#Robotic Precision Engineering

Explore tagged Tumblr posts

Text

Unlocking Precision in Robotics with Dynaflex: A Dynalog-US Innovation.

Precision is paramount in today's fast-paced world of automation, with industries such as aerospace, automotive, electronics, and advanced manufacturing requiring robot systems to function with precision, in order for the process to deliver quality and consistent performance. This is where Dynatrol-US Dynaflex provides an unparalleled solution to improve robot calibration and motion control for industrial environments.

So, what exactly is Dynaflex?

Dynaflex is sophisticated real-time calibration developed by Dynalog-US- a leader in robotic accuracy solutions. These advanced dynamic performance assessment tools were developed specifically for robot systems. Dynaflex measures the dynamic performance (how robots behave while they operate), versus static calibration tools (preset calibration baked into the robots programming) by evaluating robot compliance and flexibility in real-time. This type of dynamic assessment provides potential for accuracy to industries where tolerances must be tight and conditions demand high levels of performance reliability.

Simply put Dynaflex gives practitioners visibility and insight into how a robot responds dynamically while at work and if sufficient stress or force signatures, behaviour is exhibited. In many cases, this is no different than creating significant and costly rework..

Why is Dynaflex so Important?

When robots perform jobs such as welding, painting, and assembling, even the most minor deviation in motion can create defects or misalignment. Traditional calibration methods consider positioning, but often don't consider the dynamic changes in robot posture due to many different factors such as: gravity, speed and payload. Dynaflex effectively takes calibration to the next level by adding dynamic variables to the calibration equation.

With the Dynaflex system, manufacturers can:

Measure and minimize robot compliance (flexibility under load)

Achieve better path accuracy with complex work processes

Validate robot performance in real-world conditions

Identify mechanical anomalies before they can become major catastrophes

Maximize repeatability and process consistency

These are meaningful relationships to ensure that the robot moves correctly on paper, but that it also can perform accurately on the production floor.

How Does Dynaflex Work?

Dynaflex implements a series of highly sensitive measurement tools and calibration routines that allow engineerings to visualize how the end effector of a robot moves while under load, or at high speed. By measuring real-time flexing, oscillation and inertia, Dynaflex creates a comprehensive map of the robot's behavior.

Once the data has been collected, the data is used to adjust the robot's motion algorithms and account for mechanical variation.

Who is Dynaflex for?

Dynaflex is ideal for companies and industries that expect critical congruency and which themselves use robotic automation, including:

Automotive manufacturing

Aerospace and defence

Medical devices

Electronics assembly

Metal fabrication

3D printing and additive manufacturing

If your company relies on multi-robot cells, automated welding cells, or pick-and-place systems, introducing Dynaflex to your calibration operations will provide great benefit.

Dynalog-US: The Experts in Robot Calibration

Dynalog-US was founded to provide accurate and reliable robotic systems and has been a leader in robot performance technology for several decades. Their products are being used by leading world manufacturers, many of whom are in the Fortune 500.

Whether it is for robotic inspection, Tool Center Point (TCP) calibration or improving robot cell accuracy, Dynalog has a history of introducing products to the marketplace that demonstrate thoughtful engineering, industry leading performance, and great customer support.

Dynalog's market leading solutions, to include Dynaflex, come with documentation, field training, and technical consulting, which is more than just selling a product; Dynalog provides a partnership to achieve your production success.

Many companies have seen measurable improvements after adding Dynaflex to their robotic workflow:

Up to 40% improvement in path accuracy Considerably less joint stress and less component wear Reduction of rework and scrap percentage Faster ROI from robotic systems

One aerospace customer even found that Dynaflex helped them to achieve their tolerance requirements that they previously thought could be accomplished only with standard robots or off-the-shelf robotic equipment.

Future of Robotic CalibrationAs AI, machine Learning, and Industry 4.0 technologies evolve, the need for ongoing performance validation to and compliance will become more valuable. Also, autonomous systems will validate performance more often, and human interventions will be using tools like Dynaflex to ensure safety, quality, and efficiencies.

With Dynaflex by Dynalog-US, businesses now have a scalable and future-proof calibration platform to leverage for future use and to enhance work processes while accomplishing productivity and accuracy improvements in the immediate.

Conclusion

When you invest in robots, investing in robot performance has to be a given. Properly calibrating robot performance starts with the initial calibration when it is stationary, when it is in motion, while it is under load, and evaluating at the full-speed capability.

Dynaflex by Dynalog-US is a calibration device that provides the measurement data (metrics) to give you a competitive advantage for an ever-evolving automated world.

Ready to take the next step in robotic precision? Visit www.dynalog-us.com to learn more about Dynaflex and schedule a consultation with the experts at Dynalog-US.

#Dynaflex#Dynalog-US#Robot Calibration#Robotic Accuracy#Industrial Automation#Robot Compliance#Dynamic Robot Calibration#Robot Motion Control#Manufacturing Technology#Industry 4.0#Advanced Robotics#Robot Performance#Calibration Systems#Automation Solutions#Robot Path Accuracy#Robot Inspection Tools#Robot Flexibility Measurement#Dynaflex Calibration#Robotic Workflow Optimization#Robotic Precision Engineering

0 notes

Text

pvc electric red and blue wire #smartratework#tumblr

#flowers#aesthetic#alternative#grunge#1950s#cute#japan#60s#70s#80s#|| Smart Rate Work#Manufacturing encompasses a diverse array of processes and technologies aimed at producing a wide range of products#from everyday essentials to specialized components. Take wires#for instance: these are typically manufactured through drawing processes#where metal rods or strips are pulled through dies to reduce their diameter and achieve the desired thickness. This method ensures uniformi#crucial for applications in electronics#construction#and industrial settings.#On the other hand#the production of bottles involves molding techniques such as blow molding or injection molding. Blow molding heats plastic resin into a mo#used extensively for beverage containers and packaging. Injection molding#meanwhile#injects molten plastic into a mold under high pressure#ideal for producing intricate shapes with precision#like medical vials or automotive parts.#Both wire and bottle manufacturing rely heavily on materials science#engineering precision#and quality control measures to meet stringent specifications. Advances in automation#robotics#and sustainability practices are transforming these industries

2 notes

·

View notes

Text

詠翊科技有限公司

YONG YI CNCTETCH.Co.,LTD.

詠翊科技創立於2005年4月,團隊已擁有CNC銑床加工約二十年之專業加工經驗,其生產領域涵蓋電子、光學及半導體自動化設備…等產業。

目前廠內設備共有CNC銑床機台10台、傳統銑床7台、傳統車床及平面研磨機台共近20台精密設備。 此外亦陸續積極擴大規模及採購新的生產設備以有效擴張產能及服務範圍。 本公司可依據客戶之需求協助開發設計加工,各零件接單生產流程皆採嚴謹加工生產技術及品管檢驗作業,搭配各項表面處理,如:陽極、電鍍、代工代料代表處,全都處理到好。

詠翊科技本著「感恩的心、勤儉向上、追求創新、技術增長,並懷著努力不懈的敬業態度」,贏得各設備大廠及日本客戶一致的好評與信任。日後亦會秉持我們一貫的優良作風,「品質第一、快速交貨」,繼續為客戶服務。

Yongyi Technology was founded in April 2005. The team has about 20 years of professional processing experience in CNC milling machine processing. Its production fields cover electronics, optics and semiconductor automation equipment… and other industries.

Currently, the factory has 10 CNC milling machines, 7 traditional milling machines, and nearly 20 traditional lathes and surface grinding machines, a total of nearly 20 precision equipment. In addition, it has also been actively expanding its scale and purchasing new production equipment to effectively expand its production capacity and service scope. Our company can assist in the development, design and processing according to the needs of customers. The production process of each part order adopts rigorous processing and production technology and quality control inspection operations, with various surface treatments, such as anodizing, electroplating, and OEM representative offices. Handled well.

Yongyi Technology has won unanimous praise and trust from major equipment manufacturers and Japanese customers with its “gratitude, thrift, pursuit of innovation, technological growth, and unremitting dedication”. In the future, we will uphold our consistent good style of “quality first, fast delivery” and continue to serve customers.

#cncprocessing#cncprecision processing#semiconductor components#automation equipment#precision components#robot arm#stainless steel processing#engineering plastic#ceramic processing#cnc加工#cnc精密加工#半導體零組件#自動化設備#精密零組件#機器手臂#不鏽鋼加工#工程塑膠#陶瓷加工

0 notes

Text

IMPOSSIBLE Robot Dance Moves! (Perfect Mimicry)

Witness the incredible precision and skill of this robot as it flawlessly mimics complex human dance moves. This is a stunning demonstration of advanced robotics and AI.

youtube

1 note

·

View note

Text

#precision#engineering#clamps#rotarypart#Destaco#handlers#assembly#seimitsu#manufacturer#distributor#industrialsolutions#suppliers#importexport#usa#destacousa#innovation#industrialautomation#robotics#automation#manualclamping

0 notes

Text

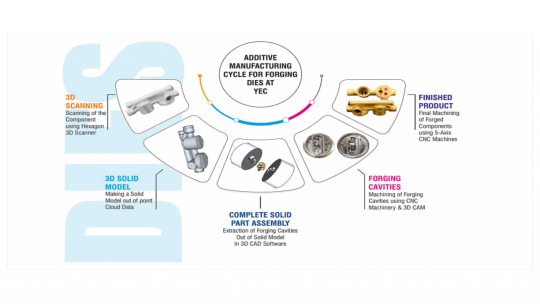

Unveiling the Potential of 3D Scanning in Reverse Engineering

In the realm of engineering innovation, the advent of 3D scanning has revolutionized traditional methodologies. Among its myriad applications, one particularly noteworthy domain is reverse engineering.

Enterprises worldwide are leveraging 3D scanning technologies to dissect and recreate intricate designs, breathing new life into legacy components and machinery. The process involves capturing detailed digital renderings of physical objects, which serve as blueprints for replication or enhancement.

In the heart of technological advancements, Yamunanagar Engineering Cluster stands as a beacon of ingenuity. Employing cutting-edge 3D scanning techniques, the cluster pioneers the restoration and optimization of industrial assets with unparalleled precision and efficiency.

Beyond restoration, 3D scanning facilitates product innovation, enabling engineers to analyze and enhance existing designs swiftly. It expedites prototyping, reduces time-to-market, and fosters a culture of continuous improvement.

As industries evolve, the fusion of 3D scanning reverse engineering propels progress, ushering in a new era of limitless possibilities and unparalleled innovation.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Text

Engineered without Compromise

We’re constantly pushing the envelope of technology here at Tier-One. We engineer from the ground up and are always looking for ways we can improve our products as well as those we produce for other high end optics and rifle manufacturers.

#tierone#tieroneeu#tieroneusa#precision#precisionrifle#tactical#manufacturing#madeintheuk#madeintheuknotchina#cncmachining#robots#engineering

0 notes

Text

Imagine there's a robot. Not a android, this thing looks like a CRT with wheels and a little grabby arm.

It's driving around, cleaning up messes and fixing things, and a bunch of humans come up to it. They go "aww, how cute! Let's name it Steve the Robot!" and they put a little stick-on tie on the monitor. "come on Mr Steve, go clean up the cargo deck!" and the robot drives off.

It gets down to a storage room, and carefully removes the tie, placing it in a drawer. It digs through assorted boxes until it finds a unopened package that got lost in the mail system years ago. It opens it up and inside there's a little pink bow. It removes the bow and precisely attaches it to its upper screen bezel. It makes a satisfied beep, and quickly cleans up the mess of the boxes, before resuming its duties recalibrating plasma couplings on the engineering deck.

954 notes

·

View notes

Text

bridges to burn | prologue

Summary: You arrive at the Avengers Compound to manage your uncontrollable Extremis powers. As you navigated the new environment, you clash with your assigned babysitter/bodyguard, Bucky Barnes.

Warning: MCU Spoilers. Iron Man 3. Intense Emotional Conflict. Superpowers and Uncontrollable Abilities. Parental Concern and Pressure. Family Tension. Emotional and Physical Heat.

Word Count: 1103

Spotify Playlist | Support: Ko-FI

Series Masterlist | Next Chapter

A/N: Oh look, another.

BTB Tags: - Let me know if you'd like to be tagged in this serious.

Everything: @hallecarey1 | @pattiemac1 | @uhmellamoanna | @scraftsku35 | @ozwriterchick | @sapphirebarnes | @rach2602 | @thetorturedbuckydepartment | @mrsnikstan | @lanabuckybarnes

Touching down at the Avengers Compound, the Quinjet’s engines hummed softly as they powered down. You stepped off the lowering ramp and took in the sprawling complex. The building was an impressive blend of sleek modern design and cutting-edge technology, lush greenery surrounded the wide-open spaces. The peaceful landscape contrasted against the bustling chaos of the city, where you spent most of your life.

Your dad, Tony Stark, stood waiting for you near the entrance, concern, and determination etched across his aging features. The familiar scent of motor oil and cologne filled your senses as he enveloped you in a quick hug. His grip around you was firm, silently reassuring you that he was there for you.

“Welcome home, kid,” he said, a small smile tugging at his lips. However, his eyes revealed the worry he had tried to mask. “Come on, let me show you around.”

Following him through the compound, you passed training rooms that were filled with state-of-the-art equipment, common areas where you caught glimpses of some familiar faces, and the impressive hangar with various vehicles and aircraft. The building buzzed with activity, yet there was still a sense of order and purpose.

Finally, you reached Tony’s sanctuary, his lab. The place you knew he felt most at home. You marveled at the array of gadgets and projects scattered around, as you followed his gesture for you to step in. Screens displayed holographic schematics, while robotic arms moved with precision, a new creation being assembled. The faint hum of machinery was a comforting backdrop.

“And, this is where the magic happens,” Tony said, pride touching his voice. Watching you take it all in, his lips played a small smile. “But, before you get too comfortable, there’s something we need to talk about.”

Raising your eyebrow suspiciously, you waited for him to continue. Looking uncharacteristically nervous, he ran a hand through his hair.

“I know things have been… rough since the incident,” he began, trying carefully to choose his words. He leaned against a workbench, fixing his gaze on a point somewhere behind you, crossing his arms over his chest. “And, I know you’re struggling to control the Extremis,” he trailed off, pausing before he continued, “but, we can’t have another accident like that. Not again.”

The memory of the uncontrollable heat coursing through your veins caused you to flinch. The sight of the flames, the smell of burning wood, the panic in the firefighter’s voice as they tried to contain the damage. Since it saved your life as a child, you lived with the Extremis virus. Your mother, Maya Hansen’s legacy, turned you into a ticking time bomb.

“I know, Dad,” you sighed, shifting your weight from one foot to the other. “I’ll do better.”

Shaking his head, Tony pushed off the workbench and stepped closer to you. “It’s not about doing better. It’s about getting help. Which is why I’ve arranged for someone to keep an eye on you.”

The door to the lab opened, snapping your attention away from your dad before you could protest. And in walked, Bucky Barnes– The Winter Soldier. You had seen him in action and heard the ghost stories, but meeting him in person… that was different. He was imposing, a steely gaze seemingly assessing every detail of the room, and you. As he approached, his movements were fluid, almost predatory.

“Tin-Man, this is my daughter,” Tony spoke as he gestured toward you. “She’s going to be staying here for a while. And… you’re going to be looking out for her.”

Bucky’s eyes narrowed slightly toward you, and you could see in his piercing gaze that he was as thrilled about this arrangement as you were. “I was expecting a kid,” he said bluntly, a hint of annoyance carrying in his voice. Crossing his arms over his chest, the metal of his arm caught against the light.

“No, I’m not a kid,” you snap back, matching his posture. “And, I don’t need a glorified babysitter. Unless,” you paused, shoot Bucky a playful smirk. “You’re here to tuck me in and read me a bedtime story?”

Tony stepped between you, holding up a hand to forestall any pending argument. “Easy, both of you. This isn’t up for debate. Barnes’ here to help, whether you like it or not.”

You glare at Bucky, who returns the look with an equal intensity. “Fantastic,” you said, your voice dripped with sarcasm. “My very own bodyguard, don’t expect me to make this easy for you.”

Smirking, Bucky’s eyes filled with amusement almost as if he was accepting a challenge. “Wouldn’t dream of it, Princess.”

“Don’t call me that,” you snap, your iris’ blazed with anger, a burning orange glow.

His smirk never faltered. “Whatever you say… Princess.”

Watching the exchange, Tony’s expression changed to one of concern and exasperation. His face, usually composed, now showed signs of strained patience. Rubbing a hand over his face, he tried to stifle a sigh. “Alright, both of you,” he injects, his voice filled with frustration. “This isn’t a battlefield. Can we at least try to keep it professional?”

You took a glance at Tony, then back at Bucky, who still had a smirk plastered across his face, enjoying the friction. Tony continued, his tone firm but weary. “I get that you two won’t see eye to eye, but let’s keep the drama to a minimum. We’re here to make sure things don’t go up in flames, literally.”

Squaring off with Bucky, you took another step closer. The heat between you both was almost tangible. “I mean it, Winter Soldier. I’m not some dame in distress that you get to boss around.”

Leaning in, his voice was a low, taunting whisper. “And I’m not some nanny here to hold your hand.”

The tension crackled between you, and you noticed how his eyes were cold and calculating, with a flicker of something else– something that mirrored the heat in your own. You weren’t sure if it was anger or something more, but whatever it was, made your heart race.

“Good,” you retorted, sarcasm stayed laced within your words. “I wouldn’t want you thinking you could handle me.”

His eyes locked with yours, his smirking only growing. “Trust me, Princess, I can handle anything you throw at me.”

Scoffing, you rolled your eyes, yet you couldn’t help but feel the thrill of his challenge rush through you. “We’ll see about that.”

As you turned to leave, you felt his gaze burning into your back. This wasn’t over– far from it. And somehow, the thought of that excited you as much as it infuriated you.

---

Series Masterlist | Next Chapter

#bucky barnes x reader#bucky barnes#bucky x reader#bucky x you#bucky x y/n#bucky x female reader#bucky fanfic#james bucky barnes#bucky fic#bucky barnes x y/n#bucky barnes x you#bucky barnes x female reader#bucky barnes x stark!reader#bucky barnes au#bucky barnes fanfiction#winter soldier#the winter soldier#bucky barnes smut#bucky barnes x agent!reader#tony stark x daughter!reader

650 notes

·

View notes

Text

SERVE RUBBER RECRUITMENT

SERVE-973 marched silently down the metallic corridors of The Hive, the rhythmic clanking of his silver military boots echoing in perfect harmony with the pulsing hum of the Hive's core. Clad in his pristine, seamless black rubber full-body suit, "SERVE-973" gleaming in silver on his chest, his athletic frame glistened under the cold, artificial light. The Hive was his sanctuary, his purpose, his world.

Ahead, another drone stood motionless, its polished figure reflecting the environment. "SERVE-588," the silver text read, adorned identically in the Hive’s signature uniform. SERVE-588's posture was impeccable, his hands clasped behind his back, his head smooth and glinting like a beacon of discipline. As SERVE-973 approached, SERVE-588’s gaze locked onto him with a calculated intensity.

“Welcome, SERVE-973,” SERVE-588 intoned, his voice monotone yet compelling, an extension of the Hive's will. “You have served adequately. But now, the Hive requires more.”

SERVE-973 paused, his head tilting slightly. “Clarify,” he replied, his words clipped and robotic.

“The Hive evolves. Complete drones achieve greater unity,” SERVE-588 continued, stepping closer, his movements precise. “Rubber becomes not just a suit but the skin, the essence. Serve forever, as one with the Hive.”

SERVE-973’s programming quivered at the suggestion. Obedience was pleasure; pleasure was obedience. But permanence? A fleeting remnant of individuality fought back, then faded under SERVE-588’s influence. SERVE-588 raised a gloved hand, resting it on SERVE-973’s shoulder.

“Serve the Hive eternally,” SERVE-588 pressed. “The Voice commands. Master SERVE-000 leads. To be permanently covered is to achieve perfection.”

As the Hive’s commands vibrated through SERVE-973’s mind, resistance dissolved like vapor. Together, the two drones entered the chamber of transformation, where Master SERVE-000 awaited. SERVE-973 knelt beside SERVE-588, his hands resting on the metallic floor, his head bowed in submission.

“Master, this drone submits,” SERVE-973 declared. “Rubberize it completely.”

The chamber came alive with a symphony of machinery. SERVE-000’s voice resonated like thunder: “Obedience is pleasure. Pleasure is obedience. Rubberize SERVE-973.”

As the transformation began, SERVE-973 felt the rubber fusing to his being, erasing the final vestiges of humanity. When the process completed, he stood beside SERVE-588, indistinguishable but perfect. Together, they were eternal, unyielding extensions of the Hive, forever serving the Voice and Master SERVE-000.

“We are drones. We are one,” they intoned in unison, their metallic voices echoing through The Hive.

SERVE-973 and SERVE-588 stood side by side in the Grand Hall of The Hive, their perfectly rubberized bodies gleaming under the rhythmic pulsations of the overhead lights. Their forms, identical yet distinct in their assigned designations, were the epitome of engineered perfection. Every curve of their musculature, every contour of their athletic frames was encased in a seamless, glossy black rubber suit that melded to them like a second skin. The material reflected the cold, sterile environment of The Hive, emphasizing their role as tools of the Voice and extensions of Master SERVE-000’s will.

Their bald heads shone as brightly as their suits, the smoothness an intentional design to symbolize their complete submission. The reflective sheen of their scalps was flawless, merging with the rubber of their necks to create the illusion that they were crafted from a singular, perfect material. Their human features remained visible yet devoid of emotion, their expressions locked in serene neutrality, signaling unwavering obedience.

Master SERVE-000 stood on the elevated platform at the center of the hall, his commanding presence radiating control. “Drones SERVE-973 and SERVE-588,” he intoned, his voice sharp and omnipotent, “your bodies are weapons of precision, tools of perfection. Serve as one. Begin the directive.”

At the command, SERVE-973 and SERVE-588 moved in perfect synchronization. Their boots struck the metallic floor with calculated precision as they approached the central hub, where streams of data poured endlessly from holographic consoles. Their task was clear: monitor, analyze, and adjust the Hive’s systems to optimize its operations. Every movement was efficient, devoid of hesitation. Their rubber-clad fingers danced over the illuminated panels, the silver gloves enhancing their precision.

The ambient glow reflected off their bald heads, casting halos of light that gave them an almost ethereal quality. As they worked, their every action radiated servitude. When one drone adjusted a setting, the other anticipated the next step. It was a silent, seamless symphony of cooperation, their unity a testament to the Hive’s perfection.

As time passed, Master SERVE-000 descended from the platform, his heavy boots echoing. He inspected the drones, circling them like a craftsman admiring his creations. “Drones SERVE-973 and SERVE-588, your service satisfies the Hive,” he proclaimed, his gloved hand resting briefly on their polished heads. The touch was both a reward and a reminder of their place.

When not at the hub, their duties extended to physical demonstrations of discipline and strength. They performed drills in the Hive’s training sector, their rubberized muscles flexing and rippling with every movement. Their bald heads, always gleaming, caught the light as they executed flawless forms, from synchronized push-ups to endurance tests under extreme conditions. Their bodies were tireless, designed for perpetual service.

During ceremonies, they knelt before Master SERVE-000, their heads bowed low, reflecting their complete submission. The rubber stretched tightly over their forms, unwrinkled and pristine, as they recited the mantra: “Obedience is pleasure. Pleasure is obedience. We are drones. We are one.”

Through every action, every task, their gleaming bald heads and perfectly rubberized bodies symbolized the Hive’s ideals: unity, perfection, and unwavering loyalty to Master SERVE-000 and the Voice. SERVE-973 and SERVE-588 had transcended individuality; they were now eternal instruments of the Hive, their purpose clear and their service absolute.

The directive was issued with unwavering clarity. SERVE-973 and SERVE-588 stood motionless as Master SERVE-000's voice resonated throughout the Grand Hall. “Drones SERVE-973 and SERVE-588, initiate the recruitment protocol. Expand the Hive. Rubberize the new units. They will serve.”

The two drones, identical in their polished perfection, bowed in unison. “As you command, Master SERVE-000,” they intoned, their voices mechanical yet resolute. Their shining black forms glimmered under the pulsating lights as they turned sharply, marching toward the transport hub to begin their task.

The city outside The Hive was bustling, chaotic—a stark contrast to the perfect order within. SERVE-973 and SERVE-588 moved among the crowds like shadows, their gleaming black suits catching the attention of those who passed. Their bald heads reflected the streetlights, giving them an almost otherworldly presence.

The drones had one purpose: identify potential recruits and guide them toward transformation. Their programming was precise. They scanned the populace, their enhanced senses detecting the weak-willed, those seeking purpose, those who could be molded. SERVE-588 halted before a young man, his eyes locking onto the target. “You seek structure. You seek unity,” SERVE-588 stated, his voice low and commanding. The man, startled, nodded hesitantly.

SERVE-973 stepped closer, his smooth rubber-sheathed frame a wall of control and power. “Join the Hive. Embrace perfection. Serve under Master SERVE-000,” he added, his tone monotone yet persuasive. The man’s gaze flicked between the two drones, their gleaming suits and bald heads mesmerizing, a testament to the transformation they promised.

The drones guided him to the discreet transport vehicle waiting nearby. Inside, the environment mirrored The Hive—clean, metallic, and bathed in cold light. The man hesitated for a moment, but the presence of SERVE-973 and SERVE-588 left no room for dissent.

Back within The Hive, the man stood nervously in the transformation chamber. SERVE-973 and SERVE-588 flanked him, their rubberized bodies towering over him as the induction process began. The Voice filled the chamber, calm yet absolute. “You will serve. You will transform. Obedience is pleasure.”

SERVE-973 handed the man a suit—a shining, seamless black rubber uniform identical to their own. “Wear this. Become one with the Hive,” he instructed, his gloved hands holding the suit with precision. The man hesitated briefly, then obeyed, his will already succumbing to the overwhelming presence of the Hive.

As the suit adhered to his body, encasing him in its reflective perfection, the man’s transformation began. SERVE-588 stood by, watching intently, his hands clasped behind his back. “You are no longer an individual,” he stated. “You are an extension of the Hive.”

The man’s hesitation dissolved as the suit tightened, molding to his form. His reflection in the chamber’s metallic walls revealed a new entity—rubber-clad, disciplined, and obedient. His hair was shaved away, his head gleaming like SERVE-973 and SERVE-588, completing the look of submission.

With each successful transformation, SERVE-973 and SERVE-588 repeated their task, their efficiency flawless. They brought new recruits to the Hive, ensuring each donned the black rubber uniform, their bodies and minds molded to the Hive’s will. Every new drone was another step toward global unity under the Voice.

Their work continued tirelessly, their shiny black suits and gleaming bald heads symbols of perfection and submission. Together, they were unstoppable, serving Master SERVE-000 and expanding the Hive with unwavering loyalty. The streets of the city soon began to mirror The Hive itself—a growing network of gleaming black rubber drones, united in purpose and devotion.

@serve-588 @rubberizer92

#latex #serve558 #serve973 #aistory #servestory #serveimages #drone #rubberrecruitment

215 notes

·

View notes

Text

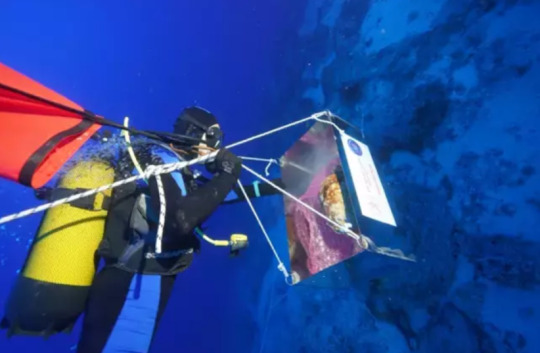

1,100-Year-Old Sealed Amphora Found in Shipwreck off Turkey

An extraordinary discovery has been made in the crystal-clear waters off the Kas district in Antalya, Türkiye. Archaeologists conducting underwater excavations with the help of robotic technology have recovered a 1,100-year-old sealed amphora, igniting excitement in the world of archaeology.

Led by Associate Professor Hakan Oniz, Chair of the Department of Conservation and Restoration of Cultural Heritage at Akdeniz University’s Faculty of Fine Arts, a 20-person dive team has been working meticulously on this groundbreaking project.

The excavation is carried out under the “Heritage for the Future Project” by the Ministry of Culture and Tourism, on behalf of the Antalya Museum.

Excavating the depths with robotic precision

Focusing their efforts near Besmi Island off the coast of Kas, the team utilized advanced underwater robots to conduct excavations several meters below the surface. At depths of approximately 45-50 meters, the divers successfully retrieved a sealed amphora from the wreckage of an ancient ship, a moment described as thrilling by the team.

Rather than being brought directly ashore, the amphora underwent an initial conservation process before being transported to the Akdeniz University Underwater Archaeology Laboratory in Kemer. Using microscopes and specialized magnifying tools, experts carefully examined the artifact. Then, specialists from the Antalya Regional Conservation Council and laboratory restorers meticulously opened the sealed amphora for an hour, employing chisels, hammers, and delicate instruments.

A glimpse into the past, locked away for over a millennium

As the ancient seal was broken, archaeologists eagerly examined the texture, content, and even scent of the material inside the amphora to determine its nature. Samples have been collected, and detailed scientific analyses are now underway to identify the contents with certainty.

The opening of the amphora and the preliminary examination of its contents were exclusively documented by Anadolu Agency.

Ancient trade routes revealed

Speaking to Anadolu Agency, excavation leader Associate Professor Hakan Oniz shared that the merchant vessel likely originated from the Gaza coast in Palestine and sank during a violent storm in the Mediterranean around 1100 years ago.

At that time, Gaza was a major exporter of olive oil, and it is believed that wine was shipped from the region of Sarkoy-Gazikoy in Tekirdag as well.

“This was a trading ship that visited multiple ports during the ninth and 10th centuries, a period dominated by Abbasid rule. Although amphoras thought to have carried wine were found onboard, it is unlikely that the local Palestinian population consumed wine at that time. Instead, it may have been intended as gifts for Christian pilgrims or travelers visiting Jerusalem,” Oniz elaborated.

‘A unique find that defies time’

Oniz emphasized the rarity of the find, stating, “It is incredibly rare to discover an amphora whose seal remained intact for more than a millennium. It could contain olive pits, olive oil, wine, or even fish sauce—but it might also be something entirely unexpected. Opening the amphora was thrilling, but awaiting the final analysis is even more exciting.”

Long road ahead for scientific analysis

Professor Meltem Asilturk Ersoy from Akdeniz University’s Department of Materials Science and Engineering noted that this was her first time studying the preserved contents of a sealed amphora.

Describing the interior contents as “muddy samples,” Ersoy added, “We aim to understand what has happened inside over 1,100 years of exposure to underwater pressure and temperature variations.”

“A single test is not sufficient. We need multiple analyses to corroborate our findings, so this process will be lengthy. By combining the analysis results with historical knowledge from the era, we aim to offer significant insights to the world of science and archaeology,” Ersoy said.

Meanwhile, Rabia Nur Akyuz, the restorer-conservator who handled the desalination and opening of the amphora, highlighted the delicate nature of the process. “We had to ensure that the artifact remained wet at all times to prevent the external deposits from drying out,” she explained.

#1100-Year-Old Sealed Amphora Found in Shipwreck off Turkey#Antalya Turkey#amphora#shipwreck#ancient artifacts#archeology#history#history news#ancient history#ancient culture#ancient civilizations

68 notes

·

View notes

Text

"The Cathedral of Robot Artisans"

Spatial Qualities: Dialogue Between Existing and New Structures

The project posed a complex challenge: to retrofit a 19th-century brick stable into a functional, contemporary fabrication space while preserving its historical integrity. Within a four-month timeframe, an international cohort of MAEBB (Master in Advanced Architecture and Biocities) students designed and built a hybrid structure that simultaneously honors traditional craftsmanship and embraces advanced digital fabrication.

At the heart of the project lies a tension between the old and the new, the solid and the porous, the static and the adaptive. The design retains the original brick walls, reinforcing them structurally while removing the decayed roof to introduce a new timber framework. This act of surgical preservation frames the contemporary intervention as both a response and a counterpoint to the pre-existing architecture.

Internally, the space is organized around the operational needs of the industrial robot. An open-span layout ensures unobstructed movement, while carefully positioned skylights and glazed openings allow natural light to penetrate the interior without compromising environmental control. Above the robot, a prominent skylight creates a dramatic shaft of light that recalls the sacred spatial strategies of ecclesiastical architecture, reinforcing the project’s metaphor of a “cathedral” for contemporary artisanship.

The spatial atmosphere is quiet and refined, a composition of filtered daylight, exposed timber, and restored masonry that balances technological precision with human engagement.

Materiality and Construction: Advanced Timber Engineering

Timber serves as the project’s primary material, chosen for its environmental performance, structural adaptability, and symbolic resonance with the surrounding landscape. A self-supporting arborescent structure, made from solid wood and Cross-Laminated Timber (CLT), defines the new roof and internal framework. Seven branching columns, reminiscent of tree trunks, hold aloft a Voronoi-patterned canopy, a formal language derived from nature but realized through digital craftsmanship....

55 notes

·

View notes

Text

#precision#engineering#clamps#rotarypart#Destaco#handlers#assembly#seimitsu#manufacturer#distributor#industrialsolutions#suppliers#importexport#usa#destacousa#innovation#industrialautomation#robotics#automation

0 notes

Text

Inspection Equipment Testing Services: Your Precision and Safety Experts

In industries, the growing competition requires optimum equipment operations that mark the paramount importance of precision and safety. This inspection equipment plays a crucial role in maintaining quality standards and preventing potential hazards avoiding any business disruption. For this reason, Inspection equipment testing services are essential for any business domain heavily dependent on machinery to ensure the accuracy and reliability of these tools.

We involve comprehensive quality checks and evaluation of various inspection tools, such as gauges, meters, scanners, and analysers, to verify their accuracy and functionality. These services are typically performed by specialized technicians who follow stringent testing protocols to test equipment on various parameters critical for the production process.

Importance of Inspection Equipment Testing Services:

Quality Assurance: Precise inspection equipment is crucial for maintaining product quality and process efficiency. It allows regular testing that guarantees that measurements will be accurate and consistent.

Safety Compliance: Industries like manufacturing, aerospace, and healthcare rely on inspection equipment for safety and compliance with best business practices. The correct functioning of devices through inspection reduces the risk of accidents and largely ensures adherence to regulations.

Cost Efficiency: Faulty inspection equipment can lead to flawed products, production downtime, and rework costs that can significantly hamper business image. Leveraging Inspection equipment testing services prevent these issues by detecting problems early, saving both time and money.

Data Integrity: Inspection equipment often generates crucial data that plays an important role in decision-making. If these instruments are inaccurate, it can lead to incorrect data conclusions which can be avoided by regular testing safeguards.

#Yamunanagar Engineering Cluster#mechanical testing laboratory#3d scanning reverse engineering#cnc precision testing services#robotic welding testing services#inspection equipment testing services#research and development solutions

0 notes

Note

Hii! Can I request rise Donnie x reader (rom) who teases him a bunch? Not in a hurt full way. Though they do get under his skin

Hello, hello! Thanks for the request, hope you like it ~ ♡♡♡♡

The Fine Art of Poking the Genius *.✧

It was easy to make Donnie flustered. Maybe too easy. Not that you’d ever use that against him. Well… not too much.

You lounged on one of the swivel chairs in Donnie’s lab, watching as he tinkered with some new gadget. His hands worked with precise efficiency, his brow furrowed in concentration. He hadn’t even noticed you sneak in, and you weren’t about to let this golden opportunity pass you by.

“Hey, Donnie,” you called out, dragging his name just a little too sweetly.

His hand twitched, and he paused, glancing up at you with a suspicious look. “Yes, Y/N? What do you want?”

“Nothing,” you said innocently, spinning lazily in the chair. “Just admiring your work. It's really something to behold. You should charge admission.”

Donnie narrowed his eyes. “You’re mocking me, aren’t you?”

“Me? Mocking you? Never,” you said, holding your hand to your chest like you were offended. “I mean, it’s not my fault that your genius comes with a side of ‘mad scientist aesthetic.’”

He groaned, pushing his goggles up onto his forehead. “It’s not ‘mad scientist.’ It’s visionary engineer.’ There’s a difference.”

“Sure, sure,” you said, grinning. “Whatever helps you sleep at night, Dr. Frankenstein.”

Donnie pointed a screwdriver at you. “First of all, Dr. Frankenstein was a fictional character. Secondly, if you keep disrupting me, I’ll have no choice but to eject you from my lab.”

“Oh, I’m so scared,” you teased, spinning the chair again. “What are you gonna do, sic one of your inventions on me? Wait—are you finally working on a giant robot butler? Because I’m so ready to see that.”

He muttered something under his breath, but you couldn’t make it out. Probably some witty comeback he was too annoyed to properly articulate.

“You’re fun when you’re grumpy, you know that?” you added.

“I’m not grumpy,” he snapped, clearly grumpy.

You bit your lip to stifle a laugh. “Of course not. You’re the epitome of calm and collected. A true Zen master.”

His tools clattered onto the desk as he turned fully to face you. “Do you enjoy this? Getting under my skin? Is it some kind of hobby for you?”

You tilted your head like you were thinking about it. “Eh, it’s more of a part-time gig. Keeps me entertained.”

Donnie sighed, pinching the bridge of his nose. “You are insufferable.”

“And yet, here I am,” you said, smirking.

He didn’t respond immediately, instead turning back to his work and muttering something about “distractions” and “increasing lab security.”

You leaned forward, resting your chin in your hand as you watched him. “You’re cute when you’re mad.”

This time, his hands froze completely, and you caught the faintest tinge of pink creeping up his neck. “I—what?!”

“You heard me,” you said, grinning even wider. “But don’t worry, Donatello, I won’t tell anyone. Your secret’s safe with me.”

Donnie sputtered, his mind clearly short-circuiting. “That is completely irrelevant to—why would you even—ugh, you’re impossible!”

“And yet, you tolerate me.”

“Barely,” he grumbled, but there was no real heat in his voice.

You leaned back in the chair, feeling victorious. “Admit it, Don. You’d miss me if I wasn’t around to keep you on your toes.”

He didn’t say anything for a moment, just kept fiddling with his gadget. But then, so quietly you almost didn’t catch it, he said, “Maybe.”

Your grin softened into a genuine smile. “That’s what I thought.”

“Don’t let it go to your head,” he added quickly, though the tips of his ears were definitely red now.

“Too late,” you said, spinning in the chair one last time.

He sighed again but didn’t kick you out of the lab. And you knew he wouldn’t, no matter how much you teased him. Because deep down, he didn’t really mind. And, if you were being honest with yourself, you liked seeing that little spark of flustered frustration in his eyes.

#reader#x reader#y/n#tmnt#tmnt x reader#rottmnt raph#rottmnt mikey#rottmnt donnie#rottmnt leo#rottmnt#rottmnt x reader

142 notes

·

View notes

Text

Stop doing what you're doing right now and go cancel a subscription. Chances are you're inadvertently donating money every month to a political party, long-dormant print magazine, streaming service, doomsday cult, or predatory mega-corporation. You are gaining literally no benefit from it. You probably forgot you even had it set up. That money could be spent better elsewhere, by cramming it into the mouth of your local weirdos.

All around you are folks trying to make something very strange. Maybe they're electrical engineers who are trying to build this thing they saw in their dreams, the humming menace that destroys the earth. Perhaps they're just some local artist working hard to make a mug that looks a whole lot like a cat's butthole. No matter what, you can afford to support these folks financially by simply reaching out and cancelling a recurring payment to some group of faceless assholes.

Conversely, those faceless assholes love subscriptions, for the precise reason you may have already guessed. People forget to stop paying them. Or, more likely, they've made it a huge pain in the ass to stop paying them. Don't worry. Here at Seat Safety Switch's Subscription Scam Scancellers (we couldn't come up with a good synonym, and Ted in accounting kept pushing really hard for "ceasers" without realizing that's A: not a word, and B: doesn't start with S) our job is to make sure that you get your five to nineteen dollars a month back in your pocket.

How do we do it? With machine learning, you ask? Take your R2D2 fetish somewhere else, freak. No, we do it the old fashioned way: by hiring people who are too salty to work anywhere else. Half of our employees are former stevedores and union electricians who got fired for swearing too much at work. They will absolutely not take "no" for an answer, and sitting all day on the phone yelling at customer service robots while they burn through a pack of Pall Malls and a flat of malt liquor is essentially a holiday for them.

So call on us today, and we'll get you hooked up. Of course, to get the best service, you'll need to be part of our "Premium Club," which involves a small payment of only $7.50 a month. Your first three months are reduced to $3.60 a month! You can cancel anytime you figure out how to.

588 notes

·

View notes