#Technology 4.0

Explore tagged Tumblr posts

Text

“Last September, I received an offer from Sam Altman, who wanted to hire me to voice the current ChatGPT 4.0 system. He told me that he felt that by my voicing the system, I could bridge the gap between tech companies and creatives and help consumers to feel comfortable with the seismic shift concerning humans and Al. He said he felt that my voice would be comforting to people.

After much consideration and for personal reasons, I declined the offer. Nine months later, my friends, family and the general public all noted how much the newest system named “Sky” sounded like me.

When I heard the released demo, I was shocked, angered and in disbelief that Mr. Altman would pursue a voice that sounded so eerily similar to mine that my closest friends and news outlets could not tell the difference. Mr. Altman even insinuated that the similarity was intentional, tweeting a single word “her” - a reference to the film in which I voiced a chat system, Samantha, who forms an intimate relationship with a human.

Two days before the ChatGPT 4.0 demo was released, Mr. Altman contacted my agent, asking me to reconsider. Before we could connect, the system was out there.

As a result of their actions, I was forced to hire legal counsel, who wrote two letters to Mr. Altman and OpenAl, setting out what they had done and asking them to detail the exact process by which they created the “Sky” voice. Consequently, OpenAl reluctantly agreed to take down the “Sky” voice.

In a time when we are all grappling with deepfakes and the protection of our own likeness, our own work, our own identities, I believe these are questions that deserve absolute clarity. I look forward to resolution in the form of transparency and the passage of appropriate legislation to help ensure that individual rights are protected.”

—Scarlett Johansson

#politics#deepfakes#scarlett johansson#sam altman#openai#tech#technology#open ai#chatgpt#chatgpt 4.0#the little mermaid#sky#sky ai#consent

240 notes

·

View notes

Text

5G-Powered Drones: Ericsson, Qualcomm And Dronus Collaboration In Developing Autonomous Drone Solutions

5G mmWave technology for industrial use. Ericsson, Qualcomm, and Dronus Collaboration in developing autonomous drone solutions. The world of industrial automation is on the cusp of a revolution, and at the forefront is a powerful combination, of 5G technology and autonomous drones. A recent collaboration between Ericsson, Qualcomm Technologies, Inc., and Dronus provides a glimpse into this exciting future.

#5G drones#Industrial automation#Indoor drone applications#Warehouse inventory management#mmWave 5G technology#Autonomous drones#Industry 4.0#5G smart factory#(PoC)#Qualcomm QRB5165 processor#Telit Cinterion#mmWave#Industrial M.2 data card#5G Modem-RF System#Native mmWave connectivity#High-performance 5G connection#Bandwidth-intensive industrial operations#drone

2 notes

·

View notes

Text

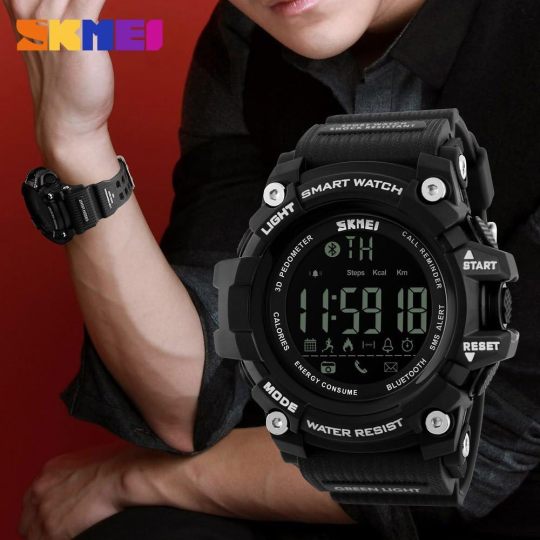

Discover the Best Smart Watch: Your Ultimate Companion for Modern Living

Step into a healthier future with the Love Life Walking Smart Watch. This cutting-edge wearable device records your daily steps, distance covered, and calorie consumption, empowering you to set and achieve your fitness goals. Its resistance and waterproof design ensure it keeps up with your active lifestyle, even during water activities.

Features:

Brand: ----------------------------------- FANMIS Model Name: ------------------------- 1227 Style: ----------------------------------- Modern Color: ----------------------------------- Black Blue Screen Size: --------------------------- 45 Millimeters Special Feature: ---------------------- Stopwatch

Order Now: Best Smart Watch

Key Features:

Comprehensive Fitness Tracking: Keep track of your daily physical activities effortlessly. The smart watch monitors step counts, measures distance traveled, and calculates calorie consumption, offering valuable insights into your fitness progress.

Stay Connected and Informed: Receive call reminders and notifications directly on your wrist, ensuring you never miss important calls or messages while on the go.

Convenient Remote Camera Control: Capture moments without hassle. Use the smart watch as a remote control for your smartphone's camera to snap pictures remotely.

Time Management Made Easy: Stay punctual with the clock, alarm, and stopwatch functions, helping you manage your time effectively throughout the day.

Seamless Smartphone Connectivity: With Bluetooth 4.0 technology, this smart watch seamlessly pairs with both Android and iPhone smartphones. Enjoy full compatibility and access to all the functions described.

Long-Lasting Battery Life: The smart watch boasts an extended battery life, ensuring it stays powered for extended periods, so you can focus on your activities without worrying about frequent charging.

Easy-to-Read Display: The user-friendly display lets you conveniently view the time of day and your fitness stats right on your wrist, making tracking your progress a breeze.

Water-Resistant Design: Dive into your fitness routine without worries. This smart watch is water-resistant up to 50 meters, making it suitable for swimming and other water-based activities.

Order Now: Best Smart Watch

#Smart Watch#Fitness Tracker#Step Counter#Distance Measuring#Calorie Consumption Management#Call Reminder#Remote Camera Control#Alarm Clock#Stopwatch#Bluetooth 4.0#Android and iPhone Compatible#Long Battery Life#Water-Resistant#Health and Wellness#Active Lifestyle#Wearable Technology#Time Management#Fitness Goals#Pedometer#Health Monitoring

2 notes

·

View notes

Text

Farming Is the Career Gen Z Has Been Looking For—They Just Don’t Know It Yet

As food demand rises and farmers age, Gen Z has a unique opportunity to make agriculture smarter, profitable, and future-ready. Here’s why farming needs their energy and ideas. We eat three times daily, sometimes even more depending on culture, yet our farmers, who produce the food, struggle to survive. Can you imagine how profitable the health sector would be if we fell sick three times a day…

#African agriculture#Agri Tech#agribusiness opportunities#Agriculture 4.0#digital agriculture#farming and innovation#farming and technology#farming careers for youth#future of farming#Gen Z farming#modern farming methods.#precision agriculture#smart farming#sustainable farming#youth in agriculture

0 notes

Text

Unlocking Precision in Robotics with Dynaflex: A Dynalog-US Innovation.

Precision is paramount in today's fast-paced world of automation, with industries such as aerospace, automotive, electronics, and advanced manufacturing requiring robot systems to function with precision, in order for the process to deliver quality and consistent performance. This is where Dynatrol-US Dynaflex provides an unparalleled solution to improve robot calibration and motion control for industrial environments.

So, what exactly is Dynaflex?

Dynaflex is sophisticated real-time calibration developed by Dynalog-US- a leader in robotic accuracy solutions. These advanced dynamic performance assessment tools were developed specifically for robot systems. Dynaflex measures the dynamic performance (how robots behave while they operate), versus static calibration tools (preset calibration baked into the robots programming) by evaluating robot compliance and flexibility in real-time. This type of dynamic assessment provides potential for accuracy to industries where tolerances must be tight and conditions demand high levels of performance reliability.

Simply put Dynaflex gives practitioners visibility and insight into how a robot responds dynamically while at work and if sufficient stress or force signatures, behaviour is exhibited. In many cases, this is no different than creating significant and costly rework..

Why is Dynaflex so Important?

When robots perform jobs such as welding, painting, and assembling, even the most minor deviation in motion can create defects or misalignment. Traditional calibration methods consider positioning, but often don't consider the dynamic changes in robot posture due to many different factors such as: gravity, speed and payload. Dynaflex effectively takes calibration to the next level by adding dynamic variables to the calibration equation.

With the Dynaflex system, manufacturers can:

Measure and minimize robot compliance (flexibility under load)

Achieve better path accuracy with complex work processes

Validate robot performance in real-world conditions

Identify mechanical anomalies before they can become major catastrophes

Maximize repeatability and process consistency

These are meaningful relationships to ensure that the robot moves correctly on paper, but that it also can perform accurately on the production floor.

How Does Dynaflex Work?

Dynaflex implements a series of highly sensitive measurement tools and calibration routines that allow engineerings to visualize how the end effector of a robot moves while under load, or at high speed. By measuring real-time flexing, oscillation and inertia, Dynaflex creates a comprehensive map of the robot's behavior.

Once the data has been collected, the data is used to adjust the robot's motion algorithms and account for mechanical variation.

Who is Dynaflex for?

Dynaflex is ideal for companies and industries that expect critical congruency and which themselves use robotic automation, including:

Automotive manufacturing

Aerospace and defence

Medical devices

Electronics assembly

Metal fabrication

3D printing and additive manufacturing

If your company relies on multi-robot cells, automated welding cells, or pick-and-place systems, introducing Dynaflex to your calibration operations will provide great benefit.

Dynalog-US: The Experts in Robot Calibration

Dynalog-US was founded to provide accurate and reliable robotic systems and has been a leader in robot performance technology for several decades. Their products are being used by leading world manufacturers, many of whom are in the Fortune 500.

Whether it is for robotic inspection, Tool Center Point (TCP) calibration or improving robot cell accuracy, Dynalog has a history of introducing products to the marketplace that demonstrate thoughtful engineering, industry leading performance, and great customer support.

Dynalog's market leading solutions, to include Dynaflex, come with documentation, field training, and technical consulting, which is more than just selling a product; Dynalog provides a partnership to achieve your production success.

Many companies have seen measurable improvements after adding Dynaflex to their robotic workflow:

Up to 40% improvement in path accuracy Considerably less joint stress and less component wear Reduction of rework and scrap percentage Faster ROI from robotic systems

One aerospace customer even found that Dynaflex helped them to achieve their tolerance requirements that they previously thought could be accomplished only with standard robots or off-the-shelf robotic equipment.

Future of Robotic CalibrationAs AI, machine Learning, and Industry 4.0 technologies evolve, the need for ongoing performance validation to and compliance will become more valuable. Also, autonomous systems will validate performance more often, and human interventions will be using tools like Dynaflex to ensure safety, quality, and efficiencies.

With Dynaflex by Dynalog-US, businesses now have a scalable and future-proof calibration platform to leverage for future use and to enhance work processes while accomplishing productivity and accuracy improvements in the immediate.

Conclusion

When you invest in robots, investing in robot performance has to be a given. Properly calibrating robot performance starts with the initial calibration when it is stationary, when it is in motion, while it is under load, and evaluating at the full-speed capability.

Dynaflex by Dynalog-US is a calibration device that provides the measurement data (metrics) to give you a competitive advantage for an ever-evolving automated world.

Ready to take the next step in robotic precision? Visit www.dynalog-us.com to learn more about Dynaflex and schedule a consultation with the experts at Dynalog-US.

#Dynaflex#Dynalog-US#Robot Calibration#Robotic Accuracy#Industrial Automation#Robot Compliance#Dynamic Robot Calibration#Robot Motion Control#Manufacturing Technology#Industry 4.0#Advanced Robotics#Robot Performance#Calibration Systems#Automation Solutions#Robot Path Accuracy#Robot Inspection Tools#Robot Flexibility Measurement#Dynaflex Calibration#Robotic Workflow Optimization#Robotic Precision Engineering

0 notes

Text

Explorando el Universo de la Robótica y la Automatización: Líderes y Tecnologías Clave

¿Qué es la Robótica y la Automatización y Para Qué Sirven? La robótica y la automatización son dos conceptos tecnológicos estrechamente relacionados que están transformando radicalmente industrias enteras y, cada vez más, aspectos de nuestra vida cotidiana. Aunque a menudo se usan indistintamente, tienen matices distintos: Robótica: Se centra específicamente en el diseño, construcción, operación…

#ABB Robotics#automatización#Automatización Industrial#Boston Dynamics#Cobots#Denso Robotics#Fabricación Avanzada#Fanuc Robotics#Festo#Industria 4.0#inteligencia artificial#KUKA Robotics#Logística Automatizada#Mitsubishi Electric Automation#Omron Adept Technologies#robótica#Robotiq#Robots Colaborativos#Robots Industriales#Robots Móviles#Rockwell Automation#Siemens Digital Industries#SoftBank Robotics#Staubli Robotics#tecnología#Universal Robots#Yaskawa Motoman

0 notes

Text

Dell PowerStoreOS 4.1: Improved Performance, Security & More

IT Future Depends on Smarter Storage. How the latest PowerStore prepares you for the future.

Dell PowerStore changes that. Due to its autonomous active/active architecture, always-on data reduction (guaranteed at 5:1), and programmable ecosystem support, PowerStore is “software-first” and flexible enough for fully coordinated deployments. PowerStore adapts to your IT demands so storage supports modern workloads.

Introducing PowerStoreOS 4.1

Dell Technologies World 2024 saw the debut of PowerStore Prime, the largest and most comprehensive Dell PowerStore release since its launch. PowerStoreOS 4.0 improved performance, reliability, and efficiency for Dell PowerStore customers globally. Building on PowerStoreOS 4.0, the next edition improves networking, security, data protection, performance monitoring, file management, and more. Now available: PowerStoreOS 4.1.

PowerStoreOS 4.1 benefits

Client advantages of PowerStoreOS 4.1 are listed below.

Quality of file resource service

PowerStoreOS 4.1 expands QoS to file resources. NAS servers, file systems, and thin clones might have bandwidth limited. Configuring file QoS requires a File IO Limit Rule and Policy. File IO limit rules and QoS policies differ from blocks because of their features. File policies can't block resources, and vice versa. Policy and rule names must be unique for each file and block.

Setting file resource QoS limits prioritises critical programs over others. Use cases for QoS include:

Service providers might limit based on customer SLAs.

Preventing loud neighbour instances when one application dominates appliance performance.

Prioritising critical applications above testing and development.

Secure file snapshots

PowerStoreOS 4.1 allows secure file system and thin clone snapshots. A secure snapshot is optional and prevents snapshot deletion until a retention date. This protects against ransom attempts and accidental snapshot deletion with the parent file system or thin clone.

A snapshot rule or manual file secure snapshot must include a retention date and time. The system automatically deletes after the retention date and time. Retention dates can be extended but not shortened. Administrators and PowerStore users cannot delete file secure snapshots.

File resource capacity accounting

PowerStore 4.0 improved block, storage container, appliance, cluster, and virtual machine capacity accounting. This data may help administrators anticipate growth patterns, plan capacity increases, arrange data wisely, and ensure the system meets Dell Technologies' data reduction guarantee. File resources now support capacity accounting.

File systems, thin clones, and NAS servers contribute to resource family capacity accounting. All file systems and thin clones on the NAS server make up its data. Because they share a resource family, thin file system clones have the same capacity accounting values. Thin clones of NAS servers may have varying capacity accounting figures according to their resource family. File capacity accounting metrics are collected every five minutes, hour, and day.

Native file import-added configuration

Native file import allows PowerStore to import file storage resources from other platforms. PowerStore supports migration session creation, monitoring, and management. No additional software, appliances, agents, third-party solutions, or host-based migration apps are needed. This allows configuration, data, and file movement to go smoothly.

Protecting data

Storage Improved direct connection

Storage Direct Protection simplifies native backup with PowerStore and PowerProtect in a single administrative interface. Configuring remote backup sessions in PowerStore Manager lets users backup block resources, get remote snapshots, and establish immediate access sessions.

In PowerStoreOS 4.1, customers may designate several storage networks for replication even with Storage Direct. Many PowerStore and Dell PowerProtect equipment can be connected over numerous physical networks. This release additionally improves Storage Direct restoration performance by four times.

Networking

Get LLDP data from PowerStore

On the local area network, network devices display their identity, capabilities, and other information using the industry-standard Link Layer Discovery Protocol (LLDP). LLDP improves end-user network visibility, making network issues easier to discover and address. End users may now examine PowerStore LLDP data using the REST API or CLI.

IPv6 deployment support

PowerStore administration, block storage, and NAS server access support IPv6 networks. PowerStore appliances may now be discovered via IPv6 by connecting to their service ports using IPv6 addresses.

Security

Enhancing MFA to assist CAC/PIV

MFA with CAC/PIV cards is available in PowerStoreOS 4.1. CAC/PIV authenticates users to STIG-enabled PowerStore clusters using US government-issued smart cards with signed x.509 certificates. The PowerStore web server uses this certificate for authentication and role mapping for authorisation when a user logs in using PowerStore Manager or CLI. Users' identities are derived from certificates under the user-defined name policy.

Temporary credentials

Temporary Credentials lets end users generate a temporary ID and secret to login and authenticate to the PowerStore system for remote replication, PowerProtect DD, and VMware vCenter integration. Temporary ID and secret expire 10 minutes after creation. Instead than using a username and password, this method is recommended.

Performance

Tracking offload performance

PowerStore for SCSI and NVMeoF implements copy, space reclamation, and zero offload commands. New offload command performance measurements were included with this version. Therefore, the user may better understand what is delivered to the equipment. These new metrics may be compared to Read, Write, and Total IOPs. PowerStore Manager and the REST API now show Xcopy, Unmap, and Write identical metrics.

In conclusion

PowerStoreOS 4.1 adds several features and improves the system. As you explore this version, remember that upgrading to the latest PowerStore code maximises ROI.

#technology#technews#govindhtech#news#technologynews#cloud computing#Dell PowerStore#PowerStore#PowerStoreOS 4.1#Quality of Service#PowerStore 4.0#Link Layer Discovery Protocol#PowerStore system

0 notes

Text

#Engineering Graduate Training#Bachelor of Engineering#Engineering College#Emerging Technologies#AI in Engineering#IoT for Engineers#Renewable Energy Engineering#Robotics and Automation#Blockchain in Engineering#5G Technology#Engineering Career#Engineering Training Programs#TVS Training & Services#Future of Engineering#Industry 4.0

0 notes

Text

Shaping the Future of Manufacturing: Embracing Smart Analytics and Cloud Innovation

Introduction

The manufacturing industry is experiencing a significant shift. Traditional production methods, once reliable, now struggle to keep up with increasing complexity, rising costs, and evolving market demands. To remain competitive, manufacturers are integrating smart analytics and cloud-based solutions into their operations, enabling real-time insights, predictive maintenance, and greater agility.

By leveraging data-driven decision-making and scalable digital infrastructure, manufacturing leaders can optimize efficiency, improve product quality, and reduce downtime. In this blog, we explore how smart analytics and cloud innovation are shaping the industry’s future, discussing real-world implementations.

The Changing Landscape of Production

Manufacturing processes have evolved significantly in recent years. Supply chains have become global and interconnected, consumer expectations have risen, and regulatory compliance has become more stringent. Despite technological advancements, many manufacturers continue to face operational inefficiencies that impact productivity and profitability.

Key Challenges in Modern Manufacturing:

Unplanned Downtime:

Unexpected equipment failures disrupt production and lead to millions in lost revenue.

Reactive Maintenance:

Relying on traditional maintenance practices often means fixing problems after they occur, increasing costs and production delays.

Quality Control Issues:

Manual inspections miss defects, leading to product recalls, waste, and dissatisfied customers.

Limited Data Visibility:

Many manufacturers struggle with fragmented, siloed data, making real-time decision-making difficult.

Scalability Constraints:

Rigid, on-premise IT infrastructures slow digital transformation efforts and limit production scalability.

Why Traditional Systems Fall Short

Legacy production systems lack predictive analytics capabilities, leading to inefficient operations.

On-premise IT infrastructure is costly, difficult to scale, and lacks real-time processing power.

Manual processes are prone to human error and prevent manufacturers from achieving optimal efficiency.

As the demand for smarter, faster, and more flexible manufacturing grows, companies must embrace advanced analytics and cloud-driven solutions to gain a competitive edge.

Smart Analytics at Work

Smart analytics is transforming manufacturing operations by enabling real-time monitoring, predictive maintenance, and data-driven optimization. By applying AI-powered insights, manufacturers can improve efficiency and minimize costly disruptions.

How Smart Analytics is Reshaping Manufacturing:

Predictive Maintenance for Reduced Downtime:

AI-driven analytics detect early warning signs of equipment failure.

Sensors monitor machinery in real time, allowing proactive repairs before breakdowns occur.

This approach reduces unplanned downtime by up to 30%, saving time and maintenance costs.

Optimized Product Design with AI:

Smart algorithms analyze design variations, ensuring stronger, lighter, and more cost-effective components.

AI-generated designs help reduce material waste and improve durability.

Example: In the automotive sector, AI-driven chassis design has lowered vehicle weight by 12-15%, improving fuel efficiency and reducing production costs.

AI-Enhanced Quality Control:

Automated computer vision systems inspect products for defects in real-time, ensuring high accuracy.

AI-powered inspections reduce defects and improve product consistency.

Example: In electronics manufacturing, AI-driven inspections have achieved up to 99.8% accuracy, significantly reducing product recalls.

By integrating smart analytics, manufacturers are enhancing operational efficiency and improving product reliability. Tudip Technologies plays a key role in implementing AI-powered solutions that help businesses optimize production processes and quality assurance.

Cloud-Enabled Manufacturing

Cloud technology is redefining how manufacturers store, manage, and utilize data. Moving operations from on-premise servers to scalable cloud platforms enhances efficiency, security, and real-time collaboration.

Benefits of Cloud Adoption in Manufacturing:

Scalability & Flexibility:

Cloud-based systems adjust dynamically to production demands.

Manufacturers can scale resources up or down without significant IT investments.

Real-Time Insights & Decision-Making:

Cloud platforms consolidate real-time production data, improving decision-making.

Supply chain tracking, inventory management, and process optimization become more efficient.

Lower IT Costs & Improved Security:

Cloud migration reduces IT maintenance expenses by up to 40%.

Advanced security protocols protect sensitive manufacturing data.

Integration with IoT & AI Technologies:

Cloud solutions seamlessly connect IoT sensors, AI-powered analytics, and factory automation tools.

AI algorithms process data faster, providing actionable insights for process improvement.

By leveraging cloud-based solutions, manufacturers can achieve cost savings, higher agility, and greater efficiency. Tudip Technologies assists companies in migrating to the cloud, ensuring seamless integration with AI-powered analytics and IoT solutions.

Real-World Success Stories

Case Study 1: AI-Powered Predictive Maintenance in Industrial Equipment

Sector: Heavy Machinery Manufacturing

Challenge: Unplanned equipment failures led to frequent production stoppages.

Solution: Implemented AI-powered predictive maintenance using IoT sensors and real-time analytics.

Results:

30% reduction in downtime, improving operational efficiency.

Improved maintenance scheduling reduced repair costs by 20%.

Case Study 2: AI-Driven Design Optimization in Automotive Components

Sector: Automotive Manufacturing

Challenge: Reducing vehicle weight while maintaining structural integrity.

Solution: Applied AI-driven generative design tools to optimize chassis components.

Results:

12-15% reduction in chassis weight, leading to 3-4% fuel efficiency improvement.

Lower material consumption cut production costs and improved sustainability.

Case Study 3: Cloud-Enabled Smart Manufacturing for Production Scaling

Sector: Consumer Goods Manufacturing

Challenge: Legacy IT infrastructure limited scalability and increased operational costs.

Solution: Migrated to a cloud-based manufacturing platform, integrating real-time analytics.

Results:

40% reduction in IT maintenance costs.

Improved production scalability and faster decision-making.

These real-world applications demonstrate how smart analytics and cloud solutions drive measurable improvements. Tudip Technologies collaborates with manufacturers to implement cutting-edge digital solutions tailored to industry-specific needs.

Conclusion: The Future of Manufacturing is Here

Manufacturing is at a turning point. Smart analytics and cloud technology are redefining industry standards, making operations more efficient, agile, and cost-effective. Companies that adopt these innovations gain a significant competitive advantage.

Key Takeaways:

AI-powered predictive maintenance minimizes downtime and boosts operational efficiency.

Generative AI improves component design, reducing material usage and increasing durability.

Automated quality control ensures near-perfect defect detection, reducing waste and recalls.

Cloud-based manufacturing enables real-time insights and seamless scalability.

Real-world results show measurable benefits across multiple industries.

The shift toward data-driven manufacturing is no longer optional—it’s essential. Forward-thinking companies are already seeing the benefits of AI, IoT, and cloud integration.

Manufacturing is evolving, and AI-driven analytics and cloud solutions are key to staying ahead. Tudip Technologies can help optimize your operations for efficiency and scalability. Reach out at [email protected] to get started!

Click the link below to learn more about the blog Shaping the Future of Manufacturing :

#Smart Manufacturing#Industry 4.0#Cloud Manufacturing#Data-Driven Manufacturing#IoT in Manufacturing#AI in Manufacturing#Manufacturing#Tudip Technologies#Tudip

1 note

·

View note

Text

TCL Showcases Groundbreaking Tech Innovations at CES 2025

✨ Experience the future at #TCLCES2025! Witness QD-Mini LED displays, NXTPAPER 4.0, and smart home innovations redefining greatness. #TCLxCES2025 #TCLPhilippines #TCLInspireGreatness #GoodGuyGadgets #LetsTalkTech

TCL CES 2025 is set to be an extraordinary event, as TCL Electronics, a top global TV brand and innovation leader, prepares to showcase its latest technological advancements. With a legacy of 31 years at the Consumer Electronics Show, TCL’s participation promises a fusion of groundbreaking display technologies and cutting-edge smart home products. TCL to Inspire Greatness at CES 2025 with its…

#CES event highlights#future tech trends#NXTPAPER 4.0#QD-Mini LED#smart home technology#TCL CES 2025#TCL innovations#TCL Philippines

0 notes

Text

"Optimizing Industries with Smart Automation Solutions"

In today’s fast-paced industrial world, staying competitive means adopting advanced technologies that enhance efficiency, reduce downtime, and ensure sustainable growth. One of the most transformative trends reshaping industries is the integration of industrial automation and IIoT (Industrial Internet of Things) solutions. These innovations are revolutionizing operations, making processes smarter, faster, and more reliable.

What is Industrial Automation? Industrial automation involves the use of advanced control systems, such as Programmable Logic Controllers (PLCs), Supervisory Control and Data Acquisition (SCADA) systems, Variable Frequency Drives (VFDs), and other technologies, to automate industrial processes. These systems eliminate the need for manual intervention in repetitive or complex tasks, improving productivity and minimizing errors.

For instance, a manufacturing plant that once relied on human operators to manage conveyor belts and packaging lines can now leverage automation to ensure seamless, error-free operations. This not only boosts production speed but also ensures consistent quality across all outputs.

The Role of IIoT in Automation The Industrial Internet of Things (IIoT) takes automation a step further by connecting devices, machines, and systems to the internet. IIoT enables real-time monitoring, predictive maintenance, and data-driven decision-making. Imagine a power plant where sensors continuously monitor equipment performance, alerting operators about potential failures before they occur. This proactive approach prevents costly downtime and extends equipment lifespan.

Why Businesses Need to Embrace Automation Industries face several challenges, including rising operational costs, labor shortages, and increasing demand for efficiency. Automation addresses these pain points by:

Improving Efficiency: Automated systems work faster and more accurately than manual processes.

Reducing Downtime: Predictive maintenance and real-time monitoring minimize unexpected breakdowns.

Ensuring Safety: Automation reduces human involvement in hazardous tasks, ensuring worker safety.

How Apical Industrial Solution & Technology Leads the Way At Apical Industrial Solution & Technology, we specialize in delivering tailored automation and IIoT solutions that drive innovation and growth. Our Siemens-certified engineers are experts in designing, developing, and supporting control systems for diverse industries. From PLCs and SCADA to VFDs and LT switchgear, we provide end-to-end solutions that transform operations.

As industries evolve, the need for automation and smart solutions will only grow. Businesses that embrace these advancements today will be the leaders of tomorrow, equipped to navigate challenges and seize opportunities in an ever-changing world

#industrial automation#IIoT solutions#PLC systems#SCADA technology#VFD drives#predictive maintenance#process optimization#smart manufacturing#automation solutions#industry 4.0

1 note

·

View note

Text

Five Ways to Explore NASAs Portfolio of Technologies with TechPort 4.0

Have you ever wanted to find all your favorite NASA technology in one place? NASA stakeholders did, too! We listened to your feedback, brainstormed user-focused features, and created the most robust technology system to date. NASA’s Space Technology Mission Directorate is excited to announce the release of TechPort version 4.0 – your gateway into our […] from NASA https://ift.tt/XtwLaVe

0 notes

Text

Revolutionizing Precision: How Automated Measuring Systems Are Changing

The Game In today’s high-tech manufacturing and robotic landscape, precision is no longer a bonus—it's essential. As industries have stricter tolerances, faster production times, and flawless quality control, you can push the limits with specialized automated measuring systems—precision, efficiency and reliability in ways traditional measurement cannot support—and Dynalog is leading the way.

What are Automated Measuring Systems?

Automated Measuring Systems (AMS) use sophisticated technology to perform measurements automatically, without operator input. Automated Measuring Systems use a combination of sensors, robotics, software and analysis to provide measurements with extremely high accuracy, in real time. AMS can verify dimensions on a complex piece of material, check the position of the end effector on a robotic tool, or complete an entire inspection routine---and can do this quickly, at a consistent level of accuracy. For the manufacturer or production facility, AMS provide lower risk of error, faster throughput, and a better quality of product quality. It is not surprising that companies, like Dynalog, are advancing these systems for industries such as automotive, aerospace, electronics and medical device manufacturing.

The Importance of Accuracy is UndeniableIn manufacturing,

a difference of just 0.01mm can mean the difference between a product that works perfectly and one that does not work. As parts become smaller and more complicated, the margin of error is decreasingly smaller! Manual measurement is often human error-prone, slow, and inconsistent.

That’s why Dynalog has automated measuring systems.

Automated measuring systems take human error out of the equation and provide repeatable, consistent, real-time measuring data. With real-time feedback, manufacturers can change their processes on the spot, eliminating scrap and saving money.Dynalog: The Leaders in Robotic Accuracy and CalibrationAt Dynalog, accuracy is not just a marketing statement, accuracy is at the core of everything they do. With extensive experience in robotic measuring, calibration, and inspection systems, they build state-of-the-art solutions for the next generation of manufacturing.Automated measuring systems integrate with robotic arms and production lines, every movement and measurement is accurate and traceable. From Robot TCP Calibration to validating robot performance, Dynalog measuring systems are for manufacturers that cannot afford to be inaccurate.Key Dynalog Solutions for Automated MeasurementDynaCal® – A cutting-edge robotic calibration system providing sub-millimeter accuracy

Advantages of Automated Measurement Systems in ManufacturingLet's look at the rationale of why automated measurement is becoming the new standard in the industry:

1. Superior PrecisionAMS (Automated Measurement Systems) eliminate the subjectivity of the human eye and achieve measurements to the micron level of precision. For high-stakes industries like aerospace and medical equipment where safety is a stringent criteria, this level of precision is critical.

2. Accelerated Production Cycles Manual inspections hinder production, whereas with AMS, measurements occur in real-time—in-line or near-line—removing bottlenecks and even shortening delivery times.

3. Minimized Scrap and ReworkBy identifying deviations early in the process, manufacturers can take steps to correct defects prior to irreversible mistakes, resulting in more yield and less scrap.

4. Data-Driven DecisionsDynalog's systems not only measure, but they analyze. The real-time data can be accessed and input into process control systems to help engineers make informed data-based decisions for continuous improvement.

5. Easy Updated IntegrationToday’s AMS systems, like Dynalog's, can actually integrate with the existing robotic systems and software, creating a quick, affordable transition to your automated solution.

#automated measuring systems#robotic measurement systems#robot calibration solutions#Dynalog measuring systems#robot TCP calibration#manufacturing automation#industrial robotics#robot inspection technology#precision measurement tools#Industry 4.0 solutions#manufacturing quality control#3D robotic measurement#Dynalog USA#robotic accuracy systems#advanced measuring systems

0 notes

Text

Explorando el Universo de la Robótica y la Automatización: Líderes y Tecnologías Clave

¿Qué es la Robótica y la Automatización y Para Qué Sirven? La robótica y la automatización son dos conceptos tecnológicos estrechamente relacionados que están transformando radicalmente industrias enteras y, cada vez más, aspectos de nuestra vida cotidiana. Aunque a menudo se usan indistintamente, tienen matices distintos: Robótica: Se centra específicamente en el diseño, construcción, operación…

#ABB Robotics#automatización#Automatización Industrial#Boston Dynamics#Cobots#Denso Robotics#Fabricación Avanzada#Fanuc Robotics#Festo#Industria 4.0#inteligencia artificial#KUKA Robotics#Logística Automatizada#Mitsubishi Electric Automation#Omron Adept Technologies#robótica#Robotiq#Robots Colaborativos#Robots Industriales#Robots Móviles#Rockwell Automation#Siemens Digital Industries#SoftBank Robotics#Staubli Robotics#tecnología#Universal Robots#Yaskawa Motoman

0 notes

Text

#real estate#virtual reality#vr in real estate#real estate technology#industrial ar#industrial vr#industrial innovation#industrial revolution#industry 4.0

0 notes

Text

Empowering MSMEs with CNC Manufacturing: Cosmos Impex Leading Industry 4.0 in India

With government support fueling MSME growth, CNC manufacturing is reaching new heights. Cosmos Impex, the best CNC machine manufacturer in India, is driving innovation with precision solutions and advanced technology. Join us as we lead the Industry 4.0 revolution and shape the future of manufacturing.

#Cosmos Impex best CNC machine manufacturer India#CNC Manufacturing Growth#Industry 4.0 in Manufacturing#Empowering MSMEs with Technology#Precision CNC Solutions#Advanced Technology for MSMEs#Future of CNC Manufacturing in India

0 notes