#Transfer molding

Text

https://www.dowellmoulds.com/blog/processes-for-molding-thermosetplastics-and-thermoplastics

#Dowell Moulds#plastic mould manufacturers in India#Injection molding#Compression molding#Transfer molding#Blow molding#Extrusion molding#Thermoset#Thermoplastic#Mold cavity#Gate#Pellets

0 notes

Text

In-mould labels are nothing but printed polypropylene labels and it takes the shape of a container post that is directly injected in the mould. The overall process results in making the mould & labels get united together. There are three key process of moulding in mould labels and the most popular process is discussed below. Read it on & learn more.

#in mould labels#in mold labeling injection molding#in mold labeling process#in mould label printing#iml in mold labeling#in mould labelling companies#iml in mould labeling#in mould#in mould printing#Bangles Heat Transfer labels#Pencil box Heat Transfer labels#Stationery Heat Transfer labels#Steel Heat Transfer labels#Container Heat Transfer labels#Hologram Transfer Label#Labels for Paint Container#Heat Transfer labels

0 notes

Video

youtube

Mold Industry Trackless Transfer Cart,Environmental PU Wheels Transfer T...

1 note

·

View note

Text

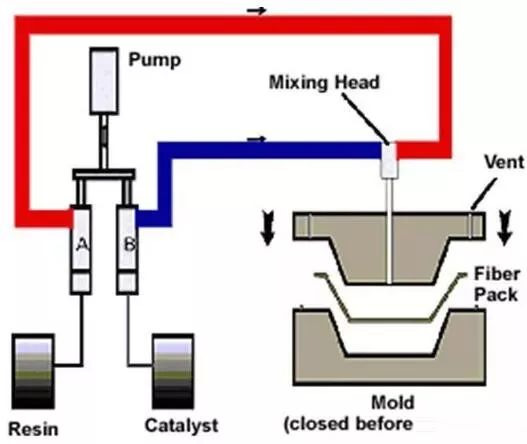

What is the RTM Molding Process for Composite Material?

RTM refers to a process technology in which low-viscosity resin flows in a closed mold, infiltrates reinforced materials and solidifies into shape. It belongs to the category of liquid forming or structural liquid forming technology of composite materials. The specific method is to pre-place reinforced materials that have been rationally designed, cut or mechanized pre-formed into the designed mold. The mold needs to be sealed and tightened around the perimeter to ensure smooth resin flow. After the mold is closed, a certain amount of resin is injected. And after the resin solidifies, the desired product can be obtained by demoulding.

The RTM molding process has the following main characteristics

RTM is a closed mold molding process. The infiltration of the reinforcement and the resin is completed by the rapid flow of pressurized resin in a closed mold cavity, instead of manual infiltration in hand lay-up and spraying processes, nor expensive mechanized infiltration in prepreg and SMC processes. RTM is a low-cost, high-quality semi-mechanized fiber/resin impregnation method.

The RTM molding process uses reinforced material preform technology that is similar to the shape of the product. Once the fiber/resin infiltration is completed, it can be cured, so a low-viscosity fast-curing resin system can be used. It can also heat the RTM mold to further improve production efficiency and product quality.

The reinforced material preform in the RTM molding process can be prepared from chopped strand mat, fiber cloth, wrinkle-free fabric, three-dimensional knitted fabric, three-dimensional braided fabric, etc. And according to the performance requirements, selective reinforcement, local reinforcement, hybrid reinforcement, and embedded and sandwich structures can be used, which can give full play to the performance designability of FRP/composite materials.

The closed-mold resin injection method of the RTM molding process can greatly reduce the toxicity of harmful resin components to the human body and the environment, and meet the increasingly stringent restrictions on the volatilization concentration of harmful gases such as styrene in advanced industries.

The RTM molding process generally adopts a low-pressure injection process, which is conducive to the preparation of complex overall structures with large sizes, complex shapes, and two-sided surfaces.

According to the requirements of the production scale, RTM molds can be selected from different grades of molds such as polyester molds, epoxy molds, surface nickel-plated material molds, alloy molds, aluminum molds and steel molds to reduce costs.

Requirements of RTM technology on epoxy resin systems

Epoxy resin has low viscosity at room temperature or lower temperature, and has a certain storage period.

Epoxy resin has good wettability, matching and adhesion to reinforced materials.

The epoxy resin system has good curing reactivity and does not produce volatile matter and other undesirable side reactions during the curing reaction. The curing temperature should not be too high, and the curing speed should be appropriate.

As a high-performance composite material, epoxy resin is also required to have high heat resistance and moisture resistance, excellent mechanical properties, especially toughness. In some special applications, it should also have certain functionalities, such as low dielectric loss, high conductivity, excellent flame retardancy, etc.

High-performance epoxy resin system is still the most widely used high-performance composite matrix. Epoxy resin systems usually used to make prepregs are difficult to mold using the RTM process due to their high viscosity and short storage life. In order to be suitable for RTM molding, YQXPOLYMER launched the 9320A/B epoxy resin curing system. 9320A/B is a special epoxy resin curing system for RTM process. This system product is composed of special epoxy resin and modified amine curing agent. The 9320A/B epoxy resin curing system has the characteristics of fast curing speed, good water resistance, high hardness, good adhesion, mechanical properties of the cured material and high Tg temperature. It can be widely used in automotive composite materials for RTM molding, cultural and sports products (fishing rods, badminton rackets, golf clubs, etc.) and other carbon fiber composite materials. The RTM process has a wide range of advantages. The molded parts have high fiber system content, low porosity, low water absorption, and good mechanical properties. Conventional resins and reinforcing materials can be used in the RTM process.

More information or free samples or price quotations, please contact us via email: [email protected] , or voice to us at: +86-28-8411-1861.

#epoxy resin#epoxy resin manufacturer#bisphenol a type epoxy resin#RTM#RTM molding process#epoxy resin supplier#epoxy resin system#RTM process#resin transfer molding#epoxy composite material#epoxy resin curing system#composite material

0 notes

Text

Causes and countermeasures of deformation of injection molded parts-9

Serial No. 9 (Friends who are interested can follow Gud Mold and view previous serials from historical messages)

3) Cooling water circuit temperature setting

Heat transfer efficiency of cooling system has a great influence on product deformation. Due to complexity of product structure, an absolutely uniform cooling effect cannot be achieved. In actual operation, connecting water lines in heat…

View On WordPress

#Causes and Countermeasures of Deformation of Injection Molded Parts#Cooling water circuit temperature#Deformation of Injection Molded Parts#Heat transfer efficiency of cooling system#injection molded parts#injection molding#injection molding production#Mold designer#Mold temperature#molding process#Product deformation

0 notes

Text

Website : https://www.finessemediums.co.nz

Address : Auckland, New Zealand

Finesse Mediums, based in Auckland, New Zealand, specializes in providing a wide range of polymer clay art supplies for artists, crafters, and jewelry makers. With a focus on quality and affordability, they offer textures, silkscreens, findings, charms, molds, and more. Catering to both local and international customers, they ensure quick delivery times and offer free shipping on larger orders. Their commitment to customer satisfaction is evident in their responsive customer service and willingness to incorporate customer feedback into their product selection.

Instagram : https://www.instagram.com/finessemediums/

Keywords:

clay sculpting tools

jewelry making with clay

pottery clay for sale

craft supplies store

handcrafted polymer clay jewelry

silkscreens for polymer clay

clay sculpting techniques

clay sculptures for sale

clay pottery supplies

clay modeling supplies

clay earrings online

polymer clay jewelry sets

polymer clay online store

clay charms for sale

polymer clay techniques

polymer clay creations for sale

clay art supplies nz

jewelry making materials australia

clay textures international

silkscreens for clay crafting

clay findings online

clay molds for artists

clay jewelry components

clay crafting materials

clay beads for jewelry

clay artistry online store

clay workshops international

clay tutorials for artists

polymer clay creations australia

clay art projects for sale

custom clay pieces nz

clay art tools online

clay design materials

clay artistry supplies australia

clay jewelry components international

clay art innovations online

polymer clay online tutorials

clay crafting ideas australia

clay artistry workshops nz

unique clay textures online

handmade silkscreens for clay

custom clay charms for sale

polymer clay molds online

clay findings and components

craft supplies for artists

clay jewelry online store

polymer clay crafting materials

clay earrings and beads

artistic clay sculptures online

online clay artistry store

international clay workshops

clay tutorials and techniques

handmade polymer clay creations

clay art projects for artists

custom clay pieces for sale

innovative clay art tools

clay modeling materials online

unique clay design components

artistry supplies for clay

clay jewelry components store

clay artistry innovations

polymer clay tutorials online

clay crafting ideas and projects

clay jewelry making materials

polymer clay art workshops

unique clay textures for sale

custom clay charms online

polymer clay molds and tools

clay findings and components store

artistic craft supplies online

unique clay jewelry components

clay sculpting tools and materials

polymer clay artistry store

clay workshops and tutorials

clay art projects and ideas

custom polymer clay pieces online

innovative clay art tools and materials

clay modeling techniques for artists

handmade clay textures online

silkscreens for artistic clay projects

custom clay charms and beads

polymer clay molds and textures

craft supplies for clay artistry

clay jewelry components for sale

clay artistry innovations online

polymer clay tutorials and techniques

unique clay jewelry making materials

polymer clay artistry workshops

innovative clay textures for sale

handmade silkscreens for polymer clay

custom polymer clay charms online

unique silkscreen tools for clay

custom charms and links collection

artistic clay embellishments shop

vibrant polymer clay creations store

personalized clay transfers online

silkscreen tools for clay artistry

unique polymer clay mold options

foil techniques for creative clay

vibrant polymer clay jewelry pieces

creative liquid clay accessory set

creative liquid clay accessory collection

handmade clay texture mold assortment

exclusive jewelry findings and links set

decorative posts for unique clay artistry

unique clay texture mold assortment

personalized clay transfer essentials kit

quality micas and glitters set for sale

alcohol inks and finishing tools assortment

bespoke polymer clay mold collection for sale

foil techniques for personalized clay art

vibrant polymer clay jewelry assortment online

creative liquid clay accessory collection for sale

handmade clay texture mold assortment for sale

exclusive jewelry findings and links set online

#creative liquid clay accessory collection#handmade clay texture mold assortment#exclusive jewelry findings and links set#decorative posts for unique clay artistry#unique clay texture mold assortment#personalized clay transfer essentials kit#quality micas and glitters set for sale#alcohol inks and finishing tools assortment#bespoke polymer clay mold collection for sale#foil techniques for personalized clay art#vibrant polymer clay jewelry assortment online#creative liquid clay accessory collection for sale#handmade clay texture mold assortment for sale#exclusive jewelry findings and links set online

1 note

·

View note

Text

OREOS DRESSED FOR THE HOLIDAY SEASON

Yes, the Bewitching Kitchen is in full festive mode! Today the Oreo cookie, brought home from a humble shelf in the grocery store, gets dressed up for major party time… Several ideas for you, but I will start with maybe my favorite, as it gives me a chance to talk about a new product I recently tried.

All my Oreos are made the same way, with compound chocolate (Wilton melting wafers, or other…

View On WordPress

#chocolate covered oreos#chocolate transfer sheets#compound chocolate#holiday baking#oreo molds#Oreos

0 notes

Text

David Datro Fofana joins Chelsea from Molde in an £8m deal - with forward signing a six-and-a-half year contract

ICYMI: David Datro Fofana joins Chelsea from Molde in an £8m deal - with forward signing a six-and-a-half year contract #ChelseaFC

Chelsea have completed the signing of Ivory Coast forward David Datro Fofana on a six-and-a-half year deal from Norwegian champions Molde.

The Blues confirmed the 20-year-old has signed a contract at Stamford Bridge until 2029, with the option of a further year.

Fofana described Chelsea as the ‘the club of my dreams’ in a short message on the club’s website.

He said: ‘Hello dear fans, I’m…

View On WordPress

0 notes

Text

Fabrizio dropping the news that a striker I like, David Datro Fofana, is almost on his way to Chelsea. Less than €13M, 19 years old, strong, fast with a quality touch, and developing under Potter? You know I’m hyped! 😎 📡

#tfd#the watchlist#david datro fofana#sustainable team building#get in graham#chelsea#molde#winter transfer window#transfers#fabrizio romano#ivory coast#norway#soccer#football#fotboll

0 notes

Text

PRODUCTOS A LA VENTA Y CÓMO PUEDES HACER USO DE ELLOS...

“Nosotros te equipamos; tu creatividad lo hace posible, tus manos lo hacen realidad”.

0 notes

Photo

Winter is coming

The cold wind can not stop us from missing

Hope all of you guys in Solar shine

Warm Far away from war

--From Wall.e

0 notes

Text

Why In-mould labels are Highly in Use: A Detail Study

In-mould labels are nothing but printed polypropylene labels and it takes the shape of a container post that is directly injected in the mould. The overall process results in making the mould & labels get united together. There are three key process of moulding in mould labels and the most popular process is discussed below. Read it on & learn more.

Inject Moulding- As the name suggests, it is a proven process where heated molten plastic is injected directly into the mould. This after cooling down takes the perfect shape of the mould or the container. The plastic polymers are fused in an automatic manner with the mould. It is shaped in such a manner that it becomes part of the product container.

Let us have a look at some of the advantages that are being provided by in mould labels.

1. Time saving & cost effective-

IML techniques generally decrease one step as the printed label is directly moulded with the container.

This generally saves a lot of time as a manufacturer.

To add more to it this process wastes less amount of raw materials.

Thereby one can save overall cost using excessive material.

The overall cost for labour & transportation cost is totally saved due to functional decrease of a single step.

As the label is attached to particular container during the moulding process itself it allows to save a whole lot of time.

2. The process is environmentally friendly-

The overall packaging and the labels are composed of the same material. This means they have the same characteristics and thereby it is quite easy to recycle. The In mould labelling companies make use of the process also makes use of few amounts of resources and raw materials and thereby it is ideal to promote a healthy ambience.

3. Hygienic & Very Robust-

In-mould labelling can stand the test of time as well as weather. It is quite durable and can withstand extremely harsh weather situation. It can be extreme heat or moisture laden ambience, the overall print and the label remains as it is. What it means is you can use them for refrigeration purpose. It is scratch resistant and non-breakable and will remain wrinkle free all throughout.

4. Mechanism is very much user friendly-

These IML films made by the In Mould Label manufacturers have very good antistatic properties; it allows decreasing static charge between the film and the machine. What it does is, it increases the overall versatility of the machine and making it more competent & compatible.

It is to be noted that in mould labelling is a miraculous technology that is tailored to enable perfect design, flexibility and advantages of productivity. It is ideal to drive in advantages over traditional processes. The usage of numerous colours along with effects and texture is a solitary operation. All these make it perfectly versatile labelling option.

Tags: in mould labels, in mold labeling injection molding, in mold labeling process, in mould label printing, iml in mold labelling, in mould labelling companies, iml in mould labelling, in mould printing

GET IN TOUCH WITH US:

Winners Labels

CB - 70, SALT LAKE CITY, KOLKATA - 700 064

CONTACT NO: +91 9830087119 / 9831070140 / 9831016222

EMAIL: [email protected]

WEBSITE: https://www.winnerslabels.com/

#In-mould labels manufacturer#In-mould labels supplier#In-mould labels#In-mould labels dealer#in mould labelling#in mold labeling process#iml in mould labeling#Hologram Transfer Label#Cosmetic Product Labels

0 notes

Text

I have a friend who’s really into cheese, but was always complaining about how quickly it molds, and it turns out the problem was that they weren’t washing their cheese-knife between meals, so by the next time they used it, the cheese residue from the previous meal had been sitting in the open air for several hours at room temperature, and they were transferring all that schmutz onto the block of cheese when they cut it. Like, forget about mold culture – at that point that knife is developing mold religion. It’s sending mold missionaries at the behest of the Mold Pope to convert the indigenous bacterial cultures.

#life#food#religion#christianity#food safety#unsanitary#i'm reasonably certain this is the plot of hollow knight

10K notes

·

View notes

Text

Comprehensive surface treatment process of materials

Surface treatment is a process that artificially forms a layer on the surface of a base material that has different mechanical, physical and chemical properties from base material.Purpose of surface treatment is to meet corrosion resistance, wear resistance, decoration or other special functional requirements of product. Our more commonly used surface treatment methods are mechanical grinding,…

View On WordPress

#Anodic Oxidation#electrolytic polishing#Electroplating#electroplating surface treatment#Electropolishing#Galvanizing#Hydro Transfer Printing#In-Mold Decoration#Metal Wired#metallurgical bonding#metallurgical bonding technology#Pad printing#Screen printing#Surface treatment#surface treatment process#Surface treatment technology#vacuum electroplating#vacuum electroplating process#Vacuum Metalizing#Vacuum plating

0 notes

Text

🌸 # PEACH BALM

୨ : sim jaeyun x fem!reader genre : fluff warnings : kissing

in which jake cant stop kissing your lips

you close your peach flavored lip balm and place it on the counter. it colors your lips a light pink giving you a soft look. you smile in the mirror before fixing your hair and walking out the restroom.

you boyfriend, jake, was sitting on the bed looking at something on his phone. when he notices your presence he looks up. "hi, baby." he says softly, reaching his arms up to grasp your body. his arms immediately wrap around your waist pulling you against him.

he shifts on the bed trying to get comfortable. once he is he stares at you, eyes trailing down your face, stopping at your lips. "peach lip balm or the cherry one?" you smile. "the peach." jake smiles and pecks your lips softly. the balm transfers to his lips so he rolls his lips together.

"you know that's my favorite balm right?" you giggle. of course you knew. every single time you put it on he'd go crazy. he'd kiss your lips until they were swollen. "i do." jake pulls you closer to him and pecks your lips again.

he pecks your lips about five times before giving you a long kiss. his lips mold around yours perfectly. the taste of your peach balm in his mouth makes you go crazy. you become dizzy by his electrifying touch.

jake cupped your cheeks and pulled you even closer to him. the kiss turn a little messy but he couldn't control himself. that peach balm does things to him. he makes you buy it over and over since it's his most favorite. he can't get enough of it.

when he pulls away, his lips are shiny. he looks at you with so much love you think you fell for him again. there was so much to love about him. so many times you swear you fell for him again. and this was one of those times.

"go put some more on so i can kiss it off again." he says, licking him lips to taste the peach again. you chuckle and get off of him. "that balm wont even last a whole week." jake smirks. "i'll buy you a new one, now go i'm waiting."

you roll your eyes, walking back into the restroom to apply more balm just so he can kiss you some more.

© ikeumi

#ohsjy ☆ collection#sim jaeyun#sim jake#jaeyun x reader#jaeyun fluff#jaeyun imagines#enhypen jaeyun#enhypen jake#enhypen jaeyun x reader#enhypen#enhypen imagines#enhypen scenarios#enhypen x reader#enha imagines#jake sim#jake x reader#sim jake x reader#sim jake fluff#sim jake imagines#sim jake x you#jake enhypen

1K notes

·

View notes

Text

CHOCOLATE-COVERED OREOS

I am slightly obsessed with these. So. Many. Possibilities. I will have to disappoint the purists, though. I do not use high-quality chocolate to make them, I go with compound chocolate. Go ahead, twist your nose, but I have to be mindful of my baking budget. Feel free to splurge and temper chocolate if you prefer.

To make them you will need the appropriate molds. Go to online sources such as…

View On WordPress

1 note

·

View note