#Printing Slicer

Explore tagged Tumblr posts

Text

Why Mintcad Created Its Own 3D Printing Slicer?

3D printing has revolutionized the engineering industry as it reduces production time, increasing the opportunities for innovation. Your digitally created Computer Aided Designs turn into real, physical products with a 3D printer.

But do you know how your CAD software communicates with a 3D printer or how the files stored locally are sent to your 3D printer? Machines understand only the machine language and hence you need some coded instructions commanding the 3D printer to print your 3D printable models. You need an intermediate communicating tool which is a slicing software.

Slicing software gets the digital file from the CAD software and accordingly instructs the 3D printer on how to print the design to obtain the intended output. To better understand this, let’s picture you’re on a business trip to a foreign country but do not know their native language. This makes it difficult for you to communicate with the locals of that place and get your work done. So, you seek the help of a local person who understands both your language and the natively spoken one, thereby communicating your message to the people there and getting your work done. Slicing software is analogous to that intermediator who translates your message to the locals.

Let’s look over how a 3D printing Slicer works and how it’s a crucial asset to a 3D printing platform or a 3D printable NFT marketplace.

What is a Slicing Software?

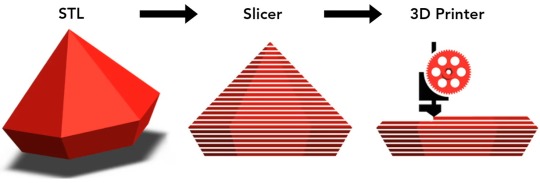

A slicing software is a crucial tool in the world of 3D printing. Technically speaking, the 3D printing slicer converts the STL file (Stereolithography or Standard Tessellation Language) into the G-code that commands the printer. It takes 3D printable models, formats like a .STL or .OBJ from a CAD software, and breaks it down into individual layers, much like slicing a loaf of bread.

These layers are then translated into vector instructions for the 3D printer, guiding it on how to build the object layer by layer. The software determines factors such as layer thickness, print speed, and support structures, ensuring that the final printed object matches the digital design. In essence, a slicer serves as the bridge between the digital design and the physical creation, making 3D printing possible.

There are many 3D printing slicing softwares available in the market including both free and paid versions. Cura, PrusaSlicer, Simplify3D and Slic3r are a few commonly used best 3D printer slicer softwares.

Mintcad comes integrated with our own homemade 3D printing slicer that makes it easy for people to slice the NFTs and make them print ready. Our proprietary slicing software Jullienne is free to use and is compatible with all types of 3D printers available in the market.

Parts of a Slicer Software

The slicing software has two major front end and back-end components i.e., the GUI and the logical algorithmic component respectively.

Front-End GUI

The Graphical User Interface component of the slicer is the one that helps the user to visualize the design and interact with the software. You can move, scale, rotate and change the settings for your 3D digital model.

Here you can view the complex 3D models into their layers.

Back-End Logic

The back end of the slicer converts the digital file and automatically generates the geometric code or the G-code which gives the necessary instruction to execute the print option.

Post the G-code generation, the slicing algorithm follows the geometric instructions and slices the 3D model into its 2D slices.

How Does Our 3D Printer Slicer Software - Jullienne Work?

You must first purchase a print from the many 3D printable NFTs that are listed on Mintcad. Learn how to buy a single print.

Once your purchased print is loaded onto our slicer the model is sliced into G-code layers that can be viewed in different anatomical directions - the coronal, axial, and sagittal planes.

Each slice is individually sent for the print operation.

Technically, the slicer converts the .STL file into a G-code that includes step by step instruction for the 3D printer on how to print.

The 3D printing is done in layers where each layer sits on another supporting layer below. However, if there are any hanging layers you can add an external supporting layer using the graphical elements like skirt, brim and raft.

You can add a single outline known as skirt surrounding the object on the print bed without actually touching the object.

A brim made of a few concentric layers gets attached to the edges of the 3D model and extend from the print bed. It keeps the print in place preventing warping while the printer works on the part.

A 3D printing support raft is a bit wider than the first layer of the print and placed beneath the object to print. It functions as the base support of the print.

All three graphical elements are easily detachable and hence the output print is an exact replica of the input file.

You can further set various print settings like the layer heights, infill percent, speed of printing, optimized print path, temperature of the extruder, filament diameter, nozzle diameter, print bed shape, etc.

Finally, you can connect it to your 3D printer and start printing.

Why Choose Mintcad’s Jullienne Slicer Software?

Mintcad is a holistic niche NFT marketplace where you can mint NFTs for your CAD files, sell your NFTs and also allow people to print it for a one-time fee. Printing an NFT or a digital 3D model requires connecting to a slicer software as an intermediary step. Instead of hunting for an external slicing software, you can get the work done on the Mintcad platform itself and for free of cost.

Here are a few reasons why Jullienne stands out as a good 3D printing slicing software:

i) Protecting Your Intellectual Property:

JULLIENNE ensures that your 3D NFT models don't need to be downloaded, allowing you to make money without sacrificing your intellectual property. This feature safeguards your creations and empowers you to profit while maintaining control over your digital assets.

ii) Supports 3D Printable NFTs:

Jullienne steps into the future by supporting 3D printable NFTs. Whether you've just acquired a Mintcad NFT or paid for a one-time print, load the file onto our slicer, and effortlessly send print commands remotely. Monitor your masterpiece in the making from anywhere.

iii) Customizable - Add Your Own Printer:

Tailor Jullienne to fit your 3D printing arsenal. While it's already prepped for most printer configurations, you have the power to add any custom printer to your toolkit, ensuring compatibility with your unique printing setup.

iv) Project Management - Never Lose Your Prints:

Bid farewell to the fear of losing print settings. Jullienne is your project vault, securely storing all your print data. Easily revisit settings, review past prints, and learn from each project, ensuring every print is a masterpiece.

v) G-code Playback - See Your Print in Action:

Witness your creation come to life with Jullienne's integrated layer playback. Visualize each layer's printing process, offering endless opportunities for optimization. See the magic unfold before your eyes, layer by layer.

vi) Access Anytime, Anywhere:

Embrace flexibility with Jullienne's browser-based app, granting you access to your files from any computer with just your login credentials. Your 3D printing projects are at your fingertips, anytime and anywhere.

vii) Real-Time Updates Without Additional Packages:

Stay informed with Jullienne's real-time updates, all without the hassle of installing extra packages. Receive notifications and insights as your prints progress, ensuring a smooth and informed 3D printing experience.

viii) Cross-Platform Compatible:

Experience Jullienne's versatility across browsers. Whether you prefer Chrome, Firefox, Safari, or Microsoft Edge, access your slicer effortlessly, breaking down platform barriers for a unified user experience.

ix) Free Of Cost

You do not need to burn a hole in your pocket to get your digital 3D model converted into a format that your 3D printer can print. You can easily and quickly do it via Mintcad’s proprietary Jullienne slicing software at free of cost.

x) User-Friendly UI/UX:

Experience an intuitive journey with Jullienne’s user-friendly interface. Navigating through your 3D printing projects becomes a breeze, making the entire process seamless and enjoyable for users of all levels.

Conclusion

A 3D printing slicer software serves as a great asset in getting your NFTs printed by converting the digital NFTs into printer understandable g-codes. Mintcad is a pioneer in integrating a proprietary slicing software into the NFT 3D printing platform making the entire process a breeze for the end users. Explore Mintcad’s slicing software Jullienne and print out some cool stuff today.

This content is originally published on Mintcad's Website: Why Mintcad Created Its Own 3D Printing Slicer?

0 notes

Text

3D printing shenanigans....

Eleanore printed by my Co- worker. Low detail and 7cm smol, but I love her. Glows in the dark btw.

Lettie print that didn't quiet work out. She ded.

Buuuut I'll keep trying..

.... with tree structures. Looks hella cursed.

Derpy Kalymos wip.

#warframe#1999#warframe 1999#3d printing#3d#blender#orca slicer#fail#it's not failure if I can learn from it#Is ThIs FaNaRt?

7 notes

·

View notes

Text

I got some nice cardstock to print it out on~ but I fucked up cutting it so I guess I’ll keep this one and send a different one to pita. maybe I won’t cut it down and just send it as is

#orlbs#p5lb#or I’ll give the ugly one to a friend who isn’t into p5 but was intetedtrf in yhe concrpt of printing comic#maybe the library has those big slicets#slicers

4 notes

·

View notes

Text

IM DOING IT!!!! YEAHH!!!!

#AND SOME OF THESE!!!! AND SOME OF THESE!!!!! /ref#I hope the print turns out alright#it’s my first time slicing a model into separate pieces#and my first time using prusa slicer#and my first time printing my own head base#right now only the beak is printing#my cat is trying to get into the studio. she wants to nap the printer so damn bad#too bad she can’t open doors 👍#fursuit making#or at least I’m trying out here man. it’s been a hot minute#also I got the head base files on Etsy and they look so good#I hope my printer does them justice 🙏

2 notes

·

View notes

Text

My 3D printing software won't let me print!!!!!

Dealing with 3D printing software issues can be a real headache, especially when it decides to play hard to get. Don’t worry; you’re not alone in this struggle. This article’ll delve into the intricacies of 3D printing software problems and provide an extensive troubleshooting guide. Whether you’re a seasoned enthusiast or just getting started, we’ve got you covered. Understanding the Hurdles:…

View On WordPress

6 notes

·

View notes

Text

Prusa Slicer - Latest Version Download

PrusaSlicer is an open-source 3D printing slicing software developed by Prusa Research. It helps users convert 3D models into G-code, the language that 3D printers understand. Initially based on Slic3r, PrusaSlicer has evolved into a powerful tool with numerous advanced features for both beginners and experienced users.

Key Features

Multi-Material Support: Allows printing with multiple filaments in a single print job.

Customizable Print Settings: Users can fine-tune layer height, infill, supports, and speeds for optimal print quality.

Adaptive Layer Heights: Adjusts layer thickness dynamically to improve surface quality while reducing print time.

Organic Supports: Generates tree-like supports that are easier to remove and conserve material.

Modifier Meshes: Enables localized changes in print settings for specific parts of a model.

Integration with Prusa Printers: Comes pre-configured for Prusa 3D printers but also supports third-party printers.

Download now from official website: https://prusa-slicer.net/

1 note

·

View note

Text

More 3d printing shenanigans I’m on a Zelda kick rn as you can see

#these are gonna be fun to paint#imma print a dragon later but first I’m printing one more of these guys#and then I found this cute lil korok piggy bank#that thing said it would take like six hours in the slicer which means it’s actually gonna take#like 7 hours to print lmao#anyway#loz#loz botw

1 note

·

View note

Text

the people at the arts resource center are so nice,,,

#marzi speaks#also REALLY glad i woke up early#i went to go print my stuffs for my class at 11 today#and i needed it double sided#the one printer that was supposed to print double-sided just wasn’t. doing that#like there was no option in the driver#so an employee (i’m assuming a boss of some sorts but idk) came over to fuck with the driver and help me out#and i was very much awkward at first. i was quiet#but he kept apologizing for how long it was taking#and i realized it was just like how finicky 3D printers are. so i used that to relate to him#and boom awkward air cleared. we were laughing and complaining abt settings and slicers and files#anyways he eventually just printed it on the faculty printer bc he knows it always works for him#so i have my print now :3#apparently they just got new computers with a new OS#so the OS probably doesn’t wanna show that printer’s double-sided option on the driver#that or the printer itself has a setting somewhere that needs to be fixed#honestly the experience made me wanna work there#unfortunately i do love using software. it is the world’s most frustrating puzzle but. yaknow#also i like the idea of my job mostly being refilling paper trays. that sounds very simole and lovely#i should look them up and see if they’re hiring

0 notes

Text

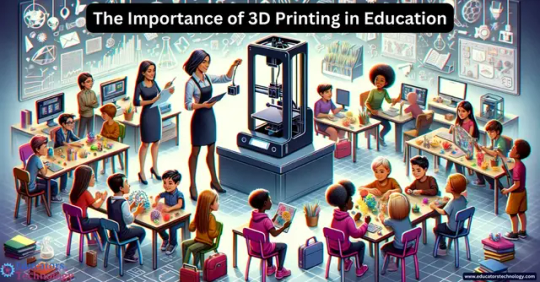

3D Printing In Classroom: A Hands-On Approach To STEM Education

The education system is continuously evolving through technological advancements paving way for better education and intellectual citizens of tomorrow. Online learning, EdTech innovations, gamification and immersive learning have reshaped the way concepts are taught, making education a more fun and an engaging experience. 3D printing is a novel addition to the technological spectrum of contemporary educational system. With the introduction of 3D printing in education, educational institutions can give a better understanding of complex concepts especially in STEM that encompasses the disciplines of Science, Technology, Engineering and Mathematics. The 3D Printing Market in Education Sector size is estimated to grow at a CAGR of 23.49% between 2022 and 2027.

In this blog we give you a brief overview of how integrating 3D printing in STEM education can enhance the overall learning experience for students while diving into the benefits of 3D printing in education.

What is 3D printing?

3D printing is the process of converting your digital CAD files, like the .STL format into a three-dimensional physical object. The digital files are created using CAD software and then printed using a slicer software. The 3D printing slicer software slices the digital file into multiple layers and generates a geometric code that instructs the 3D printer to follow a certain path to print the object. The object is printed layer by layer hence making it a part of the additive manufacturing process.

What are the Benefits of 3D Printing in Education?

Education in a STEM discipline requires more practical knowledge and hands-on training to understand the concepts better. There is an evident difference between theoretical bookish knowledge and what one learns via practical experimentation. And this is where the use of 3D printing in education comes into play.

Enhancing student engagement

Picture two scenarios: First one is where the teacher is reading out paragraphs from the textbook and drawing certain diagrams on the board to explain a scientific concept. Second scenario is where the teacher comes with the physical objects in hand to explain you the concepts.

Now which scenario would keep the students engaged and intrigued in knowing more about the subjects? The second one, obviously!

The hands-on nature of 3D printing in STEM education captures students' attention, fostering a deeper interest in STEM subjects and promoting active participation in the learning process.

Give Room to Creativity & Innovation

Students are encouraged to think creatively and solve real-world problems by designing and prototyping solutions using 3D printing technology. 3D printing is like providing students with a blank canvas and a set of vibrant colors, allowing them to paint their imaginative ideas into tangible reality.

For instance, in a physics class, students might create a working model of a simple machine like a lever or pulley, exploring innovative ways to improve its efficiency.

Hands-on Practical Training of Subjects

3D printing allows students to apply theoretical concepts from STEM subjects to tangible projects, reinforcing understanding through hands-on experience.

In an engineering class, students can design and manufacture mechanical parts using 3D printing, providing practical insights into the product development lifecycle.

Improve Problem Solving & Critical Thinking Skills of Students

The natural synergy between 3D printing and STEM education lies in their shared focus on problem-solving, critical thinking, and creativity. Utilizing 3D printing in the classroom can bridge the gap between theoretical concepts and real-world applications, making STEM subjects more engaging and relevant for students. Students tasked with designing a functional prosthetic limb ing 3D printing must overcome challenges relating to materials, ergonomics and functionality.

Teaching Complex Subjects in an Easy Way

3D printing proves invaluable in visualizing geometric shapes and figures, making abstract concepts more tangible for students studying geometry.

In mathematics, students can create 3D-printed models of geometric shapes to understand spatial relationships, turning abstract theorems into tangible objects.

Preparation for Future Technologies

Exposure to 3D printing enhances students' familiarity with advanced technologies, contributing to their overall technological literacy. Acquiring skills related to 3D printing prepares students for future careers in industries where additive manufacturing is increasingly prevalent, such as manufacturing, design, and healthcare.

Conclusion

3D printing helps elevate the learning experience for students in various sectors like art, design, science projects, mathematics, etc. Mintcad supports printing your NFTs and we have our homemade Jullienne slicing software. Our slicing software is free to use and hence anyone who wants to print their digital files can use Jullienne to slice their digital file and connect with any 3D printer of your choice. Give your kids an engaging learning experience by leveraging 3D printing in education.

This content is originally published on Mintcad's Website: 3D Printing In Classroom: A Hands-On Approach To STEM Education

0 notes

Text

This is an early version of a doll I produce and is intended to be used by printing it out and building on top of it with two part Apoxie sculpt or Milliput or something similar. It can also be imported into a 3d program of your choice and modified.

This model has been printed and tested in the past, however if you have problems with it please let me know. She has her stringing channels, magnet positions in her face, and she's been hollowed in order to save on resin used.

Right now the doll is 16in, however you can use the Bounding Box file in order to adjust it to the scale you want, note the percentage you are enlarging it and apply that percentage to all the other parts in the slicer of your choice.

YOU ARE WELCOME TO: sell printed copies of the doll, make casts of an altered print to sell, print a doll for a customer

YOU CANNOT: make a cast of the printed doll without making significant changes to the doll that has been printed. You cannot sell the files, changed or not, in a digital format. Only prints may be sold.

Reblogs appreciated!

163 notes

·

View notes

Text

Ha ha, I lied!

So, the thing with my slicer application (Chitubox) is that when you're adding supports, the software probably does a boolean union of supports to mesh, and where the tips of the supports touch your mesh, it deforms your mesh (bows it outwards, a very slight convex deformation, where the tip touches, and I suspect there might be some additional concave deformation but I haven't figured this out yet).

The 2 & 10 CR chits are challenging, because their art is recessed (whereas on the 5 & 20 they're raised, which meant that all I needed to do was make the relief a bit prouder and then sand it down flat. There's a gentle curve to the edges of the chits, so I can't just slap the 2 & 10 CR chits on a flat surface and sand it.

So I ended up manually adding & removing supports to make sure that they'd end up in places that are easy to sand. The first attempt to print worked for the 2 CR chits, which are small, but the 10 CR chits failed (not enough supports). So I added a few more strategic supports and the 10 CR chits printed fine. After sanding, washing, sanding, scrubbing, sanding, scrubbing, sanding, washing, and curing, they're done.

I don't have a photo of this yet but spray-can paint+primer did really well for filling in the print lines that I couldn't reach.

I spent the better part of the morning modeling the 2 & 10 CR "chits", or tokens, from Apple's Silo series.

I feel like working with Blender is basically a huge exercise in sunk-cost fallacy. I am 100% certain that there are far better programs out there for modeling for 3D printing, but at this point I've spent so much time Doing Battle with Blender that I feel like I just can't face the idea of starting over from scratch with something else.

Blender is fiendish: no matter how hard you try to ensure that the meshes going into a boolean operation are manifold, the result is often non-manifold, like Blender is determined to make my whole day non-manifold, and learning how to repair the non-manifold parts can be pretty dang frustrating -- nothing's more irritating than having 1 manifold edge, and you fix it, and you check again, and now you have 14 manifold edges. And there's no consistent way to fix it; sometimes you need to merge edges/vertices, some times delete and rebuild them, argh. I am pretty sure the prop makers for the show were not using Blender and if they were, I am in awe.

Now I have this batch of tokens printing out. I messed up one printed 5 CR token with too much sanding, so I'm printing out another to give it another go. Hopefully these print out all right.

The next step, after sanding these down and figuring out a way to minimize print lines in places where I can't reach with a sanding stick, is to figure out a way to sprue these up so that I can cast them in Mold Max 60 (a high-temp, flexible silicone) and then eventually, maybe, cast these things in pewter.

The super long-term goal is to make a couple of patchwork "rice bag" pouches for these, and send a set to Norm Chan & Adam Savage for them to weather (if they want to).

5 notes

·

View notes

Text

Understanding 3d Slicers for Perfect Prints

View On WordPress

1 note

·

View note

Text

This is where I am at with my articulated dragon 3D model. I now have to wait 16 hours for it to print, and we will see if there are any tweaks and anything else to fix. From what I can see in the slicer, all the parts look good, with no sticky parts. 🤞😃 Wish me luck.

32 notes

·

View notes

Text

The first set of resin Yeld miniatures is now available for sale! Our box set includes a Witch Hunter, Witch, Dog, Black Mage, Fairy Warrior and Mermaid Slicer!

We release new minis (including STL files) on the Yeld Patreon every month!

41 notes

·

View notes

Text

RAIJU

In a fit of "Fine, I'll just make it myself" after seeing that Bandai hadn't announced a Steel Haze Ortus/Alba frame kit yet, I decided to try my hand again at making a kitbash that looked close enough to the one I used in game that I could pose around. I got inspired after getting the AC6 artbook and seeing Takayuki Yanase's original drafts, and started figuring out similar looking mechs that could serve as parts. For this I used pieces from Full Metal Panic's Arbalest and Laevatein, since the chest pieces of the Laevatein had those same flat chest pauldrons that the actual Alba Frame has, and used the chest and legs from the Transient Gundam since the feet were similar. Next I used the waist from the Core Gundam 2 and I had a buddy 3D print resin parts for the side skirts and head, since I really wanted the look of the six eyes the Alba frame had. Lastly, another friend of mine was able to send along the actual 30 minute missions AC kits from Japan, and I took the beam slicer from the Steel Haze and the laser drone launcher from the weapons kit along with modifying some machine guns from Alto kits.

I used fluorescent paint for the eyes and metallic stickers so that they glow under a UV light. Mainly I used the metallic stickers to emulate all the little sensors as seen in the game. Then I printed out custom waterslide decals for the emblems used on the pauldrons. As part of the little bit of lore for it; I decided to think of it more as a derivative of the Alba Frame and gave it a slightly different designation 'ALBA-TYPE W'. This way I could justify to myself why it's not 1:1 with the one Rusty gets.

34 notes

·

View notes

Text

3D printing some cable clips, put 9 of them in the slicer and hit auto-arrange. it did this:

I want to punch something

33 notes

·

View notes