#cad modeling

Explore tagged Tumblr posts

Text

What Is Reverse Engineering and When Should You Use It?

In today’s competitive and innovation-driven manufacturing landscape, companies are continually searching for methods to optimize designs, streamline production, and gain deeper insight into existing products. One of the most powerful yet often misunderstood tools that supports these objectives is reverse engineering.

Reverse engineering enables organizations to deconstruct a product or system to understand its components, functions, and design principles. This process is not only used to replicate products but also to analyze their structure, improve upon them, or integrate them into new applications.

This article offers a comprehensive explanation of reverse engineering—what it is, how it works, the technologies involved, its applications across industries, and the scenarios where it proves most valuable.

Defining Reverse Engineering

At its core, reverse engineering is the process of disassembling or analyzing an object to understand how it was designed and manufactured. It involves extracting design information from existing products, often in the absence of technical documentation or original design files.

Unlike traditional engineering, which moves from concept to product, reverse engineering starts with the finished item and works backwards to deduce the original specifications. The insights gained are often used to:

Create 3D models and CAD files

Improve product design

Develop compatible components

Diagnose failures or weaknesses

Reproduce obsolete or legacy parts

Reverse engineering does not necessarily imply copying or duplication. Rather, it is a legitimate and valuable practice in modern product development, maintenance, and innovation.

How Reverse Engineering Works

The reverse engineering process varies depending on the object, industry, and intended outcome, but it generally follows a consistent sequence:

1. Data Acquisition

The first step involves capturing detailed information about the object’s geometry, dimensions, and features. This is typically done using advanced 3D scanning technologies such as:

Laser Scanners: Emit laser beams to detect surface contours.

Structured Light Scanners: Project light patterns and measure distortions to determine surface geometry.

Computed Tomography (CT) Scanners: Capture both internal and external features using X-ray technology.

Coordinate Measuring Machines (CMMs): Use touch probes to precisely measure specific points.

These tools collect millions of data points, forming a comprehensive digital representation of the object known as a point cloud.

2. Data Processing and Mesh Generation

The raw point cloud data is cleaned, aligned, and processed to remove noise and inconsistencies. The next step is to convert the point cloud into a polygonal mesh—a 3D surface composed of interconnected triangles.

This mesh is then optimized to ensure it accurately reflects the physical object’s shape while maintaining a manageable file size for further use.

3. 3D Modeling and CAD Conversion

Once a high-quality mesh is obtained, it is used to reconstruct the object in a computer-aided design (CAD) environment. Engineers develop a fully parametric or feature-based CAD model that replicates the part’s geometry.

At this stage, material specifications, tolerances, and functional features may also be analyzed and documented. The final CAD model can be edited, shared, or integrated into larger assemblies.

4. Analysis and Application

The finished model is then used for various purposes, including design improvements, simulation, tooling development, or manufacturing reproduction. Engineers may also perform stress tests, fit checks, and other simulations using the digital model.

Key Technologies in Reverse Engineering

Advances in digital manufacturing and metrology have significantly expanded the capabilities of reverse engineering. The following technologies are essential:

3D Scanning

High-resolution 3D scanning tools rapidly capture the surface geometry of physical objects, forming the foundation for all subsequent steps. These scanners vary in accuracy, speed, and suitability depending on the object's size, complexity, and material.

CAD Software

CAD platforms such as SolidWorks, Autodesk Inventor, Siemens NX, and others play a crucial role in interpreting scanned data and creating usable design files. These models are often parametric, allowing engineers to modify features and dimensions easily.

Simulation Tools

Finite Element Analysis (FEA) and other simulation tools are used in conjunction with CAD models to evaluate a product’s performance under various conditions. These insights support design optimization and failure analysis.

3D Printing and Prototyping

Rapid prototyping allows teams to test modifications derived from reverse engineering efforts. By printing physical models, engineers can assess fit, function, and ergonomics quickly and affordably.

When Should You Use Reverse Engineering?

Reverse engineering is applicable in a wide range of situations across multiple industries. It is especially useful when dealing with legacy components, product innovation, or systems integration. Below are the most common scenarios that justify the use of reverse engineering.

1. Recreating Obsolete or Legacy Parts

One of the primary uses of reverse engineering is to reproduce discontinued components for machines, vehicles, or systems that are no longer supported by the original manufacturer. With no access to original drawings or tooling, reverse engineering provides a reliable way to maintain critical assets and extend their lifecycle.

This is particularly valuable in aerospace, defense, rail, and heavy industries, where replacing entire systems is impractical or cost-prohibitive.

2. Product Improvement and Optimization

Reverse engineering enables manufacturers to analyze existing products and identify opportunities for improvement. Engineers can assess design weaknesses, material inefficiencies, or manufacturing complexities and apply innovative solutions to enhance performance, durability, or cost-effectiveness.

The process often leads to

Lighter and stronger designs

Reduced manufacturing steps

Better ergonomics or aesthetics

Improved energy efficiency

3. Competitive Analysis

Organisations often use reverse engineering to examine competitor products and gain insights into their features, performance, and manufacturing techniques. This helps in benchmarking, identifying intellectual property challenges, and driving innovation.

While care must be taken to respect legal and ethical boundaries, competitive reverse engineering is a legitimate practice used for market intelligence and strategic planning.

4. Integrating New Components with Existing Systems

In cases where new parts or systems need to work seamlessly with older components, reverse engineering ensures dimensional compatibility and functionality. By modeling the existing hardware accurately, engineers can design new components that align perfectly without trial and error.

This use is common in:

Automotive retrofits

Industrial equipment upgrades

Electronic system integration

5. Quality Control and Inspection

Reverse engineering is sometimes used as a validation tool in quality assurance. By scanning and modeling a manufactured part, teams can compare it to the original design and detect any deviations or defects.

This process enhances dimensional verification, especially for complex geometries that are difficult to measure with traditional tools.

6. Digital Archiving

Preserving the design data of critical components through reverse engineering creates a digital archive for future reference. This is important in museums, aerospace restoration, and asset management, ensuring that data is never lost even if physical components degrade or disappear.

Industries Benefiting from Reverse Engineering

The versatility of reverse engineering means it is widely applicable across a variety of sectors:

Aerospace

Airplane components, many of which have long service lifecycles, often require replacement or refurbishment after the original manufacturing data is lost. Reverse engineering ensures structural integrity and regulatory compliance.

Automotive

Classic cars, custom vehicles, and prototype parts benefit greatly from reverse engineering. It enables part reproduction, modification, and even digital recreation of entire vehicle systems.

Medical Devices

Medical implants, prosthetics, and surgical instruments are reverse-engineered to improve functionality, ensure anatomical fit, or replicate discontinued designs.

Consumer Electronics

Electronics companies often disassemble products to understand PCB layouts, circuitry, and design logic. This enables repair, customization, or the development of compatible accessories.

Industrial Manufacturing

Reverse engineering supports tooling design, process improvement, and machine maintenance. It is also used to digitize old parts or machinery for integration into modern workflows.

The Role of Reverse Engineering in Innovation

Beyond its practical applications, reverse engineering fosters innovation by bridging the gap between legacy knowledge and modern capabilities. It encourages experimentation, cross-functional learning, and iterative improvement.

By understanding the details of how a product works, engineers can:

Identify underutilized features

Explore alternative materials

Develop more efficient manufacturing methods

Combine legacy and modern technologies

This approach is particularly important for companies striving to remain competitive in rapidly evolving markets. It allows them to leapfrog development stages, reduce R&D costs, and bring products to market faster.

Ethical and Legal Considerations

While reverse engineering is a powerful tool, it must be practiced within ethical and legal boundaries. It is important to respect patents, copyrights, trade secrets, and intellectual property (IP) rights.

Organizations using reverse engineering must ensure their efforts do not infringe on protected designs. In many jurisdictions, reverse engineering for interoperability or repair purposes is legal, but copying patented elements without permission is not.

Working with professional providers of reverse engineering services in Australia ensures that all procedures are carried out in compliance with local laws and international IP standards.

Choosing the Right Reverse Engineering Partner

The effectiveness of reverse engineering relies heavily on the skill, experience, and tools used. Partnering with specialists who understand materials science, digital modeling, and manufacturing processes ensures accurate, high-quality results.

Providers offering reverse engineering services in Australia are equipped with advanced scanning systems, robust CAD platforms, and cross-industry expertise. They help clients navigate complex engineering challenges, from legacy part digitization to modern product development, while maintaining confidentiality and regulatory compliance.

Conclusion

Reverse engineering is a powerful, multi-purpose process that enables organizations to derive valuable design and manufacturing data from existing physical products. Whether used for reproduction, enhancement, integration, or analysis, it offers significant advantages across the product lifecycle.

By turning physical objects into digital intelligence, reverse engineering allows industries to move forward while learning from the past. It supports innovation, sustainability, and precision in a world where adaptability and speed are crucial to success.

As industries increasingly adopt digital technologies and advanced manufacturing techniques, reverse engineering will play an even more integral role—especially when executed by trusted professionals who offer comprehensive reverse engineering services in Australia and beyond.

#reverse engineering#product development#3D scanning#CAD modeling#engineering services#component analysis#design replication

1 note

·

View note

Text

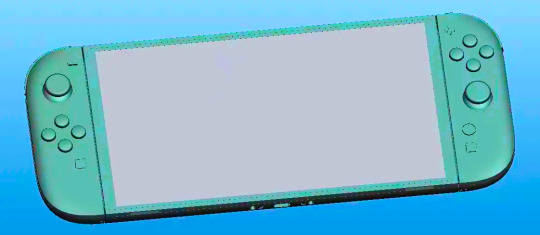

3D printing and CAD modeling

The combination of 3D printing and CAD design is transforming industries by enabling faster, more sustainable, and cost-effective production processes. At Cadify Studio, we’re here to empower your projects with cutting-edge technology and unmatched expertise.

0 notes

Text

Innovative 3D CAD Modeling by Shalin Designs

Innovative 3D CAD Modeling by Shalin Designs

Every great idea deserves the perfect design. At Shalin Designs, we specialize in delivering high-precision 3D CAD modeling services that bridge the gap between concept and reality. Our team of experienced designers combines technical expertise with creativity to provide solutions tailored to your industry.

Our Expertise

Custom 3D Designs: From product prototypes to architectural blueprints, we create detailed, accurate models.

Cutting-Edge Tools: Proficient in industry-leading software like SolidWorks, AutoCAD, and Creo.

Seamless Collaboration: We work as an extension of your team, ensuring every project meets your specifications.

Applications We Support

Mechanical Design: Optimize components and assemblies for functionality and manufacturability.

Product Development: Create 3D models for testing, presentations, or production.

Construction & Architecture: Bring your building designs to life with realistic 3D representations.

Whether you’re an innovator or a business looking to enhance your designs, Shalin Designs is your go-to partner for 3D CAD modeling.

Why Choose Us?

Expertise in CAD tools like AutoCAD, SolidWorks, and CATIA.

Affordable pricing with no compromise on quality.

Quick turnaround times to meet your deadlines.

Boost your projects with our reliable 3D CAD services today. Learn more here!

Email: [email protected]

Phone: +44 7540215955

0 notes

Text

How CAD Design and Drafting Brings Your Ideas to Life

In modern design and architecture, the ability to transform imaginative concepts into tangible realities is a remarkable feat. Shalin Designs, a leader in CAD Design and Drafting Services, excels in bridging the gap between vision and reality. This article explores how their expertise in CAD design and drafting can bring your ideas to life.

The Power of CAD Design

Computer-Aided Design (CAD) has revolutionized the design industry, providing unparalleled precision and flexibility. Shalin Designs harnesses the power of CAD to create detailed and accurate models, ensuring every aspect of a project is meticulously planned and executed. This technology allows designers to visualize and refine their ideas, making adjustments and improvements before the actual construction begins.

Precision and Accuracy

One of the standout features of CAD design is its ability to produce highly precise and accurate drawings. Shalin Designs utilizes advanced CAD software to create detailed plans that leave no room for errors. This precision not only enhances the quality of the final product but also streamlines the manufacturing process, reducing waste and saving time.

Versatility in Design

CAD design offers immense versatility, accommodating a wide range of design requirements. Whether it’s residential, commercial, or industrial projects, Shalin Designs can tailor their CAD services to meet specific needs. Their expertise spans various sectors, including architecture, furniture design, and sheet metal design, making them a one-stop solution for diverse design challenges.

Enhanced Collaboration

Effective collaboration is crucial in any design project. CAD design facilitates seamless communication between designers, clients, and other stakeholders. Shalin Designs prioritizes client involvement throughout the design process, ensuring that every detail aligns with their vision. This collaborative approach not only enhances the design quality but also fosters trust and satisfaction.

Streamlined Workflow

The integration of CAD design into the workflow significantly enhances efficiency. Shalin Designs leverages CAD to streamline the entire design and drafting process, from initial concept to final implementation. This streamlined approach minimizes delays, optimizes resource utilization, and ensures timely project completion.

Innovation and Creativity

CAD design is not just about precision; it’s also a powerful tool for innovation and creativity. Shalin Designs encourages out-of-the-box thinking, enabling designers to explore unconventional ideas and push the boundaries of traditional design. CAD’s 3D modeling capabilities allow for dynamic visualizations, helping clients see their concepts come to life in vivid detail.

Key Takeaway

Shalin Designs expertise in CAD design and drafting is instrumental in transforming ideas into reality. Their commitment to precision, versatility, collaboration, and innovation ensures that every project meets the highest standards of quality and excellence. By harnessing the power of CAD, Shalin Designs brings your visions to life, turning dreams into tangible, impactful creations.

Conclusion

In a world where design and innovation are constantly evolving, Shalin Designs stands out as a beacon of excellence in CAD design and drafting. Their ability to translate ideas into detailed, accurate, and inspiring designs is a testament to their skill and dedication. For those seeking to bring their creative visions to life, Shalin Designs is the ultimate partner in transforming dreams into reality.

0 notes

Video

youtube

GSD Duct Design #catia3dmodelling #catiav5

1 note

·

View note

Text

In the ever-evolving world of aerospace engineering, precision and innovation are paramount. One of the crucial elements in the process of designing cutting-edge aircraft and spacecraft is CAD (Computer-Aided Design) modeling and prototyping.

Introduction to CAD Modeling

CAD modeling involves the creation of digital representations of physical objects, allowing engineers and designers to visualize, analyze, and refine their concepts. It’s the foundation upon which aerospace engineering advances, enabling professionals to bring their visionary ideas to life.

The Aerospace Industry’s Reliance on CAD

In the aerospace industry, where the stakes are sky-high, CAD modeling is indispensable. It serves as the backbone of aircraft and spacecraft design, ensuring every component aligns perfectly for optimal performance.

Benefits of CAD Modeling in Aerospace

Enhanced Precision: CAD modeling offers an unparalleled level of precision. Engineers can simulate real-world conditions and interactions, fine-tuning their designs with meticulous accuracy.

Cost Reduction: By identifying potential issues in the digital realm, costly mistakes in manufacturing are minimized. This results in substantial cost savings for aerospace companies.

Iterative Design: CAD enables engineers to iterate rapidly, making adjustments and improvements efficiently. This iterative approach leads to the development of highly efficient and safe aerospace vehicles.

Read more

0 notes

Text

chibi hexsquad! drew this super quick between classes :3

#drew this on krita on the school computers in like 7 minutes after my CAD model finished rendering and then I ZOOMED to the bus stop#i made it in time tho 💪💪 im posting this from the bus rn#i wanna draw more but im just always. so busy.#and most of the time im working on my laptop so i can't doodle in the margins of my notes </3#also somehow my main sketchbook has vanished??? which SUCKSSSSS#i can't find it anywhere im thinking i left it at my mom's?? im visiting her this weekend so hopefully it's there#anyways. have little chibi hexsquad. as a treat#im trying to experiment more with the style i draw myself in :]#lilac art#lilac doodle#toh fanart#toh#Luz noceda#willow park#gus porter#amity blight#hunter toh#image id in alt text#image id included

85 notes

·

View notes

Text

Beautiful women called Battery low Approximately 20% remaining (55 minutes) are inside my computer

33 notes

·

View notes

Text

I think it’s quite amazing how my quality of life has instantly improved TENFOLD now that i don’t have to come up with words anymore and can finally sing again while I’m working.

Music really is something else…

#any uni night shifts I’ve ever pulled drawing CAD plans or 3D modelling#it’s always singing that has kept me alive :D#fuck caffeine#everything is better with music#you know it's dire though when the Lady Gaga and Britney Spears come out#that shit hits like cocain at 3am in the morning#when even Hadestown or Hamilton aren't doing it anymore :D#qverts inside thoughts

20 notes

·

View notes

Text

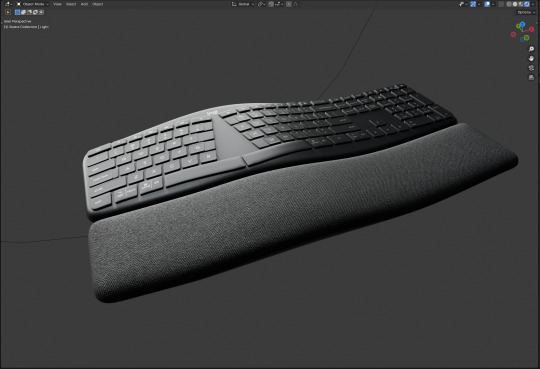

a fun pro tip is that if an online storefront has a "3D preview" of an object you can probably grab it as a glb file and throw it into blender with perfect scaling, full textures, and detailed dimensions that you can then pull off for other projects (or, like, I've seen people straight up dump Ikea furniture into blender scenes for animations)

I want to add some printed parts to this keyboard and here's a perfect to-scale model I can reference and use to do boolean operations with to make my parts fit, even on complex curves

52 notes

·

View notes

Text

Hey you fucks, it's time to learn CAD. This is your sign, there will be no right time. Open a cad program and start making. Do it now. Then send me ur models and I'll print them and put them on my fridge like the crayon drawings of our youth.

Fusion and OnShape have free versions, if you're a college student you may be able to get the most common CAD programs free while you're in school, either way, get to work.

Post inspired by @genderneutralhole 's d6 which is currently taped to my fridge

#maker#lgbt makers#queer#transgender#robotics#robots#3d printing#robot girls#cad#fusion 360#fusion#onshape#3d modeling#3d printed#3d printer

14 notes

·

View notes

Text

Leaf Weave Ring

Im looking to do some free custom 3D modeling. Shoot me a message if you're interested!

11 notes

·

View notes

Text

Professional CAD Modeling Services for All Industries

Need professional 3D CAD modeling for your project? Shalin Designs delivers high-quality and detail-oriented CAD models tailored to your specifications. From product designs to engineering components, we guarantee top-tier results. Contact us today!

1 note

·

View note

Text

Shalin Designs: Top 3D Modeling and CAD Company on GoodFirms

Looking for a reliable and efficient 3D modeling and CAD company? Look no further than Shalin Designs, a Top 3D Modeling and CAD Company on GoodFirms.

Why Shalin Designs Stands Out

Shalin Designs has carved a niche for itself in the world of CAD by specializing in quick project turnaround. They understand the importance of delivering high-quality work within tight deadlines. This is particularly valuable for clients who require fast and efficient project completion.

Our Expertise

Shalin Designs offers a comprehensive suite of 3D modeling and CAD services, including:

3D Furniture Modeling: From concept to creation, Shalin Designs brings your furniture ideas to life in 3D.

Millwork Furniture: Their team is adept at designing and detailing custom millwork for any space.

Product Design: Shalin Designs translates your product vision into a functional and visually appealing design.

CAD Design and Conversion: They offer comprehensive CAD services, including creating new designs and converting existing drawings into digital formats.

Revit Design: Shalin Designs utilizes Revit for Building Information Modeling (BIM) projects, ensuring an integrated design workflow.

Rendering: Visualize your project in stunning detail with Shalin Designs' rendering expertise.

And More: Shalin Designs offers a wide range of other services, including CAD Design, CAD Conversation, Millwork Drafting, 3D Furniture modeling, 3D Modeling, Product Design, Revit Design, Rendering, and Take-Off Services.

Client Satisfaction at the Forefront

Shalin Designs prides itself on its commitment to client satisfaction. Their impressive rating of 4.8 stars on GoodFirms, based on 6 reviews, speaks volumes about their dedication to quality and customer service. Competitive Rates and Established Experience

Founded in 2016, Shalin Designs boasts a wealth of experience in the CAD industry. They offer competitive rates, making their services accessible to a wide range of clients.

Considering Shalin Designs for Your Project?

If you're looking for a reliable, efficient, and experienced 3D modeling and CAD service provider company, Shalin Designs is a perfect choice. Visit their profile on GoodFirms to learn more about their services and see why they are a leader in the field.

0 notes

Text

A long time ago, in a galaxy far far away, this happened…

#model making#wargaming#painting#star wars#shatterpoint#star wars shatterpoint#501st#anakin skywalker#clone captain rex#bo katan#asoka tano#count dooku#jango fett#cad bane#aurra sing

96 notes

·

View notes