#Winder Rewinder machine

Link

#Winder Rewinder for Inkjet Printer Manufacturer#Winder Rewinder for Inkjet Printer#Winder Rewinder for Inkjet#Winder Rewinder#Winder Rewinder Machine

0 notes

Link

#Doctoring Rewinding Machine Manufacturer#Doctoring Rewinding Machine#Winder Rewinder Machine Manufacturer#Winder Rewinder Machine

0 notes

Link

#Winding Rewinding Machine#Winder Rewinder Machine#Rewinder Machine#Doctoring Rewinding Machine#Batch Printing machine

0 notes

Text

Trim Winder Machine Manufacturers

Blueeye Machine, located in Ahmedabad, is specialised in the manufacture of trim winders, which are designed to meet the needs of the industries that require precise winding solutions for a variety of materials.

#trim winder machine#trim winder machine manufacturer#trim winder machine supplier#trim winder machine in india#trim winder machine manufacturer in Ahmedabad

0 notes

Text

A paper tube cutting machine is a versatile and essential machine used in the paper industry. It is designed to cut large rolls of paper into smaller, more manageable rolls of desired width and length. This machine is crucial in various sectors, including printing, packaging, and converting industries.

Unwinding: The process begins with loading a large roll of paper onto the unwinding shaft. The machine then unwinds the paper roll at a controlled speed.

Slitting: The unwound paper is then passed through sharp blades or rotary knives that slit the paper into smaller widths. The number of blades can be adjusted based on the number of rolls required.

Rewinding: The slit paper is then rewound onto separate cores to form smaller rolls. The tension and speed of rewinding can be controlled to ensure the rolls are wound tightly and evenly.

Cutting: Some machines also have an integrated cutting mechanism that cuts the rewound rolls to the desired length.

Quality Control: Many Paper Slitter Rewinders come with built-in inspection systems that check for defects or irregularities in the paper.

The Paper Slitter Rewinder is known for its high efficiency, precision, and speed. It can handle a wide range of paper types and thicknesses, making it a versatile choice for businesses. With its robust construction and advanced features, this paper core machine ensures smooth and consistent operation, enhancing productivity and reducing waste. Whether you’re a small print shop or a large paper mill, a Paper Slitter Rewinder can be a valuable addition to your production line.

Paper Slitter Rewinder: Enhancing Efficiency in Manufacturing

The Paper Slitter Rewinder is a game-changer in the manufacturing industry, significantly enhancing efficiency and productivity. This machine is designed to transform large rolls of paper into smaller ones, tailored to specific requirements. Here’s how it contributes to manufacturing efficiency:

High-Speed Operation: paper tube winder machine operate at high speeds, capable of processing large volumes of paper in a short time. This speed significantly reduces production time, enabling businesses to meet high demand quickly.

Precision Cutting: With adjustable blades, the machine ensures precise and consistent cuts every time. This precision eliminates waste from inaccurate cuts, saving materials and costs.

Automation: Many models come with automated features, reducing the need for manual intervention. This automation not only saves labor costs but also minimizes human error, ensuring consistent quality.

Quality Control: With built-in inspection systems, the machine can detect and rectify defects or irregularities in the paper. This feature ensures that only high-quality paper rolls reach the end of the production line.

Space Efficiency: Despite its robust capabilities, the Paper Slitter Rewinder has a compact design that saves valuable floor space in manufacturing facilities.

By investing in a Paper Slitter Rewinder, businesses can significantly enhance their manufacturing efficiency. This core pipe-making machine not only speeds up the production process but also ensures the consistent quality of the final product, leading to increased customer satisfaction and profitability.

Paper Slitter Rewinders for Every Industry Need

Paper slitter rewinders play a pivotal role across diverse industries, addressing unique needs with precision and efficiency:

Printing Industry: In printing, these machines facilitate the production of custom-sized paper rolls, optimizing printing processes and reducing waste.

Packaging Sector: The packaging industry benefits from the adaptability of paper slitter rewinders, ensuring the creation of tailored rolls for various packaging applications, enhancing efficiency and minimizing material costs.

Converting Industries: Paper converting relies on these machines to transform large paper rolls into smaller, usable rolls with specific dimensions, meeting the requirements of different product lines.

Flexibility in Width and Length: The versatility of paper slitter rewinders allows for the customization of roll width and length, catering to the unique specifications of each industry and product.

Enhanced Productivity: With precise cutting and rewinding capabilities, these machines contribute to increased productivity, reducing downtime and enhancing overall operational efficiency in multiple sectors.

0 notes

Note

dumb question but is your bobbin wound correctly? one time i had a similar problem and rewinding my bobbin (and trimming off excess thread) helped

i got this ask forever ago im sorry i didnt see it. uhhh... you know, thats a distinct possibility? the bobbin winder on my machine is p messed up, so my wound bobbins r a lil messed up too.

so... ill keep an eye on that, tho i *think* that rn my main problem is judt. being bad at using yhr machine lol (sewing cutves....)

0 notes

Text

All You Need To Know About Wire Coiling Machine

Wire coils use in a variety of industries and applications. The wire coil industry is an ever-growing, competitive market that can be challenging.

Wire Coiling Machine: A wire coiler is set off by someone who stands on a platform and feeds steel or aluminum wires through the machine as it winds them into circles or squares. The coiler has two sets of rollers, with one set rotating clockwise while the other set rotates counterclockwise so that when the steel or aluminum wires go through them.

Advantages of using Wire Coiling Machine

Wire coiling machine are a great way to save time and money for wire production. They are a cost-effective alternative to manual labor, making the winding wire process more efficient.

These automated wire coil wrapping machines offer greater flexibility than their manual counterparts. They’re also easy to install and operate, with a low chance of failure.

Unlike manual winding equipment, they can deliver reliable service.

They help reduce the quantity of personnel needed to run the business. It helps to reduce labor and production costs dramatically.

Choosing the Right Coil Machine for Your Company

The best wire shuffling machine is the one that will suit your company’s needs. For example, if you are a jewelry manufacturer, you need a device that can produce enough coils for your production needs.

If you are looking for the best automatic coil machine, then you need to look for features like precision and speed. These will help decide which type of coil machine will work best for your company. For more Details https://dailyorbitnews.com/

Step-by-Step Guide to Choosing the Right Coil Machine for You

A coil machine winds the wire around a metal tube to create coils. This process can is done manually or with the help of machines. Choosing the suitable coil machine for you can be difficult, but there are some factors that you should consider before making a purchase.

The first thing you should consider is what type of material you will often work with; if this is steel, choose an electric coil winder because it will save time and energy. If it’s copper, choose an air-powered coiler because they are more versatile and allow for smaller coils.

If you will be working with aluminum, choose an electric coil winder because they are more powerful and efficient. The next thing that you should consider is what type of job you will usually be doing with the coils. If it’s maintenance work, choose a hand-held coiler because it will only have to be used once in a while. If it’s a production line, choose a power coiler because it will be used more often.

The next thing you should consider is the type of machine that you want to coil the wire in. For production line work, choose an electric machine or a hydraulic machine. For maintenance work, choose a hand-held coiler or a gas-powered engine-driven reeler and rewind er.

You’ll also want to consider the length of wire that you need, as well as the diameter, and subsequently gauge of steel wire that it is made from. If you have a specific length requirement, you should choose a machine with a minimum and maximum capacity to accommodate your needs in terms of both size and weight.

Last but not least, don’t forget that you also have to consider the portability of your machine. A heavy, bulky model won’t be as easy to transport as a lightweight, small one.

Conclusion

With the need for high speed and precision automation in coil winding, a modern automatic coil winding machine is an ideal solution.ReelPower Industrial offers a variety of proper coiling equipment to fulfill various demands, including massive and custom coiling machines. Do not hesitate to ask any questions about the wire coiling machine. Get in touch right now.

Source URL: http://bit.ly/42mldZj

0 notes

Text

Mini Sewing Machine With Extension Table

Mini Sewing Machine with Extension Table Upgraded movable Two vestments Double Speed Double Switches Household Kids newcomers Travel Automatic Sewing Machine

Product description:

PERFECT MINI SEWING MACHINE

Specialmini-size design for carry, erected- in beacon, thread knife

Double vestments and two pets, double switches, two power force modes

Easy to rewind the bobbins on the winding pole

Classic Straight- Line sew type for primary sewing

PACKAGE INCLUDES:

1 * Sewing Machine

1 * Extension Table

1 * Power appendage

1 * bottom Pedal

4 * Bobbins

1 * Needle

1 * Needle Threader

1 * English Manual

NOTE:

4 AA batteries( Not Included)

1. It does not rear and it has a straight sew only.

2. Before using, please read the instruction precisely and follow it to operate.

3. Beside that, make sure that vestments are on the each position of fuselage according to the instruction.

4. Before starting, please turn the bobbin winder spool a many times and confirm the vestments whether is smooth or not.

5. Must read the English instruction when you use the sewing machine, if you're still confused please communicate us.

TIPS :

You're suggested to change the needle if you're going to suture some special accoutrements .

These needle types below are compatible for this sewing machine75/11,80/12,,100/ 16( the lower size needles are good at thinner fabric, bigger size needles are good at thicker fabric)

Perfect for numerous material Suitable for silks, denim, hair, Hem pants, drapes, holes rips and etc, But too big or too hard can’t be darned.

#Mini Sewing Machine#mini sewing machine#easy home mini sewing machine#best mini sewing machine#portable mini sewing machine#magicfly mini sewing machine#personal development#business#companies#pet carrier bag#love#entrepreneur#corporate#startups#jobs#music#menswear#mike wheeler#daily mail#eddie munson#makeup#money#my writing

0 notes

Link

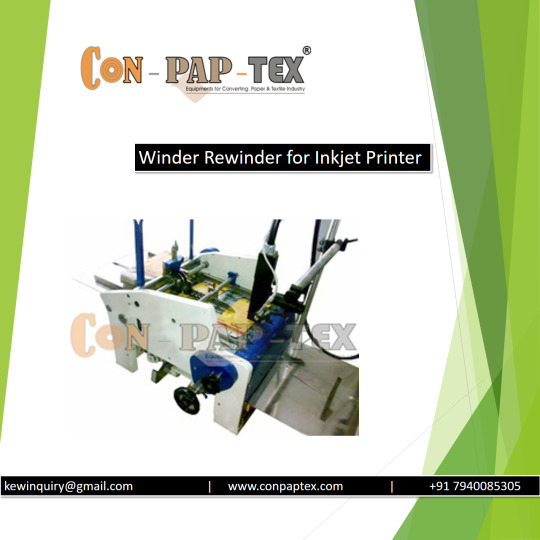

KEW ENGG MFG PVT LTD is biggest manufacturer, exporter & supplier of Winder rewinder machine for batch printing machine. The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation. For more information visit our website kew.net.in

#Winder rewinder machine#rewinder machine manufacturer#roll to roll winding rewinding machine#winder rewinder manufacturer

6 notes

·

View notes

Link

Conpaptex is biggest manufacturer of Winder Rewinder Machine at best price and standard quality. This winder rewinder machine is use in any paper, film and foil conversing industries, the Winder Rewinder Machine, Winding Rewinding Machine, Doctor Rewinding Machine are used widely for on-line printing of Mfg. Dt., Exp. Dt. B. No. etc. For more information visit our website : conpaptex.com

#Winder rewinder machine#winding machine#winder rewinder machine manufacture#winder rewinder machine at best price#winder rewinder machine for inkjet printer machine#Winder And Rewinder Machine Manufacturer#Winder Rewinder For Inkjet Printer

1 note

·

View note

Link

Slitting Rewinding Machine for Batch Printing Coding, Slitting Machines, Slitter Rewinder Machine for Industry specific Batch Printing, Batch Printing, Slitter Rewinder Machine, Doctoring Rewinding Machine, Batch Coding Machine, Packaging Machine, Printing Machine, Fabric Folding Machine, Cantilever design-balancing body for easy loading and unloading of parent / rewound reel. Movable unwind stage for Edge guiding System (Hydraulic Web Aligner).Mechanical 1.5 / 2.5 Kg. Optional Magnetic powder brake with tension controller & Torque control potentiometer. Provision for incorporating Inkjet Printing System with Hot air ink drying. The Model is specially designed for correcting badly wounded reels for inspection & doctoring operation. It is great substitute to online coding / batching operation

http://www.windingrewindingmachine.com/slitting-rewinding-machine-for-batch-printing-coding.php

#batch coding machine#batch printing machine#slitter machine manufacturer#winder Rewinder machine#Winding Rewinding Machine Manufacturer#slitter Rewinder#slitting rewinding machine#motor winding machine price#date printing machine#manual batch coding machine#Bopp tape slitting machine#batch printing machine price#rewinding machine price#paper winding machine#digital batch coding machine

1 note

·

View note

Link

We are leading Manufacturer, Exporter of Flexible Packaging, Paper, Tire-Cord, Textile Machinery. We manufacture machines like, Rotogravure Printing, Lamination, Flexo Printing, Coating, Slitter Rewinder Machine, Inspection Rewinding Machine, Doctoring Rewinding Machine, Winder Rewinder Machine for Inkjet Printer, Hydro Pneumo Web Aligner System, Web Aligner System, Web Guiding System, Roll Stretch Wrapping, BOPP Tape Cutting, Core Cutting, Edge Guiding Systems. Textile Machinery with custom application for different industries specific requirements.

#Flexible Packaging#Flexible Packaging Machine#Slitter Rewinder Machine#Slitter Rewinder#Doctoring Rewinding Machine#Doctoring Rewinding#Winder Rewinder Machine#Winder Rewinder#Web Aligner#Web Aligner Unit#Web Aligners

2 notes

·

View notes

Link

Krishna Engineering Works is Engaged In Manufacturing, Exporting, And Supplying Of Flexible Packaging, Paper, Tire – Cord, Textile Machinery & Equipment. Specialized manufacturer, Exporter and Supplier of Rubber Roller from India. We Are Dealing And In Textile Processing Machinery, Textile Weaving Machine, Textile Industry Machines, Spinning Machine, Weaving Machine, Textile Machinery Manufacturers, Flexible Packaging Industry, Flexible Packaging Companies. Rotogravure Printing Machine, Slitter Rewinder Machine, Doctoring Rewinding Machine, Roll Stretch Wrapping Machine, BOPP Tape Cutting Machine, Core Cutting Machine, Edge Guiding Systems, Winder Rewinder Machine, Rewinder Machine Manufacturers, Rubber Roller, Textile Machinery

#Rotogravure Printing Machine#Slitter Rewinder Machine#Doctoring Rewinding Machine#Roll Stretch Wrapping Machine#BOPP Tape Cutting Machine#Core Cutting Machine#Edge Guiding Systems#Winder Rewinder Machine#Rewinder Machine Manufacturers#Rubber Roller#Textile Machinery

1 note

·

View note

Link

“KRISHNA ENGINEERING WORKS” is one of the Leading Manufacturers & Exporters of Flexible Packaging, Converting, and Textile Processing & Printing & Tyre-Cord Machinery from India. Krishna Engineering Works is a company engaged in Manufacturing, exporting and supplying of Flexible Packaging, Paper, Tire-Cord, and Textile Machinery & Equipment. Specialised manufacturer, exporter and supplier of Rubber Roller, Slitter Rewinder Machine, Web Guiding System, and Doctoring Rewinding Machine from India. We manufacture machines like, Rotogravure Printing, Lamination, Flexo Printing, Coating, Slitter Rewinder Machine, Inspection Rewinding Machine, Doctoring Rewinding Machine, and Winder Rewinder Machine for Inkjet Printer, Hydro Pneumo Web Aligner System, Web Aligner System, Web Guiding System, Roll Stretch Wrapping, BOPP Tape Cutting, Core Cutting, Edge Guiding Systems, Tracking Roller Assembly, Unwinder, Rewinder, and Rubber Roller. Flexible Packaging, Paper, Tire-Cord, Textile Machinery with a custom application for different industries specific requirements.

#Rubber Roller#Slitter Rewinder Machine#Web Guiding System#Doctoring Rewinding Machine#Winder Rewinder Machine#Web Aligner System#Roll Stretch Wrapping#BOPP Tape Cutting#Core Cutting

2 notes

·

View notes

Link

KEW is the leading Pneumatic Brake Manufacturer from India. Pneumatic Brake of various sizes and types are available to fit any applications. They are simple to use, easy to replace worn out brakes pads. All type of Pneumatic Brake with heavy duty process, Electro Magnetic Brake, Pneumatic Brake manufacturer with International Standards and successful installations all over the Globe. Our Brake for Winder Rewinder Machine, Rewinder Unwinder Machine, Slitter Rewinder Machine and many more flexible packing machinery.

#Pneumatic Brake#Pneumatic Brakes#Electro Magnetic Brake#Pneumatic Brake manufacturer#Winder Rewinder Machine#Winder Rewinder#Rewinder Unwinder#Rewinder Unwinder Machine#Slitter Rewinder Machine#Slitter Rewinder Machin

2 notes

·

View notes

Link

We are a specialized manufacturer of Winding Rewinding Machine, heavy duty equipment, high-quality material used in Winding Rewinder Machine. Our Product range includes Machines Like: Winding Rewinder Machine, Winding Rewinding Table Top, Heavy Duty Winding Rewinding, High Speed Winding Rewinding, Custom Application Doctoring Rewinding, Film Winding Rewinding with Slitter, Winding and Slitting Rewinding, Winding Rewinding for Label Stock, Winding Rewinding for Special Application, Film Winding Rewinding for Batch Coding.

#Winding Rewinder Machine#Winding Rewinder Machine Manufacturer#Winding Rewinder#Winding Rewinding Machine#Winding Rewinding#Winding Rewinding Machine Manufacturer#Winding Rewindings#Winder Rewinder Machine#Winder Rewinder Machines#Winder Rewinder Machine Manufacturer#Winder Rewinder#Winder Rewinding Machine#Winder Rewinding Machines#Winder Rewinding#Winder Rewindings

1 note

·

View note