 麻やフェルト、スウェードや皮革などの「生地」に3Dプリントする方式がハイブランドや大手メーカーにて採用されはじめています。

硬質素材だけではなく、ゴムのように柔軟性のある素材を含め、60万色フルカラーで3Dプリントできる機種があります(Stratasys J850 Prime FabriX)。

Stratasys J850 Prime FabriX インクジェット方式の弱み 強度・耐久性についてはFDM方式に劣ります。 噴射した材料に光を照射し硬化させるため、太陽光での劣化もあります。その面では光造形方式と同じです。

どのようなシーンで選ぶべきか? 試作におけるデザイン性・外観の再現での用途では群を抜きます。 デザインの価値が高まる中、メーカーにおけるデザイン部門・設計部署での導入に最適です。 構想設計から最終段階まで、リアリティを持った試作品を気軽に何度も出し直しして調整しながら創ることが可能です。

Stratasysのインクジェット(PolyJet)方式について詳しい解説はこちら

PolyJet方式の製品一覧はこちら

3Dプリンターで何をしたいですか? 結合剤を噴射する バインダージェット方式 日本語表記:粉末接着方式 ISO分類:結合材噴射法(Binder jetting) その他表記:バインダージェッティング方式 バインダージェット方式の概要 インクジェット方式(マテリアルジェッティング)は材料自体を噴射する方式でした。 それに対して、バインダージェット方式は、バインダー(=結合剤)の方を噴射することで造形物を固めます。 元々は石膏に結合剤を吹き付けて固める方式でした。 石膏という材質から後加工での着色がしやすく、フィギュアの造形や、簡易なデザインイメージの確認に用いられていました。

その後、金属、樹脂、セラミック等の材料でも造形できるようになり適用できる幅は広がりました。 尚、このバインダージェット方式の生みの親であるMITの研究者は、現在Desktop Metal社で金属3Dプリンターの開発に携わっています。

バインダージェット方式 バインダージェット方式の強み サポート材が不要であること、着色がしやすいこと、造形速度が速いことが挙げられます。

バインダージェット方式の弱点 表面精度が粗いこと、強度が弱いこと、粉末を取り扱い除去する必要があり、粉末の飛散による危険性や粉じん対策が必要であること、造形後に後処理の手間が掛かることが挙げられます。

どのようなシーンで選ぶべきか? 強度は求めないデザイン確認の用途に適合すると思います。

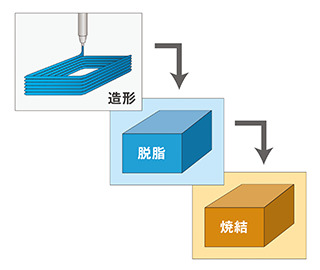

金属3Dプリンターの世界を一変 BMD方式 英語表記:Bound Metal Deposition方式 ISO分類:- その他表記:ADAM方式(Atomic Diffusion Additive Manufacturing) BMD方式の概要 金属3Dプリンターは金属粉を取り扱うため、取り扱いが容易ではありませんでした。 それを劇的に改善したのがBMD方式です。

BMD方式は、3つの段階を経て金属の造形物を作ります。

BMD方式 1.3Dプリンターでの造形 まず3Dプリンターで造形します。金属とポリマーとワックスでできた素材を熱で溶解し、積層します。 しかしこれだけでは金属部品として求められる物性が得られません。 そこで、次の段階に進みます。

2.専用の脱脂装置でバインダーを除去する 金属とバインダーが混ざった状態から、ワックスを除去します。

溶剤を用いた工程が不要となる新しい方式の装置が登場しています。

3.専用の焼結装置で焼結する ピーク温度1400℃で焼結��、固めます。

これは製造業の世界では歴史があるMIM(Metal Injection Molding)の技術を応用したものです。

製品としてはこの金属3Dプリンターを含む3つの装置を1つのシステムとして提供する形式で販売されています。

BMD方式の強み 従来の金属3Dプリンターと異なり、専用の部屋を用意する必要がありません。

従来方式では、金属粉の粉塵対策、不活性化ガスを用いるための設備投資等、総合して投資規模・総保有コストが大きくなりがちでしたが、それを解決しています。

また、3Dプリンター本体はFDM方式で造形するため、従来工法では実現できなかった複雑な形状も精度高く造形可能です。

金属3Dプリンターの導入をためらっていた企業様にこそ検討いただきたい方式です。

BMD方式の弱点 焼結の際にガスを使います。このガスのランニングコストも導入判断の評価ポイントになるでしょう。 ただし、ガスの使用量は機種によって大きな差があります。

また、有機溶剤を扱うため、オフィスで使うには局所排気装置が必要になります。 (しかし、総保有コストを考えると圧倒的な削減ができると言って良いでしょう。)

どのようなシーンで選ぶべきか? 金属素材で低コストに造形したい、金属の製品開発を高速化したい、金属パーツの多品種少量生産に使いたいといったシーンでは最適な方式です。

BMD方式の3Dプリンター Desktop Metal特設ページはこちら

3Dプリンターで何をしたいですか? 従来型の金属3Dプリンター パウダーベッド方式 ISO分類:粉末床溶融結合法(Powder Bed Fusion) その他表記:PBF方式 パウダーベッド方式の中には、レーザー熱源方式と、電子ビーム熱源方式があります。

レーザビーム熱源方式(Selective Laser Melting/SLM) 電子ビーム熱源方式(Electron Beam melting/EBM) パウダーベッド方式の概要 パウダーベッド方式は、金属粉末を敷き詰めた床に光線を照射し、その熱で焼結させる方式です。 金属のほかにナイロンや樹脂も用いられるケースがあります。

従来は金属を3Dプリンターで造形する際の主要な方式でした。

パウダーベッド方式 方式1.レーザー熱源方式 ハイパワーなレーザー光を照射することで金属粉末を焼結させます。

方式2.電子ビーム熱源方式 レーザーではなく電子ビームを照射する方式です。 レーザー熱源方式では難しかった銅の造形も可能な方式です。

パウダーベッド方式の強み BMD方式の登場で情勢は変わっていますが、金属を造形できる3Dプリンターとして有力な方式であったと言えます。

パウダーベッド方式の弱点 機器本体が高額であるということに加え、工場において設置する部屋の確保、粉塵対策・不活性化ガスの排出対策の空調設備など、装置外の投資規模が大きくなること。 オペレーターが金属粉末を吸入するリスク、金属粉末が工場内に拡散するリスクがあること。

サポート材の除去に手間が掛かること、表面がざらついた造形物になること、などが挙げられます。

どのようなシーンで選ぶべきか? 現時点では、まずパウダーベッド方式の弱点を克服したBMD方式を検討いただき、BMD方式では適合しない場合にパウダーベッド方式をあわせて検討いただくというのが良いと思います。

シート積層法 ISO分類:シート積層法(Sheet Lamination) シート積層法の概要 シート積層法は、薄いシートを重ね合わせて、接着剤や超音波で結合させる方式です。 結合した素材をレーザーでカットし成形します。

シート積層法の強み PVC、金属、紙等、他の方式ではあまり見られない材料を用いて造形可能です。 また、複数の金属素材を合わせて使うことができること等が挙げられます。

シート積層法の弱点 廃棄材料が多く出る可能性があること、他の方式に比べ造形精度が低いこと、中空構造が作りにくいこと、等が挙げられます。

どのようなシーンで選ぶべきか? 紙やPVCで造形したい場合、異なる金属素材を接合して用いたい場合などのシーンで有効になると思います。

3Dプリンターで何をしたいですか? 指向性エネルギー堆積法 ISO分類:指向性エネルギー堆積法(Directed Energy Deposition) その他表記:レーザーデポジション、レーザーメタルデポジション(LMD) 指向性エネルギー堆積法の概要 指向性エネルギー堆積法は、金属粉末を吹き付けながらレーザー光を照射することで肉盛り溶接する方式です。

指向性エネルギー堆積法の強み 金属の造形物ができること、異種材料を組み合わせて母材とは異なる金属の造形ができること、高熱で溶融するため耐久性が高い造形物ができること。また、大型造形が得意で造形速度も速い。

指向性エネルギー堆積法の弱点 金属粉末を扱うため取り扱いに注意を要すること、表面は粗い仕上がりになること、造形できる形状に制約が大きいこと等が挙げられます。

どのようなシーンで選ぶべきか? こちらも、まず従来型金属3Dプリンターの弱点を克服したBMD方式を検討いただき、BMD方式では適合しない場合に指向性エネルギー堆積法の機種を検討いただくというのが良いと思います。

CIM(Cast in motion)方式 CIMではまず「型を造るための枠」を3Dプリンターで高速造形します。その枠の中にエポキシ樹脂を流し込み、それが型になります。このエポキシ樹脂は熱硬化性樹脂のため、オーブンで加熱し固めることで機械的特性に優れた型が得られます。 型を造形するために用いた枠は、水に浸すとフレーク状に砕けるため容易に除去可能です。造形した型は、表面精度を高めるため切削加工で研磨する等、仕上げ処理を施して完成です。

型を造形するCIM方式 FRP用の成形型などにおいては、型を3Dプリンターで造形する方式が実用化されています。

パウダーベット方式 アルテックがお手伝いできること 3Dプリンターには様々な方式があり、非常に多くのメーカーがあります。

アルテックではお客様のニーズにお応えする上で、実績があり信頼性が高く、時代に適合したベストだと思えるメーカーのみ、厳選して取り扱っております。

(3Dプリンターの方式・仕組み・特徴を解説(2024年最新版) - 3Dプリンターならアルテックから)

0 notes

Text

MICROZEY PLA PRO HYPER SPEED TRANSPARAN FUŞYA 1.75 mm - 1000 Gr

MICROZEY PLA Pro - Hyper Speed filament, için yüksek hızlı FFF (FDM) baskı için özel olarak geliştirilmiş bir filamenttir. Optimize edilmiş moleküler ağırlık ve ayarlanmış akışkanlık ile MICROZEY PLA Pro - Hyper Speed, sıcak uçta daha hızlı erime ve malzeme ekstrüde edildikten sonra çok daha hızlı soğuma yeteneğine sahiptir. Bu sayede MICROZEY PLA Pro - Hyper Speed filamentlerle basılan parçalar yüksek yüzey kalitesine sahip olur ve keskin detayların çoğu korunur. En önemlisi optimize edilmiş moleküler ağırlık sayesinde MICROZEY PLA Pro - Hyper Speed mükemmel katmanlar arası bağlanma kalitesi ve Z yönü mukavemeti gösterir. Bu nedenle yüksek hızlı PLA konsept modeller, figürler ve prototip oluşturma vb. için kullanılabilir.

Yüksek yüzey kalitesi Yüksek baskı hızına uygunluk Kullanıcı ve çevre dostu Komplex yapılardaki prototip ihtiyacı için ideal Geniş renk seçeceği Yüksek yüzey sertliği Oda sıcaklığındaki uygulamalar için uygunluk Düşük koku problemi Endüstriyel kompostlama ile biyolojik olarak parçalanabilir Doğal bileşenlerden yapılmıştır Elektrikli ve elektronik cihazlarda güvenli kullanım Gıda ile temas eden uygulamalar için güvenli BPA ve stiren içermez

0 notes

Text

Cheapest 3D Printing Method

In the ever-evolving realm of manufacturing solutions, 3D printing has emerged as a frontrunner, democratizing production for professionals and hobbyists alike. Among the various 3D printing techniques, Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), stands out as the most economical option. This article delves into the reasons behind FDM’s cost-effectiveness, its applications, and strategies to maximize its potential, providing a comprehensive analysis within a 500-word limit.

Tracing the Origins of Fused Deposition Modeling (FDM):

FDM, conceptualized in the late 1980s, revolutionized additive manufacturing by offering a cost-effective alternative for creating prototypes and products. Its working principle involves melting a thermoplastic filament and depositing it layer by layer to construct a 3D object, making it a popular choice for beginners.

A Comprehensive Breakdown of 3D Printing Costs:

Initial Investment: The purchase of the 3D printer constitutes a significant part of the cost, with options ranging from budget-friendly models to sophisticated versions.

Material Expenses: Raw materials, such as filaments in FDM, represent a recurring cost that varies among different 3D printing techniques.

Operational and Maintenance Charges: Regular maintenance, power, and additional accessories contribute to ongoing operational costs.

Software Investments: Depending on project complexity, users might need software tools for designing, slicing, and managing print jobs.

Post-Processing Expenditure: Post-printing steps, such as sanding or painting, contribute to the overall cost.

Diving into FDM’s Cost-Effectiveness:

Economical Entry Points: FDM offers affordable kits for hobbyists and sophisticated systems for professionals, catering to a broad audience at a lower price point.

Budget-Friendly Filaments: FDM utilizes cheaper thermoplastic filaments like PLA and ABS, allowing for cost savings without compromising quality.

Lower Maintenance Costs: FDM printers demand less frequent and less expensive maintenance, reducing the total cost of ownership.

Open-Source Software Ecosystem: FDM benefits from a vibrant open-source community, providing free or low-cost software tools, minimizing expenses.

Simplified Post-Processing: FDM prints often require minimal post-processing, avoiding the need for specialized and costly equipment.

Contrasting FDM with Other 3D Printing Methods:

Stereolithography (SLA): SLA, known for precision, uses expensive UV-curable resins, leading to higher overall costs.

Selective Laser Sintering (SLS): Specialized powders and equipment escalate costs, making SLS less suitable for budget-conscious users.

Direct Metal Laser Sintering (DMLS): Targeting industries, DMLS involves premium materials and machinery, making it costly for everyday users.

Navigating the Ideal Applications for FDM:

Rapid Prototyping: FDM is ideal for cost-effective prototyping, allowing designers to validate concepts without hefty expenses.

Educational Ventures: FDM’s affordability makes it popular in educational institutions for hands-on learning experiences at a manageable cost.

Personal Projects and Hobbies: FDM provides a budget-friendly avenue for hobbyists to explore various projects, from crafting toys to home improvement items.

Customized Manufacturing: FDM excels in manufacturing customized parts or tools at a fraction of the cost compared to traditional methods.

Acknowledging the Limitations of FDM:

Surface Finish Concerns: FDM may exhibit visible layer lines, requiring post-processing for a smoother finish in aesthetically focused projects.

Structural Constraints: Layer-by-layer construction may lead to weaker bonds between layers, posing structural concerns in specific applications.

Limited Scope for Ultra-Fine Details: Filament thickness and nozzle diameter limitations may hinder FDM’s suitability for projects demanding intricate details.

Embracing FDM in the Expansive World of 3D Printing:

In the pursuit of the Cheapest 3D printing method, FDM stands out due to its inherent cost-effectiveness. As technology advances, aligning the choice of the method with project goals becomes crucial. FDM’s rich history, diverse applications, and continuous innovations position it prominently in the 3D printing landscape, offering a balance between affordability and quality.

0 notes

Text

The Next Frontier: How 3D Printing is Revolutionizing Manufacturing - Technology Org

New Post has been published on https://thedigitalinsider.com/the-next-frontier-how-3d-printing-is-revolutionizing-manufacturing-technology-org/

The Next Frontier: How 3D Printing is Revolutionizing Manufacturing - Technology Org

3D printing, also known as additive manufacturing, has gained significant popularity in recent years, revolutionizing the manufacturing industry. The concept of 3D printing dates back to the 1980s when it was first introduced as a rapid prototyping technology. However, it is only in the past decade that 3D printing has gained widespread recognition and adoption in various industries.

The growing popularity of 3D printing can be attributed to its ability to create complex and customized objects with ease. Traditional manufacturing methods often involve multiple steps and processes, which can be time-consuming and costly. 3D printing simplifies the manufacturing process by directly creating objects layer by layer from a digital design, eliminating the need for molds or tooling.

The central piece of a 3D printer – illustrative photo. Image credit: Christian Englmeier via Unsplash, free license

The History of 3D Pringting

The concept of additive manufacturing has existed since the 1940s. In 1945, sci-fi author Murray Leinster described a machine that could “make drawings in the air” and output plastic parts layer-by-layer in his short story “A Logic Named Joe.” However, it took a few more decades for this vision to become reality.

1980s: Early Prototyping

In 1981, Dr. Hideo Kodama of Nagoya Municipal Industrial Research Institute invented one of the first working rapid prototyping systems. It used photopolymers that could be cured by UV light to build parts additively.

In 1984, Charles “Chuck” Hull filed a patent for stereolithography (SLA), which described an additive manufacturing process using photopolymers cured layer-by-layer by UV lasers. He later co-founded the company 3D Systems to commercialize SLA 3D printers.

In 1986, Carl Deckard, an undergraduate at the University of Texas, filed a patent for selective laser sintering (SLS), another 3D printing process that used a laser to fuse powder material. Deckard’s patent was licensed by DTM corporation, which released the Sinterstation 2000, the first SLS machine, in 1992.

In 1989, S. Scott Crump invented fused deposition modeling (FDM) and patented the technology. This process used a heated nozzle to extrude thermoplastic filament material layer by layer. Crump later commercialized it through the company Stratasys, which he co-founded.

1990s: Industry Growth

In 1992, 3D Systems released the SLA-250, which was the first commercially available 3D printer. Meanwhile, Stratasys introduced their first commercial FDM 3D printer in 1992 as well.

Through the 1990s and 2000s, the industry saw rising adoption and usage of additive manufacturing for rapid prototyping across automotive, aerospace, medical, consumer goods and other industries. Both established corporations and startups expanded the capabilities of 3D printing during this period.

2000s: Patent Expiration, Desktop 3D Printers

A significant milestone came in 2009 when key SLA patents expired, opening up the technology. This allowed for the rise of desktop SLA 3D printers like the Form 1, developed by startup Formlabs in 2012.

The expiration of FDM patents around 2010 similarly saw a wave of open source FDM/FFF desktop 3D printers like the RepRap, inspiring companies like MakerBot. This drove increased adoption of desktop 3D printing.

The Basics of 3D Printing: How it Works and its Advantages

The process of 3D printing involves several steps. First, a digital design of the object is created using computer-aided design (CAD) software. This design is then converted into a format that can be read by the 3D printer. The printer then builds the object layer by layer using various materials such as plastic, metal, or even biological materials.

One of the key advantages of 3D printing is its ability to create complex geometries that are difficult or impossible to achieve with traditional manufacturing methods. Traditional methods often involve subtractive processes, where material is removed from a larger block to create the desired shape. In contrast, 3D printing is an additive process, where material is added layer by layer to create the final object.

Another advantage of 3D printing is its ability to create customized products. With traditional manufacturing methods, producing customized products can be expensive and time-consuming. However, with 3D printing, each object can be easily customized by simply modifying the digital design before printing.

From Prototyping to Production: How 3D Printing is Changing the Manufacturing Process

One of the key roles of 3D printing in manufacturing is in the prototyping stage. Traditionally, prototyping involved creating molds or tooling, which can be expensive and time-consuming. With 3D printing, prototypes can be created quickly and cost-effectively, allowing for faster iteration and refinement of designs.

However, 3D printing is not limited to prototyping alone. It has the potential to replace traditional manufacturing methods in certain applications. For example, in industries such as aerospace and automotive, where complex geometries are often required, 3D printing can offer significant advantages over traditional methods. By eliminating the need for molds or tooling, 3D printing can reduce costs and lead times while enabling the production of lightweight and optimized components.

Customization and Personalization: The Power of 3D Printing in Meeting Customer Demands

One of the key advantages of 3D printing is its ability to create customized products. Traditional manufacturing methods often involve producing large quantities of identical products, which may not meet the specific needs or preferences of individual customers. With 3D printing, each product can be easily customized to meet the unique requirements of each customer.

This ability to create customized products has a significant impact on the customer experience. Customers today are increasingly looking for personalized products that reflect their individual tastes and preferences. By offering customized products, companies can differentiate themselves from their competitors and build stronger relationships with their customers.

Reducing Costs and Waste: The Economic Benefits of 3D Printing in Manufacturing

One of the key advantages of 3D printing is its potential to reduce manufacturing costs. Traditional manufacturing methods often involve multiple steps and processes, each adding to the overall cost of production. In contrast, 3D printing simplifies the manufacturing process by directly creating objects from a digital design, eliminating the need for molds or tooling.

By reducing the number of steps and processes involved in manufacturing, 3D printing can significantly reduce costs. This is particularly beneficial for small and medium-sized enterprises (SMEs) that may not have the resources to invest in expensive molds or tooling. With 3D printing, SMEs can compete with larger companies by offering customized products at a lower cost.

In addition to reducing costs, 3D printing also has the potential to reduce waste. Traditional manufacturing methods often result in significant material waste, as excess material is removed during the production process. With 3D printing, only the required amount of material is used, minimizing waste and reducing environmental impact.

Sustainability and Environmental Impact: How 3D Printing is Helping to Reduce Carbon Footprint

In addition to reducing waste, 3D printing also has the potential to reduce carbon footprint. Traditional manufacturing methods often involve transporting raw materials and finished products over long distances, resulting in significant carbon emissions. With 3D printing, products can be manufactured locally, reducing the need for transportation and lowering carbon emissions.

Furthermore, 3D printing enables the use of more sustainable materials. For example, bio-based materials can be used in 3D printing, reducing reliance on fossil fuels and minimizing environmental impact. Additionally, 3D printing allows for the optimization of designs, resulting in lighter and more efficient products that require less energy to produce and use.

The Role of 3D Printing in Industry

The impact of 3D printing on various industries is significant. In the healthcare industry, 3D printing has revolutionized medical device manufacturing by enabling the production of customized implants and prosthetics. In the aerospace industry, 3D printing has been used to create lightweight components that improve fuel efficiency and reduce emissions.

The potential for 3D printing to disrupt traditional manufacturing industries is also significant. For example, in the automotive industry, 3D printing has the potential to transform the production of spare parts. Instead of maintaining large inventories of spare parts, manufacturers can simply 3D print the required parts on demand, reducing costs and lead times.

The Future of Manufacturing

The potential for 3D printing to revolutionize the manufacturing industry is immense. As the technology continues to evolve and improve, we can expect to see even greater adoption of 3D printing in various industries. The ability to create complex and customized objects with ease will continue to drive the growth of 3D printing in manufacturing.

However, there are also challenges and opportunities associated with 3D printing in manufacturing. One of the key challenges is the need for skilled operators who can design and operate 3D printers effectively. Additionally, there are regulatory challenges that need to be addressed, particularly in industries such as healthcare where safety and quality standards are critical.

The Challenges of 3D Printing in Manufacturing: Overcoming Technical and Regulatory Hurdles

One of the key technical challenges of 3D printing in manufacturing is the limited range of materials that can be used. While 3D printing has made significant advancements in recent years, there are still limitations in terms of the types of materials that can be used. For example, metals such as titanium and aluminum are commonly used in traditional manufacturing methods but are more challenging to 3D print.

Another technical challenge is the need for post-processing and finishing. While 3D printing can create complex geometries with ease, the surface finish of 3D printed objects is often rough and requires additional processing to achieve the desired quality. This can add time and cost to the manufacturing process.

In addition to technical challenges, there are also regulatory challenges associated with 3D printing in manufacturing. In industries such as healthcare, where safety and quality standards are critical, there is a need for regulatory frameworks to ensure that 3D printed products meet the required standards. This includes the need for validation and certification processes to ensure the safety and efficacy of 3D printed medical devices.

The Impact of 3D Printing on Supply Chain Management: Opportunities and Challenges

The potential for 3D printing to disrupt supply chain management is significant. With traditional manufacturing methods, products are often manufactured in one location and then transported to various distribution centers or retail stores. This can result in long lead times and high transportation costs.

With 3D printing, products can be manufactured locally, reducing the need for transportation and lowering lead times. This has the potential to transform supply chain management by enabling companies to produce products on demand, reducing inventory costs and improving responsiveness to customer demands.

However, integrating 3D printing into supply chain management also presents challenges. For example, companies will need to invest in 3D printing infrastructure and develop new processes and workflows to support on-demand manufacturing. Additionally, there may be challenges in terms of intellectual property protection and ensuring product quality and consistency across different manufacturing locations.

The Future of 3D Printing in Manufacturing: Emerging Trends and Technologies

The future of 3D printing in manufacturing is promising, with several emerging trends and technologies driving its growth. One of the key trends is the development of new materials that can be used in 3D printing. Researchers are exploring the use of materials such as graphene, carbon fiber, and biodegradable polymers, which offer improved strength, durability, and sustainability.

Another emerging trend is the development of multi-material and multi-color 3D printing technologies. Currently, most 3D printers can only print objects using a single material or color. However, researchers are working on developing printers that can print objects using multiple materials or colors simultaneously, opening up new possibilities for complex and customized designs.

The Promise of 3D Printing in Revolutionizing Manufacturing

3D printing has the potential to revolutionize the manufacturing industry. Its ability to create complex and customized objects with ease, reduce costs and waste, and promote sustainability makes it an attractive option for manufacturers across various industries.

While there are challenges and opportunities associated with 3D printing in manufacturing, the promise of this technology is immense. As the technology continues to evolve and improve, we can expect to see even greater adoption of 3D printing in manufacturing, leading to a more efficient, sustainable, and customer-centric manufacturing industry.

3D printing is transforming manufacturing across industries in revolutionary ways. Its ability to rapidly prototype designs, create complex geometries, enable mass customization, reduce waste, and distribute production is disrupting traditional processes. Companies are adopting 3D printing to accelerate product development, unlock new design possibilities, produce specialized components, and manufacture goods on-demand. While the technology does have some limitations currently, advancements around speed, materials, and costs are helping address these.

Overall, 3D printing provides unmatched flexibility that is spurring a manufacturing revolution. It allows for more sustainable production methods with less waste and emissions. As the capabilities of 3D printing continue to advance, its applications will expand even further. Forward-thinking companies that leverage this technology now will gain key competitive advantages. Adoption is still in early phases, signaling immense room for growth. 3D printing is undoubtedly redefining manufacturing as we know it and enabling the factories of the future.

#1980s#250#3d#3D printing#additive manufacturing#aerospace#aerospace industry#air#aluminum#applications#automotive#automotive industry#biodegradable#Biodegradable Polymers#carbon#carbon emissions#carbon fiber#carbon footprint#certification#challenge#Chemistry & materials science news#Color#colors#Companies#computer#customer experience#dates#Design#desktop#development

0 notes

Text

When you're into 3D printing, you can pick from lots of different materials. But the one people use most often is ABS filament. It's really easy to find and works great with printers that use FDM/FFF technology.

0 notes

Text

3D Printer Extruder – All You Need to Know

3D Printer Extruder – All You Need to Know

For most makers and hobbyists, 3D printing takes the form of desktop machines that use the process known as fused deposition modeling (FDM) – or fused filament fabrication (FFF), depending on who you ask.Get more news about Micro Precision Cold Extrusion Part Exporter,you can vist our website!

In a nutshell, FDM involves feeding a thread of plastic material into a hot metal block with a nozzle. The filament melts, and the printer’s movements deposit it in the desired shape. This traced path is repeated, stacking incrementally until a solid 3D object forms.

The business end of handling the material – melting it and spitting it out – happens in an assembly of parts that are together commonly known as the extruder. While not that complex mechanically, there are still plenty of parts that, in a specific sequence, allow your 3D printer to extrude plastic.

In this beginner’s guide, we’ll address the main sections of the 3D printer extruder, the variations, styles, and popular models on the market, plus the 3D printer nozzle and the usual materials therein. The 3D printer extruder is a series of parts that handle the moving and processing of plastic filament.

Some people think of the “extruder” as being exclusively the motor and associated parts that push and pull the filament. Others consider the entire assembly, including the hot end, where the melting and deposition of the filament takes place.

To keep things simple, we’re considering the entire assembly as the extruder. Explaining the extruder requires a close look at two crucial assemblies, commonly referred to as the “cold end” and the “hot end”. The Cold End As the name suggests, the cold end is just that – cold. Cold end refers to the upper portion of the 3D printer extruder system where the filament is fed and passed along into the hot end (the lower portion of the extruder system) for melting and extrusion onto the print bed.

The layout and position of your 3D printer’s cold end are generally determined by whether it is a direct or Bowden extruder. The Lulzbot Taz 6 pictured above uses a direct extruder, in which filament is pulled into the print head (the entire assembly that moves to deposit filament onto the build plate) and pushed into the hot end directly. Cold End Anatomy

The cold end of a 3D printer extruder typically consists of a stepper motor to drive the motion of extrusion, a hobbed bolt or toothed gear mounted to the motor’s shaft to transfer that movement to the filament, a spring-loaded idler (typically a bearing of some kind) to maintain pressure on the filament, and sometimes PTFE tubing to guide the filament to its destination – a necessity in Bowden extruders.

This is the broadest description of the cold end of a 3D printer extruder. However, there is a lot of variation in how the extruder works and specific terms that can apply to different arrangements, positions on the printer, and sophistication in the transferral of power from the stepper motor to the filament – let’s get into it!

0 notes

Link

0 notes

Text

MICROZEY PLA PRO HYPER SPEED NEON YEŞİL 1.75 mm - 1000 Gr

MICROZEY PLA Pro - Hyper Speed filament, için yüksek hızlı FFF (FDM) baskı için özel olarak geliştirilmiş bir filamenttir. Optimize edilmiş moleküler ağırlık ve ayarlanmış akışkanlık ile MICROZEY PLA Pro - Hyper Speed, sıcak uçta daha hızlı erime ve malzeme ekstrüde edildikten sonra çok daha hızlı soğuma yeteneğine sahiptir. Bu sayede MICROZEY PLA Pro - Hyper Speed filamentlerle basılan parçalar yüksek yüzey kalitesine sahip olur ve keskin detayların çoğu korunur. En önemlisi optimize edilmiş moleküler ağırlık sayesinde MICROZEY PLA Pro - Hyper Speed mükemmel katmanlar arası bağlanma kalitesi ve Z yönü mukavemeti gösterir. Bu nedenle yüksek hızlı PLA konsept modeller, figürler ve prototip oluşturma vb. için kullanılabilir.

Yüksek yüzey kalitesi Yüksek baskı hızına uygunluk Kullanıcı ve çevre dostu Komplex yapılardaki prototip ihtiyacı için ideal Geniş renk seçeceği Yüksek yüzey sertliği Oda sıcaklığındaki uygulamalar için uygunluk Düşük koku problemi Endüstriyel kompostlama ile biyolojik olarak parçalanabilir Doğal bileşenlerden yapılmıştır Elektrikli ve elektronik cihazlarda güvenli kullanım Gıda ile temas eden uygulamalar için güvenli BPA ve stiren içermez

0 notes

Text

Cheapest 3D Printing Method

In the ever-evolving realm of manufacturing solutions, 3D printing has emerged as a frontrunner, democratizing production for professionals and hobbyists alike. Among the various 3D printing techniques, Fused Deposition Modeling (FDM), also known as Fused Filament Fabrication (FFF), stands out as the most economical option. This article delves into the reasons behind FDM’s cost-effectiveness, its applications, and strategies to maximize its potential, providing a comprehensive analysis within a 500-word limit.

Tracing the Origins of Fused Deposition Modeling (FDM):

FDM, conceptualized in the late 1980s, revolutionized additive manufacturing by offering a cost-effective alternative for creating prototypes and products. Its working principle involves melting a thermoplastic filament and depositing it layer by layer to construct a 3D object, making it a popular choice for beginners.

A Comprehensive Breakdown of 3D Printing Costs:

Initial Investment: The purchase of the 3D printer constitutes a significant part of the cost, with options ranging from budget-friendly models to sophisticated versions.

Material Expenses: Raw materials, such as filaments in FDM, represent a recurring cost that varies among different 3D printing techniques.

Operational and Maintenance Charges: Regular maintenance, power, and additional accessories contribute to ongoing operational costs.

Software Investments: Depending on project complexity, users might need software tools for designing, slicing, and managing print jobs.

Post-Processing Expenditure: Post-printing steps, such as sanding or painting, contribute to the overall cost.

Diving into FDM’s Cost-Effectiveness:

Economical Entry Points: FDM offers affordable kits for hobbyists and sophisticated systems for professionals, catering to a broad audience at a lower price point.

Budget-Friendly Filaments: FDM utilizes cheaper thermoplastic filaments like PLA and ABS, allowing for cost savings without compromising quality.

Lower Maintenance Costs: FDM printers demand less frequent and less expensive maintenance, reducing the total cost of ownership.

Open-Source Software Ecosystem: FDM benefits from a vibrant open-source community, providing free or low-cost software tools, minimizing expenses.

Simplified Post-Processing: FDM prints often require minimal post-processing, avoiding the need for specialized and costly equipment.

Contrasting FDM with Other 3D Printing Methods:

Stereolithography (SLA): SLA, known for precision, uses expensive UV-curable resins, leading to higher overall costs.

Selective Laser Sintering (SLS): Specialized powders and equipment escalate costs, making SLS less suitable for budget-conscious users.

Direct Metal Laser Sintering (DMLS): Targeting industries, DMLS involves premium materials and machinery, making it costly for everyday users.

Navigating the Ideal Applications for FDM:

Rapid Prototyping: FDM is ideal for cost-effective prototyping, allowing designers to validate concepts without hefty expenses.

Educational Ventures: FDM’s affordability makes it popular in educational institutions for hands-on learning experiences at a manageable cost.

Personal Projects and Hobbies: FDM provides a budget-friendly avenue for hobbyists to explore various projects, from crafting toys to home improvement items.

Customized Manufacturing: FDM excels in manufacturing customized parts or tools at a fraction of the cost compared to traditional methods.

Acknowledging the Limitations of FDM:

Surface Finish Concerns: FDM may exhibit visible layer lines, requiring post-processing for a smoother finish in aesthetically focused projects.

Structural Constraints: Layer-by-layer construction may lead to weaker bonds between layers, posing structural concerns in specific applications.

Limited Scope for Ultra-Fine Details: Filament thickness and nozzle diameter limitations may hinder FDM’s suitability for projects demanding intricate details.

Embracing FDM in the Expansive World of 3D Printing:

In the pursuit of the Cheapest 3D printing method, FDM stands out due to its inherent cost-effectiveness. As technology advances, aligning the choice of the method with project goals becomes crucial. FDM’s rich history, diverse applications, and continuous innovations position it prominently in the 3D printing landscape, offering a balance between affordability and quality.

0 notes

Text

What on earth is 3D printing?

That's... a big one. Sorry in advance. It also gets a little technical. Folx, if you want to chime in in the notes what we forgot or missed, have at it, just be polite. Discussion is great. Being a jerk is not.

So you know that we sell 3D print planters (and some other stuff coming out soon), but we saw a lot of comments in our first post introducing ourselves that were curious about what 3D printing was, if it was resin printing, and how it worked.

We also didn't realize our ask box wasn't turned on until we saw a note after the post was up for several hours. Sorry! It's open now if you have questions or comments or whatever. Just be polite.

Well. We are not experts. We're going to share our own experience and understanding of what 3D printing is, most common methods, and why we do the kind of 3D printing we do.

So.

What is 3D printing?

In its all-encompassing definition, 3D printing (also called additive manufacturing if you want to get STEM-y about it) is basically creating a 3D object using a digital 3D model. The programs engineers use, like Fusion360, AutoCAD, FreeCAD, and others? Yeah. Those. Exactly.

If you're an artist, don't despair, you can create models in Blender (or whatever 3D modeler you use) and work with those for 3D printing.

If you're us, who only started modeling a few months ago, you use the program geared for children and young adults, and that's TinkerCAD. There's nothing wrong with it, it's just limited in what it can do compared to other programs. The massive benefit is it's free and the learning curve is also much more gentle than the sheer cliff we ran face-first into trying to learn the CAD programs or Blender.

If anyone has good sources to learn them (esp with Blender's new updates) we would be happy to try them. Because as much as we love 3D printing, modeling still gives us a headache.

So that's the most basic definition of 3D printing.

So, what's the most COMMON form of 3D printing?

Well, we'd say there are two:

Resin printing. There's several different methods, but the most common today still is SLA, or stereolithography. Basically, a UV laser marks a cross-section of part of an object on a layer of liquid resin. When it's exposed to the UV light it's cured and solidifies. Another layer of resin is put down, the laser process is repeated, and it continues until an object is made. What's nice about it is it lets you get high detail in very small objects, like minis for Warhammer or other games. There's also Digital Light Processing (DLP), which is like SLA but uses digital projection to expose more parts of resin to light. It can cure an entire layer at once, instead of only part. If you see a Warhammer figurine being sold, or any miniature, especially stuff for DnD or other tabletop games, it's probably resin printed.

FDM (fused deposition modeling). It's also known as FFF, or fused filament fabrication). This is what you probably think of for 3D printers if you ever saw one, where things are printed in one tiny layer at a time where a heated print head is pushing out filament in layers on a build plate. FDM is more common for practical prints, like car parts or manufacturing pieces. To us it reminds us of icing a cake. You can print with stuff like carbon fiber and nylons or flexible material like TPU. FDM is good for prototyping and larger objects, like our planters (last product plug, we swear) to. You know.

Houses.

We use FDM printing.

Why?

Most everything we're going to make doesn't need the detail that a resin printer provides. The smallest, jewelry, still isn't to the level where we'd need a resin printer -- FDM printers work in fractions of milimeters, and resin printers can go even smaller. That's not necessary for us.

Everything we make is going to be larger prints, which means more material. Filament (which we'll explain in another post) costs less than resin.

Resin is more toxic than PLA filament, which is what we use. We can handle PLA filament spools without gloves or protective goggles. Resin? Absolutely not. They ARE making plant-based resin which is less irritating, but we have no experience with it. If you do, chime in in the comments.

Resin involves cure time. You also have to wash your print after. That can add to the process time too.

So that's the extreme basics of what 3D printing is, the two most common types, and why we do FDM printing. We hope you found it helpful! We're going to try to make this a series to explain more about 3D printing in general so it's less mysterious for non-printers. What do you want us to talk about next? Let us know! Like...what different materials you can print with? What are they made of? Maybe some example pictures with different finishes? Would that be interesting? We'd love to hear from you. And we look forward to seeing the comments in the notes/tags! We couldn't go as in-depth as we wanted without turning it into a novel, so have at it in the notes. We can't wait to follow the discussion!

We're Planterful Pieces, a small business focused on offering made-to-print products that cater to the planty people of the world, whether that means you OWN plants or simply just LOVE nature. We also want to share with you all cool designs that aren't easily accessible to people who DON'T 3D print, and there's a LOT!

If you're not interested in our planters but ARE interested in future products, like our upcoming art collection, jewelry, and more, subscribe to our email newsletter on our website here (you'll have to scroll down a little). We promise we'll only email you once a month with sneak peeks, product updates, deals, or if there's an upcoming launch. Frankly, we don't have time to spam you with emails, since we'd rather be designing and printing.

Instagram

TikTok (We're bad at this but will be working on it)

Facebook

Thanks for reading!

(PS: We haven't forgotten about those interested in international shipping! If you sign up on the newsletter we can let you know as soon as it's available! We'll make posts here of course and our other socials but that's always hit or miss. This way it goes right in your inbox.)

#3d#3d printing#garden#planters#plants#shop small#small business#tech#technology#houseplant#hopefully this is interesting?#I find my writing on a computer versus mobile I have different tones#so depending on how this one goes versus my first#i might use one or the other#house plants#houseplants#warhammer#resin printing#resin#houses#3d print house#3d print construction#miniatures#minis#decor#home decor#FDM printing#SLA printing#crown#diamond

12 notes

·

View notes

Text

Atom C++ Mac

C-mac Frequency Products

Cmac Transportation

C-mac Intubation

Abstract

ObjectivesWe determined the usefulness of C-MAC video laryngoscope (C-MAC) as a safe training tool for the direct laryngoscopy technique in the emergency department.MethodsWe retrospectively analyzed an institutional airway registry of adult (≥18 years old) patients from April 2014 through October 2016. In this study, the operator used C-MAC as a direct laryngoscope (DL) with limited access to the screen, and the supervisor instructed the operator via verbal feedback while watching the screen. Patients were categorized into the DL group if a conventional DL was used and the C-DL group if a C-MAC used as a DL.ResultsOf 744 endotracheal intubations, 163 propensity score-matched pairs were generated (1-to-n matching: C-DL group, 163 vs. DL group, 428). For the propensity-matched groups, the overall first pass success rate was 69%, while those in the C-DL and DL groups were 79% and 65%, respectively. Overall, multiple attempts were required in 8% of patients, with 4% in the C-DL group and 9% in the DL group. The overall complication rate was 11%, with 4% in the C-DL group and 14% in the DL group. In multivariable analysis, the adjusted odds ratios of C-DL use for first pass success, multiple attempts, and complications were 2.05 (95% confidence interval (CI) 1.18-2.87, p ConclusionsOur study suggests that the C-MAC could be useful for training residents in the direct laryngoscopy while ensuring patient safety in the emergency department.

Install MinGW

MinGW means Minimalist GNU for Windows: GNU is a source of open source programming tools (GNU stands for GNU is Not Unix).

This shows you how to setup the atom text editor to compile and run c programs.

Gpp-compiler atomatom compile catom compile pythongcc could not be spawned atomg could not be spawned atomgcc compiler atomatom compile javaatom c ide.

Tutorial on how to write C program, in MAC (macOS Sierra), compile & run using terminal. Those terminal command also applicable for most of the common used l.

Visual Studio Code on macOS Installation. Download Visual Studio Code for macOS.; Open the browser's download list and locate the downloaded archive. Extract the archive contents.

In this handout you will download the files needed by GNU C++; in the next you will download a version of Eclipse that is already set up to use MinGW.

Jedi Academy Movie Maker's Edition. A voxel based slicer for 3D printing on FDM/FFF, binder/powder, SLS printers and laser cutters. Agar-based Electronics Design Automation toolkit (beta) Picosdk C Wrappers ⭐ 2. A set of C wrapper library projects for PicoScope® oscilloscope products.

You may want to print these instructions before proceeding, so that you can refer to them while downloading and installing MinGW. Or, just keep this document in your browser. You should read each step completely before performing the action that it describes.

MinGW

Downloading

Click MinGW.

The following page will appear in your browser (from the SourceForge web site).

Click the Download mingw-get-setup.exe(86.5 kB) link.

This file should start downloading in your standard download folder. This file is only 85KB so it should download very quickly.

The file should appear as

Terminate the window browsing the SourceForge web site.

Move this file to a more permanent location, so that you can install MinGW (and reinstall it later, if necessary).

Start the Installation instructions directly below.

Installing

C-mac Frequency Products

Double-click the icon.

The following pop-up window will appear.

Click Run.

The following pop-up window will appear.

Click Install.

The following pop-up window will appear.

You can install this software anywhere, but I recommend installing it in the default directory: C:MinGW.

Click Continue.

The following pop-up window will appear, showing the downloading progress. After about a minute, it should appear as follows.

Click Continue.

The following pop-up window will appear. Ensure on the left that Basic Setup is highlighted. Click the three boxes indicated below: mingw32-base, mingw32-gcc=g++, msys-base. After clicking each, select Mark for selection. This window should appear as follows.

Terminate (click X on) the MinGW Installation Manager (I know this is weird).

The following pop-up window should appear

Click Review Change

The following pop-up window should appear

Click Apply.

The following pop-up window will appear, showing the downloading progress.

After a while (a few minutes to an hour, depending on your download speed), it should start extracting the donwloaded files. A few minutes after that, the following pop-up window should appear.

Click Close.

Edit Path so that the MinGW and MSYSM software is findable by Eclipse.

Click Start

Click Control Panel

Click System

Click Advance system settings; you will see

Click Enviroment Variables...; you will see

In the System variables (lower) part, scroll to line starting with Path and click that line. IMPORTANT: Even though you see a highlighted PATH in the User variables (top part) look for Path (not CLASSPATH) in the lower part to change it.

Click Edit...

Copy C:MinGWbin;C:MinGWmsys1.0bin; (include everything from C to ;) and then paste it at the very start of the Variable Value text entry.

When done it should look like

Click OK (3 times)

Cmac Transportation

C-mac Intubation

MinGW is now installed. You are now ready to install Eclipse....But it is probaby a good idea to reboot your machine first, to ensure the new path is correct.

1 note

·

View note