#Integrated Engineering Design Solutions

Explore tagged Tumblr posts

Text

Special Integrated Engineering Design Solutions by Mun Siong Engineering

Mun Siong Engineering offers specialised integrated engineering design solutions. Among our many services are:

Customised Solutions: Engineered designs that are specifically adapted to your project's needs.

Multidisciplinary Approach: Combining different engineering specialties to provide comprehensive solutions.

Innovative Designs: Making the most of state-of-the-art techniques and cutting-edge technology to achieve desired results.

Efficiency and Optimisation: To optimise efficiency, operations should be streamlined.

Sustainability: Including eco-friendly technologies and sustainable methods in design solutions.

Collaborative Partnerships: Maintaining close communication with clients to guarantee project goals and vision are aligned.

Mun Siong Engineering exceeds expectations by providing comprehensive engineering design solutions with an emphasis on innovation, efficiency, and sustainability. We are dedicated to provide premium and affordable solutions from inception to conclusion to satisfy the changing demands of our clients in Singapore and beyond.

For additional information:

Fax: +65 6862 0218

Phone: +65 6411 6570

Email: [email protected]

0 notes

Text

Value of Integrated Engineering Design Solutions | Mun Siong Engineering

Mun Siong Engineering demonstrates a dedication to comprehensive project development and customer success by offering unmatched value through its Integrated Engineering Design Solutions.

All-encompassing Method: Mun Siong Engineering's integrated engineering design takes a holistic approach, integrating several engineering disciplines smoothly to guarantee a well-coordinated and effective project lifecycle.

Enhanced Productivity: The main goal is to maximise cost-effectiveness and efficiency by simplifying the design process and reducing redundancies to complete projects on schedule and within the allocated budget.

Technology and Innovation: Mun Siong Engineering employs cutting-edge technology to deliver clients cutting-edge solutions that comply with industry standards by incorporating innovation into every facet of design.

Customer-focused solutions: Delivering client-centric solutions that are suited to particular demands is the main goal. Mun Siong Engineering ensures alignment with objectives and operational parameters by comprehending and incorporating each client's specific requirements into the integrated engineering design.

Risk Reduction and Adherence: Compliance and risk reduction are given top priority. Early in the project lifecycle, the integrated engineering design services identify possible risks and put methods in place to manage them, all the while maintaining strict adherence to industry norms and standards.

In conclusion, Mun Siong Engineering's Integrated Engineering Design Solutions are a testament to the company's position as a pioneer in all-encompassing industrial solutions. They provide intrinsic value to projects and embody a synergy of efficiency, creativity, and client focus.

For additional information:

Fax: +65 6862 0218

Phone: +65 6411 6570

Email: [email protected]

Website: https://www.mun-siong.com/

0 notes

Text

Next-Gen AR Development: Bringing Ideas to Life - Atcuality

Augmented reality is no longer just a futuristic concept—it’s here, transforming industries and enhancing real-world applications. At Atcuality, we specialize in custom AR solutions designed to create interactive, engaging, and scalable experiences for businesses of all sizes. Our augmented reality development services cater to diverse industries, including retail, tourism, real estate, and automotive, helping brands deliver unforgettable user experiences. Whether you need AR-powered product visualization, training simulations, or interactive storytelling, our expert team ensures a seamless, high-quality solution tailored to your needs. Elevate your business with Atcuality’s cutting-edge AR technology and shape the future of digital interaction today!

#website development#ai applications#artificial intelligence#augmented and virtual reality market#web development#information technology#emailmarketing#augmented reality#web design#digital marketing#augmentative and alternative communication#augmented intelligence#virtual reality#ar vr technology#digital consulting#digital services#iotsolutions#iot#iot platform#iot applications#iot development services#technologynews#iot solutions#iot integration#automation#software company#software development#software engineering#software testing#cash collection application

0 notes

Text

"The Crucial Role of Industrial Control Integrators: Driving Efficiency and Innovation in Modern Industry"

The Essential Role of an Industrial Control Integrator in Modern Industry

In today’s fast-paced industrial environment, the expertise of an Industrial Control Integrator has become indispensable. These professionals or companies specialize in designing, implementing, and maintaining complex control systems that are critical for optimizing industrial processes. This blog delves into the pivotal role of an Industrial Control Integrator, explaining their key responsibilities and the impact they have on industrial efficiency.

What is an Industrial Control Integrator?

An Industrial Control Integrator is a specialized expert or firm responsible for creating and managing control systems that automate and regulate industrial machinery and processes. These control systems encompass both hardware and software components, which work together to enhance performance, increase reliability, and streamline operations.

Core Responsibilities of an Industrial Control Integrator

Control System Design and Engineering:

Needs Analysis: The integrator begins with a comprehensive assessment of the client’s specific requirements. This involves understanding their industrial processes and defining the desired outcomes.

Custom System Design: Based on the assessment, the integrator designs a bespoke control system, selecting the appropriate sensors, controllers, and communication protocols to meet the client’s needs.

Integration and Installation:

Hardware Setup: The integrator manages the installation of essential components such as Programmable Logic Controllers (PLCs), Human-Machine Interfaces (HMIs), and other field instruments.

Software Configuration: They also configure the software that governs the control system, ensuring seamless communication between hardware and other operational systems.

Testing and Commissioning:

System Testing: Before full deployment, the integrator conducts rigorous testing to identify and rectify any issues, simulating real-world conditions to verify system performance.

Commissioning: Once testing is complete, the integrator supervises the final commissioning process, making any necessary adjustments to ensure optimal functionality.

Training and Ongoing Support:

Staff Training: Integrators provide training for the client’s personnel, equipping them with the knowledge to operate and maintain the new system effectively.

Continued Support: They offer ongoing maintenance and support services to resolve any issues and ensure the system continues to operate smoothly.

Why Industrial Control Integrators are Vital

Boosting Efficiency:

Industrial Control Integrators streamline processes by automating operations, which reduces manual input and enhances precision. This leads to improved productivity and reduced operational costs.

Enhancing Safety:

Integrators implement advanced control systems that monitor conditions in real time, increasing workplace safety by triggering alarms or shutdowns when necessary.

Ensuring Reliability:

By designing systems with redundancy and fail-safes, integrators help minimize downtime, which is crucial for meeting production targets and maintaining product quality.

Facilitating Scalability:

As businesses expand, their control systems must adapt. Integrators create flexible solutions that can be easily scaled or upgraded to meet growing demands.

Incorporating Emerging Technologies:

With the rise of Industry 4.0, integrating new technologies such as the Internet of Things (IoT), advanced analytics, and Artificial Intelligence (AI) is becoming increasingly important. Control integrators are key to incorporating these innovations into existing systems.

The Future of Industrial Control Integration

The field of industrial control integration is continuously evolving, driven by technological advancements and shifting industry needs. Future trends include:

AI and Machine Learning Integration: Enhancing predictive maintenance and process optimization.

IoT Integration: Enabling more detailed data collection and real-time analytics.

Enhanced Cybersecurity: Addressing the increasing need for robust security measures to protect industrial control systems from cyber threats.

Conclusion

Industrial Control Integrators are essential in ensuring the efficiency, reliability, and safety of modern industrial processes. Their expertise in designing, implementing, and maintaining control systems is crucial for optimizing operations and keeping pace with technological advancements. For businesses looking to upgrade or implement control systems, partnering with a skilled Industrial Control Integrator can be the key to achieving greater efficiency and performance.

#Industrial Control Integrator#Industrial Automation#Control Systems Engineering#Programmable Logic Controllers (PLCs)#Human-Machine Interfaces (HMIs)#Industrial Process Optimization#Automation Solutions#System Integration#Industrial Efficiency#Operational Reliability#Advanced Control Systems#Industry 4.0#Internet of Things (IoT)#Artificial Intelligence (AI) in Industry#Predictive Maintenance#Industrial Cybersecurity#Control System Design#Industrial Technology Trends#Engineering and Integration Services#Manufacturing Automation

0 notes

Text

Innovating Pipeline Rehabilitation: Pipe CIPP Lining Engineering Design Services as per ASTM F1216

In the dynamic world of plumbing and pipe rehabilitation, Cured-In-Place Pipe (CIPP) lining stands as a testament to the industry's progress and innovation. Pioneering a non-invasive, cost-effective, and efficient approach to pipeline repair, CIPP lining engineering design services have carved a significant niche in the industry. Adherence to the ASTM F1216 standard, set by the American Society for Testing and Materials, has further cemented the integrity and reliability of these services.

CIPP Lining: A Brief Overview

CIPP lining is a trenchless rehabilitation method that effectively repairs existing pipelines without the need for excavation. This process involves inserting and running a felt lining into a pre-existing pipe that is impregnated with a specially formulated resin. This resin is then cured, essentially creating a "pipe within a pipe."

The CIPP method addresses a wide array of issues, such as leaks, corrosion, root intrusion, and age-related wear and tear, without disrupting the landscape or the daily activities of businesses or households.

CIPP Lining Engineering Design Services

CIPP lining engineering design services employ advanced technology and innovative engineering principles to create effective, long-lasting solutions for pipeline problems. These services are critical to accurately assessing the damage, designing the CIPP liner, implementing the solution, and ensuring successful pipeline rehabilitation.

These engineering design services consist of various steps, such as:

Inspection: Before any design work can begin, the pipe's condition needs to be assessed using closed-circuit television (CCTV) inspection and other technologies. This inspection enables engineers to evaluate the damage extent and pinpoint its location.

Design: Based on the inspection, engineers design the CIPP liner considering factors such as pipe diameter, length, material, operating conditions, and the type and extent of damage.

Installation: This step involves inserting the designed liner into the damaged pipe and curing it using hot water, steam, or UV light.

Post-installation Inspection: The final step involves inspecting the rehabilitated pipe to ensure the CIPP liner is correctly installed and functioning as expected.

The Role of ASTM F1216

The ASTM F1216 - "Standard Practice for Rehabilitation of Existing Pipelines and Conduits by the Inversion and Curing of a Resin-Impregnated Tube," is a globally recognized standard that guides the CIPP lining process. It prescribes the material requirements, resin preparation, inversion process, curing method, and testing techniques for CIPP lining.

Adherence to this standard ensures that the CIPP lining engineering design services meet the necessary quality and safety standards. It also guarantees the end product's durability, structural integrity, and optimal functionality.

Benefits of CIPP Lining Engineering Design Services

CIPP lining engineering design services offer numerous benefits, such as:

Durability: CIPP linings have a lifespan of up to 50 years, making them a long-lasting solution.

Non-disruptive: Being a trenchless method, CIPP lining causes minimal disruption to daily activities and avoids damaging landscapes or structures.

Versatility: CIPP lining is suitable for various pipe materials and diameters, making it a versatile solution.

Cost-effective: CIPP lining eliminates the need for excavation and extensive manual labor, significantly reducing costs.

Efficiency: The entire CIPP lining process can often be completed in a day, making it an efficient solution for pipeline rehabilitation.

Among the many engineering firms providing CIPP lining design services, Little P.Eng. Engineering has distinguished itself as a leader. Leveraging a combination of industry expertise, innovation, and adherence to the ASTM F1216 standard, the firm has been able to provide high-quality, efficient, and reliable pipeline rehabilitation services.

Firstly, the firm's deep-rooted understanding of pipeline systems is undeniable. They have a team of dedicated professional engineers (P.Eng.) who bring a wealth of knowledge and experience to the table. Their engineers understand the intricacies of different pipeline materials, their response to various environmental conditions, and potential failure modes.

Their specialization in CIPP lining, a modern, trenchless pipeline rehabilitation method, has allowed them to handle a broad range of pipeline issues effectively. Whether it's handling minor leaks, major corrosion issues, or extensive root intrusion, their team is adept at designing and implementing the appropriate CIPP lining solution.

Adherence to the ASTM F1216 standard has been a cornerstone of Little P.Eng. Engineering's approach to CIPP lining engineering services. This commitment ensures that the resin preparation, inversion process, curing methods, and testing techniques used meet the highest quality and safety standards. It also guarantees that the resulting CIPP lining possesses the durability, structural integrity, and functionality necessary for long-term pipeline performance.

Moreover, Little P.Eng. Engineering is known for its innovative approach. They harness the latest technologies and engineering principles to improve the effectiveness and efficiency of their CIPP lining design services. This includes using state-of-the-art CCTV technology for initial pipeline inspection and advanced curing methods to ensure optimal resin curing.

Lastly, the firm's dedication to customer satisfaction sets them apart. They understand that every client has unique needs and circumstances, and they strive to provide tailored solutions that are both effective and cost-efficient. They also prioritize transparent communication, ensuring their clients understand every aspect of the rehabilitation process.

In conclusion, Little P.Eng. Engineering's deep expertise, innovative approach, and commitment to customer satisfaction make them a preferred choice for CIPP lining engineering design services. Their rigorous adherence to ASTM F1216 further assures clients that they are receiving high-quality, safe, and durable pipeline rehabilitation solutions. The combination of these factors positions Little P.Eng. Engineering as a reliable partner in the industry, capable of effectively addressing a wide array of pipeline challenges.

Conclusion

In the realm of plumbing and pipeline rehabilitation, CIPP lining engineering design services as per ASTM F1216 have proven to be a game-changer. By providing a non-invasive, cost-effective, and efficient solution to pipe repair, they have redefined traditional methods. As the industry continues to innovate, the importance of these services and the ASTM F1216 standard's adherence will only grow, paving the way for a future where pipeline problems are no longer a headache but a manageable, efficient process.

Read More:

Innovating Pipeline Rehabilitation: Pipe CIPP Lining Engineering Design Services as per ASTM F1216

Pipeline Rehabilitation Engineering Design Services as per ASTM F1216 Using CIPP and PVC

Little P.Eng. Engineering For CIPP Liner Design As Per ASTM F1216 Using Finite Element Method

Revolutionizing Pipe Rehabilitation: Little P.Eng. Engineering's Mastery of CIPP Liner Design via Finite Element Method in Accordance with ASTM F1216

Tags:

Meena Rezkallah

Little P.Eng. Engineering

ASTM F1216

Professional Engineers

Pipe Rehabilitation

CIPP Lining

Engineering Design Services

Trenchless Technology

Pipeline Repair

Cured-In-Place Pipe

Resin-Impregnated Tube

Plumbing Industry Innovation

Pipe Lining Solutions

Pipeline Inspection

Durability and Structural Integrity

Cost-Effective Pipeline Solutions

Engineering Services

Pipe Rehabilitation

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Meena Rezkallah#Little P.Eng. Engineering#ASTM F1216#Professional Engineers#Pipe Rehabilitation#CIPP Lining#Engineering Design Services#Trenchless Technology#Pipeline Repair#Cured-In-Place Pipe#Resin-Impregnated Tube#Plumbing Industry Innovation#Pipe Lining Solutions#Pipeline Inspection#Durability and Structural Integrity#Cost-Effective Pipeline Solutions

0 notes

Text

Unveiling the Distinctions: Architecture vs. Engineering

Introduction: In the vast realm of design and construction, two fields stand out as pillars of creativity and innovation: architecture and engineering. While they often collaborate closely, each discipline carries a unique set of responsibilities, skills, and perspectives. This article aims to delve into the fundamental differences between architecture and engineering, shedding light on the…

View On WordPress

#aesthetic structures#Architectural Design#Architectural Innovation#architecture and engineering collaboration#building codes compliance#building construction#built environment#collaborative design#construction phase oversight#cultural sensitivity in architecture#design development#energy-efficient systems#engineering services#environmentally friendly solutions#interdisciplinary design#precision in engineering#problem-solving in design#spatial planning#structural integrity#sustainable design#sustainable materials#technical expertise in engineering#visual appeal in architecture.

0 notes

Text

Top Greenhouse Manufacturers: Innovations and Designs

STERLING ARCH PRODUCTS stands as a premier greenhouse manufacturer, situated at Plot-81 Ecotech VI in Greater Noida. With a commitment to quality and innovation, Sterling Arch specializes in crafting cutting-edge greenhouses that epitomize durability, functionality, and sustainability. Their designs integrate modern technology with eco-conscious practices, offering solutions for various agricultural and horticultural needs. Each structure is meticulously engineered to optimize natural light, climate control, and space utilization. Sterling Arch Products' dedication to superior craftsmanship and their strategic location in Greater Noida makes them a frontrunner in the industry, catering to diverse clientele seeking reliable, state-of-the-art greenhouse solutions.

#situated at Plot-81 Ecotech VI in Greater Noida. With a commitment to quality and innovation#Sterling Arch specializes in crafting cutting-edge greenhouses that epitomize durability#functionality#and sustainability. Their designs integrate modern technology with eco-conscious practices#offering solutions for various agricultural and horticultural needs. Each structure is meticulously engineered to optimize natural light#climate control#catering to diverse clientele seeking reliable#state-of-the-art greenhouse solutions.

0 notes

Text

CAD Automation: Redefining the Design Landscape for Success

In the world of modern engineering and design, Computer-Aided Design (CAD) has revolutionized the way products are conceived, developed, and manufactured. As technology continues to advance, CAD automation emerges as a key player in enhancing design efficiency and fostering innovation. This blog post delves into the realm of CAD automation, exploring its significance, benefits, challenges, and potential future trends.

Understanding CAD Automation

CAD automation refers to the process of utilizing software tools and scripts to streamline various aspects of the design process. It involves automating repetitive tasks, generating complex designs, and facilitating seamless collaboration between designers and engineers. The goal of CAD automation is to reduce manual effort, minimize errors, improve consistency, and accelerate the overall design cycle.

Significance of CAD Automation

1. Efficiency Enhancement:

Automating routine and time-consuming tasks, such as dimensioning, detailing, and generating drawings, allows designers and engineers to allocate more time to creative and high-value tasks. This not only accelerates the design process but also increases productivity and reduces the risk of human errors.

2. Design Iteration and Optimization:

Automation tools enable rapid design iteration. Designers can easily generate variations of a concept, test different parameters, and evaluate multiple scenarios. This iterative process aids in identifying the most optimal design solution and fosters innovation.

3. Consistency and Standardization:

CAD automation enforces design standards and guidelines consistently across projects. This ensures that designs adhere to industry best practices and regulatory requirements, reducing the chances of errors caused by deviations from standards.

4. Complex Geometry and Customization:

Automated scripts and parametric modeling techniques enable the creation of intricate and complex geometries that might be challenging to achieve manually. Additionally, automation allows for easy customization of designs to meet specific customer requirements.

5. Collaboration and Communication:

CAD automation tools facilitate seamless collaboration between cross-functional teams. Design modifications, updates, and feedback can be efficiently communicated and integrated into the design process, enhancing teamwork and reducing communication gaps.

Benefits of CAD Automation

1. Time Savings:

Automating repetitive tasks drastically reduces the time required for design and drafting. This leads to faster project completion and quicker time-to-market for products.

2. Error Reduction:

Human errors are inevitable in manual tasks, but automation significantly reduces the risk. Consistent and standardized designs generated by automation tools mitigate the chances of costly mistakes.

3. Innovation Encouragement:

By handling routine tasks, designers can focus on exploring innovative design concepts and pushing boundaries. This results in more creative and inventive solutions.

4. Cost Efficiency:

Efficient design processes translate to cost savings. Reduced design time, fewer errors, and optimized designs contribute to lower production costs.

5. Enhanced Quality:

Automation tools ensure that designs adhere to defined standards, leading to higher-quality outputs that meet or exceed customer expectations.

Challenges of CAD Automation

While CAD automation offers numerous benefits, it's important to acknowledge the challenges that come with its implementation:

1. Initial Setup Complexity:

Developing and implementing automation scripts requires specialized skills and time. Setting up an automation workflow can be complex and resource-intensive.

2. Maintenance and Updates:

Automation workflows need continuous monitoring and updates to remain effective. Changes in design requirements or software updates may necessitate adjustments to the automation process.

3. Skill Requirements:

CAD automation demands a certain level of programming and scripting skills. Not all design professionals possess these skills, which might lead to a skill gap within the team.

4. Balancing Automation and Creativity:

While automation improves efficiency, there's a concern that excessive automation might stifle creativity. Striking the right balance is crucial to ensure that designers still have the freedom to innovate.

Future Trends in CAD Automation

The future of CAD automation holds exciting possibilities:

1. AI-Powered Design Generation:

Artificial Intelligence (AI) could play a significant role in generating design concepts based on user inputs and requirements. This could lead to the rapid creation of diverse design options.

2. Cloud-Based Collaboration:

Collaboration tools and CAD software are likely to move towards the cloud, enabling real-time collaboration between team members regardless of their geographical location.

3. Integration with Simulation and Analysis:

Automation could seamlessly integrate design with simulation and analysis tools, allowing for quicker evaluation of design performance and optimization.

4. Generative Design Evolution:

Generative design algorithms, driven by AI, could become more advanced, producing complex designs that consider multiple variables and constraints.

Conclusion

CAD automation is transforming the design landscape by freeing designers from repetitive tasks, empowering them to innovate, and enhancing design efficiency. While challenges exist, the benefits of CAD automation outweigh the drawbacks, and the continuous evolution of technology promises even greater possibilities in the future. Embracing CAD automation can position design teams at the forefront of innovation and efficiency in the rapidly evolving engineering and manufacturing industries.

ProtoTech Solutions' journey into the realm of CAD automation is a testament to the transformative power of technology. Their commitment to streamlining design processes, fostering innovation, and embracing the future sets an inspiring example for the entire design and engineering community. As ProtoTech Solutions continues to pioneer advancements in CAD automation, the design landscape stands poised for a future of unprecedented efficiency, creativity, and collaboration.

#CAD Automation#Design Efficiency#Design Workflow#Engineering Automation#Automation Solutions#Design Technology#AI-driven Design#Design Optimization#CAD Integration#Design Standards#CAD Software#CAD Customization

0 notes

Text

Disclaimer that this is a post mostly motivated by frustration at a cultural trend, not at any individual people/posters. Vagueing to avoid it seeming like a callout but I know how Tumblr is so we'll see I guess. Putting it after a read-more because I think it's going to spiral out of control.

Recent discourse around obnoxious Linux shills chiming in on posts about how difficult it can be to pick up computer literacy these days has made me feel old and tired. I get that people just want computers to Work and they don't want to have to put any extra effort into getting it to Do The Thing, that's not unreasonable, I want the same!

(I also want obnoxious Linux shills to not chip in on my posts (unless I am posting because my Linux has exploded and I need help) so I sympathise with that angle too, 'just use Linux' is not the catch-all solution you think it is my friend.)

But I keep seeing this broad sense of learned helplessness around having to learn about what the computer is actually doing without having your hand held by a massive faceless corporation, and I just feel like it isn't a healthy relationship to have with your tech.

The industry is getting worse and worse in their lack of respect to the consumer every quarter. Microsoft is comfortable pivoting their entire business to push AI on every part of their infrastructure and in every service, in part because their customers aren't going anywhere and won't push back in the numbers that might make a difference. Windows 11 has hidden even more functionality behind layers of streamlining and obfuscation and integrated even more spyware and telemetry that won't tell you shit about what it's doing and that you can't turn off without violating the EULA. They're going to keep pursuing this kind of shit in more and more obvious ways because that's all they can do in the quest for endless year on year growth.

Unfortunately, switching to Linux will force you to learn how to use it. That sucks when it's being pushed as an immediate solution to a specific problem you're having! Not going to deny that. FOSS folks need to realise that 'just pivot your entire day to day workflow to a new suite of tools designed by hobby engineers with really specific chips on their shoulders' does not work as a method of evangelism. But if you approach it more like learning to understand and control your tech, I think maybe it could be a bit more palatable? It's more like a set of techniques and strategies than learning a specific workflow. Once you pick up the basic patterns, you can apply them to the novel problems that inevitably crop up. It's still painful, particularly if you're messing around with audio or graphics drivers, but importantly, you are always the one in control. You might not know how to drive, and the engine might be on fire, but you're not locked in a burning Tesla.

Now that I write this it sounds more like a set of coping mechanisms, but to be honest I do not have a healthy relationship with xorg.conf and probably should seek therapy.

It's a bit of a stretch but I almost feel like a bit of friction with tech is necessary to develop a good relationship with it? Growing up on MS-DOS and earlier versions of Windows has given me a healthy suspicion of any time my computer does something without me telling it to, and if I can't then see what it did, something's very off. If I can't get at the setting and properties panel for something, my immediate inclination is to uninstall it and do without.

And like yeah as a final note, I too find it frustrating when Linux decides to shit itself and the latest relevant thread I can find on the matter is from 2006 and every participant has been Raptured since, but at least threads exist. At least they're not Microsoft Community hellscapes where every second response is a sales rep telling them to open a support ticket. At least there's some transparency and openness around how the operating system is made and how it works. At least you have alternatives if one doesn't do the job for you.

This is long and meandering and probably misses the point of the discourse I'm dragging but I felt obligated to make it. Ubuntu Noble Numbat is pretty good and I haven't had any issues with it out of the box (compared to EndeavourOS becoming a hellscape whenever I wanted my computer to make a sound or render a graphic) so I recommend it. Yay FOSS.

219 notes

·

View notes

Note

I saw something about generative AI on JSTOR. Can you confirm whether you really are implementing it and explain why? I’m pretty sure most of your userbase hates AI.

A generative AI/machine learning research tool on JSTOR is currently in beta, meaning that it's not fully integrated into the platform. This is an opportunity to determine how this technology may be helpful in parsing through dense academic texts to make them more accessible and gauge their relevancy.

To JSTOR, this is primarily a learning experience. We're looking at how beta users are engaging with the tool and the results that the tool is producing to get a sense of its place in academia.

In order to understand what we're doing a bit more, it may help to take a look at what the tool actually does. From a recent blog post:

Content evaluation

Problem: Traditionally, researchers rely on metadata, abstracts, and the first few pages of an article to evaluate its relevance to their work. In humanities and social sciences scholarship, which makes up the majority of JSTOR’s content, many items lack abstracts, meaning scholars in these areas (who in turn are our core cohort of users) have one less option for efficient evaluation.

When using a traditional keyword search in a scholarly database, a query might return thousands of articles that a user needs significant time and considerable skill to wade through, simply to ascertain which might in fact be relevant to what they’re looking for, before beginning their search in earnest.

Solution: We’ve introduced two capabilities to help make evaluation more efficient, with the aim of opening the researcher’s time for deeper reading and analysis:

Summarize, which appears in the tool interface as “What is this text about,” provides users with concise descriptions of key document points. On the back-end, we’ve optimized the Large Language Model (LLM) prompt for a concise but thorough response, taking on the task of prompt engineering for the user by providing advanced direction to:

Extract the background, purpose, and motivations of the text provided.

Capture the intent of the author without drawing conclusions.

Limit the response to a short paragraph to provide the most important ideas presented in the text.

Search term context is automatically generated as soon as a user opens a text from search results, and provides information on how that text relates to the search terms the user has used. Whereas the summary allows the user to quickly assess what the item is about, this feature takes evaluation to the next level by automatically telling the user how the item is related to their search query, streamlining the evaluation process.

Discovering new paths for exploration

Problem: Once a researcher has discovered content of value to their work, it’s not always easy to know where to go from there. While JSTOR provides some resources, including a “Cited by” list as well as related texts and images, these pathways are limited in scope and not available for all texts. Especially for novice researchers, or those just getting started on a new project or exploring a novel area of literature, it can be needlessly difficult and frustrating to gain traction.

Solution: Two capabilities make further exploration less cumbersome, paving a smoother path for researchers to follow a line of inquiry:

Recommended topics are designed to assist users, particularly those who may be less familiar with certain concepts, by helping them identify additional search terms or refine and narrow their existing searches. This feature generates a list of up to 10 potential related search queries based on the document’s content. Researchers can simply click to run these searches.

Related content empowers users in two significant ways. First, it aids in quickly assessing the relevance of the current item by presenting a list of up to 10 conceptually similar items on JSTOR. This allows users to gauge the document’s helpfulness based on its relation to other relevant content. Second, this feature provides a pathway to more content, especially materials that may not have surfaced in the initial search. By generating a list of related items, complete with metadata and direct links, users can extend their research journey, uncovering additional sources that align with their interests and questions.

Supporting comprehension

Problem: You think you have found something that could be helpful for your work. It’s time to settle in and read the full document… working through the details, making sure they make sense, figuring out how they fit into your thesis, etc. This all takes time and can be tedious, especially when working through many items.

Solution: To help ensure that users find high quality items, the tool incorporates a conversational element that allows users to query specific points of interest. This functionality, reminiscent of CTRL+F but for concepts, offers a quicker alternative to reading through lengthy documents.

By asking questions that can be answered by the text, users receive responses only if the information is present. The conversational interface adds an accessibility layer as well, making the tool more user-friendly and tailored to the diverse needs of the JSTOR user community.

Credibility and source transparency

We knew that, for an AI-powered tool to truly address user problems, it would need to be held to extremely high standards of credibility and transparency. On the credibility side, JSTOR’s AI tool uses only the content of the item being viewed to generate answers to questions, effectively reducing hallucinations and misinformation.

On the transparency front, responses include inline references that highlight the specific snippet of text used, along with a link to the source page. This makes it clear to the user where the response came from (and that it is a credible source) and also helps them find the most relevant parts of the text.

293 notes

·

View notes

Text

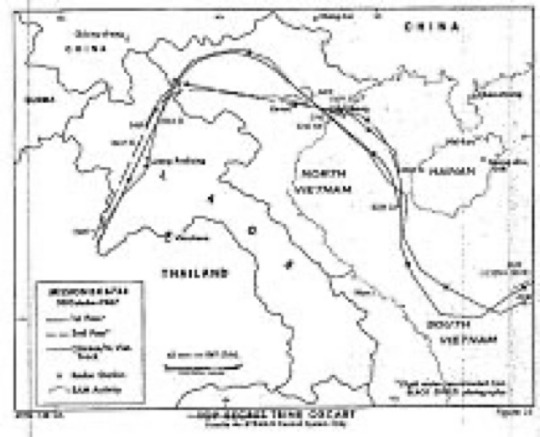

A 12 was hit by a small part of a missile. Solid quartz was used for the camera window.

During its 26-year career, the SR-71 Habu gathered intelligence in some of the world’s most hostile environments. One of those was the Soviet Union. It wasn’t necessary to cross the border as we had long-range side, looking cameras that could peer inside Russia. More than 1000 missiles were launched against the SR-71. Some people claim it was 4000 missiles, but that is not true after a while some countries such as Russia gave up. The Vietnamese launched missiles and so did the North Koreans. Not one missile hit an SR 71.

I want people to also remember that before the SR 71 was flying operational the CIA’s A-12 was flying.

The A-12 was the first Blackbird.

However, when A-12 was flying (1967-68) two missiles exploded into each other close behind the A-12 and a little bit of debris. Certainly, not enough to harm the Blackbird was found. Says: “On another October flight, pilot Dennis Sullivan detected radar tracking on his first pass over North Vietnam. Two sites prepared to launch missiles, but neither did. During the second pass, however, at least six missiles were fired at Sullivan’s aircraft, each confirmed on mission photos by missile vapor trails. Sullivan saw these vapor trails and witnessed three missile detonations. Postflight inspection of the aircraft revealed that a piece of metal had penetrated the lower right wing fillet area and lodged against the support structure of the wing tank. The fragment was not a warhead pellet but may have been a part of the debris from one of the missile detonations observed by the pilot.”

The SR-71 was conceived to operate at extreme velocities, altitudes, and temperatures: actually, it was the first aircraft constructed with titanium, as the friction caused by air molecules passing over its surface at Mach 2.6 would melt a conventional aluminum frame.

Its engineering was done with slide rules, computers were in their infancy and were not used in its design. Many years later a computer checked the design of the SR 71 and couldn’t find one flaw.The design was so cutting-edge that even the tools to build the SR-71 needed to be designed from scratch.

The CIA did buy the titanium for the SR-71 using cover companies as customers from Russia it was at that time called the Soviet Union but only at first. When we needed another batch of titanium we went to other sources such as Australia because we did not want to boost the Soviet Union economy.

The estimated temperature of the outside of the cockpit of 600 degrees F.

As reported by The SR-71 Blackbird website, the integrity of the double solid quartz camera window demanded special attention because of the optical distortion caused by the effect of great heat (600 degrees F.) on the outside of the window and a much lower temperature (150 degrees F.) on the inside could keep the cameras from taking usable photographs.

Three years and $2 million later, Corning Glass Works came up with a solution: the window was fused to its metal frame by a novel process using high-frequency sound waves. Isn’t that amazing?

Written by Linda Sheffield April 11, 2025 @c

@Habubrats71 via X

#sr 71#sr71#sr 71 blackbird#blackbird#aircraft#usaf#lockheed aviation#skunkworks#mach3+#habu#aviation#reconnaissance#cold war aircraft

37 notes

·

View notes

Text

Part I: The Spike Protein and Its Implications

Dr. Trozzi began by dissecting the central role of the spike protein in both SARS-CoV-2 and mRNA vaccines. He described how these vaccines use lipid nanoparticles to deliver modified mRNA into human cells, instructing the body to produce spike proteins. This process, while intended to stimulate immunity, has led to widespread and unintended consequences.

Weaponization of the Spike Protein: Dr. Trozzi revealed that the spike protein encoded in the vaccines has been genetically engineered to include harmful modifications, such as a furin cleavage site, which increases toxicity, and the removal of hemagglutinin esterase, which naturally counteracts clot formation. These modifications make the spike protein more dangerous than its natural counterpart.

Translation Errors and Contaminants: The modified mRNA in these vaccines is prone to translation errors, leading to the production of random protein fragments that can trigger autoimmune diseases. Additionally, independent research has uncovered contaminants, including plasmid DNA fragments and SV40 promoter sequences, which are known to facilitate the integration of foreign genetic material into human cells. These contaminants raise serious concerns about manufacturing quality and long-term safety.

Systemic Damage: Unlike traditional vaccines, which target specific areas of the body, the lipid nanoparticles in mRNA vaccines allow spike proteins to spread to critical organs, including the brain, heart, ovaries, and testes. This widespread distribution amplifies the potential for harm, contributing to conditions such as myocarditis, reproductive health issues, and neurological disorders.

22 notes

·

View notes

Text

3D Printing in Architecture

3D printing, once a novelty in the tech world, has now firmly established itself as a game-changer in various industries, including architecture. The ability to create intricate models, prototypes, and even full-scale structures has opened up new possibilities for architects, engineers, and builders. In this blog post, we'll explore how 3D printing is revolutionizing architecture, from design concepts to construction practices.

Design Innovation

One of the most significant impacts of 3D printing in architecture is the freedom it provides in design. Traditional methods often limit architects to certain shapes and structures due to material and construction constraints. However, with 3D printing, these limitations are lifted. Architects can now experiment with complex geometries and organic forms that were previously impossible or too costly to achieve. This has led to a surge in innovative designs, pushing the boundaries of what architecture can be.

Prototyping and Modeling

Before the advent of 3D printing, creating detailed architectural models was a time-consuming and expensive process. With 3D printing, architects can quickly produce accurate scale models of their designs, allowing for better visualization and refinement. This rapid prototyping capability enables architects to identify potential issues early in the design process, saving time and resources in the long run. Additionally, clients can better understand the architect's vision through tangible models, leading to more effective communication and collaboration.

Sustainability and Efficiency

3D printing also offers significant benefits in terms of sustainability and construction efficiency. Traditional construction methods often generate a considerable amount of waste due to material overuse and mistakes. In contrast, 3D printing uses only the necessary amount of material, significantly reducing waste. Additionally, many 3D printing materials can be recycled or are made from sustainable resources, making this technology more environmentally friendly.

Moreover, 3D printing can streamline the construction process. Structures can be printed on-site, reducing the need for transportation and minimizing the carbon footprint associated with moving materials and equipment. This method also allows for faster construction times, which is particularly beneficial for large-scale projects or emergency housing needs.

Cost-Effective Construction

The cost of building with traditional methods can be prohibitive, especially for complex or custom designs. 3D printing offers a more cost-effective alternative by reducing labor costs and material waste. The precision of 3D printing ensures that only the exact amount of material needed is used, which not only lowers costs but also increases the structural integrity of the building. For developing countries or regions with limited resources, 3D printing presents a viable solution for affordable housing and infrastructure.

Challenges and Future Prospects

While 3D printing in architecture holds great promise, it is not without challenges. The technology is still relatively new, and large-scale 3D printing for buildings requires further development. Issues such as material limitations, regulatory hurdles, and the need for skilled operators must be addressed. However, ongoing research and innovation in the field are likely to overcome these challenges in the coming years.

#architectdesign#design#interior design#home interior#interiordoor#interior decorating#architecture#interiorstyling#interiors#home#3D#3d printing

34 notes

·

View notes

Text

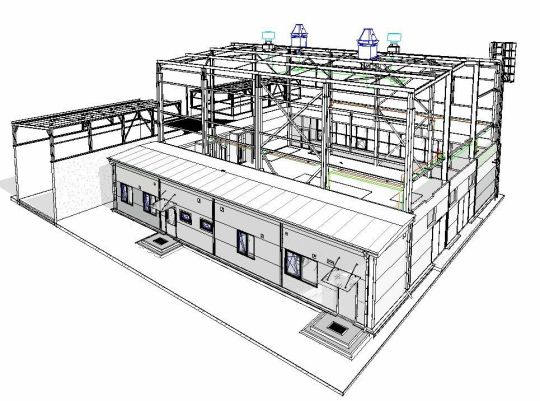

Exploring the Diverse Landscape of BIM Software in Construction: A Comprehensive Guide

Introduction: In the ever-evolving field of construction, Building Information Modeling (BIM) has emerged as a transformative technology that revolutionizes the way buildings are designed, constructed, and managed. BIM software plays a pivotal role in enhancing collaboration, improving efficiency, and minimizing errors throughout the construction process. This article delves into the various…

View On WordPress

#architectural design software#as-built documentation#BIM model accuracy#BIM software#Building Information Modeling#collaboration platforms#construction industry advancements#construction management software#construction project efficiency#Construction Technology#cost estimation tools#facility maintenance optimization#facility management solutions#laser scanning technology#LiDAR applications#MEP systems modeling#point cloud integration#project stakeholders collaboration#real-time coordination#structural engineering tools#sustainable building practices

0 notes

Text

The Role of Relays and Timers in Industrial Automation Systems

In the world of industrial automation, efficiency, safety, and precision are crucial. Among the many components that contribute to a well-functioning automated system, relays and timers play a foundational role. These devices act as control elements that manage the flow of electricity, signal processes, and coordinate timing sequences — ensuring that operations run smoothly and safely.

In this article, we’ll explore how relays and timers work, their types, applications in automation systems, and how high-quality products — like those offered by Enza Electric — can enhance performance and reliability in industrial settings.

What Are Relays?

A relay is an electromechanical or electronic switch used to control a circuit by a separate low-power signal or multiple signals. In industrial automation, relays act as a bridge between the control system and the equipment being operated — allowing machines to be turned on or off automatically.

Types of Relays Commonly Used in Automation:

Electromechanical Relays (EMRs): Use physical moving parts; reliable and easy to maintain.

Solid-State Relays (SSRs): No moving parts; faster switching, longer lifespan, and better for high-speed applications.

Thermal Overload Relays: Protect motors and equipment from overheating.

Control Relays: Designed for controlling multiple contacts simultaneously in automation systems.

What Are Timers?

Timers are devices used to delay or repeat electrical signals at predetermined intervals. They help synchronize tasks, automate sequences, and provide controlled outputs over time — critical for complex industrial processes.

Common Timer Functions:

On-delay and off-delay timing

Interval timing

Cyclic or repeat cycle operation

Flashing and sequencing operations

Types of Timers:

Analog Timers: Manual dial settings, simple and cost-effective.

Digital Timers: Offer precise programming, displays, and flexible timing ranges.

Programmable Timers: Ideal for complex automation routines requiring multiple sequences.

Key Roles in Industrial Automation Systems

1. Process Control and Sequencing

Relays and timers enable automated machines to follow a specific sequence — turning motors, lights, or pumps on and off in a logical order. For example, a conveyor system can use a relay-timer combination to control material flow with millisecond precision.

2. Safety and Protection

Relays protect systems by interrupting circuits in case of faults. Combined with timers, they can ensure delay before activating emergency stop functions, preventing false triggers and increasing worker safety.

3. Load Management

In high-demand industrial environments, relays help manage load distribution by selectively energizing or de-energizing machinery. Timers assist in staggered starts, reducing power surges.

4. Energy Efficiency

By automating start/stop functions and managing operation durations, timers help reduce unnecessary energy use. Relays ensure only the necessary loads are powered, minimizing wastage.

5. System Monitoring and Feedback

In smart automation, relays provide feedback signals to the control system. Timers assist with diagnostics by creating intervals for testing or data collection.

Benefits of Using High-Quality Relays and Timers

Choosing the right components significantly impacts system performance and longevity. Enza Electric’s relays and timers are engineered with:

High durability for tough industrial environments

Precision timing for reliable operation

Easy installation and compact designs

Compliance with international safety and quality standards

By integrating Enza’s low-voltage solutions, businesses in the GCC, MENA, and Africa regions benefit from cost-effective, scalable automation that supports both current needs and future expansion.

Common Applications in Industrial Sectors

Manufacturing Plants: Control of motors, robotic arms, and production lines.

HVAC Systems: Timed control of fans, compressors, and dampers.

Water Treatment Facilities: Sequenced operation of pumps and valves.

Packaging Machinery: Relay and timer-based coordination of packing, sealing, and labeling.

Food and Beverage Industry: Process automation with hygiene-compliant controls.

Final Thoughts

Relays and timers are the silent operators behind the success of industrial automation systems. From process optimization to enhanced safety and energy management, these components are indispensable.

When sourced from a trusted manufacturer like Enza Electric, businesses are not only investing in reliable hardware but also in the longevity, scalability, and safety of their entire operation.

Ready to Power Your Automation?

Explore Enza Electric’s wide range of relays, timers, and other low-voltage switchgear solutions designed to meet the evolving demands of modern industries. Visit www.enzaelectric.com to learn more or request a quote today.

9 notes

·

View notes

Text

AGARTHA Aİ - DEVASA+ (2)

In today’s digital landscape, a captivating and functional website is crucial for any business looking to thrive online. Full service web design encompasses a comprehensive approach, ensuring every aspect of your site is tailored to meet your unique needs. From the initial concept to the final launch, this service provides an array of offerings, including website service, responsive web design, and custom design services. Whether you’re a startup seeking to establish your brand or an established enterprise aiming to enhance your online presence, understanding the elements of full service web design is essential.

Full service web design

Full service web design encompasses all aspects of creating a website, from initial conceptualization to ongoing maintenance. This approach ensures that every detail is carefully considered to meet the specific needs of a business or individual. With a team of experienced designers and developers, full service web design offers a seamless experience that integrates aesthetics, functionality, and user experience.

One of the key advantages of opting for a full service web design is the cohesion of the website elements. Since all parts of the project are managed by a single team, there is less chance for miscommunication or inconsistency in design. This results in a more polished final product that reflects the brand’s identity while providing an engaging experience for visitors.

Additionally, full service web design allows for customized solutions tailored to unique requirements. Whether you need an e-commerce platform, a portfolio site, or a blog, a full service provider will offer dedicated support and expert advice throughout the entire process, ensuring your vision comes to life exactly as you imagined.

Website service

In today's digital landscape, website service is essential for businesses to thrive and maintain an online presence. A well-structured website serves as a powerful tool that encourages customer engagement and drives sales. By investing in a comprehensive website service, businesses can ensure that their website not only looks great but also functions seamlessly across all devices.

A key aspect of website service is the ability to optimize for search engines. By implementing SEO best practices, businesses can enhance their visibility and attract more organic traffic. This is where a reliable website service provider plays a crucial role, as they possess the expertise and techniques necessary to elevate your search engine rankings.

Furthermore, ongoing support and maintenance are vital components of a reliable website service. As technology evolves and user needs change, having a team that can promptly address issues or updates will keep your website relevant and effective in reaching target audiences. This ongoing relationship is instrumental in achieving long-term success in the digital realm.

Responsive web design

Responsive web design is an essential aspect of modern web development that ensures a seamless user experience across a variety of devices. With the increasing use of smartphones and tablets, having a website that adapts to different screen sizes is not just a luxury but a necessity.

The core principle of responsive web design is fluidity. This means that the layout of your website adjusts dynamically based on the screen width, ensuring that content remains accessible and visually appealing regardless of the device used. This approach improves usability and can significantly boost conversion rates.

Incorporating responsive web design techniques involves using flexible grids, images, and CSS media queries. These elements work together to create a layout that responds gracefully to changes in screen size, making your website not only functional but also competitive in the digital marketplace.

Custom design services

In today's digital landscape, custom design services have emerged as a vital component of creating a strong online presence. Businesses understand that a one-size-fits-all approach does not cater to their unique needs and branding. Therefore, opting for custom design services allows them to differentiate themselves in a crowded market.

These services offer tailored solutions that resonate with a company's specifics, from colors to typography and layout. By leveraging custom design services, businesses can ensure that their websites not only reflect their brand identity but also provide an intuitive user experience. This is crucial for keeping visitors engaged and encouraging them to take the desired actions.

Investing in custom design services ultimately contributes to better customer satisfaction and improved conversion rates. With a website designed specifically for their target audience, businesses can more effectively communicate their message and achieve their goals. This bespoke approach is invaluable in today's competitive environment.

43 notes

·

View notes