#Fabrics Testing

Explore tagged Tumblr posts

Text

The Role of Fabric Testing in Sustainable Textile Manufacturing

In recent years, sustainability has emerged as a pivotal focus within the textile industry. With increasing awareness about environmental impact, consumers and manufacturers alike are prioritizing eco-friendly practices. Among these practices, textiles and fabrics testing plays a crucial role in advancing sustainable textile manufacturing. Fabric testing ensures that materials not only meet quality and safety standards but also align with environmental and ethical benchmarks.

This blog explores the role of fabric testing in sustainable textile manufacturing, how testing labs contribute to green practices, and why integrating testing is essential for the future of textiles.

Understanding Sustainable Textile Manufacturing

Sustainable textile manufacturing involves producing fabrics and garments with minimal negative impact on the environment and society. Key objectives include:

Reducing water, energy, and chemical usage during production

Minimizing waste and pollution

Using renewable, recycled, or biodegradable fibers

Ensuring fair labor and ethical sourcing practices

Creating durable products to extend lifecycle and reduce landfill waste

Sustainability is not just a trend but a responsibility driven by regulatory requirements, market demand, and global initiatives like the UN Sustainable Development Goals (SDGs).

How Fabric Testing Supports Sustainability

Fabric testing, traditionally associated with quality assurance, now plays a multifaceted role in fostering sustainability across the textile value chain:

1. Ensuring Material Compliance with Eco-Standards

Textile testing labs verify compliance with recognized environmental certifications such as:

OEKO-TEX Standard 100: Ensures textiles are free from harmful substances.

Global Organic Textile Standard (GOTS): Certifies organic fibers and sustainable processing.

Bluesign: Focuses on sustainable chemical usage and emissions.

By conducting chemical residue tests, harmful dye and finishing chemical detection, and heavy metal analysis, fabric testing ensures manufacturers meet stringent sustainability criteria. This protects consumers and the environment from toxic exposure.

2. Validating Use of Recycled and Alternative Fibers

Sustainable textiles often incorporate recycled polyester, organic cotton, hemp, or bamboo. Fabric testing assesses:

Fiber content verification to confirm material authenticity

Performance testing to ensure recycled fibers meet durability and comfort standards

Compatibility of blended fibers for optimal manufacturing outcomes

Testing ensures these alternative fibers deliver quality products, encouraging wider adoption of sustainable materials.

3. Optimizing Resource Efficiency

Water, energy, and chemical consumption are critical environmental metrics in textile manufacturing. Fabric testing labs assist by:

Analyzing fabric absorbency and dye uptake to optimize dyeing processes, reducing water and chemical waste

Assessing fabric weight and thickness to balance resource use without compromising quality

Testing fabric durability and colorfastness to ensure longer-lasting products, reducing the need for frequent replacement

This data enables manufacturers to refine production techniques for greater environmental efficiency.

4. Minimizing Waste Through Quality Control

Poor quality fabrics often result in high rejection rates, waste, and reprocessing — all detrimental to sustainability goals. Comprehensive textiles and fabrics testing include:

Tensile strength and tear resistance to prevent premature damage

Pilling and abrasion resistance to ensure aesthetic longevity

Dimensional stability testing to avoid deformation during use

By catching defects early, testing reduces material waste, conserves resources, and lowers carbon footprint.

5. Supporting Sustainable Finishing Techniques

Innovations in eco-friendly fabric finishes — such as waterless dyeing, natural antimicrobials, or biodegradable coatings — require validation. Testing labs evaluate:

Chemical residues and toxicity of new finishing agents

Durability and effectiveness of sustainable finishes

Biodegradability and environmental impact post-consumer use

This ensures novel sustainable processes meet safety and performance expectations.

Benefits of Integrating Fabric Testing in Sustainable Manufacturing

1. Enhanced Consumer Trust and Brand Reputation

Sustainability claims backed by rigorous testing reassure consumers seeking safe and eco-friendly products. Transparent lab certifications and test reports build trust and strengthen brand loyalty.

2. Regulatory Compliance and Market Access

Many countries enforce regulations restricting hazardous chemicals in textiles (e.g., REACH in Europe). Fabric testing ensures compliance, preventing legal issues and enabling access to global green markets.

3. Innovation Acceleration

Testing labs enable manufacturers to trial and validate new sustainable materials and processes faster and with confidence, driving continuous improvement.

4. Cost Savings Through Waste Reduction

By identifying defects and inefficiencies early, fabric testing reduces material waste, rework, and recalls — lowering operational costs and environmental impact.

5. Contribution to Circular Economy

Testing supports design for durability, recyclability, and biodegradability, fostering circular textile systems that reuse and recycle fibers sustainably.

Real-World Example: How Fabric Testing Transforms Sustainability Efforts

Consider a manufacturer shifting from conventional polyester to recycled polyester for sportswear:

Fabric testing confirms the recycled polyester meets strength, colorfastness, and moisture-wicking requirements.

Chemical residue analysis verifies absence of harmful dyes and finishes, meeting OEKO-TEX standards.

Durability tests ensure garments last as long as conventional counterparts, reducing landfill waste.

Test data guides adjustments to dyeing processes, reducing water and energy use.

Such testing empowers manufacturers to adopt greener materials confidently while maintaining product excellence.

Choosing the Right Fabric Testing Lab for Sustainability

For textile manufacturers aiming to enhance sustainability, partnering with accredited, experienced fabric testing labs is vital. Key factors to consider:

ISO/IEC 17025 Accreditation for global recognition of lab competence

Expertise in eco-certification testing such as OEKO-TEX, GOTS, and REACH compliance

State-of-the-art equipment for advanced chemical, physical, and biodegradability testing

Customized testing packages tailored to sustainable textiles

Consultancy services to interpret results and recommend process improvements

The right lab becomes a strategic partner in achieving sustainability goals.

Conclusion

Sustainable textile manufacturing is no longer optional but a necessity to protect our planet and meet evolving market expectations. Textiles and fabrics testing lies at the heart of this transformation, ensuring materials and processes align with environmental and social responsibility without sacrificing quality.

From verifying chemical safety and fiber authenticity to optimizing resource use and supporting innovative eco-finishes, fabric testing empowers manufacturers to produce textiles that are truly sustainable. By investing in robust testing protocols and partnering with qualified labs, the textile industry can accelerate its journey toward a greener, safer, and more sustainable future.

#Textiles and Fabrics Testing#Textile Testing#Fabrics Testing#Testing Lab near me#Testing Lab in Delhi

0 notes

Text

i have a vision...

#i have all the materials just waiting on the buttons and sequins :3#got a bunch of new fabrics#including holographic sequin material i'm using for the tummy/wing scales#and i've been wanting to use that long pastel rainbow fur for something#i'm testing out a modified pattern so hopefully it all comes together *fingies crossed*#sewing stuff

97 notes

·

View notes

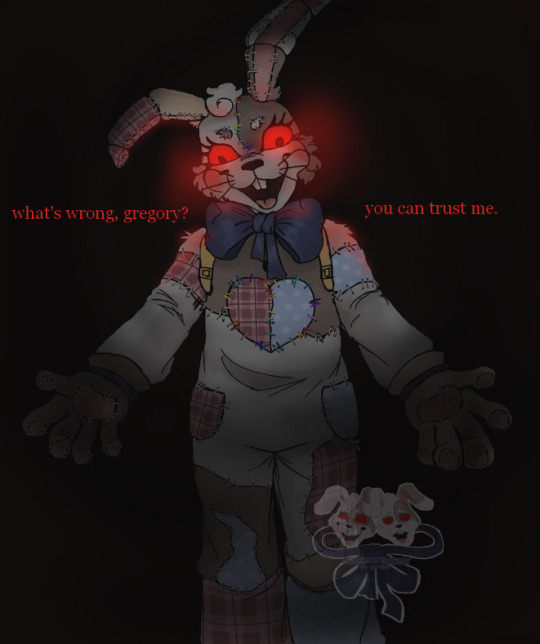

Text

turn off your eyes maybe 😭😭 damn girl we see them

#my art#vanny fnaf#fnaf vanny#vanny#vanny the bunny#security breach#fnaf sb#fnaf au#fnaf#fnaf fanart#my au#NEW VANNY DESIGN ‼️‼️MAYBE ‼️im still testing it out but i really like it#i felt like the extra red flannel fabric made it too crowded i dunno......... so now pink n blue are gonna be used#security breach: code rewritten

254 notes

·

View notes

Text

I'm not dead! Still not drawing, but I got back into lino lately and decided to try fabric printing (for fun for once, since my day job is sucking the joy out of me in that regard). One kind of paint for now, trying it out on different fabrics and different lino block types. Going to do a comparison once I try different paints, hopefully it might inspire somebody to try it :)

#linocut#block printing#fabric printing#Joanna Krótka#my art#prints#the blue t-shirt is a test one - first print of every lino I carved goes on it plus some leftover paint too

294 notes

·

View notes

Text

Finally happy with this pattern! Yellow face is the V1 design with a lot of little issues (like that floppy neck) that V2 corrects.

#plushie#handmade plush#indie plush#spoilers: it's flower AU Sun but legally distinct#and made out of bargain fabric for testing purposes#but the next one will be SOFT

88 notes

·

View notes

Text

That's the gospel truuuuuuuth~!!!

me when i listen to the gospel truth on repeat for like two days straight

anyways UHH II GIJINKAS BUT MUSES,,,,this took way too long dude im gonna start sobbing but LOOK AT THEM.

In order from left to right if the writing is a bit difficult to see: Lightbulb as Thalia, Test Tube as Clio, Microphone as Calliope, Candle as Melpomene, Clover as Terpsichore

more knife soon i promis

#inanimate insanity#microphone inanimate insanity#test tube inanimate insanity#lightbulb inanimate insanity#candle inanimate insanity#clover inanimate insanity#microphone ii#test tube ii#lightbulb ii#candle ii#clover ii#disney's hercules#atoucore#i sat and stared at mytablet for like 5 hours today finishingthis but HEY YKNOW WHAT LOOK AT MICS HAIR AND THE FABRIC#i love rendering so much

20 notes

·

View notes

Text

Pattern is almost finished, we start working with the actual fabric very soon :]

#justabeewithapen#text#picture#probably delete later?#LOOK A NORMAL AMOUNT OF FINGERS#hahah#I’ve been working slow on this since I am juggling so many projects at once rn#Made the whole thing with test fabric first before I finalized my paper pattern

40 notes

·

View notes

Text

The Role of Textile Testing in Automotive Interior Manufacturing

In the world of modern automotive design, vehicle interiors have evolved from purely functional elements to luxurious, performance-enhancing spaces. One key driver behind this transformation is the increasing use of advanced textiles and fabrics in car interiors. From seat upholstery and headliners to door panels and carpeting, textiles now define much of the vehicle’s aesthetic and comfort. However, behind the stylish appearance and tactile comfort lies a critical process—Textiles and Fabrics Testing.

Textiles and Fabrics Testing in the automotive industry ensures that interior materials meet performance, safety, and regulatory standards required for modern vehicles. As automotive manufacturers strive to deliver top-tier products to global markets, rigorous testing of interior fabrics becomes indispensable for quality assurance, customer satisfaction, and compliance.

Why Textiles and Fabrics Matter in Automotive Interiors

Automotive interiors are subjected to unique stressors not found in other textile applications. These materials must withstand high temperatures, UV exposure, friction, spills, and wear from daily use. Additionally, vehicle manufacturers must meet stringent safety and flammability standards, making textile testing a foundational step in the manufacturing process.

Common Textile Applications in Automotive Interiors:

Seat covers and backrests

Headliners and sun visors

Floor carpeting and mats

Door trim fabrics

Pillar covers

Cargo liners and trunk covers

Importance of Textiles and Fabrics Testing in the Automotive Industry

1. Ensuring Durability and Longevity

One of the core purposes of fabric testing in automotive applications is to ensure that materials can withstand long-term use without degradation. Lab tests simulate wear and tear conditions such as abrasion, fading, and temperature fluctuation to predict real-world performance.

2. Meeting Safety Regulations

Automotive textiles must comply with safety standards, especially flammability regulations. Unchecked, interior fabrics can become ignition points in accidents. Testing ensures that materials meet legal requirements like FMVSS 302, ECE R118, and other global standards.

3. Enhancing Aesthetic and Functional Quality

Fabrics used in vehicle interiors must maintain colorfastness, dimensional stability, and tactile feel over time. Testing ensures that color does not bleed, materials do not shrink or stretch excessively, and surfaces remain smooth and attractive.

4. Reducing Environmental and Chemical Risks

With growing attention to VOC emissions, odor, and chemical residue, automotive textile testing includes chemical analyses to detect formaldehyde, heavy metals, and other harmful substances, helping manufacturers meet environmental benchmarks like REACH and RoHS.

Key Tests Performed in Automotive Textile Testing Labs

1. Abrasion Resistance Testing

Tests like the Martindale or Taber methods are used to simulate fabric wear caused by repeated rubbing or friction. This determines the fabric's ability to endure long-term use without visible degradation.

2. Colorfastness Testing

Automotive interiors are exposed to sunlight and human interaction. Labs assess:

Colorfastness to light (UV resistance)

Colorfastness to rubbing (crocking)

Colorfastness to perspiration and water

3. Flammability Testing

One of the most critical safety evaluations:

FMVSS 302: Measures burn rate of interior materials.

ECE R118: Required for buses and commercial vehicles in Europe.

4. Tensile and Tear Strength

This test ensures materials won’t rip or stretch easily under pressure—essential for seat covers, which face daily stress from passengers.

5. Chemical Testing

Fabric testing labs analyze textile composition for harmful substances and odors:

Formaldehyde content

Volatile Organic Compounds (VOCs)

Phthalates and plasticizers

Heavy metal analysis

6. Thermal Aging and UV Resistance

Testing how materials hold up to prolonged heat and UV exposure is key, especially for vehicles used in hot climates.

7. Dimensional Stability and Shrinkage

Ensures fabric maintains shape after exposure to heat or humidity, preventing sagging headliners or wrinkled seat covers.

Role of Accredited Testing Labs in Automotive Compliance

To meet international quality benchmarks, automotive OEMs rely on ISO 17025 accredited textile labs. These labs offer validated procedures, traceable test results, and certification that complies with:

Automotive OEM specifications

International safety regulations

REACH and RoHS directives

Customer-specific quality requirements

Using a certified Textiles and Fabrics Testing lab ensures that materials will not just pass internal audits but also satisfy regulatory inspections across North America, Europe, Asia, and the Middle East.

How Fabric Testing Affects the Supply Chain

Textile testing impacts every stage of the automotive manufacturing supply chain:

For Material Suppliers:

Verifies compliance with OEM technical data sheets

Provides test reports for raw fabric certification

For Tier-1 and Tier-2 Suppliers:

Ensures intermediate parts (e.g., pre-stitched seat covers) meet end-use specifications

Supports quality audits and sampling procedures

For OEMs:

Prevents costly recalls due to material failure

Enhances consumer trust and brand value

Simplifies import/export through valid testing documentation

Advancements in Automotive Textile Testing

As materials science evolves, fabric testing labs have adopted advanced tools like:

Infrared Spectroscopy (FTIR): For polymer and fiber identification

Gas Chromatography (GC-MS): For VOC detection

Digital Microscopy and Surface Analysis

AI-driven test automation for faster results

These advancements allow for more precise, repeatable testing that accelerates product development without sacrificing quality.

The Future of Textile Testing in Automotive Interiors

With the rise of electric vehicles, sustainable materials, and smart fabrics, the importance of textile testing will only grow. Labs will increasingly need to:

Validate recycled and biodegradable textiles

Assess thermal and electrical conductivity in smart textiles

Ensure compatibility with sensors and electronics

As innovation in automotive interiors continues, Textiles and Fabrics Testing will remain the gatekeeper for quality, safety, and compliance.

Final Thoughts

The integration of high-performance fabrics into vehicle interiors has revolutionized automotive design. But without proper Textiles and Fabrics Testing, these innovations carry risks—from durability issues to safety violations. That’s why fabric testing labs are more than quality control checkpoints—they’re strategic partners that ensure global compliance, reduce recalls, and deliver the excellence today’s automotive market demands.

Whether you're an OEM, a component supplier, or a textile manufacturer, partnering with a competent, accredited fabric testing lab is not just recommended—it’s essential to your success in the global automotive sector.

#Textiles and Fabrics Testing#Textiles Testing#Fabrics Testing#Testing Lab near me#Testing Lab in Delhi

0 notes

Note

Did you manage to go to the sewfisticated sale before it closed? They had some interesting silks I haven't seen there before, made me think of your gowns

Oh my god. No, I just got home from traveling for Christmas.

I didn't know and I'm honestly heartbroken. Apparently the Dorchester location is staying, but the Somerville one (more accessible to me) is gone.

This feels like another good thing is gone from the world. I mean, how much longer will the store stay open? Will I end up in the same position as most people- unable to buy natural-fiber fabrics at all unless I spend a ton of money online?

Why does everything related to clothing suck now, and keep getting worse?

I'm on the verge of tears here.

#ask#boggbitch#sewing#boston#it gets harder and harder to have decent clothes in this world#especially in the style I prefer#and their fabrics are LABELED which a lot of other indie fabric stores don't do#I could go to another place and guess but I don't want to do that#and you can't burn-test in the store so....

38 notes

·

View notes

Text

there's really nothing like wearing a piece of clothing made just for you by someone who loves you.

#my mother-in-law made me a comfy dress with pockets to wear while lounging around at home and when we go up north to camp#we went to a local fabric shop a few months ago just to pick out the textiles and threads and buttons for the closures#i've been over to her house a few times for fittings (tho i don't think they were really necessary#since this is supposed to be peak comfycozy loungewear lol)#like. my mom also made clothes for me when i was a kid but she was making them principally because she liked to test out her designs#on a guinea pig who couldn't escape from her sewing room lol#this is really the first time someone has made me something just because she knew i really wanted it#and took the time to ask me what i liked and what i didn't like#idk i'm feeling very emotional about it#ray.txt#i'm very lucky. the world is on fire but really i am so very very lucky

21 notes

·

View notes

Text

I finished this a little while ago now but I made a NPC Grian plush based on galaxygermdraws' design! It's not super accurate (especially the hair eep) and its a bit messy, but this was the first plush I've ever completed and I'm quite proud of that! He's got a pipe cleaner skeleton for the tail/ antennae/ tendril (sorry for the bad view of them, I just get nervous taking photos 🥲)

hopefully an @ is ok let me know if it's not! @galaxygermdraws

#my art#hermitcraft#npc grian#I might more old craft projects maybe? just because thats a lot of what i'm working on at the moment#i still do draw but also it might be cool to show some of this stuff maybe?#theres quite a few issues w the plush but its learning. for example i learned fabric glue is the enemy#(mostly joking ^^. probably shouldnt have tested using it for appliqué on the face though)

19 notes

·

View notes

Text

colour test success

52 notes

·

View notes

Text

Anyway I started making these weird front/back shirts do people like them? 👀

Ropeslut

You Promised!

God as a Sacrifice

Alcatraz

Defeat

#I could never find the edgy more existential shirts when I went looking for them so decided to just design my own#and in the softer palette I liked either#anywho if you like them let me know I’m thinking of test ordering some tinder how the prints look on fabric and can give a few away#yugioh#bootleg#these are for the mentally ill baddies lmao#seto kaiba#jounouchi katsuya

26 notes

·

View notes

Text

What would you do for the very sane pallid woman in the dark woods?

-leave her ass to the wolves

-set boundaries

>set yourself on fire to keep her warm

have you read 'Soul of Sovereignty' by @pallisia ? Go play the free demo and be deranged about it with me.

#ysme#ysme soulsov#soulsov#cosplay#pallid woman#was this a make up test before building the little sexy orange-peachy anime number? maybe#i have fabric swatches and thoughts.

17 notes

·

View notes

Text

backing up my files & just stumbled upon a very old journal entry (september 4th 2015) that is literally the biggest egg-in-denial copium ive ever seen. godbless

#but i don't have any masculine personality traits - for what it's worth in a patriarchal society where gender is the very fabric of social#existence#well naturally if i could be a man i'd do that in a heartbeat. but i can't pretend#i'd be a convincing specimen of manhood#17..... oh baby. i was right though....#“oh what if i just want to be trans to be interesting” beloved .#well !#it's so funny. it's really so funny#i barely remember writing this in the first place#fascinating that ever since day fucking ONE the problem was#it's true though. like i was right. but you Can be a failed man instead of a failed woman and it's actually preddy fun . so !#there's this “psychology test” by françoise dolto which - apologies - only works in french#but basically as an exercise to evaluate gender among young children#the therapist tells a child to pretend/perform a gesture accompanying each word#and one of the words is “tire !”. which you could translate as either “pull[on something]” or “shoot[something]”#and the conclusions were that girl childrens overwhelmingly pantomimed pulling on a rope while boy children mimicked shooting a gun#and my father smugly told me that he had done this experiment on me at around the same age mentioned by dolto and that i#always pantomimed pulling on something which in his eyes settled the question entirely. well#maybe the future is a world where boys don't care about guns huh. maybe i was destined to be a weird ass catboy this entire time. huh!#huh the order of these tags is all messed up. solve my jigsaw puzzle boy

15 notes

·

View notes

Text

Quality Testing for Terry Bathrobes: Comfort Meets Compliance

In the textile industry, Terry fabrics and its products testing has become essential for ensuring product reliability, durability, and consumer safety. Among the wide range of terry fabric applications, terry bathrobes stand out for their comfort, luxury, and absorbency. But beyond softness and plushness lies a more technical aspect—quality testing. Testing terry bathrobes guarantees not only a premium customer experience but also compliance with national and international standards for textile quality, performance, and safety.

This blog explores the importance of quality testing for terry bathrobes, including the types of tests involved, the standards to meet, and how manufacturers can balance comfort with compliance.

What Are Terry Bathrobes?

Terry bathrobes are garments made from terry cloth, a fabric known for its looped construction and high water absorbency. These bathrobes are typically used in homes, spas, hotels, and wellness centers. They are usually made of:

100% cotton

Bamboo blends

Microfiber terry

Organic terry fabrics

Given their direct contact with the skin, and frequent use in moisture-heavy environments, terry bathrobes must meet strict quality, safety, and performance standards. That’s where Terry fabrics and its products testing comes into play.

Why Is Quality Testing Crucial for Terry Bathrobes?

While a luxurious feel and attractive design may draw buyers, long-term satisfaction and safety hinge on the fabric’s quality. Quality testing ensures that bathrobes:

Provide long-lasting comfort

Retain absorbency and softness over time

Do not release harmful chemicals onto the skin

Do not shrink or lose color after multiple washes

Comply with global textile safety regulations

Testing allows manufacturers to reduce returns, improve brand image, and expand into export markets that demand compliance certifications.

Key Tests for Terry Bathrobes

Here are the major tests performed on terry bathrobes during quality assurance processes:

1. Fabric Weight (GSM) Testing

Grams per square meter (GSM) is a critical factor in determining the plushness and absorbency of terry fabric. A high GSM (typically between 400–600) indicates better quality for bathrobes.

2. Absorbency Testing

This test evaluates how much water the fabric can hold. Quick and high absorbency is a mark of quality in bathrobes. Labs use standardized tests to measure water uptake and drying rates.

3. Colorfastness Testing

Terry bathrobes are frequently washed, so colorfastness tests are conducted to assess resistance to:

Washing

Rubbing

Perspiration

Light

This ensures the fabric retains its vibrant look without dye bleeding or fading.

4. Shrinkage Testing

Bathrobes must retain their size and shape after washing. Shrinkage tests involve laundering samples and measuring dimensional changes to ensure they fall within acceptable tolerance limits.

5. Tensile Strength and Seam Strength

This test checks the durability of the fabric and stitching. A quality terry bathrobe must endure stretching, pulling, and repeated use without tearing or fraying.

6. Chemical Residue Testing

Testing for harmful chemicals like formaldehyde, azo dyes, and heavy metals ensures that the bathrobe is safe for prolonged skin contact. This is especially critical for baby or spa-grade bathrobes.

7. pH Value Testing

A neutral pH (close to 7) is preferred for textiles to prevent skin irritation. Testing helps ensure the bathrobe is skin-friendly and suitable for sensitive users.

Compliance and Certifications

To export terry bathrobes or to sell in premium markets, manufacturers must align with industry standards. Some of the major certifications and compliance requirements include:

OEKO-TEX® Standard 100

This global certification ensures that the bathrobe is free from harmful substances. Every component of the product, including thread and dyes, must pass chemical testing.

GOTS (Global Organic Textile Standard)

For bathrobes marketed as organic, GOTS certification verifies the use of organic fibers and environmentally safe manufacturing processes.

REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals)

REACH compliance is essential for selling bathrobes in European markets. It restricts the use of certain hazardous substances in textiles.

ISO 9001 & ISO 17025

Manufacturers and testing labs adhering to ISO standards assure consistent quality management and precise test results.

Benefits of Quality Testing Terry Bathrobes

1. Enhanced Consumer Confidence

When buyers know that a terry bathrobe is OEKO-TEX® certified or GOTS-compliant, it builds trust and satisfaction.

2. Fewer Returns and Complaints

Bathrobes that retain quality over time reduce customer complaints, refunds, and negative reviews.

3. Stronger Brand Image

Companies that prioritize terry fabrics and its products testing position themselves as responsible and premium brands.

4. Export Market Access

Most international markets, including the EU and North America, demand product testing and compliance reports. Quality testing ensures your product can enter these markets smoothly.

5. Cost Optimization

Early testing during production can catch flaws before mass manufacturing, saving costs in the long run.

Choosing a Testing Lab for Terry Fabrics and Bathrobes

It’s essential to work with a certified and experienced textile testing laboratory. Here's what to look for:

ISO/IEC 17025 accreditation

Specialization in textile and apparel testing

Advanced testing equipment (e.g., HPLC, FTIR, spectrophotometers)

Capability for chemical, physical, and performance testing

Knowledge of regional compliance requirements

Many testing labs also offer pre-shipment inspection and custom testing protocols tailored for hospitality or retail standards.

Sustainable Testing Practices

Modern consumers are increasingly eco-conscious. Manufacturers are now integrating sustainable testing practices such as:

Testing organic dyes and natural finishes

Evaluating water and energy consumption during dyeing

Verifying biodegradability or recyclability of the fabric

Sustainability audits and traceability reports are becoming part of standard testing services, further reinforcing your brand’s eco-friendly image.

Conclusion

Comfort, luxury, and compliance must coexist in today’s competitive textile market. Terry fabrics and its products testing, especially for bathrobes, ensures that consumers enjoy not just a plush experience but also a safe and reliable product.

By rigorously testing for absorbency, colorfastness, chemical safety, and durability, manufacturers can maintain product excellence and regulatory compliance. Whether you're supplying to spas, hotels, or home markets, quality-tested terry bathrobes deliver both satisfaction and peace of mind.

#terry fabrics and its products testing#terry fabrics testing#fabrics testing#fabrics testing lab#testing lab near me#testing lab in delhi

0 notes