#axial flux motors

Text

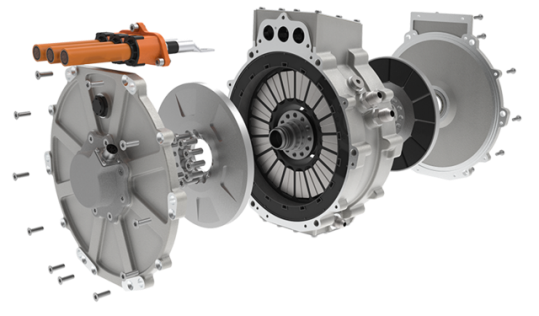

Design and manufacture of axial flux permanent magnet motors

Axial flux motors are extremely high efficiency motors where low form factor is essential. The applications for such stators are in Elevator Traction Motors (Roomless elevator design), Direct Drive Appliance Motors, EV Motor Applications,etc.

YOUYOU has developed a unique technology to manufacture axial flux motor cores.

Diameter range:20mm to 2 meter.

Email: [email protected]

Whatsapp:086-18826897469

Web: https://www.istator.com/axial-flux-stator.html

2 notes

·

View notes

Text

Axial Flux Motor Market – Forecast (2023-2028)

Axial Flux Motor Market Report Overview

The Axial Flux Motor market size is forecast to reach USD 1387.7 million by 2030, after growing at a CAGR of 11.8% during the forecast period 2024-2030. Axial flux motors are suited for applications that require a high torque density in a small footprint. Axial flow drives are also known as flattened and pancake electrically commutated motors due to their extremely low axial length-to-diameter ratio. It delivers more torque and power density than radial flux motors while using the same electrical components. When an axial flux motor has this feature, the battery lasts longer, making these motors more economically viable.

Axial flux motors are being used more frequently in a variety of new industries, including electric bikes, delivery vehicles, airport pods, electric cars, and even airplanes owing to the recent technology breakthroughs and a push towards electrification. The axial flux type was the first motor to be created in history. Therefore, it is difficult to imagine that these motors have found such a wide range of applications in the past two decades. First, it was extensively utilized for storage needs in the agricultural industry and elevators. Additionally, as axial flux motors are more efficient than radial motors, the market for them is expected to create considerable profits over the course of the projection period. Compared to a radial motor, this motor's small length offers great torque over speed. Additionally, when employed in the automotive industry, its small size and low weight reduce the weight of automobiles. In 2022, North America held 34.54% market share of the axial flux motor market, and is expected to grow at a significant compounded annual growth rate of 11.9% during the forecast period (2023-2030). The region is a hub for electric vehicle (EV) manufacturing and innovation, with automakers increasingly adopting axial flux motors for their EVs. Additionally, the growing renewable energy sector, including wind power projects, contributes to the demand for these motors. Asia Pacific, led by China, is a rapidly growing market for axial flux motors, driven by its extensive manufacturing capabilities and increasing adoption of electric vehicles. With the ever-expanding adoption of electric vehicles (EVs) in the region, China has emerged as a global leader in the EV market, which in turns fuels the demand for axial flux motors to new heights.

Furthermore, using axial motors minimizes vehicle weight by reducing the amount of space occupied by machinery. Transportation corporations' growing investment in the electric vehicle market would give substantial growth opportunities for the Axial Flux Motor Market. Product demand is expected to benefit from a growing focus on refining design and manufacturing processes in order to produce better products with greater efficiency, which further enhances the industry expansion for permanent magnet synchronous motors. Rising awareness of environmental preservation around the world is predicted to boost the adoption of electric vehicles and heat recovery ventilation, which will drive axial flux motor demand in 2024-2030.

Report Coverage

The report “Axial Flux Motor Market – Forecast (2024-2030)”, by IndustryARC, covers an in-depth analysis of the following segments of the Axial Flux Motor market.

By Cooling Process: Air Cooling, Liquid Cooling.

By Power: 1kw-15kw, 15kw-80kw, 80kw-160kw, Above 160kw.

By Application: Electric Passenger Vehicles, Commercial Vehicles, Industrial Machinery, Elevators, Robotics Actuators, and Propulsion Systems, Aircrafts & Electric Glider Planes, Yachts & Electric Boats, Electric Drones, Others.

By End-User Industry: General Manufacturing, Power, Construction, Automotive, Aerospace, Marine, Agriculture, Others.

By Geography: North America, South America, Europe, APAC, and RoW.

Key Takeaways

• The Electric Passenger Vehicles segment is expected to grow at a CAGR of 12.6% during the forecast period 2024-2030 owing to the increase in government initiatives and key players strategic approaches to maintain the dominance.

• Automotive dominated the Axial Flux Motor Market with a revenue of $238.06m in 2023 and is projected to reach $477.11m by 2030 and is also set to be the fastest-growing segment with a CAGR of 10.6% during the forecast period 2024-2030. Axial flux electric motors are in high demand across a variety of vehicle industries and across numerous geographical locations, thanks to the continuously developing automotive sector.

• Europe region is dominating the Axial Flux Motor Market with revenue of $186.68 m in 2023 and is estimated to grow at a CAGR of 11.9% during the forecast period of 2024-2030 to generate a revenue of $405.55m in 2030. The government's aggressive measures for the adoption of electric vehicles have aided the sector's massive growth throughout Europe.

• The growing demand for high power density axial flux motors is enhancing the industry expansion and is set to positively impact the market growth.

1 note

·

View note

Text

#Axial Flux Motor Market Size#Axial Flux Motor Market Share#Axial Flux Motor Market Price#Axial Flux Motor Market Trends

0 notes

Text

wish i could figure out whats up with compression clothing. the culture is always like nooooOooo you cant just MAKE them its dangerous you dont know how compression works like the people who have done the research but like if you only get them by ordering online in standard sizes they are not actually that delicately tailored to the human body. like the information on trade-secret-manufacturing data is a bitch to find but that is the only reason you couldnt just go and make your own binders and shit

#i want to try compression stockings but its such a whole thing. literally i could make stockings#maybe i need to get more autistic about it and everything will be revealed to me by divination#i have sooooo many wordpress blogs and research papers about axial flux motors collexted from a fixation binge a couple years ago i 100%#would not be able to find again if i tried

0 notes

Text

Automotive Axial Flux Motors Market Analysis, Demand, Forecast 2022-2029

BlueWeave Consulting, a leading strategic consulting and market research firm, in its recent study, estimated global automotive axial flux motors market size at USD 131.57 billion in 2022. During the forecast period between 2023 and 2029, global automotive axial flux motors market size is to grow at a robust CAGR of 24.29% reaching a value of USD 485.07 billion by 2029. Significant trends are altering the industry landscape in the global automotive axial flux motors market. The increased demand for electric vehicles (EVs) has accelerated the adoption of axial flux motors due to their small size, high power density, and efficiency. The market is seeing a growth in R&D activity to improve the performance and reliability of axial flux motors. Also, advances in materials and manufacturing techniques are propelling the development of lightweight and cost-effective axial flux motors. The incorporation of cutting-edge technology like artificial intelligence and the Internet of Things (IoT) into automotive systems is increasing demand for axial flux motors in a variety of applications.

Global Automotive Axial Flux Motors Market – Overview

A particular design configuration of electric motors used in automobiles is referred to as automotive axial flux. In contrast to the more typical radial flux layout, the magnetic flux of the motor in this arrangement is parallel to the axis of rotation. Axial flux motors have a compact and effective design because the magnetic field moves from the motor's center to its perimeter or vice versa. A higher power-to-weight ratio, better cooling, and increased torque output are all made possible by this configuration. Due to their potential to provide superior performance, better efficiency, and space-saving benefits over conventional radial flux motors, automotive axial flux motors have drawn interest in electric vehicle applications.

Sample Request @ https://www.blueweaveconsulting.com/report/automotive-axial-flux-motors-market/report-sample

Impact of COVID-19 on Global Automotive Axial Flux Motors Market

The COVID-19 pandemic significantly impacted the global automotive axial flux motors market, causing widespread disruptions across the industry. Lockdown measures, supply chain disruptions, and reduced consumer spending have led to a decline in demand for automotive axial flux products. Manufacturers have faced challenges in sourcing raw materials and components, leading to production delays and increased costs. The closure of automotive plants and decreased vehicle sales have further dampened market prospects. However, the industry has shown resilience by adopting digital platforms for sales and exploring innovative strategies. As the world recovers from the pandemic, the automotive axial flux market is expected to gradually rebound, driven by the increasing adoption of electric vehicles and government initiatives supporting sustainable transportation.

Global Automotive Axial Flux Motors Market – By Vehicle Type

On the basis of vehicle type, global automotive axial flux motors market is divided into Passenger Cars, Light Commercial Vehicles, Medium & Heavy Commercial Vehicles, and Two Wheelers segments. The largest segment within this market is the Passenger Car segment, which includes a wide range of cars designed for personal transportation. These vehicles are commonly used by individuals and families for daily commuting and leisure purposes. Following the Passenger Car segment, the other significant segments in the market include Light Commercial Vehicles, which are smaller utility vehicles used for business purposes, and Medium & Heavy Commercial Vehicles, which are larger trucks and buses used for commercial transportation. Also, the Two Wheeler segment comprises motorcycles and scooters, providing an alternative mode of transportation for individuals.

Competitive Landscape

Global automotive axial flux motors market is fiercely competitive. Major companies in the market include Magnax BV, YASA Limited, Traxial BV, Nidec Corporation, Saietta Group, EMRAX, Evans Electric, Whylot Electromechanical Solutions, Agni Motors Ltd, Turntide Technologies, Lucchi R., Protean Electric, Elaphe Propulsion Technologies, Brusa Elektronik AG, and PML Flightlink Ltd. Companies use various strategies, including increasing investments in their R&D activities, mergers, and acquisitions, joint ventures, collaborations, licensing agreements, and new product and service releases to further strengthen their position in global automotive axial flux motors market.

Contact Us:

BlueWeave Consulting & Research Pvt. Ltd

+1 866 658 6826 | +1 425 320 4776 | +44 1865 60 0662

0 notes

Text

When the AC synchronous motor utilizes permanent magnets for producing field excitation, then this becomes a Permanent Magnet Synchronous Generator. This includes permanent magnet rotor that generates high torque at zero speed, no rotor current and includes small frame size. To know more details about Permanent Magnet Synchronous Generator, visit our blog or call on +919582345931, +919873699384, +919999467601, or mail us at [email protected]

#permanent magnet synchronous generator#synchronous generator#permanent magnet alternator#permanent magnet alternator manufacturer in India#permanent magnet alternator manufacturer in Delhi#permanent magnet generator manufacturer in India#permanent magnet generator manufacturer in Delhi#low rpm permanent magnet alternator#permanent magnet generator#low rpm permanent magnet generator#axial flux permanent magnet generator#radial flux permanent magnet generator#permanent magnet generator manufacturer#permanent magnet low rpm alternator#permanent magnet alternator manufacturers#high speed permanent magnet alternators#alternator#generator#AC synchronous motor#synchronous motor#motor

1 note

·

View note

Text

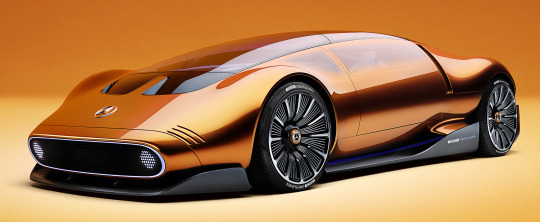

Mercedes-Benz Vision One-Eleven, 2023. A sports car study that looks to the future whilst drawing on the Mercedes concepts from the past. It is powered by lightweight and compact axial-flux electric motor technology. The car uses augmented reality so that the driver can use headset to turn the entire car into a user interface allowing you to see through the A-pillars. The design references the C-111 concepts of the late 60s and 70s

#Mercedes-Benz#Mercedes-Benz Vision One-Eleven#Mercedes-Benz C-111#2023#futuristic#concept#prototype#EV#electric car#axial-flux ev#gullwing doors

284 notes

·

View notes

Text

Pressure Drop Testing: Update

As seen in my previous post, I successfully completed the pressure drop testing across the motor!

The type of motor we use is the Emrax 228 motor linked below. Its data sheet states that it has a 13 psi drop in pressure across its ports for liquid cooling. We suspected and hoped that this is higher than in reality.

This testing was also to validate a new type of pump. On the old car we were using a diaphragm style pump, but we hope to use a centrifugal pump on the new car. These provide many benefits over diaphragm pumps including size, weight, flow rate, and power usage.

My motor cooling lead Noah made this handy table below that weighs all pros and cons of the two types of pumps.

Luckily we have two Bosch centrifugal pumps already so we plan to use one or two of these since they were free to us. The specific type of pump we have is the one linked below.

Results

I set the power supply to 12V and the pump worked perfectly! There were a few instances when the pump was not running smoothly but I think I figured out why. One contribution to the issue was that I had the reservoir over 3 feet above the pump. I think the pump just didn't provide enough pressure to move the water up that great of a height. When the pump couldn't move more water up, it created air bubbles at the intake of the pump. Centrifugal pumps cannot run dry. This caused the pump to stop working for a few seconds.

After I moved the reservoir to a lower position relative to the pump, everything seemed to work great. The pump provided such a smooth flow of water it was hard to even tell if water was in the tubes!

The two pressure gauges also seemed to work well. At the inlet into the motor the pressure read 10 psi and at the exit it was only 1.5 psi. This yields a drop in pressure of 8.5 psi which is in fact lower than the motor's data sheet. I have updated Noah about this result so he will be able to use the data in his calculations for designing one or two cooling loops.

Overall, a successful day of getting things done that I had been procrastinating lol

0 notes

Text

#AxialFluxMotors#ElectricVehicles#EVs hashtag#SustainableTransport#GreenTechnology#RenewableEnergy#MotorTechnology#Innovation#CleanEnergy#FutureMobility

0 notes

Text

The Aluminum Slug Market: Trends, Drivers, and Future Prospects

The aluminum slug market plays a pivotal role in the broader aluminum industry, supplying critical components for a diverse array of end-use applications. These small, cylindrical pieces of aluminum are essential in the manufacturing of various products, ranging from aerosol cans to automotive components. This article delves into the current trends, key drivers, challenges, and future prospects of the aluminum slug market.

Sample Report: https://www.econmarketresearch.com/request-sample/EMR0075/

Market Overview

Aluminum slugs are intermediate products in the aluminum processing chain, produced primarily through the extrusion process. They are further processed into end products by means of impact extrusion, a technique that involves forcing the slug into a mold at high pressure to create hollow shapes. This method is particularly valued for its ability to produce lightweight, durable, and corrosion-resistant items.

Key Applications

The aluminum slug market caters to several significant sectors:

Packaging Industry: One of the largest consumers of aluminum slugs is the packaging industry, especially for producing aerosol cans and beverage containers. The demand for convenient, lightweight, and recyclable packaging solutions has driven the growth in this sector.

Automotive Industry: Aluminum slugs are used to manufacture various automotive components such as shock absorber tubes, airbag inflators, and engine parts. The automotive industry's shift towards lightweight materials to enhance fuel efficiency and reduce emissions has bolstered the demand for aluminum slugs.

Pharmaceutical and Cosmetic Industries: The demand for aluminum tubes in the pharmaceutical and cosmetic industries has been robust, as these sectors require packaging that ensures product safety, hygiene, and extended shelf life.

Electrical and Electronics Industry: Aluminum’s excellent conductivity and lightweight properties make slugs valuable for producing electrical components and housings for electronic devices.

Gate Full Information: https://www.econmarketresearch.com/industry-report/aluminum-slug-market/

Other Reports:

SOC Containers Market Growth

HVAC Chillers Market Size

Aluminum Slug Market

Digital Brain Health Market Analysis

Cognitive Robotics Market Trends

Industrial IoT Display Market Share

Edible Offal Market Application

Potato and Yam Derivatives Market

Surgical Booms Market Overview

Marine Application Market Opportunities

Wind Power Parks Market Revenue

Fuel Cells In Aerospace And Defense Market

Floor Adhesive Market Sales

Pet Fitness Care Market Technology

Axial Flux Motor Market Drivers

Audio and Video Equipment Market Types

Self Stabilizing Spoon Market Challenges

Solar Backsheet Films Market Outlook

Marine Sensors Market Analysis

Dry Shipping Container Market Segmentation

Blood Stream Infection Testing Market Size

Ethyl Vanillin Market Growth

Prebiotic Fiber Market Future

Solar Watch Market Trends

Industrial and Commercial Floor Scrubbers Market Analysis

Electro-Mechanical Brake Market Share

Fiber-Reinforced Plastics Recycling Market Segmentation

Closed Cell Foam Market Drivers

Perfume Ingredient Chemicals Market Technology

Bucket Wheel Excavator Market Revenue

Female Fragrance Market Sales

Yard Crane Market Outlook

0 notes

Text

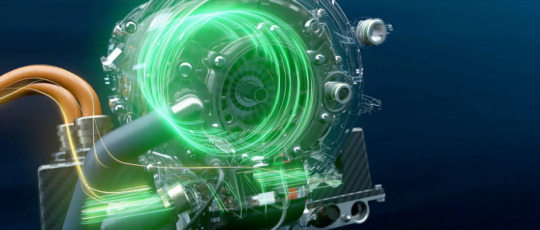

We’ve all seen how far automotive technology has come in the last decade. Specifically, the motor industry. The use of axial flux (pancake) motors in electric vehicles and aircraft has grown significantly.

Our team of physicists and mechanical technologists have spent years researching our latest axial flux induction motors, which has several unique features like high power density, larger storage space due to compact design, strength and durability, and variety of industrial usage.

Our Axial flux induction motor induces alternating current to create magnetic field in the rotor instead of relying on rare earth permanent magnets. By concurrently maintaining an equivalent level of power and torque density, our asynchronous motor technology stands out for its capacity to eliminate permanent magnets while delivering comparable performance.

0 notes

Link

#AircoreEC#AircoreMobility#AircorePowerGen#Austin#commercialtrucking#Deloitte#Futurride#GalvanizeClimateSolutions#Infinitum#InfinitumAircore#InfinitumVFD#InternationalEnergyAgency#JustClimate#LawrenceBerkeleyNationalLaboratory#marine#mining#NGP#PCBstator#RockwellAutomation#sustainableelectricmotor#sustainablemobility#Texas#U.S.DepartmentofEnergy#variablefrequencydrive#variable-speedmotor

0 notes

Text

0 notes

Text

8 Types of Electric Motors that Power EVs

In the dynamic landscape of the automotive industry, electric vehicles (EVs) have emerged as a beacon of sustainability and environmental responsibility. At the heart of these cutting-edge vehicles lies a crucial component: the electric motor. These motors are the driving force, quite literally, behind the push for a cleaner, greener transportation future. Let's take a closer look at five prominent types of electric motors that propel electric vehicles into the future.

Brushed DC Motor: The brushed DC motor, a pioneer in the realm of electric propulsion, employs a coil of wire and brushes to conduct electricity, propelling the rotor into motion. Despite its simplicity and cost-effectiveness, the brushed DC motor faces challenges such as friction-related efficiency limitations and higher maintenance demands.

Brushless DC Motor (BLDC): Addressing the limitations of its brushed counterpart, the BLDC motor boasts electronic commutation, eliminating brushes and ushering in increased efficiency, reduced maintenance, and an extended lifespan. The higher manufacturing costs and complex control algorithms are a trade-off for the enhanced performance and power density that BLDC motors offer.

Induction Motor: Widely adopted in the electric vehicle industry for its simplicity and reliability, the induction motor operates by inducing a current in the rotor through electromagnetic fields. While it excels in ruggedness and reliability, challenges include lower efficiency at low speeds and light loads, requiring additional control electronics for optimal performance.

Permanent Magnet Synchronous Motor (PMSM): The PMSM, a stalwart in the electric vehicle domain, leverages permanent magnets on the rotor to synchronize with the stator's rotating magnetic field. This design choice results in high efficiency, superior power density, and efficient regenerative braking. However, challenges such as costs associated with permanent magnets and the need for complex control algorithms persist.

Switched Reluctance Motor (SRM): A less common but promising contender, the SRM operates on the principle of magnetic reluctance, offering a simple construction and robust design. However, efficient operation requires intricate control algorithms, and performance at high speeds may be limited, making SRMs less widespread in EV applications.

Each of these electric motor types brings a unique set of advantages and challenges to the table. The rising stars, such as BLDC and PMSM motors, are witnessing increased adoption in the electric vehicle sector, driven by their efficiency, precise control, and extended lifespan. Meanwhile, emerging contenders like axial flux and toroidal motors are captivating attention with their compact designs and unique capabilities.

In the ever-evolving landscape of electric mobility, the choice of electric motor becomes a pivotal decision for manufacturers. As technology advances, innovation in electric motor design will likely overcome current limitations, paving the way for even more efficient, powerful, and reliable electric vehicles cruising our roads. The journey towards a sustainable and electrifying future continues, driven by the relentless pursuit of cleaner and greener transportation solutions.

To read more, click here.

Discover the fascinating world of advanced electric vehicles and beyond with SearchEV, your ultimate gateway to awe-inspiring EV technology and much more!

0 notes

Text

The Future of E-Motors Is Axial: How Beyond Motor’s Axial Flux Tech Saves Up to 4x on Production Material and Still Delivers Highest Power Density

http://dlvr.it/Svl1LQ

0 notes

Video

youtube

Axial Flux Synchronous Motor Prototype

1 note

·

View note