#automation in dispensing

Explore tagged Tumblr posts

Text

Automated Dispensing System – Precision That Drives Productivity

At 3DCAD Global, we specialize in designing and delivering Automated Dispensing Systems tailored to enhance precision, speed, and consistency in your manufacturing operations. Whether it’s adhesives, sealants, lubricants, or other materials, our dispensing solutions are engineered for efficiency and minimal waste.

✅ Key Features:

High-speed, repeatable dispensing

Customizable systems for varied materials

Seamless integration with existing production lines

Optimized for accuracy and cost-effectiveness

From electronics to automotive and industrial assembly, our systems reduce human error, improve throughput, and elevate product quality.

🔗 Learn more about our Automated Dispensing Solutions here: 👉 https://www.3dcad-global.com/dispensing.html

Boost your operational efficiency with 3DCAD Global — where innovation meets automation.

0 notes

Text

Girls, girls. The feed track WILL feed you both if you wait three seconds-

#ic#rotomblr#pokemon irl#pokeblr#pokeblogging#Pokefarming#Doduo#Pokemon#They are soooo stupid man#YOU HAVE SEVERAL HUNDRED FOOT OF AUTOMATED FOOD DISPENSING SYSTEM#And yet. You crave getting your heads stuck#Birds smfh

6 notes

·

View notes

Text

I know the aesthetic is "everyone is filthy and bleeding and the worlds are all polluted and rotting and everything is awful all the time" but considering one of the Ruinous Powers is literally the god of filth and disease, it would make sense for the Imperium to have a culture of purity and cleanliness actually

"To despoil the Emperor-given body of humanity is heresy of the gravest order! You wash your face young lady or the pox-father will strike you down with zits before the Sanguinalia dance!"

People on ships probably have ritual cleansing periods based on the Terran day-night cycle, Ultramar has Roman-style public baths where the Ultramarines hang out

Of course since this is 40k they're going to be absolutely unhinged about it

Commisars shooting soldiers because they're not keeping clean enough when there's mud and blood and death everywhere and they've been fighting orks for the last solid day

Men dying of thirst so the general can have his twice-daily bubble bath to show his piety

The Sisters Hospitaller do canonically daube their armour in 'protective' incenses and ointments, either for genuine protective reasons, weirdass Imperial superstitions or maybe just so they can smell pretty while they're stalking through crowded wards saving lives or torturing injured heretics before executing them with bolt pistols I don't know (her ass has NOT agreed to medical neutrality!)

so I like to think that, like we say "sing yay many verses of this song while washing your hands to make sure you've done it long enough" they're doing the same with Imperial hymns

(not sure about the Militarum's doctors since they sometimes lean into "ghastly WW1 field hospital" vibes, but the SH's actually study new things and have access to medical texts and research mutation and xenobiology so I think they have a grasp of medical sanitation and PPE, most Astartes probs do too)

Picture a Astra Militarum doctor, Sister Hospitaller and Spess Mehreen Apothecary all stood by hand-sinks singing as they wash their hands:

Happy those who do not follow the counsel of the wicked, Nor go the way of sinners, nor sit in company with heretics. Rather, the law of the Imperium is their joy; the Emperor’s law they study day and night. They are like a tree planted near streams of water that yields its fruit in season...

Some Astartes or Battle-Sisters do the whole "fight gloriously for days without rest against impossible odds until relief comes" thing that happens every week or so like clockwork and realistically come out the other side absolutely filthy and rancid, so they flagellate themselves half to death for failing to meet the ritual bathing criterias needed to maintain their divinely-granted human forms because they're terrifying religious fanatics

#maybe this is why the Astartes look so cool and the Sisters keep being drawn like they just stepped out of a spa day before fighting#''brothers! this hair gel has been passed down from the days of Sanguinius himself! No Blood Angel may go into battle without it!''#whoever designed that ridiculous Sororitas boob-plate has also shoved automated perfume dispensers into the shoulder pads#the Tau ar out there screaming WHY IS THIS THE HILL YOU CHOOSE TO DIE ON WHAT IS YOUR ACTUAL PROBLEM#warhammer 40000#warhammer 40k#warhammer 30k#warhammer 30000#adeptus astartes#adepta sororitas#space marines#sisters of battle#games workshop#worldbuilding#war crimes#somewhere there's a forge world with an STC for head & shoulders and they're making bank

69 notes

·

View notes

Text

New theory, I have angered some god of technology causing all computers to not work for me.

#wren rambles#seriously though#my phone has had issues#my computer has had issues#the 2 school computers that I logged into to print a lab report off took ten minutes to get one of them working#then the first printer I used was jammed#and the wifi has been quite slow today#oh and two of the automated hand soap dispensers wouldn’t work#the third one thankfully did

4 notes

·

View notes

Text

EHEIM Automatic Feeder Review: The Ultimate Solution for Hassle-Free Aquarium Feeding

As an aquarium enthusiast, ensuring your fish are fed consistently and correctly is a top priority. Whether you’re heading out for a vacation or simply want to automate daily feedings, the EHEIM Automatic Feeder is a game-changer. Available on Amazon, this reliable device promises to simplify fish care while keeping your aquatic friends happy and healthy. In this comprehensive review, we’ll dive…

#aquarium automation#aquarium care#aquarium feeder#aquarium feeding solution#aquarium maintenance#automatic fish feeder#battery-powered fish feeder#EHEIM automatic feeder#EHEIM Everyday Feeder#EHEIM feeder pros and cons#EHEIM fish feeder#fish feeder review#fish feeding device#fish feeding schedule#fish food dispenser#fish tank automation#fish tank feeder#programmable fish feeder#reliable fish feeder#vacation fish feeder

0 notes

Text

Optimize Parking Operations with Parkomax Technology Implement Parkomax Entry Terminals to reduce congestion, improve user satisfaction, and streamline your parking facility's entry processes.

#Entry parking terminals#Parking entry systems#Automated parking terminals#Vehicle entry terminal#Ticket dispensing machine#Parking access terminal#Smart parking entry solutions

0 notes

Text

Efficient Warehousing Starts with the Right Pallet Dispenser

In modern warehousing and logistics, efficiency is no longer optional—it’s essential. A key component in streamlining material handling operations is the pallet dispenser. Often working in tandem with a pallet stacker, this equipment automates one of the most overlooked steps in warehouse workflows: dispensing and stacking pallets.

What Is a Pallet Dispenser?

A pallet dispenser is a mechanical device designed to automatically release or stack pallets without the need for manual handling. Commonly used in distribution centers, manufacturing plants, and packaging lines, these machines reduce downtime and improve worker safety by minimizing manual lifting.

Pallet dispensers can handle wooden, plastic, and sometimes even metal pallets, and they come in various configurations—floor-mounted, overhead, or integrated into conveyor systems.

Why Warehouses Are Turning to Pallet Dispensers

As labor shortages and operational costs continue to impact supply chain dynamics, automation is becoming an integral part of warehouse optimization. Pallet dispensers, when combined with pallet stackers, can lead to significant improvements in:

Productivity: Continuous feed of pallets eliminates manual placement delays.

Safety: Reduces the risk of injuries related to lifting and moving heavy pallets.

Consistency: Ensures uniform pallet handling, reducing operational errors.

“Since we implemented a pallet dispenser and stacker combo, our warehouse throughput has improved by nearly 30%. It’s reduced both idle time and workplace injuries.” — Carlos M., Logistics Manager, Northern Freight Solutions

Pallet Dispenser vs. Pallet Stacker: Understanding the Difference

While both are used in handling pallets, their functions differ:

Integrating both systems creates a closed-loop pallet management solution, minimizing idle time and maximizing operational flow.

Use Cases Across Industries

Pallet dispensers are not industry-specific. They are used in:

Food & Beverage: For maintaining hygiene and preventing contamination through minimal contact.

Pharmaceuticals: Ensuring consistent pallet availability during automated packaging.

Retail Distribution: Speeding up order fulfillment operations.

Automotive: Managing heavy-duty pallets for parts and components.

How to Choose the Right Pallet Dispenser

Selecting the ideal pallet dispenser depends on several operational factors:

Pallet Type and Size: Compatibility with standard or custom pallet dimensions.

Capacity: Number of pallets handled per cycle or per hour.

Integration Requirements: Whether it needs to work alongside conveyors, robots, or pallet stackers.

Space Constraints: Floor-mounted vs. overhead models depending on available warehouse space.

“Choosing a dispenser that integrates easily with our conveyor line made a significant difference. It wasn’t just about the machine—it was about how well it fit into our existing layout.” — Stephanie T., Plant Supervisor, Midstate Manufacturing Co.

Maintenance and Lifecycle Cost

Though typically low-maintenance, routine checks on mechanical parts, sensors, and hydraulic components are essential for longevity. Many dispensers offer diagnostics features to alert users of wear and tear, further reducing downtime.

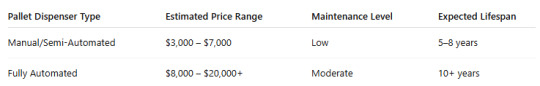

Here’s a general overview of cost expectations: Pallet Dispenser

Final Thoughts

For operations seeking to reduce manual labor, enhance safety, and improve throughput, a pallet dispenser paired with a pallet stacker offers a robust, scalable solution. With proven applications across diverse industries, it's clear that these machines are more than just convenience—they're a strategic investment in productivity.

0 notes

Text

Flux Dispensers Market Set to Hit $434.7 Million by 2035

Industry revenue for Flux Dispensers is estimated to rise to $434.7 million by 2035 from $231.4 million of 2024. The revenue growth of market players is expected to average at 5.9% annually for the period 2024 to 2035.

Check detailed insights here - https://datastringconsulting.com/industry-analysis/flux-dispensers-market-research-report

Flux Dispensers are critical across several key applications including soldering operations, automotive assemblies, and aerospace manufacturing. The report unwinds growth & revenue expansion opportunities at Flux Dispensers' Material Compatibility, Application Areas, Technology Type, and End-User Industry, including industry revenue forecasts.

Industry Leadership and Competitive Landscape

The Flux Dispensers market is characterized by intense competition, with leading players such as Nordson Corporation, Henkel Corporation, Illinois Tool Works Inc., Techcon Systems, JBC Soldering Tools, Dymax Corporation, Fisnar Inc., Dover Corporation, Fuji Corporation, Intelligent Precision Systems, DKSH Holding AG, and Valco Cincinnati Consumer Products Inc. pushing the boundaries of innovation and forging strategic partnerships to capture larger market share.

The Flux Dispensers market is projected to expand substantially, driven by technological advancements and growing demand for precision in electronic assembly, automotive manufacturing, and aerospace. This growth is expected to be further supported by industry trends such as the transition from manual to automated systems, providing better operational efficiency and reducing the risk of human error in manufacturing processes.

Regional Shifts and Emerging Markets

Vietnam, Thailand, and Indonesia have emerged as fast-growing demand hubs within the Flux Dispensers market, with expected growth rates ranging from 3.8% to 5.7% for the period from 2025 to 2030. These regions have become key players in flux dispenser applications, particularly in automotive assembly and electronics manufacturing. Furthermore, these emerging markets offer new opportunities for market players to expand their footprint and diversify their revenue sources.

North America remains a leading region for Flux Dispensers, driven by the strong demand from the electronics and automotive industries. The necessity for precision in soldering processes has fueled the growth of flux dispensing tools, and innovations in dispensing technology continue to provide competitive advantages for local manufacturers.

Technological Advancements in Flux Dispensers

The Flux Dispensers industry has undergone significant technological advancements, shifting from manual to automated dispensing systems. Automated flux dispensers offer higher precision, greater operational efficiency, and a safer working environment, reducing the risk of human error and workplace hazards. This transition has revolutionized industries such as electronics assembly, printed circuit board manufacturing, and microchip production, making automated flux dispensers integral to high-precision applications.

Research Scope

Material Compatibility: Rosin Flux, No-Clean Flux, Water Soluble Flux

Application Areas: Electronics Assembly, Automotive Assembly, Aerospace Manufacturing, Others

Technology Type: Manual, Automated, Semi-automatic

Dispenser Capacity: Small Scale, Medium Scale, Large Scale

End-User Industry: Consumer Electronics, Transportation, Defense & Aerospace, Others

About DataString Consulting

DataString Consulting offers a complete range of market research and business intelligence solutions for both B2C and B2B markets under one roof. We provide bespoke market research projects tailored to meet the specific strategic objectives of your business. Our leadership team has more than 30 years of combined experience in market and business research and strategy advisory globally. We monitor high-growth segments across more than 15 industries, offering insights that help companies formulate effective strategies for market expansion and diversification.

Contact Us to learn more about how we can help you with strategy consulting, opportunity assessment, and solutions to business challenges.

#Flux Dispensers Market#Flux Dispensers#Market Growth#Industry Forecast#Electronics Assembly#Automotive Repairs#Solar Panel Manufacturing#Medical Device Production#Technology Advancements#Environmental Regulations#Market Leadership#Market Expansion#Revenue Forecast#Supply Chain Evolution#Strategic Collaborations#Market Opportunities#Electronics Manufacturing#Global Market Insights#Industry Trends#Emerging Markets#North America Market#Asia-Pacific Market#Vietnam Market#Thailand Market#Indonesia Market#Industrial Automation#Precision Manufacturing#Flux Dispensing Systems#Market Research#DataString Consulting

0 notes

Text

Vertical Glue Mixer: Efficient and Uniform Adhesive Mixing for Plywood Manufacturing

In plywood production, efficiency and precision are the most important factors in ensuring high-quality board production. One of the most crucial elements in this production is the Vertical Glue Mixer—a revolution in uniform adhesive mixing for better plywood bonding. If what you're searching for is an advanced glue mixing technology that maximizes productivity and reduces waste, this futuristic machine is a production-line essential.

Why a Vertical Glue Mixer?

A Vertical Glue Mixer is specifically designed to provide homogeneous adhesive mixing for plywood, ensuring a consistent glue spread on veneers. Unlike conventional mixers, a vertical mixer offers better blending, reduced glue wastage, and improved bonding strength, making it a preferred choice for modern plywood factories.

Key Benefits of a Vertical Glue Mixer

1. Superior Mixing Efficiency

Vertical design allows for complete and even blending of adhesives, which creates even viscosity and consistency across the batch. This produces improved plywood adhesion, minimizing defects in the finished product.

2. Economical Glue Use

Effective adhesive dispensing implies that manufacturers can lower the use of glue without affecting the quality, resulting in extensive cost benefits in the long run.

3. Reduced Production Cycle Times

Using a high-speed mixing device, a vertical glue mixer reduces preparation time, enabling production cycles to be completed quickly and output to be maximized.

4. Minimal Maintenance & Longevity

Designed with robust parts and sophisticated automation, these mixers have negligible maintenance needs, making them a sound long-term investment for plywood production.

5. Eco-Friendly Operations

By minimizing glue waste and maximizing adhesive blending efficiency, a Vertical Glue Mixer supports an environmentally friendlier plywood production process with decreased ecological footprint.

Selecting the Most Suitable Vertical Glue Mixer for Your Plywood Operation

In selecting a Vertical Glue Mixer, there are important considerations to make:

✔️ Mixing Capacity – Select a machine in conformity with your volume of production.

✔️ Automation Features – Choose a model with easy-to-use controls for convenient operation.

✔️ Material Compatibility – Use one that can handle different adhesive types for general applications.

✔️ Manufacturer Reputation – Buy equipment from a reputable plywood machinery manufacturer for guaranteed quality.

A Vertical Glue Mixer is an important investment for plywood plant owners who want to improve efficiency, quality, and cost savings. By adopting this performance-intensive adhesive mixing system into your production process, you can achieve smooth operations, better plywood bonding, and increased profitability.

Want to find the ideal Vertical Glue Mixer for your plywood factory? Contact DNH Engineers a renowned manufacturer of plywood machinery and give your production a boost! Visit www.dnhengineers.com for more details.

#In plywood production#efficiency and precision are the most important factors in ensuring high-quality board production. One of the most crucial elements in this#this futuristic machine is a production-line essential.#Why a Vertical Glue Mixer?#A Vertical Glue Mixer is specifically designed to provide homogeneous adhesive mixing for plywood#ensuring a consistent glue spread on veneers. Unlike conventional mixers#a vertical mixer offers better blending#reduced glue wastage#and improved bonding strength#making it a preferred choice for modern plywood factories.#Key Benefits of a Vertical Glue Mixer#1. Superior Mixing Efficiency#Vertical design allows for complete and even blending of adhesives#which creates even viscosity and consistency across the batch. This produces improved plywood adhesion#minimizing defects in the finished product.#2. Economical Glue Use#Effective adhesive dispensing implies that manufacturers can lower the use of glue without affecting the quality#resulting in extensive cost benefits in the long run.#3. Reduced Production Cycle Times#Using a high-speed mixing device#a vertical glue mixer reduces preparation time#enabling production cycles to be completed quickly and output to be maximized.#4. Minimal Maintenance & Longevity#Designed with robust parts and sophisticated automation#these mixers have negligible maintenance needs#making them a sound long-term investment for plywood production.#5. Eco-Friendly Operations#By minimizing glue waste and maximizing adhesive blending efficiency#a Vertical Glue Mixer supports an environmentally friendlier plywood production process with decreased ecological footprint.#Selecting the Most Suitable Vertical Glue Mixer for Your Plywood Operation

0 notes

Text

Automation in Dispensing

At 3DCAD Global, we deliver cutting-edge automated dispensing solutions engineered for high precision, consistency, and efficiency. Our systems are ideal for adhesive dispensing, sealant application, fluid dispensing, epoxy dispensing, and coating automation—catering to a diverse range of industries including electronics, automotive, medical devices, and consumer goods.

Our robotic dispensing systems are designed to reduce material waste, enhance product quality, and streamline production. Whether you're working with viscous fluids, two-part resins, or UV-curable materials, our solutions ensure controlled and repeatable dispensing every time.

Why Choose Our Dispensing Automation Solutions? Customizable dispensing platforms to match your exact process requirements

High-precision dispensing valves for micro-dosing and high-volume applications

Integration-ready with PLC, SCADA, and MES systems

Scalable systems for both low and high-volume manufacturing

Reduced downtime and minimal material waste

Expert support from design to commissioning

We understand that every application is unique. That’s why we offer fully tailored automated fluid dispensing systems to improve throughput, maintain accuracy, and cut down on operational costs.

0 notes

Text

The Role of Coin Changers in Vending Machines and Automated Retail

In today’s fast-paced retail environment, convenience and efficiency are key factors in ensuring customer satisfaction. While digital payments are growing, cash transactions remain an essential part of vending machines and automated retail systems. A vending machine coin changer plays a critical role in streamlining cash transactions, reducing downtime, and enhancing overall operational efficiency.

How Coin Changers Improve Vending Machine Functionality

1. Seamless Cash Transactions

A vending machine coin changer ensures that customers can easily make purchases using coins, eliminating the frustration of exact change requirements. These devices accurately count and dispense change, making transactions quick and hassle-free.

2. Reduced Downtime and Maintenance

Advanced automatic coin dispensers are designed to handle high volumes of cash efficiently. They prevent coin jams and errors that could otherwise lead to vending machine failures. This reliability reduces downtime, ensuring machines remain operational for longer periods.

3. Enhanced Customer Experience

Nothing frustrates a customer more than a vending machine rejecting their money or failing to give proper change. A high-quality coin changer ensures smooth operation, improving user satisfaction and encouraging repeat transactions.

4. Cost Savings and Cash Automation

Businesses benefit from cash automation as it minimizes the need for manual cash handling. Coin changers optimize cash flow by ensuring accurate transactions, reducing errors, and lowering labor costs.

Frequently Asked Questions (FAQs)

1. How does a vending machine coin changer work?

A coin changer accepts coins, validates their authenticity, and dispenses the correct change. It uses sensors and advanced mechanisms to recognize different coin denominations and ensure accurate transactions.

2. Can a coin changer work with different currencies?

Some advanced automatic coin dispensers are designed to handle multiple currencies. However, businesses should check for compatibility before purchasing.

3. How often should a vending machine coin changer be maintained?

Regular cleaning and maintenance are recommended every few months to prevent coin jams and ensure smooth operation.

4. What should I do if my vending machine’s coin changer stops working?

First, check for any coin jams and clean the sensor area. If the issue persists, refer to the manufacturer’s troubleshooting guide or seek professional repair services.

Enhance Your Vending Machine Performance Today!

Investing in a reliable vending machine coin changer can significantly improve your business’s efficiency and customer satisfaction. At Lynde Ordway, we offer high-quality automatic coin dispensers designed for durability and accuracy.

Upgrade your vending machines today! Contact us to find the perfect coin changer for your business.

0 notes

Text

Demonstrating the latest automated bingo card dispenser.

0 notes

Video

youtube

🤖 Is Your Soap Dispenser Smart Enough? ✨ Try This Touchless Solution!

#youtube#soap dispenser#automatic#automatic gadgets#smart home devices#smart home automation#home automation#new gadgets#kitchen gadgets#new technology#sensor#touchles#kitchenessentials#bathroom essentials#hadnwash#handwash

0 notes

Text

The Evolution of Pallet Dispensers: Enhancing Efficiency in Warehousing

Understanding the Role of a Pallet Dispenser

In modern warehousing and logistics, efficiency is key. A pallet dispenser is an automated or semi-automated system designed to streamline pallet handling, reducing manual labor and improving workflow. These machines automatically dispense pallets one at a time, eliminating the need for manual stacking and unstacking, which can be time-consuming and hazardous.

For businesses operating in high-volume industries, integrating a pallet dispenser into their supply chain ensures seamless operations while reducing workplace injuries associated with manual pallet handling.

How a Pallet Dispenser Works

A pallet dispenser functions by holding a stack of pallets and releasing them one at a time as needed. These systems are often integrated with conveyor system manufacturers who design complete automated solutions for warehouses and production lines.

Typically, the process works as follows:

A stack of pallets is loaded into the dispenser.

The dispenser lifts the entire stack while allowing one pallet to slide out from the bottom.

The released pallet is then used for loading products, either manually or through an automated system.

The remaining stack lowers, preparing for the next dispensing cycle.

This automation reduces downtime and ensures a steady supply of pallets, improving productivity in distribution centers and manufacturing facilities.

Key Benefits of Using a Pallet Dispenser

1. Improved Workplace Safety

Handling pallets manually can lead to injuries such as back strain, pinched fingers, and other musculoskeletal disorders. Automating pallet dispensing reduces these risks and ensures compliance with workplace safety standards.

2. Increased Efficiency

A pallet dispenser significantly reduces time spent retrieving and organizing pallets. Workers can focus on more value-added tasks, leading to increased output and efficiency in operations.

3. Space Optimization

Warehouses with limited space can benefit from a pallet dispenser as it helps in keeping pallets neatly stacked and accessible, reducing clutter and optimizing storage areas.

4. Cost Savings

By minimizing manual labor and potential injuries, businesses can save on operational costs, including worker compensation and downtime. A well-integrated system from a trusted conveyor system manufacturer ensures that automation leads to long-term cost savings.

Industries Benefiting from Pallet Dispensers

E-commerce and Retail

With the rise of online shopping, warehouses need efficient ways to move goods. Pallet dispensers help in quickly deploying pallets for packing and shipping operations, keeping up with high-demand fulfillment requirements.

Manufacturing

Manufacturing plants rely on a consistent supply of pallets for transporting raw materials and finished goods. A pallet dispenser ensures a steady workflow without bottlenecks in production lines.

Food and Beverage Industry

Hygiene and efficiency are crucial in food handling. Automated pallet dispensers reduce human contact with pallets, minimizing contamination risks while keeping the supply chain smooth.

Pharmaceutical Sector

Pharmaceutical warehouses require precision and automation for handling goods. Pallet dispensers ensure that pallets are readily available for moving medical supplies without manual intervention.

Integrating a Pallet Dispenser with a Conveyor System

To maximize automation, many businesses integrate pallet dispensers with conveyor systems. A conveyor system manufacturer can design a setup that seamlessly moves pallets from dispensers to different workstations, ensuring a continuous flow in operations.

Some common integrations include:

Automated Guided Vehicles (AGVs): These transport pallets to specific locations within a facility.

Roller and Belt Conveyors: These systems work alongside pallet dispensers to move pallets efficiently across warehouse zones.

Robotic Arms: In some setups, robotic arms pick pallets from dispensers and place them onto conveyors for further processing.

Testimonials: Real-World Success Stories

“Game-Changer for Our Warehouse” – Mark T., Warehouse Operations Manager

“Implementing a pallet dispenser in our facility has dramatically reduced our reliance on manual labor. Productivity has increased, and we’ve seen a significant drop in workplace injuries related to pallet handling.”

“Seamless Integration with Our Conveyor System” – Sarah L., Logistics Director

“Our conveyor system manufacturer recommended a pallet dispenser to improve efficiency, and it has exceeded our expectations. Now, we have a continuous flow of pallets without interruptions, making our warehouse operations smoother.”

Choosing the Right Pallet Dispenser

When selecting a pallet dispenser, consider the following factors:

Capacity: Determine how many pallets the dispenser needs to hold at a time.

Type of Pallets: Ensure compatibility with different pallet sizes and materials (wood, plastic, metal).

Automation Level: Decide whether a fully automated or semi-automated system suits your operation.

Integration Needs: Check if the dispenser can work with existing conveyor systems and other warehouse automation tools.

Durability and Maintenance: Opt for a robust system with low maintenance requirements to ensure long-term reliability.

Conclusion

A pallet dispenser is a critical component in modern warehousing and manufacturing, providing efficiency, safety, and cost savings. When integrated with conveyor systems, these dispensers contribute to a seamless supply chain, reducing bottlenecks and enhancing productivity.

0 notes

Text

We bring you fluid dispensing systems from Techcon to improve industrial hygiene and enhance productivity and efficiency.

TECHCON, whose solutions offer superior accuracy and durability, has innovated further to create the TS 9800 Series dispensing systems which not only deliver fluids in a contactless mode but also dispense 10-20 times faster than a contact dispense process.

The in-built piezo jet valve completes up to 2000 cycles per second with 97% accuracy. The contactless method does not damage the product on which the fluid is dispensed – thus achieving more efficiency than a contact-based valve with no wastage or downtime.

It is accompanied by the TECHCON TS980 Smart Controller with advanced touchscreen controls and intuitive user interfaces, enabling fast setup.

For more: https://zurl.co/ltVU

#dispenser#fluiddispensing#industrial automation and robotics#automated test equipment manufacturers#collaborative robots#end of arm tooling#melss#Techcon

0 notes

Text

Automated Media Dispensing System

An Automated Media Dispensing System is a device used in laboratories, particularly in microbiology and molecular biology, to accurately dispense liquid media, such as agar, broth, or culture media, into petri dishes, tubes, or other containers.

0 notes