#Optical Encoders Technology

Explore tagged Tumblr posts

Text

Disco Elysium has a lot of fascinating fictional technology but I have been rotating the radiocomputer in my mind for months now. From what I can gather, they operate in a way very similar to modern cloud computing. It doesn't seem like the mainframes we interact with have any processing capability. Instead, they use antennas to process "on air":

SOONA, THE PROGRAMMER - "Alright, well... All radiocomputers perform operations up on air, so in order to gain more processing power you need to invest in a *good antenna*."

The only information we get about what "on air" really means is from the same conversation with Soona:

YOU - "Wait, what's 'on air'?" SOONA, THE PROGRAMMER - "On the *front*. The unified front of radiowaves, licensed and controlled by Lintel in the East-Insulindic region." SOONA, THE PROGRAMMER - "It's all around us," she waves her hand, "that's what 'on air' means."

The nonspecific language used here really invokes cloud computing to me. I think there are two main possibilities for how this could work, one being much more likely than the other.

The more likely answer is that information is sent to and from the in-game equivalent of data centers, which would host massive computers with processing capabilities. I'm not sure what their processors would look like, but they'd almost certainly be analog (the lost Feld tape computers are most likely the in-game equivalent of early digital computers).

The significantly less likely (but more interesting) answer is that in-game radio waves are somehow capable of processing information on their own. I have no idea how this would work, and as far as I know there's no real-world analog. But it's clear the world of Disco Elysium has some crazy things happening with radio waves (see how they interact with the pale), so I'm not ruling it out entirely.

The filament memories are like hard drives, but my guess is they would function more similarly to an optical disc (CDs, DVDs), which use patterns in the disc to encode information that's read using lasers or light. The filaments glow inside the mainframe, so it's not a huge leap to assume they're read using light.

The amount of thought put into radiocomputers is so fascinating. As far as I can tell, their version of the internet has been wireless from the get-go, which makes perfect sense! Antennas and other wireless radio technologies would have to be pretty damn powerful to communicate across and force dimensions on the pale. And you have to assume huge amounts of government money has gone into funding their research and development for those purposes. The technology of radiocomputers is so tailored to the world of Disco Elysium, and it's been a lot of fun trying to untangle how exactly they would work.

#i would loooove to hear other people's thoughts on this!! i tried to find conversations abt it and didn't come up with much#also if anyone wants me to elaborate on the feld tape computer thing lmk... its a long post so i didn't want to go into more detail#but i do have Thoughts about it#cyan.txt#disco elysium#disco elysium meta#soona the programmer

624 notes

·

View notes

Text

Spin-controlled generation of a complete polarization set with randomly interleaved plasmonic metasurfaces

Optical metasurfaces are finely crafted two-dimensional artificial nanostructures composed of meticulously designed arrays of ultrathin artificial atoms. These surfaces possess capabilities beyond natural materials, enabling multifunctional control of electromagnetic waves. By designing the shape, size, rotation, and position of these artificial atoms, optical metasurfaces can precisely manipulate electromagnetic waves at subwavelength spatial resolutions, offering vast potential applications in the field of photonics. Among the many applications, the control of polarization states using optical metasurfaces has been extensively studied. The development of polarization-encoded multifunctional metasurfaces represents a significant leap in optical technology, allowing a wider range of functions to be integrated into a single metasurface.

Read more.

#Materials Science#Science#Metamaterials#Optics#Nanotechnology#Metasurfaces#Plasmonics#Polarization#Spintronics

9 notes

·

View notes

Text

Quantum Simulation: A Frontier in Scientific Research

Quantum simulation, a burgeoning field in modern physics, leverages the unique properties of quantum systems to replicate and investigate the behavior of other complex quantum systems. This approach offers a powerful tool to study intricate quantum phenomena that are otherwise challenging to analyze using classical computational methods or experimental setups. By harnessing the principles of quantum mechanics, quantum simulation enables researchers to explore parameter spaces inaccessible to classical simulations and gain unique insights into the underlying physics.

One of the primary platforms for quantum simulation is ultracold atomic gases, cooled to temperatures close to absolute zero. The low temperatures and high phase-space density of these systems allow for the study of individual atoms and molecules in a highly controlled environment, with minimal interactions with the surrounding environment. Optical lattices, created by interfering laser beams, provide a versatile and highly controllable platform for quantum simulations. By adjusting the laser parameters, researchers can engineer various types of lattice structures, enabling the study of phenomena such as Anderson localization, quantum phase transitions, and many-body dynamics. The periodic potential created by the optical lattice can mimic the crystal lattice of solid-state systems, allowing for the investigation of condensed matter physics in a clean and controllable environment.

Superconducting qubits, trapped ions, and nitrogen-vacancy centers in diamonds are alternative platforms for quantum simulation, each with its unique strengths and capabilities. Superconducting qubits use superconducting circuits to encode quantum information and exhibit long coherence times. Trapped ions allow for precise control and readout of their quantum states using electromagnetic fields. Nitrogen-vacancy centers in diamonds offer long-lived spins and coupling to other spins, making them useful for quantum information processing and sensing applications.

A significant challenge in quantum simulation is minimizing and correcting errors, which can arise from imperfections in the experimental setup or external disturbances. These errors can lead to decoherence, causing the quantum system to lose its coherence and become difficult to control. Researchers have developed robust quantum simulation methods and error correction codes to mitigate these errors and extend the capabilities of quantum simulations. Techniques such as quantum error correction, dynamical error suppression, and fault-tolerant quantum computing aim to overcome these challenges and enable longer and more accurate quantum simulations.

Quantum simulation has enabled the discovery of new phases, such as topological insulators and supersolids, and the study of strongly correlated systems, like high-temperature superconductors. By mimicking condensed matter systems in the laboratory, researchers can observe and understand their behavior in detail, leading to a deeper understanding of quantum phenomena and the development of new materials and technologies. Quantum simulations have the potential to revolutionize fields such as condensed matter physics, materials science, and chemistry. By simulating molecular Hamiltonians, quantum simulations can provide insights into chemical reactions, electronic structures, and excited states, with implications for drug discovery and materials design. Furthermore, quantum simulations can accelerate materials discovery by predicting the properties of new materials and optimizing existing ones for specific applications.

Esteban Adrian Martinez: Introduction to Quantum Simulators (Summer School on Collective Behaviour in Quantum Matter, September 2018)

youtube

Tuesday, November 5, 2024

#quantum simulation#physics#ultracold atomic gases#optical lattices#superconducting qubits#trapped ions#nitrogen vacancy centers#decoherence#error correction#materials discovery#drug discovery#talk#ai assisted writing#machine art#Youtube

3 notes

·

View notes

Text

youtube

NASA’s Laser Comms Demo Makes Deep Space Record, Completes First Phase

The Deep Space Optical Communications tech demo has completed several key milestones, culminating in sending a signal to Mars’ farthest distance from Earth.

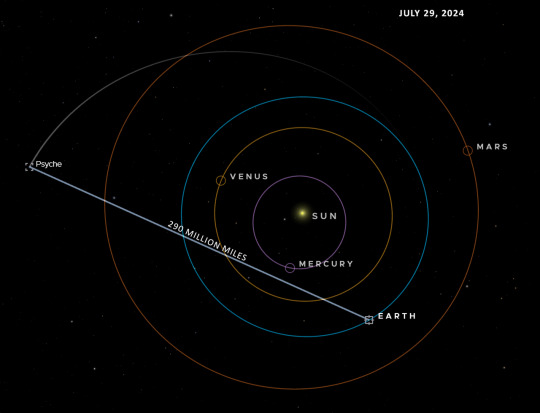

NASA’s Deep Space Optical Communications technology demonstration broke yet another record for laser communications this summer by sending a laser signal from Earth to NASA’s Psyche spacecraft about 290 million miles (460 million kilometers) away. That’s the same distance between our planet and Mars when the two planets are farthest apart.

Soon after reaching that milestone on July 29, the technology demonstration concluded the first phase of its operations since launching aboard Psyche on Oct. 13, 2023.

“The milestone is significant. Laser communication requires a very high level of precision, and before we launched with Psyche, we didn’t know how much performance degradation we would see at our farthest distances,” said Meera Srinivasan, the project’s operations lead at NASA’s Jet Propulsion Laboratory in Southern California. “Now the techniques we use to track and point have been verified, confirming that optical communications can be a robust and transformative way to explore the solar system.”

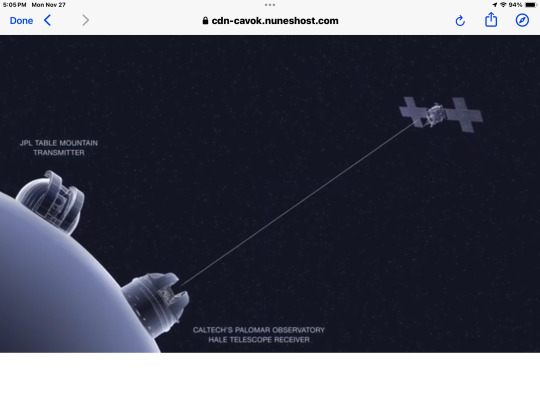

Managed by JPL, the Deep Space Optical Communications experiment consists of a flight laser transceiver and two ground stations. Caltech’s historic 200-inch (5-meter) aperture Hale Telescope at Caltech’s Palomar Observatory in San Diego County, California, acts as the downlink station to which the laser transceiver sends its data from deep space. The Optical Communications Telescope Laboratory at JPL’s Table Mountain facility near Wrightwood, California, acts as the uplink station, capable of transmitting 7 kilowatts of laser power to send data to the transceiver.

By transporting data at rates up to 100 times higher than radio frequencies, lasers can enable the transmission of complex scientific information as well as high-definition imagery and video, which are needed to support humanity’s next giant leap when astronauts travel to Mars and beyond.

As for the spacecraft, Psyche remains healthy and stable, using ion propulsion to accelerate toward a metal-rich asteroid in the main asteroid belt between Mars and Jupiter.

Exceeding Goals

The technology demonstration’s data is sent to and from Psyche as bits encoded in near-infrared light, which has a higher frequency than radio waves. That higher frequency enables more data to be packed into a transmission, allowing far higher rates of data transfer.

Even when Psyche was about 33 million miles (53 million kilometers) away — comparable to Mars’ closest approach to Earth — the technology demonstration could transmit data at the system’s maximum rate of 267 megabits per second. That bit rate is similar to broadband internet download speeds. As the spacecraft travels farther away, the rate at which it can send and receive data is reduced, as expected.

On June 24, when Psyche was about 240 million miles (390 million kilometers) from Earth — more than 2½ times the distance between our planet and the Sun — the project achieved a sustained downlink data rate of 6.25 megabits per second, with a maximum rate of 8.3 megabits per second. While this rate is significantly lower than the experiment’s maximum, it is far higher than what a radio frequency communications system using comparable power can achieve over that distance.

This Is a Test

The goal of Deep Space Optical Communications is to demonstrate technology that can reliably transmit data at higher speeds than other space communication technologies like radio frequency systems. In seeking to achieve this goal, the project had an opportunity to test unique data sets like art and high-definition video along with engineering data from the Psyche spacecraft. For example, one downlink included digital versions of Arizona State University’s “Psyche Inspired” artwork, images of the team’s pets, and a 45-second ultra-high-definition video that spoofs television test patterns from the previous century and depicts scenes from Earth and space.

The technology demonstration beamed the first ultra-high-definition video from space, featuring a cat named Taters, from the Psyche spacecraft to Earth on Dec. 11, 2023, from 19 million miles away. (Artwork, images, and videos were uploaded to Psyche and stored in its memory before launch.)

“A key goal for the system was to prove that the data-rate reduction was proportional to the inverse square of distance,” said Abi Biswas, the technology demonstration’s project technologist at JPL. “We met that goal and transferred huge quantities of test data to and from the Psyche spacecraft via laser.” Almost 11 terabits of data have been downlinked during the first phase of the demo.

The flight transceiver is powered down and will be powered back up on Nov. 4. That activity will prove that the flight hardware can operate for at least a year.

“We’ll power on the flight laser transceiver and do a short checkout of its functionality,” said Ken Andrews, project flight operations lead at JPL. “Once that’s achieved, we can look forward to operating the transceiver at its full design capabilities during our post-conjunction phase that starts later in the year.”

More About Deep Space Optical Communications

This demonstration is the latest in a series of optical communication experiments funded by the Space Technology Mission Directorate’s Technology Demonstration Missions Program managed at NASA’s Marshall Space Flight Center in Huntsville, Alabama, and the agency’s SCaN (Space Communications and Navigation) program within the Space Operations Mission Directorate. Development of the flight laser transceiver is supported by MIT Lincoln Laboratory, L3 Harris, CACI, First Mode, and Controlled Dynamics Inc. Fibertek, Coherent, Caltech Optical Observatories, and Dotfast support the ground systems. Some of the technology was developed through NASA’s Small Business Innovation Research program.

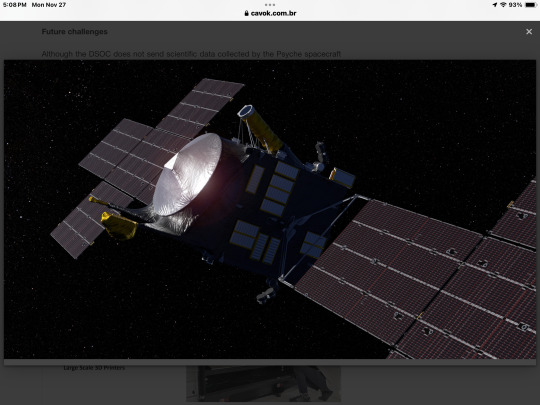

TOP IMAGE: NASA’s Psyche spacecraft is depicted receiving a laser signal from the Deep Space Optical Communications uplink ground station at JPL’s Table Mountain Facility in this artist’s concept. The DSOC experiment consists of an uplink and downlink station, plus a flight laser transceiver flying with Psyche. Credit: NASA/JPL-Caltech

LOWER IMAGE: This visualization shows Psyche’s position on July 29 when the uplink station for NASA’s Deep Space Optical Communications sent a laser signal about 290 million miles to the spacecraft. See an interactive version of the Psyche spacecraft in NASA’s Eyes on the Solar System. Credit: NASA/JPL-Caltech

2 notes

·

View notes

Text

Impact of Digital Signal Processing in Electrical Engineering - Arya College

Arya College of Engineering & I.T is the best college of Jaipur, Digital SignalProcessing (DSP) has become a cornerstone of modern electrical engineering, influenced a wide range of applications and driven significant technological advancements. This comprehensive overview will explore the impact of DSP in electrical engineering, highlighting its applications, benefits, and emerging trends.

Understanding Digital Signal Processing

Definition and Fundamentals

Digital Signal Processing involves the manipulation of signals that have been converted into a digital format. This process typically includes sampling, quantization, and various mathematical operations to analyze and modify the signals. The primary goal of DSP is to enhance the quality and functionality of signals, making them more suitable for various applications.

Key components of DSP include:

Analog-to-Digital Conversion (ADC): This process converts analog signals into digital form, allowing for digital manipulation.

Digital Filters: These algorithms are used to enhance or suppress certain aspects of a signal, such as noise reduction or frequency shaping.

Fourier Transform: A mathematical technique that transforms signals from the time domain to the frequency domain, enabling frequency analysis.

Importance of DSP in Electrical Engineering

DSP has revolutionized the way engineers approach signal processing, offering numerous advantages over traditional analog methods:

Precision and Accuracy: Digital systems can achieve higher precision and reduce errors through error detection and correction algorithms.

Flexibility: DSP systems can be easily reprogrammed or updated to accommodate new requirements or improvements, making them adaptable to changing technologies.

Complex Processing Capabilities: Digital processors can perform complex mathematical operations that are difficult to achieve with analog systems, enabling advanced applications such as real-time image processing and speech recognition.

Applications of Digital Signal Processing

The versatility of DSP has led to its adoption across various fields within electrical engineering and beyond:

1. Audio and Speech Processing

DSP is extensively used in audio applications, including:

Audio Compression: Techniques like MP3 and AAC reduce file sizes while preserving sound quality, making audio files easier to store and transmit.

Speech Recognition: DSP algorithms are crucial for converting spoken language into text, enabling voice-activated assistants and transcription services.

2. Image and Video Processing

In the realm of visual media, DSP techniques enhance the quality and efficiency of image and video data:

Digital Image Processing: Applications include noise reduction, image enhancement, and feature extraction, which are essential for fields such as medical imaging and remote sensing.

Video Compression: Standards like H.264 and HEVC enable efficient storage and streaming of high-definition video content.

3. Telecommunications

DSP plays a vital role in modern communication systems:

Modulation and Demodulation: DSP techniques are used in encoding and decoding signals for transmission over various media, including wireless and optical networks.

Error Correction: Algorithms such as Reed-Solomon and Turbo codes enhance data integrity during transmission, ensuring reliable communication.

4. Radar and Sonar Systems

DSP is fundamental in radar and sonar applications, where it is used for:

Object Detection: DSP processes signals to identify and track objects, crucial for air traffic control and maritime navigation.

Environmental Monitoring: Sonar systems utilize DSP to analyze underwater acoustics for applications in marine biology and oceanography.

5. Biomedical Engineering

In healthcare, DSP enhances diagnostic and therapeutic technologies:

Medical Imaging: Techniques such as MRI and CT scans rely on DSP for image reconstruction and analysis, improving diagnostic accuracy.

Wearable Health Monitoring: Devices that track physiological signals (e.g., heart rate, glucose levels) use DSP to process and interpret data in real time.

Trends in Digital Signal Processing

As technology evolves, several trends are shaping the future of DSP:

1. Integration with Artificial Intelligence

The convergence of DSP and AI is leading to smarter systems capable of learning and adapting to user needs. Machine learning algorithms can enhance traditional DSP techniques, enabling more sophisticated applications in areas like autonomous vehicles and smart home devices.

2. Increased Use of FPGAs and ASICs

Field-Programmable Gate Arrays (FPGAs) and Application-Specific Integrated Circuits (ASICs) are increasingly used for implementing DSP algorithms. These technologies offer high performance and efficiency, making them suitable for real-time processing in demanding applications such as telecommunications and multimedia.

3. Internet of Things (IoT)

The proliferation of IoT devices is driving demand for efficient DSP solutions that can process data locally. This trend emphasizes the need for low-power, high-performance DSP algorithms that can operate on resource-constrained devices.

4. Cloud-Based DSP

Cloud computing is transforming how DSP is implemented, allowing for scalable processing power and storage. This shift enables complex signal processing tasks to be performed remotely, facilitating real-time analysis and data sharing across devices.

Conclusion

Digital Signal Processing has significantly impacted electrical engineering, enhancing the quality and functionality of signals across various applications. Its versatility and adaptability make it a critical component of modern technology, driving innovations in audio, image processing, telecommunications, and biomedical fields. As DSP continues to evolve, emerging trends such as AI integration, IoT, and cloud computing will further expand its capabilities and applications, ensuring that it remains at the forefront of technological advancement. The ongoing development of DSP technologies promises to enhance our ability to process and utilize information in increasingly sophisticated ways, shaping the future of engineering and technology.

3 notes

·

View notes

Text

Atom Computing is Ushering in a New Era of Quantum Research

Atom Computing

Recently, quantum computers constructed from arrays of ultracold atoms have become a major contender in the race to produce machines powered by qubits that can surpass their classical counterparts in performance. Although the first completely functional quantum processors to be programmed via the cloud have been produced by alternative hardware architectures, further advancements indicate that atom-based platforms may be superior in terms of future scalability.

This scaling benefit results from the atomic qubits being exclusively cooled, trapped, and manipulated via photonic technology. Neutral-atom quantum computers can be primarily constructed using currently available optical components and systems that have already been optimised for accuracy and dependability, eschewing the need for intricate cryogenic systems or chip fabrication processes.

A physicist at Princeton University in the United States named Jeff Thompson and his team have been developing a quantum computer based on arrays of ytterbium atoms. “The traps are optical tweezers, the atoms are controlled with laser beams and the imaging is done with a camera,” Thompson explains. “The engineering that can be done with the optical system is the only thing limiting the scalability of the platform, and a lot of that work has already been done in the industry of optical components and megapixel devices.”

Enormous atomic arrays

Many attractive properties of neutral atoms make them suitable for quantum information encoding. Firstly, they are all the same, meaning that there is no need to tune or calibrate individual qubits because they are all flawless and devoid of any flaws that could be introduced during creation. Important quantum features like superposition and entanglement are preserved over sufficiently long periods to enable computation, and their quantum states and interactions are likewise well understood and characterised.

The pursuit of fault tolerance This important development made atomic qubits a competitive platform for digital quantum computing, spurring research teams and quantum companies to investigate and improve the efficiency of various atomic systems. Although rubidium remains a popular option, ytterbium is seen by certain groups to provide some important advantages for large-scale quantum computing. Thompson argues that because ytterbium has a nuclear spin of one half, the qubit can be encoded entirely in the nuclear spin.”They found that pure nuclear-spin qubits can maintain coherence times of many seconds without special procedures, even though all atom- or ion-based qubits havegood coherence by default.”

Examining rational qubits

In the meanwhile, Lukin’s Harvard group has perhaps made the closest approach to error-corrected quantum computing to yet, collaborating with a number of academic partners and the Boston-based startup QuEra Computing. Utilising so-called logical qubits, which distribute the quantum information among several physical qubits to reduce error effects, is a critical advancement.

One or two logical qubits have been produced in previous demonstrations using different hardware platforms, but Lukin and colleagues demonstrated by the end of 2023 that they could produce 48 logical qubits from 280 atomic qubits. They were able to move and operate each logical block as a single unit by using optical multiplexing to illuminate every rubidium atom inside a logical qubit with identical light beams. This hardware-efficient control technique stops mistakes in the physical qubits from growing into a logical defect since every atom in the logical block is treated separately.

The researchers additionally partitioned their design into three functional zones to enable more scalable processing of these logical qubits. The first is utilised to ensure that these stable quantum states are separated from processing mistakes in other sections of the hardware by manipulating and storing the logical qubits, coupled with a reservoir of physical qubits that may be called upon. Next, logical qubit pairs can be “shuttled” into the second entangling zone, where two-qubit gate operations are driven with fidelity exceeding 99.5% by a single excitation laser. Each gate operation’s result is measured in the final readout zone, which doesn’t interfere with the ongoing processing duties.

Future scalability Another noteworthy development is that QuEra has secured a multimillion-dollar contract at the UK’s National Quantum Computing Centre (NQCC) to construct a version of this logical processor. By March 2025, the national lab will have seven prototype quantum computers installed, including platforms that take advantage of superconducting qubits and trapped ions, as well as a neutral-atom system based on cesium from Infleqtion (previously ColdQuanta). The QuEra system will be one of these systems.

Replenishing the supply of atoms In order to create a path to larger-scale machines, the Atom Computing team has included additional optical technologies into its revised platform. Bloom states, “They could have just bought some really big lasers if They wanted to go from 100 to 1,000 qubits.” “However, they wanted to get the array on a path where they can keep expanding it to hundreds of thousands or even a million atoms without encountering problems with the laser power.”

Combining the atomic control offered by optical tweezers with the trapping capability of optical lattices which are primarily found in the most accurate atomic clocks in the world has been the solution for Atom Computing. By adding an optical buildup cavity to create constructive interference between multiple reflected laserThese optical lattices can improve their performance by creating a subwavelength grid of potential wells via laser beam interference.”With just a moderate amount of laser power, They can create a huge array of deep traps with these in-vacuum optics,” adds.”They could rise higher, but decided to show an arrangement that traps 1,225 ytterbium.”

Read more on Govindhtech.com

2 notes

·

View notes

Text

"Scientists at Heriot-Watt University in Edinburgh, Scotland, have found a powerful new way to program optical circuits that are critical to the delivery of future technologies such as unhackable communications networks and ultrafast quantum computers.

"Light can carry a lot of information, and optical circuits that compute with light—instead of electricity—are seen as the next big leap in computing technology," explains Professor Mehul Malik, an experimental physicist and Professor of Physics at Heriot-Watt's School of Engineering and Physical Sciences.

"But as optical circuits get bigger and more complex, they're harder to control and make—and this can affect their performance. Our research shows an alternative—and more versatile—way of engineering optical circuits, using a process that occurs naturally in nature.""

"Professor Malik said the power of light was in its multiple dimensions.

"We can encode a lot of information on a single particle of light," he explained. "On its spatial structure, on its temporal structure, on its color. And if you can compute with all of those properties at once, that unlocks a massive amount of processing power.""

continue reading article

#physics#quantum physics#light#energy#information#optics#photonics#optical fiber#safe technology#communication#quantum computing#nature#quantum mechanics#multidimensional#science#technology

3 notes

·

View notes

Text

'First light': NASA receives laser beam message from 16 million kilometers away

Fernando Valduga By Fernando Valduga 11/27/2023 - 08:43 in Space, Technology

An innovative experiment flying aboard NASA's Psyche mission has just reached its first major milestone by successfully carrying out the most distant demonstration of laser communications.

The technological demonstration may one day help NASA's missions to investigate space more deeply and discover more discoveries about the origin of the universe.

Launched in mid-October, Psyche is currently on its way to humanity's first glimpse of a metallic asteroid between the orbits of Mars and Jupiter. The probe will spend the next six years traveling about 3.6 billion kilometers to reach its namesake, located on the outside of the main asteroid belt.

Along with the tour is the demonstration of Deep Space Optical Communications technology, or DSOC, which is carrying out its own mission during the first two years of the trip.

The technological demonstration was designed to be the most distant experiment of the U.S. space agency of high-bandwidth laser communications, testing the sending and receiving of data to and from Earth using a near-infrared invisible laser. The laser can send data from 10 to 100 times the speed of traditional radio wave systems that NASA uses in other missions. If it is totally successful in the coming years, this experience could be the future basis of the technology used to communicate with humans who explore Mars.

And the DSOC recently achieved what engineers called the "first light", the feat of successfully sending and receiving their first data.

The experiment sent for the first time a laser encoded with data from far beyond the Moon. The test data were sent from almost 16 million kilometers away and arrived at the Hale Telescope at the Palomar Observatory of the California Institute of Technology in Pasadena, California.

The distance between DSOC and Hale was about 40 times greater than the Moon is from Earth.

Psyche Probe.

“Achieveing the first light is one of the many critical milestones of the DSOC in the coming months, paving the way for communications with higher data rates, capable of sending scientific information, high-definition images and video streaming in support of humanity's next giant leap: sending human beings to Mars,” Trudy Kortes, director of technology demonstrations at NASA's Directorate of Space Technology Missions, said in a statement.

Sending lasers through space

The first light, which occurred on November 14, happened when the laser flight transceiver instrument in Psyche received a laser beacon sent from the Optical Communications Telescope Laboratory at the Table Mountain facility of NASA's Jet Propulsion Laboratory near Wrightwood, California.

The initial beacon received by Psyche's transceiver helped the instrument point its laser to send data back to the Hale Telescope, which is located about 160 kilometers south of Table Mountain.

“The test (of November 14) was the first to fully incorporate ground resources and the flight transceiver, requiring the DSOC and Psyche operations teams to work together,” Meera Srinivasan, DSOC operations leader at JPL, located in Pasadena, California, said in a statement. "It was a formidable challenge and we have much more work to do, but in a short time we were able to transmit, receive and decode some data."

This is not the first time that laser communications have been tested in space. The first bidirectional laser communication test took place in December 2021, when NASA's Laser Communications Relay Demonstration was launched and went into orbit about 22,000 miles (35,406 kilometers) from Earth.

Since then, experiments have sent optical communications from the Earth's low orbit to the Moon. And the Artemis II spacecraft will use laser communications to send high-definition videos of a manned trip around the Moon. But DSOC marks the first time that laser communications have been sent through deep space, which requires incredibly accurate aiming and pointing over millions of kilometers.

The initial test of the capabilities of the technical demonstration will allow the team to work on the refinement of the systems used in the laser pointing accuracy. As soon as the team ticks this box, the DSOC will be ready to send and receive data to the Hale Telescope as the spacecraft moves away from Earth.

Future challenges

Although the DSOC does not send scientific data collected by the Psyche spacecraft because it is an experiment, the laser will be used to send bits of test data encoded in the photons of the laser, or quantum light particles.

Detector matrices on Earth can capture the Psyche signal and extract the data from the photons. This type of optical communication can change the way NASA sends and receives data from its deep space missions.

“Optical communication is a blessing for scientists and researchers who always want more from their space missions and will allow human exploration of deep space,” Dr. Jason Mitchell, director of the Advanced Communications and Navigation Technologies Division of the Department of Communications and NASA's Space Navigation program said in a statement. "More data means more discoveries."

As Psyche continues his journey, more challenges await him.

youtube

The DSOC team will monitor how long it takes for laser messages to travel through space. During the first light, the laser took only 50 seconds to travel from Psyche to Earth. At the farthest distance between the spacecraft and the Earth, the laser is expected to take 20 minutes to travel one direction. And during that time, the spacecraft will continue to move and the Earth will rotate.

Meanwhile, the Psyche spacecraft continues to prepare for its main mission, connecting propulsion systems and testing the scientific instruments needed to study the asteroid when it arrives in July 2029. The mission will be able to determine whether the asteroid is the exposed nucleus of an ancient planetary building block since the beginning of the solar system.

Source: CNN

Tags: SpaceNASA

Sharing

tweet

Fernando Valduga

Fernando Valduga

Aviation photographer and pilot since 1992, has participated in several events and air operations, such as Cruzex, AirVenture, Dayton Airshow and FIDAE. He has work published in specialized aviation magazines in Brazil and abroad. Uses Canon equipment during his photographic work in the world of aviation.

Related news

SPACE

Space Operations Command reveals official 'futuristic' painting

11/26/2023 - 6:01 PM

A Chollima-1 rocket launched North Korea's first spy satellite on Tuesday, after two failed attempts since the summer. (Photo: NKNA)

SPACE

North Korea claims that it has successfully put spy satellite into orbit and will launch more

22/11/2023 - 21:17

Sierra Space's first Dream Chaser vehicle, called Tenacity, will soon go to a NASA facility in Ohio for environmental testing before a launch scheduled for spring 2024. (Photo: Sierra Space)

SPACE

Sierra Space completes the assembly of the first Dream Chaser, Tenacity

22/11/2023 - 11:14

TECHNOLOGY

NASA starts X-59 Quesst painting process

20/11/2023 - 23:03

SPACE

VIDEO AND IMAGES: SpaceX's Starship launch fails minutes after reaching space

11/18/2023 - 4:30 PM

SPACE

Satellite with Saab technology is launched by SpaceX

14/11/2023 - 08:10

3 notes

·

View notes

Text

Shafted Hall Effect Sensors Market: Technological Advancements Reshaping Illumination Control

MARKET INSIGHTS

The global Shafted Hall Effect Sensors Market size was valued at US$ 567.8 million in 2024 and is projected to reach US$ 945.2 million by 2032, at a CAGR of 7.60% during the forecast period 2025-2032.

Shafted Hall effect sensors are compact magnetic field sensing devices with injection-molded housings designed for precision measurement in rotary and linear motion applications. These sensors operate on the Hall effect principle, where they detect changes in magnetic fields to measure position, speed, or directional movement. Their rugged construction allows operation across wide temperature ranges (-40°C to 150°C) while maintaining resistance to moisture and environmental contaminants.

The market growth is driven by increasing automation in industrial sectors and rising demand for contactless sensing solutions in automotive applications. While the industrial equipment segment currently dominates with over 45% market share, the automotive sector is witnessing accelerated adoption due to electrification trends. Recent advancements include miniaturized form factors with improved signal-to-noise ratios, enabling higher precision in tight spaces. Key players like Sensata Technologies and TE Connectivity are expanding their portfolios with IoT-enabled sensors featuring integrated diagnostics.

MARKET DYNAMICS

MARKET DRIVERS

Growing Industrial Automation to Fuel Demand for Shafted Hall Effect Sensors

The rapid expansion of industrial automation across manufacturing sectors is driving significant demand for shafted Hall effect sensors. These sensors play a critical role in position sensing, speed detection, and angular measurement in automated systems. The global industrial automation market is projected to maintain a robust growth rate, creating parallel opportunities for shafted Hall effect sensor manufacturers. Their durability, precision, and ability to operate in harsh environments make them indispensable components in modern automated production lines. Recent advancements in Industry 4.0 technologies have further intensified this demand, particularly for sensors that can deliver accurate real-time data for process optimization.

Electric Vehicle Revolution to Accelerate Market Expansion

The automotive industry’s accelerated shift toward electric vehicles presents a substantial growth opportunity for shafted Hall effect sensors. These sensors are essential components in EV powertrains, battery management systems, and motor control units. With global EV sales surpassing 10 million units annually and projected to grow exponentially, the demand for reliable position sensing solutions is reaching unprecedented levels. Major automotive manufacturers are increasingly specifying shafted Hall effect sensors for their compact size, resistance to vibration, and ability to operate in electromagnetic interference-rich environments characteristic of electric vehicles.

Furthermore, government initiatives supporting EV adoption across major economies are creating favorable conditions for sensor manufacturers:

➤ Several national policies now include stringent requirements for position sensing accuracy in EV components, directly benefiting high-performance Hall effect sensor suppliers.

MARKET RESTRAINTS

Intense Price Competition from Alternative Technologies to Limit Growth

While shafted Hall effect sensors offer numerous advantages, the market faces considerable pressure from competing technologies such as optical encoders and inductive sensors. These alternatives have seen significant price reductions in recent years, making them attractive options for cost-sensitive applications. The average selling price for standard shafted Hall effect sensors has declined steadily, squeezing profit margins for manufacturers. This pricing pressure is particularly acute in high-volume consumer applications where even marginal cost differences significantly influence purchasing decisions.

Additionally, the growing adoption of integrated sensor solutions that combine multiple sensing modalities presents a competitive challenge for standalone Hall effect sensor providers.

MARKET CHALLENGES

Complex Supply Chain Disruptions to Impact Production Capacities

The shafted Hall effect sensor market continues to grapple with multifaceted supply chain challenges that emerged following recent global disruptions. Semiconductor material shortages have particularly affected sensor production, given their reliance on specialized magnetic materials and integrated circuits. Lead times for certain critical components have extended dramatically, forcing manufacturers to either maintain larger inventories or risk production delays. These challenges are compounded by rising transportation costs and geopolitical factors affecting rare earth material supplies essential for sensor manufacturing.

Other Significant Challenges Include:

Technical Limitations in Extreme Environments While shafted Hall effect sensors perform well in most industrial conditions, their reliability can be compromised in extremely high-temperature or highly corrosive environments. This limitation restricts their applicability in certain heavy industrial and aerospace applications where alternative technologies may be preferred.

Miniaturization Demands The persistent industry trend toward smaller form factors presents engineering challenges for maintaining sensor accuracy and durability in ever-shrinking packages, requiring continuous R&D investments.

MARKET OPPORTUNITIES

Emerging IoT Applications to Create New Growth Verticals

The rapid proliferation of Industrial Internet of Things (IIoT) deployments is opening substantial new opportunities for shafted Hall effect sensor manufacturers. These sensors are increasingly being integrated into predictive maintenance systems and smart equipment monitoring solutions. The ability of Hall effect sensors to provide reliable, contactless position data makes them ideal for IIoT applications where continuous monitoring is essential. Market analysts project strong growth in this segment as industries increasingly adopt condition-based maintenance strategies that rely on real-time sensor data.

Medical Device Innovations to Drive Premium Sensor Demand

The medical equipment sector is emerging as a high-growth market for precision shafted Hall effect sensors. These components are finding increasing use in advanced imaging systems, robotic surgical equipment, and portable medical devices. The medical sensor market commands premium pricing due to stringent reliability requirements and regulatory certifications. Several leading sensor manufacturers have recently introduced medical-grade shafted Hall effect sensors with enhanced EMI resistance and sterilization capability, specifically targeting this lucrative segment.

SHAFTED HALL EFFECT SENSORS MARKET TRENDS

Automotive Electrification Drives Demand for Hall Effect Sensors

The global shafted Hall Effect sensors market is witnessing significant growth, driven primarily by the increasing electrification of automotive systems. These compact, durable sensors play a critical role in modern vehicle systems, enabling precise angular position sensing in throttle valves, pedal positions, and transmission systems. With electric vehicle production expected to grow at a CAGR of over 26% through 2030, OEMs are incorporating more Hall Effect sensors to monitor motor position and speed in electrified powertrains. The automotive sector now accounts for nearly 42% of all shafted Hall Effect sensor applications globally.

Other Key Trends

Miniaturization and IoT Integration

The demand for compact, rugged position sensors has increased across industrial automation and consumer electronics sectors. Shafted Hall Effect sensors – combining high accuracy with small form factors – are increasingly being integrated into IoT-enabled devices. Their ability to operate in harsh environments without physical contact makes them ideal for smart factory equipment, where they monitor parameters like fluid levels, valve positions, and actuator movements. The industrial segment is projected to account for over 28% of market revenue by 2030 as Industry 4.0 adoption accelerates.

Technological Advancements in Sensing Capabilities

Recent innovations are expanding the capabilities of shafted Hall Effect sensors to meet evolving industry needs. Rotary Hall Effect sensors now achieve angular resolutions below 0.1°, while linear variants offer sub-millimeter precision. Manufacturers are also developing multi-axial sensing solutions that combine position and speed measurement in single packages, reducing system complexity. These advancements are particularly valuable in medical devices and robotics, where precision motion control is critical. The integration of self-diagnostics and digital interfaces (like I²C and SPI) is further enhancing their utility in connected industrial systems.

COMPETITIVE LANDSCAPE

Key Industry Players

Innovation and Global Expansion Drive Market Competition

The global Shafted Hall Effect Sensors market is moderately fragmented, with established multinational corporations competing alongside specialized regional players. Sensata Technologies leads the market with its comprehensive portfolio of rugged, high-performance sensors designed for automotive and industrial applications. The company’s strong engineering capabilities and vertically integrated manufacturing give it a competitive edge in pricing and quality control.

TE Connectivity and Amphenol Corporation maintain significant market positions due to their extensive distribution networks and ability to provide customized sensor solutions. These companies have strategically expanded their production facilities in Asia to capitalize on growing demand from China’s automotive sector.

Several European manufacturers like Gefran and Elen srl have carved out strong niches in precision industrial applications. Their expertise in developing sensors that operate reliably in harsh environments has made them preferred suppliers for heavy machinery and automation systems.

Meanwhile, DiscoverIE Plc and Novotechnik are investing heavily in next-generation Hall Effect technologies that integrate digital interfaces and IoT capabilities. These enhancements allow for predictive maintenance features – a key value proposition for industrial customers looking to minimize downtime.

List of Key Shafted Hall Effect Sensor Manufacturers

Sensata Technologies (U.S.)

TE Connectivity (Switzerland)

Amphenol Corporation (U.S.)

Gefran (Italy)

Elen srl (Italy)

Servotech Instrumentation (India)

P3 America (U.S.)

Novotechnik (Germany)

Vishay (U.S.)

DiscoverIE Plc (U.K.)

Segment Analysis:

By Type

Rotary Hall Effect Sensor Segment Leads Due to Wide Industrial and Automotive Applications

The market is segmented based on type into:

Rotary Hall Effect Sensor

Linear Hall Effect Sensor

By Application

Industrial Equipment Segment Dominates Market Owing to Automation and Process Control Requirements

The market is segmented based on application into:

Industrial Equipment

Automotive

Telecommunications Equipment

Others

By End-User

Manufacturing Sector Holds Major Share Due to Precision Measurement Needs

The market is segmented based on end-user into:

Manufacturing Industries

Automotive OEMs

Telecom Providers

Consumer Electronics

Others

Regional Analysis: Shafted Hall Effect Sensors Market

North America The North American market for shafted Hall effect sensors is driven by strong demand from the industrial automation and automotive sectors, particularly in the U.S. and Canada. The U.S. accounts for the majority of the regional market due to heavy investments in Industry 4.0 adoption, with leading manufacturers such as Sensata Technologies and TE Connectivity headquartered here. Stringent safety regulations in automotive applications, particularly in electric vehicles (EVs), further boost demand. However, the market faces challenges from increasing competition from alternative sensing technologies and supply chain disruptions.

Europe Europe remains a key market for shafted Hall effect sensors, driven by advancements in industrial automation and strong automotive manufacturing activities in Germany, France, and Italy. The EU’s focus on precision engineering and energy-efficient solutions supports sensor adoption in high-performance applications. Market leaders like Gefran and Novotechnik have capitalized on the region’s emphasis on quality-controlled manufacturing. However, strict regulatory compliance and elevated production costs compared to Asian manufacturers present constraints for market expansion.

Asia-Pacific The Asia-Pacific region dominates global consumption of shafted Hall effect sensors, primarily due to rapid industrialization in China, Japan, and India. China, being a manufacturing powerhouse, leads in both production and utilization of these sensors across automotive and telecommunications sectors. Cost-effectiveness and scalability of local suppliers such as Vishay and Servotech Instrumentation fuel market growth. Meanwhile, Japan’s precision manufacturing industry and India’s expanding automation sector contribute significantly. Though price sensitivity remains a challenge, increasing investments in smart manufacturing are expected to sustain demand.

South America Market growth in South America is gradual, influenced by Brazil’s and Argentina’s emerging industrial sectors. While adoption of shafted Hall effect sensors is primarily seen in automotive manufacturing, economic instability limits widespread industrial automation. Local players face competition from imported products, yet the growing focus on upgrading manufacturing facilities hints at untapped potential. Regulatory gaps and limited R&D investments hinder faster technological adoption despite the expanding market.

Middle East & Africa This region shows moderate demand, primarily driven by industrial and automotive applications in GCC countries such as Saudi Arabia and the UAE. Investments in smart infrastructure and gradual industrial diversification are creating opportunities for sensor integration. However, the market’s growth remains constrained by reliance on imports and limited local manufacturing capabilities. Though still nascent, strategic collaborations with international players like Amphenol Corporation could enhance market penetration in the long term.

Report Scope

This market research report provides a comprehensive analysis of the global and regional Shafted Hall Effect Sensors markets, covering the forecast period 2025–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments, and market value across major regions and segments. The global Shafted Hall Effect Sensors market was valued at USD 260 million in 2024 and is projected to reach USD 380 million by 2032, growing at a CAGR of 4.8%.

Segmentation Analysis: Detailed breakdown by product type (Rotary Hall Effect Sensor, Linear Hall Effect Sensor), application (Industrial Equipment, Automotive, Telecommunications Equipment), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (USD 85 million in 2024), Europe, Asia-Pacific (fastest growing at 6.2% CAGR), Latin America, and Middle East & Africa, including country-level analysis.

Competitive Landscape: Profiles of leading market participants including Sensata Technologies (12% market share), TE Connectivity, Amphenol Corporation, and Vishay, covering product portfolios, R&D investments, and strategic developments.

Technology Trends & Innovation: Assessment of miniaturization trends, integration with IoT systems, and advancements in magnetic sensing technologies.

Market Drivers & Restraints: Evaluation of factors including industrial automation growth, automotive electrification trends, and challenges related to raw material pricing volatility.

Stakeholder Analysis: Strategic insights for sensor manufacturers, OEMs, system integrators, and investors regarding market opportunities and competitive positioning.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/laser-diode-cover-glass-market-valued.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/q-switches-for-industrial-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ntc-smd-thermistor-market-emerging_19.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/lightning-rod-for-building-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/cpe-chip-market-analysis-cagr-of-121.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/line-array-detector-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/tape-heaters-market-industry-size-share.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/wavelength-division-multiplexing-module.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/electronic-spacer-market-report.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/5g-iot-chip-market-technology-trends.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/polarization-beam-combiner-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/amorphous-selenium-detector-market-key.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/output-mode-cleaners-market-industry.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/digitally-controlled-attenuators-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/thin-double-sided-fpc-market-key.html

0 notes

Text

Understanding the Role of Hollow Shaft Rotary Encoders in Modern Robotics

Introduction to Rotary Encoders in Robotics

Rotary encoders are fundamental components in robotic systems, serving as critical feedback devices that measure the rotation, position, and direction of motor shafts. These sensors translate mechanical motion into electrical signals, which control systems then interpret to ensure precise movement. Among the various types of rotary encoders, hollow shaft rotary encoders have emerged as a key player due to their compact design, ease of integration, and high reliability. As robotics continues to permeate sectors like manufacturing, healthcare, logistics, and consumer electronics, understanding the specific contributions of hollow shaft rotary encoders becomes vital. Their importance lies not only in their functional capabilities but also in how they influence design flexibility and performance optimization in robotic applications. By integrating seamlessly into existing architectures, these encoders reduce mechanical complexity while improving feedback accuracy. This comprehensive examination will explore how these components are revolutionizing modern robotics, from their design advantages to their roles in various robotic subsystems.

Evolution of Rotary Encoders and Robotic Needs

The development of rotary encoders parallels the evolution of robotics itself. Early robotic systems relied on open-loop controls, often leading to inaccuracies and inefficiencies. As the demand for precision and repeatability grew, rotary encoders became indispensable. Initially, these sensors were bulky and susceptible to environmental interference. Over time, however, innovations in materials, signal processing, and miniaturization led to more robust and compact designs. Hollow shaft rotary encoders, in particular, emerged as a response to the need for space-saving yet highly accurate feedback devices. Robotics has evolved from simple pick-and-place machines to complex, autonomous entities requiring precise coordination across multiple axes. This shift necessitated encoders capable of delivering consistent, high-resolution feedback without contributing to design bulk. In mobile robots, surgical devices, and industrial arms, space is a premium commodity. Hollow shaft encoders allow engineers to route cables or mechanical shafts through the encoder's center, optimizing spatial configuration and reducing wear on moving parts. This evolution marks a significant turning point in the interplay between sensor technology and robotic capability.

Anatomy of a Hollow Shaft Rotary Encoder

At its core, a hollow shaft rotary encoder consists of a rotor, stator, and signal processing circuitry housed in a compact unit. What distinguishes it from other encoder types is the central hollow section through which a shaft or cabling can pass. This seemingly simple design offers substantial advantages. The rotor attaches directly to the rotating shaft, while the stator remains fixed to the structure. As the shaft turns, the encoder senses the angular displacement and transmits corresponding electrical signals. These signals may be digital or analog, depending on the encoder type and application. Typically, hollow shaft encoders utilize optical, magnetic, or capacitive technologies to detect movement. Optical encoders, for instance, use a light source and a photo-detector array to interpret interruptions in a coded disc. This method provides high-resolution data, essential for robotic operations requiring micrometer-level precision. Additionally, many hollow shaft encoders incorporate features like integrated bearings, multi-turn tracking, and error correction protocols, ensuring they maintain accuracy even under high-speed or high-vibration conditions.

Integration in Robotic Joint Systems

One of the primary applications of hollow shaft rotary encoders in robotics is within joint systems. Whether in humanoid robots or articulated industrial arms, joint movement must be monitored and controlled with utmost precision. Hollow shaft encoders facilitate this by being mounted directly onto the joint actuators, enabling real-time position feedback. Their hollow design allows power and data cables to pass through the joint axis, reducing external cabling and potential points of failure. This configuration not only enhances the mechanical efficiency of the joint but also simplifies maintenance and design. In collaborative robots, or cobots, where safety and fluid motion are paramount, these encoders help ensure smooth articulation and responsive behavior. They support closed-loop control systems that adjust motor output dynamically based on encoder feedback. This loop is crucial for tasks like pick-and-place operations, precision welding, or surgical manipulations, where even millimeter-level deviations can compromise functionality or safety. By offering a balance of compactness, accuracy, and reliability, hollow shaft rotary encoders are central to robotic articulation systems.

Enhancing Mobility in Autonomous Robots

Autonomous mobile robots (AMRs) require robust sensory systems to navigate complex environments accurately. Hollow shaft rotary encoders play an essential role in this context by providing reliable feedback on wheel or track rotation. Unlike incremental encoders that only track changes in position, absolute feedback systems offer the advantage of positional memory. This becomes crucial in navigation, where knowing the robot's exact orientation at any given time determines path planning and obstacle avoidance efficacy. In differential drive systems, for instance, encoders mounted on each wheel shaft measure relative speeds and directions, allowing for accurate steering and speed control. The compact nature of hollow shaft encoders is especially beneficial in mobile platforms, where every millimeter of space impacts battery size, payload capacity, or sensor load. Their integration also enhances durability since fewer external mechanical parts mean less exposure to dust, moisture, or mechanical wear. This synergy of design efficiency and functional robustness makes hollow shaft encoders indispensable in robotic mobility subsystems.

Role in Precision Tasks and Fine Manipulation

Modern robotics increasingly involves tasks requiring fine motor control, such as electronic assembly, 3D printing, and medical interventions. In these scenarios, the encoder’s resolution and responsiveness directly impact task accuracy. Hollow shaft rotary encoders contribute significantly by enabling micro-adjustments based on real-time positional data. In robotic arms used for electronic manufacturing, for instance, components must be placed with sub-millimeter accuracy. The encoder's feedback ensures that the tool tip follows the programmed path without deviation. Similarly, in 3D printing, layer consistency and nozzle positioning depend heavily on precise rotary feedback. Medical robotics, particularly in minimally invasive surgery, represents another frontier where precision is non-negotiable. Here, hollow shaft encoders are used in tool actuation systems, allowing surgeons to perform complex procedures remotely with high confidence in the robot's positional accuracy. The encoders’ inherent design also aids in sterilization and integration within tight surgical tool assemblies. Thus, their role extends from mechanical feedback to enabling new capabilities in high-precision robotic tasks.

Environmental Robustness and Industrial Viability

Robotic systems often operate in harsh environments—factories, outdoor settings, or hazardous locations. Devices integrated into such systems must exhibit resilience to temperature fluctuations, vibrations, dust, and moisture. Hollow shaft rotary encoders are increasingly engineered with these challenges in mind. Manufacturers offer variants with IP-rated enclosures, corrosion-resistant materials, and sealed optical systems. This robustness allows them to function reliably in automotive assembly lines, mining robots, or agricultural drones. In temperature-controlled warehouse automation, for example, encoders must perform consistently despite frequent exposure to cold or variable humidity levels. The absence of exposed cables and the encoder’s enclosed design minimize contamination risks and mechanical wear. These features contribute to lower maintenance demands and longer operational lifespans, which are critical in high-throughput industrial settings. Moreover, their compatibility with various communication protocols—such as EtherCAT, CANopen, and SSI—ensures that they can be integrated into diverse control architectures without extensive modification. This adaptability further cements their place in modern industrial robotics.

Supporting Safety and Redundancy Mechanisms

Safety is a fundamental concern in robotics, particularly in collaborative or human-facing environments. Encoders play a vital role in ensuring operational safety by providing accurate position feedback for motion verification and error detection. Hollow shaft rotary encoders are especially suited for redundant systems, where multiple sensors verify each other's outputs. This redundancy ensures that if one sensor fails, the system can continue operating safely or shut down in a controlled manner. In safety-rated robotic arms, encoders are often employed in tandem with other sensors to monitor limits and ensure compliance with predefined safety envelopes. Their high resolution and low latency make them ideal for such critical feedback loops. Additionally, their compact form factor allows for integration into secondary safety circuits without adding bulk. The feedback from these encoders also enables soft-limit programming, which prevents actuators from moving beyond safe zones. In service robots or exoskeletons, where human safety is paramount, this encoder-driven feedback becomes essential for real-time decision-making and reactive control.

Future Outlook: Smart Integration and Predictive Maintenance

As robotics evolves towards greater autonomy and intelligence, the role of feedback devices like hollow shaft rotary encoders is also transforming. Modern encoders are increasingly being equipped with smart features such as self-diagnostics, condition monitoring, and real-time data streaming. These capabilities feed into predictive maintenance systems, helping operators detect wear or misalignment before it causes failure. For example, by monitoring signal consistency or rotational anomalies, the encoder can alert the system to potential mechanical issues. This proactive approach reduces downtime and extends the life of robotic assets. Furthermore, as artificial intelligence becomes integral to robotics, encoder data can be used to train machine learning models for movement optimization and adaptive control. Smart encoders also support advanced communication standards that facilitate seamless integration into IoT-enabled infrastructures. This trend indicates a shift from passive sensing to active data contribution, where encoders not only report motion but also enhance system intelligence. Such evolution positions hollow shaft rotary encoders as foundational components in next-generation robotic ecosystems.

Precision Engineering Meets Practical Application

The intersection of precision engineering and practical robotic application is where hollow shaft rotary encoders demonstrate their full potential. As manufacturing tolerances tighten and robotic roles diversify, the demand for encoders that can deliver high-resolution feedback in compact, rugged packages continues to grow. These devices are not only vital for motion tracking but also contribute to reducing system complexity, enhancing safety, and enabling adaptive control. Their utility spans industries and use-cases, from autonomous warehouse robots to robotic-assisted surgery. As designers push the boundaries of what robots can achieve, they increasingly turn to encoders that offer a balance of size, accuracy, and integration flexibility. Among these, the hollow shaft rotary encoder stands out for its ability to combine mechanical elegance with technical performance. Its role in facilitating the compact, precise, and reliable movement is central to the continued advancement of robotics.

Enhancing Control Through Advanced Feedback Systems

In many robotic systems, especially those with complex kinematics, advanced feedback is necessary to synchronize multiple actuators. Here, the absolute rotary encoder proves instrumental. By providing unique position values that do not require recalibration after power loss, these encoders enhance system reliability and responsiveness. This becomes particularly valuable in automated systems that must resume operation immediately after interruptions. Their use simplifies control algorithms and reduces computational overhead, which in turn allows for more fluid and responsive robotic behavior. From industrial automation lines to mobile robotic platforms, absolute encoders bring consistency and predictability, even under dynamic load changes or complex trajectories. When integrated with real-time control loops, they enable smoother transitions, better torque management, and reduced mechanical stress. These benefits contribute to more agile and longer-lasting robotic systems.

Meeting Modern Demands with Cutting-Edge Solutions

The robotic landscape is shifting rapidly, driven by needs for flexibility, scalability, and intelligence. In this context, the absolute position encoder emerges as a critical component, especially in scenarios where exact positioning is non-negotiable. Whether it’s aligning robotic cameras, controlling prosthetic limbs, or managing the angular position of robotic grippers, these encoders deliver the granularity required for high-precision tasks. They also facilitate seamless feedback for AI-driven decisions, particularly in adaptive robotics that interact with unpredictable environments. The encoder's ability to provide exact position data without drift ensures consistent performance across repetitive tasks. In emerging sectors like robotics-as-a-service or modular robotics, where plug-and-play compatibility is essential, these encoders ensure that new modules or replacements can integrate smoothly and function reliably. As expectations for precision, speed, and autonomy grow, so too does the importance of dependable, high-performance feedback systems like the absolute position encoder.

0 notes

Text

Small Servo Motors and Drives: Big Performance in a Compact Package

When you think of high-precision motion systems, it's easy to imagine large, complex machines operating in sprawling factories. But what about applications where space is limited, yet the demand for performance remains sky-high? This is where small servo motors and drives come into play—offering the same precision and control as their larger counterparts, in a much smaller footprint.

At their core, small servo systems provide closed-loop motion control using a servo motor and a dedicated drive. The combination ensures that position, speed, and torque are tightly managed, which is essential in applications like robotics, medical equipment, lab automation, and compact assembly lines.

1. Miniature Size, Maximum Accuracy

Don’t let their size fool you—small servo motors are engineered to deliver incredible accuracy. With high-resolution encoders and fast feedback loops, these motors can achieve micron-level precision. For industries where detail matters—like electronics, 3D printing, or optical manufacturing—this is a critical advantage.

2. Space-Saving, Cost-Saving

One of the biggest advantages of small servo motors and drives is their ability to save valuable space. Compact control cabinets, lightweight end-of-arm tools, and portable machines benefit greatly from these scaled-down systems.

But space isn’t the only thing saved—costs come down too. Smaller systems typically consume less power, generate less heat, and require fewer support components, making them more efficient both operationally and financially.

3. Highly Responsive for Delicate Tasks

In precision operations such as dosing, cutting, or delicate part manipulation, speed without control is useless. THM Huade’s small servo motors and drives are built for fast, intelligent response to changing loads or commands. Whether you’re operating a miniature conveyor belt or a robotic gripper, every movement is smooth and predictable.

4. Plug-and-Play Integration

Small servo drives from THM Huade come with user-friendly interfaces and are compatible with popular industrial control systems like EtherCAT and Modbus. The drives support both position and torque modes and offer configuration flexibility, so you can adapt them easily to a wide variety of compact machinery.

5. Built for Versatility

These small systems might be designed for tight spaces, but their capabilities are expansive. From lab automation to packaging equipment, and from laser cutters to textile machines—small servo motors and drives prove themselves in virtually any application where precision and footprint matter.

Why Choose THM Huade?

At THM Huade, we understand the challenges of fitting high-performance automation into limited space. Our small servo motors and drives are designed with engineers and integrators in mind—offering powerful functionality, long-term reliability, and seamless integration with your existing systems.

Backed by technical support and decades of industry experience, our solutions are built to help you scale precision, not just machinery.

💡 Interested in upgrading your compact motion system with intelligent servo technology? Visit THM Huade to discover small servo motors and drives that deliver big results in tight spaces.

#SmallServoMotors#ServoDrives#THMHuade#PrecisionAutomation#CompactMachinery#MiniServoSystems#SmartManufacturing#MotionControlTech#IndustrialAutomation#HighPrecisionDrives

0 notes

Text

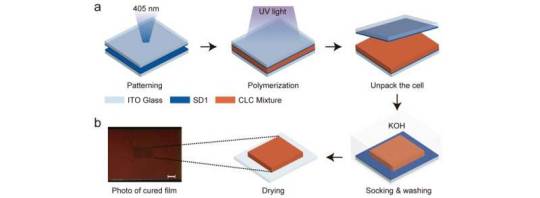

Geometric phase-encoded liquid crystal optical sensing

Sensing technology, integral to environmental monitoring, data acquisition, and precision data processing, is evolving rapidly. Researchers are at the forefront of developing swift, accessible, and cost-effective sensors. Among these innovations, cholesteric liquid crystals (CLCs) in stimulus-responsive photonic crystals exhibit exceptional promise. Their unique helical structure and photonic properties enable the production of vivid, power-independent structural colors, paving the way for advanced visual analysis tools. However, a significant challenge hinders CLC's broader application in optical sensing: Although they visibly alter color in response to stimuli, accurately gauging these changes necessitates costly spectroscopic equipment, constraining their practical deployment. Responding to the growing need for compact and planar optical elements, researchers have investigated Pancharatnam-Berry geometric phases, derived from light's spin-orbit interactions. Recent developments include integrating the geometric phase into reflected light via CLC helical superstructures, leading to novel photonic applications.

Read more.

7 notes

·

View notes

Text

Automated Production and Testing Processes of Rocker Switches

1. Introduction

With the rapid development of industrial automation, the manufacturing process of rocker switches has undergone a transformation from traditional manual production to highly automated, precision-controlled production lines. This shift not only improves production efficiency and product consistency but also enhances the competitiveness of enterprises in the market. This article will provide a comprehensive overview of the automated production and testing processes of rocker switches, including automated terminal insertion, automated spot welding, automated LED placement, as well as contact resistance testing, travel and pressure testing, continuity time measurement, and industrial vision-based appearance inspection. These technologies represent a high degree of integration between mechanical systems, electronic control, and intelligent algorithms.

2. Automated Assembly Processes in Rocker Switch Production

2.1 Automated Terminal Insertion

Terminal insertion is one of the most critical steps in rocker switch production. Traditional manual insertion is prone to positional deviation and insertion force instability, which may cause defective contact or product rejection. Modern production lines adopt servo-controlled automated terminal insertion systems, which use multi-axis manipulators to position terminals precisely. High-precision optical sensors ensure insertion depth and orientation consistency.

For instance, the system automatically picks the copper terminal from the feeder, precisely aligns it with the switch base, and inserts it at a controlled speed and pressure. This ensures the mechanical integrity of the assembly and avoids micro-damage to the plastic shell, laying a solid foundation for subsequent spot welding.

2.2 Automated Spot Welding

Spot welding ensures the electrical connection between terminals and leads. The automated welding station uses resistance spot welding controlled by pulse current and time curves to precisely fuse metal interfaces.

Advanced systems are equipped with closed-loop current monitoring and displacement sensors, allowing real-time compensation for contact surface changes, thus ensuring stable and low-resistance welded joints. Additionally, the system is integrated with fume extraction and safety monitoring modules, improving the working environment and overall safety.

2.3 Automated LED Placement

Rocker switches with indicator lights require precise LED placement. Automated LED placement machines use high-speed pick-and-place heads and machine vision calibration to accurately position the LED within the switch cavity. The polarity and brightness are verified in real time during the process to ensure optical performance and visual consistency.

This process ensures that the LED does not shift during encapsulation or welding, maintaining long-term reliability and aesthetic appeal of the final product.

3. Automated Testing Systems for Rocker Switches

To ensure product reliability, each rocker switch must undergo comprehensive electrical and mechanical performance tests before leaving the factory.

3.1 Contact Resistance Test

The contact resistance test evaluates the resistance value across the conductive path under rated pressure. Modern automated testing equipment uses a 4-wire Kelvin method to eliminate lead resistance influence. The system can test multiple switches simultaneously, display resistance distribution curves in real-time, and automatically classify unqualified products.

Typical requirement: contact resistance < 50 mΩ (depending on the application scenario).

3.2 Travel and Pressure Test

Travel and pressure tests ensure the rocker switch provides the correct tactile feedback. High-precision linear actuators simulate human finger pressing motion, while pressure sensors and displacement encoders collect force-displacement data.

This allows evaluation of stroke range (e.g., 1.8–2.5 mm), actuation force (e.g., 300–600 gf), and pressing smoothness. Abnormalities such as mechanical jamming, misalignment, or inconsistent feedback can be identified and rejected automatically.

3.3 Continuity Time Measurement

Continuity time refers to the response speed of the switch after actuation. The test system uses high-speed data acquisition cards to detect signal transition points and calculate the time difference between actuation and circuit conduction.