#Data-Driven Manufacturing

Explore tagged Tumblr posts

Text

Shaping the Future of Manufacturing: Embracing Smart Analytics and Cloud Innovation

Introduction

The manufacturing industry is experiencing a significant shift. Traditional production methods, once reliable, now struggle to keep up with increasing complexity, rising costs, and evolving market demands. To remain competitive, manufacturers are integrating smart analytics and cloud-based solutions into their operations, enabling real-time insights, predictive maintenance, and greater agility.

By leveraging data-driven decision-making and scalable digital infrastructure, manufacturing leaders can optimize efficiency, improve product quality, and reduce downtime. In this blog, we explore how smart analytics and cloud innovation are shaping the industry’s future, discussing real-world implementations.

The Changing Landscape of Production

Manufacturing processes have evolved significantly in recent years. Supply chains have become global and interconnected, consumer expectations have risen, and regulatory compliance has become more stringent. Despite technological advancements, many manufacturers continue to face operational inefficiencies that impact productivity and profitability.

Key Challenges in Modern Manufacturing:

Unplanned Downtime:

Unexpected equipment failures disrupt production and lead to millions in lost revenue.

Reactive Maintenance:

Relying on traditional maintenance practices often means fixing problems after they occur, increasing costs and production delays.

Quality Control Issues:

Manual inspections miss defects, leading to product recalls, waste, and dissatisfied customers.

Limited Data Visibility:

Many manufacturers struggle with fragmented, siloed data, making real-time decision-making difficult.

Scalability Constraints:

Rigid, on-premise IT infrastructures slow digital transformation efforts and limit production scalability.

Why Traditional Systems Fall Short

Legacy production systems lack predictive analytics capabilities, leading to inefficient operations.

On-premise IT infrastructure is costly, difficult to scale, and lacks real-time processing power.

Manual processes are prone to human error and prevent manufacturers from achieving optimal efficiency.

As the demand for smarter, faster, and more flexible manufacturing grows, companies must embrace advanced analytics and cloud-driven solutions to gain a competitive edge.

Smart Analytics at Work

Smart analytics is transforming manufacturing operations by enabling real-time monitoring, predictive maintenance, and data-driven optimization. By applying AI-powered insights, manufacturers can improve efficiency and minimize costly disruptions.

How Smart Analytics is Reshaping Manufacturing:

Predictive Maintenance for Reduced Downtime:

AI-driven analytics detect early warning signs of equipment failure.

Sensors monitor machinery in real time, allowing proactive repairs before breakdowns occur.

This approach reduces unplanned downtime by up to 30%, saving time and maintenance costs.

Optimized Product Design with AI:

Smart algorithms analyze design variations, ensuring stronger, lighter, and more cost-effective components.

AI-generated designs help reduce material waste and improve durability.

Example: In the automotive sector, AI-driven chassis design has lowered vehicle weight by 12-15%, improving fuel efficiency and reducing production costs.

AI-Enhanced Quality Control:

Automated computer vision systems inspect products for defects in real-time, ensuring high accuracy.

AI-powered inspections reduce defects and improve product consistency.

Example: In electronics manufacturing, AI-driven inspections have achieved up to 99.8% accuracy, significantly reducing product recalls.

By integrating smart analytics, manufacturers are enhancing operational efficiency and improving product reliability. Tudip Technologies plays a key role in implementing AI-powered solutions that help businesses optimize production processes and quality assurance.

Cloud-Enabled Manufacturing

Cloud technology is redefining how manufacturers store, manage, and utilize data. Moving operations from on-premise servers to scalable cloud platforms enhances efficiency, security, and real-time collaboration.

Benefits of Cloud Adoption in Manufacturing:

Scalability & Flexibility:

Cloud-based systems adjust dynamically to production demands.

Manufacturers can scale resources up or down without significant IT investments.

Real-Time Insights & Decision-Making:

Cloud platforms consolidate real-time production data, improving decision-making.

Supply chain tracking, inventory management, and process optimization become more efficient.

Lower IT Costs & Improved Security:

Cloud migration reduces IT maintenance expenses by up to 40%.

Advanced security protocols protect sensitive manufacturing data.

Integration with IoT & AI Technologies:

Cloud solutions seamlessly connect IoT sensors, AI-powered analytics, and factory automation tools.

AI algorithms process data faster, providing actionable insights for process improvement.

By leveraging cloud-based solutions, manufacturers can achieve cost savings, higher agility, and greater efficiency. Tudip Technologies assists companies in migrating to the cloud, ensuring seamless integration with AI-powered analytics and IoT solutions.

Real-World Success Stories

Case Study 1: AI-Powered Predictive Maintenance in Industrial Equipment

Sector: Heavy Machinery Manufacturing

Challenge: Unplanned equipment failures led to frequent production stoppages.

Solution: Implemented AI-powered predictive maintenance using IoT sensors and real-time analytics.

Results:

30% reduction in downtime, improving operational efficiency.

Improved maintenance scheduling reduced repair costs by 20%.

Case Study 2: AI-Driven Design Optimization in Automotive Components

Sector: Automotive Manufacturing

Challenge: Reducing vehicle weight while maintaining structural integrity.

Solution: Applied AI-driven generative design tools to optimize chassis components.

Results:

12-15% reduction in chassis weight, leading to 3-4% fuel efficiency improvement.

Lower material consumption cut production costs and improved sustainability.

Case Study 3: Cloud-Enabled Smart Manufacturing for Production Scaling

Sector: Consumer Goods Manufacturing

Challenge: Legacy IT infrastructure limited scalability and increased operational costs.

Solution: Migrated to a cloud-based manufacturing platform, integrating real-time analytics.

Results:

40% reduction in IT maintenance costs.

Improved production scalability and faster decision-making.

These real-world applications demonstrate how smart analytics and cloud solutions drive measurable improvements. Tudip Technologies collaborates with manufacturers to implement cutting-edge digital solutions tailored to industry-specific needs.

Conclusion: The Future of Manufacturing is Here

Manufacturing is at a turning point. Smart analytics and cloud technology are redefining industry standards, making operations more efficient, agile, and cost-effective. Companies that adopt these innovations gain a significant competitive advantage.

Key Takeaways:

AI-powered predictive maintenance minimizes downtime and boosts operational efficiency.

Generative AI improves component design, reducing material usage and increasing durability.

Automated quality control ensures near-perfect defect detection, reducing waste and recalls.

Cloud-based manufacturing enables real-time insights and seamless scalability.

Real-world results show measurable benefits across multiple industries.

The shift toward data-driven manufacturing is no longer optional—it’s essential. Forward-thinking companies are already seeing the benefits of AI, IoT, and cloud integration.

Manufacturing is evolving, and AI-driven analytics and cloud solutions are key to staying ahead. Tudip Technologies can help optimize your operations for efficiency and scalability. Reach out at [email protected] to get started!

Click the link below to learn more about the blog Shaping the Future of Manufacturing :

#Smart Manufacturing#Industry 4.0#Cloud Manufacturing#Data-Driven Manufacturing#IoT in Manufacturing#AI in Manufacturing#Manufacturing#Tudip Technologies#Tudip

1 note

·

View note

Text

Top 5 DeepSeek AI Features Powering Industry Innovation

Table of Contents1. The Problem: Why Legacy Tools Can’t Keep Up2. What Makes DeepSeek AI Unique?3. 5 Game-Changing DeepSeek AI Features (with Real Stories)3.1 Adaptive Learning Engine3.2 Real-Time Anomaly Detection3.3 Natural Language Reports3.4 Multi-Cloud Sync3.5 Ethical AI Auditor4. How These Features Solve Everyday Challenges5. Step-by-Step: Getting Started with DeepSeek AI6. FAQs: Your…

#affordable AI solutions#AI automation#AI for educators#AI for entrepreneurs#AI for non-techies#AI for small business#AI in manufacturing#AI innovation 2024#AI time management#business growth tools#data-driven decisions#DeepSeek AI Features#ethical AI solutions#healthcare AI tools#no-code AI tools#Predictive Analytics#real-time analytics#remote work AI#retail AI features#startup AI tech

2 notes

·

View notes

Text

IoT in Action: Transforming Industries with Intelligent Connectivity

The Power of Connectivity

The Internet of Things (IoT) has become a cornerstone of innovation, as it reimagines industries and redefines the way business is conducted. In bridging the physical and digital worlds, IoT enables seamless connectivity, smarter decision-making, and unprecedented efficiency. Today, in the competitive landscape, intelligent connectivity is no longer just a technology advancement; for businesses wanting to be relevant and continue to thrive, it is now a strategic imperative.

IoT is not simply about connecting devices; it’s about creating ecosystems that work collaboratively to drive value. With industries relying heavily on real-time data and actionable insights, IoT-powered connectivity has become the backbone of operational excellence and growth. Let’s explore how this transformative technology is revolutionizing key sectors, with a focus on how businesses can leverage it effectively.

Applications of IoT in Key Industries

1.Smart Manufacturing: Efficiency Through Connectivity

Manufacturing has embraced IoT as a tool to streamline operations and boost productivity. By embedding sensors in machinery and integrating real-time monitoring systems, manufacturers can:

Predict and Prevent Downtime: IoT-enabled predictive maintenance reduces unplanned outages, saving time and money.

Optimize Resource Allocation: Smart systems track inventory, raw materials, and energy consumption, ensuring optimal usage.

Enhance Quality Control: Real-time data from production lines helps identify defects early, maintaining high-quality standards.

Example: A global automotive manufacturer integrated IoT sensors into its assembly lines, reducing equipment downtime by 25% and improving production efficiency by 30%. The ability to monitor machinery health in real time transformed their operations, delivering significant cost savings.

2.Healthcare: Improve Patient Outcomes

In healthcare, IoT has been a game-changer in enabling connected medical devices and systems that enhance patient care and operational efficiency. The main applications include:

Remote Patient Monitoring: Devices track vital signs in real time, allowing healthcare providers to offer timely interventions.

Smart Hospital Systems: IoT-enabled equipment and sensors optimize resource utilization, from patient beds to medical supplies.

Data-Driven Decisions: IoT integrates patient data across systems, providing actionable insights for personalized treatment plans.

Example: A major hospital has put into operation IoT-enabled wearables for chronic disease management. This solution reduced the number of readmissions to hospitals by 20% and empowered patients to take an active role in their health.

3.Retail: Revolutionizing Customer Experiences

IoT is revolutionizing retail through increased customer interaction and streamlined operations. Connected devices and smart analytics allow retailers to:

Personalize Shopping Experiences: IoT systems track customer preferences, offering tailored recommendations in real time.

Improve Inventory Management: Smart shelves and sensors keep stock levels optimal, reducing wastage and improving availability.

Enable Smooth Transactions: IoT-driven payment systems make checkout easier and much faster, increasing customers’ convenience

Example: A retail chain leveraged IoT to integrate smart shelves that automatically update inventory data. This reduced out-of-stock situations by 40%, improving customer satisfaction and driving higher sales.

Role of Intelligent Connectivity in Business Transformation

Intelligent connectivity lies at the heart of IoT’s transformative potential. By connecting devices, systems, and processes, businesses can:

Accelerate Decision-Making: Real-time data sharing enables faster, more informed decisions, giving companies a competitive edge.

It increases collaboration by allowing smooth communication between departments and teams, making the entire system more efficient.

Adapt to Market Dynamics: IoT enables companies to respond quickly to changes in demand, supply chain disruptions, or operational challenges.

Intelligent connectivity is not just about technology; it’s about creating value by aligning IoT solutions with business objectives. This strategic approach guarantees that IoT investments will deliver measurable outcomes, from cost savings to improved customer loyalty.

How Tudip Technologies Powers Intelligent Connectivity

Tudip Technologies specializes in designing and implementing IoT solutions that drive meaningful transformation for businesses. With a focus on innovation and collaboration, Tudip ensures that its clients achieve operational excellence through intelligent connectivity.

Tailored Solution for Every Business Industry

Tudip understands that no two businesses are alike. By customizing IoT strategies to address specific challenges, Tudip helps clients unlock the full potential of connectivity. Examples include:

Smart Supply Chains: Implementing IoT systems that provide real-time visibility into inventory and logistics, reducing delays and improving efficiency.

Energy Management: Developing IoT frameworks to monitor and optimize energy usage, driving sustainability and cost savings.

Healthcare Innovations: Designing networked medical devices that allow remote patient monitoring and data integration without a hitch.

The Future of Connected Systems

The demand for intelligent connectivity will keep increasing as the industries continue to evolve. Emerging trends in IoT include edge computing, 5G networks, and AI-powered analytics, which promise to redefine possibilities for connected ecosystems.

Businesses that embrace these advancements stand to gain:

Greater Resilience: IoT enables adaptive systems that can withstand market fluctuations and operational challenges.

Enhanced Innovation: Connected technologies open doors to new business models, revenue streams, and customer experiences.

Sustainable Growth: IoT optimizes resources and processes, contributing to long-term environmental and economic sustainability.

The future belongs to those who see connectivity not just as a technological tool but as a strategic enabler of transformation. The right partner will help businesses transform IoT from a concept into a competitive advantage.

Conclusion: Embracing Intelligent Connectivity with Tudip

IoT is not just changing the way businesses operate—it’s redefining what’s possible. From manufacturing and healthcare to retail and beyond, intelligent connectivity is driving innovation, efficiency, and growth across industries.

Tudip Technologies is at the forefront of this transformation, offering customized IoT solutions that deliver real results. By prioritizing collaboration, adaptability, and measurable outcomes, Tudip ensures that its clients stay ahead in an increasingly connected world.

Now is the time to embrace the power of IoT and unlock its potential for your business. With Tudip as your partner, the journey to intelligent connectivity is not just achievable—it’s inevitable.

Click the link below to learn more about the blog IoT in Action: Transforming Industries with Intelligent Connectivity https://tudip.com/blog-post/iot-in-action-transforming-industries-with-intelligent-connectivity/

#Tudip#IoT#intelligent connectivity#real-time data#predictive maintenance#smart manufacturing#remote patient monitoring#healthcare IoT#retail IoT#smart shelves#supply chain optimization#edge computing#AI-powered analytics#5G networks#industrial IoT#connected devices#digital transformation#operational efficiency#business intelligence#automation#data-driven decision-making#IoT solutions#smart systems#enterprise IoT#IoT-powered connectivity#sustainable growth#technology innovation#machine learning#cloud computing#smart sensors

0 notes

Text

Revolutionize your manufacturing process with generative AI: predictive maintenance, enhanced design, improved quality control, and streamlined supply chains. Embrace the future!

#AI In Inventory Management#AI-Powered Manufacturing Data Analysis#Generative AI In Smart Factories#AI In Manufacturing Innovation#Generative AI For Production Planning#AI In Operational Efficiency#AI-Driven Manufacturing Transformation#Generative AI For Lean Manufacturing#AI In Manufacturing Logistics#AI-Enhanced Production Processes#Generative AI For Equipment Monitoring#AI In Supply Chain Optimization#Generative AI For Manufacturing Agility#AI-Powered Factory Automation#AI In Process Control#Generative AI For Production Optimization

0 notes

Text

Revolutionize manufacturing decisions with AI-driven Business Intelligence. Dive into data insights, powering efficiency and innovation. Discover more!

#AI-Based BI Tools#Smart Manufacturing Intelligence#Data-Driven Decision-Making#Natural Language Generation#Generative AI Algorithms#Generative AI in BI#Traditional Analytics Methodologies#Generative AI#Predictive Maintenance

0 notes

Text

Revolutionize manufacturing decisions with AI-driven Business Intelligence. Dive into data insights, powering efficiency and innovation. Discover more!

#AI-Based BI Tools#Smart Manufacturing Intelligence#Data-Driven Decision-Making#Natural Language Generation#Generative AI Algorithms#Generative AI in BI#Traditional Analytics Methodologies#Generative AI#Predictive Maintenance

1 note

·

View note

Text

Data-driven assessment is based on the analysis and interpretation of data to guide strategic business decisions that align with the goals, objectives, and initiatives of a company. It is an evidence-based approach that relies on data to make informed decisions. According to IDC, the global data is growing from 45 zettabytes in 2019 to an estimated 175 zettabytes by 2025! Backed by data, everyone in the company can be empowered to innovate and work on new ideas.

#data driven assessments#digital transformation for manufacturing#digital transformation manufacturing industry

0 notes

Text

Data-Driven Decision-Making: The Core of PdM Excellence

#leak detection software#predicting energy consumption#smart manufacturing solutions#PdM solutions#PdM#Data-Driven Decision#data driven insights

0 notes

Text

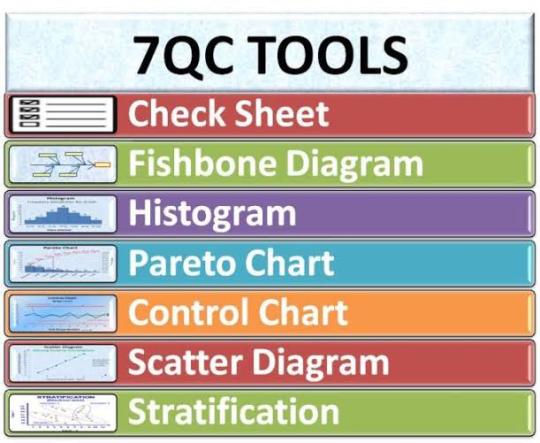

What are 7 QC Tools? 7 QC Tools: The Foundation of Quality Management

In the realm of quality management, the 7 Quality Control (QC) tools, also known as the 7 Basic Tools of Quality, serve as the bedrock for analyzing and improving processes. These powerful tools, developed by Dr. Kaoru Ishikawa, are indispensable for identifying issues, making informed decisions, and enhancing overall quality. This article delves into the details of the 7 QC tools, their…

View On WordPress

#7 QC Tools#Business Excellence#Cause-and-Effect Diagrams#Check Sheets#Continuous Improvement#Control Charts#Cost Savings#Customer Satisfaction#data analysis#Data-Driven#Decision Making#Defect Concentration Diagrams#Flowcharts#Healthcare#Histograms#Manufacturing#Operational Excellence#Pareto Charts#Problem Identification#Process Improvement#Process Stability#Quality Control#Quality Management#Root Cause Analysis#Service Sector#Versatile Solutions

0 notes

Text

Can AI Revolutionize 3D Concrete Printing? Exploring the Future of Construction

Introduction The field of construction is undergoing a transformative revolution with the advent of 3D concrete printing technology. This cutting-edge approach promises faster, cost-effective, and eco-friendly construction, revolutionizing the way we build structures. Now, the convergence of artificial intelligence (AI) with 3D concrete printing is pushing the boundaries even further, introducing…

View On WordPress

#3D Concrete Printing#Additive Manufacturing#AI#AI integration#AI-driven Construction#Architecture#artificial intelligence#Building Efficiency#Collaborative Robotics#construction#Construction Automation#construction industry#Construction Revolution#Construction Trends#Cost of Implementation#Data Privacy#Design Optimization#Eco-friendly Construction#future of construction#innovation#Material Selection#Predictive Maintenance#quality control#Real-Time Monitoring#Regulatory Compliance#Robotics#Security#Smart Robotic Systems#Sustainable Building#Sustainable Construction

0 notes

Text

How Data-Driven Quality Checks Improve Product Reliability

Introduction

Manufacturers today operate in a highly competitive environment where product quality and reliability directly impact profitability and customer trust. Traditional quality control methods, which relied on manual inspections and reactive maintenance, often led to delays, inconsistencies, and high production costs. The shift toward data-driven quality checks has transformed manufacturing, enabling businesses to predict defects, optimize processes, and ensure consistency at scale.

At Tudip Technologies, we understand the growing need for automated, data-driven quality assurance solutions. By integrating predictive analytics, real-time monitoring, and AI-powered inspections, we help manufacturers improve operational efficiency and minimize production flaws. This blog explores how data-driven quality checks enhance product reliability and process efficiency while addressing industry challenges.

Why Traditional Quality Checks Are No Longer Sufficient

For decades, manufacturers have relied on random sampling, manual inspections, and periodic audits to ensure quality. However, these methods come with significant drawbacks:

Delayed Issue Detection: Problems are often identified too late, leading to costly rework.

Human Error: Subjective assessments lead to inconsistencies.

Limited Scalability: As production volumes increase, manual checks become inefficient.

Higher Operational Costs: Frequent breakdowns and quality failures increase overall production expenses.

By shifting to real-time, data-driven quality assurance, manufacturers can reduce defects, production downtime, and material waste, ensuring a more efficient and cost-effective production cycle.

How Data-Driven Quality Checks Enhance Product Reliability

1. AI-Powered Defect Detection for Faster Decision-MakingThe integration of computer vision and AI-powered image analysis allows manufacturers to detect minute product defects with a higher level of accuracy. AI models trained on historical defect patterns can:

Identify flaws in surface textures, dimensions, and material integrity faster than human inspectors.

Improve precision by reducing false positives and missed defects.

Continuously learn from past defect data to enhance detection accuracy over time.

For manufacturers operating in automotive, electronics, and precision manufacturing, AI-powered inspections significantly improve product quality consistency and customer satisfaction.

2. Real-Time Quality Monitoring & Predictive Maintenance

Instead of reacting to production failures, manufacturers can monitor quality metrics in real time through IoT sensors and predictive analytics. This allows businesses to:

Detect anomalies in production lines before they cause defects.

Optimize machine performance to reduce unexpected breakdowns.

Reduce unplanned downtime by scheduling proactive maintenance based on real-time data insights.

By integrating machine learning-driven monitoring systems, manufacturers can increase equipment lifespan, lower maintenance costs, and maintain production efficiency.

3. Automated Process Optimization to Reduce Variability

Variations in production workflows often lead to inconsistent quality levels. Through automated data analysis, manufacturers can:

Identify variability in production batches and standardize processes accordingly.

Optimize operational parameters in real time for greater uniformity.

Reduce scrap rates by identifying root causes of inconsistencies.

Tudip Technologies has worked with global manufacturing clients to implement real-time data-driven process optimizations, resulting in higher product reliability and lower defect rates.

4. Historical Data Analysis for Continuous Improvement

Manufacturers often need to analyze long-term trends to improve quality assurance. Cloud-based data storage and AI-driven analytics help:

Identify recurring quality issues across different production runs.

Compare past and present defect trends to refine quality control processes.

Automate compliance reporting, ensuring adherence to industry standards.

By leveraging big data analytics, businesses can develop data-backed strategies for long-term improvements in quality, compliance, and operational efficiency.

Industry Impact: Real-World Applications of Data-Driven Quality Checks

Electronics Manufacturing

High-precision electronics require defect-free components to function reliably. Data-driven quality assurance ensures:

Automated PCB inspections with AI-based optical analysis.

Material integrity testing to detect potential failures.

Automated troubleshooting to prevent device malfunctions.

Automotive Industry

Car manufacturers benefit from real-time defect tracking and predictive maintenance, reducing recalls and increasing vehicle safety.

Chassis and frame inspections for structural integrity.

AI-powered failure prediction in critical components like brakes and engines.

Supplier quality checks to ensure consistency in parts procurement.

Pharmaceutical Manufacturing

In the pharmaceutical industry, precision and compliance are critical. Data-driven quality checks help:

Detects anomalies in drug formulations to ensure patient safety.

Monitor environmental factors affecting production (temperature, humidity).

Automate batch testing to maintain regulatory compliance.

Challenges in Implementing Data-Driven Quality Control

While data-driven quality checks provide significant benefits, manufacturers may face challenges in:

Data Integration: Combining quality data from multiple sources can be complex.

Initial Investment Costs: Implementing AI and IoT-driven monitoring requires infrastructure upgrades.

Skill Gaps: Managing data analytics and AI models requires trained professionals.

However, Tudip Technologies helps businesses navigate these challenges by offering scalable, cost-effective, and customized solutions to integrate real-time analytics and AI-driven quality control systems.

Looking Ahead: The Future of Quality Assurance in Manufacturing

The future of quality control will be shaped by:

Autonomous defect detection systems that eliminate manual inspections.

AI-powered root cause analysis, reducing long-term quality issues.

Edge computing in quality monitoring, enabling real-time decision-making at production sites.

As the industry moves toward smart factories and Industry 4.0, manufacturers must adopt data-driven quality control strategies to stay competitive.

Conclusion

The shift to data-driven quality checks is transforming manufacturing by improving defect detection, predictive maintenance, automated process optimization, and long-term product reliability. Companies leveraging AI, IoT, and real-time analytics are setting new benchmarks for efficiency, consistency, and cost-effectiveness.

Click the link below to learn more about the blog How Data-Driven Quality Checks Improve Product Reliability: https://tudip.com/blog-post/leveraging-generative-ai-in-coding-practices/.

#Data-Driven Quality Control#Product Reliability Testing#Predictive Quality Analytics#Data Analytics in Manufacturing Quality#Manufacturing#Tudip Technologies#Tudip

1 note

·

View note

Text

Let us look into some IoT examples and how they are transforming the manufacturing industry.

#technology#tech#digital transformation#iot software development company#iot#industrial automation#automation#cloud computing#data driven#data automation#digital twins#manufacturing industry#iot solutions#iot services

0 notes

Text

Tesla has made Autopilot a standard feature in its cars, and more recently, rolled out a more ambitious “Full Self-Driving” (FSD) systems to hundreds of thousands of its vehicles. Now we learn from an analysis of National Highway Traffic Safety Administration (NHTSA) data conducted by The Washington Post that those systems, particularly FSD, are associated with dramatically more crashes than previously thought. Thanks to a 2021 regulation, automakers must disclose data about crashes involving self-driving or driver assistance technology. Since that time, Tesla has racked up at least 736 such crashes, causing 17 fatalities. This technology never should have been allowed on the road, and regulators should be taking a much harder look at driver assistance features in general, requiring manufacturers to prove that they actually improve safety, rather than trusting the word of a duplicitous oligarch. The primary defense of FSD is the tech utopian assumption that whatever its problems, it cannot possibly be worse than human drivers. Tesla has claimed that the FSD crash rate is one-fifth that of human drivers, and Musk has argued that it’s therefore morally obligatory to use it: “At the point of which you believe that adding autonomy reduces injury and death, I think you have a moral obligation to deploy it even though you’re going to get sued and blamed by a lot of people.” Yet if Musk’s own data about the usage of FSD are at all accurate, this cannot possibly be true. Back in April, he claimed that there have been 150 million miles driven with FSD on an investor call, a reasonable figure given that would be just 375 miles for each of the 400,000 cars with the technology. Assuming that all these crashes involved FSD—a plausible guess given that FSD has been dramatically expanded over the last year, and two-thirds of the crashes in the data have happened during that time—that implies a fatal accident rate of 11.3 deaths per 100 million miles traveled. The overall fatal accident rate for auto travel, according to NHTSA, was 1.35 deaths per 100 million miles traveled in 2022. In other words, Tesla’s FSD system is likely on the order of ten times more dangerous at driving than humans.

3K notes

·

View notes

Text

Revolutionize manufacturing decisions with AI-driven Business Intelligence. Dive into data insights, powering efficiency and innovation. Discover more!

#AI-Based BI Tools#Smart Manufacturing Intelligence#Data-Driven Decision-Making#Natural Language Generation#Generative AI Algorithms#Generative AI in BI#Traditional Analytics Methodologies#Generative AI#Predictive Maintenance

1 note

·

View note

Text

"The Netherlands is pulling even further ahead of its peers in the shift to a recycling-driven circular economy, new data shows.

According to the European Commission’s statistics office, 27.5% of the material resources used in the country come from recycled waste.

For context, Belgium is a distant second, with a “circularity rate” of 22.2%, while the EU average is 11.5% – a mere 0.8 percentage point increase from 2010.

“We are a frontrunner, but we have a very long way to go still, and we’re fully aware of that,” Martijn Tak, a policy advisor in the Dutch ministry of infrastructure and water management, tells The Progress Playbook.

The Netherlands aims to halve the use of primary abiotic raw materials by 2030 and run the economy entirely on recycled materials by 2050. Amsterdam, a pioneer of the “doughnut economics” concept, is behind much of the progress.

Why it matters

The world produces some 2 billion tonnes of municipal solid waste each year, and this could rise to 3.4 billion tonnes annually by 2050, according to the World Bank.

Landfills are already a major contributor to planet-heating greenhouse gases, and discarded trash takes a heavy toll on both biodiversity and human health.

“A circular economy is not the goal itself,” Tak says. “It’s a solution for societal issues like climate change, biodiversity loss, environmental pollution, and resource-security for the country.”

A fresh approach

While the Netherlands initially focused primarily on waste management, “we realised years ago that’s not good enough for a circular economy.”

In 2017, the state signed a “raw materials agreement” with municipalities, manufacturers, trade unions and environmental organisations to collaborate more closely on circular economy projects.

It followed that up with a national implementation programme, and in early 2023, published a roadmap to 2030, which includes specific targets for product groups like furniture and textiles. An English version was produced so that policymakers in other markets could learn from the Netherlands’ experiences, Tak says.

The programme is focused on reducing the volume of materials used throughout the economy partly by enhancing efficiencies, substituting raw materials for bio-based and recycled ones, extending the lifetimes of products wherever possible, and recycling.

It also aims to factor environmental damage into product prices, require a certain percentage of second-hand materials in the manufacturing process, and promote design methods that extend the lifetimes of products by making them easier to repair.

There’s also an element of subsidisation, including funding for “circular craft centres and repair cafés”.

This idea is already in play. In Amsterdam, a repair centre run by refugees, and backed by the city and outdoor clothing brand Patagonia, is helping big brands breathe new life into old clothes.

Meanwhile, government ministries aim to aid progress by prioritising the procurement of recycled or recyclable electrical equipment and construction materials, for instance.

State support is critical to levelling the playing field, analysts say...

Long Road Ahead

The government also wants manufacturers – including clothing and beverages companies – to take full responsibility for products discarded by consumers.

“Producer responsibility for textiles is already in place, but it’s work in progress to fully implement it,” Tak says.

And the household waste collection process remains a challenge considering that small city apartments aren’t conducive to having multiple bins, and sparsely populated rural areas are tougher to service.

“Getting the collection system right is a challenge, but again, it’s work in progress.”

...Nevertheless, Tak says wealthy countries should be leading the way towards a fully circular economy as they’re historically the biggest consumers of natural resources."

-via The Progress Playbook, December 13, 2023

#netherlands#dutch#circular economy#waste management#sustainable#recycle#environment#climate action#pollution#plastic pollution#landfill#good news#hope

522 notes

·

View notes

Text

Kenn Dahl says he has always been a careful driver. The owner of a software company near Seattle, he drives a leased Chevrolet Bolt. He’s never been responsible for an accident.

So Mr. Dahl, 65, was surprised in 2022 when the cost of his car insurance jumped by 21 percent. Quotes from other insurance companies were also high. One insurance agent told him his LexisNexis report was a factor.

LexisNexis is a New York-based global data broker with a “Risk Solutions” division that caters to the auto insurance industry and has traditionally kept tabs on car accidents and tickets. Upon Mr. Dahl’s request, LexisNexis sent him a 258-page “consumer disclosure report,” which it must provide per the Fair Credit Reporting Act.

What it contained stunned him: more than 130 pages detailing each time he or his wife had driven the Bolt over the previous six months. It included the dates of 640 trips, their start and end times, the distance driven and an accounting of any speeding, hard braking or sharp accelerations. The only thing it didn’t have is where they had driven the car.

On a Thursday morning in June for example, the car had been driven 7.33 miles in 18 minutes; there had been two rapid accelerations and two incidents of hard braking.

According to the report, the trip details had been provided by General Motors — the manufacturer of the Chevy Bolt.

Eight insurance companies had requested information about Mr. Dahl from LexisNexis over the previous month.

(continue reading)

75 notes

·

View notes