#Motion Control

Explore tagged Tumblr posts

Text

How Does a Mitsubishi Servo Drive Supplier Empower Precision?

A Mitsubishi Servo Drive Supplier in kuwait delivers high-performance motion control solutions for industries that demand accuracy and reliability. With advanced servo drives, you can achieve precise speed, torque, and positioning in your automation systems. Upgrade your machinery and experience seamless operations with our expert support. Explore our range and contact us today for tailored servo drive solutions!

0 notes

Text

One time, I dreamt that modern wardrobes each had a new interactive screen built inside. Certain models of wardrobe can have either a screen built into it or have a projector screen, which can all be turned on with a push of a button. In certain models however, you have to turn on the interactive part of the screens with a lever, which allows them to respond to certain commands on the motion control remote (similar to a Wii remote) that all models come with. There are even some models of wardrobe that expand when you turn them on, in addition to turning on the screen. The games that these interactive screens come with include “I Spy” style games, in which the player has to find certain objects in different settings, and shooter games similar to the classic NES game “Duck Hunt” but set in space.

#one time i dreamt#wardrobe#weird dreams#dreams#interactive game#i spy#hardware#shooter games#electronic devices#duck hunt#console#motion control

1 note

·

View note

Text

Played Skyrim for the first time last night on my friend's switch

She was like "Oh you might wanna turn off motion controls"

Absolutely not. I Tae Bo'd them Draugr's asses. This is how we do it in Argon!

0 notes

Text

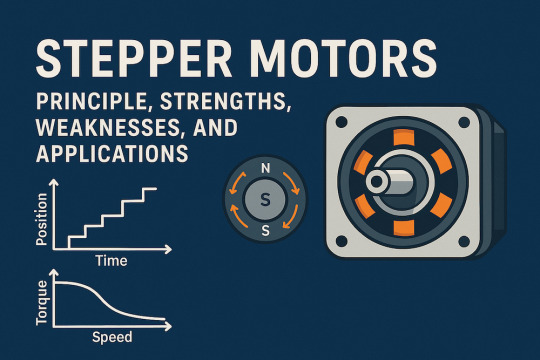

Understanding Stepper Motors: A Technical Overview

This student-friendly guide compares stepper motors with DC and servo motors for precision motion control.

0 notes

Text

Motion control, transmission line, RS-422 physical layer, air conditioning

SP485E Series 10 Mbps 5 V Enhanced Low EMI Half Duplex RS-485 Transceiver-NSOIC8

0 notes

Text

Motion Control - Blåmuggost (Beatservice Records)

8DPromo · Motion Control - Blåmuggost (Beatservice Records)

Celebrating thirty years in an industry as volatile as the music industry is no mean feat. One of Norway's finest electronic record labels, Beatservice Records, marks this massive milestone by unveiling a special EP featuring four unreleased tracks from Motion Control's treasured back catalog. Bergen's Oddgeir Hvidsten began releasing music as part of the ambient trio Neural Network in the mid-1990s. A desire to create more rhythm-oriented productions led to the formation of the Motion Control moniker alongside fellow Neural Network member Lars Kristian Sande. Their early releases were heavily influenced by the pioneering Detroit techno greats, with the first EPs on Universal Code and the subsequent Digits album on Beatservice Records in 1998 housing a swell of melodic, future-facing techno. Their sound then leaned into the realms of disco-infused house for the follow-up album Groove Tool. Taking four unreleased tracks from their archives, the EP kicks off with "Blåmuggost." Created in connection with Motion Control's live show at the club Blå in Oslo for Beatservice Records's fifth anniversary in 1999, the track has remained a hidden treasure until now. Combining an EBM-engineered bassline and robo-disco undertones, cascading claps meet with rapid-fire synth squelches for a peak-time hit of interplanetary body music. Next, "Hjul" rotates the listener's brain. A percussive techno head-scrambler that fuses crunched snares, dizzying synth loops, and pulsating bass grooves. The flip side reveals a deeper facet of Motion Control's material. "Hysj" is an introspective, space-age dwelling, synapse-firing cut full of sweeping strings, interlocking percussive touches, and cosmic top lines: mood-setting, spell-casting brilliance. Closing out the EP, the pace lowers for an intergalactic downtempo number titled "Conga Ambience." Grooving chillout electronics, laced with bouncing Arps, modulating pads, and metallic drum hits. This track is a homage to the eerie, shaky analog sounds of the late 1970s.

Steve ‘Griffo’ Griffiths (Fluid Radio Show) – “I heard this on SoundCloud and was like ‘yeah’. Now that I’ve heard it a few times on promo I’m ‘Hell Yeah!’ 99 out of 10.” Rory Hoy (BigBeatTastic Radio Show) – “This is a really solid release. Supporting.” Psycho-Jones (Kater Blau) – “I love it, thanks!” Severino (HorseMeatDisco) – “Yessssss!” Eric Shans (3Bridge Records) – “Nice old school ambient techno flavors.” Simon Kirk (Proton Radio) – “Stunning EP. Really futuristic vibe throughout. Hjul is my top pick, the strings are beautiful.”

Available Now From: Beatport, Bandcamp, Apple Music, And Spotify.

0 notes

Text

How Siemens Controllers Are Revolutionizing Music Production Studios

In the rapidly evolving world of music production, the quest for greater efficiency, precision, and creative control has led to significant advancements in technology. Among the innovations driving these changes are Siemens controllers, which are revolutionizing how music is produced, mixed, and mastered. By integrating Siemens' cutting-edge automation technology into music production studios, professionals are achieving new levels of productivity and sonic quality. Here's how Siemens controllers are making waves in the music industry.

Siemens Controllers: The Backbone of Modern Music Studios

Siemens controllers, including programmable logic controllers (PLCs) and motor controllers, are renowned for their reliability and precision in various industrial applications. However, their impact extends beyond traditional manufacturing environments. In modern music production studios, Siemens controllers are enhancing automation, improving control over studio equipment, and streamlining production processes.

One notable example is the use of Siemens’ SIMATIC PLCs in controlling and automating audio equipment. These advanced controllers manage everything from digital mixing consoles to automated fader adjustments, providing sound engineers and producers with a level of control that was previously unattainable.

Enhancing Efficiency with Siemens Automation Technology

Efficiency is paramount in a music production studio, where time is often as valuable as creativity. Siemens controllers play a crucial role in automating repetitive tasks and optimizing workflows. For instance, automated mixing and mastering processes are facilitated by Siemens controllers, which handle complex signal routing and processing tasks with precision.

By integrating Siemens’ automation technology, studios can reduce the time spent on manual adjustments and focus more on the creative aspects of music production. Automated systems controlled by Siemens controllers ensure that equipment settings are consistent and repeatable, which is essential for achieving high-quality results across multiple sessions and projects.

Precision Control with Siemens Motor and Motion Controllers

In a music studio, precise control over equipment is essential for achieving the desired sound quality. Siemens motor controllers and motion control systems provide unparalleled accuracy in adjusting audio equipment. Whether it’s controlling the movement of a motorized microphone stand or fine-tuning the position of speakers and monitors, Siemens controllers ensure that every adjustment is executed with pinpoint accuracy.

The ability to program and control these adjustments via Siemens’ programmable logic controllers allows sound engineers to create intricate setups and configurations that can be replicated with ease. This level of control enhances the overall quality of recordings and ensures that the production process is smooth and efficient.

Streamlining Production with Advanced Automation and Process Automation

Process automation is transforming music production studios by automating complex workflows and enhancing overall efficiency. Siemens controllers are at the heart of this transformation, offering solutions that streamline various aspects of the production process.

For example, Siemens controllers can automate the setup and calibration of audio equipment, reducing the time needed for manual adjustments. This automation extends to the management of recording sessions, where Siemens controllers handle tasks such as track switching, level adjustments, and signal routing with minimal human intervention.

Additionally, the integration of Siemens controllers into digital audio workstations (DAWs) allows for seamless control of software and hardware components. This integration ensures that all elements of the production process work in harmony, resulting in a more cohesive and efficient workflow.

The Impact of Siemens Controllers on Creative Processes

Beyond improving efficiency and precision, Siemens controllers also have a significant impact on the creative processes within music production studios. By automating routine tasks, these controllers free up time for producers and engineers to focus on creative experimentation and innovation.

The ability to program complex automation sequences and recall them with ease enables sound engineers to explore new creative possibilities. For instance, automated dynamic changes in a mix or the creation of intricate effects can be accomplished effortlessly using Siemens controllers, allowing for greater experimentation and artistic expression.

Implementing Siemens Controllers in Your Music Studio

Integrating Siemens controllers into a music production studio involves several key steps. First, assess your studio’s current setup and identify areas where automation and control improvements can be made. Siemens offers a range of controllers and automation solutions, including the SIMATIC PLCs and motor controllers, that can be customized to meet your specific needs.

Once the appropriate Siemens controllers are selected, the next step is to implement them into your studio’s infrastructure. This process may include configuring the controllers, integrating them with existing equipment, and training staff to utilize the new technology effectively.

Ongoing maintenance and support are essential to ensure that Siemens controllers continue to perform optimally. Siemens provides comprehensive support services, including technical assistance and software updates, to help you maximize the benefits of their controllers and maintain peak performance.

Conclusion

Siemens controllers are revolutionizing music production studios by enhancing efficiency, precision, and creativity. With their advanced automation technology, including programmable logic controllers (PLCs) and motor controllers, Siemens is setting new standards for control and automation in the music industry. By integrating Siemens controllers into your music production setup, you can streamline workflows, improve the quality of your productions, and unlock new creative possibilities. As the music industry continues to evolve, Siemens controllers will remain at the forefront of innovation, driving the future of music production.

#siemens#siemens controller#siemens controllers#industrial automation#programmable logic controllers#motor controllers#motion control#factory automation#automation technology#process automation#simatic#controllers#automation#controller#production#automated

0 notes

Text

The Benefits of Siemens' Building Automation Systems

Siemens is a leader in the field of automation technology, and their building automation systems exemplify this expertise. These systems provide numerous benefits, ranging from enhanced efficiency and comfort to significant energy savings and sustainability. Leveraging technologies such as Simatic and Motion Control, Siemens' solutions are integral to modernizing and optimizing building operations, particularly in industrial and manufacturing settings.

Enhanced Efficiency and Productivity

One of the primary benefits of Siemens' building automation systems is the significant improvement in operational efficiency. By automating various building functions such as heating, ventilation, air conditioning (HVAC), lighting, and security, Siemens helps reduce the need for manual intervention and allows for seamless integration and control. This not only streamlines operations but also frees up personnel to focus on more critical tasks, thereby increasing overall productivity.

In industrial and manufacturing environments, where precision and efficiency are paramount, Siemens’ Simatic automation technology plays a crucial role. Simatic systems ensure that all building functions operate optimally, contributing to smoother production processes and reducing the likelihood of disruptions that can lead to costly downtime.

Energy Savings and Sustainability

Energy efficiency is a key concern for any modern building, especially in industrial and manufacturing sectors where energy consumption is typically high. Siemens' building automation systems are designed to optimize energy use by intelligently managing building functions based on real-time data and pre-set parameters. For example, Siemens' advanced HVAC controls adjust heating and cooling based on occupancy and usage patterns, ensuring that energy is not wasted on unoccupied spaces.

Additionally, the integration of Motion Control technology allows for precise control of mechanical systems, further enhancing energy efficiency. By reducing unnecessary motion and ensuring that systems operate only when needed, Siemens' automation technology helps lower energy consumption and operational costs. This not only results in significant cost savings but also supports sustainability initiatives by reducing the building's carbon footprint.

Improved Comfort and Safety

Siemens' building automation systems are designed to enhance the comfort and safety of building occupants. Automated HVAC systems maintain optimal temperature and air quality, ensuring a comfortable environment for workers and visitors. Intelligent lighting controls adjust illumination based on natural light availability and occupancy, creating a well-lit and energy-efficient workspace.

In addition to comfort, Siemens' automation technology significantly improves building safety. Automated security systems, including access control, surveillance, and alarm systems, ensure that industrial and manufacturing facilities are secure. These systems can be monitored and controlled remotely, providing real-time alerts and enabling swift responses to any security breaches or emergencies.

Scalability and Flexibility

One of the standout features of Siemens' building automation systems is their scalability and flexibility. Whether it’s a small industrial facility or a large manufacturing plant, Siemens' solutions can be tailored to meet specific needs and scaled up or down as required. The modular design of Simatic and other Siemens automation products allows for easy integration with existing systems and future expansion.

This flexibility is particularly beneficial in manufacturing environments, where production demands and processes can change frequently. Siemens' building automation systems can adapt to these changes, ensuring that the building's infrastructure remains aligned with production needs. This adaptability also extends to new technologies and innovations, ensuring that Siemens' systems remain cutting-edge and capable of meeting future challenges.

Data-Driven Insights and Decision Making

Siemens' building automation systems are equipped with advanced data analytics capabilities, providing valuable insights into building operations. By collecting and analyzing data from various building systems, Siemens enables facility managers to make informed decisions that enhance efficiency, reduce costs, and improve overall performance.

In industrial and manufacturing settings, these data-driven insights can be particularly valuable. For example, predictive maintenance powered by Siemens' automation technology can identify potential issues before they lead to equipment failure, minimizing downtime and maintaining production continuity. Additionally, energy usage data can be analyzed to identify areas for further efficiency improvements, supporting continuous optimization efforts.

Integration with Industrial Automation

Siemens' expertise in industrial automation seamlessly extends to their building automation systems. This integration ensures that the entire facility, from production lines to building infrastructure, operates cohesively. By utilizing Simatic and Motion Control technologies across both production and building systems, Siemens provides a unified automation solution that enhances overall efficiency and productivity.

This holistic approach to automation is particularly beneficial in complex manufacturing environments, where the interplay between building systems and production processes can significantly impact performance. Siemens' integrated solutions ensure that all aspects of the facility work together harmoniously, creating a more efficient and productive operation.

Conclusion

Siemens' building automation systems offer a wide range of benefits that enhance the efficiency, comfort, safety, and sustainability of industrial and manufacturing facilities. Leveraging advanced automation technologies such as Simatic and Motion Control, Siemens provides scalable, flexible, and data-driven solutions that optimize building operations. By integrating these systems with industrial automation, Siemens ensures a cohesive and efficient facility, ultimately driving productivity and reducing operational costs. As a leader in automation technology, Siemens continues to set the standard for building automation, supporting the evolving needs of modern industrial and manufacturing environments.

0 notes

Text

https://www.igus.in/

Igus stands as a testament to the power of innovation, sustainability, and customer-centricity in driving progress within the industrial sector. From humble beginnings in Cologne to global acclaim, igus continues to redefine possibilities in motion plastics, setting benchmarks for reliability, efficiency, and environmental responsibility. As industries evolve and challenges grow more complex, igus remains steadfast in its commitment to shaping the future of motion technology, one innovative solution at a time.

0 notes

Text

Precision and Performance with Servo Drives Enhance the precision and performance of your machinery with advanced servo drives. Discover their benefits in motion control applications and how they can improve your operations. Servo drives offer high accuracy and efficiency, making them ideal for applications requiring precise control of motion and positioning.

0 notes

Text

Why Choose a Mitsubishi Servo Drive Supplier in Kuwait Now?

Selecting a Mitsubishi Servo Drive Supplier in Kuwait guarantees access to high-performance motion control for your automation systems. Benefit from genuine Mitsubishi technology, expert support, and fast delivery to keep your operations running smoothly. Whether for robotics or manufacturing, the right supplier ensures reliability and precision. Take your automation to the next level-contact us through our website for tailored servo drive solutions!

0 notes

Text

Construction Zone: Free Riders

#Sonic Riders#Sega#Sonic Free Riders#Microsoft Xbox 360#Construction Zone#The Modern Era#Free Riders#Sonic the Hedgehog#Microsoft Kinect#motion control#tumblr polls

0 notes

Text

Gaming would be a lot better if every game was Wii remote compatible.

COD could get every dollar in my wallet every year if they allowed me to waggle a Wiimote instead of using a K-and-M or a controller.

0 notes

Text

Reviving VisualSizer: Upgrading for the Future with a New C# Version

After several years on hiatus, I’m thrilled to revive my all-time favorite project—the VisualSizer motor sizing software for Windows! It was time to bring this powerful tool back to life and make it even better for engineers and motion control professionals.

0 notes

Text

An endless domino effect - Technology Org

New Post has been published on https://thedigitalinsider.com/an-endless-domino-effect-technology-org/

An endless domino effect - Technology Org

If it walks like a particle, and talks like a particle… it may still not be a particle. A topological soliton is a special type of wave or dislocation which behaves like a particle: it can move around but cannot spread out and disappear like you would expect from, say, a ripple on the surface of a pond. In a new study published in Nature, researchers from the University of Amsterdam demonstrate the atypical behaviour of topological solitons in a robotic metamaterial, which may be used to control how robots move, sense their surroundings and communicate.

Topological solitons can be found in many places and at many different length scales. For example, they take the form of kinks in coiled telephone cords and large molecules such as proteins. At a very different scale, a black hole can be understood as a topological soliton in the fabric of spacetime. Solitons play an important role in biological systems, being relevant for protein folding and morphogenesis – the development of cells or organs.

The unique features of topological solitons – that they can move around but always retain their shape and cannot suddenly disappear – are particularly interesting when combined with so-called non-reciprocal interactions. “In such an interaction, an agent A reacts to an agent B differently to the way agent B reacts to agent A,” explains Jonas Veenstra, a PhD student at the University of Amsterdam and first author of the new publication.

Veenstra continues: “Non-reciprocal interactions are commonplace in society and complex living systems but have long been overlooked by most physicists because they can only exist in a system out of equilibrium. By introducing non-reciprocal interactions in materials, we hope to blur the boundary between materials and machines and to create animate or lifelike materials.”

The Machine Materials Laboratory where Veenstra does his research specialises in designing metamaterials: artificial materials and robotic systems that interact with their environment in a programmable fashion. The research team decided to study the interplay between non-reciprocal interactions and topological solitons almost two years ago, when then-students Anahita Sarvi and Chris Ventura Meinersen decided to follow up on their research project for the MSc course ‘Academic Skills for Research’.

Solitons moving like dominoes

The soliton-hosting metamaterial developed by the researchers consists of a chain of rotating rods that are linked to each other by elastic bands – see the figure below. Each rod is mounted on a little motor which applies a small force to the rod, depending on how it is oriented with respect to its neighbours. Importantly, the force applied depends on which side the neighbour is on, making the interactions between neighbouring rods non-reciprocal. Finally, magnets on the rods are attracted by magnets placed next to the chain in such a way that each rod has two preferred positions, rotated either to the left or the right.

The robotic metamaterial with a soliton and anti-soliton lying at the boundaries between left- and right-leaning sections of the chain. Each blue rod is connected to its neighbours with pink elastic bands, and a little motor under each rod makes the interactions between neighbouring rods non-reciprocal. Image credit: Jonas Veenstra.

Solitons in this metamaterial are the locations where left- and right-rotated sections of the chain meet. The complementary boundaries between right- and left-rotated chain sections are then so-called ‘anti-solitons’. This is analogous to kinks in an old-fashioned coiled telephone cord, where clockwise and anticlockwise-rotating sections of the cord meet.

When the motors in the chain are turned off, the solitons and anti-solitons can be manually pushed around in either direction. However, once the motors – and thereby the reciprocal interactions – are turned on, the solitons and anti-solitons automatically slide along the chain. They both move in the same direction, with a speed set by the anti-reciprocity imposed by the motors.

Veenstra: “A lot of research has focussed on moving topological solitons by applying external forces. In systems studied so far, solitons and anti-solitons were found to naturally travel in opposite directions. However, if you want to control the behaviour of (anti-)solitons, you might want to drive them in the same direction. We discovered that non-reciprocal interactions achieve exactly this. The non-reciprocal forces are proportional to the rotation caused by the soliton, such that each soliton generates its own driving force.”

The movement of the solitons is similar to a chain of dominoes falling, each one toppling its neighbour. However, unlike dominoes, the non-reciprocal interactions ensure that the ‘toppling’ can only happen in one direction. And while dominoes can only fall down once, a soliton moving along the metamaterial simply sets up the chain for an anti-soliton to move through it in the same direction. In other words, any number of alternating solitons and anti-solitons can move through the chain without the need to ‘reset’.

Motion control

Understanding the role of non-reciprocal driving will not only help us better to understand the behaviour of topological solitons in living systems, but can also lead to technological advances. The mechanism that generates the self-driving, one-directional solitons uncovered in this study, can be used to control the motion of different types of waves (known as waveguiding), or to endow a metamaterial with a basic information processing capability such as filtering.

[embedded content]

Future robots can also use topological solitons for basic robotic functionalities such as movement, sending out signals and sensing their surroundings. These functionalities would then not be controlled from a central point, but rather emerge from the sum of the robot’s active parts.

All in all, the domino effect of solitons in metamaterials, now an interesting observation in the lab, may soon start to play a role in different branches of engineering and design.

Source: University of Amsterdam

You can offer your link to a page which is relevant to the topic of this post.

#artificial#black hole#Blue#blur#Cells#course#Design#development#direction#domino#engineering#Environment#fashion#Features#form#Fundamental physics news#Future#Hosting#how#interaction#it#Link#Magnets#materials#metamaterials#molecules#motion control#movement#nature#One

0 notes

Text

Quiver Tree Forest… Despite the light pollution of neighboring city Keetmanshoop, the Milky Way was bright enough so one can say it’s a bortle 1-2 sky, which is actually the case everywhere in Namibia. (gear in tags, settings and process here )

eg_astrophotography

#Nikon D750 astro-modified on iOptron Sky Guider pro#Sigma Art 50mm f1.4#Genie Mini motion control device for panorama#astrophotography#astronomy#namibia#photography#curators on tumblr

3K notes

·

View notes