#Reflow Soldering

Text

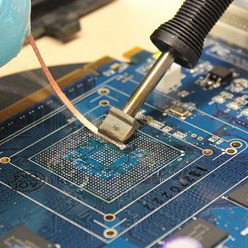

Soldering plays a significant role in the performance of electronics. Soldering is the process of connecting electronic components to a PCB using solder, a metal alloy that melts and solidifies to create strong electrical and mechanical connections. This process is fundamental to the functionality of the PCB because it establishes the electrical pathways between components.

0 notes

Text

Reliable, Affordable & Trustworthy Electronics PCB Repair Services & Courses Across Canada/USA

Wireless Training Center is a well-known name in the electronics industry, providing top-notch Electronics PCB repair services in Canada and the USA. With years of experience and expertise, we have established ourselves as one of the best providers of PCB Repair Technician Courses in Canada/ USA.

Wireless Training Center has highly skilled and experienced technicians. Our technicians have been trained to the highest industry standards and are equipped with the latest tools and technology to provide the best possible service and Courses. We can troubleshoot and repair a wide range of PCB issues, including faulty components, damaged circuits, and broken connections.

We use only high-quality components and materials in repairs, ensuring that the repaired PCB will be reliable and long-lasting. Wireless Training Center's PCB repair services are not limited to any specific industry or application. We have experience working with a wide range of PCBs, including those used in the telecommunications, medical, automotive, and industrial sectors. Whether it's a simple repair or a complex overhaul, we have the expertise and experience to get the job done right. This makes us a one-stop-shop for all your electronics needs, whether you're looking for Certified Circuit Board Repair Professionals Training Course or MacBook and iMAC Mother Board Repair Courses in Montreal, Toronto and Vancouver.

Wireless Training Center is also known for its exceptional customer service. We understand that when a customer's PCB is not working, it can have a significant impact on their business operations. That's why we offer quick service to our customers. We also deliver a range of service and course options, including PCB, SMT Rework, reflow and repair training in Canada / USA, to ensure that customers can get their PCBs fixed as quickly and conveniently as possible.

For further info give us a call at (778) 835–2763 or visit us at: https://wirelesstrainingcenter.com/

#PCB#SMT Rework#reflow and repair training in Canada / USA#SMT#THT#Hand Soldering workshops in Canada/ USA#MacBook and iMAC Repair Training Courses in Canada#Cell Phone Repair Course in Calgary#Cell Phone Repair Classes in Mississauga#Circuit Board Certifications#BGA Rework Certifications#Certified Circuit Board Repair Professionals Training Course#Electronics PCB repair services

0 notes

Link

Get the best SMT and SMD Reflow Services in Gandhinagar and Ahmedabad, India. Our experienced team delivers fast, efficient, and high-quality results. Contact us now to get started!

Our services play a crucial role in the production of process control instruments for industrial and commercial applications, such as temperature, pressure, and flow control solutions.

#smd reflow#surface mountain device#smt#electronics manufacturing service#pcb contract manufacturing#pcb assembly#pcb soldering#pcb wave-soldering in ahmedabad#gandhinagar#ahmedabad#electronics industry#electronics in gandhinagar

0 notes

Text

Reflow solder oven

REFLOW SOLDER OVEN SERIES

The cooling is more rapid than the heating, as fast cooling encourages the solder to form into a crystalline structure which creates a superior bond to the underlying board. The fourth chamber quickly cools the board, down to temperatures of 86 Degrees Fahrenheit. This process generally takes 30-40 seconds. Timing is crucial here, as the solder must melt fully without having time to flow off the board or start vaporizing. Several heating methods can be used here, although conventional convection baking is still the most common. The heart of the reflow soldering process happens here, where the circuit board is rapidly heated to maximum temperatures to fully melt the solder and bond it to the circuit board. Once the thermal soak is finished and the piece moves on, the board should be at thermal equilibrium. This ensures even heat distribution, as well as activating chemicals in the solder paste that prevent the solder from turning into microbeads, which it otherwise would. Having reached the desired pre-heating point, the board passes to the second chamber for a thermal soak at that temperature, for 60-120 seconds. This stage can last several minutes, as the temperature is only raised by about 3-5 degrees Fahrenheit per second. The heat distribution must be uniform, or the board could warp. The first and lengthiest stage is the pre-heating of the circuit, which requires bringing it up to a given temperature slowly.

REFLOW SOLDER OVEN SERIES

These marvels of engineering can automatically handle the heating and cooling of each circuit board, sending it through a series of internal chambers for treatment. Modern manufacturers utilizing surface mounted technology use all-in-one devices called Reflow Soldering Ovens to ensure proper circuit boards. Much like when cooking dinner, too little or too much heat can quickly ruin the project. While there are several possible techniques, the board has to be precisely raised to temperatures in excess of 200 degrees, to properly melt the solder. The hard part is the baking that follows. Rather than using space-hungry holes through the board, SMT-based circuits have components which are placed directly onto the board, using a solder paste which also works as a glue. Manufacturing based on Surface-Mounted Technology has taken over electrical engineering, and for good reason.

1 note

·

View note

Text

Reflow soldering is a preferred method for PCB assembly

Reflow soldering is the most generally utilized type of soldering utilized for PCB gathering. It gives dependable fastening to the immense assortment of parts and cushion sizes required while being not difficult to screen and control. Infrared reflow patching has been utilized for a long time in PCB assembly, and it is currently ready to give extremely great welding that can address the issues of today's hardware creation regions.

The fundamental cycle behind reflow soldering includes patch glue being applied to the significant region of the board. The parts are then positioned, and afterward, the assembly is gone through a passage where the board is warmed in a controlled way so the patch glue liquefies and the parts are electrically gotten to the printed circuit board. There is a rise in the utilization of reflow soldering innovation since it is feasible to dependably bind surface mount parts, especially those with exceptionally fine pitch leads.

This makes it ideal for use with the parts utilized inefficiently manufactured hardware items. When it comes to PCB assembly, reflow soldering manufacturing is the most broadly utilized technique for welding, which is generally utilized for PCB assembly. It offers trustworthy soldering for a wide range of the extents of part and cushion expected, as well as making it simple to control.

Soldering is one of the most effective ways of creating PCBs

The reason for reflow fastening is to be adequate welding joints with pre-warming the parts/PCB/bind glue first and afterward liquefying the patch, which is opposed to overheating without harm. Reflow soldering manufacturing is an interaction that utilizes the glue to interface one or thousands of little electrical parts to their contact pads and afterward, it will control the entire soldering by heating.

The binding glue reflows in a liquid stage to make the super durable weld joints. Furthermore, heating should be possible by passing the glue together with the reflow broiler as well as under an infrared light or by binding individual joints with a desoldering hot air pencil. Reflow soldering manufacturing makes it conceivable to dependably weld surface mount parts, particularly the parts with extremely fine pitch leads.

It's also preferable for use with parts utilized inefficiently manufactured hardware items. For effective reflow soldering manufacturing, you need to ensure that the reflow welding process is a triumph. You will require a reasonable machine which you can find at Southern Machinery (SMTHELP).

Find everything you need at Southern Machinery (SMTHELP)

You will require appropriate reflow profile conditions, make a certain PCB component impression plan, get a definite and very much planned printed PCB, have choices for the repeatable position for surface mount parts, ensure that your PCB is top-notch, and select high-quality weld glue. Reflow soldering is ordinarily utilized in PCB creation. Component sizes and assortments of parts are handily checked and controlled during this interaction.

In the present electronic necessities, this is a great way of patching components. Southern Machinery (SMTHELP) is an expert SMT supplier with broad involvement with PCB manufacturing, supporting some of the biggest names in the industry over the years. From equipment for reflow soldering manufacturing to Automatic PIN insertion machines, we've got everything you need.

0 notes

Text

Ohh my absolute goodness..

side note, one look at Heavy and Medic on the character lineup at the teamfortress.com homepage tells you EVERYTHING about their marriage

Anyway, the god... damn... I can't get over... just, Engineer TF2 and the duality of his character. Like, he's one-hundred percent someone to pull on gator skin boots, a ten gallon, get all yee-hawed up for a night out at the dance hall. But then go home and infodump about hotchkiss drives, stress-strain curves, and reflow soldering.

There are some specific competitive lines that comes to mind that are JARRING to hear in his honeyed-up Texas voice along with shit like "hooo-whee, makin' bacon!" and "START PRAYIN', BOY." Maybe that's just a huge part of the appeal to his character, but think about his BUDDIES, too.

Medic is probably quite familiar with American stereotypes pre-Gravel Wars, doesn't expect much from a bumbling rural southerner with a generic set of tools upon first glance. but.., he's a bit BLOWN AWAY when Engie gets all inquisitive about the ins and outs of the medi-gun. Wants to look into how the serum works as a mechanical component, the powering and logic behind it all, even overwhelms med's (limited) level of delicate mechanical knowledge. his arc is all, "okay, so, this little guy might be a bigger-brained fella than I expected!" The punting of med's early-day ego and subsequent forging of their friendship is just so... ourgh... I love characters and arcs and stories and growth and...

Also, Soldier! The all-American Ultra Yank who doesn't see eye-to-eye with Engie at first. They've both got contrasting leadership qualities when it comes down to it, fr, a- a- and, AND, soldier HATES nerds. Engie's a nerd. Big time. It takes a while for that mutual love respect to build up, you know? do you catch my drift? I'm just rambling now.

ALSO also, Engineer himself going from the more introverted, lone-wolf type we see in Meet the Engineer to a sort of leader, the level-headed de-escalator we see in Expiration Date. The guy who feels for and loves his team, but no doubt brings out the 'Texas' in 'em all. It's kinda cute. I imagine he taught everyone square dancing at some point, 'cause how else would they know?

In the end, I just love to think of Engie as being one of the cornerstones of the team's overall culture. i mean, he's a solid family guy - cooks the breakfasts, fixes the (practical) problems, heck, plays music, tells stories, keeps 'em together when times are tough. We ALL know that some of him has to rub off on the team he bunks with for years. Not in a father-figure way, nahh, but certainly in a Dad Friend way. Big difference.

(Can you tell who my favorite character is yet? (demo, actually. And Heavy. come to think of it, the defense trio is the love of my life. My boys. (I could write and MLA-formatted essay about the balance of culture and personality within the Tuefort Nine, citations intact.)))

#tf2 headcanons#tf2 engineer#tf2#More rambling#I adore Engineer TF2#I adore TF2...#Demo/Engie is a fuckin' treat btw#I hc Medic being the most egotistical of em at the start of things#love changes a man#Spy's lines mocking engie are probably my favorite genre of tf2 voiceline too#also I am south texan and an adorer of the lovingly vibrant dance culture here#That might have something to do with it#Ultra Yank sounded so funny in my head#Me realizing 50% of these are repeated from past posts LOL

45 notes

·

View notes

Text

i know it' not this reductively simple, but i'm trying to sorta hone in on why i feel so untrusting of modern technology....

an analogue clock can be made by a clockmaker, by a person, with metals and tools. the metals have to come from somewhere and the tools need to be made, but that can be done by other people.

a digital clock has to be made by corporations. it needs ICs and PCBs, transistors and semiconductors, layers of phosphors and rare earth metals deposited in layers so thin your eyes can't see them, assembled together and reflow soldered by machines that are themselves too complex to be built by a person, down and down for layers. sure if you wanna pedantically miss the point i could buy the parts and solder them together myself, i can program a microcontroller, but none of that tech gets into my hands without being made by strata of corporations, and all harm they cause by squeezing enough blood from the proverbial stone in order to do it at shareholder-pleasing profit.

analogue clocks are made by people, digital clocks are made by corporations... and while supply chains cling to the crumbling cliff of the modern global world, the kids don't know how to read the analogue clock we have sitting on the bench.

16 notes

·

View notes

Photo

Finally got a 120v→100v step-down transformer for my Sony HB-FX1D on the way. This system was imported from Japan as a parts machine, but merely needed a reflow on the composite connector, which had developed dry solder joints.

Although intended for use on Japan’s 100v power grid, most electrical components have a tolerance of 20% which makes running it on the US’ power grid at 120v no issue - the power supply just runs hotter than usual. Perfectly fine for testing purposes, though using that step-down would be wise for the long haul.

126 notes

·

View notes

Text

Just How Carries Out A PCB Assembly Procedure Job?

The PCB assembly process begins with PCB fabrication, adhered to by part purchase. Parts are then put on the board utilizing automated pick-and-place devices. Solder insert is applied to connection parts during the course of reflow soldering. Inspection methods like AOI as well as practical testing ensure quality. Finally, panels are packaged for delivery after passing QC checks.

4 notes

·

View notes

Text

Selective soldering 🔧🔬🔥

Selective soldering involves attaching specific components to printed circuit boards (PCBs) and molded modules, a method particularly useful for items susceptible to heat damage from standard reflow ovens or wave soldering found in conventional surface-mount technology (SMT) or through-hole assembly techniques. Typically, this method is applied after an initial SMT oven reflow phase. The components targeted for selective soldering are often nestled among others already soldered via a surface-mount reflow method. This demands high precision in the selective soldering process to prevent damage to the surrounding elements.

#adafruit#selectivesoldering#pcbassembly#electronicsmanufacturing#surface-mount#throughhole#reflowprocess#precisionengineering#solderingtechnology#circuitboarddesign#manufacturinginnovation#techadvancements

5 notes

·

View notes

Note

I OWN THAT SEWING MACHINE??

How did you get working?

mostly i just cleaned it out and oiled it and it worked!! the good news is these machines are fairly bulletproof, so it doesn't take a lot to get them working again

your first step should be to plug in the serial number into this website -- this will tell you exactly what model of guy you have, so you'll be able to look up instructions and check if you've got missing parts. (or if you've got the original instruction manual you can use that!)

the things you will probably need to replace are the belt (leather treadle belts have a tendency to turn brittle with age) and the needle (old needles tend to also be brittle and possibly rusty, which is Not Great for fabric). helpfully, singer model 15s use the same standard needle shape as nearly all modern sewing machines, so you can stick just about any modern needle in there. a new treadle belt, as well as replacements for any missing or damaged parts, can be had from the internet -- there are a ton of vintage sewing machine parts sellers on ebay. (you'll need to cut the new treadle belt to length and possibly rosin it; i had to tighten mine two or three times before it was driving the machine nicely.)

and then, of course, Everything Needs To Be Cleaned. you'll want a bottle of sewing machine oil, a jug of cleaning vinegar, dish soap, and an ultrasonic cleaner (incredibly handy general household tool, $25ish on amazon). also large amounts of q-tips and paper towels, and various sizes of flat-head screwdrivers. possibly also a dremel tool. (if the machine needs a surface cleaning, wipe it down GENTLY with sewing machine oil -- many harsher cleaning substances will damage the shellac or the pretty gold decals.)

stuff i took off my machine to clean:

throat plate + slidey bit next to it

hook and bobbin case, and the circular track thing the hook slides back and forth in (i don't know what this is called)

side plate and thread tension assembly

needle holder and thread guide

presser foot and its thumb screw

round plate on the back and its thumb screw (i could've gotten away without cleaning this but i wanted it to be Shiny)

(also: take pictures while you disassemble everything so you remember how it goes back together!!)

an ultrasonic cleaner bath with vinegar will remove rust (you may have to run it a few times); an ultrasonic cleaner bath with warm soapy water will remove dirt and gunk (ancient thread dust + ancient sewing machine oil = horrible black gunk). the parts WILL NOT be stainless steel, so you WILL need to dry them off after they come out of the bath; don't leave them on a wet paper towel or they'll rust again. (i made this mistake about three or four separate times and i wanted to kick my own ass every time. for parts that are hard to dry with paper towels + q-tips, you might want to use a solder reflow station or hairdryer (the poor man's solder reflow station) to dry them.) it's also good to wipe stuff down with a very light coating of sewing machine oil just for a little extra rust protection. for stuff you want to be Extra Shiny, like the throat plate, you can use the dremel tool and a wire brush or a fine grit sanding attachment and get it nice and polished :)

But Watch Out -- some of the screws may be VERY stiff and you definitely don't want to strip the heads. if a screw is just not budging, try drenching it in sewing machine oil (in such a way that the oil will run down into the threads) and waiting half an hour or so.

while all the plates and stuff are going through the ultrasonic cleaner, it's time to clean and lubricate the inside! (and the treadle. the treadle might also be stiff. pro tip: take the belt off while you're working on lubricating the treadle so you can make sure it runs smooth without the sewing machine.) there should be little holes for oil everywhere you're supposed to oil (including the underside! with the belt off the machine should fold out of the treadle table so you can access these bits), but you can oil other areas of metal-on-metal movement too if it seems like they need it. the basic control loop here is oil something -> spin the hand wheel a bit and listen carefully for squeaking or other Bad Noises -> oil something (etc.) until it's all running smooth. if there is gunk on any of the moving parts (or dead spiders. apparently spiders LOVE to go inside of model 15s and die there) apply q-tips until they're clean. or a paper towel + vinegar for bits that are rusty.

and then you put it back together and try it out!! (AND SEND ME PICTURES I WANNA SEEEEE)

#the trashcan speaks#sewing machine go brrr#also be careful not to lose any of the tiny ass bobbin case screws :/ :/ :/

11 notes

·

View notes

Text

Become a Pro at Fixing Smartphones: Enroll Now in Our Cell Phone Repair Classes

Cell phones are a vital part of our lives. People use their phones for everything from searching for a job to staying in touch with their family to ordering something. However, cell phones are a lot more fragile than they seem. Cell phone repair classes are now common in most major cities. In today's world, cell phones are important to everyone. They have replaced the need for many other devices. But if you don't know how to repair them, you run the risk of being inconvenienced by the cost of keeping your phone in proper working order. By taking Cell Phone Repair Classes in Mississauga, Toronto, Montreal, Vancouver at Wireless Training Center, you'll be given the tools to find and fix problems with your phone. It's a great way to save money!

As the number of people using cell phones has increased, so has the demand for qualified technicians to fix them. The Wireless Training Center offers a complete program that trains students in all aspects of Cell Phone Repair. Our classes cover everything from diagnostics and troubleshooting to soldering and component replacement, so you can become a qualified cell phone repair technician.

Our Cell Phone Repair Course is designed for both beginners and experienced technicians alike. In our classes, you'll learn how to fix Smartphones of all types and brands. This course is perfect for Repair novices who have little-to-no experience working on Smartphones. The course will introduce participants to basic elements of troubleshooting, diagnosing, inspecting, testing, fault tracing, repairing, and Micro-soldering skills. By the end of the course, participants will have completed level 4 training and Certification.

At Wireless Training Center, we offer iPhone, iPad, MacBook, iMAC Motherboard Troubleshooting, diagnostics, repair classes. With experienced instructors, detailed course material, and easy-to-understand modules, you will be able to not just fix any kind of Smartphone but also be able to give it a complete overhaul - making sure that your customers get nothing but the best service possible!

So don’t wait anymore; enroll now in our cell phone repair classes and become a pro at fixing Smartphones today! Give us a call at (778) 835–2763 or visit us at: https://wirelesstrainingcenter.com/

#PCB#SMT Rework#reflow and repair training in Canada / USA#SMT#THT#Hand Soldering workshops in Canada/ USA#PCB Repair Technician Courses in Canada/ USA#Electronics PCB repair services#Apple service technician training courses in Canada

0 notes

Text

LED PCB Assembly

What is the LED Circuit Board assembly?

Generally, LED PCB assembly is considered to be a circuit board that has the LED components soldered to it. The LED is soldered to the printed circuit board and features a chip that creates the light as electrically connected. A thermal heat sink and a ceramic base are used to bond the chip. Not all the PCB products can be used in Led industry, as an LED PCB is easy to create a high volume of heat, but making it hard to cool with traditional methods. For this reason, metal core PCB is widely used in LED application because of their enhanced ability to dissipate heat, especially aluminum pcb is often used to fabricate PCB for LED lights.

We’ve had great LED PCB assembly experiences with top LED chips to brand such as Cree, Luxeon, Osram, Nichia, Lumileds, MLS, EVERLIGHT, Samsung, LG, Seoul., etc. PCB LED lights can be incorporated into numerous lighting applications due to their combination of excellent energy efficiency, low cost and maximum design flexibility.

Application of LED PCB Assembly

Hitechpcba serves customers in different industries, providing highly reliable and innovative LED PCBs for various applications:

• Horticulture light LED PCB Assembly

• LED controller PCB Assembly

• Computer LED display and indicators

• LED lights PCB Assembly for medical use

• Automotive LED PCBs Assembly include PCBs for brake lights and headlights

• Street lighting LED PCB Assembly

• Flashlights and camping accessories

• Traffic light PCB Assembly

• Commercial lighting LED PCB Assembly

LED PCB Assembly specification

Number of layers for LED PCB

These layers are made up of aluminum and magnesium, but now have Copper base material and Ceramic base materials for LED PCB industry, we can meet it.

Aluminum LED PCBs stand out among other PCBs because it has a good insulation characteristic and has a better machinery performance, the cheap cost is one important factor too.

Types of layers for LED PCB Assembly

Normally, the base layer is made using aluminum alloy metal.

This aluminum alloy substrate used in making the base makes it ideal for through-hole technology which transfers and dissipates heat.

A thermal insulation layer is made using some ceramic polymer which has good viscoelasticity characteristics.

It is highly heat resistant and protects the PCB against heat and mechanical stress.

The circuit layer, which is covered by a copper foil which can range from one to ten ounces.

LED Board type- single or in panel

Some boards are shapeless. For this reason, LED PCB panels are used. This reduces time, labor production and testing time.

Some LED PCB Assembly is done on a single board while others are done on panel boards.

LED PCB Assembly Process

Roughly, the PCBA process can be divided into theses phases: soldering paste printing > SMT (surface mounted technology) > reflow soldering > AOI (automated optical inspection)> THT (through-hole technology) > wave soldering > touch-up and cleaning > IC-programming > FCT (functional tests) > aging testing.

Below we show you the process.

Step1. Summarizing Project Information

Before contacting your supplier, make sure you have all the project information. Suppliers will need info following for quoting LED PCB assembly:

Gerber

BOM

LED PCB specification

Quotation quantity

Once you have gathered these information, you can contact us and request for a quote.

Of course, you can also provide the schematic, LED PCB Assembly pictures and even samples to us. The more details they have, the more accurate the supplier’s quotation will be.

Step2. Discussion and details about custom LED PCB Assembly

Different projects will have different requirements. Remember the special requirements mentioned in step 1? That’s going to be the focus of this session. Equipment and engineering capacity will not be identical between suppliers. Make sure your supplier has the equipment to produce and assemble major components and the corresponding testing capabilities.

For example, some vendors don’t have X-ray testing equipment, which means they can’t check the mount quality of BGA chips. Outsourcing this step will increase risk and cost. That’s what you don’t want.

Also, pay attention to time taken by the supplier to quote. Motherboards often contain hundreds or even thousands of components, and they are supplied by different manufacturers. To ensure the quality of the components, the supplier sourcing team will make multi-inquiries from these manufacturers or authorized suppliers to match customer’s requirement, which usually takes 2-3 business days, and even longer for some scarce chips. Therefore, if your project is complex and the supplier quotes you within few hours, double check with them.

Step3. Sample and feedback

After confirming the PI, the supplier will usually provide pre-production samples for your approval. At the same time, the supplier will also confirm with you the logistics plan of the bulk goods. Make sure they understand your shipping requirements, including details on packaging, customs clearance, taxes, etc.

For us to have a successful LED PCB Assembly process, its functions must be defined. Compliance requirement is defined to reduce the effect when components are selected.

The Bill of Materials is then generated from the information installed on the LED PCB.

All this information is used to assemble components which are identified from MOB to the LED PCB.

After that, the routing of traces is determined to each component, based on the size, shape of the circuit board and location of connectors.

Hitech Circuits is trusted by thousands of electronic engineers on their LED PCB assembly projects, from consumer, led bulb to precisely medical LED light, we can help you from the beginning of design stage; From commercial flood LED to industrial high power LED, from automotive LED to military LED, Venture is the perfect place for your LED PCB assembly requirement.

Hitech Circuits has been participated in hundreds and thousands of LED lighting projects, by providing LED PCB and also LED PCB assembly service.

Our LED PCB assembly had covered both ends of the Lighting Class LED size spectrum, assembling some of the largest (2 meter long boards) and some of the smallest LED Lighting applications which used in Medical Endoscopes.

LED PCB Assembly is very crucial in the current industrial development. Many electrical devises are being innovated and the old once being improved.

LED PCBs are useful due to the fact that they are made using materials that can transfer and dissipate heat. This characteristic increases device durability.

The world is changing with new technology, especially PCB technology that plays an essential role in the application of LED circuits. And the LED industry is taking advantage of this technology and growing faster.

As a full feature PCB solutions provider with more than a decade of experience, we're capable to provide LED PCB fabrication, components procurement and LED PCB assembly all under one roof. We can work with you to develop metal core PCB, aluminum circuit boards customized to your specific applications. We feature competitively priced PCBs made with standard FR-4 material that includes a thermal aluminum clad layer that will efficiently dissipate heat, keep all LED PCB components cool and significantly enhance the performance of your products.

LED pcb board, LED pcb assembly

LED with its advantages of high brightness, high efficiency, low heat, long life, is considered the most development potential in the 21st century lighting. In the market and policy driven by the rapid development of the domestic LED industry blowout has formed a relatively complete industrial chain, including the production of epitaxial wafers, chip preparation, packaging, integration, LED application. In 2010, China's LED industry scale, up from $ 827 billion in 2019 to 220 billion yuan, an annual growth rate of over 70%, higher than the 50% level of growth of the global LED lighting industry output value. Among them, the middle and lower reaches of the most complete industrial chain, accounting for 90% of the overall percentage of the GDP.Chinahas become the world's leading LED manufacturing base and important application market.

To further promote the technological innovation of the LED industry, construction and wide application of independent industry chain, China Electronic Appliance Corporation and industry associations to organize the theme of "Focus on the core energy LED Exhibition will be held November 9-11, 2010 in Shanghai International Expo Center and the 78th China Electronics Fair over the same period will be held will create from raw materials, epitaxial wafers, chip, LED bracket, LED accessories, LED packaging and supporting materials, the LED backlight upstream firm to the upstream and downstream enterprises of the display, lighting, landscaping, decorative lighting, traffic lights, automotive lighting, special lighting, to the equipment, instrumentation, software, finance, consulting and other service enterprises and technological exchanges and market trading platform, help the domestic industry sustained and healthy development, and promote the steady expansion of the LED application market.

In the LED industry chain upstream of the epitaxial wafers and LED chips accounted for 70% of the profits of the whole industry, and technology-intensive, capital-intensive, where the core technology of the LED. Well-known epitaxial wafer and chip production enterprises will be exhibited a number of energy-efficient, low heat, cost-effective LED products, many of whom have excellent products of international advanced level.

LED electronic pcb assembly manufacturing 100% Original LED Chip with one-stop in-house pcba services

3 notes

·

View notes

Text

What is PCB Assembly ?

PCB Assembly manufacturer - Hitech Circuits Co., Limited

It’s the step in the manufacturing process in which you populate a blank board with the electronic components needed to make it into a functional printed circuit board. It’s these components that make a board into the circuit that enables an electronic product to function. PCB assembly typically takes place via one of two processes:

1. Surface-mount technology

SMT: SMT stands for “Surface Mount Technology“. The SMT components are very small sizes and comes in various packages like 0201, 0402, 0603, 1608 packages for resistors and capacitors. Similarly for Integrated circuits ICs we have SOIC, TSSOP, QFP and BGA.

The SMT components assembly is very difficult for human hands and can be time taking process so it is mostly done by automated pick and place machine.

2. Through-hole manufacturing

THT: THT stands for “Through hole Technology”. The components with leads and wires, like resistors, capacitors, inductors, PDIP ICs, transformers, transistors, IGBTs, MOSFETS are example.

The component has to be inserted on one side of PCB and pulled by leg on other side and cut the leg and solder it. The THT components assembly is usually done by hand soldering and is relatively easy.

Printed Circuit Board Assembly Techniques

There are only two common PCBA techniques available for use by a PCB designer. The methods are:

1. Automated PCB Assembly Techniques

Generally, this technique employs the use of state of the art machines, which are fully automatic. For example, the surface mount components are worth positioning with the aid of an automated pick and place machine.

Again, reflow soldering is commonly for surface mount components usually done in a reflow oven. An automated solder stencil is also used to apply the solder paste on the PCB.

Finally, high tech inspection machines are used to confirm and check the quality of the PCBA. Some of which include: Automated optical inspection machine (AOI), X-ray inspection machines, etc.

Above all, due to the precise monitoring, control of soldering, no human input and versatile machines.

This technique ensures utmost efficiency, output consistencies, and limits defects.

2. Manual PCB Assembly Techniques

This method is favorite for use with through-hole parts, which needs manual placement on the board. Besides, with these through-hole parts, it’s advisable you use wave soldering. Note that in the through- hole assembly process, you need to place the components and electronics on the PCB.

After that, you use wave soldering to solder the leads. Typically, you will need an individual to insert a component into a marked PTH. Once done, transfer the PCB to the next station where the next person will be on standby tasked with fixing another part.

What are the Benefits of SMT PCB Assembly?

SMT assembly provides many benefits and some of them are as follows:

It can be used to incorporate small components.

In SMT, the components can be placed on both sides of the board.

It assures high component densities.

Fewer holes need to be drilled for surface mounting than through-hole.

It require low initial costs and time for setting up the mass production.

SMT is the simpler and faster-automated assembly when compared to through-hole.

Errors regarding the component placement can be easily rectified.

Surface mount PCBs feature strong joints, which can easily withstand vibrations.

What are the techniques used in Surface Mount Technology?

There are several techniques for the reflow process. After applying the solder paste or a flux mixture on the board and after placing the components, the boards are conveyed to a reflow soldering oven. The techniques used for reflowing soldering include infrared lamps, hot gas convection, fluorocarbon liquids with a high boiling point, and so on.

What are the different testing methods used in SMT PCB Assembly?

Hitech Circuits as the PCB assembly manufacturer, we perform the following testing and inspection to ensure the quality of surface mount PCBs.

Automated Optical Inspection (AOI): This is performed before and after the soldering to identify the component placement, presence, and solder quality.

X-ray Testing: In this type of testing, the operator relies on the X-ray images of the PCB to check the solder joints and lead-less components such as Quad Flat Packs and ball grid arrays, which are generally not visible to naked eyes.

In-Circuit Testing (ICT): This method is used to detect manufacturing defects by testing the electrical properties in the SMT Assembly.

What type of files or documents should I send for SMT PCB Assembly?

Gerber Files: The file contains all details of physical board layers including solder masks, copper layers, drill data, legends, and so on.

Bill of Materials (BOM): This contains information on the list of items needed for the PCB manufacturing and the instructions of manufacturing.

Pick and Place File: This file contains information on all components to be used in the PCB design and their rotation and X-Y coordinates.

The whole process of PCB Assembly

1. Bare board loader machine

The first step in the PCB assembly is to arrange the bare boards on the rack, and the machine will automatically send the boards one by one into the SMT assembly line.

2. Printing solder paste

When PCB on the SMT production line, firstly, we have to print solder paste on it, and the solder paste will be printed on the pads of the PCB. These solder pastes will be melt and solder the electronic parts to the circuit board when it passes through the high-temperature reflow oven.

In addition, when testing new products, some people will use film board/adhesive cardboard instead of solder paste, which can increase the efficiency for adjusting the SMT machines.

3. Solder paste inspection machine(SPI)

Since the quality of solder paste printing is related to the quality of welding of subsequent parts, some SMT factories will use optical machine to check the quality of solder paste after printed the solder paste in order to ensure stable quality. If there any poorly printed solder paste board, we will wash off the solder paste on it and reprint, or remove the excess solder paste if there is redundant solder paste on it.

4. High speed SMT machine

Usually, we will put some small electronic parts (such as small resistors, capacitors, and inductors) to be printed on the circuit board first, and these parts will be slightly stuck by the solder paste just printed on the circuit board, so even if the speed of printing is very fast and the parts on the board will not fall away. But large parts are not suitable for use in such high speed SMT machines, which will slow down the speed of small parts assembly. And the parts will be shifted from the original position due to the rapid movement of the board.

5. Universal SMT machine

Universal SMT machine is also known as "slow machine", it will be assembled some large electronic components, such as BGA IC, connectors, etc., these parts need more accurate positions, so the alignment is very important. Use a camera to take a picture to confirm the position of the parts, so the speed is much slower than High speed SMT machine we taked before. Due to the size of the components here, not all of them are packed in tape and reel, and some may be packed in trays or tubes. But if you want the SMT machine to recognize the trays or tube-shaped packaging materials, you must configure an additional machine.

Generally, traditional SMT machines are using the principle of suction to move electronic parts, and in order to place the parts successfully, and there must be the flat surface on these electronic components for the suction nozzle of the SMT machine to absorb. However, for some electronic parts don’t have a flat surface for these machines, and it is necessary to order special nozzles for these special-shaped parts, or add a flat tape on the parts, or wear a flat cap for thees electronic parts.

6. Manual parts or visual inspection

After assembled all parts by the high speed SMT machine or Universal SMT machine and before going through the high-temperature reflow oven, and we will set up a visual inspection station here and to pick out the deviation parts or missing components boards etc., because we have to use a soldering iron to repair if there are still defectives boards after passing the high-temperature oven, which will affect the quality of the product and will also increase the cost. in addition, for some larger electronic parts or traditional DIP parts or some special reasons cannot be processed by the SMT machine before, they will be manually placed on pcb here.

7. Reflow oven

The purpose of reflow oven is to melt the solder paste and form a non-metallic compound on the component feet and the circuit board, that means to solder electronic components on the circuit board. The temperature rise and fall curves often affect the soldering quality of the entire circuit board. According to the characteristics of the solder materials, usually the reflow oven will set the preheating zone, soaking zone, reflow zone, and cooling zone to achieve the best soldering effect.

For example, the melting point for SAC305 solder paste with lead-free is about 217°C, which means that the temperature of the reflow oven must be higher than the melting points to remelt the solder paste. What's more, the maximum temperature in the reflow furnace should not exceed 250°C, otherwise many parts will be deformed or melted because they cannot withstand such a high temperature.

Basically, after the pcb passed through the reflow oven, the assembly for the entire circuit board is almost complete. If there are hand-soldered parts, we need to transfer to DIP process, and then we have to check the quality after reflow oven by QC department.

8. Automatic optical inspection(AOI)

The main purpose of setting up AOI is because some high density boards can’t be process the following ICT test, so we used AOI inspection to replace it. But even using AOI inspections, there still have the blind spots for such checking, for example, the solder pads under the components cannot be checked by AOI. At present, it can only check whether the parts have side standing issue, missing parts, displacement, polarity direction, solder bridges, lack of soldering etc., but cannot checking the BGA solderability, resistance value, capacitance value, inductance value and other components quality, so far AOI inspection can’t completely replace ICT test.

Therefore, there is still some risk if only AOI inspection is used to replace ICT testing, but ICT test is also not 100% make sure the good quality, we suggest these two ways can be combined with together to make sure the good quality.

9. PCB unloader machine

After the board is fully assembled, it will be retracted to the unloder machine, which has been designed to allow the SMT machine to automatically pick and place the board without damaging the quality for PCB.

10. Visual inspection for finished products

Normally there will be a visual inspection area in our SMT production line whether there is an AOI station or not, and it will help to check if there are any defectives after completed assembled the pcbs. If there is an AOI station, it can reduce the visual inspection worker on our SMT line, and to reduce the potential cost, and because it is still necessary to check some places that cannot be judged by AOI, many SMT factories will provide the mainly visual inspection templates at this station, which is convenient for visual inspection worker to inspect some key parts and polarity for components.

11. DIP process

DIP process is a very important process in the whole PCBA processing, and the processing quality will directly affect the functional for PCBA boards, so it is necessary to pay more attention to the DIP process. There are many preliminary preparations for DIP process. The basic process is to re-process the electronic components first, like to cut the extra pins for some DIP components, our staff received the components according to the BOM list, and will check whether the material part numbers and specifications are correct or not, and performs pre-production pre-processing according to the PCBA samples. The steps are: Use various related equipment (automatic capacitor pins cutting machine, jumper bending machine, diode and triode automatic forming machine, automatic belt forming machine and other machines) for processing.

12. ICT test

Printed Circuit board open/short circuit test (ICT, In-Circuit Test), The purpose of ICT test is mainly to test whether the components and circuits on the printed circuit board are open or short issues. It can also measure the basic characteristics of most components, such as resistance, capacitance, and inductance values to judge whether the functions of these parts are damaged, wrong parts or missing parts etc. after passing through the high-temperature reflow oven.

ICT test machines are divided into advanced and basic machines. The basic ICT test machines are generally called MDA (Manufacturing Defect Analyzer). It’s just to measure the basic characteristics of electronic components and judge open and short circuits issue we talked above.

In addition to all the functions of the basic ICT test machines, for advanced ICT test machine can also test the whole PCBA by using power, start to testing the PCBA boards by setting the program in the test machine. The advantage is that it can simulate the function of the printed circuit board under the actual power-on condition, this test can partly replace the following functional test machine (Function Test). But the cost for the test fixture of this advanced ICT test can probably buy a car, it’s too expensive and we suggest it can be used in mass production products.

13. PCBA function test

Functional testing is to make up for the ICT test, because ICT only tests the open and short circuits on the the PCBA board, and other functions such as BGA and other fuctions are not tested, so it is necessary to use a functional testing machine to test all functions on the whole PCBA board.

14. Cutting board (assembly board de-panel)

Normally, printed circuit boards will be produced in panel, and it will be assembled to increase the efficiency of SMT production. It means several single boards in one panel, such as two-in-one, four-in-one etc. After finished all the pcb assembly process, it needs to be cut into single boards, and for some printed circuit boards with only single boards also need to cut off some redundant board edges.

There are several ways to cut the printed circuit board. You can design the V-cut using the blade cutting machine (Scoring) or directly manually break off the board (not recommended). For more high density circuit boards, it will be used the professional splitting machine or the router to split the board without any damage the electronic components and printed circuit boards, but the cost and working hours will be a little longer.

Why Choose Hitech Circuits PCB Assembly Manufacturer for Your PCB Assembly Projects?

There are several PCB manufacturers specializing in PCB assemblyservices. However, Hitech Circuits PCB Assembly stands out owing to the following:

Assistance in Material Procurement:

Technically, in PCB assembly services, the quality of parts is the responsibility of the OEM; however, we ease your job by assisting you to make the right selection. We can help you procure all your parts of the same type own a single part number, thanks to our supply chain and vendor network as well as experience. This saves time and cost that goes in ordering single parts as you plan.

Testing procedures:

We are very focused on quality and thus implement stringent testing procedures at each stage of the assembly and after completion.

Fast Turnaround Times:

Our well-equipped facility and the right tools enable us to complete your requirements well before time, and without compromising on the quality or functioning of the PCBs. For simple designs we revert in 24 to 48 hours.

Cost Effectiveness:

While PCB assembly is a cost-effective alternative, we go a step further and assure that the parts you list are of a good quality and suitable for your requirement. Also, you can control the part flow and replenish them as needed. This eliminates the need to buy extra stock and store it.

Quick Quote:

We offer a quick quote based on your BOM. All you need is a detailed BOM, Gerber files, your application requirement sheet, and quantity.

We’re not one to stand still, which is why we use the latest equipment and the finest minds to create your PCB projects. We’re constantly keeping our finger on the pulse of the latest trends. And as a result, we know how to deliver the highest standards of PCB assembly to meet all your requirements.

Our dedicated, friendly customer service team also means that we support you every step of the way. Offering our expert guidance to ensure a complete PCB project that you’re happy with.

Contact us today

No matter what your printed circuit board assemblyneeds are, we always aim to deliver efficient, dependable solutions. For more information about our services, do not hesitate to get in touch with us today for a no-obligation quote

2 notes

·

View notes

Text

making dino nuggies in the toaster oven label NOT FOR FOOD USE because it has been repurposed as a solder reflow oven and I only use leaded solder because im not a wimp

#only the last part is true#dino nuggets#soldering#tech#ham radio#diy#maker#cooking#baking#late night hiley

4 notes

·

View notes