#Mobile Conveyor System

Explore tagged Tumblr posts

Text

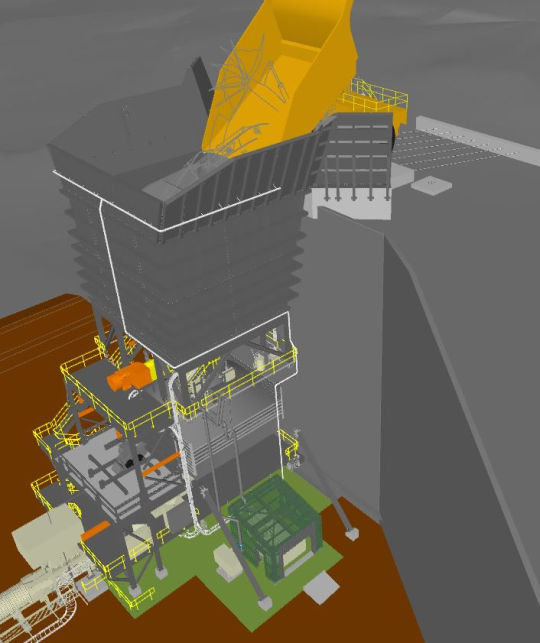

Little P.Eng. Engineering: Leading the Way in Bulk Material Transport Design across North America

In industries where massive volumes of materials are processed, the importance of efficient and safe bulk material transport cannot be overstated. Little P.Eng. Engineering stands as a beacon of excellence in this niche, offering top-tier structural and mechanical designs for a variety of equipment across Canada and the USA.

The Genesis of Bulk Material Transport

Bulk material transport is an integral cog in the machine of large-scale industries. Be it mining, manufacturing, or agriculture, the ability to move vast amounts of raw or processed materials efficiently ensures seamless operations and reduced downtimes. This task's complexity demands innovative solutions tailored to specific needs and geographic conditions.

Decoding Little P.Eng. Engineering's Portfolio

Apron Feeders:

Role: Essential in mining and heavy industry, they deliver a steady feed of materials to other machines.

Little P.Eng. Precision: Custom designs account for rugged conditions, ensuring robustness, minimal wear-tear, and efficient feeding speeds.

Belt Conveyors:

Role: The backbone of many industries, they transport materials over short to long distances.

Little P.Eng.'s Approach: Focus on load-bearing capacity, adaptive designs for different terrains, and durability in varied climatic conditions.

Belt Feeders:

Role: Controlled feeding of bulk materials, often used in coordination with other systems.

Little P.Eng.'s Vision: Precision-engineered for accurate delivery rates and volumes, ensuring no overloading or wastage.

Mobile Conveyor Bridges:

Role: Vital for large mining operations, they offer flexibility in transporting materials across significant distances.

Little P.Eng.'s Craft: Mobility and stability converge, ensuring these bridges can be relocated effortlessly without compromising safety.

Mobile Transfer Conveyors:

Role: As the name suggests, these conveyors are mobile and are often used in tandem with other stationary equipment.

Little P.Eng. Insight: Prioritizing easy maneuverability, these conveyors also spotlight on energy efficiency and fast material transfer.

Tube Conveyors:

Role: They provide enclosed transport, often used for grains, powders, or any material susceptible to external contamination or spillage.

Little P.Eng.'s Touch: Airtight sealing, efficient transport mechanism, and designs that reduce maintenance downtimes.

In-plant Conveyor Systems:

Role: Within factories or processing plants, they link various stages of production or processing.

Little P.Eng. Expertise: Modular designs that fit seamlessly into existing infrastructures, ensuring no workflow disruption.

Pipe Conveyor Systems:

Role: Offering enclosed transport, they are often used for materials like coal, ensuring no spillage or dust emissions.

Little P.Eng.'s Specialty: Enhanced curvature ability, ensuring a smaller footprint and efficient transport even in space-constrained areas.

Steel Belt Conveyors:

Role: Handling materials at high temperatures or those that might be abrasive or cut regular belts.

Little P.Eng. Mastery: Heat-resilient designs, ensuring prolonged lifespans even under intense conditions.

The North American Landscape: Challenges and Innovations

From the icy terrains of Northern Canada to the industrious heartlands of the USA, each region poses its unique challenges. Whether it's dealing with permafrost or ensuring equipment can withstand desert heat, Little P.Eng. Engineering's designs embody adaptability, ensuring machinery performs at its peak regardless of external conditions.

Moreover, with both countries emphasizing sustainable operations, the engineering firm ensures eco-friendly designs, minimizing energy consumption and environmental impact.

Conclusion

In an age where efficiency can dictate market standings, Little P.Eng. Engineering's contribution to the bulk material transport sector across Canada and the USA is undeniable. Through an intricate understanding of mechanics, topography, and industrial needs, the firm crafts solutions that don't just move materials but advance industries.

Read more:

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Tags:

Little P.Eng. Engineering

Structural design

Mechanical design

Mining equipment

Tailored equipment design

Bulk material transport

Modular design

Apron feeders

Belt conveyors

Belt feeders

Mobile conveyor bridges

Mobile transfer conveyors

Tube conveyor systems

In-plant conveyor systems

Pipe conveyor systems

Steel belt conveyors

North American industry

Sustainable operations

Material movement solutions

Efficient material transport

Custom machinery design

Industrial innovations

Canada industrial machinery

USA industrial machinery

Adaptability in design

Eco-friendly machinery

High-temperature material handling

Enclosed transport systems

Production workflow

Advanced material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Mechanical design#Mining equipment#Tailored equipment design#Bulk material transport#Modular design#Apron feeders#Belt conveyors#Belt feeders#Mobile conveyor bridges#Mobile transfer conveyors#Tube conveyor systems#In-plant conveyor systems#Pipe conveyor systems#Steel belt conveyors#North American industry#Sustainable operations#Material movement solutions#Efficient material transport#Custom machinery design#Industrial innovations#Canada industrial machinery#USA industrial machinery#Adaptability in design#Eco-friendly machinery#High-temperature material handling#Enclosed transport systems#Production workflow#Advanced material handling

0 notes

Text

crashdown - pt 1

Armored Core VI: Fires of Rubicon [Handler Walter x C4-621]

Premise: A badly injured 621 makes a bad landing, and Handler Walter is going to have to get him back to good health.

(he/him 621, slow burn plot) -- [link to the fic on AO3]

Note: Okay so, this is literally the first fanfiction I've written in uhhhh��� I think the last time was like literally a decade ago? Like, the last time I wrote fanfiction, Pacific Rim was a new movie. So… keep that in mind I guess. But I wanted more Handler Walter x 621 so I figured I should fill that hole (heh) myself instead of whining.

A deafening roar filled the air as an Armored Core hurtled towards the hangar at breakneck speed. C4-621 was no stranger to playing things a little too loosely when it came to mobility, nor rushing in to a landing. This time, though? This time was different, and Walter could tell that much. Having this level of skill as Handler required an innate understanding of one's pilot, and this Handler knew there was something terribly wrong with his hound.

Walter's gruff voice crackled over the radio. "You're coming in too hot, 621. Pull back on your entry speed."

No response. This wasn't particularly surprising, as 621 was especially taciturn—a trait he shared with most pilots with Gen 4 augmentations. Given the circumstances, it remained worrisome. Unless 621 deviated from the norm, Walter had no means to discern whether the issue lay with the AC, the pilot, or if he was reaching the pilot's ears at all.

Stormy blue-grey eyes darted back and forth between the displays. The first presented a diagram of 621's AC, a nimble reverse-joint mech dubbed 'Crashdown'—a name whose irony wasn't lost in the present chaos. Critical damage indicators flashed red on several parts of the AC, yet the boosters and piloting systems maintained normal operation. Shifting his gaze to the second screen, he observed a live feed of Crashdown rapidly closing the gap between itself and the hangar entryway. The AC struggled visibly, grappling to maintain a stable flight path as it repeatedly drifted to one side and over-corrected to the other.

"621, I repeat: Pull back on entry speed. At your current trajectory, you won't touch down in the hangar entryway safely. If you cannot make the landing, decelerate and find a safe landing zone so you and your AC can be retrieved."

Still no response.

Walter's stomach churned uneasily. He was not often easily fazed, but the idea of losing a pilot to such a preventable crash left a foul taste in his mouth. He'd lost plenty of hounds prior to 621, and to a myriad of endings. Everything from pilots falling in combat to an enemy AC, to sudden and fatal eruptions of coral. But this? This was too much.

The radio abruptly crackled to life, muffled sounds coming through with heavy distortion. None of the noise formed coherent words, but it was clear that 621 was conscious and attempting to communicate. What precisely he was trying to convey remained unclear, but it was, at the very least, an indication that he hadn't reached a point where he couldn't operate his AC at all.

"621! You're still coming in too hot! You need to stabilize your AC before you take out the entire hangar bay!" Walter watched helplessly as the unit bobbed and weaved, making a desperate, last-ditch attempt to decelerate before crossing the threshold.

It was too late. Crashdown grazed the side of the hangar entryway, the impact propelling the AC into one side of the bay retrieval arms. The automated arm violently tore away from the conveyor rail, sliding across the metal floor with a shrill sound before finally lurching to a stop alongside the Armored Core itself. The remaining arm futilely attempted to retrieve the AC, tugging at one side of the mech ineffectively before ultimately surrendering.

Walter exited the lift from the comms room, rushing towards the fallen machine as quickly as his aging legs allowed. His bad leg throbbed as he pushed it beyond its limits, but he shoved the pain to the back of his mind. He wasn't entirely certain whether the urgency stemmed from a desire to salvage such a valuable asset, or a genuine concern for his pilot's well-being. Either way, losing his hound to such a clusterfuck of a crash would be a massive loss.

Walter strained his voice to shout over sirens and loud machinery, his fists clenched so tight his gloves were the only thing stopping him from drawing blood from his palms. Wake up, 621. Get out of there. He repeated these words in his thoughts, nearly convincing himself that through sheer repetition, they could manifest into reality. Seconds felt like minutes. Minutes felt like an eternity.

A quiet creak emanated from the core, followed by a weak thud. Then another. The emergency hatch cover popped off the core, barely missing Walter as it clattered onto the metal grating. He didn't flinch, his body already completely tense, waiting to see 621 emerge from the machine. A slender silhouette materialized, gingerly making its way out of the escape tunnel. The figure tried to descend the sloped nose of the AC's cockpit core, but frailty and injury overwhelmed him, leading to a tumble the remainder of the way, crashing onto the floor below.

Walter rushed to the pilot's side, kneeling to scoop him up off the cold floor. "We'll get you taken care of, 621. Just rest."

621 didn't reply, just squeezed his handler's arm weakly. He was in bad shape, but he was alive, and that was more than Walter could have hoped for.

#fanfiction#gay shipping#text post#armored core 6#armored core 6: fires of rubicon#handler walter#c4-621#handler walter x c4-621#he/him 621#slow burn plot before we ever get to smut

2 notes

·

View notes

Text

5 ways to make your fulfillment center run more efficiently

Running a fulfillment center can be extremely challenging in today’s complex and challenging business environment. As an online seller, it's important to ensure that your fulfillment center runs efficiently to meet the demands of your customers. In this blog, we will explore the best five ways to make your fulfillment center run more efficiently.

Optimize your inventory management system

Managing your inventory is one of the most important aspects of running a fulfillment center efficiently. An effective inventory management system can help you track your stock levels and ensure that you have enough products on hand to meet customer demand. Use inventory management software that integrates with your order management system to help you track inventory in real time and avoid stockouts. Utilize demand forecasting to make sure you have enough inventory to fulfill orders during peak demand periods.

Implement efficient picking and packing processes

Picking and packing are the two most critical processes in the order fulfillment cycle. Optimize your picking and packing processes by grouping orders by proximity, picking in batches, and using barcode scanning to avoid errors. Use automation and packing materials that are appropriate for the product being shipped to ensure that items arrive in good condition. You can also implement a quality control process to ensure accuracy and minimize errors.

Invest in automation

Automation can help you improve efficiency and reduce labor costs. Consider investing in automation tools such as conveyor belts, sortation systems, and robots to streamline your fulfillment process. Automation can also help you increase throughput and accuracy, reduce manual labor, and minimize errors. On the other hand, instead of installing all these tools, you can simply partner with NimbusPost, a tech-enabled shipping aggregator that already has 540 fully-equipped facilities and several types of warehouses to provide easy order fulfillment.

Streamline your shipping process

Shipping is a crucial aspect of fulfillment. To make your shipping process more efficient, use shipping software that integrates with your order management system. This can help you automate shipping label generation and reduce manual data entry. Choose a reliable courier service in India or a global shipping partner to ensure timely delivery and track your shipments in real time.

Train and empower your staff

Your employees are the backbone of your fulfillment center. To improve efficiency, provide regular training to ensure that they understand their roles and responsibilities. Empower your staff by giving them the tools and resources they need to succeed, such as mobile devices for picking and packing or access to real-time inventory information. Encourage open communication and solicit feedback to identify opportunities for improvement.

Conclusion

There are several ways to make your fulfillment center run more efficiently. You can follow the mentioned ways to improve your fulfillment center’s efficiency or just hire a solid shipping aggregator to get everything handled without stress at the best rates

2 notes

·

View notes

Text

What are the latest warehouse automation technologies?

Gone are the days of manual labour and static, inefficient operations. Today, we stand at the forefront of a revolution driven by the latest warehouse automation technologies. These innovations reshape how businesses handle inventory, fulfil orders, and optimize supply chains.

From autonomous robots and artificial intelligence to the Internet of Things (IoT) and advanced data analytics, we'll explore how these technologies enhance efficiency, reduce costs, and ensure seamless operations in modern warehouses.

1-Robotic Process Automation (RPA): RPA involves using software robots to automate repetitive tasks like data entry, order processing, and inventory tracking. The robots interact with various systems and applications to streamline workflows.

2-Autonomous Mobile Robots (AMRs): Robotic vehicles called AMRs navigate and operate in warehouses without fixed infrastructure, such as conveyor belts or tracks. They perform tasks like picking, packing, and transporting goods.

3-Automated Guided Vehicles (AGVs): AGVs are similar to AMRs but typically follow fixed paths or routes guided by physical markers or magnetic tape. They are commonly used for material transport in warehouses and distribution centres.

4-Goods-to-Person Systems: This approach involves bringing the items to the workers rather than having workers travel throughout the warehouse to pick items. Automated systems retrieve and deliver goods to a workstation, reducing walking time and improving efficiency.

5-Automated Storage and Retrieval Systems (AS/RS): AS/RS systems use robotics to store and retrieve items from racks or shelves automatically. These systems can significantly increase storage density and optimize space utilization.

6-Collaborative Robots (Cobots): Cobots are designed to work alongside human workers. They can assist with tasks like picking, packing and sorting, enhancing efficiency and safety.

7-Warehouse Management Systems (WMS): While not a physical automation technology, modern WMS software uses advanced algorithms and AI to optimize inventory management, order fulfilment, and warehouse processes.

8-Vision Systems and Machine Learning: Computer vision technology combined with machine learning can be utilized for tasks such as object recognition, inventory movement tracking, and quality control.

9-IoT and Sensor Networks: Internet of Things (IoT) devices and sensors collect real-time data on inventory levels, environmental conditions, equipment health, and more, enabling better decision-making and predictive maintenance.

10-Voice and Wearable Technologies: Wearable devices and voice-guided picking systems can provide workers with real-time information and instructions, improving accuracy and efficiency.11-Automated Packaging Solutions: These systems automate the packaging process by selecting the appropriate box size, sealing packages, and applying labels, reducing manual labour and ensuring consistent packaging quality.

1 note

·

View note

Text

Porto Flavia, Sardinia, Italy.

Porto Flavia is a Sardinian public works built between 1922 and 1924 in Masua in the province of Iglesias in southern Sardinia. A 600 meter long tunnel overlooking the sea in front of Sugar Loaf.

Ships stopped to load the minerals destined for the foundries of Northern Europe below the point, reducing transport costs and times.

The system was and is made up of 2 superimposed tunnels separated vertically by 9 silos. In the upper gallery the silos were loaded from the surrounding island, in the lower one equipped with a conveyor belt they then loaded the ships using a lead and zinc mobile arm.

Flavia is the name of the daughter of Cesare Vercelli, designer and construction manager for the construction of the work.

Italy

1K notes

·

View notes

Text

Essential Automation Components for Mobile Production Lines

Essential automation components play a key role in boosting efficiency and accuracy in mobile production lines. These components include robotic arms for precise assembly, sensors for real-time monitoring, PLCs (Programmable Logic Controllers) for system control, and conveyors for smooth material handling. Together, they help reduce manual labor, speed up production, and ensure consistent quality. Automation in mobile manufacturing also improves safety and reduces human error. By integrating advanced automation technologies, manufacturers can meet high demand, lower costs, and stay competitive. Choosing the right components is crucial for building a fast, reliable, and scalable mobile production system.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#industrial automation applications#Manufacturing#mobile manufacturing automation#PLC in phone manufacturing#sensors in smartphone production#Apple factory automation#Samsung manufacturing components

0 notes

Text

Driving the Future: How Automated Guided Vehicles Are Powering Warehouse Automation

In the world of logistics and supply chain management, speed, precision, and adaptability are everything. As customer expectations grow and same-day delivery becomes the norm, businesses are under constant pressure to move goods faster, more efficiently, and with fewer errors. One of the standout technologies stepping up to meet this demand is the automated guided vehicle (AGV). These intelligent, self-navigating machines are reshaping the future of warehouse automation, bringing in a new era of smart logistics.

What Is an Automated Guided Vehicle?

An automated guided vehicle is a mobile robot that follows predefined paths or navigates using advanced sensors and software to transport materials within a facility. They are typically used in warehouses, manufacturing plants, and distribution centers to move pallets, racks, or carts with minimal human intervention.

Unlike traditional forklifts or conveyor systems, AGVs can operate autonomously, making them ideal for repetitive, time-sensitive, and high-volume tasks. They come in various forms—tugger AGVs, unit load carriers, pallet trucks, and even customized bots tailored for specific industries.

The Rise of Warehouse Automation

Warehouse automation is no longer a futuristic concept, it’s happening right now. Businesses across the globe are investing in technologies that minimize manual labor, reduce errors, and optimize space. Automation helps reduce operational costs while maximizing output and ensuring consistent performance.

From automated storage and retrieval systems (ASRS) to robotic picking arms, the landscape of warehousing is transforming rapidly. But among all the technologies, the automated guided vehicle stands out for its flexibility, scalability, and cost-effectiveness.

Why AGVs Are a Game-Changer in Warehouse Automation

1. Labor Optimization

One of the most significant benefits of using automated guided vehicles is the reduction in dependency on manual labor. With increasing labor shortages and rising wages, AGVs offer a long-term solution to manpower constraints. They can work 24/7, don’t require breaks, and can be reprogrammed as operational needs change.

This allows human workers to focus on more complex, decision-based tasks, like inventory analysis, customer support, and quality control, while AGVs take care of the heavy lifting, literally and figuratively.

2. Enhanced Safety and Accuracy

Warehouses can be hazardous places, especially when there’s a high volume of forklifts and human operators working simultaneously. AGVs reduce the risk of workplace injuries by following strict safety protocols and moving along controlled paths.

Thanks to advanced sensors and real-time navigation systems, these machines can detect obstacles, avoid collisions, and stop immediately if something unexpected appears in their path. This makes them a safer and more accurate alternative in the automation journey.

3. Scalability and Flexibility

One of the biggest advantages of warehouse automation using AGVs is scalability. Whether you're operating a small facility or a sprawling distribution center, AGV fleets can grow with your business. You can start small, test their performance, and gradually expand the system as your operations scale.

Additionally, AGVs can be reprogrammed to adapt to layout changes, new workflows, or seasonal demands, giving businesses more flexibility than fixed conveyors or static systems.

4. Cost Efficiency in the Long Run

While the upfront cost of investing in an automated guided vehicle may seem high, the long-term ROI makes it worthwhile. Reduced labor costs, fewer workplace accidents, improved order accuracy, and minimized downtime all contribute to lower operational expenses.

AGVs also help extend the life of your warehouse infrastructure by reducing wear and tear on floors, shelves, and racking systems due to their precision movements and consistent handling.

5. Real-Time Data and Integration

Modern AGVs don’t just move materials, they also collect valuable data in real time. When integrated with warehouse management systems (WMS), AGVs can help track inventory, monitor productivity, and provide insights that inform business decisions.

This data-driven approach helps identify bottlenecks, predict maintenance needs, and ensure optimal performance across the entire warehouse automation ecosystem.

Industry Applications of AGVs

AGVs are used across a variety of industries, including:

E-commerce and Retail: To handle high order volumes and reduce picking times.

Pharmaceuticals: For precise and sterile material handling.

Automotive: To move heavy parts and components across the production floor.

Food and Beverage: For transporting items in temperature-controlled environments.

No matter the industry, the role of the automated guided vehicle is the same: improve efficiency, reduce costs, and support consistent, high-volume operations.

Are AGVs Right for Every Warehouse?

While an automated guided vehicle offers a wealth of benefits, they’re not a one-size-fits-all solution. Businesses need to assess their current layout, workflows, and automation goals. AGVs work best in facilities with predictable routes, consistent volumes, and clearly defined tasks.

However, as technology continues to evolve, new generations of AGVs with better navigation, faster speeds, and adaptive AI are making them more viable for even complex and dynamic environments.

As the demand for faster, more efficient logistics grows, warehouse automation is becoming not just a competitive edge, but a necessity. Automated guided vehicles represent one of the most impactful and accessible technologies in this space. They offer a perfect blend of precision, scalability, and cost savings that businesses of all sizes can benefit from.

If you're looking to modernize your operations, reduce manual workload, and future-proof your supply chain, investing in AGVs is a strategic move that pays dividends now and in the years to come.

0 notes

Text

Small Concrete Batch Plant

Small Concrete Batch Plant: A Game-Changer in Modern Construction

Introduction In the evolving world of construction, precision, efficiency, and adaptability are paramount. As urban projects become more complex and rural developments demand versatility, the construction industry increasingly turns to scalable solutions that fit the unique needs of each job site. One such innovation reshaping how concrete is produced and delivered is the small concrete batch plant. Compact yet powerful, this equipment offers remarkable benefits for construction professionals who seek to maximize quality while maintaining flexibility and cost-effectiveness. Whether you're working on sidewalks, residential homes, or smaller commercial developments, a small concrete batch plant can serve as the cornerstone of your operation.

What Is a Small Concrete Batch Plant? A small concrete batch plant is a piece of equipment designed to mix small volumes of concrete on-site or at a nearby location. Unlike large-scale stationary batch plants that serve high-output construction demands, these smaller versions are built for maneuverability, fast setup, and efficient operation on projects where high capacity is unnecessary or logistically challenging. Typically, a small concrete batch plant includes the following components: • A cement silo or bin • Aggregate batching system • Weighing system • Conveyor belts or screw conveyors • Water supply and control systems • A central mixer All of these parts work together to ensure precise measurement and mixing, which leads to high-quality concrete batches tailored to the project at hand.

Key Benefits of Using a Small Concrete Batch Plant

Flexibility and Mobility One of the greatest advantages of a small concrete batch plant is its mobility. Many of these units are trailer-mounted or modular, allowing them to be easily transported to various job sites. This is especially helpful for contractors working in remote areas, urban locations with tight spaces, or on multiple smaller projects in a single day. Being able to mix on-site eliminates the need to rely on external concrete suppliers, reducing wait times and improving productivity.

Cost Savings Operating a large concrete plant comes with significant overhead—space, labor, fuel, and maintenance costs can quickly add up. A small concrete batch plant minimizes many of these expenses. By producing only what you need, when you need it, you cut down on waste and prevent the cost of over-ordering or spoilage due to delays. Additionally, by taking control of concrete production in-house, contractors can eliminate third-party markup fees.

Time Efficiency Time is money on any job site. Small concrete batch plants deliver fresh, ready-to-use concrete without the long transport times associated with off-site production. This results in more accurate scheduling, faster turnaround, and the ability to respond quickly to changes in project scope or conditions.

High-Quality Control Concrete mix consistency is vital for the strength and longevity of structures. A small concrete batch plant gives operators complete control over the mix ratio, allowing for real-time adjustments based on site conditions or application requirements. This level of customization improves overall quality assurance and ensures compliance with engineering standards.

Lower Environmental Impact Because these plants produce smaller batches, they tend to use fewer raw materials at one time and can reduce waste through more precise measurement. Additionally, on-site production decreases the need for transport trucks, helping cut down on emissions and fuel use. This is a major plus for construction firms aiming to meet sustainability goals or work within green building frameworks.

Ideal Applications for a Small Concrete Batch Plant A small concrete batch plant shines in situations where agility and efficiency are key. These include: Residential Construction Single-family homes, driveways, patios, and footings often require smaller amounts of concrete delivered consistently and reliably. A mobile plant makes it easier to pour exactly what’s needed without the constraints of scheduling deliveries from a central plant. Municipal and Infrastructure Projects From sidewalks and curbs to light pole foundations and park improvements, public works projects often benefit from the scalability and responsiveness that a small concrete batch plant provides. Remote or Rural Sites Delivering concrete to off-the-grid locations poses logistical challenges. Small batch plants can be hauled in, set up quickly, and operated with minimal infrastructure, making them ideal for rural job sites or temporary installations. Repairs and Maintenance Whether you're fixing roadways, patching concrete structures, or performing routine maintenance, small jobs don’t justify large batch deliveries. A small concrete batch plant allows for timely, small-volume mixing that fits the task.

Considerations Before Choosing a Small Concrete Batch Plant While a small concrete batch plant is an excellent tool for many construction applications, choosing the right model requires careful planning. Here are a few factors to evaluate: Capacity Requirements Determine how much concrete you’ll typically need per batch and per day. Small plants vary widely in output, so choose one that fits your average volume without overpaying for unused capacity. Automation and Control Systems Some batch plants offer advanced features such as digital controls, automated ingredient feeders, and remote monitoring. These tools enhance accuracy and ease of use, especially for crews with limited training. Power Source Depending on the job site, you may need a plant that runs on diesel, electricity, or even hybrid options. Consider power availability and fuel costs when choosing the appropriate setup. Ease of Setup and Transport For maximum efficiency, look for a unit that can be assembled and disassembled quickly, with minimal tools and personnel. Lightweight, compact models offer more flexibility for fast-moving crews. Regulatory Compliance Always verify that your small concrete batch plant meets local safety, noise, and environmental regulations. This includes proper containment of materials and dust suppression measures.

Innovations in Small Concrete Batch Plants Modern technology has enhanced the functionality of small batch plants, making them smarter and more efficient than ever. Some cutting-edge advancements include: • Real-time Mix Monitoring: Sensors track the moisture content and temperature of aggregates, ensuring optimal mix performance. • IoT Connectivity: Operators can monitor and manage batching operations remotely, improving oversight and accountability. • Pre-programmed Mix Designs: Recipes can be stored and recalled for specific project types, ensuring consistency across different job sites. These advancements contribute to a more streamlined, reliable operation that enhances productivity and reduces manual errors.

Conclusion A small concrete batch plant is more than just a scaled-down version of a full-size mixing facility—it’s a dynamic, cost-effective solution for contractors who value flexibility, control, and efficiency. Whether you're navigating tight city streets or setting up shop on a rural job site, these compact powerhouses offer a way to produce consistent, high-quality concrete on demand. By investing in the right small batch plant, you position your business for greater independence, improved margins, and the ability to tackle a broader range of projects with confidence. In the ever-changing landscape of construction, that kind of adaptability isn't just nice to have—it's essential.

concretebatchingplants #concretebatchingplant #batchingplant #concreteplants #cement #screwconveyor #manufacturer #parkercolorado #denver #castlerockcolorado #denvercolorado #littletoncolorado #lonetreecolorado

1 note

·

View note

Text

Cardan Shafts Applications in UAE Industries

In the heart of the Middle East, the United Arab Emirates (UAE) is recognized for its booming industrial sectors, including oil & gas, construction, maritime, and manufacturing. A critical mechanical component supporting the smooth operation of these industries is the Cardan shaft—also known as a universal joint shaft. This blog dives into the various applications and significance of Cardan Shafts in UAE, highlighting their role in ensuring efficiency, flexibility, and durability in industrial machinery.

What is a Cardan Shaft?

A Cardan shaft is a mechanical drive shaft used to transmit torque and rotation, even when the shafts are not in a straight line. It enables power transfer between components located at varying angles and distances, making it ideal for heavy-duty applications.

Key Industries Using Cardan Shafts in UAE

1. Oil and Gas Sector

The oil & gas industry is the backbone of the UAE economy. Cardan shafts are widely used in drilling rigs, pumping systems, and pipeline operations. Their ability to handle high torque and misalignments makes them indispensable in harsh desert and offshore environments.

Application Highlights:

Drill string drives

Rotary tables

Mud pumps

Offshore platform equipment

2. Construction and Heavy Equipment

UAE's massive infrastructure growth relies heavily on construction machinery such as excavators, cranes, and concrete mixers. Cardan shafts provide reliable torque transmission between engine and axles or other rotating equipment.

Application Highlights:

Concrete batching plants

Tunnel boring machines

Mobile cranes and loaders

3. Manufacturing and Production Plants

Cardan shafts in UAE are critical in various manufacturing processes, including steel, paper, and textiles. They are used in rolling mills, conveyors, and heavy processing equipment where uninterrupted power transfer is essential.

Application Highlights:

Conveyor systems

Rolling and forging mills

Textile spinning machines

4. Marine and Shipping Industry

Given UAE's strategic coastal position, the marine sector thrives. Cardan shafts are vital in ship propulsion systems and marine engines, where vibration resistance and durability are critical.

Application Highlights:

Marine propulsion

Deck machinery

Power take-off (PTO) systems

5. Power Generation

Power plants in the UAE, including renewable and gas-fired plants, use Cardan shafts in turbines, generators, and auxiliary equipment, where they accommodate angular misalignments and thermal expansion.

Why Cardan Shafts are Ideal for UAE Conditions

High Load Capacity: Perfect for heavy industrial applications.

Resistance to Harsh Environments: Operates well in high temperatures, dust, and saline conditions.

Maintenance Friendly: Designed for durability and easy servicing, reducing downtime.

Customizable Designs: Adapted for various sizes, torque levels, and operational angles.

Local Availability and Services

With the rising demand for Cardan Shafts in UAE, many local and international suppliers offer custom solutions, on-site servicing, and spare parts. Companies based in Dubai, Abu Dhabi, and Sharjah provide industry-grade shafts for both OEMs and end-users.

0 notes

Text

Innovative Technology Solutions for 3PL and 4PL Providers

In today’s fast-paced global economy, third-party logistics (3PL) and fourth-party logistics (4PL) providers play a pivotal role in streamlining supply chains and enhancing customer satisfaction. However, as customer expectations evolve and supply chains grow more complex, the logistics sector must lean heavily on technology to stay competitive and efficient. Modern technology solutions are not just operational tools; they are strategic enablers that drive agility, visibility, and growth across logistics operations.

The Digital Evolution of 3PL and 4PL

Both 3PL and 4PL providers have embraced digital transformation to meet the demands of a market that values speed, transparency, and customization. While 3PL companies focus primarily on handling transportation, warehousing, and distribution, 4PL providers manage entire supply chains, acting as a single point of contact between businesses and multiple logistics providers. Technology acts as the backbone for both models, empowering them to offer value-added services, optimize resources, and enhance collaboration.

Key Technology Solutions Shaping the Industry

Cloud-Based Transportation Management Systems (TMS) TMS platforms provide real-time visibility into the movement of goods, enabling better decision-making and cost control. Cloud-based solutions allow for scalability, quick deployment, and seamless integration with other systems like ERP and WMS, offering 3PL and 4PL providers greater flexibility and responsiveness.

Warehouse Automation and Robotics Automation technologies such as autonomous mobile robots (AMRs), automated picking systems, and smart conveyors dramatically improve warehouse efficiency. They reduce labor costs, minimize errors, and boost throughput, enabling faster fulfillment and enhanced service levels.

Artificial Intelligence (AI) and Machine Learning (ML) AI and ML empower logistics providers to optimize route planning, forecast demand, and manage inventory more effectively. Predictive analytics also helps anticipate disruptions, allowing providers to create proactive contingency plans and maintain high service reliability.

Internet of Things (IoT) and Telematics Connected devices, such as smart sensors and GPS tracking systems, provide real-time data on shipment location, condition, and environment. This transparency helps ensure product integrity, especially for sensitive goods, and supports better decision-making throughout the supply chain.

Blockchain for Secure Transactions Blockchain technology brings new levels of security and transparency to supply chains. It enables tamper-proof record-keeping, simplifies dispute resolution, and ensures compliance with regulatory standards — critical advantages for 4PL providers managing complex networks.

Advanced Data Analytics and Reporting Tools Access to granular, real-time data allows logistics providers to monitor key performance indicators (KPIs), track delivery performance, and uncover areas for continuous improvement. Sophisticated reporting tools transform data into actionable insights, helping organizations drive strategic decisions.

Digital Twin Technology Digital twins create virtual replicas of physical logistics assets, such as warehouses, transportation routes, or entire supply chains. By simulating various scenarios, 3PL and 4PL providers can optimize operations, reduce risks, and improve resilience against unforeseen disruptions.

Future Trends: The Next Frontier

Looking ahead, the integration of autonomous vehicles, drones, and edge computing will further redefine logistics operations. As sustainability becomes a non-negotiable priority, green logistics technologies, such as carbon footprint tracking and optimized energy management systems, will become standard offerings.

Moreover, customer-centric innovations, such as personalized dashboards and enhanced last-mile delivery solutions, will continue to distinguish leading providers from the competition.

Conclusion

For 3PL and 4PL providers, technology adoption is no longer a choice — it is a strategic imperative. By investing in innovative solutions, these providers can elevate their operations from traditional logistics services to intelligent, value-driven partnerships. Embracing technological advancements today will position logistics organizations to meet the challenges of tomorrow with confidence, agility, and foresight.

0 notes

Text

Crouzet Products at Aeliya Marine: Powering the Future of Industrial Automation

In the constantly changing age of industrial automation, having trusted, precision-built components is key. Whether you’re creating new-generation technologies or supporting vital marine and industrial applications, the reliability of your automation components directly reflects your performance, efficiency, and bottom line.

Among the automation giants, Crouzet is a leader in innovation and excellence. Renowned for their world-class expertise in manufacturing relays, switches, controllers, and motion solutions, Crouzet has established a strong reputation through decades of uncompromising focus on quality.

At Aeliya Marine Tech, we are pleased to introduce you to an in-depth range of Crouzet products to fulfill your various industrial requirements. Be you an engineer, procurement manager, maintenance expert, or an automation enthusiast, Aeliya Marine is your go-to partner to source world-class Crouzet solutions with utmost confidence.

In this detailed guide, we’ll explore Crouzet’s rich legacy, the key categories of products they offer, the applications they power, and why Aeliya Marine is your go-to destination for purchasing authentic Crouzet automation equipment.

A Legacy of Innovation : Who is Crouzet ?

Established in France in 1921, Crouzet has grown its heritage through precision, dependability, and customer-driven innovation. It specializes in designing and producing automation control components for critical applications in diversified industries like aerospace, automotive, medical, rail, and industrial automation.

From the original electromechanical timers to today’s intelligent smart automation modules, Crouzet has remained dedicated to providing smarter, safer, and more efficient solutions. Its components are designed to withstand the toughest environments and provide high performance in the most demanding applications.

Nowadays, Crouzet is present globally, backed up by research and development labs, production plants, and a robust distribution partner network such as Aeliya Marine that makes its solutions readily available to customers worldwide.

Crouzet Product Categories Available at Aeliya Marine

At Aeliya Marine, you can find an extensive variety of Crouzet products designed to fulfill the needs of contemporary industrial control and automation solutions. Below is an overview of the main categories:

1. Timers and Counters Crouzet is world-renowned for its high-performance counters and timers. Applications vary from basic time-delay relays to intricate sequencing operations in production lines. Their products are characterized by high precision, durability, and flexibility with digital and analog models available.

Highlights:

Multi-function timers

Digital and analog counters

DIN rail and panel mount options

Long operational lifespan

2. Relays and Solid-State Relays

Crouzet relays are relied upon for switching applications between various voltages and currents, providing the highest reliability in control systems.

Types are:

Electromechanical relays

Solid-state relays (SSR)

Monitoring and measuring relays

Applications:

Control panels

HVAC systems

Automation systems

Machine tools

3. Switches and Sensors

For accurate detection and actuation applications, Crouzet provides a variety of switches and position sensors. Their limit switches, microswitches, and proximity sensors provide the reliability required in mission-critical systems.

Typical Uses:

Door interlocks

Conveyor belt systems

Safety monitoring

Industrial robotics

4. Motion Control Solutions

Crouzet’s electronic drives, brushless DC motors, and geared motors provide a trusted motion control for mobility and automation applications.

Product Range:

DC Brushless Motors

Stepper Motors

Gear Motors

Integrated Drives

Their efficiency, long lifetime, and small size make them ideal for medical equipment, mobile robots, and automated machinery.

5. Controllers and Programmable Logic Devices

In addition, Crouzet supplies programmable controllers, used extensively to automate small machines, process controls, and lighting systems. Easy yet robust, their Millenium 3 Logic Controllers are especially favored by OEMs and engineers seeking adaptable automation.

Important Features:

Easy to program

Expansibility

Multi-protocol communications

Why Crouzet ?

In today’s aggressive industrial and marine automation markets, Crouzet has a number of important differentiators:

Tried-and-True Reliability : Designed to withstand harsh environments, including marine applications.

Innovative Design : Crouzet continuously innovates, embedding new technologies to optimize functionality and usability.

Global Standards : Their products meet stringent international standards (such as IEC, UL, and CE) ensuring you’re investing in quality.

Versatility : Suitable for diverse applications from small devices to complex industrial machinery.

Industries Powered by Crouzet

The versatility and robustness of Crouzet products mean they are trusted across multiple industries:

Marine and Shipbuilding : Automation, navigation systems, motor controls, safety mechanisms.

Manufacturing : Robotics, conveyors, production lines, and quality control automation.

Aerospace and Defense : Aircraft systems, defense equipment, communication controls.

Medical Devices : Surgical devices, imaging systems, hospital automation.

Railway and Transportation : Train doors, signaling systems, and safety monitoring.

Energy and Environment : Wind turbines, solar trackers, and water treatment plants.

Why Buy Crouzet Products from Aeliya Marine?

Aeliya Marine Tech is not only another supplier — we are a specialized industrial and marine automation partner that customers trust globally.

Here’s why clients select us consistently :

Broad Selection : From old models to the newest Crouzet innovations — we carry it all.

Original Products : 100% original parts directly sourced from reputable manufacturers and distributors.

Competitive Prices : We think quality automation should be affordable.

Quick Global Shipping : No matter where you are in India, the Middle East, Europe, or the Americas, we ship quickly.

Expert Advice : Our technical experts help you choose the appropriate components for your projects.

Customer Satisfaction : Customized service, hassle-free buying, and post-sales support.

At Aeliya Marine, we know the vital role of dependable automation in industrial and marine processes. That’s why we don’t just sell products — we develop long-term partnerships with our customers, making their systems operate reliably and efficiently.

Featured Crouzet Products You Can Discover

Crouzet Timer Relay Series : Accurate time management solutions for automation cycles.

Crouzet 841 Series Relays : Compact, heavy-duty relays for switching.

Crouzet Limit Switches : Accurate detection in manufacturing systems.

Crouzet Millenium 3 Logic Controllers : Programmable, compact, flexible PLCs.

Crouzet DC Motors and Drives : Robust motors for industrial and robotic movement.

And many more!

How to Order Crouzet Products from Aeliya Marine

Ordering from Aeliya Marine is easy and hassle-free :

Browse our Crouzet collection here.

Select your required product(s).

Contact our sales team for a quotation if needed.

Checkout securely through our website.

Sit back and relax we’ll deliver your product safely and promptly.

For bulk orders, special discounts, or technical inquiries, you can also get in touch with us directly. We’re always ready to assist you!

Industrial and marine automation requires components engineered to perfection components that will be relied upon to perform, even in the most demanding conditions. Crouzet has consistently demonstrated that precision, quality, and innovation are the core of their solutions. And with Aeliya Marine Tech, we’re pleased to be able to bring these first-class solutions to you personally.

Settle for nothing less when it comes to your automation requirements. Discover the entire lineup of Crouzet products today at Aeliya Marine and fuel your success!

Shop Now Crouzet at Aeliya Marine Tech

#industrial equipment#automation#industrial spare parts#industrialautomation#industrial and marine automation#industrial automation#marine automation#pcb#amplifier#meter#Crouzet

0 notes

Text

Discover the rugged 3-pin knurled toggle switch with dual-position ON-OFF-ON functionality, 5A 125VAC rating, and anti-vibration locking. Ideal for industrial panels, machinery, and harsh environments.

Precision Control for Demanding Environments

The 3-Pin Knurled Handle Toggle Switch with Locking Mechanism (ON-OFF-ON, 5A 125VAC) delivers reliable circuit control in industrial, automotive, and commercial applications. Engineered for operators requiring tactile feedback and accidental activation prevention, this switch combines ergonomic design with MIL-SPEC durability.

Key Technical Specifications

✅ Electrical Rating: 5A 125VAC / 3A 250VAC (UL/CSA certified) ✅ Contact Configuration: SPDT (Single Pole Double Throw) ✅ Termination: 3 Quick-Connect 6.3mm Tab Terminals ✅ Actuation Force: 4.5N ±1N (Positive Tactile Feedback) ✅ Mechanical Life: 50,000+ Cycles (per IEC 61058-1) ✅ IP Rating: IP65 (Front Panel Seal Against Dust/Light Splashes)

Critical Design Features

1. Anti-Vibration Locking Mechanism

30° Toggle Lock Position Secures ON/OFF States in High-Shock Environments

Prevents Unintended Toggling in Mobile Equipment (Forklifts, AGVs, Tractors)

2. Knurled Grip Handle

Zinc Alloy Actuator with Diamond-Knurled Surface Enhances Glove-Friendly Operation

-40°C to +85°C Operational Range (MIL-STD-810G Compliant)

3. ON-OFF-ON Functionality

Dual Circuit Control for Forward/Reverse or Dual-Speed Motor Applications

Silver Alloy Contacts Ensure <100mΩ Contact Resistance

Industry Applications

Industrial Automation: CNC Control Panels, Conveyor Systems

Transportation: Marine Dashboards, Heavy-Duty Truck Consoles

Energy: Solar Inverter Switching, Generator Control

Safety Systems: Emergency Stop Circuits, Fire Suppression Activation

Why Engineers Specify This Switch

🔹 UL94 V-0 Flame-Retardant Housing – Meets IEC 60695-2-12 Glow-Wire Compliance 🔹 Tool-Free Installation – 13mm Panel Cutout with Integrated Lock Washer 🔹 EMI/RFI Shielding – Nickel-Plated Brass Stem Reduces Signal Interference

0 notes

Text

4 Types of Material Handling Equipment: A Complete Guide

Material handling equipment is crucial across industries, improving operational efficiency, ensuring safety, and increasing overall productivity. Whether it’s in warehouses, factories, construction sites, or logistics centers, the right material handling equipment ensures that goods and raw materials are stored, transported, and managed effectively. In this article, we’ll explore the different types of material handling equipment and how each type contributes to a seamless workflow.

What is Material Handling Equipment?

Material handling equipment consists of mechanical devices and systems designed to transport, safeguard, store, and manage materials across manufacturing, warehousing, distribution, and disposal processes. These tools minimize manual effort, reduce workplace injuries, and optimize the use of space and resources.

Major Types of Material Handling Equipment

Material handling equipment is typically divided into four main categories:

Storage and Handling Equipment

This type of equipment is used to hold materials for a short or long period. It’s ideal for inventory control, space optimization, and organization of goods.

Examples:

Pallet Racks: Ideal for storing goods on pallets in warehouse environments.

Shelving Units: Used for lighter goods and smaller inventories.

Bins and Containers: Keep small parts and components organized.

Stacking Frames: Allow secure stacking of loads while preventing damage or crushing to the products.

Mezzanines: Elevated platforms that expand storage without using extra floor space.

Benefits:

Reduces clutter

Enhances safety

Improves space utilization

Bulk Material Handling Equipment

This category is used for handling large volumes of loose materials such as sand, minerals, liquids, or grains.

Examples:

Conveyor Belts: Continuously move materials over long distances.

Hoppers: Hold and funnel bulk materials into a process.

Silos: Store bulk items like grains or cement.

Stackers: Move bulk materials into piles.

Reclaimers: Retrieve stored bulk materials.

Benefits:

Minimizes spillage

Handles high-volume materials efficiently

Reduces manual labour

Industrial Trucks

Industrial trucks are vehicles used to transport materials in facilities like warehouses and factories. These can be manual or powered.

Examples:

Forklifts: Lift and move heavy loads in short distances.

Pallet Jacks: Designed to lift and transport palletized loads with ease and efficiency.

Hand Trucks: Transport boxes or small packages.

Order Pickers: Help workers pick items from warehouse racks.

Tow Tractors: Pull heavy loads across longer distances.

Benefits:

Increases speed and efficiency

Reduces injury risks

Flexible and mobile

Engineered Systems (Automated Systems)

These are automated material handling systems designed for high-volume operations. They combine advanced software and hardware systems to optimize and automate the flow of materials seamlessly.

Examples:

Automated Storage and Retrieval Systems (AS/RS): Automatically store and retrieve items.

Conveyor Systems: Move materials between processes or stations.

Robotic Delivery Systems: Transport goods using AI and sensors.

Automated Guided Vehicles (AGVs):��Self-navigating vehicles used in warehouses.

Benefits:

Reduces manpower

Increases accuracy and speed

Supports smart inventory management

How to Select the Right Material Handling Equipment

When choosing the ideal material handling equipment for your needs, keep the following key factors in mind:

Type of Material: Know the size, weight, and sensitivity of the materials.

Volume of Goods: Choose equipment based on daily or hourly volume.

Operational Space: Optimize layout with space-saving options like vertical lifts.

Budget Constraints: Balance between cost and functionality.

Industry Regulations: Ensure compliance with safety and environmental standards.

Industries That Use Material Handling Equipment

Material handling equipment is vital across a range of industries, including:

Manufacturing

Warehousing and Distribution

Construction

Mining

Agriculture

Healthcare and Pharmaceuticals

Conclusion

Material handling equipment is essential to the core of both industrial and commercial operations. Understanding the various types of material handling equipment and their applications helps businesses select the right tools to optimize efficiency, ensure safety, and reduce operational costs. Whether you’re dealing with bulk materials or individual packages, investing in the right equipment can lead to long-term productivity and success.

Looking to upgrade your facility’s efficiency? Explore our wide range of high-quality material handling equipment tailored for every industry need!

0 notes

Text

Automated Material Handling Equipment Market: Innovations and Technological Advancements Reshaping Industries Worldwide

The Automated Material Handling Equipment (AMHE) market is experiencing significant growth, driven by advancements in technology and an increasing demand for efficient and cost-effective solutions in various industries. These systems are designed to automate processes such as the transportation, storage, and retrieval of materials in warehouses, manufacturing plants, distribution centers, and other industrial settings. AMHE includes a broad range of equipment, such as conveyors, automated guided vehicles (AGVs), cranes, robots, and sortation systems, all of which work together to streamline material flow and improve operational efficiency.

Market Drivers

Several key factors are contributing to the rapid expansion of the Automated Material Handling Equipment market. One of the main drivers is the increasing demand for automation in industries such as manufacturing, logistics, e-commerce, and retail. The need for faster and more accurate material handling solutions, as well as the growing pressure to meet customer demands for quick deliveries, is pushing companies to adopt automation technologies.

The rising labor costs and the shortage of skilled labor are also influencing the market. Many businesses are turning to automated systems to reduce reliance on human labor, thereby lowering operational costs and improving productivity. Additionally, automated systems can work around the clock, ensuring higher efficiency and reducing the chances of human error. This results in enhanced throughput, better utilization of resources, and improved safety.

Technological advancements in robotics, artificial intelligence (AI), and the Internet of Things (IoT) are also playing a crucial role in the growth of the market. AMHE systems are becoming increasingly intelligent and capable of performing complex tasks, such as inventory management, predictive maintenance, and real-time data analysis. These innovations make automation systems more versatile and adaptable to a variety of industries, thus broadening their applications.

Market Segmentation

The Automated Material Handling Equipment market can be segmented based on the type of equipment, end-user industry, and region.

By Type of Equipment:

Conveyors: These are commonly used in manufacturing and distribution centers for transporting goods and materials. Conveyors offer an efficient means of material handling by reducing the need for manual labor and enhancing operational efficiency.

Automated Guided Vehicles (AGVs): AGVs are mobile robots used to transport materials within a facility. They follow pre-programmed paths and are equipped with sensors to avoid obstacles, improving the flow of materials while ensuring safety.

Robotic Systems: Robotic systems, such as robotic arms, are widely used in material handling for tasks such as sorting, picking, and packaging. They are often used in combination with other automated equipment to optimize processes.

Cranes and Hoists: These systems are used for lifting and transporting heavy materials in industrial settings. Cranes and hoists are vital in sectors such as construction and manufacturing.

Sortation Systems: These systems are designed to sort products based on predefined criteria such as size, color, or destination. They are typically used in warehouses and distribution centers for efficient order fulfillment.

By End-User Industry:

E-commerce and Retail: The e-commerce industry is one of the largest adopters of automated material handling systems. With the increase in online shopping, there is a growing need for efficient fulfillment centers that can handle large volumes of orders quickly and accurately.

Manufacturing: In manufacturing, AMHE systems are used to streamline processes such as assembly, packaging, and delivery. The automotive and electronics industries, in particular, rely heavily on automated material handling to improve production efficiency.

Logistics and Warehousing: The logistics industry is also a major consumer of AMHE, as it allows companies to optimize their supply chains, reduce transit times, and improve inventory management.

Food and Beverage: In the food and beverage sector, automated systems are used for tasks such as sorting, packaging, and palletizing. These systems ensure that products are handled hygienically and meet safety standards.

Pharmaceuticals: Automated systems in the pharmaceutical industry are crucial for ensuring the accuracy and safety of products. They help with tasks such as inventory management, sorting, and packaging of sensitive pharmaceutical products.

Regional Insights

The Automated Material Handling Equipment market is experiencing significant growth across various regions, with North America, Europe, and Asia Pacific being key players.

North America: North America, especially the United States, is one of the largest markets for AMHE, driven by the high adoption rate of advanced technologies in industries such as e-commerce, manufacturing, and logistics. The region's strong focus on research and development, along with the presence of several key market players, is also contributing to market growth.

Europe: Europe is another prominent region in the AMHE market, with countries like Germany, the UK, and France leading the way. The European market is characterized by a high demand for automation in manufacturing, logistics, and e-commerce, particularly in countries with strong industrial sectors.

Asia Pacific: The Asia Pacific region is expected to see the highest growth in the Automated Material Handling Equipment market. This can be attributed to the rapid industrialization in countries like China, Japan, and India. The increasing demand for automation in manufacturing and logistics, coupled with the region’s large population and growing e-commerce sector, is driving market expansion.

Challenges

Despite the significant growth potential, the AMHE market faces several challenges. One of the main obstacles is the high initial cost of implementing automated systems, which can be a barrier for small and medium-sized enterprises (SMEs). Additionally, the complexity of integrating new automated systems with existing infrastructure can lead to disruptions in operations.

Moreover, the rapid pace of technological advancements in automation means that businesses must constantly invest in upgrading their systems to remain competitive. This presents a challenge for companies in terms of budget allocation and resource management.

Conclusion

The Automated Material Handling Equipment market is poised for substantial growth, driven by the need for efficiency, cost reduction, and technological advancements. As industries continue to embrace automation to meet the demands of modern supply chains, the market for AMHE is expected to expand significantly in the coming years. However, businesses must carefully consider factors such as initial costs and system integration to ensure successful adoption.

0 notes

Text

Built for the Mine: Heavy-Duty Solutions from COMET Equipment

Australia’s mining industry doesn’t slow down—and neither should your gear. At COMET Equipment, we design and deliver rugged tools that thrive in tough conditions. Whether you’re expanding operations or upgrading your fleet, our mining equipment, lorry water tank systems, and stacker reclaimer Australia units are built to perform without compromise.

Our range of mining equipment suits the fast-paced demands of Aussie worksites. From haul roads to processing plants, COMET supplies everything from mobile conveyors to crushing and screening gear that gets the job done. We focus on durability, uptime, and easy servicing, so your crew spends more time moving material and less time dealing with breakdowns.

Water is just as essential as machines on any site. That’s where a heavy-duty lorry water tank becomes a game-changer. COMET’s tanks are built for hard terrain and tougher jobs. They’re engineered to fit a wide range of lorries and come with spray systems designed for dust control, fire prevention, and haul road maintenance. With a COMET lorry water tank, your site stays safe, efficient, and compliant with environmental standards.

When stockpiling and material movement matter, our stacker reclaimer Australia range delivers the goods. Designed for high-capacity storage yards, our stackers and reclaimers are perfect for coal, iron ore, and bulk minerals. Built with strong frames, custom height adjustments, and smooth operational control, the COMET stacker reclaimer Australia lineup gives you reliability and throughput you can count on.

In this industry, there’s no room for second-rate tools. At COMET Equipment, we build and supply what Australian mining professionals need—gear that lasts, performs, and helps you deliver results. From the pit to the port, we’ve got the solution ready.

Browse the full range today at cometequipment.com and gear up for your next big project with confidence.

Source

0 notes

Text

What Is Automation in Operations? A Deep Dive into Its Impact on Palatine, Illinois Businesses

In recent years, automation in operations has emerged as a powerful force reshaping how businesses across Illinois function. In Palatine—a growing village within the Chicago metropolitan area—industries are rapidly adapting automation technologies to streamline workflows, boost efficiency, and enhance scalability.

Whether it’s a manufacturing plant using automated machinery or a logistics center implementing smart tracking systems, the transformation is visible across sectors. Businesses in Palatine, Illinois, are now recognizing that automation is no longer optional but essential for remaining competitive and agile in today's fast-paced market.

What Does Automation in Operations Actually Mean?

At its core, automation in operations refers to the use of technology—like machines, control systems, and software—to perform tasks that were traditionally done manually. These tasks may involve manufacturing, processing, monitoring, or even decision-making.

By integrating automation into operations, companies in Palatine can:

Reduce human error

Minimize repetitive labor

Increase productivity

Save time and money

Improve customer satisfaction through consistent output

From robotic process automation (RPA) in administrative tasks to programmable logic controllers (PLCs) in assembly lines, automation is making every facet of business more responsive and resilient.

Key Industries in Palatine Benefiting from Automation

Palatine is home to a mix of manufacturing, distribution, healthcare, and tech-based businesses. Automation plays a distinct role in each of these sectors, helping them scale while maintaining quality and cost-efficiency.

Manufacturing and Assembly Palatine’s proximity to industrial hubs in Illinois makes it ideal for manufacturers looking to modernize. With automation, local facilities can now rely on CNC machines, robotic arms, and automated conveyors to handle tasks that once took multiple shifts to complete. These systems also reduce the risk of injury and ensure higher output consistency.

Warehousing and Logistics The demand for faster delivery and real-time tracking has pushed logistics companies in Palatine to invest in warehouse automation. This includes:

Autonomous mobile robots (AMRs) Smart inventory management systems Automated sortation and packaging equipment

With these tools, operations become more efficient, and human workers are freed up for tasks requiring judgment and flexibility.

Healthcare and Medical Devices Palatine’s healthcare facilities and medical device manufacturers are also leveraging automation to handle high-volume processes with precision. From sterile packaging lines to automated diagnostic equipment, these solutions improve both patient safety and operational efficiency.

Food and Beverage Processing Automation ensures consistency in quality, taste, and safety in food production—something that’s critical to food manufacturers operating in and around Palatine. Automated mixers, dispensers, and inspection systems can significantly increase throughput while meeting strict regulatory standards.

Advantages of Adopting Automation in Local Operations

Integrating automation into day-to-day operations offers many advantages that go beyond simple productivity gains. For businesses in Palatine, Illinois these benefits include:

Enhanced Accuracy and Reliability Machines don’t tire, lose focus, or skip steps. By reducing manual intervention, automation ensures greater consistency and accuracy—especially important in industries like pharmaceuticals and electronics.

Cost Savings Over Time Though automation may require a higher upfront investment, it often results in long-term cost reductions by decreasing labor costs, minimizing waste, and reducing downtime.

Scalability and Flexibility Automated systems can easily adapt to different product lines or changing workloads. This scalability allows Palatine businesses to grow without a complete overhaul of their infrastructure.

Improved Data and Decision-Making Many automated systems provide real-time data and analytics, empowering businesses to make informed decisions. This insight is vital for continuous improvement and optimizing resource allocation.

Challenges Faced and How Palatine Businesses Are Overcoming Them

Despite its numerous benefits, automation isn’t without challenges—especially for small to mid-sized enterprises (SMEs). Concerns include:

Initial cost of installation Integration with existing systems Employee resistance to change

However, businesses in Palatine are actively overcoming these hurdles through phased implementation and workforce training. Community colleges and technical institutes in the area also offer courses in automation technology, helping bridge the skills gap and prepare workers for the future of industry.

Automation in Operations and the Human Workforce

One common misconception is that automation replaces human jobs entirely. In reality, it often transforms them.

In Palatine, we’re seeing a shift where routine tasks are automated, allowing workers to focus on more strategic, creative, or safety-critical roles. For example, instead of manually inspecting each unit on an assembly line, workers now oversee quality control systems and use data dashboards to make decisions.

By automating low-value tasks, companies also improve job satisfaction and reduce burnout, creating a healthier work environment.

The Future of Operational Automation in Palatine, Illinois

Looking ahead, the automation trend in Palatine is only expected to grow. With technologies like artificial intelligence, machine learning, and the Internet of Things (IoT) gaining traction, the possibilities for automation are expanding every day.

Imagine predictive maintenance systems that can fix equipment before it fails, or AI-driven scheduling tools that adapt production in real time based on customer demand. These aren’t distant dreams—they’re becoming a reality right here in Palatine.

To fully benefit, businesses must continue to invest in innovation, prioritize workforce development, and collaborate with trusted automation experts.

Start Your Automation Journey Today

If your business in Palatine, Illinois is ready to integrate smarter systems into your daily operations, professional support is key. Partnering with an experienced automation provider ensures smooth planning, installation, and maintenance of your systems.

One such reliable partner is Xtreme Automation LLC. With a focus on engineering excellence, smart control systems, and industrial automation, they serve businesses across Illinois with customized automation solutions built for real-world performance.

0 notes