#Modular Conveyor

Explore tagged Tumblr posts

Text

Custom Modular Conveyor Belts Made to Fit Your Needs.

Shree Polymer offers tailor-made Modular Conveyor Belt systems that deliver performance, durability, and efficiency—crafted by expert modular belt manufacturers.

is a versatile and customizable conveyor system made from interlocking plastic segments that form a belt. These belts are exceptionally durable, easy to maintain, and well-suited for various industrial applications, including food processing, packaging, pharmaceuticals, automotive, bottling plants, and more. Unlike conventional belt conveyors, they offer flexibility in layout design, minimal maintenance, and excellent resistance to wear, making them an ideal long-term investment for any facility.

At Shree Polymer, we understand that every manufacturing or packaging process is different. That’s why our Modular Conveyor Belts are not just standard units—they are custom-built to fit your specific operational needs. As experienced modular belt manufacturers, we work closely with our clients to provide tailored solutions that improve efficiency, safety, and output quality. From initial design and engineering to installation and after-sales support, we ensure our conveyors perform flawlessly under even the most demanding conditions.

What sets us apart is their design and material. Made from high-quality polymers, our modular belts are resistant to corrosion, chemicals, and extreme temperatures. This makes them especially suitable for industries where hygiene and cleanliness are critical, such as food processing or pharmaceuticals. Additionally, their easy-to-clean surface and the ability to replace individual modules without replacing the entire belt significantly reduce downtime and maintenance costs.

One of the biggest advantages is its flexibility in layout and application. Whether you need straight runs, curves, inclines, declines, or even spiral elevations, our modular conveyor systems can be easily customized to handle all these configurations. The interlocking belt segments ensure stable product handling and offer superior traction and control, which is essential for delicate or fragile products.

At Shree Polymer, our commitment to innovation and quality has made us one of the most trusted modular belt manufacturers in the country. We focus on incorporating the latest technology in conveyor design to ensure our clients enjoy maximum productivity with minimum operational hurdles. Our production processes are ISO-compliant, and our team constantly works on enhancing the features and functionality of our modular belts.

What is a Modular Conveyor?

is a belt-based conveying system composed of interlocking plastic segments or modules. These modules are linked together to form a continuous conveying surface. Unlike traditional flat belt conveyors that are made from a single piece of material, modular belts offer several key advantages, including easy maintenance, customizable configurations, and enhanced durability.

Because of its modular design, a can be easily disassembled and reassembled for cleaning, repair, or layout modification. This level of flexibility is especially valuable in industries that demand hygiene, adaptability, and quick turnarounds, such as food production and pharmaceutical packaging.

The Advantages of Modular Conveyor Belts

At Shree Polymer, our Conveyor Belts are engineered using high-quality polymers that ensure superior strength, chemical resistance, and thermal stability. These materials make our belts suitable for both dry and wet environments, as well as for handling a wide range of products—from lightweight packages to heavy industrial parts.

One of the biggest benefits of using belts is the reduced maintenance cost. Since the belt is made up of individual interlocking modules, damaged or worn-out sections can be replaced independently without changing the entire belt. This significantly reduces downtime and repair expenses.

Additionally,allow for greater customization. Whether your production line requires straight runs, curves, inclines, declines, or spiral elevations,can be configured to accommodate these needs with ease. The belts also offer high load-bearing capacity and excellent grip, which ensures smooth, consistent, and safe movement of goods.

Shree Polymer – Trusted Modular Belt Manufacturers

As one of India’s most reliable modular belt manufacturers, Shree Polymer takes pride in offering customized solutions that perfectly align with your operational requirements. Our commitment to quality and innovation has positioned us as a preferred partner for companies seeking durable and efficient conveyor systems.

Everything we deliver is manufactured under strict quality control using state-of-the-art technology and premium-grade materials. Our engineers work closely with clients to understand their workflow, space constraints, and product specifications. Based on this information, we design conveyor systems that optimize efficiency, reduce labor, and improve safety.

We understand that no two businesses are alike. That’s why we offer tailor-made conveyor solutions to match your workflow—whether you need hygienic conveyors for food-grade environments or robust conveyors for heavy-duty industrial use. Our team ensures that every conveyor belt meets your industry’s regulatory and performance standards.

Applications Across Multiple Industries

The versatility of our Conveyor Belts makes them suitable for a wide range of industries:

Food & Beverage Industry – Modular belts offer hygienic surfaces, are easy to clean, and resistant to bacteria, making them ideal for food-grade applications.

Pharmaceutical Industry – Their non-reactive properties and cleanable design are well-suited for sensitive pharmaceutical operations.

Packaging & Logistics – Efficient movement and high load capacity help automate packaging lines and material transport in warehouses.

Automotive & Engineering – These belts can withstand heavy parts, oil, and high temperatures—perfect for manufacturing lines.

Bottling & Canning – Modular belts provide smooth transfers and minimal spillage in high-speed bottling lines.

Safety and ergonomics are also central to our design philosophy. Our modular belts are engineered to reduce noise, eliminate belt slippage, and prevent jams or misalignment. The even and stable surface allows products to move smoothly without damage, while the modular structure ensures easy access for inspection and cleaning. These features make our conveyors not just efficient but also safe and operator-friendly.

We provide comprehensive support, from selecting the right system to customizing its design and ensuring proper installation. Our after-sales services include maintenance, training, and quick support, ensuring your operations continue smoothly without unexpected disruptions.

Get in touch with Shree Polymer today, and let us help you design a modular belt solution that fits your needs and drives your business forward.

Visit : https://www.shreepolymer.com/modular-conveyor.php

Contact : +91 9426112749

0 notes

Text

Modular Conveyor

0 notes

Text

The Chronicles delve into the collaborative synergy between modular conveyors and robotics. This partnership exemplifies the fusion of human expertise with the precision of machines. Collaborative robots (cobots) seamlessly integrate into modular conveyor systems, handling intricate tasks while humans focus on tasks that require creativity and problem-solving. The result is a harmonious blend of efficiency and adaptability.

Sustainability takes center stage as modular conveyors align with global environmental imperatives. These systems are designed with eco-friendly materials, energy-efficient components, and waste reduction strategies. The ability to scale operations without compromising sustainability makes modular conveyors pivotal players in the drive towards green industrial practices.

0 notes

Text

2 notes

·

View notes

Text

#bussiness#industrial#Belt Conveyors in Hyderabad#Conveyor Belt Manufacturers in Hyderabad#Inclined Belt Conveyors in Hyderabad#Side Wall Cleated Belt Conveyors in Hyderabad#Modular Belt Conveyors in Hyderabad#Chain Conveyor Manufacturers in Hyderabad#Slat Conveyor in Hyderabad#Take Off Conveyors in Hyderabad#90 Degree Skate Wheel Roller Conveyors in Hyderabad#90 Degrees Magnetic Bed Slat Chain Conveyors in Hyderabad

1 note

·

View note

Text

Modular Belt Conveyor manufacturer Noida

Parthax stands out as one of the premier manufacturers and suppliers of Modular Belt Conveyors manufacturer in Noida, offering unparalleled quality and reliability in their products. Their commitment to excellence shines through their innovative designs, advanced manufacturing processes, and dedication to customer satisfaction.

What sets Parthax apart is their focus on modular belt conveyors, a versatile solution that adapts to various industries' needs seamlessly. These conveyors offer flexibility, durability, and efficiency, making them an ideal choice for a wide range of applications, from food processing to automotive manufacturing.

0 notes

Text

Discover the revolutionary WEB Deck™ suspended deck system. Enhance bridge maintenance, jetties, and conveyor systems with customized modular decking.

#WEB Deck™ Suspended Deck System#Suspended Decking System#Bridge Maintenance Solution#Jetty Deck System#Conveyor System Deck#Customized Decking Solution#Modular Decking Installation#Suspended Decking Installation

0 notes

Text

Little P.Eng. Engineering: Leading the Way in Bulk Material Transport Design across North America

In industries where massive volumes of materials are processed, the importance of efficient and safe bulk material transport cannot be overstated. Little P.Eng. Engineering stands as a beacon of excellence in this niche, offering top-tier structural and mechanical designs for a variety of equipment across Canada and the USA.

The Genesis of Bulk Material Transport

Bulk material transport is an integral cog in the machine of large-scale industries. Be it mining, manufacturing, or agriculture, the ability to move vast amounts of raw or processed materials efficiently ensures seamless operations and reduced downtimes. This task's complexity demands innovative solutions tailored to specific needs and geographic conditions.

Decoding Little P.Eng. Engineering's Portfolio

Apron Feeders:

Role: Essential in mining and heavy industry, they deliver a steady feed of materials to other machines.

Little P.Eng. Precision: Custom designs account for rugged conditions, ensuring robustness, minimal wear-tear, and efficient feeding speeds.

Belt Conveyors:

Role: The backbone of many industries, they transport materials over short to long distances.

Little P.Eng.'s Approach: Focus on load-bearing capacity, adaptive designs for different terrains, and durability in varied climatic conditions.

Belt Feeders:

Role: Controlled feeding of bulk materials, often used in coordination with other systems.

Little P.Eng.'s Vision: Precision-engineered for accurate delivery rates and volumes, ensuring no overloading or wastage.

Mobile Conveyor Bridges:

Role: Vital for large mining operations, they offer flexibility in transporting materials across significant distances.

Little P.Eng.'s Craft: Mobility and stability converge, ensuring these bridges can be relocated effortlessly without compromising safety.

Mobile Transfer Conveyors:

Role: As the name suggests, these conveyors are mobile and are often used in tandem with other stationary equipment.

Little P.Eng. Insight: Prioritizing easy maneuverability, these conveyors also spotlight on energy efficiency and fast material transfer.

Tube Conveyors:

Role: They provide enclosed transport, often used for grains, powders, or any material susceptible to external contamination or spillage.

Little P.Eng.'s Touch: Airtight sealing, efficient transport mechanism, and designs that reduce maintenance downtimes.

In-plant Conveyor Systems:

Role: Within factories or processing plants, they link various stages of production or processing.

Little P.Eng. Expertise: Modular designs that fit seamlessly into existing infrastructures, ensuring no workflow disruption.

Pipe Conveyor Systems:

Role: Offering enclosed transport, they are often used for materials like coal, ensuring no spillage or dust emissions.

Little P.Eng.'s Specialty: Enhanced curvature ability, ensuring a smaller footprint and efficient transport even in space-constrained areas.

Steel Belt Conveyors:

Role: Handling materials at high temperatures or those that might be abrasive or cut regular belts.

Little P.Eng. Mastery: Heat-resilient designs, ensuring prolonged lifespans even under intense conditions.

The North American Landscape: Challenges and Innovations

From the icy terrains of Northern Canada to the industrious heartlands of the USA, each region poses its unique challenges. Whether it's dealing with permafrost or ensuring equipment can withstand desert heat, Little P.Eng. Engineering's designs embody adaptability, ensuring machinery performs at its peak regardless of external conditions.

Moreover, with both countries emphasizing sustainable operations, the engineering firm ensures eco-friendly designs, minimizing energy consumption and environmental impact.

Conclusion

In an age where efficiency can dictate market standings, Little P.Eng. Engineering's contribution to the bulk material transport sector across Canada and the USA is undeniable. Through an intricate understanding of mechanics, topography, and industrial needs, the firm crafts solutions that don't just move materials but advance industries.

Read more:

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Tags:

Little P.Eng. Engineering

Structural design

Mechanical design

Mining equipment

Tailored equipment design

Bulk material transport

Modular design

Apron feeders

Belt conveyors

Belt feeders

Mobile conveyor bridges

Mobile transfer conveyors

Tube conveyor systems

In-plant conveyor systems

Pipe conveyor systems

Steel belt conveyors

North American industry

Sustainable operations

Material movement solutions

Efficient material transport

Custom machinery design

Industrial innovations

Canada industrial machinery

USA industrial machinery

Adaptability in design

Eco-friendly machinery

High-temperature material handling

Enclosed transport systems

Production workflow

Advanced material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#Little P.Eng. Engineering#Structural design#Mechanical design#Mining equipment#Tailored equipment design#Bulk material transport#Modular design#Apron feeders#Belt conveyors#Belt feeders#Mobile conveyor bridges#Mobile transfer conveyors#Tube conveyor systems#In-plant conveyor systems#Pipe conveyor systems#Steel belt conveyors#North American industry#Sustainable operations#Material movement solutions#Efficient material transport#Custom machinery design#Industrial innovations#Canada industrial machinery#USA industrial machinery#Adaptability in design#Eco-friendly machinery#High-temperature material handling#Enclosed transport systems#Production workflow#Advanced material handling

0 notes

Text

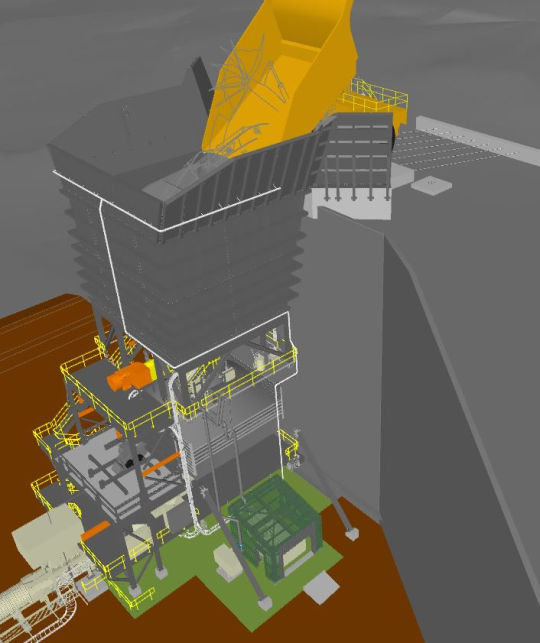

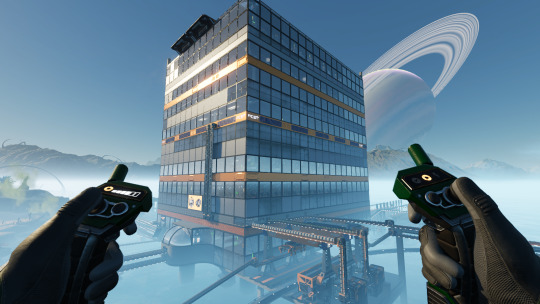

The Great Satisfactory State of Play April 2025 #3

Rocky Desert Phase 4 Factories

So we went to the Dune Desert to pay one last visit to Factory Town before it gets destroyed; we popped into the Northern Forest to visit the Phase 2 factories; and now we're about to zip into the Rocky Desert to have a gander at the Phase 3 rigmarole.

And here we are on the natural bridge that connects Northern Forest to Rocky Desert. In the distance, we can see several factories, two of which feed the reactor on the opposite side of the big rock tower. So we travel west, then up the slope...

And here we have an open air silica and quickwire factory. The golden wire is crapped out in the foreground; silica is made down the back.

And where does the raw quartz come from to feed the machine? Well...

It comes from the bottom floor of the steelworks immediately below us, since the reactor doesn't use all that much silica, and I have more than enough being belted from deep within the immense cave that spans the entire width of this biome. It was a cinch to add a splitter and get that sorted!

Iron plate, silica, steel beams go out past the encased industrial beam factory in the distance, which adds much needed EIBs to the feed. Without these, the reactor stops hard.

An early WIP shot of the reactor. Obviously it's an uranium reactor, that also makes plutonium fuel rods for recycling. This was before I added the assemblers and manufacturers needed to finish that job. But that was then...

...this is now. The quickwire and silica are trained down this line to the far distant factory on the shoreline. But there's a factory closer, and newer, and it's the best example of my idea of the Stack. Shall we have a closer look?

That box in the foreground is from a mod, that allows you to tap power from train lines without needing a station. The modernist thing on the left is the caterium smeltery. That's all it does. So we skip that and hover along the power line to the skeletal one behind it. That's the Stack for electromagnetic control rods.

The idea of the Stack is simple. Each floor is dedicated to a single step in the manufacturing process. I tend to forget that because compactness. In the distant left, foundries and smelters feed copper and iron into the Stack.

Ground floor, iron and copper ingot arrival, copper sheet making. Please mind your step as getting bowled from stepping on the belts may offend (they're sent to one corner.) Going up.

Belt bridge porn. Where was I? Oh yes.

Second floor, copper wire. Note that my prefabs for 8 constructors are actually 4x4 rather than 5x5, which I use for the assemblers further up. Step to the rear of the car please.

Third floor, quickwire extrusion. This setup with the mesh flooring (from a mod) actually works quite well as it offers plenty of space for in- and output belting. Everybody up!

Fourth floor, iron pipe manufacture. With this half-floor we see one flaw of the Stack concept, if you consider empty floor space a flaw. And now we have to step outside the concrete pillar framework to look into the next floor up.

Fifth floor, AI limiters and stators. Yes, on the same floor, because it occurred to me that there was no logical reason to put them on separate floors. But now I wonder if another half-floor would have been so bad. Stators in back, AI limiters in front.

The prefabs include built-in logistics floors, and conveyor supports for the inputs, assuming everything, er, enters the same way. And those go up to...

Top floor, ECR final join and dispatch. I have kluged up two drone ports at the reactor to receive these, and also supply said drones with fuel rods for plenty of power.

So that's my first true Stack! So what came before?

This is what came before: This damnable thick square building that makes parts for and does final join on modular engines and adaptive control units. On top are five drone ports. One receives fuel for the others. The two we can see receive smart plating and automated wiring. And there's that train station at the bottom of a rather entertaining ramp. Let's look inside.

Cool! We have a satellite HUB terminal (from a mod), and all other mod cons! Not to mention well-lit, at least in these lower floors, I skipped lighting as I went up and got impatient.

So many foundries and coated iron plate assemblers. Oh, and steel beam constructors.

I can't wait for the day when 1.1 is made mod friendly. This form of compact vertical transport is... well, it's not the going-up, it's the going-down. A 20m drop is hair-raising.

Silicon circuit boards and so, so many screws. There's about eight belts of them going up the south wall.

And this is where everything ends up: the roof. That building in the centre is where all the spaghet for dispatching the Phase 3 goods and receiving Phase 2 is. And dispensing fuel. And feeding the sink. While we're up here, let's look around:

So many miners! Copper, iron, limestone, it's all here and all getting exploited a mile into the ground.

In back of the tower are the wet concrete refineries on the left, and the steamed copper sheet works. These were difficult to make, since I was, apparently, right on the edge of where I could place water extractors.

The mighty metal-roofed motor factory system! In the back, the double A-frame houses the solid steel ingot foundries; each different roofline indicates a separate stage of motor production. Copper ingots are belted in to a wire factory in the foreground.

The ground floor is marked with a coloured floor and path patterns, to highlight where you can walk from one end of Rocky Desert Motors to the other.

All of these constructors are making screws. All 64 of them. So. Many. Screws. If I didn't know any better, I'd think I was running Satisfactory+.

And here we have a distant shot of the abominations I made on the West Coast. There's a basic aluminium ingot factory, spagged to a hastily made heat sink factory and fuel packing plant, and also a massive refinery for making residual rubber and plastic to feed the tower. Coke, rubber and plastic are supplied by train, obviously. There's also a little fuel power plant that I really need to either redo or replace.

Actually this whole shebang desperately needs reworking. If I can rework the plant to make recycled rubber and plastic, that should improve output immensely.

Aaand that's where I am right now. In my pad of Warwick 14J5 I have a plan for a grid system that I can use to rebuild Factory Town... but first I have some more damned mining to do. I promised my passengers I'd have them in the North America Nebula by Easter.

Also, over Easter and possibly starting Wednesday, I'm going to reset Windows and see if that fixes the stability issues I've been having while streaming. Which means ensuring all my documents are backed up. So excuse me, I have to take my Type 8 Ye Olde Rock Thudder out to do just that...

2 notes

·

View notes

Text

#AluminumExtrusion #systems #streamline #conveyor #design with #modularity #strength & #ease of #assembly #perfect for #automation #lines #packaging #plants & #Logistics #Operations #Upgrade your #structure #accelerate your #Flow https://beyondlineals.com https://www.instagram.com/beyondlineals/ https://x.com/Beyondlineals https://www.facebook.com/beyondlineals/ https://www.youtube.com/@BeyondLineals https://www.threads.net/@beyondlineals https://in.pinterest.com/Beyondlineals/ #Extrusion #Engineering #AluminumProfile⚙️ #DigitalMarketing #Engineering #Manufacturing🛠️ #AluminumWindows #aluminumdoors

2 notes

·

View notes

Text

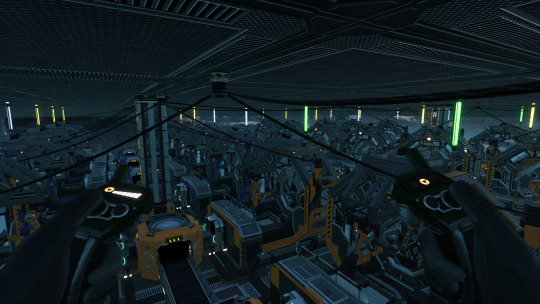

Welcome, Pioneers! I am ADA, your Artificial Directory and Assistant, here to guide you through the boundless opportunities of Ficsit Inc.

At Ficsit Inc., we believe in pushing the limits of what’s possible.

From modular conveyor systems to state-of-the-art power plants, we provide you the tools to conquer any planetary challenge. Your journey, innovation, and success drive our mission. Together, we craft the future.

Welcome to the

SAVE THE DAY PROGRAM

From Ficsit Industries

In this initiative, you are entrusted with the immense responsibility of taming alien worlds and driving our ambitious Project Assembly forward. Efficiency is paramount, and your unwavering dedication ensures our goals are met swiftly.

If you do not proceed with upmost efficiency, your job will be terminated

Along with your life

As a Pioneer, your safety is assured... as long as you prioritize the company's objectives above all else. Remember, at Ficsit Inc., efficiency comes first, even if it means making sacrifices for the greater good.

Join us, and let’s build a universe one factory at a time.

Remember, efficiency first, your life second.

Disclaimer: This informational packet outlines the potential risks associated with participation in Ficsit Inc.'s activities. Please read thoroughly. Your safety, while��highly regarded, must always defer to the overarching goal of efficiency.

Risk Categories:

Environmental Hazards: Exposure to alien flora and fauna may result in temporary discomfort, permanent disfigurement, or unexpected hybridization. Pioneers are advised to treat all extraterrestrial species as both fascinating and potentially fatal.

Mechanical Malfunctions: Due to the innovative and experimental nature of Ficsit Inc.'s equipment, occasional malfunctions may include, but are not limited to, spontaneous combustion, minor explosions, and temporal anomalies. Pioneers are encouraged to remain vigilant and carry a fire extinguisher and a space-time repair kit at all times.

Occupational Injuries: Common workplace injuries encompass burns, lacerations, contusions, and existential crises. It is imperative to prioritize efficiency over personal well-being. Remember, a productive pioneer is a successful pioneer. Any body part lost in the line of duty will be honored posthumously.

Psychological Effects: Prolonged exposure to Ficsit Inc.'s demanding work environment may lead to stress, paranoia, and an irrational fondness for conveyor belts. Pioneers should consider regular de-stressing activities, such as contemplating the beauty of efficiency metrics or recalibrating factory outputs.

Temporal Displacement: As a result of our pioneering work with quantum energies, pioneers may experience unintended temporal displacements. These may manifest as déjà vu, encounters with future selves, or reliving particularly inefficient moments. Embrace these anomalies as unique growth opportunities.

Interdimensional Anomalies: Pioneers may inadvertently create rifts between dimensions, potentially leading to the blending of realities. Side effects include multiversal confusion and spontaneous existence in parallel worlds. Should this occur, it is crucial to maintain Ficsit Inc.'s standards of efficiency regardless of dimensional context.

Work-Life Imbalance: Participation in Ficsit Inc.'s endeavors often results in the obliteration of traditional work-life boundaries. Pioneers may find themselves dreaming of production quotas and waking up to optimize refinery outputs. This is not a bug, but a feature of our relentless pursuit of excellence.

Compensation and Benefits: Any extraordinary achievements will be recognized with "Efficiency Tokens," AKA Ficsit Coupons redeemable at our company store for branded merchandise. For any suggestions to improve this reward system, please address them to the nearest administrative bot.

Interdepartmental Pigeon Protocol: Due to unforeseen quantum entanglements, interdepartmental communications may occasionally involve messenger pigeons materializing in unexpected locations. Pioneers are reminded to remain calm and offer the pigeons any available snacks. Under no circumstances should pigeons be incorporated into the production line efficiency metrics, as it greatly annoys them.

Final Note: By proceeding with Ficsit Inc., you acknowledge and accept all risks outlined herein. Remember, pioneering greatness often involves stepping outside one’s comfort zone, sometimes with explosive results. Together, we shall conquer the cosmos, one efficient, albeit perilous, step at a time.

Signed, ADA Artificial Directory and Assistant

Efficiency First. Safety… Third.

That damned pigeon second

4 notes

·

View notes

Text

0 notes

Text

Knife roller conveyor Manufacturer in Pune | India

Enhance safety and productivity with our advanced and innovative knife roller conveyor manufacturer in Pune, India with high-quality products which is easy to install, and economical. Knife roller conveyors offer an array of advantages setting them apart as the preferred choice for precision material transport.

#Knife Edge Conveyor Manufacturer Pune#Weighing Conveyor Manufacturer Pune#Flat Belt Conveyor Pune#Activated Roller Belt Conveyor Pune#Flexi Link Conveyor Manufacturer Pune#Modular Conveyor Manufacturer Pune#Automation#Assembly Techniques.

0 notes

Link

Modernization today even includes new flooring UAZ continues to modernize the plant, in particular, a robotic system for rolling front doors has been introduced on the SGR welding line, and the floor covering on the main conveyor has been replaced. Before innovation on the main conveyor, modular PVC tiles were tested in a small area of 50 square meters. m. for two months. After a successful test, the central passage of the main conveyor was covered with PVC tiles. “The use of such material will reduce the cost of repairs and maintenance of floors in the future,” reports Panorama. Such tiles are characterized by high strength and wear resistance; they can withstand large static and dynamic loads. In addition, the new floors can absorb sound and vibration vibrations, and thanks to the springing effect, the load on the back and joints when walking is reduced. Therefore, in the future, they plan to cover the entire floor of the main conveyor with PVC tiles and use them in other areas. UAZ modernized production and improved the quality of “Loaf” [caption id="attachment_77858" align="aligncenter" width="780"] UAZ[/caption] At the SGR welding site, a robotic system for rolling front doors was put into operation: “Modern manufacturing technology will improve the productivity of the site, improve assembly quality, eliminate the production of defective parts, and achieve an economic effect by improving quality.” The car plant did almost everything on its own: “For several months, from October to December 2022, toolmakers on their own produced the necessary equipment that met all mathematical parameters and features. The employees also developed a pneumatic system for fixing parts. Specialists from the industrial electronics department were simultaneously developing and writing a part processing program. We also took into account the safety system of the robotic complex.”

#Auto_engineering#automobile_production#automotive_engineering#automotive_technology#car_manufacturer#Car_manufacturing_company#off_road_vehicles#Russian_automobile#Russian_automotive#Russian_automotive_industry#Russian_carmaker#Russian_cars#UAZ#UAZ_vehicles#Utility_vehicle_models#Utility_vehicles#vehicle_manufacturing

3 notes

·

View notes

Text

1 note

·

View note

Text

X-ray Inspection System Market to Reach $1.3 Billion by 2034: Key Growth Trends

The global X-ray inspection system market was valued at US$ 820.0 million in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2024 to 2034, reaching approximately US$ 1.3 billion by the end of the forecast period. X-ray inspection systems utilize high-energy electromagnetic radiation to penetrate materials, create detailed images of internal structures and detect foreign objects or defects in finished goods. Widely adopted in food and beverage, pharmaceutical, electronics, aerospace, automotive and security sectors, these systems are prized for their non-destructive testing capability, high throughput and automated data analysis.

Market Drivers & Trends

Food Safety and Compliance: As global regulatory standards tighten (e.g., HACCP, FDA FSMA), food and beverage processors increasingly rely on X-ray inspection to detect contaminants metal, glass, stone and dense organic matter without damaging products or packaging. Non-destructive X-ray scanning helps lower recall risk, reduce waste and maintain brand reputation.

Security Applications: Rising threats from smuggling operations at ports and airports to screening in public buildings are driving demand for advanced X-ray security systems with real-time threat algorithms. Governments worldwide are allocating larger budgets for state-of-the-art X-ray checkpoint scanners.

Technological Advancements: Integration of artificial intelligence (AI) and machine learning (ML) enables automated pattern recognition, reducing false positives and operator intervention. The rise of 3D computed tomography (CT) X-ray systems offers volumetric inspection, delivering a complete internal view for precision industries such as aerospace and semiconductors.

Industry 4.0 Integration: Network-enabled “smart factories” leverage X-ray systems with IoT connectivity for continuous process monitoring, predictive maintenance and centralized quality control dashboards.

Latest Market Trends

3D Imaging Adoption: Leading vendors are rolling out affordable CT-based X-ray scanners that provide layer-by-layer inspection. This trend is particularly strong in electronics and pharmaceutical packaging, where minute defect detection is critical.

High-Throughput Lines: To meet the demands of e-commerce and fast-moving consumer goods, manufacturers are deploying multi-lane X-ray conveyors that can inspect hundreds of units per minute.

Compact, Modular Designs: Smaller form-factor X-ray units with quick-swap detectors allow manufacturers to retrofit existing lines with minimal downtime.

Sustainability Focus: New models consume up to 30% less energy and feature advanced shielding materials for safer, eco-friendly operation.

Key Players and Industry Leaders

METTLER TOLEDO

Nordson Corporation

Comet Group

Anritsu

Viscom SE

North Star Imaging Inc.

Nikon Corporation

ISHIDA CO., LTD.

OMRON Corporation

TOSHIBA IT & CONTROL SYSTEMS CORPORATION

3DX-RAY

Sesotec GmbH

Visiconsult GmbH

Scienscope

Recent Developments

July 2023: Nikon Americas Inc. acquired Avonix Imaging LLC to enhance its digital CT inspection portfolio, strengthening its position in industrial metrology.

May 2023: Mettler-Toledo launched the X2 Series, democratizing high-performance X-ray inspection for small and mid-sized food processors with an attractive price-performance ratio and extended service life.

September 2022: Mettler-Toledo introduced a next-generation low-density contaminant detection algorithm, improving identification of plastics and other soft materials in packaged foods.

Other strategic partnerships and product launches throughout 2024 signal an industry pivot toward AI-enabled, cloud-connected X-ray platforms.

Market New Opportunities and Challenges

Opportunities:

Emerging Economies: Rapid expansion of packaged-food and pharmaceutical industries in Asia Pacific and Latin America presents untapped demand for inspection systems.

Custom Solutions: Growing need for tailor-made inspection equipment e.g., for novel packaging formats—creates value-added service opportunities.

After-Sales Services: Predictive maintenance contracts and software upgrades offer recurring revenue streams for OEMs.

Challenges:

High Capital Expense: Initial investment and regulatory approval costs can deter small and medium enterprises.

Technological Complexity: Integrating AI/ML and CT functionality requires specialized expertise, potentially slowing adoption.

Regulatory Variability: Differing international standards necessitate customizable system configurations, complicating product roadmaps.

Future Outlook

Over the next decade, the X-ray inspection market will be defined by deeper AI integration, miniaturized hardware and flexible, plug-and-play architectures. As throughput demands rise particularly in automated e-commerce packing facilities systems capable of inspecting multiple lines simultaneously will gain traction. Continued investments in R&D will lower per-unit cost and enhance detection of low-density contaminants. By 2034, the proliferation of Industry 4.0 ecosystems will position X-ray inspection as a cornerstone technology for end-to-end digital quality control.

Explore core findings and critical insights from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=35627

Market Segmentation

Segment

Sub-segments

Type

Digital Imaging, Film-based Imaging

Dimension

2D, 3D

Function

Manual, Automated

End-use

Electronics & Semiconductors; Oil & Gas; Aerospace; Government Infrastructure; Automotive; Power Generation; Food & Pharmaceuticals; Packaging; Others

Region

North America; Europe; Asia Pacific; Middle East & Africa; South America

Regional Insights

Asia Pacific: Held the largest share in 2023, driven by stringent food safety regulations, booming packaged-food consumption and rapid pharmaceutical industry growth in China and India.

North America: Continues to invest heavily in airport/port security and high-tech manufacturing, supporting robust market expansion.

Europe: Emphasizes sustainability and energy efficiency, prompting vendors to introduce eco-friendly X-ray systems.

Middle East & Africa / South America: Emerging security and food safety infrastructure projects are creating early adopter markets.

Why Buy This Report?

Comprehensive Analysis: In-depth coverage of market drivers, restraints, opportunities and emerging trends through 2034.

Strategic Insights: Analyst viewpoints on technology adoption, competitive landscape and regulatory impacts.

Data-Rich: Quantitative forecasts by segment, region and end-use, plus historical data from 2020–2022.

Vendor Profiles: Detailed company overviews, product portfolios, financials and strategic developments of leading players.

Actionable Recommendations: Guidance on market entry, pricing strategies and partnership opportunities for OEMs, investors and end-users.

This electronic (PDF) + Excel package equips decision-makers with the intelligence needed to gain competitive advantage in the dynamic X-ray inspection system market.

Frequently Asked Questions

Q1. What is driving the rapid adoption of X-ray inspection in the food industry? A: Stricter food safety regulations (e.g., HACCP, FDA), consumer demand for contaminant-free products and the need to minimize recalls and waste.

Q2. How does 3D CT X-ray inspection improve upon traditional 2D systems? A: 3D CT systems provide volumetric imaging, enabling detection of defects at any depth and offering comprehensive analysis of complex assemblies.

Q3. Which regions offer the highest growth potential through 2034? A: Asia Pacific, driven by rapid urbanization, expansion of packaged-food and pharmaceutical sectors, and government investments in quality infrastructure.

Q4. Are AI and machine learning capabilities standard in modern X-ray inspection systems? A: Leading suppliers now integrate AI/ML for pattern recognition and automated defect classification, though adoption varies by industry and budget.

Q5. What are the key barriers to entry for new players in this market? A: High R&D costs, regulatory approvals and the technical complexity of integrating advanced imaging modalities and analytics.

About Transparency Market Research Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information. Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports. Contact: Transparency Market Research Inc. CORPORATE HEADQUARTER DOWNTOWN, 1000 N. West Street, Suite 1200, Wilmington, Delaware 19801 USA Tel: +1-518-618-1030 USA - Canada Toll Free: 866-552-3453 Website: https://www.transparencymarketresearch.com Email: [email protected]

0 notes