#Failure Modes and Effects Analysis

Explore tagged Tumblr posts

Text

“Inspection, Verification & Audit in the Automotive Industry”

“Inspection, Verification & Audit in the Automotive Industry: Key Tools and Best Practices for Quality Assurance” 🧰 1. Introduction In the highly competitive and regulated automotive industry, maintaining the highest standards of quality control is crucial. Whether you’re ensuring components meet specific measurements, verifying that designs match product specifications, or auditing processes…

#4m#4M analysis automotive#80/20 Rule#8d#audit#Automotive manufacturing#Automotive quality control#Benchmarking#Cause & Effect Diagram#Cause & Effect Diagram (Ishikawa/Fishbone Diagram)#Cause & effect diagram automotive#Customers#Failure Modes and Effects Analysis#Fishbone Diagram#FMEA#Gage R&R#IATF 16949 compliance#Inputs#Inspection#Ishikawa diagram#ISO 9001 standards#Machine#Man#Material#Method#Mistake-Proofing#Outputs#pareto analysis#Pareto Chart#Pareto chart in quality control

0 notes

Text

5 Things You Don’t Know AI Can Do for You in FMEA Development

Omnex Systems O-BOT, our cutting-edge AI-powered platform, transforms the way you handle Design and Process FMEAs. By utilizing insights from our AQuA Pro module, O-BOT provides tailored suggestions, significantly reducing engineering review times.

0 notes

Text

Across many industries, Failure Modes and Effects Analysis (FMEA) is a proactive risk management tool used to detect possible failures in systems, products, or processes and lessen their impact. FMEA training gives professionals the know-how to apply this potent methodology successfully. This post will examine the advantages, uses, and contributions of FMEA training to improving operational quality and efficiency.

#fmea#fmea training#online fmea training#fmea training online#failure mode and effective analysis training#punyam academy

0 notes

Text

Learn the principles and techniques of hypothesis testing to make data-driven decisions and draw valid conclusions. Enhance your statistical analysis skills. Enroll now!

0 notes

Text

An analysis on how Sir Pentious' character design represents his personality and development perfectly (beware of Hazbin Hotel spoilers)

Let's get this out of the way: Sir Pentious is a snake, an animal mostly known for generally believed negative traits such as poison, deceit and betrayal. We don't know WHY he's in Hell, maybe he was a "snake oil salesman" considering he comes from the Victorian times and he's into hyping up what he does, or maybe he was into war. Thing is, he's a Sinner whose design just scream "Evil".

(BTW, a snake could also represent "fertility": looking at you, Egg Boiz!)

He always had eyes all around him not just because of a stylistic choice.

Sir Pentious always felt like he was watched, and had to watch out for any danger.

"Everyone here is too nice: obviously it must be a lie! I can sense they are planning to kill me, but when?! HOW?! I must be PREPARED!"

Sadly, he's been constantly berated by other demons, far more effective in destruction, status, cruelty and charisma. Alastor won't ever bother to remember him, Cherri always ones up him, and the Vs, the ones he admires to most, won't care less about him.

To the point that Vox sent him as a spy without the intention to save him if things were going to fail. Heck, he even openly tells him to die while calling him a failure.

So of course he's got reasons to have trust issues, or taking everything so seriously, being constantly reminded of what he can't accomplish. So he puts an air of grandure that may be very flamboyant, but is VERY frail.

But, if we have to be frank here, his biggest source of insecurities... is himself.

He has eyes on his tail (his softer, more vulnerable side, which is ironically made even MORE lieable to getting hurt because of how sensitive those organs are), and inside his hood, so he could look out better for danger when on alert mode.

Heck, even the mark on his hood kinda resembles one eye.

Problem is, when you see his hood folded, when he's at ease, neutral or sad, those are not looking at outside sources.

They're looking at him, at his back. A constant stare that happens everytime he lets his guard down and shows how vulnerable he is. A gaze that can sense all of his weakness, his struggles, his insecurities.

And it's all him.

Pentious constantly believes that his inferiority complex will fade away once he'll accomplish something grand that will make others accept him. But he is his biggest critic, his worst enemy: HE is the one who believes he's a failure, that he'll never gain approval from others.

This show takes place in Hell, but this is Sir Pentious' personal Hell: insecurity born out of self hatred. Doomed to feel everyone's gaze upon him, including his own. Believing the danger to his self esteem is from others, when it's really from him.

But then he's accepted at the Hazbin Hotel: Charlie forgives him, he bonds with Angel, Husk and Niffty who don't care a bit about what he's accomplished or not, or what he's done in the past.

He feels more comfortable in showing his vulnerable side, and no one judges him for how easy it is for him to get emotional.

Of course he's still very insecure, considering how he struggles to confess to Cherri, but notice how he stops building machines or planning to attack others as soon as he starts bonding with the others: he doesn't have a reason to destroy or attack, now that he knows he's loved.

And his final design, when he goes to Heaven, shows how much he's changed, yet stayed the same. He may have died a hero, but he's still the same awkward snake we've come to love.

Speaking of love, let's talk about that!

No more eyes on his tail, now it's just on his chest (showing he's opened his heart), his glasses are now heart shaped, and even the markings inside his hood resemble kiss marks more than anything else.

And look: the mark on his hood is now heart shaped!

Why all these hearts? Why did all the eyes disappeared from his body? Even his eyes that were looking at his back?

Simple: love. Love defeated his insecurities and self hatred. He died for love.

He died protecting his friends, his new family, his new home.

He confessed and kissed Cherri knowing full well he wouldn't have made it, and yet he went anyway.

The usually cowardly and timid Pentious actually faced a great danger with courage and determination: he acted selflessly by putting himself in harm's way, he didn't steal (naturally) and by going against Adam he did indeed "stick it to the man"!

He used his weaponry knowhow and battle experience not to conquer, but to save his loved ones.

His only thought up until his demise was: "I'll go down protecting them".

And he's been rewarded not only by becoming an angel, but also being spawned directly in front of Emily and Sera, two Seraphim, the highest rank for an angel to have, who have also been depicted as snakes of fire throughout history! Sir Pentious, the lowly demon considered a failure by everyone, actually has been noticed by the Seraphim! He's come so far!

He's now come to represent the REAL symbolism of a snake: the duality of death and rebirth, transformation and immortality (ironically a reference to the fact he's been around since 1888 without ever dying from any Extermination or blessed weapons).

And isn't so poetic that a snake, the "source of the original evil", was the first sinner to ascend to Heaven? Or that this episode was released on February 1st, or National Serpent Day?

And of course, as the Bible itself says:

"Greater love has no one than this: to lay down one’s life for one’s friends."

(John 15:13)

And knowing him, I'm confident in saying he'll keep helping his friends even in his new position, like the soft hearted noodle he's always been, but was to afraid to show it up until now.

#Vivziepop#Hazbin Hotel#Hazbin Hotel Spoilers#Hazbin Spoilers#Sir Pentious#Fave Character#Comfort Character#Personal Rambles#What a wonderful lovable character he turned out to be 🥲#Character Analysis

3K notes

·

View notes

Note

feel free to answer when you’re not drunk but can you elaborate on the material basis for why USian communist orgs dont believe in revolution? is what you’re saying basically that - to put it crudely - workers in the US are alienated from the means of production so they dont know shit about how production actually works and therefore don’t understand how it can be seized and altered to serve the proletariat?

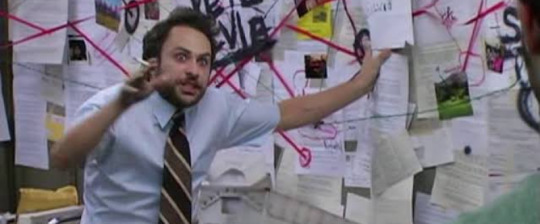

Time to elaborate some on this post now that I'm awake and sober! 😁

Big disclaimer that these are largely my theories, which have yet to be proven or disproven through revolutionary practice!!! (I'm working on it. . . . 🙇♀️)

Yeah you've got my material analysis right--though I'm not sure if "alienated" is the correct word (maybe "estranged"? thought it's been a minute since I read The 1844 Manuscripts). To clarify, though, when I say "the material basis for this degraded self-confidence," I of course don't mean it in a sense of direct causality! The loss of revolutionary confidence is strictly the result of previous generations of communists in the US failing to accurately interpret their circumstances and put forward an appropriate plan of attack. The shift in the mode of production following the neo-liberal turn merely provided the soil for weeds, which communists failed to cut down. As George Jackson put it, "when revolution fails, [. . .] it's the fault of the vanguard party." [1]

In my analysis, there have been two main failures which lead us into our current dearth of revolutionary confidence: first the failure of the socialist workers movement in the 1930s, and second the failure of the socialist movements for national liberation (often called the New Left) in the 1970s.

The first failure I haven't studied as thoroughly, but my rough understanding is that the workers movement, which held strong communist influence at the dawn of the 20th century, was effectively blunted by the New Deal, through which FDR divided the working class by paying off white workers at the expense of the oppressed nationalities. CPUSA, which had thusfar only made stumbling progress on addressing issues of racism, was ill-equipped to navigate this rupture in its base, leaving it vulnerable enough for Uncle Sam to massacre the party's revolutionary spirit during the period of McCarthyism.

Then in the 1960s, the trajectory of the civil rights movment lead black USAmericans to start viewing their communities as an "internal colony" of US imperialism, which could be best liberated through the strategies of national liberation which had worked (or were working) in China, Korea, Cuba, and Vietnam (with fairly little attention paid to the USSR and Eastern Europe). The explosive impact of the Black Panther Party inspired the formation of a bunch of groups in racialized or otherwise oppressed communities (e.g., the Young Lords, the Brown Berets, the Red Guard Party, the American Indian Movement, the Gay Liberation Front, the Street Transvestite Action Revolutionaries, etc.), and whilst these groups did attempt to form a unified front against the DotB, [2] their movements ultimately failed to coalesce, and were stamped out as individually as they were formed. Imo, had there then been in the US a genuinely revolutionary communist party, with a basis of support within the proletariat, I would be blogging to-day from the United Socialist States of Turtle Island--instead, the trade unions largely rejected this movement, and even moved closer to the right to distance themselves from this tendancy! [3]

The labor movement here (such as it exists) has been largely devoid of socialist character for decades now, and a lot of the New Left veterans circled around to blaming the our proletariat for the period of intense counterrevolution that was the neo-liberal turn. When the Regan administration launched a comprehensive assault on the unions, communists were not there in enough force to organize a successful counter attack.

Imo, for communist revolution to succeed in the US we will need a movement that has a thorough counter to national/racial/sexual oppression, otherwise the DotB will continue to run us through their highly advanced proletariat-dividing-machine until Germany finally nukes us all. We also need a movement that is internationalist in its foundation, otherwise they will use imperial chauvanism to divert our cause! Personally, I'm skeptical that the US proletariat is even a revolutionary class at this point, as our immediate economic interest is to defend the empire that subsidizes our relative luxury. If anything, we're in a similar position to the French peasantry who voted Louis Bonaparte in 1848. But like the French (and the Russian, and Chinese, and Korean, etc.) peasants, we can recognize our long-term interests and rally behind a communist movement that successfuly demonstrates the importance of proletarian revolution!

This is why I continue to maintain that the cornerstone of US communism rn should be a proletarian movement against imperialism (that is, against the material infrastructure through which "our" government projects its global hegemony)! Of course, idk how to build this yet--but to all my followers in the US, let's make a deal: you go out and start communist organizing in your community, and we can meet up and check notes when one of us figures out how to advance the level of struggle. 😉

Blood in My Eye. Pg 14.

Most notably through the Revolutionary People's Constitutional Convention.

The effect of the Sino-Soviet Split on US socialism in this period is something I still need to properly study, but it feels wrong not to mention it at all here. My rough impression so far is that, as most established socialist states and older socialist organizations sided with the Soviets, the New Left who mostly sided with the PRC found themselves isolated from the global movement that had initially inspired them. But yeah this is just my impression from tertiary sources, so please please correct me if you know better. 🙏

#ask#thought cabinet#communism#get organized#we have nothing to lose but our chains. we have a world to win

40 notes

·

View notes

Text

Economy and ecocide

Both animal and earth liberation offer key footholds in the imagination, but we’re not there yet. You could say anti-speciesism and deep ecology are revolutionary, yet not necessarily in a political sense, only a moral one. Indeed, the best-known thinkers of both movements – Peter Singer and Arne N��ss – sought to analyse the oppression of other animals and the earth in isolation from a critique of the state and capital, taking it for granted that the system isn’t inherently ecocidal. Both intellectual movements – themselves outcomes of the New Left – thereby found themselves looking at oppression in a way suspiciously similar to identity politics, offering practical proposals focused around personalistic evolution and legislative change. The corresponding activist movements have, of course, often utilised much more radical tactics, but even militant strategies run a certain risk: promoting animal or earth liberation in separation from an assault on social hierarchy overall.

The theory of social ecology introduced by Bookchin is extremely useful here. The point of social ecology, as the term suggests, is to provide a combined analysis of social and ecological issues. More specifically, Bookchin argued that the domination of the natural world is rooted in domination within society, especially hierarchies such as the state, capitalism, and patriarchy. The ways in which humans mistreat nonhumans are in so many ways an extension of how humans mistreat one another; hence, rampant hierarchy between ourselves can only lead to the subjugation of life in general. It’s no coincidence that those societies most heavily burdened by economic inequality are almost always the ones that treat their environment the worst. Nor should we expect a liberal response, one focused on piecemeal reforms and consumer choice, to effectively challenge the devastation. On the contrary, achieving balance within Nature is one and the same with creating a nonhierarchical society, which is exactly why most social ecologists pose social revolution as the only viable response to the growing environmental crisis. In short, this world cannot be made green: promoting sound ecology means creating new worlds altogether.

The ecological problems inherent in capitalism are amongst the most urgent to consider. It’s becoming increasingly impossible to ignore the ecocidal tendencies of the dominant mode of production; far from being an outcome merely of this or that version of capitalism, however, the devastation of the natural world stems from its simplest and most irrevocable features. The basic motor driving capitalist production is the need for businesses to generate profit. And profit is generated by converting natural resources into products that are sold on the market. Moreover, businesses will be successful, in the eyes of capitalist logic, to the extent they’re profitable. Which means that the success of the capitalist economy equates, roughly speaking, to the extent to which it uses up natural resources. The fact that businesses are incentivised to use these resources as efficiently as possible (less money spent on purchasing and processing them) makes little difference, given that any sound business will merely reinvest the money saved into consuming even more, thereby maximising profit. The basic equation is thus, on the one hand, that more production means more profit, and also that more production means more ecocide.

Capitalism offers no hope of a way out. Its need for growth is absolutely insatiable. Without achieving constant economic expansion, any business tempts the possibility of recession or even bankruptcy, inviting competitors to undercut its share of the market. With the economy as a whole, too, the mere failure to maintain endless growth is defined as a crisis. To even consider a limit to the conversion of our living, breathing environment into mere stuff speaks a foreign language to a corporation.

It’s no mystery that the vast majority of the natural world has already been destroyed, as is one and the same with the smooth functioning of the capitalist machine. And what a hideous notion of “wealth” it offers: collapsed fisheries, wiped out forests, chewed up landscapes, topsoil turned to dust, fossil fuel reserves bled dry. Far from slowing down, no less, the rate of depletion is only speeding up, exactly as the mantra of constant growth requires. Since the Industrial Revolution, especially, we’ve been living well beyond our means, something that’s only risen enormously since the mid-20th century. The economic demand for higher levels of consumption has been met with an exponentially rising global population of consumers, as well as the flooding of the market with ever more useless crap, but it can’t go on like this forever. We’re hurtling towards a crunch of one sort or another, and one of two things must go: either capitalism, or the planet.

Life and the economy exist in a fundamental state of tension with one another. To the extent that the health of one is coextensive with the devastation of the other. We’re never far from the latest report either of a catastrophic oil spill or endangered species being driven to extinction, nor another “revelation” as to the living hell of factory farms. Yet the basic contradiction of liberal discourse is to bemoan these horrors whilst refusing to question the economic conditions that necessitate them. We need to be outraged without being surprised: the cause of such abject abuse can only be a mode of production that disregards everything irrelevant to the generation of profit. Economists describe those factors unconducive to immediate growth simply as “externalities,” unintelligible to capitalist logic and utterly devoid of concern. Carbon emissions, for example, are released into the atmosphere merely as a side-effect of industrialised production; given that there’s no economic incentive to avoid this outcome, any hope of an alternative is quite futile. Even the very real threat of climate change – the imminent ruination of life as we know it – fails to offer a conceivable problem for the economy. The laws of the market literally deem it irrational to deal with such a problem, given that any corporation would be bankrupt long before the prevention of catastrophe offered the chance of a return to its shareholders. Nor can we expect capitalist governments to intervene effectively instead, precisely because their success, too, is measured first and foremost with respect to short-term economic growth.

It might seem a strange thing, therefore, that most people find themselves going along with business as usual. Yet there’s an important explanation here, and that’s “green capitalism” – the vilest of oxymorons. Green capitalism can be summarised as the idea that the market can be used to fix the deepening environmental crisis. It began gaining influence in the Global North in the ‘80s, largely in response to a combination of two factors: on the one hand, corporations realised that many consumers possessed a newfound, sincere desire to protect the environment; on the other hand, however, the majority of these consumers seemed to prefer an environmentalism compatible with the preservation of normality. In particular, green capitalism appeals to the expectation that the health of the planet be maintained alongside our resource-intensive lifestyles, cemented amongst the burgeoning Western middle class throughout the 20th century. But really this indulgence is only the ultimate form of consumerism, putting a price-tag even on the sense of moral righteousness. As the planet suffocates, the solution offered by green capitalism is to consume even more, as if we’re honestly expected to believe that organic meat, hybrid cars, and energy-saving lightbulbs are going to save us. Most people simply cannot afford the luxury of appeasing their guilt whilst the environment is ravaged. And even if we somehow could, it wouldn’t make much of a difference, given that the overwhelming majority of pollution – including greenhouse gases – is emitted only by a relatively small group of corporations, not the sum of individual consumers. The green economy markets a million different things, yet each of them is only a different version of the same futile product: the hope the planet can be saved without attacking the economy.

All the talk of “sustainability” is but a distraction from questioning the unquestionable, painting over that which is fundamentally rotten. What’s really being sustained here is capitalism, not the planet. Even an allegedly renewable capitalist economy – one based, for example, on industrial solar, wind, or tidal power – would just be another means of powering a system that, at its core, is both antisocial and ecocidal. All the idea offers is a greenwashed version of what we already have: a monopoly on energy held by corporations and the state, resource-intensive consumption for privileged members of society, and the inevitable exhaustion of what little remains of the living planet. Moreover, we can hardly be sure a shift towards renewables would stop climate change, even if most governments somehow agreed to it. It’s highly doubtful whether the global economy could be fundamentally restructured in time to avert catastrophe. Nor should we assume that, compared with maintaining a reliance on fossil fuels, such immense construction efforts won’t actually release significantly more carbon emissions in the short-term, marring our efforts in the decisive years ahead of us.

There’s no limit to the hollow excuses the defenders of the existent will throw at us. But now is the time to be done with them, decisively parting ways with the certainties of this world, which nowadays offer but the certainty of extinction. For biodiversity to outlast the century, humanity must dare to call into question the economy itself. Which is often an unthinkable task, given that the economy has been the main beneficiary of the religious urge, eagerly seeking new form since the death of God – the steady withdrawal of theism as a stabilising moral force. Yet there’s no chance for redemption here. No afterlife in which to seek salvation, nor another planet to escape to. The economy needs to be destroyed. It has to be torn down completely. Or else it will only arrive at its destination, completing its suicidal dash for the cliff edge, taking each of us with it.

Destroying the economy isn’t a matter of forgetting about meeting our everyday material needs, as if to do away with economic considerations altogether. What it does mean is realising that the economy – the subsumption of the totality of our needs within a single, monolithic, globalised system of production – could never be squared with the perseverance of life. Levelling this structure is a process of reclaiming the conditions of existence, piece by piece, by localising and demassifying them. It’s a call to form communes aimed at self-sufficiency, each of them striving to meet its material needs – food, energy, accommodation, and so on – wholly within the means of what they can produce for themselves. Which is a political undertaking as much as an ecological one, given that the autonomy of any community is surely inseparable from it being the source of its own potency, its own vitality. Anything short of that risks one of two things: either dependence on an external body for your most basic needs, or else the necessity of outward expansion, defined in equal parts by imperialism and ecocide.

More specifically, taking apart the economy is synonymous with dismantling the institution of private property. Communising the means of production has often been recognised as the material basis of human autonomy, given that, as long as we lack direct access to the resources needed to survive and flourish, there’s no choice but to accept the exploitative terms of work dictated by the ruling class. What’s more rarely recognised, however, is just how relevant the critique of property is to the liberation of nonhuman life. The domination of animals and the land is facilitated primarily by their legal status as human property, something that confers our mastery over them. Animal liberation would be unthinkable without pushing back the frontiers of property relations, as was the case with resistance to other forms of slavery, including the trans-Atlantic slave trade and many traditional forms of marriage. Earth liberation, moreover, describes the completion of this historical progression, entailing the abolition of property altogether. There’s no doubt that using the land respectfully is compatible with appreciating its intrinsic value; by contrast, treating it as property – that is, owning it – necessarily declares an inferior status. In this sense, animal and earth liberation, far from being even slightly reconcilable with capitalism, begin to look inseparable from the communist project.

As far as destroying the economy goes, though, the state would never allow it. Not willingly. To refer to the state as distinct from the economy might well be an overstatement; at the very least, the needs of the economy constitute its supreme law. Even avowedly radical political parties – social democratic alternatives to austerity, for example – purport to serve the economy even better than the status quo itself. No departure from this logic is conceivable within the realm of politics. After all, the primary role of the state has always been to safeguard the needs of capital: it was at the forefront of the assimilation of the peasantry into the industrial proletariat, as well as the expansion of market relations across the globe. What you see nowadays, moreover, is the reinvention of this union for the secular age: whilst the state once tasked itself with representing the divine will, today it represents the economy, mediating between the masses and that which is sacrosanct, keeping our needs locked into the growth-imperative. There’s an enduring temptation to think that state and economy can somehow be separated (most Marxists favour this approach, still serving up whichever reheated variant of the state socialist paradox). And yet, of all the stupid ideas tried out in the long, weary history of civilisation, few have claimed more lives than the anti-capitalist sympathy for statecraft. Either the state and the economy are confronted as one, or not at all.

To bring it back to social ecology with a simple summary, taking nonhuman liberation seriously means living our lives outside and against the system that engulfs us. The state and capital cannot be reformed or compromised with, because theirs is a nature that is fundamentally extra-terrestrial. Not in the sense, of course, that they originate from beyond this planet, but instead because their existence is inherently incompatible with that of the earth.

The time for timid critiques is over. This is the moment to make serious plans for desertion. At such an unforgiving moment in history, there can be no pretensions of neutrality: working for the economy can only mean complicity in our own annihilation. That leaves each of us with a vital choice, one between compliance with social hierarchy and the perseverance of life itself. Suddenly the phrase “revolution or death,” tagged on a wall during Trump’s inauguration, takes on a whole new meaning. There you have it: revolution or death.

#anti-civ#anti-speciesism#autonomous zones#climate crisis#deep ecology#insurrectionary#social ecology#strategy#anarchism#climate change#resistance#autonomy#revolution#ecology#community building#practical anarchism#anarchist society#practical#practical anarchy#anarchy#daily posts#communism#anti capitalist#anti capitalism#late stage capitalism#organization#grassroots#grass roots#anarchists#libraries

6 notes

·

View notes

Text

Why are headlight bulbs only rated for 150 hours or so?

It is well known that headlight bulbs (mainly halogen bulbs) have a short life span – usually only rated for 150-500 hours – due to basic physics and the tradeoff between brightness, efficiency and cost. The reasons are as follows:

⚙️ The core reason for the short life of halogen bulbs Vibration and fatigue of filament

Halogen bulbs use tungsten wire, and their luminous temperature is about 2,500°C.

Road vibration can cause microscopic cracks → filament breaks.

Impact: Rugged roads can reduce the lifespan of light bulbs to less than 100 hours.

Tungsten evaporation

Extremely high temperatures can cause tungsten atoms to evaporate.

A mixed gas (halogen cycle) causes some tungsten (but not all) to be redeposited onto the filament.

Results: The filament thins over time → eventually fails.

Pollutant sensitivity

During the installation process, skin oils will form hot spots when they are stained on the glass.

Air leaks in the seal will cause the bulb to oxidize quickly (bulbs turn black = scrapped early). Electric surge

The voltage spike (~12V → 15V) during startup will cause stress on the filament. Trade-offs: Brightness and Lifespan

High-performance halogen lamps (e.g., Osram Night Breaker: 150-250 hours) operate with higher temperatures and more than 90% brightness.

Standard bulbs (for example, Sylvania Basic: over 500 hours) focus more on life than output power.

📊 Lifespan comparison of different bulb types Bulb Type | Average Life | Brightness (Lumens) | Cause of Fault Halogen lamp | 150-1,000 hours | 1,000-1,500 lumens | Filament break HID/Xenon Lamp | 2,000-10,000 hours | 3,000-5,000 lumens | Electrode corrosion/Ballast fault LED | 20,000-50,000 hours | 1,800-20,000 lumens | Drive/radiator failure

💡 Why don’t manufacturers produce halogen lamps that have a longer life? Cost Engineering: Automakers prioritize 5-20 light bulbs over expensive alternatives.

Regulatory Focus: The DOT/ECE standard tests light output/beam mode, not life.

Brightness deviation: Excessive pursuit of filament life will lead to "upgraded" bulbs being sold at high prices.

🔧 Extend the life of halogen bulbs: professional skills Never touch the glass: Use gloves/isopropanol wipes to prevent oil stains.

Stable voltage: Install the relay wiring harness → Directly powered by battery can avoid unstable factory wiring.

Reduce the number of switches: Turn on the light only when needed (cold starts up to the maximum pressure on the filament).

Choose a rugged bulb:

Philips X-tremeVision Pro150: Silicon film filament coating (250+ hours).

PIAA Xtreme White: Dual filament support, shock-resistant.

🚗 Why LED/HID has longer service life (but each has its advantages and disadvantages) LED: No filament → Shock resistant. Disadvantages: Complex thermal management.

HID: Gas discharge → No filament fatigue. Disadvantages: High voltage ballast failure.

⚖️ Hourly Cost Analysis Bulb Type | Cost per pair | Lifetime (hours) | Cost per hour Basic halogen lamp | 15 | 500 | 0.03 Advanced Halogen Lamp | 45 | 250 | 0.18 LED (SNGL) | 180 | 30,000 | 0.006

🌐 Key points

The premature failure of halogen bulbs is due to a deliberate engineering compromise: durability is sacrificed to maximize brightness/cost-effectiveness. To extend service life: Stick to standard halogen lamps (approximately 500 hours) + operate with caution, or

Switch to LED lights (if legal and optically compatible) – despite the high upfront costs, it’s worth it in the long run.

LED lights are the ultimate solution for vehicles driving on rough roads or burning out frequently, while HID lights offer a compromise for vehicles equipped with projectors. Always prioritize the appropriate voltage and installation to maximize the life of the bulb. 🔧

#led lights#car lights#led car light#led auto light#youtube#led headlights#led light#led headlight bulbs#ledlighting#young artist#halogen headlights#halogen bulb#halogen#cars#car rental#electric cars#classic cars#car#carlos sainz#porsche#truck#automobile#lamborghini#bmw#autonomous vehicle headlights#overtake another vehicle#older vehicles#vehicle#headlamps#headlight restoration

2 notes

·

View notes

Text

this book is like porn for me

Preparation when an automobile breaks down in the desert means simply avoiding death from dehydration by having had enough foresight to carry along some water. This example implies the double failure that has killed many a bold explorer. One failure occurs before the adventure begins by counting on a single vehicle and not carrying enough water to walk out or to survive until another vehicle can come to the rescue. The second failure, engine trouble, usually nothing more than an inconvenience, proves fatal. The double failure problem is well known to engineers who design life-support equipment such as diving gear and spacesuits. They devise diagrams to analyze potential failures or faults in systems that will affect the probability of survival in specific failure modes. These fault analysis diagrams, or trees, can become quite complex for even relatively straightforward systems. However, most of the essential information can be gleaned from simple diagrams, if properly constructed, and it is surprising how few explorers actually use this approach in planning an expedition. Fortunately, the prudent explorer appreciates the bottom line: the way to ensure safety and dependability is to build in redundancy. Deciding how much redundancy is enough is the tough part.

The double failure problem and the value of redundancy can be illustrated with diagrams using a technique called nodal condensation probability. In planning an expedition, if one anticipates event A, a 1-in-1000 failure with a 99% chance of survival, the probability of death is only 1 in 100,000. These odds are acceptable to most people. However, if a second independent failure possibility, B, is added to the expedition with the same probability and the same survival rate, the two probabilities must be summed, giving an expected risk of death of 1 in 50,000 for the expedition. This arrangement of events, known as a linear system, is depicted in Figure 1.3. (Not copied over here.) One must also consider the effect of a rare double failure because the odds of surviving the second failure may approach zero if it occurs after the first failure. A good example is ejecting from a burning jet aircraft with a defective explosive canopy bolt. If an independent probability of 1:1000 is assigned to each event, the probability of experiencing the double failure is 1:1000 squared, or only one in a million. The chances of living through it however, are virtually zero. Overall, the expected probability of death in this linear system is 2.1:100,000. Next, consider the problem of starting an expedition with a failure already in place. This is illustrated in the bottom half of Figure 1.3. In the desert example above, the motorist left town without a supply of drinking water. In this case, the event, a, is assigned a probability of 1 because it happened, but it did not happen in the desert and the motorist can find water anytime before departure. The probability of dying of dehydration is nil. The second failure, b in Figure 1.3, has a probability of 1:1000, but now the probability of death is 1. This means the overall risk of dying on the expedition has gone from 2.1:100,000 to 1:1000, nearly a fiftyfold increase. These calculations give one an appreciation for why most of the deaths in mountaineering, deep sea diving, parachuting, and so on are due to double failures that involve at least one human error. The initial failure often encompasses a critical failure of preparation.

5 notes

·

View notes

Text

With Zelda, I think you gotta acknowledge that-- not from a place of ineptitude or lack of care-- the Devs have always been like:

Which is fine. But also, without throwing out the canon details given in the games themselves, I think you gotta be able to take that as free leave to gather up all the franchise materials and be like:

In both a critical and joyful way.

I think if Zelda makes you feel critical more than not, maybe it's not all that good for you to engage with it. I imagine that there's probably a lot of people like that, who kinda like the vibes or were players in their childhood but don't really want to engage the actual media, who are more comfy in the sub-fandom space of heavily reimagined Zelda fanworks. The way I see that is, they're curating their experience heavily.

I'm a fan of the core and official franchise materials mostly, but from my perspective-- there is a lot of lore to play with, and there are intended and interesting themes all over the place. There are a lot of connections that are there on purpose. There is subtext to find. There are a few overarching tales that do have some masterful craftsmanship behind them and they aren't happy accidents fans make up. These things are canon, they are cornerstones that help make the franchise overall fantastic. I think the Zelda team have been consistently passionate and skilled people throughout most of the franchise who produced excellent works.

But not all things intended are good, and not all good is intended, and sometimes there's unhappy accidents, mishandling, biases, and questionable themes and messaging too. There are intended connections that have negative implications. It also doesn't mean that there hasn't been a decline in quality in certain games or glaring issues in others.

Both can be true.

Being realistic about the issues and talking about them is important, but I think some slide entirely into a habit of accepting really bad faith takes at face value. I think that loses a lot of the usefulness of effective critique-- which isn't supposed to be a solely negative thing, on its own. It goes both ways.

In a franchise that hugely centres itself around player investment and interpretation, while also not prioritising the narrative intention over gameplay experience as a whole because of this, sometimes there are roads that lead nowhere in terms of overall story. This can be both a disappointing thing, and a good one. Because I, as the fan, am invited to fill them in, and sometimes that's also clearly part of the intent-- and I don't see that as me doing some kind of heavy lift. If I felt that way, I probably wouldn't be a fan.

Regardless of whether people appreciate that approach or not, I think it's important when engaging with media that we can identify when this is the case. Like when something is a conscious choice and when it's not. Whether or not something is actually a failure or weakness of structure in the media itself, or if there's a different reason for a feeling of disconnect in reception. Because there's a difference there between dissection of the meta in how something is presented and why and what the result was, versus criticism or deeper analysis of its conception and construction and chosen ingredients.

One examines reception and impact of the final product -- which is a critical part of the discussion in Zelda especially given its larger reliance around the player interpretation-- and the other looks at the mechanics of how it came to be that and why. Those are deeply related, but also very distinct, focuses in these discussions.

I think if I start lovingly pulling apart Zelda, it's important to me that I have a clear idea of which mode I'm in.

Y'know what I mean?

#shut up hero#this isn't about totk but for the record#i personally think totk was perhaps the most glaring structural failure in the franchise since LOZ2#and i think some of the heads of the zelda team are feeling burnt out and unsure how to move forward#i think the interviews are telling that fujibayashi let his arrogance get the better of him and Aonuma honestly just sounds a little lost#and I feel like they're trying hard to save face#i think they know they fumbled hard but aren't used to it#but that's just the impression i got personally

4 notes

·

View notes

Text

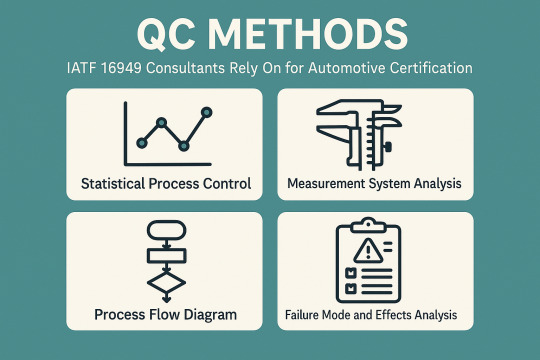

QC Methods IATF 16949 Consultants Rely On for Automotive Certification

In the competitive world of automotive manufacturing, quality is not something to strive for; it is imperative. Based on customer expectations, we must also ensure safety, reliability, and compliance with regulations. That’s where a globally recognized quality management standard designed specifically for the automotive sector comes into play in the form of IATF 16949.

IATF 16949 is more than a certification; it embodies a culture of continual improvement and process excellence. Becoming certified, though, is a labyrinth of requirements, documents, and audits. Here is where the role of IATF 16949 Consultants becomes crucial, as they help organizations navigate the process with their knowledge and clear insights.

Fundamentals of IATF 16949 in UAE

IATF 16949 is based on the fundamentals of ISO 9001, but with many automotive-specific requirements that are required for product development, production, and servicing. The main goal of IATF 16949 Certification in Abu Dhabi is to create a quality management system that promotes continual improvement, focuses on defect prevention, and reduces variation and waste in the automotive supply chain.

Main Goals of the Certification:

Maintain the quality of the products

Enhance customer satisfaction

Increase productivity in the manufacturing process

Create a culture of continual improvement

Benefits of the Certification:

Increased reliability and performance of the product

It increases the credibility in the market, and also the customers start trusting the product.

Easier access for global automotive supply chains

Lower operational costs and recall costs

As IATF 16949 Certification Consultants, your role is to ensure organizations meet the exacting standards of IATF 16949, thereby enhancing their organizational processes.

The IATF 16949 standard process can be lengthy and requires a lot of documentation, internal audits, and compliance reviews. Enter consultants to the rescue.

Benefits of Hiring a Consultant:

Quicker: It reduces the process of implementation and certification.

Quality: Prevents costly mistakes and unsuccessful audits.

Risk Mitigation: You are prepared to meet compliance and customer expectations

Widely-used QC Tools in IATF 16949

To get the correct products, organizations implement Quality Control (QC) tools. IATF 16949 Consultants in Dubai are essential to help solve problem diagnosis, process control, and decision-making.

Significant QC Tools:

Cause-and-Effect Diagram (Fishbone or Ishikawa): Assists in determining the root causes of quality and performance problems.

Collects Real-time data for analysis, check Sheet

Control Chart: Control charts are used to test process stability.

Histogram: Shows how the data is distributed to identify variability.

Pareto Chart: Emphasizes significant problems through the 80/20 rule.

Scatter Diagram: This shows the correlation between two different variables.

Process Diagram: Charting out process steps, using this step to identify; Also helps identify dead ends or redundancies

Tools Related to Advanced Quality Planning (Core Tools):

APQP (Advanced Product Quality Planning): A framework for product and process design.

PPAP (Production Part Approval Process): Verifies that a product meets the customer needs of design needs before bulk production.

Failure Mode and Effects Analysis (FMEA): Assesses potential risks in products and processes.

MSA (Measurement System Analysis): Evaluates the accuracy and precision of the measurement systems.

Statistical Process Control (SPC): Utilizes statistical techniques to monitor and control processes.

The Role of QC Tools in the Quality Systems:

Resolution: If the issue is recurring, trace back the roots and take preventive measures

Maintain Consistency: Process control

Decision-Making: Focus your actions on objective data and trends.

Continuous Improvement: This principle involves the concept of constant improvement.

Tools for Quality Control Implementation of IATF 16949

It is also worth noting that the above QC tools are not just theoretical but are embedded in the DNA of IATF 16949 Certification in Dubai.

How do QC Tools Help Compliance?

FMEA reinforces risk-based thinking, which is a fundamental requirement.

Ongoing validation and monitoring of process: Control Charts and SPC

Corrective actions based on the data based on Pareto Charts and Histograms

APQP and PPAP are structured for the planning and validation of a product.

Example Scenarios:

One of the quality suppliers identifies repetitive defects in a certain part by Pareto analysis and resolves it by Fishbone diagrams and FMEA.

MSA and SPC data are used by an organization during PPAP submission to demonstrate process capability and measurement reliability.

Consultant's Role:

Based on certain challenges, recommend tools.

Develop templates, offer training, and provide software solutions.

Tools must be used effectively and in compliance with expectations.

While the benefits are numerous, many organizations struggle with certification.

Common Obstacles:

A failure to understand the requirements.

Documentation that is incomplete or poorly maintained.

Inconsistent use of QC tools.

Resistance to change or continuous improvement at the community level.

Mistakes in using QC tools or the wrong tools used:

Tools that do audits but are not used for decision-making.

Data that has been collected but not processed or acted on.

Staff was trained never to read charts and metrics

How IATF 16949 Consultants Help in Dealing with Challenges?

Analyze requirements, discover commonalities, and factor them into incremental steps.

Educate staff on how to use the tools correctly.

Get them involved and make it real with workshops and real-world scenarios.

Develop a sense of quality across the organization.

Conclusion

The IATF 16949 is not only a badge but a testament to excellence, consistency, and customer satisfaction in the automotive industry. Expert guidance and practical tools are needed in order to reach and maintain this standard.

IATF 16949 Consultants in UAE know what has gone wrong in the past and the strategies, processes, and ways of thinking that will help a company successfully implement the standard and prepare for and respond to audits. On the other hand, QC tools are the eyes and ears of your quality management system, detecting problems and informing decisions.

Collectively, they enable automotive suppliers to raise the bar in the industry. Investing in expert consultants and embracing QC tools is not just smart—it's essential for any organization seeking sustainable growth and operational excellence.

0 notes

Text

How to Keep Your Check Sheet in 7 QC Tools Current and Move It Forward

In the world of quality control and continuous improvement, the 7 QC tools are the foundation for solving problems and enhancing processes. Among these tools, the Check Sheet in 7 QC tools is one of the simplest yet most powerful methods for collecting real-time data in a structured, visual format.

However, just creating a check sheet once isn’t enough. To keep it valuable and relevant, you must update, improve, and align it with your changing process needs. In this blog, we’ll explore how to keep your Check Sheet current and how to enhance its effectiveness over time.

✅ Why Check Sheets Matter in Quality Control

A Check Sheet helps collect data at the source—during inspections, operations, or even customer service. It’s a tool to track:

Defects and error types

Equipment failures

Downtime causes

Frequencies of events

Inspection results

Used correctly, it helps teams spot trends, make decisions based on evidence, and take corrective actions. But if the format is outdated or misaligned with current operations, it loses effectiveness.

✅ Steps to Keep Your Check Sheet Current and Effective

1. Revisit Your Quality Objectives

Begin by asking: What are we trying to measure or control?

As business priorities shift—new product lines, new machines, or different customer complaints—your Check Sheet must reflect those changes. Update your data categories, frequencies, and timeframes to match your current quality goals.

2. Validate the Categories and Data Points

Are you still tracking the right issues? A Check Sheet created months ago may be collecting data that’s no longer useful.

✔ Eliminate outdated categories ✔ Add new defect types or failure modes ✔ Clarify ambiguous terms ✔ Ensure frontline operators understand each category

3. Keep the Format Simple and Clear

A cluttered or confusing Check Sheet leads to inconsistent data collection. Stick to these principles:

Use plain language

Keep columns/rows organized

Avoid excessive detail

Use tick marks or symbols for faster recording

Consider using digital versions (spreadsheets or apps) for efficiency

4. Align Check Sheets with Process Changes

Have you changed tools, materials, or workflows recently?

Update your Check Sheet to reflect these adjustments. For example, if you’ve introduced automation, you might need to track machine error codes instead of manual defects.

5. Standardize Across Shifts and Teams

Inconsistent data ruins trend analysis. Make sure everyone uses the Check Sheet the same way by:

Providing short training or refresher sessions

Using standardized formats across shifts and departments

Clarifying who fills it out and when

Reviewing entries regularly for completeness

6. Review Data Trends and Take Action

A Check Sheet isn’t valuable unless you do something with the data.

Summarize data weekly or monthly

Identify defect patterns, peak times, or recurring failures

Share findings with relevant teams

Link data to corrective actions, Kaizen events, or root cause analysis

7. Digitize for Better Insights

While paper-based Check Sheets are still useful, digital versions offer advantages like:

Real-time data capture

Easy filtering and analysis

Automatic charts and graphs

Remote sharing with quality teams

Consider using tools like Excel, Google Sheets, or quality management software.

✅ When to Revise or Replace Your Check Sheet

Your Check Sheet may need a revamp if:

The same issues have been solved and no longer occur

New types of defects are emerging

Operators complain it’s too complicated

The data collected isn’t helping decisions

The process being monitored has changed

Don’t be afraid to revise or rebuild your Check Sheet—it’s a living tool.

✅ Benefits of Keeping Your Check Sheet Updated

Ensures accurate, real-time data collection

Helps identify trends before they become major issues

Supports faster problem-solving

Increases operator engagement and ownership

Provides valuable input for other QC tools like Pareto Charts or Control Charts

✅ Conclusion

A Check Sheet may look simple—but when updated and used effectively, it becomes a powerful tool for improving quality. By regularly reviewing and refining it, you ensure it continues to support real-time decision-making, reduce defects, and drive continuous improvement.

Remember, in the spirit of the 7 QC tools, quality is not a one-time act—it’s a habit.

#7QCTools#CheckSheet#QualityControl#ContinuousImprovement#ProcessImprovement#QualityManagement#DataDriven#ManufacturingExcellence#QualityAssurance#RootCauseAnalysis

0 notes

Text

Precision Solutions for Defence and Aerospace Electronics

In the high-stakes sectors of defence and aerospace, reliability, performance, and precision are non-negotiable. Whether it's mission-critical communications equipment, avionics systems, or advanced sensor technologies, the quality of electronic manufacturing plays a pivotal role in national security, flight safety, and technological superiority. This is where defence and aerospace electronic manufacturing becomes an essential pillar of innovation and resilience—and where trusted providers like Masters & Young excel.

With decades of proven expertise, Masters & Young specialises in delivering cutting-edge technology and precision-engineered solutions tailored to meet the exacting standards of the defence and aerospace industries. Our commitment to innovation, quality, and compliance ensures that every component we manufacture performs flawlessly, even under the most extreme conditions.

Why Defence and Aerospace Require Specialised Electronic Manufacturing

The demands of defence and aerospace electronic manufacturing far exceed those of consumer or general industrial electronics. The equipment must operate in highly controlled and often hostile environments—extreme temperatures, high G-forces, electromagnetic interference, and more. Components must not only perform consistently but also adhere to strict regulatory frameworks and certifications such as ISO 9001, AS9100, and IPC standards.

Critical applications in these sectors include:

Military communication systems

Guidance and navigation electronics

Radar and surveillance systems

Flight control modules

Electronic warfare and cybersecurity infrastructure

Satellite and space-based electronics

Given the complexity and importance of these applications, manufacturers must employ robust quality control, advanced testing methodologies, and skilled engineering expertise to deliver compliant, high-performance products.

Masters & Young: Leading the Way in Defence and Aerospace Solutions

At Masters & Young, our reputation is built on decades of consistent delivery, technical innovation, and deep understanding of the unique requirements of defence and aerospace projects. We provide end-to-end electronic manufacturing services (EMS), from design consultation and prototyping to production, testing, and compliance certification.

Our core strengths include:

Precision Engineering: Every circuit board and electronic assembly is crafted with attention to detail and adherence to tight tolerances, ensuring optimal function and longevity.

Advanced Manufacturing Capabilities: Our facilities are equipped with the latest surface mount technology (SMT), automated optical inspection (AOI), and X-ray inspection tools to ensure the highest manufacturing quality.

Custom Solutions: We understand that each defence or aerospace application is unique. That’s why we offer tailored solutions that align with specific client objectives, environmental demands, and operational protocols.

Compliance & Certification: Masters & Young operates within stringent defence and aerospace manufacturing frameworks, offering full traceability, secure documentation, and compliance with relevant industry standards.

The Importance of Reliability in Defence and Aerospace Electronics

When it comes to defence and aerospace electronic manufacturing, there is no room for error. System failures can lead to mission compromise, loss of critical assets, or even loss of life. That’s why our engineering and production teams follow a rigorous quality management system that includes:

In-depth testing and validation protocols

Environmental stress screening (ESS)

Functional and in-circuit testing (ICT)

EMI/EMC testing for compliance

Failure mode and effects analysis (FMEA)

These practices ensure that each product not only meets but exceeds performance benchmarks and reliability expectations.

Collaborating with Defence and Aerospace Industry Leaders

Masters & Young has long-standing partnerships with government agencies, defence contractors, and aerospace innovators. Our proven track record of supporting classified and non-classified projects has positioned us as a preferred supplier for high-performance, mission-critical electronics across Australia and beyond.

Whether it’s upgrading radar systems, developing electronic control units (ECUs), or manufacturing embedded systems for aircraft and defence vehicles, we deliver solutions that push boundaries while maintaining the utmost quality and security.

Final Thoughts

The future of national defence and aerospace innovation hinges on the strength of its technology—and that begins with superior electronic manufacturing. At Masters & Young, we take pride in being at the forefront of this crucial sector, offering reliable, precise, and compliant defence and aerospace electronic manufacturing solutions.

If you’re seeking a partner who understands the stakes and delivers with unmatched expertise, trust Masters & Young to meet your requirements with precision, integrity, and innovation.

0 notes

Text

Precision Solutions for Defence and Aerospace Electronics

In the high-stakes sectors of defence and aerospace, reliability, performance, and precision are non-negotiable. Whether it's mission-critical communications equipment, avionics systems, or advanced sensor technologies, the quality of electronic manufacturing plays a pivotal role in national security, flight safety, and technological superiority. This is where defence and aerospace electronic manufacturing becomes an essential pillar of innovation and resilience—and where trusted providers like Masters & Young excel.

With decades of proven expertise, Masters & Young specialises in delivering cutting-edge technology and precision-engineered solutions tailored to meet the exacting standards of the defence and aerospace industries. Our commitment to innovation, quality, and compliance ensures that every component we manufacture performs flawlessly, even under the most extreme conditions.

Why Defence and Aerospace Require Specialised Electronic Manufacturing

The demands of defence and aerospace electronic manufacturing far exceed those of consumer or general industrial electronics. The equipment must operate in highly controlled and often hostile environments—extreme temperatures, high G-forces, electromagnetic interference, and more. Components must not only perform consistently but also adhere to strict regulatory frameworks and certifications such as ISO 9001, AS9100, and IPC standards.

Critical applications in these sectors include:

Military communication systems

Guidance and navigation electronics

Radar and surveillance systems

Flight control modules

Electronic warfare and cybersecurity infrastructure

Satellite and space-based electronics

Given the complexity and importance of these applications, manufacturers must employ robust quality control, advanced testing methodologies, and skilled engineering expertise to deliver compliant, high-performance products.

Masters & Young: Leading the Way in Defence and Aerospace Solutions

At Masters & Young, our reputation is built on decades of consistent delivery, technical innovation, and deep understanding of the unique requirements of defence and aerospace projects. We provide end-to-end electronic manufacturing services (EMS), from design consultation and prototyping to production, testing, and compliance certification.

Our core strengths include:

Precision Engineering: Every circuit board and electronic assembly is crafted with attention to detail and adherence to tight tolerances, ensuring optimal function and longevity.

Advanced Manufacturing Capabilities: Our facilities are equipped with the latest surface mount technology (SMT), automated optical inspection (AOI), and X-ray inspection tools to ensure the highest manufacturing quality.

Custom Solutions: We understand that each defence or aerospace application is unique. That’s why we offer tailored solutions that align with specific client objectives, environmental demands, and operational protocols.

Compliance & Certification: Masters & Young operates within stringent defence and aerospace manufacturing frameworks, offering full traceability, secure documentation, and compliance with relevant industry standards.

The Importance of Reliability in Defence and Aerospace Electronics

When it comes to defence and aerospace electronic manufacturing, there is no room for error. System failures can lead to mission compromise, loss of critical assets, or even loss of life. That’s why our engineering and production teams follow a rigorous quality management system that includes:

In-depth testing and validation protocols

Environmental stress screening (ESS)

Functional and in-circuit testing (ICT)

EMI/EMC testing for compliance

Failure mode and effects analysis (FMEA)

These practices ensure that each product not only meets but exceeds performance benchmarks and reliability expectations.

Collaborating with Defence and Aerospace Industry Leaders

Masters & Young has long-standing partnerships with government agencies, defence contractors, and aerospace innovators. Our proven track record of supporting classified and non-classified projects has positioned us as a preferred supplier for high-performance, mission-critical electronics across Australia and beyond.

Whether it’s upgrading radar systems, developing electronic control units (ECUs), or manufacturing embedded systems for aircraft and defence vehicles, we deliver solutions that push boundaries while maintaining the utmost quality and security.

Final Thoughts

The future of national defence and aerospace innovation hinges on the strength of its technology—and that begins with superior electronic manufacturing. At Masters & Young, we take pride in being at the forefront of this crucial sector, offering reliable, precise, and compliant defence and aerospace electronic manufacturing solutions. If you’re seeking a partner who understands the stakes and delivers with unmatched expertise, trust Masters & Young to meet your requirements with precision, integrity, and innovation.

0 notes

Text

Precision Solutions for Defence and Aerospace Electronics

In the high-stakes sectors of defence and aerospace, reliability, performance, and precision are non-negotiable. Whether it's mission-critical communications equipment, avionics systems, or advanced sensor technologies, the quality of electronic manufacturing plays a pivotal role in national security, flight safety, and technological superiority. This is where defence and aerospace electronic manufacturing becomes an essential pillar of innovation and resilience—and where trusted providers like Masters & Young excel.

With decades of proven expertise, Masters & Young specialises in delivering cutting-edge technology and precision-engineered solutions tailored to meet the exacting standards of the defence and aerospace industries. Our commitment to innovation, quality, and compliance ensures that every component we manufacture performs flawlessly, even under the most extreme conditions.

Why Defence and Aerospace Require Specialised Electronic Manufacturing

The demands of defence and aerospace electronic manufacturing far exceed those of consumer or general industrial electronics. The equipment must operate in highly controlled and often hostile environments—extreme temperatures, high G-forces, electromagnetic interference, and more. Components must not only perform consistently but also adhere to strict regulatory frameworks and certifications such as ISO 9001, AS9100, and IPC standards.

Critical applications in these sectors include:

Military communication systems

Guidance and navigation electronics

Radar and surveillance systems

Flight control modules

Electronic warfare and cybersecurity infrastructure

Satellite and space-based electronics

Given the complexity and importance of these applications, manufacturers must employ robust quality control, advanced testing methodologies, and skilled engineering expertise to deliver compliant, high-performance products.

Masters & Young: Leading the Way in Defence and Aerospace Solutions

At Masters & Young, our reputation is built on decades of consistent delivery, technical innovation, and deep understanding of the unique requirements of defence and aerospace projects. We provide end-to-end electronic manufacturing services (EMS), from design consultation and prototyping to production, testing, and compliance certification.

Our core strengths include:

Precision Engineering: Every circuit board and electronic assembly is crafted with attention to detail and adherence to tight tolerances, ensuring optimal function and longevity.

Advanced Manufacturing Capabilities: Our facilities are equipped with the latest surface mount technology (SMT), automated optical inspection (AOI), and X-ray inspection tools to ensure the highest manufacturing quality.

Custom Solutions: We understand that each defence or aerospace application is unique. That’s why we offer tailored solutions that align with specific client objectives, environmental demands, and operational protocols.

Compliance & Certification: Masters & Young operates within stringent defence and aerospace manufacturing frameworks, offering full traceability, secure documentation, and compliance with relevant industry standards.

The Importance of Reliability in Defence and Aerospace Electronics

When it comes to defence and aerospace electronic manufacturing, there is no room for error. System failures can lead to mission compromise, loss of critical assets, or even loss of life. That’s why our engineering and production teams follow a rigorous quality management system that includes:

In-depth testing and validation protocols

Environmental stress screening (ESS)

Functional and in-circuit testing (ICT)

EMI/EMC testing for compliance

Failure mode and effects analysis (FMEA)

These practices ensure that each product not only meets but exceeds performance benchmarks and reliability expectations.

Collaborating with Defence and Aerospace Industry Leaders

Masters & Young has long-standing partnerships with government agencies, defence contractors, and aerospace innovators. Our proven track record of supporting classified and non-classified projects has positioned us as a preferred supplier for high-performance, mission-critical electronics across Australia and beyond.

Whether it’s upgrading radar systems, developing electronic control units (ECUs), or manufacturing embedded systems for aircraft and defence vehicles, we deliver solutions that push boundaries while maintaining the utmost quality and security.

Final Thoughts

The future of national defence and aerospace innovation hinges on the strength of its technology—and that begins with superior electronic manufacturing. At Masters & Young, we take pride in being at the forefront of this crucial sector, offering reliable, precise, and compliant defence and aerospace electronic manufacturing solutions.

If you’re seeking a partner who understands the stakes and delivers with unmatched expertise, trust Masters & Young to meet your requirements with precision, integrity, and innovation.

0 notes

Text

Enhancing Operational Safety through HAZOP and PHA Methodologies

In high-risk industries such as chemical manufacturing, oil and gas, and pharmaceuticals, ensuring safe operations is a fundamental responsibility. Central to this responsibility is the systematic identification and management of potential hazards that could lead to catastrophic events. Two widely accepted and practiced methodologies for achieving this are Hazard and Operability Study (HAZOP) and Process Hazard Analysis (PHA). These techniques form the backbone of effective process safety management, playing a critical role in proactive risk assessment and risk management.

Understanding HAZOP and Its Role in Risk Identification

HAZOP is a structured and systematic technique used to evaluate processes and identify potential deviations from intended operations. Developed originally for the chemical industry, HAZOP examines process parameters such as flow, temperature, pressure, and composition, using guide words like "more," "less," "none," and "reverse" to explore deviations. Each deviation is scrutinized to determine its possible causes and consequences, thereby helping teams uncover hidden vulnerabilities in process design.

The strength of HAZOP lies in its collaborative and interdisciplinary approach. This diversity ensures a comprehensive analysis and strengthens the organization’s overall safety strategy. While primarily applied during the design phase of a process, HAZOP can also be conducted during operational changes, maintenance planning, and incident investigations.

PHA: A Broader Framework for Process Safety

Process Hazard Analysis encompasses a suite of analytical techniques to identify and mitigate hazards in industrial processes. HAZOP is just one method under the PHA umbrella, alongside others like What-If Analysis, Failure Mode and Effects Analysis (FMEA), and Fault Tree Analysis (FTA). Each technique is selected based on the complexity, scale, and nature of the operation under study.

PHA is mandated by regulations in many jurisdictions, particularly for processes involving highly hazardous chemicals. It is an essential element of process safety management programs and is often revisited periodically to account for changes in processes, regulations, or organizational structure. PHA studies not only identify risks but also provide recommendations to reduce their likelihood or mitigate their consequences.

Integrating HAZID in the Risk Assessment Process

Another critical tool closely associated with HAZOP and PHA is Hazard Identification (HAZID). While HAZOP focuses on process deviations and their potential outcomes, HAZID is broader in scope and is often used in the early stages of project development. It helps identify external and non-process hazards such as environmental factors, human errors, or external impacts (e.g., natural disasters). HAZID sessions are typically less structured than HAZOP but offer valuable insights into overall operational vulnerabilities.

By integrating HAZID early and conducting PHA and HAZOP as the project matures, organizations can establish a layered and robust approach to risk management. This comprehensive strategy allows the identification of potential threats and the implementation of preventive and mitigative controls across the entire lifecycle of a process or facility.

The Value of Process Safety Management Systems

All these methodologies feed into a larger framework of process safety management (PSM). PSM systems provide the policies, procedures, and practices required to manage hazardous processes safely. They encompass elements such as training, mechanical integrity, change management, and emergency response planning. HAZOP and PHA are crucial inputs to PSM, ensuring that operational risks are clearly understood and effectively controlled.

The implementation of a mature PSM program reflects a company's commitment to safety, regulatory compliance, and operational excellence. It enables continuous improvement through lessons learned, incident investigations, and audits. Moreover, a strong PSM culture enhances workforce confidence and stakeholder trust.

Conclusion

HAZOP and PHA are essential methodologies that support safer and more reliable industrial operations. Their structured approach to hazard identification and risk evaluation not only helps in preventing accidents but also strengthens regulatory compliance and operational integrity. When combined with HAZID and embedded within a broader process safety management framework, these tools offer a powerful defense against unforeseen incidents. Organizations that invest in these proactive strategies stand to gain not only in safety performance but also in operational efficiency and reputation. Through continuous application and improvement of these methodologies, industries can build a sustainable path toward safer operations.

Read More- https://synergenog.com/hazop-vs-pha/

0 notes