#Tissue engineering scaffolds

Explore tagged Tumblr posts

Text

Biomaterials are at the forefront of regenerative medicine and implant technology! 🌱🔬 From creating sustainable solutions to advancing healthcare, these innovations are shaping the future of medical science. Discover how science and nature unite for better healing! 🌟

#Biomaterials in regenerative medicine#Innovative medical implants#Natural and synthetic biomaterials#Tissue engineering scaffolds#Advanced drug delivery systems#Biocompatibility challenges#3D printing in biomaterials

0 notes

Text

Advanced Biomanufacturing Solutions: How Biofabrication is Meeting the Need for Complex Biologics in the Biotechnology Industry

Biofabrication Market: A Growing Industry with Promising Future

Biofabrication is an emerging technological field that focuses on manufacturing structures for tissue engineering and regenerative medicine. This field has gained significant attention in recent years due to its potential to revolutionize the healthcare industry. In this article, we will explore the biofabrication market, its size, growth projections, and the key factors driving its growth.

Market Size and Growth Projections

The biofabrication market is expected to grow significantly in the coming years. According to a report by Intent Market Research, the global biofabrication market size is anticipated to reach USD 80 Billion by the end of 2036, growing at a CAGR of 10% during the forecast period, i.e., 2024-2036. Another report estimates the market size to be USD 22.76 Billion in 2023 and predicts it to reach USD 48.27 Billion by 2031, with a CAGR of 10.2% from 2024 to 2031.

Key Factors Driving Growth

Several factors are driving the growth of the biofabrication market. One of the primary factors is the increasing demand for biologics and biosimilars. The development of biologics accounts for around 40% of all pharmaceutical R&D spending, making it essential for advancing healthcare. Additionally, biomanufacturing accelerates scientific research, boosts economic growth, and provides jobs, making it a vital industry for the future.

Another key factor driving growth is the advancements in biofabrication techniques. Recent advancements in volumetric bioprinting, scaffold-free bioassembly, and hybrid biofabrication strategies have improved the scale, rate, and intricacy at which tissues can be fabricated. These advancements have the potential to recapitulate the structure and complexity of native tissues, making them suitable for various applications such as biomimetically engineered models for drug discovery, cosmetics testing, tissue regeneration, and medical devices.

Regional Analysis

The biofabrication market is expected to grow significantly in various regions. North America is expected to hold the largest share of 36% during the forecast period due to the robust presence of large biopharmaceutical businesses and the improved infrastructure in biological research. The Asia-Pacific region is expected to witness the fastest growth due to the rapid adoption of advanced technologies and the high prevalence of chronic diseases.

Competitive Landscape

The biofabrication market is highly competitive, with several key players operating in the market. Some of the major players include Applikon Biotechnology BV, bbi-biotech GmbH, Danaher Corporation, Eppendorf AG, Esco Group of Companies, GEA Group Aktiengesellschaft, Meissner Filtration Products, Inc., Merck KGaA, PBS Biotech, Inc., Pierre Guérin, Sartorius AG, Shanghai Bailun Biotechnology Co. Ltd., Solaris Biotechnology Srl., Thermo Fisher Scientific Inc., and ZETA GmbH.

Conclusion

In conclusion, the biofabrication market is expected to grow significantly in the coming years due to the increasing demand for biologics and biosimilars, advancements in biofabrication techniques, and the growing demand for advanced biomanufacturing solutions. The market is expected to be driven by key players operating in the market, and regional growth is expected to vary. As the industry continues to evolve, it is essential to stay updated on the latest advancements and trends to capitalize on the growth opportunities in the biofabrication market.

#Biofabrication#biomanufacturing#biologics#biosimilars#regenerative medicine#tissue engineering#biomimetic engineering#biotechnology#biopharmaceutical industry#advanced biomanufacturing solutions#volumetric bioprinting#scaffold-free bioassembly#hybrid biofabrication strategies#biomanufacturing techniques#biomanufacturing market

0 notes

Text

Rooting for You

Deep underground, bargains are made between living things. Symbiotic relationships allow fungi to weave their whisker-like hyphae among the roots of plants. This is mutually beneficial: the fungus is rewarded with nutrients while expanding the plant’s thirsty root system. But this biological bonding might benefit us too. Here, researchers grow a plant in a pit of sandy silica nanoparticles. Its roots burrow tunnels in the particles which then harden after a blast of extreme heat, a process known as sintering which leaves a network of tiny channels behind in the transformed glass. A blue liquid is sucked through the tunnels via capillary action, similar to how chemicals move into and around our tissues. Such techniques might allow tissue engineers to explore new designs for microfluidic devices, using plants and fungi as tiny biodegradable scaffolds.

Written by John Ankers

Clip from a video from work by Tetsuro Koga, Shota Nakashima & Fujio Tsumori

Department of Aeronautics and Astronautics, Graduate School of Kyushu University, Fukuoka, Japan

Video originally published with a Creative Commons Attribution – NonCommercial – NoDerivs (CC BY-NC-ND 4.0)

Published in Scientific Reports, September 2024

You can also follow BPoD on Instagram, Twitter, Facebook and Bluesky

11 notes

·

View notes

Text

T-Rex Leather !

Creative agency VML, genomic engineering leader The Organoid Company, and biotech innovator Lab-Grown Leather Ltd. have joined forces to develop the world’s first T-Rex leather—a cruelty-free, eco-friendly alternative to traditional leather crafted from the DNA of one of history’s most formidable predators.

The process begins with The Organoid Company reconstructing T-Rex DNA sequences, which are then engineered into a custom cell line. These cells are integrated into Lab-Grown Leather’s Advanced Tissue Engineering Platform (ATEP™), where they self-assemble into a scaffold-free leather structure.

Unlike other bio-based alternatives that rely on synthetic scaffolds, this method allows cells to form their own natural matrix, resulting in a material that is structurally identical to traditional leather—only stronger and more sustainable.

#art#design#fashion#women's fashion#luxury lifestyle#dressing room#walking closet#leather#t rex dinosaurs#t rex#VML#the organoid compagny#genomic#biotech#eco-friendly#surreal#DNA#sustainability#sustainableliving#sustainablefashion

7 notes

·

View notes

Text

Scientists create method to bond hydrogels and other polymeric materials using chitosan

Hydrogels are versatile biomaterials conquering an increasing number of biomedical areas. Consisting of water-swollen molecular networks that can be tailored to mimic the mechanical and chemical features of various organs and tissues, they can interface within the body and on its outer surfaces without causing any damage to even the most delicate parts of the human anatomy. Hydrogels are already used in clinical practice for the therapeutic delivery of drugs to fight pathogens; as intraocular and contact lenses, and corneal prostheses in ophthalmology; bone cement, wound dressings, blood-coagulating bandages, and 3D scaffolds in tissue engineering and regeneration. However, attaching hydrogel polymers quickly and strongly to one another has remained an unmet need as traditional methods often result in weaker adhesion after longer-than-desired adhesion times, and rely on complex procedures.

Read more.

20 notes

·

View notes

Text

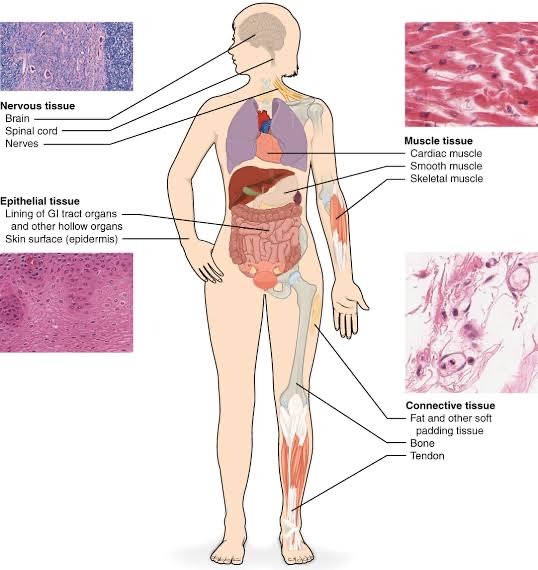

Human Tissues: An Anatomy and Physiology Exploration

In the captivating realm of human anatomy and physiology, tissues are the cornerstone, weaving the intricate tapestry of our bodily functions. Let's embark on a journey to uncover the different types of tissues, delving into their unique characteristics and significance.

1. Epithelial Tissue: The Body's Protective Shield

Epithelial tissue lines surfaces, cavities, and glands, acting as our first line of defense. Stratified, simple, squamous, cuboidal, and columnar epithelia all serve distinct functions in various bodily structures.

2. Connective Tissue: The Structural Framework

Connective tissues serve as the architectural scaffolding, binding and supporting other tissues. Dense, loose, cartilage, bone, and blood, each with its specialized properties, contribute to the body's structural integrity.

3. Muscle Tissue: The Engine of Movement

Muscle tissues are the driving force behind movement and force generation. Skeletal, smooth, and cardiac muscles exhibit unique characteristics and play crucial roles in our mobility and vital functions.

4. Nervous Tissue: The Information Superhighway

Nervous tissue conducts electrical impulses, facilitating rapid communication within the body. Neurons and neuroglia work in harmony to transmit and process vital information.

Diverse and specialized, these tissue types ensure the harmonious functioning of our body systems. Join us in this captivating journey through the pages of OpenStax Anatomy and Physiology to explore the intricacies of human biology. 📚🧬

Prepare to be captivated by the precise design and functionality of human tissues as we navigate the intricate world of anatomy and physiology! 📖🔬

References

OpenStax Anatomy and Physiology, Section 4.1

OpenStax Anatomy and Physiology, Section 4.2

OpenStax Anatomy and Physiology, Section 4.3

OpenStax Anatomy and Physiology, Section 4.4

OpenStax Anatomy and Physiology, available at https://openstax.org/details/books/anatomy-and-physiology.

#science#biology#college#education#school#student#medicine#doctors#healthcare#health#human physiology#humanphysiologynotes#human anatomy#anatomy#nursing#medical stuff

17 notes

·

View notes

Text

The Art of Building Meat: Bioprinting Techniques in Cultured Meat Market Production

Introduction:

The future of food is taking shape in bioreactors and 3D printers. Cultured Meat Market, also known as clean meat or lab-grown meat, emerges as a revolutionary solution to the environmental and ethical concerns surrounding traditional meat production. This article delves into the fascinating world of bioprinting techniques, a key component in creating complex, delicious cultured meat products.

Download FREE Sample: https://www.nextmsc.com/cultured-meat-market/request-sample

Cultured Meat: A Sustainable Disruption

Traditional meat production carries a significant environmental burden, contributing to deforestation, greenhouse gas emissions, and water pollution. Cultured meat offers a promising alternative, growing meat from animal cells in a controlled environment.

Here's a simplified breakdown of the process:

Cell Collection: A small sample of muscle stem cells is obtained from an animal through a minimally invasive procedure.

Cell Culture: These cells are multiplied in a nutrient-rich medium within bioreactors.

Differentiation and Maturation: Controlled growth factors in the medium stimulate the cells to differentiate and mature into muscle tissue.

Bioprinting: This innovative step allows for precise arrangement of the cells to create the desired structure and texture of meat.

Maturation and Processing: The bioprinted meat undergoes further maturation and processing to achieve the final product.

Inquire before buying: https://www.nextmsc.com/cultured-meat-market/inquire-before-buying

Bioprinting: Engineering the Future of Meat

Bioprinting takes cultured meat production to a whole new level. Here's how it works:

Digital Design: A computer-aided design (CAD) model is created to define the desired structure of the meat product, such as a steak or a burger patty.

Bioink Preparation: A biocompatible material, often containing a mixture of cells, nutrients, and scaffolding materials, is prepared for printing.

3D Printing Process: The bioink is loaded into a bioprinter, which uses computer-controlled mechanisms to deposit the bioink layer-by-layer, replicating the designed structure.

Cell Culture and Maturation: Once printed, the bioprinted cells are allowed to mature and grow within a bioreactor, mimicking the natural development of muscle tissue.

Benefits of Bioprinting for Cultured Meat

Bioprinting offers several advantages in the production of cultured meat:

Complex Structures: Bioprinting allows for the creation of complex, multi-cellular structures that mimic the texture and marbling of traditional meat cuts. This is difficult to achieve with traditional culturing techniques.

Fat Distribution: Bioprinting enables precise control over fat distribution within the meat, allowing for the creation of leaner or marbled cuts as desired.

Customization: Bioprinting paves the way for personalized meat products tailored to specific dietary needs or preferences.

Vascularization: Bioprinting can potentially be used to create vascular networks within the cultured meat, promoting cell growth and mimicking the natural delivery of nutrients and oxygen.

Types of Bioprinting Techniques for Cultured Meat

Several bioprinting techniques are being explored for cultured meat production, each with its own advantages and limitations:

Extrusion-based Bioprinting: This common technique uses a pressurized system to deposit bioink through a nozzle, creating a filamentous structure. It's suitable for high-viscosity bioinks but may have limitations in resolution.

Inkjet Bioprinting: Similar to an inkjet printer, this technique uses a jet of bioink droplets to create a patterned structure. It offers high resolution but may be limited in the types of bioinks it can handle.

Stereolithography (SLA): This light-based technique uses a laser to solidify layers of bioink resin, building the desired structure layer-by-layer. It offers high accuracy but may require specialized biomaterials.

Challenges and Opportunities in Bioprinting for Cultured Meat

While bioprinting holds immense promise, some challenges need to be addressed:

Cost Reduction: Bioprinting equipment and bioink development are currently expensive, requiring cost optimization for large-scale production.

Bioink Development: Creating bioinks that are biocompatible, support cell growth, and allow for precise printing remains an ongoing area of research.

Scalability: Scaling up bioprinting processes to meet commercial production demands requires further advancements in technology and infrastructure.

However, these challenges offer exciting opportunities for innovation:

Advancements in Biomaterial Science: Development of affordable and efficient bioinks specifically tailored for cultured meat is crucial for large-scale adoption.

Bioprinter Design and Optimization: Improvements in bioprinter design can increase printing speed, resolution, and efficiency for cost-effective production.

Collaboration Between Researchers and Industry: Collaboration can accelerate research and development efforts to overcome technical hurdles and improve bioprinting techniques.

Conclusion: A Bite of the Future - Bioprinted Cultured Meat

Bioprinting represents a transformative leap in the world of cultured meat. This technology holds the potential to create delicious, sustainable, and ethical meat alternatives, replicating the textures and flavors we crave.

While challenges remain in terms of cost reduction, bioink development, and scalability, ongoing research and collaboration are paving the way for advancements. Bioprinting paves the way for a future where:

Cultured meat becomes readily available and affordable for consumers.

Bioprinting techniques can create a wider variety of meat products, from steaks to sausages.

Consumers can enjoy the taste and texture of meat while making a positive environmental impact.

2 notes

·

View notes

Text

Round 1B

Erykah Badu’s Baduizm: On and on and on and on, my cypher keeps moving like a rolling stone. Baduizm is the groundbreaking debut album by Erykah Badu, released in early 1997 by Kedar and Universal Records. The album a cornerstone of the neo-soul movement, blending elements of R&B, jazz, and hip-hop in an experimentally-retro musical experience, which drew favorable comparisons from the critics of the time to soul music of the 70s. Badu's sound is recognizable for her sultry vocals and introspective or socially conscious lyrics, while the album’s production stands out with warm, rich live instrumentation. Featuring the singles On & On and Next Lifetime, the album not only stood tall as a leading example in the evolution of the soul genre but also established her as a new force in contemporary music, leaving an indelible mark on the world of R&B and soul moving forward. Baduizm debuted at #2 on the US Billboard charts and #1 on the Billboard R&B/Hip-Hop Album charts, and is certified triple Platinum in the US; it would also win the Grammy for Best R&B Album under the banner of neo-soul.

EMOUSE: The Vacanti Mouse Emails: In August 1997, scientists Charles and Joseph Vacanti published a paper in the journal Plastic and Reconstructive Surgery regarding their research into tissue engineering and regenerative medicine. In the journal, they printed a picture of a mouse with what appeared to be a human ear growing out of its back; within months of this publication, every one of your aunts would forward you an email chain containing the “Ear Mouse” photo, proclaiming it to be a horrifying example of genetic modification and decrying the ethics of scientists playing God. (Note: I’ve opted to show you a cuter photo for the bracket.) In actuality, to create the ear-like structure on the mouse's back, researchers implanted a biodegradable scaffold made of a synthetic material seeded with cartilage cells into the mouse. Over time, the cartilage cells grew and formed the ear-shaped structure; no genetic modification was involved. This did not stop the spread of the emails, which often lacked text entirely or misrepresented what was shown, and incensed both animal rights activists and far-right religious groups to the extent that full-page ads were taken out in major news publications like the New York Times expressing outrage. While the photo remains divisive today, the Vacanti Mouse is an iconic image in discussions about the potential of regenerative medicine and the ethical considerations surrounding such research.

6 notes

·

View notes

Text

Xrumon Arigah’s Surgical Extraction Procedure

AS WRITTEN AND DICTATED BY ULLANE WISTIM, M.D, IN THE CROWN CLINIC

PREP BEFORE OPERATION:

All surgeons will be fed, watered, well rested, and having used the restroom. They will have woken up shortly before the operation starts due to its duration. All surgeons will be wearing proper attire - head covers, masks, and scrub suits. Sterile scrub suits, shoes, gloves, and goggles will be provided by the clinic, donned upon entry into the operating room to provide the lowest possible bacterial contamination during the operation.

The operating theater will be prepared with sufficient room to remove, lift, and rotate sections of the suit to provide access to all the systems requiring detachment. These sections will be held and maneuvered with hover-tech above the operating surgeons for maximum ease of access to the patient and a clear field for operations.

The patient will have been scanned by intraoperative CT prior to the operation, and 3D imagery of these scans will be displayed on wall screens to give surgeons access to all information about his internal organs. These images can be changed at will with simple voice commands.

Lard’s note: The person in the suit would be kept standing while being worked on - picture a sort of medical stand, keeping the patient upright even while unconscious, which allows mechanics/doctors access to everything except the literal soles of the feet. Which they shouldn't need access to, and even if they did, they could just move the stand onto a lift of some kind.

Surgeons will be sustained via nutritionally sufficient meal drinks provided. Short rest breaks will be allowed in shifts. Surgeons requiring restroom breaks will need to be sterilized before returning to the operating room.

Robots will be present with biological waste containers to ferry waste away for autoclaving. Robots will also be present to bring and take away tools and equipment.

The suit will be put into maintenance mode so that the subject can be safely operated on, and general anesthetic will be performed. A catheter will be inserted and IVs will be connected to supply sources on movable, levitating robots. The subject will have already undergone fasting, being shaved, and using clinic-issue painkillers for two weeks instead of his standard variety.

LIST OF SURGICAL TOOLS:

Harmonic Scalpel - A surgical instrument used to simultaneously cut and cauterize tissue. Ultrasonic energy is converted to mechanical energy at the active blade to apply pressure and then seal with a denatured protein coagulum. It has almost no thermal spread and smoke production, making it the safest model possible.

Protective Goggles - In appearance they are ordinary surgical goggles, and provide protection from spurts of blood and other bodily fluids the same way. They can be adjusted with the tap of a button or voice command to provide advanced perception of oxygenated versus un-oxygenated blood, and generate vein road maps.

LIST OF CLINIC INVENTIONS:

Internal Laryngeal Rebreather - A liquid that goes down the patient’s throat and expands into the airway, becoming an internal, independent structure instead of an external mask that would impede other surgeries. The oxygen intake is reduced, so it is inadvisable to wear for long periods - this is why it will only be utilized in later stages of the surgery.

Regenerative Serum - A substance derived from Thrixe Varzim’s tissue that allows for controlled regeneration of a troll’s body. It speeds healing and can allow for minor regrowth of lost biological matter. It must be used in small doses to not accidentally cause cancerous activity or undo surgical work, as it only regrows tissue in its natural form.

Bio-Sponge Buds - A modified version of the synthetic troll flesh already utilized by the clinic, these have been custom engineered by Ullane Wistim out of Xrumon Arigah’s DNA, monofilament fibers, and a bioabsorbable scaffold for optimal integration and structural integrity in his stomach wall.

Nanotechnology - A specific brand created by Friday Lovely, these tiny repair vehicles made of her own radiation-resistant DNA can be programmed to fulfill a variety of tasks during surgery.

SURGERY PROCESSES, IN ORDER:

VISUAL SENSOR SUITE DISCONNECTION STEPS:

Due to it hampering the eventual necessary removal of the helmet, the visual sensor suite will be disconnected first.

The head will be held in an altered 3-pin skull fixation device (to accommodate the patient’s standing position) to keep it absolutely still during the surgeries.

3D image-guidance will be used to display the patient’s internal condition to the 3D computer model created from the CT scan.

The helmet sections will be adjusted and slide aside so that the suite may be accessed. The skin will be prepped with an antiseptic. A cranial drill will be used to drill through the skull, exposing the dura, which will be peeled back to allow access to the brain.

The optic nerve will be held and isolated via forceps as it is packed with cottonoids for protection. The cells grown into the conduits will be dissociated by injections of TrypLE, so that the conduits may be safely removed without damaging the vitreous humor.

His eyes will be monitored for their light response (and integrity of the optic nerve) at all times. Regenerative serum will be immediately applied via infused cottonoids if damage is sustained.

The skull bone will be sealed back in place with laser soldering.

It will be likely the patient has sustained minor vision loss due to scar buildup around the conduits, but this will be addressed post-surgery.

PSIIONIC DAMPENER REMOVAL STEPS:

Dioscuri’s Area is the part of the troll brain where psiionic energy is generated; it is tied to voluntary motor functions, as while psiionic abilities are not muscularly based, even passively present powers require focus from the user to manipulate at will.

Fortunately for Xrumon Arigah, he has no psiionic powers, so removal is safe in that regard.

The dampener will be removed second, after the visual sensor suite. After its removal, psiionic influence on the surgery will be possible via Ullane Wistim and Friday Lovely’s psiionics.

Once the helmet sections are slid back to expose the head, the skull will be cut into via cranial drill and the dampener will be located. Once it is located the wires attaching it to the Dioscuri region will be carefully detached via a stent-retriever inserted by way of a micro catheter.

Once all wires have been detached and removed from the body, the dampener itself will be extracted.

As with all neurological operations during this surgery, laser soldering will once more be used to seal the brain tissue after incision and prevent damage and blood loss.

VITAL SIGNS MONITOR REMOVAL STEPS:

The monitor must first be removed from where it is hooked into the patient’s brain stem by PEDOT clusters. Sterile saline solution will be used to sanitize and avoid excess heating while drilling through the skull to reach the clusters, microspheres meshed with the brainstem via hydrogels.

A lighted scope will be used to view the site clearly, and it will be clipped to prevent full circulation so the patient does not die of blood loss. The clusters will be detached via a syringe inserted into the capillary of the correct cerebellar blood vessel to extract all the PEDOTS clusters, earlier located during the CT scan.

A small window will be drilled into the bone above the spinal cord to observe the monitor site and to make it possible to extract after the wires are detached, all the way down to the base of the vertebrae at the conus medullaris.

A few key incisions along the spine will be made to access the scar tissue around the wires, and nanotech delivering extracorporeal shockwave treatment will be used to loosen and draw them out by gentle tissue dissolution around the sites.

The neck muscles will be spread apart to allow extraction via retractor, then a bony well will be drilled to access the monitor, using a silicone replica of the monitor as a guide to ensure the exact necessary depth and no further.

The monitor will then be set aside, along with the wires.

ADVANCED WARFARE CENTER REMOVAL STEPS:

Located prior via CT scan, the microchips will be reached by syringes piercing the brain matter exactly where the chips in their capsules are located.

Care must be taken to ensure the brain tissue itself is not damaged in the process. As is standard, regenerative serum injections will be prepped in case damage is sustained.

The microchips will be set aside and later prepped for hazardous waste disposal.

BREATH OF LIFE SYSTEM REMOVAL STEPS:

Infrared fluorescent imaging will be used to provide a real-time model of the patient’s lungs and the structures within during this operation.

A bite block followed by an endoscope will be placed down the patient’s throat. This will deliver nanotech to dissolve the anti-clotting coating on the cannulas so that hemostatic nanoparticles may temporarily clot his blood to prevent the patient choking to death.

The oxygenator membrane and pump will be disabled by nanotech to safely cut off its power source, then the lung pumps’ tubes loosened and detached gradually. The tubes - cannulas- will be disassembled into their glass and wire components, and removed back up the endoscope via nanotech, and set aside. This step will need to be done incrementally over several minutes to ensure safe disconnect.

The stomach tube will also need to be disconnected and disassembled. All tubes require time to do so properly, as the cannulas are structured to avoid bubbling in the blood vessels and support a smooth transition to prevent improper drainage and maintain regular flow levels.

As the drainage is redirected, more hemostatic particles will both absorb the excess and other nanoparticles will temporarily graft and re-direct blood to other vessels so the patient does not die of blood loss.

In the likely case of damage caused during the surgery, nanotech carrying regenerative serum will also be accompanying the disassembly units. Regardless of additional harm, the vessels the tubes were attached to will need to be repaired by this method before the nanotech is removed once more.

Finally, a ventilator will need to be attached afterward to help his lungs transition back to their usual functionality.

BLOODFLOW REGULATOR REMOVAL STEPS:

The chest will be cut open below the collarbone, and pacing leads will be attached to the cardiac veins. Plastic tubing will be inserted over leads as sheaths to break up the scar tissue that has formed around the vein sites. The leads will be anchored via suture after fixation to prevent dislodging.

The regulator will first be disconnected from the devilfish reflex kit via surgical scissor and the wound sealed via harmonic scalpel, then disconnected from the heart itself.

A smaller, less powerful biventricular pacemaker will be installed to ease the loss of the old one, as his heart has come to depend on it. It will be implanted inside the heart itself, with a lead attached to a vein under the collarbone on one side and the pulse generator on the other.

In time, he will ideally be able to survive without one entirely.

DEVILFISH REFLEX KIT DISCONNECTION STEPS:

All conduits must be disconnected from the relevant nerve clusters without paralyzing the patient from damage to his nervous system or incurring fatal amounts of blood loss. This stage of the surgery will be the longest; surgeons will be swapped out every three hours to ensure focus and quality of work is retained.

The conduits will be cut via robotically operated surgical scissors, and harmonic scalpels will be used to seal openings.

In case of any damage, nerves can later be repaired via a few different methods: suture, grafting, or transfer. This will be a future operation, as any damage will only be able to be patched and not fully repaired in the present moment due to time constraints.

Intraoperative cell salvage will be used to prevent the patient from dying of blood loss. Blood will be collected, combined with anticoagulant, centrifuged, washed in saline, and reinfused periodically by robots.

One to two surgeons will operate a robotic set of instruments to detach the conduits - allowing for tremor-free and magnified views of the vital nerve clusters - as others perform the cell salvage and set the conduits aside, ready to pause in case of emergencies.

ANTI-TOXIN FILTER DISCONNECTION STEPS:

The dialysis units in the suit must be safely disconnected from the subject’s kidneys and liver.

The hazards primarily involve not tearing the fistula connection site, as the vein and artery connection will bleed heavily if torn during removal of the tubing. Excessive clotting should also be avoided.

The units must be prepared for removal. First, they will be switched off, then the units’ lines must be clamped to prevent blood loss. Saline will be kept on hand for emergency infusions, and to flush the tubes in case of any clotting.

Nanotech will be used to disconnect the tubing by loosening it safely so the needles may be removed nigh-instantly via scalpel and needle pliers. To best prevent damage and complications, they will be removed at the same angle they were inserted, and with moderate compression via nanotech to both prevent excess clotting and circulatory issues.

The kidney units themselves must be removed via disassembly via laparoscopic tube (similarly to the breath of life regulator) and the wound sealed shut using subcuticular stitches (placed below the epidermal layer).

The liver unit will follow the same process, using the same supracostal incision.

An external dialysis machine will then be connected following the removal of all three units, to ensure his body does not fail from the dependence it will have likely developed during its time connected to the units.

IRON JAW REMOVAL STEPS:

The front portion of the helmet will be opened, and the mouth propped open with gags.

The patient will be switched from breathing tubes to the laryngeal airway mask substitute, allowing direct access to the tongue.

This substitute will also contain the solvent to dissolve the hardening compound. When the compound is fully dissolved, it and the solvent can be safely swallowed.

WAVEFORM ALIGNMENT RETICULATOR DISCONNECTION STEPS:

First, the stomach will be inflated via tube-delivered carbon dioxide gas, to have a clear view of its lining.

The reticulator itself will first be secured via medical cinch. The clips holding the tube in place will be removed and the primed buds containing bio-sponge will be placed in the clips’ former locations via syringe.

The tube will be pulled through the stomach wall as the buds generate and weave a mesh plug over the hole in under a second. This allows for the minimum possible leakage.

The tube removal site will then be covered with a sterile dressing to further contain any later leakage and later changed periodically.

Afterward, the patient will receive medication to reduce his stomach acid to facilitate the healing and successful graft of the stomach hole.

CLEAN CHAIN REACTOR REMOVAL STEPS:

The final operation. Before it is undertaken, the vitals of the suit must be checked to ensure all other disconnects are stable.

Xrumon must still be under anesthesia, and he must be stabilized with fresh IV fluids to prepare him for full life-support disconnect.

Much like the reticulator, the reactor will follow similar securement and removal steps, and the stomach hole will need to be plugged using the same method as above. Once this hole is plugged, Xrumon will be fully detached from the suit.

Once this is done, the patient laid down to rest and stabilize with the aforementioned post-surgery procedures and the suit itself must be set aside.

---

ULLANE’S BACKUP PLAN, SHOULD XRUMON SEEM IRRECOVERABLY ON THE BRINK OF DEATH, AS A PROJECTED MESSAGE THAT WILL SHOW IF SHE IS COMPELLED TO USE UP ALL HER PSIIONIC ENERGY IN ONE BURST:

To my staff, should this be necessary -

I have had ports installed under my skin like those of helms. So that if I must overclock my psiionics to save Xrumon’s life, I will be immediately stabilized, preventing brain damage if not other damage from burnout, though the ports are also designed to release regenerative serum if such occurs. I have fallen unconscious, and can be safely revived after an hour’s rest.

I know you’ll question me; you’re right to. But even if this is the wrong decision, it’s the one I’m making. Ideally, it won’t be necessary.

I would still rather do it to ensure his survival. He must live.

No matter what.

- Ullane Wistim

5 notes

·

View notes

Text

How 3D Printing in India Is Transforming Industries with Affordable 3D Printers

The world of manufacturing is undergoing a silent revolution, and 3D printing in India is at the forefront of this exciting change. Over the last decade, 3D printers in India have become more affordable, accessible, and capable, making them a key tool across various industries, from healthcare to education and even the arts. Today, businesses, startups, and hobbyists alike are harnessing the power of 3D printers in India to create prototypes, final products, and even intricate art pieces like never before.

https://a3dxyz.com/wp-content/uploads/Goa_Customer_3DPrinter_Installation.webp

The Growth of 3D Printing in India

Initially, 3D printing was considered expensive and limited to niche markets. However, the scenario has changed drastically. With falling costs and increasing awareness, 3D printing in India has witnessed tremendous growth. Industries such as automotive, aerospace, and medical technology are investing heavily in 3D printers in India to speed up production and reduce costs.

Startups and entrepreneurs have especially embraced 3D printing in India. Thanks to the "Make in India" initiative and government support for manufacturing innovation, more companies are developing indigenous 3D printers in India that rival international models in quality and performance. As a result, India now boasts a thriving ecosystem of 3D printing service providers, hardware manufacturers, and design consultancies.

Why Industries Are Choosing 3D Printers in India

There are several reasons why industries are rapidly adopting 3D printers in India. The most significant is cost efficiency. Traditional manufacturing methods often involve expensive molds and tools. In contrast, 3D printers in India allow companies to produce complex shapes and customized parts at a fraction of the cost.

Speed is another factor. What once took weeks or months to manufacture can now be completed within days using 3D printers in India. Rapid prototyping has never been easier, allowing companies to test and modify designs quickly without incurring high costs.

Customization is the third major advantage. Whether it's a custom-designed prosthetic limb or a one-of-a-kind automotive component, 3D printing in India allows manufacturers to create highly personalized products with ease.

How 3D Printing Is Impacting Key Sectors

Healthcare

One of the most impressive impacts of 3D printing in India can be seen in the healthcare sector. Hospitals and medical researchers are using 3D printers in India to create prosthetic limbs, dental implants, surgical tools, and even tissue scaffolds. Customized prosthetics that once cost thousands of dollars are now affordable and accessible to many more people, improving lives across the country.

Education

Educational institutions are integrating 3D printers in India into their curriculums, helping students learn through hands-on experiences. Engineering colleges, architecture schools, and even primary schools are investing in 3D printers in India to foster creativity, problem-solving skills, and innovation among students.

Manufacturing and Automotive

Automotive giants and small-scale manufacturers alike are turning to 3D printers in India for faster and cheaper prototype development. Instead of waiting months for a new part design to be manufactured overseas, companies can now design, print, and test their components locally in just a matter of days.

Arts and Design

The creative community has also embraced 3D printing in India. Artists and designers are using 3D printers in India to craft intricate sculptures, jewelry, and fashion pieces. The ability to turn digital designs into tangible products has opened up endless possibilities for creativity and innovation.

The Future of 3D Printing in India

The future looks incredibly bright for 3D printing in India. Analysts predict that the market for 3D printers in India will grow by more than 20% annually over the next five years. The rise of affordable 3D printers, locally sourced materials, and advancements in software will make it easier than ever for individuals and businesses to adopt this technology.

Additionally, research and development are moving toward bioprinting, construction 3D printing, and metal 3D printing, promising even greater breakthroughs. With continuous investment in infrastructure, education, and R&D, 3D printing in India is poised to become a global leader in additive manufacturing.

How to Choose the Best 3D Printers in India

If you're considering entering the world of 3D printing in India, selecting the right printer is crucial. First, assess your needs—whether you're looking to create prototypes, final products, or art projects. Next, compare popular models of 3D printers in India based on factors like print quality, material compatibility, speed, and cost.

Some of the most trusted brands offering 3D printers in India include Ultimaker, Creality, and Indian startups like Divide By Zero and Imaginarium. Many of these companies also provide excellent after-sales service, which is essential for maintaining your equipment in top condition.

Additionally, consider the availability of consumables like filaments and resins locally. An abundant supply of materials will ensure that you can continue printing without delays.

Final Thoughts

There has never been a better time to explore the potential of 3D printing in India. With increasing affordability, expanding applications, and the spirit of innovation, 3D printers in India are changing the way we design, manufacture, and create. Whether you are a business leader, an entrepreneur, a student, or an artist, the world of 3D printing offers exciting opportunities to bring your ideas to life.

0 notes

Text

Helping Heal Bone

A 3D-printed scaffold with cryogel fibres incorporating vessel growth- and bone formation-enhancing peptides for promoting bone regeneration at the site of skull damage or defect

Read the published research article here

Image from work by Yuxuan Wei and Hao Pan, and colleagues

Zhejiang Engineering Research Center for Tissue Repair Materials, Wenzhou Institute, University of Chinese Academy of Sciences, Wenzhou, Zhejiang, China

Image originally published with a Creative Commons Attribution 4.0 International (CC BY-NC 4.0)

Published in Science Advances, February 2024

You can also follow BPoD on Instagram, Twitter and Facebook

17 notes

·

View notes

Text

3D-printed collagen scaffolds mimic living tissues and may replace animal testing

- By Nuadox Crew -

Engineers at the University of Pittsburgh have developed a groundbreaking method for 3D printing collagen-based scaffolds—called CHIPS—that support the growth and self-organization of living cells into functional tissues.

Led by Daniel Shiwarski in collaboration with Adam Feinberg from Carnegie Mellon, this innovation combines natural biomaterials with advanced microfluidic design to mimic real organ environments.

Unlike traditional synthetic models, these collagen structures allow cells to grow, interact, and function as they would in the body, including responding to stimuli like glucose.

Integrated with a custom bioreactor system (VAPOR), the platform enables complex 3D vascular networks and offers a more human-relevant alternative to animal testing.

All designs are open-source, with the long-term goal of modeling diseases like hypertension and replacing animal studies in biomedical research.

Header image: Online cover of Science Advances, April issue. Credit: Daniel Shiwarski.

Read more at University of Pittsburgh Swanson School of Engineering

Scientific paper: “3D bioprinting of collagen-based high-resolution internally perfusable scaffolds for engineering fully biologic tissue systems” by Daniel J. Shiwarski, Andrew R. Hudson, Joshua W. Tashman, Ezgi Bakirci, Samuel Moss, Brian D. Coffin and Adam W. Feinberg, 23 April 2025, Science Advances. DOI: 10.1126/sciadv.adu5905

Related Content

Scientists achieve the milestone of being the first to successfully 3D-print functional human brain tissue

Other Recent News

Household washing machines may leave behind harmful pathogens on clothing.

Facial and eye biomarkers reveal new insights into tinnitus severity, offering potential for treatment testing.

Uncovered mechanisms improve understanding of advanced AI memory devices.

One molecule significantly enhances both the efficiency and durability of perovskite solar cells.

0 notes

Text

Chitosan's Sustainable Rise: Unpacking the Future of the Chitosan Market Through 2032

Market Overview and Growth Drivers

The chitosan market is experiencing significant momentum, driven by increasing demand across a variety of industries. Derived from chitin, which is commonly sourced from shrimp and crab shells, chitosan is a biodegradable, non-toxic, and biocompatible polymer that is gaining popularity in several sectors, notably pharmaceuticals, biomedicine, water treatment, cosmetics, and agriculture. Its versatility and natural origin make it a key material in the push toward more sustainable and eco-friendly products. As industries pivot to greener alternatives, chitosan is poised to play an even larger role in the years ahead.

Get Sample Copy @ https://www.meticulousresearch.com/download-sample-report/cp_id=6106?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=02-05-2025

Increasing Demand from the Pharmaceutical and Biomedical Sectors

One of the most impactful growth drivers in the chitosan market is its increasing adoption within the pharmaceutical and biomedical fields. The biopolymer's unique characteristics—such as biocompatibility, non-toxicity, and biodegradability—make it suitable for various medical applications. In the pharmaceutical industry, chitosan is being used extensively for drug delivery systems, especially for medications that require enhanced solubility and controlled release. The ability of chitosan to form nanoparticles that can encapsulate active pharmaceutical ingredients has proven to improve both the efficacy and stability of these drugs. It also plays a role in reducing side effects and increasing patient adherence to treatment regimens.

Moreover, chitosan’s application in the biomedical sector goes beyond drug delivery. It is increasingly being utilized in wound healing, surgical sutures, and tissue regeneration. Its natural antimicrobial properties and compatibility with human tissues help promote faster healing and prevent infections. Chitosan-based products are showing promise in tissue engineering, where they serve as scaffolds that support new cell growth while naturally degrading in the body over time, eliminating the need for surgical removal.

Rising Demand for Chitosan in Water Treatment Solutions

Water purification is another major area where chitosan is proving to be highly valuable. As concerns over water scarcity and pollution intensify, especially in urban and industrial regions, the need for eco-friendly water treatment solutions has grown. Chitosan is widely used as a natural flocculant in water treatment processes. Its positive charge allows it to bind effectively with negatively charged impurities, including heavy metals, oils, and various organic pollutants. This property makes it extremely useful in both municipal and industrial water treatment facilities.

The compound’s application in water treatment is not just limited to basic purification. Research is actively expanding into the development of chitosan-based nanomaterials and advanced composites. These innovations aim to improve the efficiency of processes such as filtration, desalination, and wastewater recycling. As global populations grow and demand for clean water rises, chitosan’s role in sustainable water management will become even more critical.

Chitosan Market Trends

Rising Demand for Eco-friendly and Sustainable Solutions

The broader market trend of seeking environmentally responsible materials is having a strong impact on the chitosan industry. As awareness about chemical pollution, plastic waste, and the need for sustainable resources grows, industries and consumers alike are leaning toward bio-based alternatives. Chitosan fits perfectly into this narrative. Its biodegradability and lack of toxicity make it an attractive substitute for synthetic polymers and chemicals in applications ranging from agriculture to food packaging and cosmetics.

In water treatment, for instance, chitosan-based flocculants are a safer alternative to synthetic compounds, which can pose environmental risks. Their use does not harm aquatic ecosystems when applied in recommended dosages. Increasing government regulations promoting sustainability and the growing popularity of green products are further fueling this trend. Industries are now investing more heavily in research to develop new chitosan derivatives that can meet the evolving needs of sustainable product development.

Get Full Report @ https://www.meticulousresearch.com/product/chitosan-market-6106?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=02-05-2025

Chitosan Market Analysis: Top Market Opportunity

By Source: The Shrimps Segment to Dominate the Market in 2025

In terms of raw material sources, the shrimp segment is expected to hold the largest market share in 2025. The abundance and cost-effectiveness of shrimp waste, which contains high chitin content, make it the most practical and scalable source for chitosan extraction. Well-established extraction techniques, combined with the growing global aquaculture industry, especially in regions like Asia-Pacific, North America, and Latin America, ensure a steady supply of raw materials.

Shrimp-derived chitosan is not only widely available but also suitable for a broad range of industrial applications, from pharmaceuticals and personal care products to agriculture and food. The increasing shift toward bio-based and sustainable materials across industries is further boosting demand for shrimp-based chitosan. As shrimp production continues to rise globally, the availability of shells and byproducts used in chitosan extraction is also set to grow, reinforcing the dominance of this segment.

Geographical Analysis

Asia-Pacific Dominates the Chitosan Market

Regionally, Asia-Pacific is forecasted to hold the largest share of the global chitosan market in 2025. Countries like China, India, and South Korea are leading the way, supported by the abundant availability of raw materials, particularly shrimp and crab shells. Additionally, these countries are experiencing rapid industrialization and urbanization, which has led to increased pollution and water scarcity. As a result, there is growing demand for water treatment solutions in the region, much of which is being met through eco-friendly products like chitosan.

The growth of the aquaculture industry, particularly in China and India, further contributes to the region’s dominance, providing a consistent supply of shell waste needed for chitosan production. Moreover, Asia-Pacific is witnessing strong growth in the pharmaceutical, cosmetics, and food and beverage industries, all of which are increasingly incorporating bio-based materials into their formulations. In particular, China is expected to be the region’s top consumer of chitosan by 2025, thanks to the country’s expanding demand for natural ingredients in health, beauty, and food applications.

North America to Register the Fastest Growth

Although Asia-Pacific holds the largest market share, North America is projected to record the highest CAGR from 2025 to 2032. This growth is being fueled by increasing environmental awareness and favorable government initiatives promoting sustainable alternatives across various industries. The region is seeing strong interest in chitosan for use in water treatment, biopharmaceuticals, and natural cosmetics.

In addition, North America is home to a number of innovative companies focused on the production of premium-grade chitosan for advanced medical and industrial applications. These firms are investing in R&D to develop next-generation chitosan products that meet the growing demand for high-performance, sustainable solutions.

Key Players in the Chitosan Market

The chitosan market features a range of global players actively working to innovate and expand their product offerings. Leading companies include Heppe Medical Chitosan GmbH (Germany), KitoZyme S.A. (Belgium), Marine Hydrocolloids Private Limited (India), Panvo Organics Pvt Ltd. (India), Dainichiseika Color & Chemicals Mfg. Co., Ltd. (Japan), Marshall Marine Products Private Limited (India), Primex ehf (Iceland), Qingdao Yunzhou Biochemistry Co. Ltd. (China), Austanz Chitin Pty Ltd (Australia), BIO21 Co., Ltd. (Thailand), Golden-Shell Pharmaceuticals Co., Ltd. (China), Advanced Biopolymers AS (Norway), Tidal Vision Products, Inc. (U.S.), and Chitinor AS (Norway).

Recent Industry Developments

Recent product launches and strategic initiatives are shaping the future of the chitosan market. In September 2025, CuanTec Ltd (U.K.) introduced its Chrystal chitosan range. These high-specification products are available in various forms—powders, granules, and solutions—and are targeted at biomedical uses such as wound care. With a high viscosity and 89% degree of deacetylation, this range is designed for advanced applications.

Meanwhile, in August 2022, The trū Shrimp Company (U.S.) began production of its trū chitosan line for medical, pharmaceutical, and cosmetic use. These new developments reflect the growing focus on specialized, high-purity chitosan products tailored for high-value sectors, emphasizing the market’s evolution toward premium and customized offerings.

Get Sample Copy @ https://www.meticulousresearch.com/download-sample-report/cp_id=6106?utm_source=Blog&utm_medium=Product&utm_campaign=SB&utm_content=02-05-2025

0 notes

Text

Chitosan Market Anticipated to Grow Due to Biomedical Demand

Chitosan, a versatile biopolymer obtained through the deacetylation of chitin, finds extensive applications across industries such as healthcare, agriculture, water treatment, cosmetics, and food preservation. Its inherent advantages—biodegradability, biocompatibility, non-toxicity, film-forming ability, and inherent antimicrobial activity—make it an increasingly preferred material for advanced drug delivery systems, wound dressings, and tissue engineering scaffolds. In agriculture, chitosan-based formulations serve as biofertilizers and biopesticides, enhancing crop yield and reducing reliance on synthetic chemicals. In water treatment, its high affinity for heavy metals and dyes enables efficient removal of contaminants, while in cosmetics, it acts as a natural thickener, moisturizing agent, and preservative extender. Rising consumer demand for eco-friendly and sustainable products is propelling R&D efforts to develop novel chitosan derivatives with improved solubility and functional properties. Chitosan Market - https://www.patreon.com/posts/chitosan-market-127799726

#ChitosanMarket#ChitosanMarketShare#EnzymaticProduction#Biopolymers#BiomedicalApplications#CoherentMarketInsights

0 notes

Text

Innovations in Biomedical Materials: Shaping the Future of Healthcare

The biomedical materials market is undergoing significant transformation, fueled by advancements in medical technologies, growing healthcare needs, and the push for more biocompatible solutions in treatment and diagnostics. According to insights from Persistence Market Research, the increasing integration of these materials into a wide range of healthcare applications is playing a pivotal role in modernizing the way medical conditions are treated, especially in regenerative medicine, orthopedics, and cardiovascular therapy.

Evolving Role of Biomedical Materials in Healthcare

Biomedical materials—engineered substances used to replace, restore, or enhance biological functions—have evolved beyond traditional implants and prosthetics. They now encompass a broad spectrum of natural and synthetic materials tailored for use in tissue engineering, wound healing, drug delivery, and biosensors. These materials are designed to interact with biological systems safely and effectively, which makes them critical components in both invasive and non-invasive medical procedures.

The rise in chronic diseases, aging populations, and the demand for advanced medical care have driven the need for more functional and adaptive materials. Biomedical materials offer numerous advantages, including reduced rejection rates, enhanced healing times, and greater customization for patient-specific conditions.

Surge in Demand for Regenerative Medicine

One of the most prominent areas benefiting from biomedical materials is regenerative medicine. The ability of certain biomaterials to support cell growth and tissue regeneration has opened new frontiers in treating injuries, degenerative diseases, and even organ failure. Hydrogels, bioactive ceramics, and biodegradable polymers are among the key materials being explored for these purposes.

Scientists and engineers are developing scaffold-based materials that act as temporary structures to support new tissue formation. These materials mimic the natural extracellular matrix and are increasingly used in reconstructive surgeries and stem cell therapies. The regenerative potential of biomedical materials is particularly vital in orthopedic and dental surgeries, where bone and soft tissue repair is essential.

Innovations in Drug Delivery Systems

Biomedical materials are playing a growing role in the development of sophisticated drug delivery systems. These materials are engineered to control the rate, time, and place of drug release, ensuring improved efficacy and reduced side effects. Biodegradable polymers and nanomaterials have become instrumental in creating targeted delivery systems for cancer therapies, hormone treatments, and chronic disease management.

Smart biomaterials that respond to stimuli such as pH, temperature, or enzymes are being investigated for their ability to deliver therapeutics with precision. These responsive systems offer a way to minimize systemic exposure and enhance patient compliance, especially in long-term treatments.

Orthopedic and Cardiovascular Applications Drive Market Expansion

Orthopedic implants, such as hip and knee replacements, have long relied on biomedical materials for durability and biocompatibility. Innovations in materials science have led to the development of implants that are not only more resistant to wear and corrosion but also support better integration with bone tissue. Materials like titanium alloys, bioactive glasses, and composite polymers are increasingly used in joint replacements and fracture fixation devices.

Similarly, in the cardiovascular field, biomedical materials are essential in the fabrication of stents, grafts, and heart valves. These materials must meet strict performance criteria, including flexibility, tensile strength, and minimal thrombogenicity. The development of bioresorbable stents and polymer-coated devices illustrates how the market continues to evolve in response to clinical demands.

Biocompatibility and Regulatory Considerations

The primary requirement for any biomedical material is biocompatibility—its ability to perform without eliciting an adverse reaction from the body. Achieving this involves rigorous testing and adherence to global regulatory standards. Regulatory frameworks such as those from the FDA and the European Medicines Agency ensure that materials used in medical applications meet safety, efficacy, and quality benchmarks.

As the biomedical materials market grows, manufacturers are investing in R&D to develop new formulations that meet evolving standards. The focus is shifting toward materials that degrade harmlessly in the body, reducing the need for secondary surgeries and enhancing overall patient outcomes.

Technological Advancements and Material Innovations

Nanotechnology, 3D printing, and biofabrication are reshaping the biomedical materials landscape. Nanomaterials, for instance, offer enhanced surface properties and drug-carrying capacity, while 3D printing allows for the creation of custom implants and scaffolds tailored to patient-specific anatomies. These technologies enable faster prototyping and significantly reduce time-to-market for innovative medical products.

Biofabrication—a technique combining cells and biomaterials to create tissue-like structures—is paving the way for the future of personalized medicine. This approach is being researched for applications such as artificial skin, blood vessels, and even organ printing, highlighting the versatility and growing importance of biomedical materials.

Market Dynamics: Drivers and Restraints

Several key factors are driving the growth of the biomedical materials market. The global burden of chronic and degenerative diseases is increasing, creating a higher demand for advanced treatment solutions. Coupled with growing awareness about the benefits of minimally invasive procedures and an uptick in surgical interventions, the use of specialized biomedical materials is on the rise.

On the other hand, challenges such as high development costs, complex manufacturing processes, and stringent regulatory requirements can act as restraints. Moreover, the need for specialized infrastructure and trained professionals to handle these materials further limits their adoption in some regions, particularly in developing economies.

Regional Outlook and Growth Potential

North America remains a leading region in the biomedical materials market, supported by a well-established healthcare infrastructure, robust R&D investments, and favorable reimbursement policies. The presence of major industry players and advanced research institutions further contributes to the region’s market dominance.

Europe follows closely, benefiting from progressive healthcare reforms and collaborative efforts between universities and biotech firms. Countries such as Germany, the UK, and France are at the forefront of biomaterials innovation, especially in orthopedics and cardiovascular therapy.

Asia Pacific is emerging as a high-growth region, driven by expanding healthcare access, increased healthcare spending, and a growing elderly population. Countries like China, India, and Japan are investing in local manufacturing and medical research, which is expected to fuel market expansion in the coming years.

Competitive Landscape and Strategic Developments

The biomedical materials market is characterized by intense competition and continuous innovation. Leading players are focusing on mergers, acquisitions, and strategic partnerships to expand their product portfolios and global reach. Collaborations between material science companies and healthcare providers are enabling faster translation of research into commercially viable products.

Companies are also prioritizing sustainability and environmental impact in their R&D efforts, exploring plant-based and biodegradable materials that align with the principles of green chemistry and circular economy.

Future Outlook

The future of the biomedical materials market looks promising, with immense potential for growth and innovation. As healthcare systems evolve to accommodate the needs of an aging population and manage chronic diseases more effectively, the demand for safer, more efficient, and personalized medical solutions will intensify.

Advancements in biotechnology, materials science, and engineering are expected to converge, leading to the development of next-generation biomedical materials that are smarter, more adaptive, and more integrated with digital healthcare systems. From AI-assisted design of biomaterials to integration with wearable technologies, the scope for innovation is vast.

Conclusion

The biomedical materials market is poised to become a cornerstone of modern healthcare, offering transformative solutions across diverse medical applications. With growing emphasis on biocompatibility, patient-centric care, and technological integration, the market will continue to attract significant investment and research. Persistence Market Research highlights that stakeholders across the value chain must collaborate closely to address regulatory, technological, and accessibility challenges, ensuring that biomedical materials can fully deliver on their promise to improve patient outcomes and healthcare efficiency.

0 notes

Text

Biological Skin Substitutes Market Share, Top Trends and Forecast 2037

The Biological Skin Substitutes Market is experiencing sustained growth due to rising incidences of acute and chronic wounds, along with growing advancements in tissue engineering. In 2024, the market was valued at approximately USD 379.46 million, and it is forecast to reach USD 813.50 million by 2037, growing at a Compound Annual Growth Rate (CAGR) of 8.89% during the forecast period. This growth reflects increasing global demand for advanced wound care products that enhance healing and minimize complications.

Biological Skin Substitutes Industry Demand

Biological skin substitutes are bioengineered or naturally derived materials used to replace damaged skin, promote healing, and restore tissue function. These substitutes may come from human or animal tissues or be synthetically engineered with biological components to replicate the properties of natural skin.

They are commonly used in treating burns, chronic ulcers, surgical wounds, and for applications in reconstructive surgery. Compared to traditional wound care methods, biological skin substitutes offer improved healing, reduced infection risks, and better cosmetic outcomes.

Key Industry Demand Factors:

Cost-Effectiveness: Despite higher upfront costs, biological skin substitutes reduce overall treatment expenses by accelerating wound healing and reducing hospital stays and complications.

Ease of Administration: These products are designed for relatively straightforward clinical application, enabling broader use across a range of care settings, from specialized centers to outpatient clinics.

Long Shelf Life and Accessibility: Many biological skin substitutes are manufactured and preserved in ways that extend their shelf life, making them more readily available for emergency and long-term care.

Rising geriatric populations, increased rates of diabetes and obesity (which contribute to chronic wounds), and advances in tissue preservation techniques are further fueling market demand.

Biological Skin Substitutes Market: Growth Drivers & Key Restraint

Growth Drivers –

High Prevalence of Chronic and Acute Wounds The increasing global incidence of burns, diabetic foot ulcers, pressure ulcers, and surgical wounds has led to rising demand for efficient wound care solutions.

Technological Advancements in Bioengineering Innovations in biomaterials, regenerative medicine, and tissue scaffolding have enabled the development of more effective and biocompatible skin substitutes, enhancing healing outcomes and reducing rejection rates.

Expansion of Specialized Wound Care and Home Healthcare The growing presence of wound care centers and the shift toward home-based care have widened the usage of easy-to-apply biological skin products that require minimal professional intervention.

Request Report Sample@ https://www.kennethresearch.com/sample-request-10352534

Restraint –

High Production Costs and Regulatory Challenges Manufacturing biological skin substitutes involves sophisticated processes, and strict regulatory approval standards can delay market entry. Additionally, price sensitivity in low-income regions limits adoption, despite clinical benefits.

Biological Skin Substitutes Market: Segment Analysis

Segment Analysis by Product Type (Human Donor Tissue-Derived Products, Acellular Animal-Derived Products, Bioengineered Skin Substitutes):

Human Donor Tissue-Derived Products: These products are derived from cadaveric or live donor skin, processed to reduce immunogenicity. They are widely used in burn care and are known for excellent integration with host tissue.

Acellular Animal-Derived Products: These substitutes are primarily sourced from porcine or bovine collagen and are processed to remove cellular components while preserving structural integrity.

Bioengineered Skin Substitutes: Engineered using synthetic scaffolds integrated with biological components or live cells, these substitutes are cutting-edge solutions for complex wounds and are often used in reconstructive and cosmetic procedures.

Segment Analysis by Application (Acute Wounds (e.g., Burns, Surgical Wounds), Chronic Wounds (e.g., Diabetic Foot Ulcers, Pressure Ulcers, Venous Leg Ulcers), Reconstructive Surgery):

Acute Wounds (e.g., Burns, Surgical Wounds): The use of biological skin substitutes in acute wound care is significant due to the urgency and severity of tissue damage, requiring fast-acting solutions that can promote rapid regeneration and minimize infection.

Chronic Wounds (e.g., Diabetic Foot Ulcers, Pressure Ulcers, Venous Leg Ulcers): Chronic wounds are a leading driver of long-term care costs. Biological skin substitutes are increasingly used to manage these wounds by promoting granulation and epithelialization where standard therapies fail.

Reconstructive Surgery: These products support tissue regeneration and aesthetic restoration in reconstructive surgeries following trauma, cancer resection, or congenital anomalies.

Segment Analysis by End‑User(Hospitals and Clinics, Ambulatory Surgical Centers, Specialized Wound Care Centers, Home Healthcare Settings):

Hospitals and Clinics: The primary users of biological skin substitutes, hospitals manage both trauma and chronic wound cases. They benefit from advanced treatment protocols and multidisciplinary teams.

Ambulatory Surgical Centers: These centers use skin substitutes for elective procedures and post-operative wound management, especially in reconstructive and cosmetic surgeries.

Specialized Wound Care Centers: These facilities focus on non-healing wounds and chronic conditions, using advanced products like biological skin substitutes as a standard part of therapy.

Home Healthcare Settings: The increasing availability of easy-to-use, ready-to-apply skin substitutes enables patients to manage chronic wounds at home, reducing hospital readmissions and supporting long-term care.

Biological Skin Substitutes Market: Regional Insights

North America:

North America holds the U.S. leads in the adoption of novel wound care technologies, supported by strong R&D initiatives and a high prevalence of diabetic and aging populations.

Europe:

Europe maintains a robust presence, driven by government-supported healthcare systems and a growing focus on aging-related chronic wound care. Countries such as Germany, the UK, and France are investing in regenerative medicine and advanced wound care, promoting the adoption of biological skin substitutes in both public and private healthcare sectors.

Asia-Pacific (APAC):

The APAC region is poised for significant growth, fueled by expanding healthcare infrastructure, rising awareness of modern wound care solutions, and a growing burden of diabetes and burn injuries. Countries like China, India, and Japan are seeing increased investments in biotechnology and medical device sectors, opening new opportunities for biological skin substitute manufacturers.

Access our detailed report link:https://www.kennethresearch.com/report-details/biological-skin-substitutes-market/10352534

Top Players in the Biological Skin Substitutes Market

Organogenesis Inc.,Integra LifeSciences,Smith & Nephew,Mölnlycke Health Care,Medtronic,KCI, an Acelity Company,Gunze Limited,Japan Tissue Engineering Co., Ltd.,Avita Medical,HansBiomed Corporation,Stratatech Corporation,Vericel Corporation,Covalon Technologies Ltd.,Tissue Regenix Group,Bioventus,Shire Regenerative Medicine,Amniox Medical,Human BioSciences,Osiris Therapeutics,CellResearch Corporation

0 notes