#PCB Box Build

Explore tagged Tumblr posts

Text

2 notes

·

View notes

Text

0 notes

Text

Our Expertise

inYantra Technologies have two decades of experience in PCB Assembly and Box-Build, currently we are producing around 500+ varieties of PCBAs per month & 10 million PCBAs per annum. We support our customers from concept till commercialization while ensuring handholding until the new product is stabilized. We help our customers establish their complete supply chain and ensure ‘Design for Manufacturability’ that reduces/eliminates their field failure for longer product durability.

End-to-End Support

We pride ourselves on our ability to support our customers from concept to commercialization. This means that we are there every step of the way, ensuring that every aspect of the product development process is seamless and efficient. Our commitment doesn’t end with product launch; we continue to offer hand-holding support until the new product is fully stabilized in the market.

Supply Chain Management

In today’s global market, establishing a reliable and efficient supply chain is crucial. We assist our customers in building their complete supply chain, ensuring that all components and materials are sourced from trusted suppliers. This not only reduces costs but also enhances the overall quality and reliability of the final product.

Design for Manufacturability (DFM)

Our expertise in Design for Manufacturability (DFM) ensures that the products we develop are not only of the highest quality but also optimized for production. By focusing on DFM, we help reduce or eliminate field failures, leading to longer product durability and greater customer satisfaction.

Our Technology

At inYantra, we believe that cutting-edge technology is the key to producing the best products. Our expert and dynamic design team leverages advanced techniques and world-class processes for both Surface-Mount Device (SMD) and Through-Hole technology. This allows us to manufacture best-in-class products that are ‘first-time right’—meaning they meet all specifications and quality standards on the first attempt.

Lean Manufacturing

Our focus on lean manufacturing principles ensures that we minimize waste and maximize efficiency throughout the production process. This approach not only reduces costs but also leads to faster turnaround times for our customers.

Quality Assurance

We take quality seriously, which is why we conduct comprehensive Gauge R&R (Repeatability and Reproducibility) studies, CP (Capability) & CPK (Process Capability Index) measurements, and maintain a Kaizen-focused approach to continuous improvement. Our commitment to consistent quality and reliability is evident in every product we manufacture.

Customized Testing

Understanding that each product has unique requirements, we offer product-specific customized testing to ensure that every unit meets the highest standards. Our process-driven production is guided by detailed DFM analysis, process flow charts, control plans, and Process Failure Modes and Effects Analysis (FMEA), all of which contribute to producing reliable and robust products.

Conclusion

At inYantra, our combination of deep industry expertise and cutting-edge technology allows us to deliver superior PCB Assembly and Box-Build services. Whether you’re a start-up bringing a new concept to life or an established company looking to optimize your supply chain and manufacturing processes, we are here to support you every step of the way. With a focus on quality, reliability, and customer satisfaction, inYantra is your trusted partner in the world of electronics manufacturing.

1 note

·

View note

Text

A box build assembly involves integrating printed circuit boards (PCBs), cables, and various electronic components into a complete enclosure or chassis. This stage follows PCB fabrication and component assembly, representing a crucial step in the electronics manufacturing process. Combining mechanical, electrical, and aesthetic considerations, box build assembly results in a finished electronic product ready for consumer use. This complex process demands expertise in project management, supply chain coordination, quality control, mechanical integration, and rigorous testing. Companies specializing in box build assembly are often referred to as contract manufacturers or electronic manufacturing services (EMS). https://www.hitechpcba.com/pcb-assembly

For any box build assembly needs, please feel free to contact us. Email:[email protected]

0 notes

Text

Discover the best practices for collaborating effectively with box build assembly manufacturers. Learn how to streamline communication, ensure quality, and achieve successful outcomes for your projects.

#box build assembly manufacturers#box build assembly#pcb assembly#pcb manufacturer#pcb#pcb manufacturers

0 notes

Text

I bought an 8bitdo Retro mechanical keyboard!

(Picture not mine, source from PC World.)

I wanted a plastic keyboard, I really do not actually use the knob on a Keychron board I have, it still comes in a scooped keycap profile, and it has a companion numpad with a calculator built in. Win/win/win!

This keyboard comes in four designs (not colorways, full designs) themed after the NES, the Famicom, the IBM Model M, and the Commodore 64 keyboard. The NES keycaps have multiple different fonts on them, the Famicom keycaps have Japanese sublegends, the Model M keycaps have a mock stepped Caps Lock key, and the Commodore 64 keycaps are an apparently off-the-shelf SA set from one of many, many, many keycap companies floating around China (I recognize their font and profile shape from Akko ASA keycaps and numerous other scooped profile keycap sets you can have cheaply off of Aliexpress and Amazon. Do check those out, genuinely, you'd struggle to find a bad scooped keycap set these days and I love scooped profiles over Cherry and OEM.)

The build quality of the actual keyboard itself is good, feels like a very similar plastic blend to what 8bitdo uses for its controllers like their Pro 2. Stabilizers are smooth and don't rattle, the legends on the keycaps are reasonably sharp and in NES-appropriate font, the keycaps themselves are MDA profile (I would prefer SA, but beggars can't be choosers) and are somewhat thin but still good quality, dye-sublimated PBT, no warp on the spacebar. Arrow keys are a separate color from the two tones that make up the main keycap set and made to resemble a d-pad. The keyboard itself is somewhat light, but my perception is skewed from using a metal keyboard for a long time, and this is after all a plastic shell, top-mounted keyboard. Even so I think I'll probably end up cracking open the keyboard and putting in some liquid silicone as noise-dampening and additional weight.

Two knobs control both wireless functionality and computer software volume, the wireless knob is heavy with only three options while the volume one is light with many individual steps. The volume knob can be somewhat unresponsive on individual steps. Bluetooth is very responsive and wants to pair with my computer the moment it's flicked over to, and 2.4ghz wireless comes with a receiver that slots into the back of the keyboard magnetically for storage. A power light on the right of the keyboard mimics the NES power light and pulses while charging, is steady while using wireless or when fully charged and connected over USB.

The underlying PCB is south-facing hotswap sockets (who the hell cares their orientation, this only matters for lighting, which this keyboard doesn't have). By default the keyboard comes with Kailh box whites, a very light clicky switch. I yanked them out immediately and put Boba U4T tactiles in because they're the king of all switches. They thunk nicely in this chassis, the Kailh whites weren't slouches either, they did pick a good stock choice for switch without resorting to Gateron or Outemu blue horseshit.

The NES version of the keyboard came with a two-button macro pad that hooks over TRRS cable (you recognize it as a 3.5mm jack or headphone cable) to one of four ports on the top-right of the keyboard. These are essentially just two keyboard switches with giant keycaps on a separate board and the buttons are populated by Gateron greens. The switches are nowhere close to heavy enough to approximate a button, and I gave them Kailh box navies. Still not enough, but better.

These keyboards also come wiiiiiith a companion number pad!

(Picture credit the 8bitdo store.)

While I don't actually have this one in hand just yet I do have it on order. It looks like it'll be about the same build quality as the main keyboard, and it caught my eye for four reasons and ended up making me purchase the full set as a result:

The numpad has a built in calculator.

Same aesthetic choices as the main keyboard (NES, Famicom, IBM Model M, Commodore 64)

Magnetically attaches to the right side of the keyboard to transform it into a more era appropriate full-size.

Far and away the cheapest wireless mechanical numpad with calculator on the market, sitting at $45.

An important note though is that the Famicom and NES keypads don't attach to their respective keyboards, simply because their respective keyboards don't have magnets inside the sides of the chassis to allow for it. I have some cheap button magnets laying around that I'll use for this purpose and probably see if they're strong enough to be placed on the inside of the board and allow for the numpad to connect to it. I also imagine there's going to be a repop or v2 of this keyboard in the future that has this done already, seeing as the Commodore 64 version of the board and I believe the Model M version of the board already have that.

I'll reblog this and give some actual definitive thoughts on the numpad once it's in my hands.

As far as the board itself is concerned, I quite like it. The keycap profile is agreeable, the nostalgia pandering targeted me with laser precision, the board sounds quite good acoustically (especially for being a top-mount keyboard!) and it has a volume knob I'll see if I can reprogram some day. While I normally hate TKL layouts, I'm putting up with it because it will eventually be a fullsize with the numpad. Worth $150 total? Don't know, can't answer that for you, it's worth it to me but I very specifically wanted a keyboard themed after an old Nintendo console with no setup required and no chasing down or commissioning GMK keycap sets. I also wanted a calculator numpad.

#look at my flop reviews boy#mechanical keyboards#keyboards#mechanical keyboard#keyboard#tech#gadgets#computers#nintendo#NES#nintendo entertainment system

47 notes

·

View notes

Text

Rockwell XFV-12A

Rockwell XFV-12A

by Alex Stoll

Around 1970 the Navy could not see how it was going to be able to replace its old Essex and Midway carriers with Nimitz-class supercarriers. Admiral Elmo Zumwalt directed a study of alternatives which resulted in the Sea Control Ship (SCS), a mini-carrier equipped with V/STOL fighters and ASW aircraft. The USN invited manufactures to propose demonstration programs for a new aircraft, called the V/STOL Fighter Technology Prototype, to replace the outdated Harrier and serve on the SCS or other ships much smaller than conventional carriers: BAe and MD proposed an improved Harrier and a supersonic Harrier with a PCB (Plenum-Chamber Burning) engine; Boeing and Northrop proposed jet-powered tail-sitters; Lockheed-California proposed a propeller-driven tail-sitter; and Rockwell proposed a canard-delta aircraft powered by a large and enormously powerful engine that used the ejector-lift system for V/STOL. The Navy awarded the contract to Rockwell in 1972, instead of choosing designs based on proved technology, and the XFV-12A designation (twelth in the V series, not in the F series; the F-12 was the interceptor verison of the Blackbird) was allotted. Even though the forward fuselage and landing gear of the A-4 and the wing box, air intakes, and fuel tanks of the F-4 were used to speed the program up, it still ran far behind schedule. The prototype was rolled out in December 1976 and the first flight was scheduled for 1979.

Engine Configuration For takeoff and landing, the entire engine was ducted to hollow-section "ejector flaps" (also called augmentor flaps) out along the wings and the canard by pilot command via a diverter valve box. The high-energy hot gas forced fresh air from above through the ejector flaps at a ratio of 7.5:1 to boost thrust by 70 percent. The ejector flaps could be raised or lowered to provide a smooth transition from vertical to horizontal flight or vice versa. After the XFV-12A's cancellation, de Havilland Canada designed an aircraft with ejectors build into the roots of a delta wing. GD incorporated their concept into the E-7, a F-16-based delta-winged STOVL aircraft. DHC built a large powered model and tested it in 1987. The EL system was large and control was difficult as a result of the large air mass moving through the wing root during transition, and nothing came of it (though not because the EL couldn't produce enough thrust as in the XFV-12A's case) despite the attractive low exhaust velocity.

Cancellation Rockwell and Pratt & Whitney experienced several major technical problems, and the thrust boost from the ejector flap system was never as large in the full-scale aircraft as predicted from data collected by test rigs and sub-scale models; the XFV-12A could not leave the ground. Eventually funding dried up, the SCS was canceled, and the program proved a disappointment; however, in most future ASTOVL programs, large-scale powered models were used because of the experience gained in the XFV-12A program.

124 notes

·

View notes

Text

Good news: the PCB bus boards for my new Eurorack case came today!

Bad news: building and installing all of them requires 54 of the little 16-pin box headers, and I only actually have 10 on hand. And while I could order them, I really shouldn't until more money comes in, around about Friday.

At any rate, also included in the shipment were a couple of simple modules from Sourcery Studios: their ASMR (A Simple Mixer, Right?) five-channel mixer and their POW module, which provides power LEDs for each rail, a box header for plugging in modules for testing, and a USB-A jack for powering things from the 5V rail. (It also has a switch I won't be using, as it's meant for a different power setup than the one I'm using.) So I'll probably build those before I get to the actual case build.

5 notes

·

View notes

Text

AMZFX - PRE-AMP

"This is a dual op amp booster that was the predecessor to the dual op amp pcb that I sell on my site. I'm not sure how old it is but it pre-dates the internet! I used this pedal sometimes when playing live. A tap of the footswitch toggles between the two channels that can be set for different gains. The enclosure is a folded sheet-metal aluminum box that was widely available. It is a little large compared to modern pedal builds. The power supply jack is a 3.5mm phone jack style socket, such as was used on the original Rat pedals. The bypass is a soft-touch electronic switch circuit using a cmos chip. This was before microprocessors became very small and cheap, but cd4066 cmos switches cost pennies and were available everywhere."

cred: muzique.com/dual-boost, instagram.com/amzfx

17 notes

·

View notes

Text

Interactive mouthpiece opens new opportunities for health data, assistive technology, and hands-free interactions

New Post has been published on https://thedigitalinsider.com/interactive-mouthpiece-opens-new-opportunities-for-health-data-assistive-technology-and-hands-free-interactions/

Interactive mouthpiece opens new opportunities for health data, assistive technology, and hands-free interactions

When you think about hands-free devices, you might picture Alexa and other voice-activated in-home assistants, Bluetooth earpieces, or asking Siri to make a phone call in your car. You might not imagine using your mouth to communicate with other devices like a computer or a phone remotely.

Thinking outside the box, MIT Computer Science and Artificial Intelligence Laboratory (CSAIL) and Aarhus University researchers have now engineered “MouthIO,” a dental brace that can be fabricated with sensors and feedback components to capture in-mouth interactions and data. This interactive wearable could eventually assist dentists and other doctors with collecting health data and help motor-impaired individuals interact with a phone, computer, or fitness tracker using their mouths.

Resembling an electronic retainer, MouthIO is a see-through brace that fits the specifications of your upper or lower set of teeth from a scan. The researchers created a plugin for the modeling software Blender to help users tailor the device to fit a dental scan, where you can then 3D print your design in dental resin. This computer-aided design tool allows users to digitally customize a panel (called PCB housing) on the side to integrate electronic components like batteries, sensors (including detectors for temperature and acceleration, as well as tongue-touch sensors), and actuators (like vibration motors and LEDs for feedback). You can also place small electronics outside of the PCB housing on individual teeth.

Play video

MouthIO: Fabricating Customizable Oral User Interfaces with Integrated Sensing and Actuation Video: MIT CSAIL

The active mouth

“The mouth is a really interesting place for an interactive wearable and can open up many opportunities, but has remained largely unexplored due to its complexity,” says senior author Michael Wessely, a former CSAIL postdoc and senior author on a paper about MouthIO who is now an assistant professor at Aarhus University. “This compact, humid environment has elaborate geometries, making it hard to build a wearable interface to place inside. With MouthIO, though, we’ve developed a new kind of device that’s comfortable, safe, and almost invisible to others. Dentists and other doctors are eager about MouthIO for its potential to provide new health insights, tracking things like teeth grinding and potentially bacteria in your saliva.”

The excitement for MouthIO’s potential in health monitoring stems from initial experiments. The team found that their device could track bruxism (the habit of grinding teeth) by embedding an accelerometer within the brace to track jaw movements. When attached to the lower set of teeth, MouthIO detected when users grind and bite, with the data charted to show how often users did each.

Wessely and his colleagues’ customizable brace could one day help users with motor impairments, too. The team connected small touchpads to MouthIO, helping detect when a user’s tongue taps their teeth. These interactions could be sent via Bluetooth to scroll across a webpage, for example, allowing the tongue to act as a “third hand” to open up a new avenue for hands-free interaction.

“MouthIO is a great example how miniature electronics now allow us to integrate sensing into a broad range of everyday interactions,” says study co-author Stefanie Mueller, the TIBCO Career Development Associate Professor in the MIT departments of Electrical Engineering and Computer Science and Mechanical Engineering and leader of the HCI Engineering Group at CSAIL. “I’m especially excited about the potential to help improve accessibility and track potential health issues among users.”

Molding and making MouthIO

To get a 3D model of your teeth, you can first create a physical impression and fill it with plaster. You can then scan your mold with a mobile app like Polycam and upload that to Blender. Using the researchers’ plugin within this program, you can clean up your dental scan to outline a precise brace design. Finally, you 3D print your digital creation in clear dental resin, where the electronic components can then be soldered on. Users can create a standard brace that covers their teeth, or opt for an “open-bite” design within their Blender plugin. The latter fits more like open-finger gloves, exposing the tips of your teeth, which helps users avoid lisping and talk naturally.

This “do it yourself” method costs roughly $15 to produce and takes two hours to be 3D-printed. MouthIO can also be fabricated with a more expensive, professional-level teeth scanner similar to what dentists and orthodontists use, which is faster and less labor-intensive.

Compared to its closed counterpart, which fully covers your teeth, the researchers view the open-bite design as a more comfortable option. The team preferred to use it for beverage monitoring experiments, where they fabricated a brace capable of alerting users when a drink was too hot. This iteration of MouthIO had a temperature sensor and a monitor embedded within the PCB housing that vibrated when a drink exceeded 65 degrees Celsius (or 149 degrees Fahrenheit). This could help individuals with mouth numbness better understand what they’re consuming.

In a user study, participants also preferred the open-bite version of MouthIO. “We found that our device could be suitable for everyday use in the future,” says study lead author and Aarhus University PhD student Yijing Jiang. “Since the tongue can touch the front teeth in our open-bite design, users don’t have a lisp. This made users feel more comfortable wearing the device during extended periods with breaks, similar to how people use retainers.”

The team’s initial findings indicate that MouthIO is a cost-effective, accessible, and customizable interface, and the team is working on a more long-term study to evaluate its viability further. They’re looking to improve its design, including experimenting with more flexible materials, and placing it in other parts of the mouth, like the cheek and the palate. Among these ideas, the researchers have already prototyped two new designs for MouthIO: a single-sided brace for even higher comfort when wearing MouthIO while also being fully invisible to others, and another fully capable of wireless charging and communication.

Jiang, Mueller, and Wessely’s co-authors include PhD student Julia Kleinau, master’s student Till Max Eckroth, and associate professor Eve Hoggan, all of Aarhus University. Their work was supported by a Novo Nordisk Foundation grant and was presented at ACM’s Symposium on User Interface Software and Technology.

#3-D printing#3d#3D model#Accessibility#alexa#app#artificial#Artificial Intelligence#Assistive technology#author#Bacteria#batteries#bluetooth#box#Capture#career#career development#communication#complexity#computer#Computer Science#Computer Science and Artificial Intelligence Laboratory (CSAIL)#Computer science and technology#data#dental#Design#development#devices#do it yourself#Electrical engineering and computer science (EECS)

2 notes

·

View notes

Text

Services at inYantra Technologies Pune, India

0 notes

Text

0 notes

Text

A controller with a scroll wheel, you say?

Well this is a little funny. Yesterday I posted the first part of a series of post on the fine details of how computers work, mentioning how I've been looking into this as part of a personal project I've been working on, and today I wake up to see Masahiro Sakurai posting a youtube video lamenting the lack of... this exact thing I'm working on.

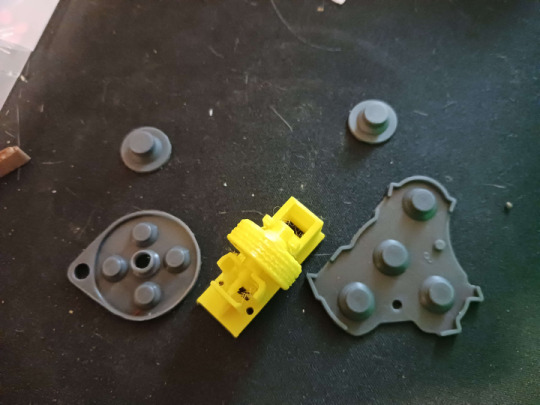

Apologies for how much cat hair is in this photo, that's a bit of an occupational hazard, but this here is a photo I took back in September when most of the parts I had to order were in for the prototyping of this thing:

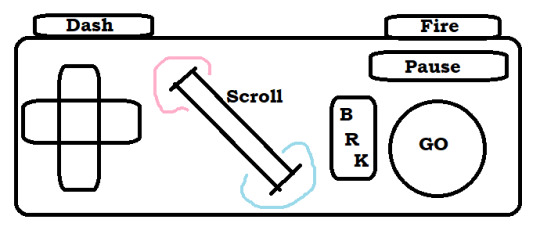

That's a really bad MS Paint mockup, but yeah. I'm designing my own game console, and one of the key features is a big ol' scroll wheel right in the center of the controller. Another is that I'm planning to just put all the designs of the circuit boards and 3D printer files for the casing/buttons up online for free, making it this totally open DIY thing where anyone who's a big enough nerd can just make a couple downloads, order some dirt cheap components, and build their own copy of the system (or people with better setups than me can build and sell them, whatever). So I'm not super worried about anyone stealing my ideas or whatever, but I WOULD like to establish a standard and all that, and figured it was worth noting that this is something I've been slowly working towards for like a year or two now, and didn't just get the idea from this video:

youtube

But yeah, now that the idea's out in the public consciousness, here's the plan for the controller (that I was planning to keep under my hat until I had a working prototype and some demo software sometime next year).

First off, the plan is that this is to be the standard controller for a whole console I'm also plucking away at designing, which is a bit more ambitious of a project, so I figure I might as well make it compatible with something that's already out there. So specifically, I'm designing this so that you can take one, plug it right into an SNES (or with a different connector at the end, an NES, because turns out they use the exact same input handling standard and it's just the shape of the plastic on the end that differs), and have it just work. Or mostly work anyway. I'm hoping I can process a signal out of the scroll wheel in a way that it either just needs the 3 extra bits of the input signal I don't have buttons for in my design (more on that later) or failing that, I can get it to output the same sort of signal as one wheel in the SNES mouse, which just rides along the second data line very few things use. I think that plan might break multitap compatibility and require an extra chip on the controller PCB, but it would leave this slightly more compatible with existing games on the same hardware. I might also do something weird with the button mapping to be sure NES select is on a shoulder and it works right out of the box with that whole library.

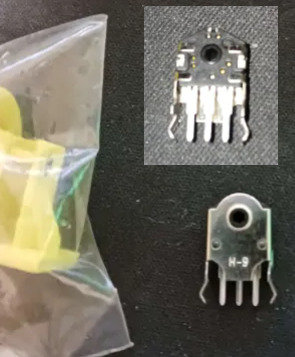

Working out exactly how to handle signals from the scroll wheel happens to be the point I'm currently stuck on by the way. I got this baggie full of rotary encoders for just a few cents which... almost fit in my first draft 3D printed wheel housing, but I have NO documentation on them, not even a part number/manufacturer besides "H-9," the pins don't fit a breadboard, and I've kinda been scrambling for rent so I can't afford a nice multimeter or oscilloscope to poke around with. Plus again I need to redesign this wheel print to even get it to spin right, and... this was a gift from a friend with a printer who is Not Local. Solvable problem, just needs more time and/or outside expertise.

But yeah, once I have those kinks worked out, it should be easy enough to get a custom board design made, replicas of end-cap of the controller cord are another problem easily solved by ordering a 1 dollar part or 3D printing something. The actual cord might be tricky since I don't know where you actually order something like that from, but it should be easy enough for anyone who doesn't mind a little assembly work to put one of these together and have it good to go for any software made with it in mind, or retrogames where you don't mind a weird button count. So... what's the pitch on this scroll wheel anyway?

Well for starters, there's the stuff Sakurai got into this morning. Any sort of RPG or text heavy game can use it to quickly scroll through menu options, or stuff in a text-heavy game. You could also pan the screen with it, something a lot of early 16-bit games assigned to the shoulder buttons or holding up and down while getting used to the new options the hardware was giving them.

Past that, you'll notice in my design it's at a 45 degree angle. I might have to tweak it a little, but my thinking is for a game that uses it heavily, one thumb or the other can slide over easily enough (I'm going for a pretty compact overall design) so we can have some games where you take your thumb off the D-pad, and have this nice analogue steering wheel. Nice for fine control in a racing game, or if you want some little radio-tuning/safe-cracking sorta deal.

Alternatively, move your right thumb over, use the D-pad to steer, shoot and dodge or whatever with shoulder buttons, and use the wheel to rotate a turret for a twin-stick sort of game maybe.

Or just use it for the sort of stuff mouse based games stick on the scrollwheel. Changing weapons, changing powerups... I'm planning to officially label the directions "hot" and "cold" to encourage weird gimmicky things like... I dunno, a platformer where you have a thermostat in your controller you can always mess with, freeze water coming out of pipes, crank up flame jets? Have a shot charging mechanic where you just really crank it to get to max strength? Weird minigame stuff. There's some fun space to explore with it.

Then we have the rest of the design here... which basically comes down to me being just plain sick of how every controller made by anyone in the past... 20 years give or take has kind of the exact same layout? 4 good face buttons, a D-pad, 4 shoulder buttons, 2 sticks, and 1-4 annoying to reach tiny awkward middle buttons, and we're just kind of overdue for a change-up?

Like first of all, hey, this is just too many buttons. There's a ton of games that really only need a D-pad, and maybe 3 buttons (attack jump pause) and the two things that aren't fully standardized is how awkwardly placed the D-pad is and how awful and awkwardly placed the pause button is. Shoulder buttons can be nice, but I've never really felt like 4 of them awkwardly crammed on the rim has been really useful or ergonomic, and that's coming from someone who's been playing a ton of FF14, which gets more use out of them than anything else I could name. And really, aside from games doing fake twin-stick stuff and using the whole grid like a second D-pad, I'm having a really hard time thinking of any game I've ever played that really makes good use of 4 good face buttons? Like people will use them if they've got'em sure, but unless you do that keyboard style thing where you lay the controller on a table and use all your fingers, you can really only comfortably hit 2 face buttons without sliding your thumb away from them, maybe comfortably make a quick pivot to a third.

Also, really, a lot of designers just sort of feel compelled to map SOMETHING to every button, even if it's clear the design didn't really need them. So basically I figure I'll try kinda just taking a "less is more" approach here. Here's the buttons that it's comfortable to rest your thumbs and fingers on, here's a dedicated pause/menu button where people often stick a kind of redundant menu button, here's my gimmicky scrollwheel. That's it, work around that.

I'm also going a little Gamecube inspired (literally using replacement membranes for one in my prototype design, even). Gonna make a great big primary button and use different shapes for the other two. Trying to label these in a less arbitrary fashion than most. If shooting a gun is a thing you do in this game, and there isn't a real good reason not to, default it to this nice right trigger you can hold down all the time. If we're advancing through menus or jumping or holding down gas in a car, here's the big GO button. Need brakes, need to break stuff with a melee attack? Go back in a menu system? There's your other face button. Have a quick dash move or a run you hold down, let's just use the other shoulder.

So yeah. That's my controller. Need to work out the kinks on the scroll wheel, source a cord, and hopefully I can slap things together and this will be something you can just order bits for piecemeal and put together for like, $5-10 after shipping? Maybe less? The parts are shockingly cheap so far.

But yeah if anyone has any insight to the scroll wheel or cord issues, let me know. Also the whole thing is presently a tad back-burnered because I am in a serious financial crisis and I don't want to have electronics spread all over my table if I have to abruptly find a new place to live if I can't scrape next month's rent together. So as usual, donations are incredibly welcome.

2 notes

·

View notes

Text

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#electronics#cleanenergy#industry#manufacturing#renewableenergy#quality#technology#EMS#Electronic Manufacturing Services#Indian EMS#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India

2 notes

·

View notes

Text

Choosing the Right Electronics Manufacturing Services Provider in India: What You Need to Know

The electronics industry is witnessing exponential growth, driven by rising global demand for smart devices, IoT integration, and automation. In this dynamic landscape, partnering with a reliable Electronics Manufacturing Services Provider in India has become a strategic necessity for companies aiming to scale production, improve quality, and reduce time-to-market.

India, emerging as a global hub for electronics manufacturing, provides a cost-effective and quality-focused environment for Original Equipment Manufacturers (OEMs) across various sectors, including consumer electronics, automotive, and industrial applications. If you're a business looking to collaborate with a top-tier electronics manufacturing services provider in India, understanding what to look for and how the right EMS partner can support your growth is essential.

What Are Electronics Manufacturing Services?

Electronics Manufacturing Services (EMS) refer to companies that design, manufacture, test, distribute, and provide return and repair services for electronic components and assemblies. These providers are key partners for OEMs who prefer to outsource manufacturing to experts rather than maintain in-house capabilities. An EMS partner typically offers:

- PCB (Printed Circuit Board) assembly

- Surface Mount Technology (SMT) and Through-Hole assembly

- Prototyping and NPI (New Product Introduction) support

- Functional and in-circuit testing

- Box build and final system integration

- Supply chain management

- Aftermarket support and logistics

Why Choose an EMS Provider in India?

India is rapidly climbing the ranks as a preferred destination for electronics manufacturing due to several favorable factors:

1) Cost-Effectiveness: Manufacturing in India offers significant cost savings without compromising on quality. Lower labor costs, competitive overheads, and government-backed subsidies help original equipment manufacturers (OEMs) remain profitable.

2) Government Incentives: Under the “Make in India” initiative and Production Linked Incentive (PLI) schemes, EMS providers in India receive various tax incentives, subsidies, and support that help reduce total manufacturing costs for OEMs.

3) Skilled Workforce: India has a large, educated, and technically proficient workforce, especially in areas such as PCB assembly, quality assurance, and embedded system development.

4) Strategic Location: With its proximity to global markets in Asia, Europe, and the Middle East, India serves as a logistics hub, boasting strong port infrastructure and connectivity.

Key Advantages of Partnering with an EMS Provider

Partnering with an EMS provider isn’t just about outsourcing production; it’s about building a long-term relationship that enhances your competitiveness and operational efficiency. Here’s how:

1) Faster Time-to-Market: An experienced EMS provider can expedite design iterations, prototyping, and mass production, thereby reducing the time required to bring new products to market.

2) Quality Control: Top EMS companies adhere to global standards, including ISO 9001, IATF 16949, and IPC-A-610, for electronics assembly and testing, ensuring high-quality, defect-free output.

3) Scalability: Whether you’re launching a niche product or scaling up to millions of units, EMS partners provide the flexibility to adjust production volumes efficiently.

4) Focus on Core Competencies: Outsourcing manufacturing enables OEMs to focus on design, innovation, marketing, and customer experience while their EMS partner handles operations and fulfillment.

5) Integrated Supply Chain: With robust procurement capabilities and established vendor relationships, EMS providers help mitigate risks associated with component shortages, cost volatility, and logistics challenges.

What to Look for in an Electronics Manufacturing Services Provider in India

Not all EMS companies offer the same capabilities. When evaluating an EMS provider, consider the following:

1) End-to-End Capabilities: Choose a provider that can support your product lifecycle—from prototyping and low-volume builds to high-volume production and post-sales support.

2) Industry Experience: Look for providers with proven experience in your specific industry, whether it’s medical devices, automotive electronics, consumer goods, or industrial controls.

3) Quality Certifications: Ensure they meet global quality and safety standards, such as ISO, RoHS, and IPC compliance. These standards reflect a commitment to performance, safety, and environmental responsibility.

4) Engineering Support: Strong design-for-manufacturability (DFM) and design-for-testability (DFT) expertise ensure fewer production errors and reduced costs.

5) Communication & Project Management: A transparent approach to communication, real-time reporting, and dedicated account managers ensure that your projects stay on track.

Resolute Electronics: A Trusted EMS Partner in India

One EMS provider that stands out in India’s manufacturing ecosystem is Resolute Electronics, a company known for its customer-first approach and robust capabilities. With state-of-the-art infrastructure, skilled engineers, and a commitment to quality, Resolute has established itself as a trusted provider of electronics manufacturing services in India, serving both global and domestic Original Equipment Manufacturers (OEMs). Their service offerings include:

- Advanced SMT lines for high-speed PCB assembly

- Precision testing with automated optical inspection (AOI), ICT, and functional test setups

- Comprehensive prototyping and NPI support

- Custom enclosures and complete box builds

- Scalable manufacturing solutions for startups to enterprise-level companies

Resolute Electronics also stands out for its flexibility, attention to detail, and ability to bring complex product ideas to life, making it an ideal partner for companies looking to outsource manufacturing without compromising control or visibility.

The Future of EMS in India

As global brands seek to diversify their supply chains and reduce dependence on single-region sourcing, India is poised to play a more significant role in global electronics production. The country’s EMS sector is expected to experience rapid growth over the next decade, driven by both domestic demand and export potential.

With this evolution, OEMs have a unique opportunity to collaborate with EMS partners like Resolute Electronics, who combine technical excellence, responsive service, and innovation to drive business growth.

Conclusion

The right electronics manufacturing services provider in India can be a game-changer for your business, enhancing product quality, reducing costs, and speeding up your time to market. As the demand for smart, connected devices grows, choosing an EMS partner with proven expertise, state-of-the-art facilities, and a flexible engagement model will position your brand for long-term success. Whether you're a startup looking to bring your first product to life or a global brand aiming to scale efficiently, partnering with an EMS provider like Resolute Electronics ensures your electronics manufacturing needs are in expert hands.

0 notes

Text

Understanding CEM in Modern Electronics: A Practical Insight

Understanding CEM in Modern Electronics: A Practical Insight

In today’s complex electronics landscape, product innovation and efficient manufacturing go hand in hand. For engineers, designers, and procurement professionals, choosing the right electronics partner is no longer a matter of convenience—it’s essential to product success. At Arrival Electronics Limited, a company based in Arundel, West Sussex, clients find an experienced and well-established resource for navigating the ever-changing world of electronic components and contract manufacturing.

Whether you are developing a product prototype or managing large-scale production, understanding the value and structure of CEM—Contract Electronics Manufacturing—is key to maintaining consistency, reliability, and supply chain strength. This article breaks down the concept of contract electronics manufacturing in practical terms, why it matters, and what to consider when selecting the right partner for your business.

CEM Explained: How Outsourced Electronics Manufacturing Supports Product Success

CEM refers to the process where a company outsources some or all of its electronic manufacturing responsibilities to a third-party provider. These services can include the assembly of printed circuit boards (PCBs), box builds, cable assemblies, and even full system integration. For many businesses, this arrangement helps bridge the gap between concept and market delivery without investing in internal production facilities.

But the advantages of outsourcing electronic manufacturing are not limited to infrastructure savings. A seasoned provider brings value through quality control, compliance assurance, procurement efficiency, and reduced lead times. The focus is not just on manufacturing but on delivering consistent results across the entire product lifecycle.

The Role of Contract Manufacturing in Product Development

In the early stages of product development, design and testing cycles can be both time-intensive and cost-sensitive. Working with an experienced manufacturing partner during this phase ensures that designs are ready for production, not just in theory but in practice. This includes:

Design for Manufacture (DfM) input: Ensuring that designs can be replicated reliably at scale.

Component sourcing guidance: Helping identify component availability, pricing trends, and lifecycle risks.

Rapid prototyping: Allowing for multiple iterations and validation cycles before full production.

The value of this support is particularly noticeable in industries with tight regulatory requirements or highly customized designs. Knowing that your product is being assembled by a team familiar with these challenges adds a layer of assurance often missed when production is fragmented or uncoordinated.

Quality Control and Compliance in Electronics Manufacturing

Consistency is everything when it comes to electronics. A single deviation in assembly quality or component specification can compromise an entire batch of products. Reputable manufacturers implement rigorous quality control standards—often including ISO certifications and IPC-A-610 class ratings—to ensure production meets both industry standards and client expectations.

In addition, experienced production partners are frequently tasked with managing regulatory documentation. For sectors like medical, automotive, aerospace, and defence, regulatory compliance is not just about paperwork—it’s a vital part of risk management and long-term reliability.

With experienced providers, clients benefit from:

Traceability systems to track component origins and manufacturing data

Test procedures tailored to the client’s performance standards

Material compliance such as RoHS, REACH, and conflict mineral regulations

This commitment to precision manufacturing and documentation forms the foundation of long-term supply stability.

Supply Chain Management and Procurement

One of the most significant advantages of working with an experienced electronics manufacturing partner is procurement efficiency. The global electronics supply chain can be unpredictable—affected by material shortages, geopolitical issues, and currency fluctuations. A reliable provider has both the scale and supplier relationships to manage these challenges on your behalf.

By centralizing procurement and inventory management, the risk of component obsolescence, stockouts, and delivery delays is greatly reduced. Strategic sourcing, long-term supplier contracts, and access to authorized distribution channels allow clients to focus on core design and development tasks.

In many cases, these providers also help negotiate better pricing through consolidated purchasing volumes, improving overall cost-effectiveness without compromising on quality.

Customization and Flexibility in Electronics Manufacturing

Different companies have different requirements. Some need full assembly and testing; others only need PCB population or logistics support. A flexible production model is one that adapts to these varying levels of engagement.

For example, some clients may request:

Box build and enclosure integration

Cable and wire harness manufacturing

Programming and firmware upload

Functional testing and diagnostics

A well-structured manufacturing relationship allows businesses to adjust their production effort (either up or down) based on demand, without renegotiating contracts or reorganizing supply infrastructure. This adaptability is particularly important for startups, R&D teams, and businesses with seasonal product cycles.

The Importance of Local Manufacturing Support

While many companies consider offshore production due to lower costs, working with a local manufacturing partner still provides key advantages in terms of quality and communication. UK-based providers offer accessible collaboration, faster turnaround times, and streamlined logistics—all important factors in today’s competitive electronics environment.

Local manufacturing also contributes to:

Greater visibility during production runs

Faster issue resolution if engineering changes are required

Reduced transportation risks, especially for fragile or sensitive components

Working with a local partner ensures better control, particularly when dealing with niche products, custom builds, or compliance-heavy applications.

Trends in Electronics Manufacturing for 2025 and Beyond

As the demand for smarter, more integrated electronics continues to grow, so do the expectations placed on modern manufacturing services. Emerging technologies such as IoT-enabled devices, wearable electronics, and electric vehicle systems require a more advanced and flexible approach to assembly and testing.

In response, many manufacturing specialists are expanding their capabilities to include:

Microelectronics assembly

High-frequency RF product support

Environmentally controlled production environments

Long-term product lifecycle support

These advancements are not confined to high-volume production. Niche developers and innovators also benefit from working with partners that understand how to manage intricate designs and deliver dependable, high-quality builds.

Choosing the Right Manufacturing Partner

With so many electronics manufacturing options available, how do you decide which one is right for your project?

Here are five practical factors to consider:

Experience: Look for a provider with a strong track record in your specific industry. Practical experience brings valuable insight, especially when navigating technical designs and regulatory requirements.

Certifications: Confirm that the company holds relevant and current industry certifications, as these reflect adherence to recognized quality standards.

Transparency: A trustworthy partner will be clear about their production capabilities, timelines, and internal processes from the start.

Technical Support: It's beneficial to work with a team that offers design-stage assistance—not just assembly. Early input can prevent delays and reduce costs.

Location: Think about the practical benefits of working with a nearby provider, including easier communication, faster lead times, and simplified logistics.

By considering these factors carefully, you can reduce risk and improve the likelihood of a successful, long-term collaboration.

Why Contract Electronics Manufacturing Still Matters

In a world where electronics innovation is constant, outsourced production remains a vital service for product teams aiming to maintain focus and efficiency. It’s not just about handing off manufacturing—it’s about building the right partnerships. With increasing pressure to deliver quality products on time and within budget, working with a capable electronics manufacturing partner is a smart and strategic move.

This type of collaboration allows businesses to stay agile while drawing on technical expertise, stable supply chains, and reliable assembly processes. It helps bridge the gap between concept and product delivery—without the need for extensive internal infrastructure.

Conclusion

From component sourcing and design guidance to full assembly and product lifecycle support, Arrival Electronics Limited provides the practical expertise and trusted service needed in today’s competitive electronics industry. Located in West Sussex, the team works closely with clients across the UK and beyond, delivering dependable contract manufacturing solutions built on transparency, experience, and technical depth.

If you're looking for a CEM provider who understands your challenges and delivers reliable, detail-oriented service, consider a partner with proven experience and a commitment to quality at every stage of your project.

0 notes