#Printed circuit board copying

Explore tagged Tumblr posts

Text

We bullied HP into a minor act of disenshittification

I'm on a 20+ city book tour for my new novel PICKS AND SHOVELS. Catch me TORONTO TOMORROW (Feb 23) at Another Story Books, and in NYC on WEDNESDAY (26 Feb) with JOHN HODGMAN. More tour dates here.

Here in the darkest days of the enshittocene, enshittification is low quality and plentiful, but even in this target-rich environment, one company stands out as pioneering champions of enshittification: HP.

Every page in the enshittification playbook was printed in farcically expensive HP ink, and if you try to run a copy off for yourself, the printer will stop five times and force you to print a "calibration page" that is solid color from top to bottom, consuming about $10 worth of ink. Don't like it? Die mad.

HP drips with contempt for its customers. They make printer-scanners that won't scan unless all four ink cartridges are installed and haven't reached their best-before dates. They make printers that won't print black and white if your $50 magenta cartridge is low. They sell you printers with special half-full cartridges that need to be replaced pretty much as soon as the printer has run off its mandatory "calibration" pages. The full-serving ink you buy to replace those special demitasse cartridges is also booby-trapped – HP reports them as empty when they're still 20% full.

HP tricks customers into signing up for irrevocable subscriptions where you have to pay every month, whether or not you print, and if you exceed your subscription cap, the printer refuses to work, no matter how much ink is left. Now, about those HP ink subscriptions. When the company launched them, they offered a pot-sweetener meant to tempt in the wary: a one-price "lifetime subscription" that would let you print 15 pages every month, for so long as you owned the printer. But a couple years later, all those "free ink for life" customers got an email telling them that they were being migrated to a monthly payment plan, and if they didn't like it, they could eat shit and throw away their printers:

https://pluralistic.net/2020/11/06/horrible-products/#inkwars

HP pioneered the use of copyright law to prevent third parties from refilling ink cartridges or making their own compatible cartridges. Section 1201 of Bill Clinton's Digital Millennium Copyright Act makes it a felony to distribute a "circumvention device" to bypass access controls on a copyrighted work. By designing its cartridges do undertake a little cryptographic handshake with the printer to verify their "authenticity," HP ensures that anyone who markets a bypass device to let you choose which ink you use in your own damn printer is a felon, liable to five years in prison and a $500 fine under DMCA 1201.

Of course, nature finds a way. Hardware hackers have come up with some insanely cool bypass devices for HP printer cartridges, like these paper-thin, flexible, adhesive-backed circuit boards that wrap around third party cartridges, intercepting communications between the printer and a salvaged HP security chip:

https://pluralistic.net/2024/09/30/life-finds-a-way/#ink-stained-wretches

But HP fights back, and they fight dirty. For example, they periodically push out "security updates" for their printers that break compatibility with third party cartridges. To prevent HP customers from discovering and blocking these fake security updates, HP designs them to lie dormant for months after installation, until everyone has clicked "OK," and then all those Manchurian Printers wake up and betray their owners by refusing to use their ink:

https://www.eff.org/deeplinks/2020/11/ink-stained-wretches-battle-soul-digital-freedom-taking-place-inside-your-printer

All of this has allowed HP to monotonically raise – and raise – and raise – the price of printer ink to the point where it is now the most expensive fluid a civilian can purchase without a permit. Printer ink now runs over $10,000/gallon, meaning that you print out your grocery lists with colored water that costs more than the semen of a Kentucky Derby winner.

HP is truly the poster child for enshittification, and also, patient zero in the enshittification pandemic:

https://pluralistic.net/2021/02/18/ink-stained-wretches/#hache-pe

HP's enshittificatory impulses run wild. They hunt relentlessly for ways to make things worse for their customers in order to make things better for themselves. Last week, they came up with a humdinger, even by their own standards. They announced that people who called their customer service line would be subject to mandatory 15-minute waits, even if there was a rep who was free to talk with them:

https://www.theregister.com/2025/02/20/hp_deliberately_adds_15_minutes/

During this mandatory 15-minute wait, customers would be bombarded with a recorded voice demanding that they solve their problems by consulting HP's website and its awful chatbots. In a competitive market, businesses can contain their customer service costs by making better products. In a monopolistic market like the printer racket, companies can deliberately introduce maddening antifeatures to their products, and then fob off the customers who reach such a peak of frustrated rage that they resort to calling a customer support number on chatbot that will use its spicy autocomplete to hallucinate nonexistent drivers and imaginary troubleshooting steps.

When I saw this, I thought, whelp, that's HP all right. Shameless.

But they're not entirely shameless. Within a day of Paul Kunert breaking the story in The Register, HP had reversed its policy, citing "feedback" (a corporate euphemism that means "fury"):

https://www.theregister.com/2025/02/21/hp_ditches_15_minute_wait_time_call_centers/

This is a rare win for the forces of disenhittification and it deserves recognition. It turns out that in these Mangionean times, companies can actually be bullied into comporting themselves with marginally less sleaze and cruelty. It's especially noteworthy that this took place in the UK, where Prime Minister Kier Starmer has invited tech companies to pick Britons' pockets without fear of consequence, by firing the top competition regulator and replacing him with the former head of Amazon UK:

https://pluralistic.net/2025/01/22/autocrats-of-trade/#dingo-babysitter

Even in these degraded times, we can get these fuckers. When Sonos enshittifies its smart speakers, we can get its CEO fired:

https://www.theverge.com/2025/1/13/24342179/sonos-ceo-patrick-spence-resignation-reason-app

When Unity sticks its hand in the pockets of every game dev in the world, we can get its entire executive team shitcanned:

https://venturebeat.com/games/john-riccitiello-steps-down-as-ceo-of-unity-after-pricing-battle/

It doesn't always work. Enshittifiers rack up some Ws, and make bank even as they immiserate 500 million users (looking at you, Steve Huffman – the people have long memories):

https://en.wikipedia.org/wiki/2023_Reddit_API_controversy

But if we can bully the psychotic monsters who populate HP's Executive Row out of their enshittificatory plans, then it's worth trying it every time.

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2025/02/22/ink-spattered-pitchforks/#racehorse-semen

#pluralistic#hp#enshittification#ai#chatbots#customer service#angry mobs#pitchforks#sonos#reddit#ripoffs#disenshittification#counting coup

560 notes

·

View notes

Text

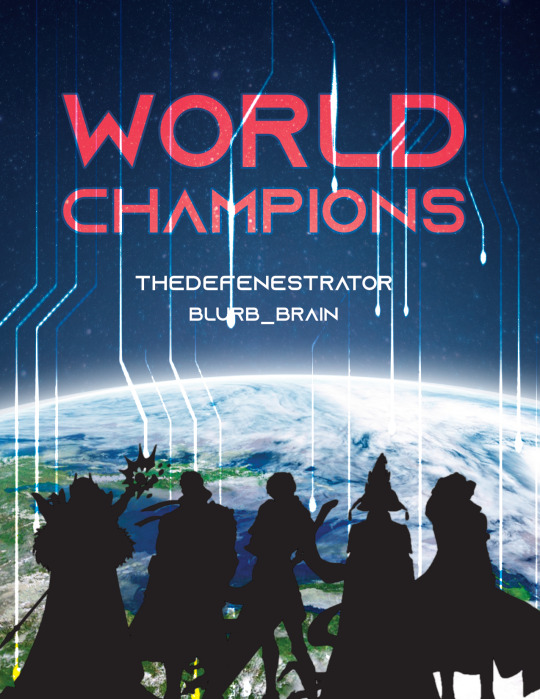

World Champions | Artwork for World Champions by TheDefenestrator by TheDefenestrator, art by Blurb_brain

Fandom: The King's Avatar | 全职高手

Rating: Teen And Up Audiences

Category: Gen

Words: 71 944

At the end of season 4 of the Glory Pro Alliance, the government finally receives the information it has been waiting for: The other players have caught up. Or, In which Glory has been a government recruitment ploy for remote-piloted mecha operators all along.

About the Book

FONTS: Mundo Serif, Azonix [dafont], Segoe UI Symbol

IMAGES: Illustration by Blurb_brain [AO3]; cover image by NASA ID: 440611 [Rawpixel]; Planet Earth background ID: 6331593 [Rawpixel]; Circuit lines background ID: 3117935 [Rawpixel]; endpapers' image by Eric Eastman [Unsplash]; Swoksaar, Desert Dust, Lord Grim, Vaccaria, and Cloud Piercer [The King's Avatar Wikia]

MATERIALS: regular printer paper (8.5"x11", 96 bright, 20lb), 80pt bookboard, Iris Bookcloth (colour: Black Pearl), Neenah cardstock (8.5"x11", bright white, 65lb), waxed linen thread (white, 30/3 size), embroidery floss (shades 3750, 350, 3845, 370), leather cording (1.9mm diameter), Reeves’ acrylic paint (Mars Black, Phthalo Blue, Titanum White), Americana acrylic paint (glow in the dark), ph neutral pva glue (Books by Hand)

PROGRAMS USED: Typeset in Affinity Publisher, cover/title page/endpapers designed in Affinity Designer/Photo, QR codes generated with LibreOffice Writer, PDF arranged for printing with Bookbinder-JS

BINDING STYLE: quarto, case bound (slightly rounded, with oxford hollow, forgot to use tapes)

.

Fenes' "Glory's tech isn't handwaved" AU. This was great! Funny and creative, and I'm both amazed and full of admiration for Fenes' ability to juggle so many characters.

I was feeling excited and ambitious with this one. Tried some new fun things (double core endbands, painted edges) and used some new equipment (a lying press).

The Text

TITLE/HEADINGS FONT: Azonix says 'SciFi' to me, it's a bold, non-serif, sleek font.

BODY FONT: Mundo Serif, it's a decent serif body font I haven't used before. Felt like it worked with Azonix.

SCENE BREAKS: a special character in Segoe UI Symbol of a black & white icon of Earth, the globe showing Asia.

TYPESETTING: Finished typesetting the fic, left document open on my laptop, laptop's battery failed, file now crashes immediately upon reopening, issue persists with copied versions of file (; ̄Д ̄) . Thankfully I had a backup file for the typeset with the barebones of the text, so I didn't have to restart from scratch...

Title Page

My thinking: it takes place in space, the world's at stake, and it's the dawn of a new horizon for Earth. Glory and the titular champions are represented by Swoksaar, Desert Dust, Lord Grim, Vaccaria, and Cloud Piercer – the captains of what I'd call the 'big 5' teams. A circuitry board background element hints at the tech/mecha nature of the story's competition. It may not match Blurb's art, but I hope I was able to convey some of what the story is about.

The circuitry image is used as decoration throughout the book. I only used the avatars of the top five teams' captains because too many silhouettes would lessen their impact and readability. (Removing the backgrounds was tedious, but worth it.)

Here's what it should have looked like. The test prints for this and the BB art were fine, but I think my inkjet started running out of ink just when I printed the final copies and I didn't reprint them. (Too impatient, really wanted to finish up and read the book)

The Cover

World Champions is another Big Bang fic, and once again I based some of my design choices off of the accompanying artwork. The dominant colours of Blurb_brain's illustration are red and blue-green.

COVER PAPER: For the decorative cover material I used NASA's ASTER image of Poyang Lake. NASA has some really interesting photography some of which remind me of marbled paper, thought it could be interesting. I chose this image of Poyang Lake because 1) it's in China, 2) the colours were similar to Blurb's awesome illustration (fate strikes again, dropping matching images and artwork into my lap!), and 3) NASA is tangentially relevant to the fic, which takes place in space.

BOOKCLOTH: Verona bookcloth in the shade Black Pearl, a lovely dark navy blue colour. Thought it suited the cover paper and title page. (Bought it for this fic specifically, but the colour goes well with almost all of my decorative papers so it should see a lot of use in the future!)

Endpapers

The final decision that held this project at a standstill for two months. In the end I drew inspiration from the matchups against the final opponent in the story. The image I used is a little chaotic and a little too unrelated to identify why I picked it without an explanation, but this book is for me and I know why, so there. (Note that I played around with the colours and cropped the photo.)

Endpaper inspiration: the maps for the matches against the Infilhites

"a long bridge through an enormous tube-like hall, where light seem to come from every side through stained glass windows. It was visually confusing, limited lateral motion" "a warehouse, crates stacked on and beside metal racks that went all the way to the ceiling." "a house of mirrors, fully enclosed to be sure the Infhillte couldn’t fly out of it." "like a volcano, rivers of lava moving sluggishly down a slope, occasional vents of overheated air nearby." "a series of overlapping bridges between halls and stairways, level after level layered over an open abyss."

Trimming & Painting the Edges

Going all out, a 2-for1 deal: the opportunity to use my lying press for the first time and learn a new technique!

TRIMMING: Used a paring chisel and lying press.

CHISEL: The 1.25" wide paring chisel I used was form a modern manufacturer. (Vintage paring chisels are very thin, enough so that you can bend/flex the blade. But don't do that.) It's long and wide blade made it easier to register against the surface of the press for consistent cuts. Looks like this one below from Lee Valley.

LYING PRESS: My dad's project. Solid black walnut, hand carved screws and internal threads — he even made the tools to make the threads too! The jaws of the press are each 3 7/8" wide. It's big and heavy (though much smaller than full-sized professional ones omg), but there's enough of a flat surface to register the chisel against. A thicc boi, much like this one below from Bookbinding Supplies.

PAINTED EDGES: The idea was to have dark navy edges, speckled with white stars. I used acrylic from a tube to paint the edges — tutorials recommended it over liquid bottled acrylic, and I had an old set hanging around. Had to water it down because otherwise the paint just flaked off.

My test of trimming and painting went well. Then the trimmed book itself came out slightly crooked, the paint required significantly more watering-down than before, and the white paint did not want to be both opaque and speckle-able. Unfortunate, but still book-shaped! And now I have an idea of what to do differently next time.

Also, did not like the glow-in-the-dark paint. Looked too translucent in the light when compared to the white acrylic, and needed a thicker coat to be visible in the dark. (The thickness combined with the translucence and base colour kinda reminded me of boogers... Ended up scrapping most of it off, so there's not much left to glow.)

Endbands

Still in the mood to have fun and go all-out, I attempted double-core endbands for the first time.

TUTORIAL: YouTube @ BookbindersChronicle: Bookbinding 101 Sewing Headbands Session 2. Also watched @ DAS Bookbinding's Double-Core Endband // Adventures in Bookbinding, but I personally found Chronicle's closeup video easier to follow.

I used embroidery floss from a 100pk of assorted colours off Amazon, wrapped around a core of 1.9mm leather cording from Michaels. I drew from Blurb_brain's art for the general colours, choosing a dark base, with red, blue-green, and gold. The specific shades were picked to go with the cover.

#World Champions#TheDefenestrator#Blurb_brain#qzgs#tka#the king's avatar#fanfiction#bookbinding#fanbinding

107 notes

·

View notes

Text

Harris-Fandel Co. - The Liverpool Fuzz

"In November of 1968 a new fuzz box was introduced to the world through the pages of Billboard magazine. The pop publication ran a little blurb proclaiming a new fuzz-tone that "shatters sound" and can "last more than 1,000 hours without a battery change". Known as the Liverpool Fuzz Tone, from Ridinger Associates, it was a fairly unique circuit for the time that utilized 3 germanium transistors and ran off of 9v. Primitive and raw, it was a hidden gem of American 60's fuzz. One month later the Liverpool Fuzz was given a similar treatment in the UK publication Beat Instrumental. Although lacking in classic American hyperbole, this small write-up served as the European introduction to one of the most prolific builders of the 1970s. And finally, a few months later we would get to actually see the Liverpool Fuzz highlighted in a photo ad, seemingly associated with New England distributor Harris-Fandel, showing a small table-top unit with a hardwired output cable and an on/off switch. And while the late 60s were flooded with unoriginal copies and clones, the Liverpool Fuzz Tone immediately stood out, and still holds a very significance place in the history of guitar effects…

So what's the deal with this thing and why is it so important?

Well for those unaware, this is the first effect built and released by Ridinger Associates, or better known as Steve Ridinger of Danelectro fame, Arion Effects, and most importantly fOXX! The story is that he originally built the first Liverpool Fuzzes in 1966 when he was just 14 yrs old. The lore goes on to say that as a young teenager he didn't have the money to buy a fuzz pedal, nor did he have access to any fuzz schematics, so he came up with a fuzz/drive circuit of his own. These early units were all hand-wired using perfboard. Around 1968 he did a deal with a US distributor and also outsourced the manufacturing to a third party who paired it down to a small black enclosure and incorporated a printed circuit board for a cheaper/faster build. Ridinger estimates between 500-1,000 were produced in this time (1966-1969). And while that seems like a large number compared to some other pedals we have discussed, the nondescript nature of the blank black enclosure combined with no labeling of any kind, has made it near impossible to track one of these down. And at this point I have only seen 2 in my 20+ years of collecting. Following the Liverpool Fuzz, Ridinger created and released the Fox Wa Pedal, which would be the first time he would use the "Fox" name, and ultimately lead to him starting the fOXX brand just a year later. In the world of vintage guitar pedal collectors these two effects mean a lot. Without Steve Ridinger deciding to dip his toes into building, marketing and distributing stompboxes at such an early age, we may never have heard of fOXX or the best fuzz of all-time, the Tone Machine! And it all started in 1966 with a little hand-built effect called the Liverpool Fuzz Tone."

cred: tonemachinesblog.com; facebook.com/Ed Skymall; facebook.com/Chris Martin

16 notes

·

View notes

Text

Exterminator

Gottlieb has always been a household name in the field of pinball tables and amusement machines, but much less so in the world of arcade coin-ops, where they are only remembered for Q*bert. The swearing orange weirdo is still fairly recognizable to this day, but all of Gottlieb’s few other coin-ops have been forgotten, despite getting made during the “golden age of arcades” and being well-regarded at the time. Exterminator, their very last one, released under the Premier Technology company (the only one that ever appeared under that brand, which was specialized in pinball tables),was designed and programmed mostly by Warren Davis, the same developer behind Q*bert. Despite this, it never was a big hit with arcade owners or gamers. That might have to do with the machine having a complex custom printed circuit board, designed to handle the game’s advanced graphics, that broke often. Or the fact that the dedicated cabinet was produced in only around 250 copies, while conversion kits were way more popular. Or maybe because it was such a dang weird game.

Read more...

#hardcore gaming 101#federico tiraboschi#review#exterminator#arcade#atari st#commodore 64#commodore amiga#ibm pc#shoot em up#unique visuals#zx spectrum#gottlieb#video games#retro games

14 notes

·

View notes

Text

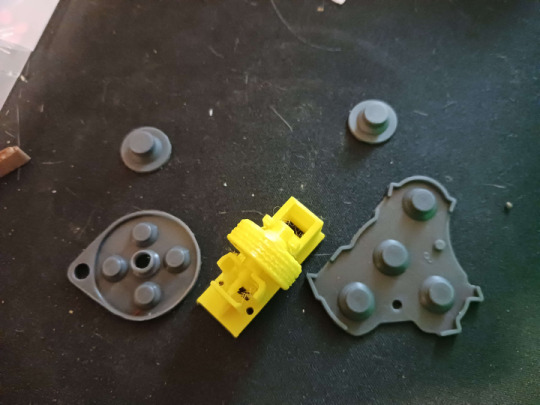

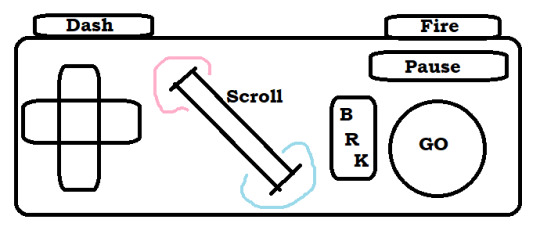

A controller with a scroll wheel, you say?

Well this is a little funny. Yesterday I posted the first part of a series of post on the fine details of how computers work, mentioning how I've been looking into this as part of a personal project I've been working on, and today I wake up to see Masahiro Sakurai posting a youtube video lamenting the lack of... this exact thing I'm working on.

Apologies for how much cat hair is in this photo, that's a bit of an occupational hazard, but this here is a photo I took back in September when most of the parts I had to order were in for the prototyping of this thing:

That's a really bad MS Paint mockup, but yeah. I'm designing my own game console, and one of the key features is a big ol' scroll wheel right in the center of the controller. Another is that I'm planning to just put all the designs of the circuit boards and 3D printer files for the casing/buttons up online for free, making it this totally open DIY thing where anyone who's a big enough nerd can just make a couple downloads, order some dirt cheap components, and build their own copy of the system (or people with better setups than me can build and sell them, whatever). So I'm not super worried about anyone stealing my ideas or whatever, but I WOULD like to establish a standard and all that, and figured it was worth noting that this is something I've been slowly working towards for like a year or two now, and didn't just get the idea from this video:

youtube

But yeah, now that the idea's out in the public consciousness, here's the plan for the controller (that I was planning to keep under my hat until I had a working prototype and some demo software sometime next year).

First off, the plan is that this is to be the standard controller for a whole console I'm also plucking away at designing, which is a bit more ambitious of a project, so I figure I might as well make it compatible with something that's already out there. So specifically, I'm designing this so that you can take one, plug it right into an SNES (or with a different connector at the end, an NES, because turns out they use the exact same input handling standard and it's just the shape of the plastic on the end that differs), and have it just work. Or mostly work anyway. I'm hoping I can process a signal out of the scroll wheel in a way that it either just needs the 3 extra bits of the input signal I don't have buttons for in my design (more on that later) or failing that, I can get it to output the same sort of signal as one wheel in the SNES mouse, which just rides along the second data line very few things use. I think that plan might break multitap compatibility and require an extra chip on the controller PCB, but it would leave this slightly more compatible with existing games on the same hardware. I might also do something weird with the button mapping to be sure NES select is on a shoulder and it works right out of the box with that whole library.

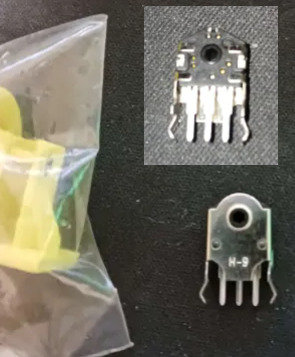

Working out exactly how to handle signals from the scroll wheel happens to be the point I'm currently stuck on by the way. I got this baggie full of rotary encoders for just a few cents which... almost fit in my first draft 3D printed wheel housing, but I have NO documentation on them, not even a part number/manufacturer besides "H-9," the pins don't fit a breadboard, and I've kinda been scrambling for rent so I can't afford a nice multimeter or oscilloscope to poke around with. Plus again I need to redesign this wheel print to even get it to spin right, and... this was a gift from a friend with a printer who is Not Local. Solvable problem, just needs more time and/or outside expertise.

But yeah, once I have those kinks worked out, it should be easy enough to get a custom board design made, replicas of end-cap of the controller cord are another problem easily solved by ordering a 1 dollar part or 3D printing something. The actual cord might be tricky since I don't know where you actually order something like that from, but it should be easy enough for anyone who doesn't mind a little assembly work to put one of these together and have it good to go for any software made with it in mind, or retrogames where you don't mind a weird button count. So... what's the pitch on this scroll wheel anyway?

Well for starters, there's the stuff Sakurai got into this morning. Any sort of RPG or text heavy game can use it to quickly scroll through menu options, or stuff in a text-heavy game. You could also pan the screen with it, something a lot of early 16-bit games assigned to the shoulder buttons or holding up and down while getting used to the new options the hardware was giving them.

Past that, you'll notice in my design it's at a 45 degree angle. I might have to tweak it a little, but my thinking is for a game that uses it heavily, one thumb or the other can slide over easily enough (I'm going for a pretty compact overall design) so we can have some games where you take your thumb off the D-pad, and have this nice analogue steering wheel. Nice for fine control in a racing game, or if you want some little radio-tuning/safe-cracking sorta deal.

Alternatively, move your right thumb over, use the D-pad to steer, shoot and dodge or whatever with shoulder buttons, and use the wheel to rotate a turret for a twin-stick sort of game maybe.

Or just use it for the sort of stuff mouse based games stick on the scrollwheel. Changing weapons, changing powerups... I'm planning to officially label the directions "hot" and "cold" to encourage weird gimmicky things like... I dunno, a platformer where you have a thermostat in your controller you can always mess with, freeze water coming out of pipes, crank up flame jets? Have a shot charging mechanic where you just really crank it to get to max strength? Weird minigame stuff. There's some fun space to explore with it.

Then we have the rest of the design here... which basically comes down to me being just plain sick of how every controller made by anyone in the past... 20 years give or take has kind of the exact same layout? 4 good face buttons, a D-pad, 4 shoulder buttons, 2 sticks, and 1-4 annoying to reach tiny awkward middle buttons, and we're just kind of overdue for a change-up?

Like first of all, hey, this is just too many buttons. There's a ton of games that really only need a D-pad, and maybe 3 buttons (attack jump pause) and the two things that aren't fully standardized is how awkwardly placed the D-pad is and how awful and awkwardly placed the pause button is. Shoulder buttons can be nice, but I've never really felt like 4 of them awkwardly crammed on the rim has been really useful or ergonomic, and that's coming from someone who's been playing a ton of FF14, which gets more use out of them than anything else I could name. And really, aside from games doing fake twin-stick stuff and using the whole grid like a second D-pad, I'm having a really hard time thinking of any game I've ever played that really makes good use of 4 good face buttons? Like people will use them if they've got'em sure, but unless you do that keyboard style thing where you lay the controller on a table and use all your fingers, you can really only comfortably hit 2 face buttons without sliding your thumb away from them, maybe comfortably make a quick pivot to a third.

Also, really, a lot of designers just sort of feel compelled to map SOMETHING to every button, even if it's clear the design didn't really need them. So basically I figure I'll try kinda just taking a "less is more" approach here. Here's the buttons that it's comfortable to rest your thumbs and fingers on, here's a dedicated pause/menu button where people often stick a kind of redundant menu button, here's my gimmicky scrollwheel. That's it, work around that.

I'm also going a little Gamecube inspired (literally using replacement membranes for one in my prototype design, even). Gonna make a great big primary button and use different shapes for the other two. Trying to label these in a less arbitrary fashion than most. If shooting a gun is a thing you do in this game, and there isn't a real good reason not to, default it to this nice right trigger you can hold down all the time. If we're advancing through menus or jumping or holding down gas in a car, here's the big GO button. Need brakes, need to break stuff with a melee attack? Go back in a menu system? There's your other face button. Have a quick dash move or a run you hold down, let's just use the other shoulder.

So yeah. That's my controller. Need to work out the kinks on the scroll wheel, source a cord, and hopefully I can slap things together and this will be something you can just order bits for piecemeal and put together for like, $5-10 after shipping? Maybe less? The parts are shockingly cheap so far.

But yeah if anyone has any insight to the scroll wheel or cord issues, let me know. Also the whole thing is presently a tad back-burnered because I am in a serious financial crisis and I don't want to have electronics spread all over my table if I have to abruptly find a new place to live if I can't scrape next month's rent together. So as usual, donations are incredibly welcome.

2 notes

·

View notes

Text

Automation Meets Precision: The Rise of the Inspection Robots Market

Market Overview

The inspection robots market is expanding rapidly as industries across the globe adopt automation technologies to streamline operations, enhance quality control, and meet stringent regulatory standards. Key drivers of this growth include the increasing demand for automated inspection processes, heightened focus on product quality and safety, and the widespread implementation of Industry 4.0 technologies. With continued innovation in robotics, artificial intelligence, and sensor systems, inspection robots are evolving into critical assets in modern industrial environments.

Get Sample Copy @ https://www.meticulousresearch.com/download-sample-report/cp_id=5513?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=30-04-2025

Growing Demand for Automated Inspection Processes

One of the most important factors fueling the inspection robots market is the rising demand for automation in quality control processes. These systems are designed to conduct inspections with minimal human involvement, offering significant benefits such as early defect detection, reduced rework, improved compliance, and enhanced product reliability. In the automotive industry, for example, automated robots are widely used for dimensional measurement and surface defect detection. In electronics, they ensure precise component placement on printed circuit boards (PCBs), while in food and pharmaceutical sectors, inspection robots help identify contaminants, securing product integrity and adherence to safety standards.

To stay ahead in this dynamic market, many companies are entering partnerships aimed at accelerating innovation. A notable example is the November 2023 partnership between GMV Innovating Solutions (Spain) and ANYbotics AG (Switzerland). Together, they focused on boosting inspection efficiency by deploying autonomous robots capable of carrying out inspections in industrial environments. These kinds of collaborations are becoming increasingly common as companies seek to reduce operational costs, enhance accuracy, and embrace smart manufacturing.

Stringent Government Regulations & Compliances Related to Product Quality & Safety

The growing complexity of global regulations concerning product safety and quality is another major catalyst for the adoption of inspection robots. Organizations must comply with strict standards, including FDA regulations, GMP (Good Manufacturing Practices), ISO certifications, HACCP protocols, and CE marking, among others. These regulations ensure products are manufactured consistently and safely, especially in critical industries like pharmaceuticals, food & beverages, and medical devices.

Inspection robots are uniquely positioned to help companies meet these requirements. They leverage a range of advanced technologies, including AI, LIDAR, 3D mapping, ultrasonic and infrared sensors, and machine vision systems, to perform comprehensive and reliable product assessments. Their ability to work tirelessly, accurately, and without fatigue makes them a powerful tool in maintaining high product standards while minimizing human error. As the demand for safe and defect-free products continues to grow, the role of inspection robots becomes even more critical.

Technological Advancements in Inspection Robots

Continuous technological innovation is unlocking new capabilities for inspection robots. The integration of artificial intelligence, machine learning algorithms, and sophisticated sensor systems has significantly improved the robots’ ability to handle complex inspections. These technologies enable real-time data analysis, anomaly detection, and even predictive maintenance, which are vital for optimizing equipment uptime and operational efficiency.

Modern inspection robots also feature enhanced mobility and adaptability, allowing them to function effectively in challenging industrial environments. Whether it's confined pipelines in the oil & gas sector or hazardous zones in nuclear facilities, inspection robots now offer durability and flexibility that was previously unachievable. By reducing the need for manual inspections in such environments, these robots enhance workplace safety and lower long-term operational costs. As a result, industries such as power generation, aerospace, and manufacturing are increasingly turning to these technologies to automate routine checks and ensure consistent quality.

Get Full Report @ https://www.meticulousresearch.com/product/inspection-robots-market-5513?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=30-04-2025

Stationary Robots Segment Expected to Dominate by Type

Within the market, the stationary robots segment is projected to lead in 2024. Stationary robots are fixed in position and perform dedicated tasks like component examination, defect detection, or continuous monitoring in a controlled area. These systems are particularly popular in manufacturing setups, where they provide consistency, speed, and accuracy in inspecting parts or assemblies. They are equipped with high-resolution cameras, specialized sensors, and advanced analytical software that enables them to deliver precise insights in real-time.

In industries like pharmaceuticals, stationary robots are also instrumental in packaging and monitoring processes, ensuring regulatory compliance and product safety. By reducing labor costs and streamlining workflows, stationary robots play a vital role in modern manufacturing and industrial inspection processes. Their integration into smart production lines makes them a key contributor to enhanced productivity and operational excellence.

Asia-Pacific Leads the Global Market

In 2024, the Asia-Pacific region is projected to hold the largest share—approximately 63.2%—of the global inspection robots market. This dominance is attributed to the region’s rapid technological advancements, widespread automation adoption, and strong presence of robotics and electronics manufacturers. Countries like China, Japan, South Korea, Taiwan, and India are not only driving demand for advanced inspection systems but also investing heavily in smart factories and industry 4.0 infrastructure.

The region is also expected to witness the highest compound annual growth rate (CAGR) of 22.3% during the forecast period. This momentum is being driven by government initiatives supporting industrial digitization, the development of manufacturing hubs, and increased awareness about quality assurance across sectors. With such factors in play, Asia-Pacific is likely to remain a key growth engine for the inspection robots industry in the years to come.

Key Companies in the Inspection Robots Market

The competitive landscape of the inspection robots market includes several prominent players that are continuously innovating and expanding their technological capabilities. The key companies profiled in the market include:

ABB Ltd (Sweden)

Fanuc Corporation (Japan)

Yaskawa Electric Corporation (Japan)

KUKA AG (Germany)

Mitsubishi Heavy Industries, Ltd. (Japan)

Kawasaki Heavy Industries, Ltd. (Japan)

Denso Corporation (Japan)

Seiko Epson Corporation (Japan)

Universal Robots A/S (Denmark)

Waygate Technologies (Germany)

Eddyfi Technologies (Canada)

ANYbotics AG (Switzerland)

Hangzhou Shenhao Technology Co., Ltd. (China)

Robotnik Automation S.L. (Spain)

PetroBot Technologies Private Limited (India)

Systemantics India Pvt. Ltd. (India)

SMP Robotics Systems Corp. (U.S.)

Energy Robotics GmbH (Germany)

These companies are focusing on partnerships, R&D, and product innovations to maintain their competitive edge.

Recent Developments Among Key Industry Players

Innovation and collaboration remain at the forefront of this rapidly evolving sector. Some of the notable recent developments include:

In January 2024, ANYbotics partnered with Cognite AS (Norway) to offer a combined solution for remote inspection using autonomous data collection and real-time analysis.

In October 2023, Eddyfi Technologies launched the VersaTrax Series—robotic crawlers designed for inspections in confined and hazardous environments across sectors like oil & gas, marine, and power generation.

In May 2023, Robotnik Automation introduced the RB-WATCHER, a mobile surveillance robot capable of detecting intrusions and fires.

In April 2022, SMP Robotics announced a distribution partnership with Team 1ST Technologies LLC (U.S.) to expand its footprint in Mexico.

These advancements reflect the growing role of automation in making inspections safer, more accurate, and cost-effective.

Get Sample Copy @ https://www.meticulousresearch.com/download-sample-report/cp_id=5513?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=30-04-2025

0 notes

Text

Fluid Dispensing Equipment Market: Key Trends and Growth Opportunities

The global fluid dispensing equipment market size is expected to reach USD 11.47 billion by 2030, registering at a CAGR of 4.7% over the forecast period, according to a new report by Grand View Research, Inc. Growing demand for accurate and efficient systems for dispensing fluids as an alternative to manpower engagement in these processes to be a key driving factor for the industry growth.

The industry is characterized by the advent of automation technologies in various stage of production processes. The technology’s greater scope across automotive, electrical & electronics, and medical devices manufacturing has enabled higher sales of fluid dispensing equipment in these industries.

However, with evolving construction practices and increased usage of automated machinery for masonry, prefabrication and precast processes is expected to provide growth opportunities for industry participants.

Curious about the Fluid Dispensing Equipment Market? Download your FREE sample copy now and get a sneak peek into the latest insights and trends.

Fluid Dispensing Equipment Market Report Highlights

• Adhesives & sealants are widely used across manufacturing stages to provide bonding between two materials, i.e., components, parts or overlays. Adhesives demand precision, accuracy, and consistency while being applied to surfaces

• Asia Pacific region led the market and accounted for over 43.8% of the global revenue in 2022. The region, particularly Korea and Taiwan, is a hub for semiconductors and other electronic component manufacturing and has the presence of leading companies such as Samsung, ZTE, and Foxconn

• Favorable capital spending by these end-users for procuring equipment and related systems will be a huge contributor towards Asia Pacific growth. Another significant force favoring the region’s growth is increasing automotive production and investments from western OEMs in the region

• The U.S. is a relatively mature region compared to those in Asia and is characterized by the presence of leading equipment suppliers and technological know-how. The U.S. is expected to account for nearly 17% of the global market value by 2030

Fluid Dispensing Equipment Market Segmentation

Grand View Research has segmented the global fluid dispensing equipment market report on based on product, application, and region:

Fluid Dispensing Equipment Product Outlook (Revenue, USD Million; 2018 - 2030)

• Flux

• Lubricant

• Solder Paste

• Adhesives & Sealants

o Epoxy Adhesives

o Epoxy Underfill

o Others

• Conformal Coatings

• Others

Fluid Dispensing Equipment Application Outlook (Revenue, USD Million; 2018 - 2030)

• Electrical & Electronics Assembly

o Semiconductor Packaging

o Printed Circuit Boards

o Others

• Medical Devices

• Transportation

• Construction

• Others

Fluid Dispensing Equipment Regional Outlook (Revenue, USD Million; 2018 - 2030)

• North America

o U.S.

• Europe

o Germany

o U.K.

• Asia Pacific

o China

o Japan

o India

• Central & South America

• Middle East & Africa

List of Key Players in Fluid Dispensing Equipment Market

• Nordson Corporation

• Asymtek; Protec Co. Ltd.

• AdvanJet

• Speedline Technologies

• Musashi Engineering Inc.

• GPD Global Inc.

• Fisnar Inc.

• Henkel AG & Co. KGaA

• Techcon Systems

• Intertronics

• Valco Melton Inc.

• Dymax Corporation

• Henline Adhesive Equipment Corporation

• ITW Dynatec

Order a free sample PDF of the Fluid Dispensing Equipment Market Intelligence Study, published by Grand View Research.

#Fluid Dispensing Equipment Market#Fluid Dispensing Equipment Market Size#Fluid Dispensing Equipment Market Share#Fluid Dispensing Equipment Market Analysis#Fluid Dispensing Equipment Market Growth

0 notes

Text

Electronic Chemicals and Materials Market Share by Region: Trends and Forecasts for 2032

The global electronic chemicals and materials market has been experiencing robust growth and is poised to continue its upward trajectory in the coming years. With technological advancements across various sectors, the demand for specialized chemicals and materials used in the manufacture of electronic devices is set to expand significantly. In this article, we explore the size, share, and growth analysis of the electronic chemicals and materials market through 2032.

Electronic chemicals and materials encompass a broad range of substances and compounds used in the production of semiconductors, printed circuit boards (PCBs), flat panel displays, solar panels, and other electronic devices. These materials are crucial for the functioning of electronic products that we use every day, from smartphones and laptops to renewable energy technologies and automotive systems.

Request a Free Sample Copy - https://www.skyquestt.com/sample-request/electronic-chemicals-and-materials-market

The electronic chemicals and materials market includes components like:

- Semiconductor chemicals: Photoresists, etching chemicals, and others used in semiconductor fabrication.

- Printed circuit board materials: Copper foil, solder mask, and other materials essential for PCB manufacturing.

- Display materials: Polymers, liquid crystals, and other compounds vital for flat-panel displays.

- Solar materials: Silicon, substrates, and conductive materials used in the creation of solar panels.

- Battery chemicals: Materials used in the production of batteries for electronic devices and electric vehicles.

Market Size and Forecast

The global electronic chemicals and materials market was valued at USD 62.07 Billion in 2024 to USD 108.64 Billion by 2032 and is expected to grow at a compound annual growth rate (CAGR) of 7.24% between 2025 and 2032. This growth can be attributed to several factors:

1. Increasing demand for consumer electronics: With the rise in disposable income and changing consumer lifestyles, the demand for electronic products such as smartphones, wearables, and laptops is on the rise. This, in turn, is driving the need for electronic chemicals and materials.

2. Advancements in semiconductor technologies: As the world continues to rely more heavily on digital technologies, semiconductors remain at the heart of this growth. The increasing complexity of semiconductor devices and the push for smaller, faster, and more energy-efficient chips will require more advanced chemicals and materials.

3. Electrification of transportation: The rapid adoption of electric vehicles (EVs) has created a significant demand for battery materials. As EV manufacturers seek to enhance the energy density and charging speed of their batteries, there is a growing need for advanced battery chemicals.

4. Development of renewable energy sources: Solar power is a key contributor to the renewable energy sector. As countries strive to reduce their carbon footprint, the demand for solar panels—and consequently, the materials used to make them—is increasing. This will continue to boost the demand for electronic chemicals and materials over the coming years.

5. Global manufacturing expansion: In regions like Asia-Pacific, particularly China, South Korea, and Japan, the presence of major electronics manufacturers is driving demand for electronic chemicals and materials. Similarly, North America and Europe are also seeing an uptick in demand due to the rapid growth in electric vehicle production and semiconductor manufacturing.

Make an Inquiry to Address your Specific Business Needs - https://www.skyquestt.com/speak-with-analyst/electronic-chemicals-and-materials-market

Market Segmentation

The electronic chemicals and materials market can be segmented based on type, application, and region.

By Type

1. Semiconductor Chemicals: These materials are crucial in the production of semiconductors and integrated circuits (ICs). Semiconductors represent the largest share of the market due to their widespread application across electronics, automotive, and telecommunication industries.

2. PCB Materials: Printed circuit boards are an essential component of all electronic devices, ranging from consumer electronics to automotive systems. Materials such as copper, solder, and substrates make up a significant portion of the market.

3. Display Materials: Liquid crystals, polymer materials, and conductive films used in the creation of displays, particularly in flat-panel televisions, smartphones, and computer screens, are seeing significant growth.

4. Battery Chemicals: The production of lithium-ion batteries used in smartphones, laptops, and electric vehicles is fueling the demand for battery chemicals, such as lithium, cobalt, and nickel-based materials.

By Application

1. Consumer Electronics: Smartphones, laptops, tablets, and other devices are the largest consumers of electronic chemicals and materials.

2. Automotive: As electric vehicles (EVs) gain traction, the demand for specialized materials in battery technology, as well as advanced electronic components in automobiles, is rapidly increasing.

3. Renewable Energy: Solar panels, energy storage systems, and other clean technologies rely heavily on electronic materials, creating significant growth opportunities.

4. Telecommunication: The demand for high-performance electronic devices and components, driven by the proliferation of 5G networks, is contributing to the growth of the market.

Regional Analysis

The electronic chemicals and materials market is geographically diverse, with key regions including North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa.

- Asia-Pacific: This region holds the largest share of the market, primarily driven by the presence of leading electronics manufacturers in countries like China, South Korea, and Japan. Additionally, the region’s growing semiconductor industry and the widespread adoption of electric vehicles are contributing to the market’s growth.

- North America: The increasing demand for electronic materials in automotive applications (especially EVs) and the development of advanced semiconductor technologies are key growth drivers in North America.

- Europe: Similar to North America, Europe is witnessing a surge in demand for electric vehicles and renewable energy technologies, which in turn is bolstering the demand for electronic chemicals and materials.

Take Action Now: Secure Your Electronic Chemicals and Materials Market Today - https://www.skyquestt.com/buy-now/electronic-chemicals-and-materials-market

Market Trends and Drivers

1. Miniaturization of Electronic Devices: As devices become smaller and more powerful, there is an increasing need for specialized chemicals that can enable the production of smaller, more efficient components, such as transistors, capacitors, and resistors.

2. Focus on Sustainability: With growing environmental concerns, there is a greater emphasis on sustainable production methods for electronic materials. Innovations in recycling and the development of eco-friendly materials are gaining momentum.

3. Advancement in Semiconductor Fabrication: As the semiconductor industry moves towards more advanced technologies like 5G, AI, and quantum computing, there is a growing demand for specialized chemicals that can meet the stringent requirements of next-generation chips.

Electronic Chemicals and Materials Market Top Players Company Profiles

Shin-Etsu Chemical Co., Ltd. (Japan)

Linde Plc (England)

Fujifilm Corporation (Japan)

Resonac Holding Corporation (Japan)

Air Liquide (Paris)

Solvay (Belgium)

BASF SE(Germany)

Mitsui Chemicals America, Inc. (US)

Merck KGaA (Germany)

Covestro AG (Germany)

SUMCO Corp. (Japan)

Air Products & Chemicals, Inc. (US)

Songwon (South Korea)

Cabot Microelectronics Corporation

Dow Chemical Company

Honeywell International Inc.

Huntsman Corporation

Kanto Chemical Co., Inc.

Momentive Performance Materials Inc.

Samsung SDI Co., Ltd.

Challenges

Despite the strong growth prospects, the electronic chemicals and materials market faces some challenges:

- Supply Chain Issues: The market’s reliance on complex global supply chains for key materials such as rare earth elements and lithium can be impacted by geopolitical tensions and disruptions like those seen during the COVID-19 pandemic.

- Cost Volatility: The prices of raw materials, particularly those required for battery production, are subject to fluctuations, which can impact the overall cost of production.

Read Electronic Chemicals and Materials Market Report Today - https://www.skyquestt.com/report/electronic-chemicals-and-materials-market

The electronic chemicals and materials market is on a strong growth trajectory, driven by the ongoing advancements in consumer electronics, electric vehicles, semiconductor fabrication, and renewable energy technologies. With a projected market value of USD 108.64 billion by 2032, the sector offers abundant opportunities for innovation and expansion. Companies involved in the production of electronic chemicals and materials will continue to play a critical role in powering the next generation of technological advancements and addressing the challenges posed by a rapidly evolving global market.

#ElectronicChemicals#SemiconductorMaterials#ElectronicMaterials#TechMaterials#MaterialScience#ElectronicsIndustry#Nanotechnology#TechInnovation#ElectronicsManufacturing#ChemicalsMarket#SustainableTech#AdvancedMaterials#SmartElectronics#ElectronicComponents#SemiconductorIndustry#HighTechMaterials#ElectronicsProduction#IndustrialChemicals#MaterialsScience#Nanomaterials

0 notes

Text

How to make a PCB

Today, I will cover in detail and show the process of making a printed circuit board at home. In addition to a soldering iron and a pair of side cutters, you will need a laser printer, an iron, a micro drill, and a few other tools for this job.

I test my designs on traced PCBs and do not use universal prototyping boards. It’s more convenient for me personally, and here’s why.

On the one hand, tracing a PCB takes time. On the other hand, it is also required to carefully arrange components and connections on a universal board. Additionally, you will need to cut traces on a stripboard or, on the contrary, make the traces you need on a breadboard if it is a matrix of pre-drilled holes with separate copper pads.

A board designed in CAD can then be copied in any number, either by making it yourself or by ordering from a factory, all new and shiny, already with a solder mask and silkscreen printing.

Finally, repairing and modifying a circuit on a printed board can be easier than on a universal one. Especially if long pins of the components on a universal board are used as tracks.

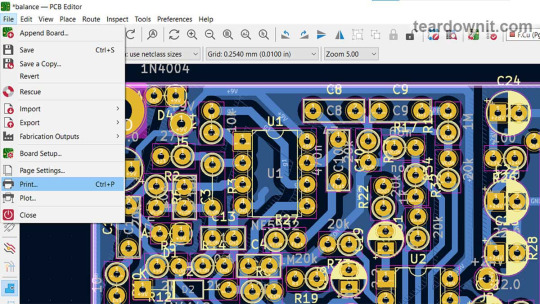

So, I drew the scheme in Schematic Editor, part of the KiCad 7.0 software package. This will be a microphone preamp; I will describe it more thoroughly in the upcoming posts. Moreover, this essay is on making the actual board, not its schematics.

Next, one needs to run the footprint assignment tool and specify the footprint for each and every component.

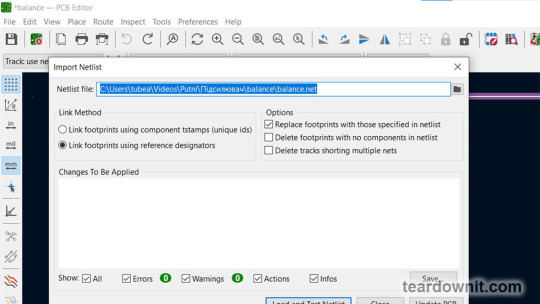

Then, we need to export the netlist.

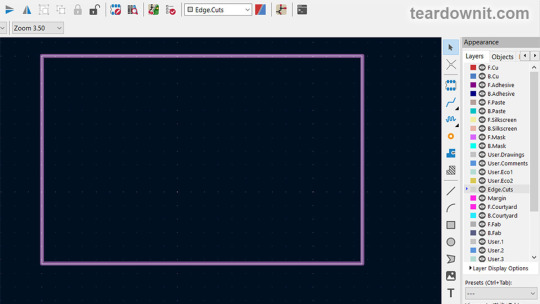

On the Edge. Cuts layer draw a rectangle that specifies the dimensions of our future PCB.

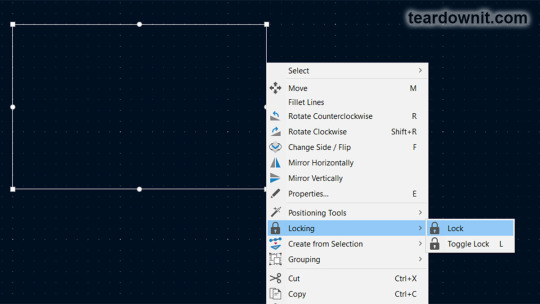

Now, we need to lock that rectangle so that it does not stand out too much and prevent it from being changed while we continue to draw our board layout.

One should ensure the Locked Items checkbox is unchecked on the Selection Filter.

Next, open PCB Editor and import the netlist.

Click Load and Test Netlist, and then Update PCB.

Then, you can place the components and draw the tracks.

We can view a 3D model of the future board at any time.

Once all the components are in place and the traces and polygons are drawn, one can print an image of the copper layer. You should turn off the toner save mode on your laser printer.

You can use glossy photo paper (designed for inkjet printing), any pages from glossy ad brochures or magazines, or special heat transfer paper for laser printers from electronics enthusiasts' stores. It is often colored yellow.

My board is single-sided, with all the components on the front side and all the copper on the backside. Therefore, we select the B.Cu and Edge.Cut layers for printing. The print scale should be 1:1.

If printing the front copper layer of F.Cu, we need to check the "Print Mirrored" checkbox.

Next, you must cut out a board of the required size from foil fiberglass. Some of us have access to professional cutters or use tin snips.

Others can utilize a rotary power tool with a cutting wheel or even an angle grinder. This is not the best option since fiberglass dust contains microscopic glass particles that irritate the skin and are very harmful if inhaled.

Due to its material, fiberglass PCB quickly dulls any tool except a diamond one. You can see the PCB with a hacksaw, but it will end up its teeth very quickly.

I use an adjustable tile hole cutter for cutting fiberglass. It contains two carbide cutters that can scratch a deep groove in the board and then simply break it along this groove.

These cutters are specifically designed for working on rigid materials, so CEM will not soon dull them. With this technique of cutting the PCB by scraping the track, we minimize the amount of glass dust and do not scatter it in the air.

Next, you need to carefully clean the surface of the copper foil. You can use the finest sandpaper, mild abrasive powder, or steel wool for dish cleaning. I use just a hard eraser. The point of cleaning is not only to remove dirt, oils, and oxides but also to cause micro-scratches for the toner to stick to.

Immediately after, the board must be thoroughly washed to remove any small foreign particles, then fried and degreased with acetone, lighter fluid, ethyl, or isopropyl alcohol.

So, we have a clean, dry fiberglass blank and a piece of glossy paper with traces printed on it. Textolite and paper are the same size. I fold them together and wrap them in a layer of office paper, newspaper, or, better yet, rolling paper.

Thin paper is needed so the glossy paper does not move relative to the PCB. Now, we place the wrapped board blank on a heat-resistant flat surface that we don't mind getting dirty. I use a stack of a few cardboard packaging sheets.

We take the iron, turn it on, and set the temperature as high as it goes. We place it on the blank board and iron it for three to four minutes so the blank has time to warm up nicely.

There is no need to press too hard, but the pressure should be firm. The skill comes with experience. To hold the hot workpiece while ironing, you can use a chopstick.

Remove the iron from the board and turn it off. Remove the wrapping paper from the board after it has cooled off, and place the PCB and the glossy paper in a warm water bath.

Next, slowly and carefully tear off the paper piece by piece from the fiberglass. The tracks and pads on the copper foil should be imprinted.

If some part of the board's design comes off, it can be restored with a permanent marker after the board is completely dry. If a significant piece of the polygon has fallen off, you can just tape it.

Next, I glue strips of tape on the non-foil side of the board to make small hanging rings to hold the board while etching. Throwing a chopstick through these rings is convenient to keep the board hanging. For etching to occur evenly, the board must be swiveled from side to side to mix the solution.

I use a ferric chloride solution for etching, which can be used multiple times. You can store it in a plastic or glass container with a non-metallic lid. This poisonous solution will corrode almost any metal, including stainless steel, so it should be stored, marked, and used cautiously.

To prepare an etching solution, you must take water at room temperature, pour it into a non-metallic container, and add ferric chloride little by little, stirring until the ferric chloride stops dissolving.

The solution will heat up during the dissolution process, not as much as when slaking lime, but noticeably. There is no need to filter the prepared solution or remove the sediment from the bottom of the container.

The optimal temperature for etching the board is 105–130°F (40–55°C). You can heat the solution past that, but then it may wash away permanent marker drawings.

I use plastic food containers for etching and a microwave to heat up the solution. I place the plastic container with the lid loosely closed inside a second bigger one with a lid on and turn on the microwave for one minute. This way, I can be sure that ferric chloride will not damage the microwave.

Once the excess copper on the board has completely dissolved, the board should be immediately washed with plenty of water using a toothbrush. If you do this over a metal sink, be sure not to leave a drop of etching solution anywhere; it can eat right through the sink.

Using acetone, we erased the toner from the washed and dried board and began drilling holes with a microdrill.

Trying the board in the case.

Then, you can begin soldering the components immediately. Still, the best results are obtained if you tin the entire copper foil. I use solder paste for this; just remember that it is toxic, and after working with it, you must wash your hands and wipe the table's surface clean.

Apply solder paste using a spatula in as thin a layer as possible, as if applying thermal paste to a processor. Next, heat the copper foil with a soldering iron.

Now, wipe or rinse the board with the same degreaser liquid you've used before transferring the toner, and you can place and solder the components.

0 notes

Text

Light-Emitting Diode (LED) Mounter Market Growth and Industry by 2024-2032

The Reports and Insights, a leading market research company, has recently releases report titled “Light-Emitting Diode (LED) Mounter Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Light-Emitting Diode (LED) Mounter Market share, size, trends, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Light-Emitting Diode (LED) Mounter?

As per Reports and Insights analysis, the light-emitting diode (LED) mounter market is expected to grow at a CAGR of 9.7% during the forecast period of 2024 to 2032.

What are Light-Emitting Diode (LED) Mounter Market?

A light-emitting diode (LED) mounter, also known as an LED pick-and-place machine, is an automated device used in electronics manufacturing to precisely place LED components onto printed circuit boards (PCBs). Equipped with advanced vision systems and precision robotic arms, the machine picks LEDs from feeders and positions them accurately on the PCB as per design specifications. This process ensures high-speed and precise placement of small, delicate LEDs, essential for producing LED displays, lighting solutions, and various electronic devices. Automation by the LED mounter significantly reduces manual labor, enhances production efficiency, and minimizes assembly errors.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1909

What are the growth prospects and trends in the Light-Emitting Diode (LED) Mounter Market industry?

The light-emitting diode (LED) mounter market growth is driven by various factors and trends. The light-emitting diode (LED) mounter market is rapidly growing, fueled by the increasing demand for LED displays, lighting solutions, and advanced electronic devices. The expanding automotive, consumer electronics, and telecommunications industries drive the need for efficient, high-speed, and precise LED assembly. Innovations in LED technology and advancements in automation and robotics further accelerate market growth. The trend towards miniaturizing electronic devices also requires highly accurate placement machines. The Asia-Pacific region, especially China and Japan, leads the market due to its strong electronics manufacturing presence, while North America and Europe show robust demand driven by technological advancements and high adoption rates. Hence, all these factors contribute to light-emitting diode (LED) mounter market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

By Product Type:

High-speed LED mounters

Medium-speed LED mounters

Low-speed LED mounters

By Application:

Consumer electronics

Automotive

Aerospace and defense

Industrial

Healthcare

Others

By End-use Industry:

Electronics manufacturing services (EMS)

Original equipment manufacturers (OEMs)

By Organization Size:

Small and Medium Enterprises (SMEs)

Large Enterprises

Market Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

The U.K.

France

Spain

Italy

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

India

Japan

South Korea

Australia

New Zealand

ASEAN

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

United Arab Emirates

South Africa

Egypt

Israel

Rest of MEA.

Who are the key players operating in the industry?

The report covers the major market players including:

ASM Pacific Technology Ltd.

Fuji Machine Mfg. Co. Ltd.

Juki Corporation

Panasonic Corporation

Mycronic AB

Yamaha Motor Co., Ltd.

Hanwha Precision Machinery Co., Ltd.

Nordson Corporation

Kulicke & Soffa Industries, Inc.

HAN'S Laser Technology Industry Group Co., Ltd.

Hitachi High-Tech Corporation

Nordson Corporation

Essemtec AG

OMRON Corporation

ITW EAE

Discover more: https://www.reportsandinsights.com/report/light-emitting-diode-led-mounter-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd. 1820 Avenue M, Brooklyn, NY, 11230, United States Contact No: +1-(347)-748-1518 Email: [email protected] Website: https://www.reportsandinsights.com/ Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/ Follow us on twitter: https://twitter.com/ReportsandInsi1

#Light-Emitting Diode (LED) Mounter Market Size#Light-Emitting Diode (LED) Mounter Market Share#Light-Emitting Diode (LED) Mounter Market Demand#Light-Emitting Diode (LED) Mounter Market Analysis

0 notes

Text

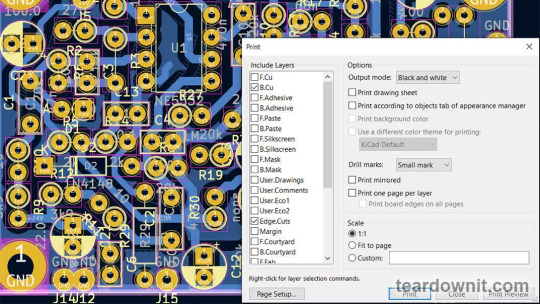

Electronic Design Automation Software Market Size And Share Report, 2030

Electronic Design Automation Software Market Growth & Trends

The global electronic design automation software market size is anticipated to reach USD 22.21 billion by 2030, expanding at a CAGR of 9.1% from 2023 to 2030, according to a new study by Grand View Research Inc. The growing usage of advanced electronic components across different areas of healthcare, automotive, and consumer electronic sectors is driving Electronic Design Automation (EDA) software market growth. Apart from this, the proliferation of the Internet of Things (IoT) and connected devices further promotes EDA software market advancement.

Miniaturization of devices and chips is expected to create lucrative opportunities for EDA software. This software assists chipmakers in lowering the errors in Integrated Circuit (IC) and chips, thereby driving the electronic design automation software industry growth. The exponential growth of the integrated circuits market is driving the need for electronic design automation software. The software is increasingly being adopted for designing electronic systems such as printed circuit boards and integrated circuits, supporting the growth of the EDA market.

Furthermore, developments in technology, growing digitization, growth of the electronics manufacturing industry, and increasing adoption of advanced rendering & simulation tools by hardware designers are expected to positively influence the electronic design automation software industry growth over the forecast period. Furthermore, the increasing acceptance and awareness of smart fitness devices are factors enabling electronic design companies to invest in innovative design software tools for designing enhanced & compact products, thereby propelling the EDA software market growth over the forecast period.

Growing demand for EDA software is encouraging various market players to adopt various business strategies to achieve higher profitability in the market for electronic design automation software. Market players are unveiling new solutions by partnering with technology providers to improve their brand identity, propelling the EDA software market growth. For instance, in January 2022, Altium LLC announced a partnership with MacroFab, Inc., a U.S.-based cloud platform provider for electronic production, to launch “Altimade.” The new solution combines elastic manufacturing capabilities and real-time supply chain data, available on the Altium 365 electronic design platform. Altimade empowers customers to request instant quotes and place orders for manufacturing their PCB assembly without exiting the design environment.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/electronic-design-automation-eda-software-market

Electronic Design Automation Software Market Report Highlights

The services segment is expected to register a CAGR of 10.6% from 2023 to 2030. The segment growth can be attributed to the increasing proclivity of OEMs to outsource their design needs. Furthermore, electronic circuit boards are in high demand in the industry due to their increasing importance in a variety of vital electronic products such as mobile phones and tablets

The cloud segment is expected to register a CAGR of 10.8% from 2023 to 2030. Cloud-based deployment allows for faster distribution, less maintenance, lower costs, and more scalability

The healthcare segment is expected to register a CAGR of 11.5% from 2023 to 2030. The segment growth can be attributed to the benefits of EDA software in healthcare, such as lower costs, improved patient outcomes, faster design & development, enabled regulatory compliance of medical devices, and simulation and testing of medical equipment

The microprocessors & controllers segment is expected to register a CAGR of 9.5% from 2023 to 2030. The increased use of microprocessors in consumer devices such as smartphones, personal computers (PCs), and laptops is expected to drive global demand for the segment

Asia Pacific is anticipated to emerge as the fastest-growing region over the forecast period at a CAGR of 9.6%. A surge in demand for electronic devices together with the prevalence of key electronic component manufacturers in Greater China is expected to drive regional growth

Electronic Design Automation Software Market Segmentation

Grand View Research has segmented the global electronic design automation software market based on product, deployment, application, end-use, and region:

Electronic Design Automation (EDA) Software Product Outlook (Revenue, USD Billion, 2018 - 2030)

Computer-aided Engineering (CAE)

IC Physical Design and Verification

Printed Circuit Board and Multi-chip Module (PCB and MCM)

Semiconductor Intellectual Property (SIP)

Services

Electronic Design Automation (EDA) Software Deployment Outlook (Revenue, USD Billion, 2018 - 2030)

Cloud

On-premise

Electronic Design Automation (EDA) Software Application Outlook (Revenue, USD Billion, 2018 - 2030)

Aerospace and Defense

Automotive

Healthcare

Industrial

Consumer Electronics

Others

Electronic Design Automation (EDA) Software End-use Outlook (Revenue, USD Billion, 2018 - 2030)

Microprocessors & Controllers

Memory Management Unit (MMU)

Others

Electronic Design Automation (EDA) Software Regional Outlook (Revenue, USD Billion, 2018 - 2030)

North America

Europe

Asia Pacific

Latin America

Middle East & Africa

List of Key Players in the Electronic Design Automation Software Market

Advanced Micro Devices, Inc.

Aldec, Inc.

Altair Engineering Inc.

Altium LLC

Autodesk, Inc.

ANSYS, Inc.

Cadence Design Systems, Inc.

eInfochips

EMA Design Automation, Inc.

Keysight Technologies

Microsemi

Synopsys, Inc.

Silvaco, Inc.

The MathWorks, Inc.

Vennsa Technologies

Zuken

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/electronic-design-automation-eda-software-market

#Electronic Design Automation Software Market#Electronic Design Automation Software Market Size#Electronic Design Automation Software Market Share

0 notes

Text

Flame Retardants Market Overview Analysis, Trends, Share, Size, Type & Future Forecast to 2034

Flame retardants are chemicals added to materials such as plastics, textiles, and coatings to inhibit ignition and prevent the spread of fire. They play a vital role in enhancing safety in industries like construction, electronics, and transportation.

The flame retardant market is expected to develop at a compound annual growth rate (CAGR) of 7.2% between 2024 and 2034, reaching USD 16,462.41 million in 2034, according to an average growth pattern. The market is projected to be at USD 9,845.59 million in 2024.

Get a Sample Copy of Report, Click Here: https://wemarketresearch.com/reports/request-free-sample-pdf/flame-retardants-market/1589

Types of Flame Retardants

Flame retardants can be classified into several categories based on their chemical composition and application:

Halogenated Flame Retardants (HFRs):

Contain chlorine or bromine.

Effective but controversial due to their potential environmental and health hazards.

Common in plastics and textiles.

Non-Halogenated Flame Retardants:

Phosphorus-based: Used in epoxy resins, polyurethane, and textiles.

Nitrogen-based: Effective for thermoplastics and synthetic fibers.

Mineral-based: Includes aluminum hydroxide and magnesium hydroxide, which act as heat absorbers.

Inorganic Flame Retardants:

Provide thermal stability and are used in applications where halogen-free products are required.

Intumescent Flame Retardants:

Expand when exposed to heat, forming a char layer that protects the underlying material.

Applications Across Industries

Construction: Used in insulation materials (polystyrene, polyurethane foams) and structural components to meet building codes for fire resistance.

Electronics & Electrical Equipment:

Protects circuit boards, cables, and plastic casings.

Ensures compliance with safety standards such as RoHS (Restriction of Hazardous Substances) and WEEE (Waste Electrical and Electronic Equipment).

Automotive & Transportation:

Essential in vehicle interiors, upholstery, and composite materials for safety.

Lightweight flame retardant materials help reduce vehicle weight and improve fuel efficiency.

Textiles:

Flame retardant treatments are applied to fabrics used in furniture, curtains, and protective clothing for industries like firefighting and military.

Aerospace:

Critical for materials used in aircraft interiors, cables, and structural components to meet stringent fire safety norms.

Flame Retardants Market Key Drivers

Rising Fire Safety Regulations: Governments and international organizations are imposing stricter fire safety norms, fueling the adoption of flame retardants in construction and consumer goods.

Growth in End-Use Industries:

Construction: Flame retardants are crucial for insulation materials and structural components.

Electronics: Their use in printed circuit boards, casings, and wires is essential for preventing fire hazards.

Transportation: Flame retardants enhance safety in automobiles, aircraft, and trains.

Urbanization and Infrastructure Development: The rapid growth in construction activities globally, especially in developing regions, is boosting demand.

Increased Awareness of Fire Hazards: Growing awareness about fire safety in households, workplaces, and public spaces supports market expansion.

Flame Retardants Market Challenges and Opportunities

Challenges:

High cost of production and raw materials for eco-friendly flame retardants.

Limited awareness and adoption in small-scale industries.

Balancing performance with environmental impact.

Opportunities:

Expanding markets in Asia-Pacific, Latin America, and Africa due to urbanization.

Development of multifunctional flame retardants that offer additional properties like UV resistance or antimicrobial effects.

Flame Retardants Market Segmentation,

By Type:

Alumina Trihydrate

Brominated Flame Retardant

Antimony Trioxide

Phosphorous Flame Retardant

Others

By Application:

Unsaturated Polyester Resins

Epoxy Resins

PVC

Rubber

Polyolefins

Others (Engineering Thermoplastics and PET)

By End User Industry:

Construction

Automotive & Transportation

Electronics

Others (Textiles, Aerospace, and Adhesives)

By Region:

North America

Latin America

Europe

East Asia

South Asia

Oceania

Middle East and Africa

Key companies profiled in this research study are,

The Flame Retardants Market is dominated by a few large companies, such as

BASF SE

Clariant AG

Huntsman Corporation

Israel Chemicals Limited (ICL)

Albemarle Corporation

·DuPont de Nemours, Inc.

Arkema S.A.

Solvay S.A.

Dow Chemical Company

Ferro Corporation

Nabaltec AG

Shanghai Pret Composites Co., Ltd.

Jiangsu Kuaima Chemical Co., Ltd.

Flame Retardants Industry: Regional Analysis

Asia Pacific Market Forecast