#Textile Machine Monitoring

Explore tagged Tumblr posts

Text

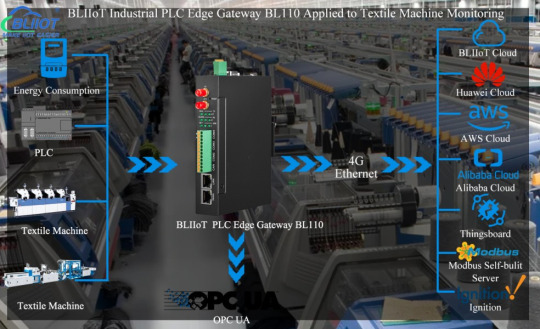

BLIIoT Industrial PLC Edge Gateway BL110 Applied to Textile Machine Monitoring

1. Foreword

With the continuous and rapid development of the textile industry, intelligent control technology, field bus technology and digital display technology have been widely used in textile equipment. In order to improve the management of small sample spinning equipment and improve the competitiveness of enterprises, textile equipment enterprises want to use advanced automation technology and information technology to carry out informatization transformation of equipment.

2. Textile Machine Remote Monitoring System

The entire system network is divided into 3 layers: management layer, control layer and equipment layer Spinning equipment mainly includes digital sample carding machine, sample draw frame, sample comber, sample roving frame, sample spinning frame and sample doubling machine , through the BLIIoT Industrial PLC Edge Gateway BL110 and the core controller of the textile machine equipment (such as PLC), combined with communication methods such as 4G, Wifi, Ethernet and GPRS, the data collected by each device includes the operating status of the equipment, output, efficiency, Process parameters, abnormal alarm information and other teaching data are transmitted to the server/cloud.

The system can use the BLIIoT Industrial PLC Edge Gateway BL110 to collect meter data, and the online monitoring module can monitor the voltage, current, power, power factor, energy consumption and other indicators of the host and auxiliary equipment in real time, and can realize the following functions: compare the energy consumption of different machines Data, check abnormal data in a timely manner; reproduce the power change trend of the machine in the last 24, 48, and 72 hours, and find equipment problems in time; count the total power consumption of the machine, process, variety, etc., and the data of power consumption per ton of yarn to form various Class reports, visually compare and display devices with abnormal power consumption, and provide targeted improvement suggestions.

3. BLIIoT Industrial PLC Edge Gateway BL110

◆ Using 4G wireless network and Ethernet redundant data upload method, stable and reliable;

◆ Embedded ARM9 32-bit Linux kernel real-time operating system and watchdog function;

◆ Wide working voltage design with anti-reverse protection design;

◆ Supports Mitsubishi, Siemens, Delta, Schneider, ABB, Huichuan, Omron, Panasonic, Hollysys and other PLC protocols;

◆ 4 serial ports support modbus master-slave protocol, support modbus / mqtt / private custom protocol upload;

◆ All 4 serial ports support transparent transmission, and the CAN port supports data of CAN communication equipment, such as server;

◆ It can collect the data of the network port PLC or other network port equipment through the Ethernet interface;

◆ Support OPC client function, can read data provided by OPC server of other manufacturers;

◆ Support multiple data storage functions according to cycle, change, condition, etc .;

◆ Support multi-level data security rights management function;

◆ Support multiple alarm conditions, such as alarm conditions, urgency, confirmation rules, push rules, and SMS push;

◆ Support power failure alarm function; (optional)

◆ Support remote PLC download programming and remote collection of PLC equipment, set conditions to stop PLC operation;

◆ Support routing function and access video surveillance camera;

◆ Support mainstream public cloud platforms such as Alibaba Cloud and AWS Cloud;

◆ Support third-party manufacturers custom development, provide hardware and SDK interface

◆ Support BLRMS;

◆ Embedded TCP / IP protocol stack, support TCP, UDP protocol, TCP Server and TCP Client services;

4. Summarize

By connecting the textile equipment and PLC to BLIIoT Industrial PLC Edge Gateway BL110, real-time data collection is carried out on the equipment, and the equipment operation status and fault alarm information are fed back to the management personnel in a timely manner, so that the equipment can be checked online and offline, operation failure and other information anytime and anywhere, and with the help of the equipment maintenance express line Realize operations such as remote uploading and downloading of programs, remote programming and debugging.

The data collection of intelligent instruments on the textile factory site can realize real-time monitoring of production environment and energy consumption, monitoring of environmental temperature and humidity, gas and energy consumption data, can feed back accurate and reliable data to the staff, and take timely measures for management and control. It plays an important role in equipment and personal safety as well as energy saving optimization.

More information about BLIIoT Industrial PLC Edge Gateway BL110: https://gateway-iot.com/industrial-iot-edge-gateway-p00272p1.html

#iot devices#smartcities#iot solutions#industrial automation#industrial iot#datacollection#Textile Machine Monitoring

0 notes

Text

100 Inventions by Women

LIFE-SAVING/MEDICAL/GLOBAL IMPACT:

Artificial Heart Valve – Nina Starr Braunwald

Stem Cell Isolation from Bone Marrow – Ann Tsukamoto

Chemotherapy Drug Research – Gertrude Elion

Antifungal Antibiotic (Nystatin) – Rachel Fuller Brown & Elizabeth Lee Hazen

Apgar Score (Newborn Health Assessment) – Virginia Apgar

Vaccination Distribution Logistics – Sara Josephine Baker

Hand-Held Laser Device for Cataracts – Patricia Bath

Portable Life-Saving Heart Monitor – Dr. Helen Brooke Taussig

Medical Mask Design – Ellen Ochoa

Dental Filling Techniques – Lucy Hobbs Taylor

Radiation Treatment Research – Cécile Vogt

Ultrasound Advancements – Denise Grey

Biodegradable Sanitary Pads – Arunachalam Muruganantham (with women-led testing teams)

First Computer Algorithm – Ada Lovelace

COBOL Programming Language – Grace Hopper

Computer Compiler – Grace Hopper

FORTRAN/FORUMAC Language Development – Jean E. Sammet

Caller ID and Call Waiting – Dr. Shirley Ann Jackson

Voice over Internet Protocol (VoIP) – Marian Croak

Wireless Transmission Technology – Hedy Lamarr

Polaroid Camera Chemistry / Digital Projection Optics – Edith Clarke

Jet Propulsion Systems Work – Yvonne Brill

Infrared Astronomy Tech – Nancy Roman

Astronomical Data Archiving – Henrietta Swan Leavitt

Nuclear Physics Research Tools – Chien-Shiung Wu

Protein Folding Software – Eleanor Dodson

Global Network for Earthquake Detection – Inge Lehmann

Earthquake Resistant Structures – Edith Clarke

Water Distillation Device – Maria Telkes

Portable Water Filtration Devices – Theresa Dankovich

Solar Thermal Storage System – Maria Telkes

Solar-Powered House – Mária Telkes

Solar Cooker Advancements – Barbara Kerr

Microbiome Research – Maria Gloria Dominguez-Bello

Marine Navigation System – Ida Hyde

Anti-Malarial Drug Work – Tu Youyou

Digital Payment Security Algorithms – Radia Perlman

Wireless Transmitters for Aviation – Harriet Quimby

Contributions to Touchscreen Tech – Dr. Annette V. Simmonds

Robotic Surgery Systems – Paula Hammond

Battery-Powered Baby Stroller – Ann Moore

Smart Textile Sensor Fabric – Leah Buechley

Voice-Activated Devices – Kimberly Bryant

Artificial Limb Enhancements – Aimee Mullins

Crash Test Dummies for Women – Astrid Linder

Shark Repellent – Julia Child

3D Illusionary Display Tech – Valerie Thomas

Biodegradable Plastics – Julia F. Carney

Ink Chemistry for Inkjet Printers – Margaret Wu

Computerised Telephone Switching – Erna Hoover

Word Processor Innovations – Evelyn Berezin

Braille Printer Software – Carol Shaw

⸻

HOUSEHOLD & SAFETY INNOVATIONS:

Home Security System – Marie Van Brittan Brown

Fire Escape – Anna Connelly

Life Raft – Maria Beasley

Windshield Wiper – Mary Anderson

Car Heater – Margaret Wilcox

Toilet Paper Holder – Mary Beatrice Davidson Kenner

Foot-Pedal Trash Can – Lillian Moller Gilbreth

Retractable Dog Leash – Mary A. Delaney

Disposable Diaper Cover – Marion Donovan

Disposable Glove Design – Kathryn Croft

Ice Cream Maker – Nancy Johnson

Electric Refrigerator Improvements – Florence Parpart

Fold-Out Bed – Sarah E. Goode

Flat-Bottomed Paper Bag Machine – Margaret Knight

Square-Bottomed Paper Bag – Margaret Knight

Street-Cleaning Machine – Florence Parpart

Improved Ironing Board – Sarah Boone

Underwater Telescope – Sarah Mather

Clothes Wringer – Ellene Alice Bailey

Coffee Filter – Melitta Bentz

Scotchgard (Fabric Protector) – Patsy Sherman

Liquid Paper (Correction Fluid) – Bette Nesmith Graham

Leak-Proof Diapers – Valerie Hunter Gordon

FOOD/CONVENIENCE/CULTURAL IMPACT:

Chocolate Chip Cookie – Ruth Graves Wakefield

Monopoly (The Landlord’s Game) – Elizabeth Magie

Snugli Baby Carrier – Ann Moore

Barrel-Style Curling Iron – Theora Stephens

Natural Hair Product Line – Madame C.J. Walker

Virtual Reality Journalism – Nonny de la Peña

Digital Camera Sensor Contributions – Edith Clarke

Textile Color Processing – Beulah Henry

Ice Cream Freezer – Nancy Johnson

Spray-On Skin (ReCell) – Fiona Wood

Langmuir-Blodgett Film – Katharine Burr Blodgett

Fish & Marine Signal Flares – Martha Coston

Windshield Washer System – Charlotte Bridgwood

Smart Clothing / Sensor Integration – Leah Buechley

Fibre Optic Pressure Sensors – Mary Lou Jepsen

#women#inventions#technology#world#history#invented#creations#healthcare#home#education#science#feminism#feminist

48 notes

·

View notes

Text

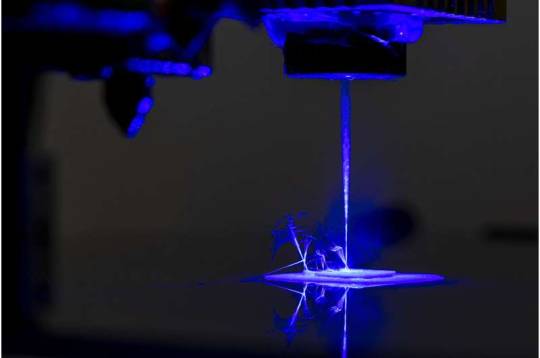

No assembly required: Innovative 3D printing method streamlines multi-materials manufacturing

University of Missouri researchers have developed a way to create complex devices with multiple materials—including plastics, metals and semiconductors—all with a single machine. The research, which was recently published in Nature Communications, outlines a novel 3D printing and laser process to manufacture multi-material, multi-layered sensors, circuit boards and even textiles with electronic components. It's called the Freeform Multi-material Assembly Process, and it promises to revolutionize the fabrication of new products. By printing sensors embedded within a structure, the machine can make things that can sense environmental conditions, including temperature and pressure. For other researchers, that could mean having a natural-looking object such as a rock or seashell that could measure the movement of ocean water. For the public, applications could include wearable devices that monitor blood pressure and other vital signs.

Read more.

17 notes

·

View notes

Text

Udaan by InAmigos Foundation: Elevating Women, Empowering Futures

In the rapidly evolving socio-economic landscape of India, millions of women remain underserved by mainstream development efforts—not due to a lack of talent, but a lack of access. In response, Project Udaan, a flagship initiative by the InAmigos Foundation, emerges not merely as a program, but as a model of scalable women's empowerment.

Udaan—meaning “flight” in Hindi—represents the aspirations of rural and semi-urban women striving to break free from intergenerational limitations. By engineering opportunity and integrating sustainable socio-technical models, Udaan transforms potential into productivity and promise into progress.

Mission: Creating the Blueprint for Women’s Self-Reliance

At its core, Project Udaan seeks to:

Empower women with industry-aligned, income-generating skills

Foster micro-entrepreneurship rooted in local demand and resources

Facilitate financial and digital inclusion

Strengthen leadership, health, and rights-based awareness

Embed resilience through holistic community engagement

Each intervention is data-informed, impact-monitored, and custom-built for long-term sustainability—a hallmark of InAmigos Foundation’s field-tested grassroots methodology.

A Multi-Layered Model for Empowerment

Project Udaan is built upon a structured architecture that integrates training, enterprise, and technology to ensure sustainable outcomes. This model moves beyond skill development into livelihood generation and measurable socio-economic change.

1. Skill Development Infrastructure

The first layer of Udaan is a robust skill development framework that delivers localized, employment-focused education. Training modules are modular, scalable, and aligned with the socio-economic profiles of the target communities.

Core domains include:

Digital Literacy: Basic computing, mobile internet use, app navigation, and digital payment systems

Tailoring and Textile Production: Pattern making, machine stitching, finishing techniques, and indigenous craft techniques

Food Processing and Packaging: Pickle-making, spice grinding, home-based snack units, sustainable packaging

Salon and Beauty Skills: Basic grooming, hygiene standards, customer interaction, and hygiene protocols

Financial Literacy and Budgeting: Saving schemes, credit access, banking interfaces, micro-investments

Communication and Self-Presentation: Workplace confidence, customer handling, local language fluency

2. Microenterprise Enablement and Livelihood Incubation

To ensure that learning transitions into economic self-reliance, Udaan incorporates a post-training enterprise enablement process. It identifies local market demand and builds backward linkages to equip women to launch sustainable businesses.

The support ecosystem includes:

Access to seed capital via self-help group (SHG) networks, microfinance partners, and NGO grants

Distribution of startup kits such as sewing machines, kitchen equipment, or salon tools

Digital onboarding support for online marketplaces such as Amazon Saheli, Flipkart Samarth, and Meesho

Offline retail support through tie-ups with local haats, trade exhibitions, and cooperative stores

Licensing and certification where applicable for food safety or textile quality standards

3. Tech-Driven Monitoring and Impact Tracking

Transparency and precision are fundamental to Udaan’s growth. InAmigos Foundation employs its in-house Tech4Change platform to manage operations, monitor performance, and scale the intervention scientifically.

The platform allows:

Real-time monitoring of attendance, skill mastery, and certification via QR codes and mobile tracking

Impact evaluation using household income change, asset ownership, and healthcare uptake metrics

GIS-based mapping of intervention zones and visualization of under-reached areas

Predictive modeling through AI to identify at-risk participants and suggest personalized intervention strategies

Human-Centered, Community-Rooted

Empowerment is not merely a process of economic inclusion—it is a cultural and psychological shift. Project Udaan incorporates gender-sensitive design and community-first outreach to create lasting change.

Key interventions include:

Strengthening of SHG structures and women-led federations to serve as peer mentors

Family sensitization programs targeting male allies—fathers, husbands, brothers—to reduce resistance and build trust

Legal and rights-based awareness campaigns focused on menstrual hygiene, reproductive health, domestic violence laws, and maternal care

Measured Impact and Proven Scalability

Project Udaan has consistently delivered quantifiable outcomes at the grassroots level. As of the latest cycle:

Over 900 women have completed intensive training programs across 60 villages and 4 districts

Nearly 70 percent of participating women reported an average income increase of 30 to 60 percent within 9 months of program completion

420+ micro-enterprises have been launched, 180 of which are now self-sustaining and generating employment for others

More than 5,000 indirect beneficiaries—including children, elderly dependents, and second-generation SHG members—have experienced improved access to nutrition, education, and mobility

Over 20 institutional partnerships and corporate CSR collaborations have supported infrastructure, curriculum design, and digital enablement.

Partnership Opportunities: Driving Collective Impact

The InAmigos Foundation invites corporations, philanthropic institutions, and ecosystem enablers to co-create impact through structured partnerships.

Opportunities include:

Funding the establishment of skill hubs in high-need regions

Supporting enterprise starter kits and training batches through CSR allocations

Mentoring women entrepreneurs via employee volunteering and capacity-building workshops

Co-hosting exhibitions, market linkages, and rural entrepreneurship fairs

Enabling long-term research and impact analytics for policy influence

These partnerships offer direct ESG alignment, brand elevation, and access to inclusive value chains while contributing to a model that demonstrably works.

What Makes Project Udaan Unique?

Unlike one-size-fits-all skilling programs, Project Udaan is rooted in real-world constraints and community aspirations. It succeeds because it combines:

Skill training aligned with current and emerging market demand

Income-first design that integrates microenterprise creation and financial access

Localized community ownership that ensures sustainability and adoption

Tech-enabled operations that ensure transparency and iterative learning

Holistic empowerment encompassing economic, social, and psychological dimensions

By balancing professional training with emotional transformation and economic opportunity, Udaan represents a new blueprint for inclusive growth.

From Promise to Power

Project Udaan, driven by the InAmigos Foundation, proves that when equipped with tools, trust, and training, rural and semi-urban women are capable of becoming not just contributors, but catalysts for socio-economic renewal.

They don’t merely escape poverty—they design their own systems of progress. They don’t just participate—they lead.

Each sewing machine, digital training module, or microloan is not a transaction—it is a declaration of possibility.

This is not charity. This is infrastructure. This is equity, by design.

Udaan is not just a program. It is a platform for a new India.

For partnership inquiries, CSR collaborations, and donation pathways, contact: www.inamigosfoundation.org/Udaan Email: [email protected]

3 notes

·

View notes

Note

lmk when the listing is posted I would love to apply. what are the qualifications

He sighs, not looking up from his sewing machine.

"We have a few different roles to fill.

For one, it would be nice to have someone who explicitly studied fashion merchandising or marketing. It was something that I dabbled in, but of course my and Arvyne's specialties lie in design and textile sciences, and I admit, we are not as well-organized as we ought to be.

However, that is less important than actual clothesmaking. That is where we need the most help, simply because we need to be able to keep up with our orders. We outsource aid for our regular clothing lines, and simply tailor as necessary in-shop, but our specialty is actually in custom clothing and designs, and it is not something I or Arvyne would feel comfortable outsourcing. It just would not be up to my own standards, and it would be unfair on our clientele.

We would both prefer trolls with a degree in textile sciences, of course, but a sufficient amount of skill and attention to detail would be enough for us. A trial period would also be absolutely necessary, so we could monitor their work before making our final decision. I know we can't afford to be too picky, but... I do not want our quality to suffer."

9 notes

·

View notes

Text

Top Trends in Digital Textile Printing for 2025

Digital textile printing continues to revolutionize the textile industry, offering unmatched precision, customization, and speed. As we step into 2025, True Colors Group is at the forefront of innovation, ensuring businesses stay ahead of the curve. Here are the top trends shaping the future of digital textile printing.

Sustainability Takes Center Stage

Environmental concerns are driving the adoption of sustainable practices across industries, and textile printing is no exception. Digital textile printing significantly reduces water and energy usage compared to traditional methods, making it a preferred choice for eco-conscious businesses. True Colors Group emphasizes sustainability by using advanced printing machines that minimize waste while delivering vibrant, high-quality results.

Enhanced Print Speeds and Precision

Advancements in printing machine technology have led to faster production times without compromising quality. In 2025, expect to see digital textile printing machines equipped with AI-driven features that ensure flawless precision and consistent results, even for large-scale production runs. These developments empower businesses to meet growing demand while maintaining impeccable standards.

Rise of Customization and Personalization

Consumers increasingly seek unique, personalized products, and digital textile printing is the perfect solution. From custom apparel to personalized home décor, businesses can use digital technology to create bespoke designs with ease. True Colors Group leverages this trend by providing cutting-edge sublimation printing options that cater to diverse customer needs.

Integration of Smart Technologies

Smart technologies, including IoT and AI, are transforming how printing machines operate. These innovations enable real-time monitoring, predictive maintenance, and seamless workflow integration, reducing downtime and enhancing efficiency. True Colors Group stays ahead by adopting smart textile printing solutions that ensure optimal performance and customer satisfaction.

Expanding Applications in Fashion and Beyond

While fashion remains a primary focus for digital textile printing, new applications are emerging in sectors like interior design, automotive, and sportswear. Sublimation printing is particularly popular for creating durable, high-quality prints on a variety of materials, including polyester and blended fabrics.

In 2025, True Colors Group continues to push boundaries in digital textile printing, offering businesses the tools and expertise needed to succeed in a competitive market. By embracing these trends, companies can unlock new opportunities and deliver exceptional value to their customers.

2 notes

·

View notes

Text

Top 5 Misconceptions About Biomass Gasifiers (And the Truth Behind Them)

As industries and rural enterprises seek cleaner alternatives to fossil fuels, biomass gasifiers are gaining attention for their reliability and sustainability. However, despite growing adoption, several myths and misconceptions still surround this technology.

At Veera Group, we’ve worked with hundreds of clients across India, helping them understand and unlock the full potential of biomass gasification. Today, we’re debunking the top 5 misconceptions about biomass gasifiers—and showing why they’re one of the most practical and powerful renewable energy options available today.

Misconception #1: “Biomass Gasifiers Are Only for Large Factories”

Truth: This is one of the most common myths. Many people believe that gasifier systems are too complex or large for small and medium-sized enterprises (SMEs). In reality, biomass gasifiers are scalable and can be customized to meet the needs of both small workshops and large industries.

Veera Group’s biomass gasifier machines are available in various capacities—ranging from a few kilowatts to hundreds. Whether you’re a rural entrepreneur or a factory owner, there’s a solution that fits your energy profile.

Misconception #2: “Biomass Feedstock Is Expensive and Hard to Find”

Truth: Biomass fuel is one of the most affordable and readily available energy sources in rural and agro-based regions. Materials like rice husk, coconut shells, wood chips, and groundnut shells are often agricultural waste products that would otherwise be discarded or burned.

In fact, one of the biggest advantages of biomass gasification is its ability to utilize local waste resources—reducing costs and environmental impact. Veera Group helps clients source and manage their biomass supply chain for consistent and cost-effective operations.

Misconception #3: “Gasifier Systems Are Difficult to Operate and Maintain”

Truth: While the science behind gasification may seem complex, modern gasifier machines are user-friendly and designed for easy operation. Veera Group provides complete training for operators, including how to start, monitor, and maintain the system.

Routine tasks such as feedstock loading, ash removal, and system checks can be handled by local staff with basic technical skills. Plus, Veera Group offers after-sales service and remote diagnostics to ensure smooth, uninterrupted performance.

Misconception #4: “Biomass Energy Is Not Reliable for Continuous Operations”

Truth: Unlike solar and wind power, which are weather-dependent, biomass gasifiers offer on-demand, continuous energy output. As long as there’s feedstock, your system will produce gas for thermal applications or electricity generation.

Industries that operate 24/7—such as food processing, textile manufacturing, and engineering workshops—have successfully replaced diesel generators with biomass gasifiers. You can read about these real-world applications in the Veera Group blog.

Misconception #5: “Gasifiers Produce a Lot of Pollution”

Truth: When designed and operated properly, biomass gasifiers are a clean energy solution. They produce significantly fewer emissions compared to diesel and coal, and they prevent open-air burning of biomass—one of the leading causes of rural air pollution.

Modern gasifier systems from Veera Group include gas cleaning units and emission controls that comply with environmental norms. Not only are you switching to a renewable fuel, but you’re also actively contributing to cleaner air and a greener planet.

Conclusion

Misconceptions can hold back progress—but the facts speak for themselves. Biomass gasification is safe, affordable, reliable, and sustainable. With a trusted partner like Veera Group, industries of all sizes can confidently adopt biomass energy and enjoy long-term benefits.

If you’ve hesitated because of these myths, it’s time to reconsider. Visit Veera Group’s biomass gasifier machine page to learn more or contact their team for a free consultation tailored to your needs.

1 note

·

View note

Text

AI-Powered Textile Dyeing: Revolutionizing Sustainability and Quality

The textile dyeing industry is undergoing a major transformation thanks to AI and machine learning (ML). Traditional dyeing is water- and chemical-intensive, often resulting in inconsistent colors and significant waste. Now, AI-driven technologies are optimizing every step of the dyeing process—cutting waste, improving quality, and reducing environmental impact.

How AI is changing textile dyeing:

🔹Precision Color Prediction: Machine learning models trained on hundreds of fabric samples can accurately predict how colors will change from wet to dry states, eliminating costly errors and reducing fabric waste. This breakthrough helps manufacturers catch color mismatches early, saving time and resources.

🔹Real-Time Process Optimization: AI algorithms dynamically adjust water, dye, and chemical use based on fabric type and dye properties. Companies like Alchemie Technology have reported up to 95% reductions in water consumption during dyeing, a monumental leap for sustainability.

🔹AI-Driven Dyeing Machines: Baldwin Technology and others have developed AI-powered finishing systems that automatically regulate dye flow and application, ensuring uniform color distribution and minimizing dye waste.

🔹Digital Twin Technology: Siemens and industry leaders use virtual replicas of the dyeing process to simulate and optimize production before actual runs, reducing trial-and-error waste and improving efficiency.

🔹On-Demand Customization: AI enables precise color matching and tailored dye recipes, supporting personalized fashion trends while minimizing inventory and overproduction.

🔹Predictive Maintenance: AI monitors dyeing machinery to forecast maintenance needs, reducing downtime and extending equipment life, which enhances operational efficiency and sustainability.

Why this matters:

Textile dyeing accounts for a large share of global water pollution and resource use. AI integration is driving a fundamental shift, enabling manufacturers to meet high-quality standards while drastically lowering environmental footprints. This STEM-driven innovation supports circular economy goals and aligns with growing consumer demand for sustainable fashion.

The future of textile manufacturing is intelligent, efficient, and green, powered by AI and STEM expertise.

#STEM #Sustainability #AI #TextileInnovation #CleanTech #CircularEconomy #FashionTech #GreenManufacturing

0 notes

Text

10 Best Practices for Digital Tensile Testing

Source of Info: https://www.perfectgroupindia.co.in/10-best-practices-for-digital-tensile-testing.php

One of the fundamental techniques used in material analysis to assess the mechanical characteristics of different materials is digital tensile testing. It yields very useful data regarding tensile strength, elasticity, ductility, and other properties for a wide range of materials, including metals, polymers, textiles, and composites. It is crucial to comprehend the best practices in order to maximize the effectiveness of this potent method. The following list of the top ten digital tensile testing best practices will assist you in optimizing your material analysis workflow and discovering fresh avenues for material characterization.

Calibration Confidence Make sure your testing apparatus is calibrated accurately and up to date to start with a strong base. Frequent calibration checks provide accurate and dependable results, boosting the confidence you have in your testing procedure.

Sample Selection Savvy Make careful selections of your samples, taking into account aspects like surface condition, size, shape, and homogeneity of material. Properly prepared samples minimize variability and improve data integrity by guaranteeing consistency and repeatability in test results.

Gripping Guidance Right sample holding is essential for precise and representative test results. Choose grips that are appropriate for the shape and type of material you are using to ensure even stress distribution and avoid early sample failure.

Strain Sensibility Optimize strain measurement accuracy by selecting an appropriate extensometer and ensuring proper installation and alignment. Precise strain control enables detailed analysis of material behavior under various loading conditions.

Speed Selection To properly capture important material responses, strike the ideal balance between the speed of the test and the rate at which data is acquired. Adjust testing parameters based on the deformation properties of your material to prevent over- or undersampling of the data.

Temperature Tact Consider the effects of temperature on the properties of the materials by conducting tests in controlled environments. Temperature baths or chambers allow for the assessment of both mechanical and thermal properties while preserving the integrity of the specimen.

Data Delve Utilize cutting-edge software features to process post-test data and monitor in real-time as you delve deeply into analyze data. To fully comprehend the performance of a material, extract insightful information from fracture analysis, stress-strain curves, and modulus calculations.

Safety Spotlight Give priority to safety procedures so that during testing operations both people and equipment are protected. To effectively reduce potential hazards, put in place the necessary safety measures, such as personnel training, emergency stop mechanisms, and machine guarding.

Standard Compliance Adhere to relevant industry standards and testing protocols to ensure consistency and comparability of results. Familiarize yourself with ASTM, ISO, or other applicable standards, and follow prescribed procedures meticulously to maintain credibility and reliability in your testing endeavors.

Continuous Improvement Embrace a culture of continuous improvement by soliciting feedback, conducting regular audits, and staying abreast of technological advancements in digital tensile testing. Strive for excellence in every aspect of your testing process, driving innovation and pushing the boundaries of material analysis.

Conclusion In conclusion, you can fully realize the potential of this adaptable method for material characterization by learning the best practices for digital tensile testing. You may improve the precision, dependability, and effectiveness of your testing processes by following calibration guidelines, making the most of sample preparation, and utilizing cutting-edge data analysis technologies. As you proceed with your material analysis journey, adopt these best practices as a guide to help you make ground-breaking discoveries and breakthroughs in the fields of materials science and engineering.

Build an environment of ongoing learning and development within your company by working together with colleagues and industry experts to share best practices and insights. In materials science and engineering, you can lead significant breakthroughs and stay ahead of the curve by adopting a proactive and forward-thinking approach, which will ultimately shape the field's future.

Frequently Asked Questions (FAQs)

Q: What is digital tensile testing? Digital tensile testing is a method used to evaluate the mechanical properties of materials by applying tension until the material breaks.

Q: Why is digital tensile testing important? Understanding a material's strength, elasticity, and ductility is essential for a variety of industries, including manufacturing, construction, and aerospace. Digital tensile testing offers valuable insights into these properties.

Q: How often should calibration checks be performed? As advised by the manufacturer, calibration checks ought to be carried out on a regular basis—typically, at least once a year or whenever there is a substantial alteration in the testing environment.

Q: What types of materials can be tested using digital tensile testing? Metals, polymers, textiles, and composites are just a few of the materials that can be tested using digital tensile testing.

Q: How can I improve the accuracy of my digital tensile testing results? To improve accuracy, ensure proper sample preparation, select appropriate testing parameters, and adhere to relevant industry standards and protocols.

0 notes

Text

How Andon Devices Improve Manufacturing Efficiency – A Smart Factory Essential

Introduction

In today’s competitive manufacturing landscape, operational efficiency and real-time communication are critical. As factories move toward Industry 4.0, tools like the Andon device are becoming essential for lean production environments. An Andon system serves as an immediate visual and/or audible alert mechanism that highlights issues on the shop floor, enabling faster response times and reducing costly downtimes.

What is an Andon Device?

An Andon device is a signal system used in industrial settings to alert operators, supervisors, or maintenance teams about problems or abnormalities in real time. Traditionally, Andon systems were simple light signals. However, modern solutions—like those offered by Glansa Solutions—come with digital displays, IoT integration, and real-time data tracking.

Why Use an Andon Device?

Real-Time Communication: Operators can immediately alert others to issues without leaving their station.

Reduced Downtime: Early detection allows teams to resolve problems faster.

Increased Accountability: Tracks how long issues persist and who responded.

Better Decision Making: Collected data helps in analyzing production trends and implementing continuous improvements.

Key Features of Glansa’s Andon System

✔️ Visual and audible alerting

✔️ Custom-configurable signals

✔️ Web-based dashboard for real-time monitoring

✔️ Seamless integration with ERP and MES systems

✔️ IoT-enabled for smart factory use

Use Cases in Manufacturing

Glansa’s Andon devices are used in various sectors including automotive, electronics, textiles, and FMCG industries. Whether it’s to notify quality checks, machine breakdowns, or material shortages, Andon devices ensure faster responses and increased production visibility.

Why Choose Glansa Solutions?

Glansa Solutions is a trusted name in industrial automation and smart factory tools. With years of experience, we deliver scalable and intelligent Andon systems that help manufacturers meet their production goals while embracing digital transformation.

Conclusion

Investing in a robust Andon device is a smart move for manufacturers aiming to boost shop floor transparency and operational efficiency. With solutions like those from Glansa, businesses can stay ahead in the era of smart manufacturing.

📍 Learn more: https://glansa.com

#Andon Device#Manufacturing Technology#Glansa Solutions#Lean Manufacturing#Production Monitoring#Smart Factory#Industrial Automation#Shop Floor Management

0 notes

Text

Understanding the Quality Standards of Spun Polyester Yarn in India

When it comes to the textile industry, quality is everything — especially in yarn manufacturing. Among the many varieties of yarns available, spun polyester yarn stands out for its strength, durability, and versatility. In India, which is a global textile powerhouse, maintaining high-quality standards in yarn production is not just a benchmark — it’s a necessity. This blog explores how Spun Polyester Yarn Producers in India, including reputed names like SD Polytech, are setting industry standards and meeting international expectations.

What Is Spun Polyester Yarn?

Spun polyester yarn is made from polyester fibers that are spun together to form a strong, stable thread. It is widely used in various applications such as garments, home furnishings, and industrial textiles. Compared to filament polyester yarn, spun polyester is softer and behaves similarly to cotton — making it a popular blend in technical and everyday fabrics.

The Importance of Quality Standards in Yarn Production

High-quality yarn ensures:

Better fabric performance

Consistency in dyeing and finishing

Higher durability and tensile strength

Improved machinability for manufacturers

For these reasons, quality control plays a pivotal role in the entire yarn manufacturing process.

Key Quality Parameters Followed by Indian Producers

Reputed Spun Polyester Yarn Producers in India adhere to strict quality parameters, including:

Fiber Length & Strength: Ensures smooth spinning and minimizes breakage.

Evenness & Twist Consistency: Critical for uniform fabric texture.

Color Fastness: For better dye uptake and vibrant, lasting colors.

Moisture Content: Proper conditioning of yarn for flexibility and durability.

Contamination Control: Using modern machinery to eliminate neps and foreign particles.

These parameters are often guided by BIS (Bureau of Indian Standards), ISO certifications, and customer-specific quality audits.

How SD Polytech Sets the Benchmark

Among the leading names in this sector, SD Polytech is recognized as both a Cotton Yarn Manufacturer in India and a pioneer in high-performance synthetic and blended yarns. Their production units are equipped with:

Automated spinning systems

Uster-tested quality monitoring

Blending technology for technical yarns

Sustainable processing units with eco-friendly practices

Their commitment to international standards and innovative solutions makes them a preferred supplier for global and domestic textile brands.

The Intersection of Polyester and Cotton: Hybrid Innovation

Many Indian manufacturers, including SD Polytech, are exploring cotton-polyester blends to combine the softness of natural fiber with the resilience of synthetics. These technical yarns offer excellent strength, moisture management, and versatility — suitable for sportswear, uniforms, and industrial fabrics.

Why Indian Producers Are Global Favorites

India’s competitive edge lies in:

Skilled labor

Access to raw materials

Technological advancements

Strong supply chain infrastructure

The best Spun Polyester Yarn Producers in India not only cater to domestic markets but also export to Europe, the USA, the Middle East, and Southeast Asia, ensuring consistent quality and timely delivery.

Final Thoughts

In the fast-evolving world of textiles, quality isn’t optional — it’s essential. Indian yarn manufacturers, especially leaders like SD Polytech, are not just meeting global expectations but often exceeding them. Whether you're sourcing polyester, cotton, or blended yarns, partnering with a quality-driven producer ensures long-term benefits for your brand.

Looking for a reliable Cotton Yarn Manufacturer in India or a top-tier producer of Spun Polyester Yarn? SD Polytech offers a blend of innovation, quality, and trust — making them a go-to name in the yarn manufacturing industry.

Also Read:

The Role of Cotton Yarn Manufacturers in Delhi’s Textile Growth

How Technical Yarns Are Revolutionizing the Textile Industry

0 notes

Text

Mastering Modern Beekeeping: Tools, Techniques, and Trusted Suppliers

Introduction

Beekeeping today is at the intersection of tradition and innovation. Hobbyists and large-scale commercial beekeepers alike now rely on data-driven decisions, advanced tools, and access to reliable suppliers. Achieving excellence requires not only a deep understanding of bee biology but also mastery over the tools, techniques, and logistics that support consistent, safe, and productive hive management.

Heliotrope Bee, established in 2012 in the global textile hub of Sialkot, Pakistan, has evolved into the world’s largest manufacturer and supplier of beekeeping apparel and accessories. In this comprehensive guide, we explore essential modern equipment and methods, examine best practices developed by industry leaders, and elaborate on how selecting the right supplier—like Heliotrope Bee—can elevate your operations to new heights.

1. Core Beekeeping Tools in the Modern Apiary

1.1 Hive Tools and Frame Manipulation

The foundation of any hive interaction is the humble hive tool. Today’s models—crafted from stainless steel or reinforced alloys—feature ergonomic grips and integrated scrapers for:

Prising open supers

Cleaning propolis from frames

Separating hive bodies

Despite machine precision in hive construction, these tools remain indispensable. Keeping them clean and sharp ensures efficiency and longevity.

1.2 Smokers with Precision Flow Control

Smokers have advanced from metal cones to units with airflow regulators and double-walled barrels for insulation. Maintain a consistent, cool smoke stream for:

Reducing bee defensiveness

Minimizing queen stress

Preparing the hive for inspections

Heliotrope Bee offers protective garments designed to withstand smoker heat and provide mobility when flames and tools are active.

1.3 Frame Grippers, Brushes, and Feeding Tools

Modern hives use magnetic frame grippers to lift frames cleanly and avoid accidental brood or comb damage. Soft, bristle-free bee brushes allow easy clearing of bees without injuring them, and automated feeders support supplemental feed during nectar dearths.

Heliotrope Bee’s vents and reinforced gloves are engineered to give maximum tactile feedback during these tasks.

2. Instruments for Scientific Hive Monitoring

Beekeeping has gone high-tech with on-hive sensors and data systems that track:

Internal temperature

Humidity

Hive weight

Bee vibration activity

These metrics help detect swarming, brood collapse, or queen failure—often before visible signs appear. Portable readers allow apiary-wide monitoring from mobile devices, enabling remote alerts for critical events.

Heliotrope Bee collaborates with technology suppliers to outfit keepers with sensor-ready suits and reinforced pockets for data devices, maximizing efficiency and safety.

3. Inspection & Health Management Protocols

3.1 Integrated Pest and Disease Control

Effective Integrated Pest Management (IPM) requires:

Routine alcohol washes or sugar rolls for Varroa assessment

Screened bottom boards for passive mite control

Targeted biotechnical interventions like drone brood removal

High-quality protective wear minimizes the risk to keepers when administering treatments such as oxalic or thymol applications.

3.2 Seasonal and Forensic Hive Audits

Create documented inspection logs that capture:

Mid-spring brood expansion

Summer honey supers

Fall preparations including mite reduction

Winter hive conditions via entrance monitoring

With the right tools and quality gear—like those manufactured by Heliotrope Bee—hive audits become both thorough and safe.

4. Extraction and Post-Harvest Equipment

4.1 Centrifugal Extractors and Decapping Tools

Modern extractors range from manual spin baskets to automated radial systems with multi-frame loading, pumps, and auto-settling. Decapping heads and electric hot knives rapidly remove wax cappings.

Proper protective clothing remains essential in extraction rooms to prevent burns, minimize residue contamination, and ensure worker safety.

4.2 Honey Filtration, Settling, and Bottling

Honey is filtered through graduated mesh filters to remove debris without stripping natural pollen. Two-stage settling tanks remove entrained air and assist with crystallization control before bottling.

Quality control involves moisture readings (under 18%) and hydrometer checks. Protective wear must be both food-safe and easy to clean—requirements met by Heliotrope Bee’s protective gear.

5. Pollination Services: Tools Beyond Honey Production

5.1 Mobile Apiary Setups

For large-scale pollination—such as almond orchards or pumpkin fields—hives are mounted on pallets or trailers. Tools include:

Walk-behind hive lifts

Framed slat guards for transport

Mobile pest-control shields

Heliotrope Bee outfits traveling apiaries with durable, washable gear to handle long hours in field conditions.

5.2 Schedule Logistics & Hive Placement

Success in pollination hinges on:

Bloom forecasting software

GPS hive mapping

Standardized team gear for multi-site crews

Uniforms and safety standards across crews help companies maintain professionalism. Heliotrope Bee supports this with logo-ready apparel and tailored safety kits.

6. Scaling Operations: Beekeeping as a Business

6.1 Managing Workforce, Training, and SOPs

Operational scale demands:

Documented Standard Operating Procedures

Health screening and training materials for teams

Scheduled equipment maintenance and PPE replacement

Heliotrope Bee’s gear delivery system includes batch tracking and reorders—ideal for talent onboarding and ensuring consistency across staff.

6.2 Supply Chain Resilience

Global events like pandemics or weather disruptions demand stable supply chains. With its large-scale manufacturing, Heliotrope Bee provides:

Bulk orders with short lead times

Reliable logistics to all continents

Custom safety calibration for region-specific needs

7. Sustainability in Tool and Gear Production

7.1 Ergonomic Design Meets Eco-Friendly Materials

Heliotrope Bee uses:

GOTS-certified cotton

Water-based dyes

Recyclable packaging materials

Factory-level labor standards

Paying attention to ethical sourcing and worker safety improves brand reputation and supports long-term sustainability.

7.2 Reduce, Reuse, Repair, Repeat

Encourage practices like:

Washing rather than replacing gear

Re-stitching and padding gloves

Passing down kits as seasons end

Heliotrope Bee offers repair kits and small-batch custom runs, reducing waste and supporting local fractional economies.

8. Choosing the Right Supplier: Key Considerations

Product Quality & Testing

CSA and ASTM-rated materials

Field trials with commercial keepers

Fit adjustments based on climate and workflow

Customization & Branding

OEM/ODM services

Logo embroidery and color matching

Bundle offers (jackets + gloves + veils)

Lead Time & Delivery

Modular logistics for global distribution

Inventory reorders with low minimums

Technical Support & Community

Care guides, user manuals, training videos

After-sales support for sizing or replacements

Heliotrope Bee excels in each of these categories, making it the trusted partner for growers, commercial apiaries, educators, and hobbyists.

9. Building Competence: Training Tools and Resources

9.1 Video & Mobile Tool Integration

Visual guides should show correct tool usage and inspection techniques. Heliotrope Bee provides mobile-ready suits with integrated sleeves for tablets and smart devices.

9.2 Certification & Workshops

Working with agricultural colleges and extension services, Heliotrope Bee contributes gear and licensing kits for apiculture education and regulations compliance.

10. Key Takeaways and Action Plan

For serious beekeepers seeking to improve safety and efficiency:

Prioritize high-quality hive tools and monitoring tech

Embrace protection gear evolved and tested by professionals

Implement systematic health management and documentation

Scale your operation with predictable tool and gear supply

Invest in sustainable gear practices and environmentally-responsible suppliers

Heliotrope Bee, as the world’s largest manufacturer and supplier of beekeeping supplies, offers comprehensive solutions—from tool compatibility to field-ready protective wear and training programs—to help you master modern beekeeping.

Conclusion: Excellence in Beekeeping Requires Trusted Partners

Mastery in modern apiculture requires thoughtful combination of knowledge, equipment, and logistics. Whether you're optimizing honey yields or supporting pollination contracts, your choice of supplies matters.

As your go-to partner, Heliotrope Bee offers the depth of product, the reliability of a global supplier, and the integrity of ethical manufacturing. Let’s elevate your beekeeping operation—together.

📧 Contact our expert team at [email protected]

#bumblebees#insects#worms#snails#birdsong#honey bee#pollinators#invertebrates#caterpillars#ants#beekeeper#bee#beekeeping#bees#save the bees#insect

0 notes

Text

Why Siemens SIMATIC S7-1200 PLC is Ideal for Modern Industries

In today’s rapid-paced manufacturing environment, the roles of automation are the improvement in productivity, quality, and efficiency. At the core of many intelligent automation systems, there is the versatile and powerful PLC SIMATIC S7-1200 developed by Siemens.

Learn more about, Top 10 Features of the SIMATIC S7 1200 That Makes It a Game Changer

What is SIMATIC S7-1200?

The SIMATIC S7-1200 is a compact and modular PLC designed for small to medium automation tasks. It is scalable in nature and comes with integrated communication and user-friendly programming using the TIA Portal (Totally Integrated Automation). Be it a simple machine or a highly complex process; the Siemens SIMATIC S7-1200 strikes a perfect balance between performance and affordability.

Key Features of Siemens SIMATIC S7-1200 PLC

Packed with features, the Siemens SIMATIC S7-1200 PLC can adapt perfectly to a variety of industrial applications.

Modular Design: Easily expand your system by attaching different signal modules, communication modules, or signal boards.

Integrated Communication: Provides a built-in PROFINET interface.

High-Speed Processing: Operation with precise control and response.

Web Server: Access to the system diagnostics remotely through a web-based interface.

Security Functions: Protect with a password and access control security functions.

Energy Monitoring: Optimizes power usage in the production processes.

This makes the SIMATIC S7-1200 a perfect fit to be a controller for packaging, HVAC, conveyor systems, and other applications.

Why Choose Siemens SIMATIC S7-1200 for Automation?

Scalability:

Automation needs grow with Siemens SIMATIC S7-1200; start small and work your way up along with your processes.

Programming Flexibility:

This system supports ladder diagrams, function block diagrams, and structured text, allowing both newbie and seasoned programmers to use them.

Robust Performance:

Operating under harsh industrial conditions, the Siemens SIMATIC S7-1200 PLC looks after consistent performance even when challenged by environmental conditions.

Integrated System Diagnostics:

Diagnose and fix problems immediately without the aid of external tools to minimize system downtime and maximize operational efficiency.

Learn more, Why Siemens PLC S7-1200 is the best choice for Compact Automation System

Applications of SIMATIC S7 1200

The SIMATIC S7-1200 finds applications in several industrial fields, including:

Automotive: Automated assembly lines and robotics are controlled.

Food & Beverage: Packaging and processing lines are handled with precision.

Textile: Improves control of dyeing and printing machines.

Water treatment: Monitoring and control of pumps and filters are performed.

Material Handling: Smart conveyors and warehouse automation present a challenging application.

Because of its versatility, the Siemens SIMATIC S7-1200 PLC continues to be a very reliable solution in the industrial automation world.

Conclusion

Whether updating an existing automation system or embarking on a brand-new project, the S7-1200 affords the performance, flexibility, and reliability you need. Its intelligence and easy integration make it a wise choice in any industrial setting.

If you are considering procurement or implantation of Siemens SIMATIC S7-1200 PLC, Naksh Technology Solutions LLP is your trusted partner. With years of experience in the field of industrial automation coupled with a sturdy portfolio of Siemens products, Naksh Technology ensures the development of seamless solutions that fit your business needs.

0 notes

Text

Colorimeter Market Future Trends Shaping Innovations in Quality Control and Color Measurement Technologies

The colorimeter market is poised for significant growth and transformation as future trends reshape how color measurement technologies are developed and applied across various industries. Colorimeters, essential instruments for objectively measuring color, play a critical role in quality control, product development, and color matching processes. As industries increasingly demand accurate and efficient color management, evolving technologies and shifting market needs are driving innovation and expanding the scope of colorimeter applications. This article explores the key future trends shaping the colorimeter market and their impact on the industry landscape.

Growing Demand for Portable and Handheld Colorimeters

One of the most prominent future trends in the colorimeter market is the rising demand for portable and handheld devices. Advances in miniaturization and sensor technology have enabled manufacturers to develop compact, lightweight colorimeters that deliver precise color measurements in the field.

These portable instruments offer significant advantages over traditional benchtop models, providing users with convenience, ease of use, and rapid data acquisition. Sectors such as textiles, printing, food and beverages, cosmetics, and automotive increasingly rely on handheld colorimeters for on-site quality control and color verification. The trend toward portability is expected to accelerate as more industries adopt color measurement solutions to improve operational efficiency.

Integration with Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) integration represent a cutting-edge trend that is set to revolutionize the colorimeter market. By incorporating AI algorithms, colorimeters can offer enhanced data analysis, predictive color matching, and adaptive calibration features.

AI-powered colorimeters can automatically adjust for environmental variables such as lighting and surface texture, improving measurement accuracy and consistency. Machine learning models can also analyze historical color data to optimize production processes and reduce waste. This fusion of AI and color measurement technology is opening new possibilities for smarter, more autonomous color management systems.

Expansion of Applications Across Diverse Industries

The future of the colorimeter market is marked by expanding applications beyond traditional sectors. While industries like textiles, paints and coatings, and plastics have long been major users, newer industries are increasingly recognizing the value of precise color measurement.

Healthcare and pharmaceuticals are adopting colorimeters for monitoring product quality and ensuring consistency in drug formulations. Food and beverage manufacturers use colorimeters to verify freshness, ripeness, and product appearance. Even the electronics industry applies color measurement for display calibration and manufacturing processes. This broadening of applications is fueling market growth and encouraging manufacturers to develop specialized colorimeters tailored to specific industry needs.

Advancements in Spectral and Multispectral Colorimetry

Technological advancements are driving a shift toward more sophisticated spectral and multispectral colorimeters. Unlike traditional tristimulus colorimeters that measure color based on three primary channels, spectral colorimeters capture detailed spectral data across multiple wavelengths.

This approach enables higher accuracy and better color discrimination, especially for complex or metameric colors. Multispectral colorimeters extend this capability by measuring reflectance or transmittance across even more wavelength bands, allowing precise analysis of materials under various lighting conditions. The adoption of these advanced devices is expected to increase in industries requiring the utmost color precision, such as automotive coatings, art restoration, and high-end printing.

Increasing Importance of User-Friendly Interfaces and Connectivity

The market is witnessing a shift toward user-centric design in colorimeter products, with an emphasis on intuitive interfaces, touchscreen displays, and wireless connectivity. Modern colorimeters often feature smartphone or tablet compatibility, enabling data transfer, remote operation, and cloud-based analysis.

This trend enhances user experience and facilitates seamless integration into digital quality control workflows. Wireless connectivity also supports real-time monitoring and reporting, critical for fast-paced manufacturing environments. As Industry 4.0 concepts gain traction, connected colorimeters will become integral components of smart factories and automated production lines.

Emphasis on Environmental Sustainability and Compliance

Sustainability considerations are increasingly influencing colorimeter market trends. Regulatory bodies and consumers alike are demanding environmentally responsible production processes, which include precise color control to minimize material waste and ensure compliance with eco-friendly standards.

Colorimeters help manufacturers reduce rework and defective products by enabling accurate color matching from the start. Furthermore, some newer models are designed with energy-efficient components and recyclable materials, aligning with broader sustainability goals. This focus on green manufacturing practices is expected to shape product development and marketing strategies in the colorimeter market.

Growth in Emerging Markets and Regional Adoption

Emerging markets in Asia-Pacific, Latin America, and Africa present significant opportunities for the colorimeter market’s future growth. Rapid industrialization, expanding manufacturing sectors, and rising quality standards are driving demand for color measurement instruments in these regions.

Countries like China, India, Brazil, and Mexico are investing in advanced quality control technologies, including colorimeters, to enhance their competitiveness in global markets. Regional manufacturers are also tailoring products to meet local needs, such as rugged designs for harsh environments or cost-effective models for small and medium enterprises. This geographic expansion diversifies the market and encourages innovation.

Conclusion

The colorimeter market future trends reflect a dynamic and evolving landscape characterized by technological innovation, expanding applications, and growing user demands. The rise of portable and handheld devices, integration of AI and machine learning, advances in spectral measurement, and enhanced connectivity are driving the market toward smarter, more versatile color management solutions.

Additionally, sustainability imperatives and emerging market growth provide further momentum for the industry. Companies that invest in developing user-friendly, high-precision, and environmentally conscious colorimeters will be well-positioned to capitalize on these trends. As accurate color measurement becomes increasingly vital across industries, the colorimeter market is set for sustained expansion and transformative innovation.

0 notes

Text

Innovations in Women's Garments: Labisa Fashion Smart Textile Manufacturing

In the ever-evolving world of fashion, smart textile manufacturing is revolutionizing women's garments, offering enhanced functionality without compromising style. Labisa Fashion stands at the forefront of this transformation, integrating advanced technologies into their designs to meet the dynamic needs of today's consumers.

Introduction to Smart Textile Manufacturing

Smart textiles are fabrics embedded with digital components such as sensors and actuators. These textiles can sense environmental conditions or stimuli from the wearer and respond accordingly. The evolution of smart textile manufacturing has been significant, with applications ranging from health monitoring to adaptive clothing. In the fashion industry, smart textiles offer opportunities to create garments that are not only aesthetically pleasing but also functional, enhancing the wearer's experience.

Labisa Fashion – A Pioneer in Smart Textile Innovation

Based in Mumbai, Labisa Fashion has over a decade of experience in crafting exquisite women's ethnic wear that celebrates tradition and modernity. Their dedication to quality and innovation has established them as a trusted name in the industry. By integrating smart textile design into their collections, Labisa Fashion offers garments that blend traditional aesthetics with modern functionality, catering to the evolving preferences of consumers.

Types of Smart Textiles in Fashion

Smart textile clothes in fashion can be categorized into three types:

Passive Smart Textiles: These textiles can sense environmental conditions or stimuli but do not act upon them.

Active Smart Textiles: These fabrics can sense and react to environmental conditions or stimuli.

Ultra-Smart Textiles: These are the most advanced, capable of both sensing and adapting autonomously.

Advanced Materials Used in Smart Textiles

The key to developing high-quality smart textile clothes lies in the materials used. Some of the most innovative materials include:

Conductive Fabrics: These allow electricity to pass through, making them ideal for integrating wearable technology.

Shape-Memory Polymers: These textiles can change their shape based on external stimuli like temperature.

Phase Change Materials (PCM): These regulate body temperature by absorbing, storing, and releasing heat.

Nano-Coatings: Enhances fabric durability while adding self-cleaning and water-repellent properties.

The Manufacturing Process of Smart Textiles

At Labisa Fashion, smart textile manufacturing follows a structured process:

Material Selection and Preparation: Choosing high-quality smart fabrics that offer durability and functionality.

Weaving and Knitting Techniques: Integrating smart fibers with traditional weaving methods.

Electronics Integration: Incorporating sensors and conductive threads seamlessly into the garment.

Testing and Quality Assurance: Ensuring every product meets high performance and durability standards.

Key Technologies in Smart Textile Production

Wearable Sensors and IoT Integration: Enables real-time monitoring and data collection.

3D Printing in Textile Manufacturing: Allows for customized and intricate designs.

AI and Machine Learning: Optimizes production efficiency and enhances fabric functionality.

Applications of Smart Textiles in Women's Fashion

Wearable Health Monitoring: Smart fabrics track vital signs and health metrics.

Adaptive and Interactive Clothing: Textiles that change color or adjust fit based on movement.

Sustainable and Eco-Friendly Textiles: Reducing waste and promoting longevity in fashion.

Challenges in Smart Textile Manufacturing

While smart textile design offers numerous advantages, some challenges include:

High Production Costs: Advanced materials and technology make it a costly investment.

Durability and Maintenance Issues: Integrating electronics with textiles requires high durability.

Scalability and Mass Production Limitations: Adapting these designs for large-scale production can be complex.

Sustainable Approaches in Smart Textile Manufacturing

To ensure sustainability, Labisa Fashion prioritizes:

Eco-Friendly Materials: Using organic and biodegradable textiles.

Circular Fashion and Recycling: Encouraging reusability to minimize waste.

Ethical Production Practices: Ensuring fair labor practices in the supply chain.

Future Trends in Smart Textile Manufacturing

The future of smart textile design is bright, with emerging trends such as:

AI-Driven Customization: Personalized clothing based on user preferences.

Self-Healing and Biodegradable Textiles: Enhancing garment longevity and sustainability.

Integration with Augmented Reality (AR) and Virtual Reality (VR): Creating immersive fashion experiences.

Competitive Landscape – How Labisa Fashion Stands Out

Unique Selling Proposition (USP): Combining traditional elegance with smart technology.

Market Growth and Expansion Strategies: Expanding into global markets with innovative designs.

How to Buy Smart Textile Products from Labisa Fashion

Bulk buyers, distributors, and wholesalers looking to invest in high-quality smart textile clothes can connect with Labisa Fashion through the following channels:

Phone: Afzal: +91 98929 39564, Labisa Sales: +91 81699 85975

Email: [email protected], [email protected]

Address: Sion West, Dharavi, Mumbai, Mumbai 400017

Final Thoughts – Elevate Your Business with Smart Textiles

For businesses in the fashion industry, investing in smart textile manufacturing is the future. Labisa Fashion offers innovative, high-quality designs that combine tradition with cutting-edge technology. If you're looking to stock the latest in smart textile garments, reach out today and explore our collection designed for the modern woman.

Would you like to place a bulk order? Get in touch with our team and bring the future of fashion to your customers.

0 notes

Text

Seminar Topics Ideas for Computer Science

There are some Seminar topic ideas for Computer Science that we have prepared, the most relevant and modern seminar and project topics for Computer Science Engineering (CSE) in 2025 from various lists and trending technologies throughout the year.

Best & Trending Seminar Topics For Computer Science

Artificial Intelligence (AI) & Machine Learning

Examine Application areas in industries including deep learning, neural networks, and generative AI like ChatGPT and other AI-driven services.

Blockchain Technology & Cryptocurrency: Apart from digital currencies, blockchain is transforming the supply chain, secure transactions, and decentralized applications.

Quantum Computing: Study quantum algorithms and advancements in quantum hardware, like cryptography and complex problem solutions.

Cybersecurity & Ethical Hacking: Debate zero trust security, privacy, and ethical hacking methodologies, as well as newer ways of dealing with advanced persistent threats.

Cloud Computing & Edge Computing: Discuss cloud infrastructure and edge AI in IoT and distributed systems, and their effects.

Internet of Things (IoT) & IoT Security: Discuss smart devices and networked sensors as well as security in the modern connected world.

Augmented Reality (AR) & Virtual Reality (VR): Discuss immersive technologies with particular interest in their use in education, health care, and amusement.

Analyzing Data Science & Big Data: Talk about big data, data mining, its impact on business intelligence, decision-making, and predictive analytics.

NLP & AI Generative: Aiming at sentiment analysis, large language models NLP for low-resource languages.

XAI & AI Ethics: Discuss issues with transparency, fairness, and accountability within AI systems, which are critical for the responsible use of technology.

Sustainability & Green Computing

Research on sustainable IT, eco-friendly hardware, and energy-efficient computing.

Human-Computer Interaction: Research on innovations related to user experience, accessibility, intuitive interface design, and more.

5G & Next Gen Networking: Evaluate how 5G affects connectivity, the Internet of Things, and smart cities.

Robotic Process Automation & Autonomous Systems

Evaluate automation in business process robotics and examine the future of autonomous drones and vehicles.

Bioinformatics & Computational Biology: Discuss AI-powered genomics and drug discovery, and the life sciences computing focus.

Smart Textiles & Wearable Technology: Research on innovations in interactive textiles, health monitoring, and fitness.

Game Design and Development: Discuss modern game development with new engines, AI, Virtual Reality, and more.

Digital Image Processing

Digital Image Processing & Computer Vision: Image recognition, identifying human faces, and analysing videos in real time.

DevOps & Continuous Integration/Deployment: Define modern software development, automation of processes, and pipelines for deployment.

Fog Computing & Edge AI: Emphasis on computing frameworks that are further away from the center of control for faster data processing, enhanced data security, and increased privacy.

Latest Topics for Computer Science Students

Apart from Seminar Topics Ideas for Computer Science, there are some latest topics for the students

Arya College of Engineering & I.T. has many Courses and topics for students for their growth and development, and future building them are some below:-

AI-based Diagnosis and Medicine Creation through Healthcare Informatics

This field of projects applies artificial intelligence with special importance to machine and deep learning on large-scale healthcare datasets, including detecting diseases in medical imagery or predicting patient outcomes based on evaluation data.

Blockchain Technology applied to manage the supply chain

Supply chain management has greatly benefited from Blockchain Technology for its impenetrable transparency, traceability, and security.

Solution for Cloud Storage with Encryption

The development of cloud computing necessitates securing data, which is of utmost importance. This area of research being pursued focuses on creating cloud storage solutions that incorporate high-level encryption for the assurance of privacy and confidentiality of data.

Real-time Emotion Recognition

Based on Deep Learning Recognition of emotion systems undertake facial expression recognition, voice or sound signal analysis, as well as other psychological applications using deep learning algorithms trained using Convolution Neural Networks (CNN) and Recurrent Neural Networks (RNN) models.

IoT-Based Smart Home Automation System

The projects involve the use of sensors and actuators, and microcontrollers to aid in the automation of home appliances, creative lighting, security, and energy management.

The Use of Machine Learning for Cybersecurity

Threat Detection Machine learning methods prepare trained models that are capable of examining mobile traffic in networks and traffic of containers, scanning installed, logically separated computer frameworks.

Educational and Training Tools on AR and VR

Augmented reality (AR) and virtual reality (VR) enhance learning through immersive and interactive experiences.

Automatic Software Testing Tools

Throughout the past two decades, interest in designing automatic testing tools has increased significantly, and a noteworthy number of such tools have been developed.

Software testing

It can be automated to improve reliability and reduce manual effort.

Voice Virtual Assistants and Chatbots

These efforts include speech recognition, natural language processing (NLP), and AI that can be used to build assistants that answer questions, power devices, or automate workflows.

Crypto Wallets and Crypto Watermarking

Secured wallets for crypto-coins have several aspects: cryptography, secure key storage, and user authentication.

Fog Computing Applications

Fog computing pushes cloud services to the network edge, minimizing latency and bandwidth consumption.

WSNs in Environmental Monitoring

Wireless sensor networks (WSNs) employ spatially dispersed sensors for the measurement of environmental values, including temperature, humidity, or pollution.

Real-time Emotion Recognition

Shipping And Research Overview, Three Categories Of Smart Wearable Technology Projects

AI Integration in Game Development

In contemporary games, AI is employed in the form of NPC behaviors, procedural content, and dynamic difficulty adjustment.

Privacy-Preserving Solutions with Secure Multi-Party Computation

Secure multi-party computation (SMPC) enables multiple parties to collaboratively compute a function on their inputs without revealing these inputs.

Conclusion

There are so many Additional Seminar Topics: Ideas for Computer Science, but these are some Important topics that help students to get an idea for computer science and take their own decision for their future growth.

Source: Click Here

#best btech college in jaipur#best engineering college in jaipur#best engineering college in rajasthan#top engineering college in jaipur#best btech college in rajasthan

0 notes