#ferromagnetic powder

Text

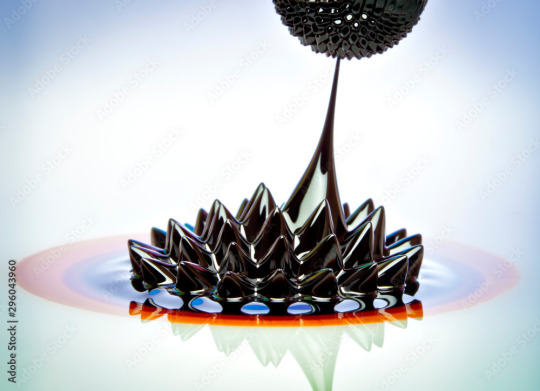

miguel o’hara with some slime for anon!

❤️-🕷️-💙 / ❤️-🕸️-💙 / ❤️-🕷️-💙

#stim#stimboard#across the spider-verse#miguel o'hara#sfw#blue#red#black#orange#spiderman 2099#slime#glow#big batch#science#watercolors#computers#technology#poking#hands#gloves#pouring#beakers#long nails#shiny#stretching#ferromagnetic powder#water#requests#spiderman

63 notes

·

View notes

Text

Competitive Landscape Analysis of Ferrite Permanent Magnet Industry

Competitive Landscape Analysis of Ferrite Permanent Magnet Industry

1. Major companies

Ferrite permanent magnet products mainly include 4 series, 6 series, 9 series, 12 series, 15 series, etc. TDK has been able to mass produce 15 series high-end magnetic materials, but China’s 15 series products are still in the research and development stage, and 9 series and above The proportion of products is…

View On WordPress

#ceramic ferrite magnets#Ferrite#Ferrite magnet#ferrite magnetic materials#Ferrite Magnets#ferrite permanent magnets#ferrite permanent magnet#ferromagnetic#Lamination steels#magnet composition#Magnet Maker#Magnetic alloy#magnetic field#magnetic fields#magnetic force#magnetic material#Magnetic Metals#magnetic properties#magnetic structures#Magnetic powder#Magnetism#paramagnetic materials#Permanent Magnet#Rare Earth Magnets#Sintered NdFeB Magnets#sintered soft magnetic materials

1 note

·

View note

Photo

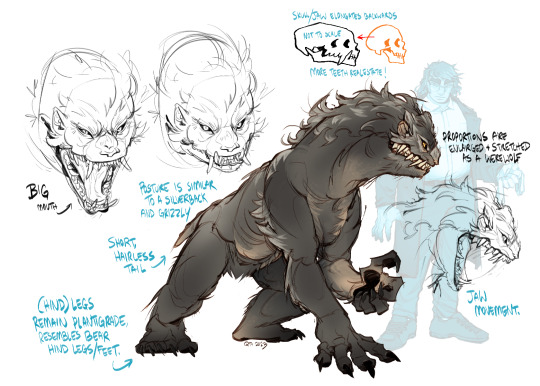

Updated refs for my OCs Alphi (they/them) and Zun (she/her). I completely redid Zun’s werewolf form (again/again) and am a little happier with it now!

Alphi’s a mage that works with ferromagnetic metals and Zun is a lycanthrope under house-arrest (that house being her state). Together they work to track and contain hostile witches, mages, and werewolves.

If you’re interested in a breakdown of the changes I’ve made, among other OC things, please consider checking out my Patreon.

Image descriptions:

Images 1 and 2: Thumbnail crops of the two characters in the main image. The first is a portrait crop of Alphi, a person with long braided powder-blue hair and heterochromia. The second is of Zun, a bespectacled woman with dark grey hair that ends in patchy silver spots.

Image 3: a compilation of notes surrounding a full body illustration of Alphi and Zun. Alphi is a tall and slender individual wearing a bright magenta coat off-shoulder. Zun is a more plainly dressed, stouter, stockier woman with extremities that end in a charcoal colour.

Image 4: a compilation of notes surrounding an illustration of Zun’s werewolf form. Its fur is primarily dark grey with silver patches and its posture resembles that of a silverback gorilla and grizzly bear. The skull is elongated, with very long rows of teeth. Her face retains vague semblances of her human form.

1K notes

·

View notes

Text

🧭⚔️☔️Observations about the earth-aligned "Kun" exorcism sword

Discussions of potential spoilers beneath the cut.

It appears to take various forms both segmented and whole in the latest trailer, but seems to have a solidity to it that's unlike the Li exorcism sword's organic fire-like form.

And the blade itself seems to be...nonexistent upon first unsheathing the exorcism sword?

It does not emerge until Shingi summons this concentric sigil, which matches the markings on his body.

As a side note: this sigil fascinates me. To fully understand why, please refer to my analysis video about the Asian Philsophy of the Universe.

I include a visual from that post for convenience:

If I were to hazard a guess, outer circle has eight prongs to represent the 8 trigrams, and the next one in with 4 prongs represent the older and younger variants of Yin and Yang? I'm willing to bet that the innermost circles represent Ryo-Gi (Yin & Yang) and Tai Chi (existence) respectively.

It also somewhat resembles the Luo Pan - a concentric compass used for Feng Shui practices. Look - I even found the character for "Kun" engraved onto it!

I wrote a little bit about it in this post. In summary, the latest lore video says that the Shuuga operates much like a magnetic field.

So what I'm getting at is, I believe sigil represents some kind of magnetic forcefield and the actual blade (and maybe even the ofuda derived from it) may be formed by some kind of ferromagnetic material which can be moulded to various shapes. Ferrofluid, or magnetic powder, perhaps?

There are plenty of stones that are magnetic - meteorites, lodestones, various igneous rocks seem to be the most thematically appropriate. And it kind of aligns with my theory that Shingi has shifted from an earth aligned to metal aligned being.

36 notes

·

View notes

Text

eleanor lamb stimboard for 🗺️ anon :•]

[ID: A 3x3 stimboard of 8 GIFs surrounding a center image.

GIF 1: A medium light skinned hand removing a wire-to-board connector from a circuit board.

GIF 2: Beetroot juice being poured into a small glass with a slightly-cloudy white liquid and ice in it.

GIF 3: Closeup footage of a memory card being placed into a laptop.

GIF 4: Dark red liquid spreading through water.

Image: Eleanor Lamb from Bioshock 2.

GIF 5: A lightbulb filled with red liquid and black ferromagnetic powder placed against a magnet, all the floating powder collecting around the magnet.

GIF 6: Light-skinned hands holding the cd tray of an optical drive. One of the thumbs spins the black circle that is the spindle table, while the other one slides the black rectangle that is the laser pickup back and forth.

GIF 7: A light-skinned hand showing off and spinning a small cup-shapes charm filled with red liquid and floating clear cubes inside.

GIF 8: A light-skinned hand moving a plastic lever back and forth in the metal frame of an optical drive, causing other levers to move.

End ID]

#scopostims original boards#stim#stimblr#stimboard#stimmy#tech#technology#liquid#bath bomb#red#black#eleanor lamb#bioshock#bioshock 2#🗺️ anon

60 notes

·

View notes

Text

Soft Magnetic Composite Market Report Relive the Future Opportunities and Trending Technology in the Modern Chemical Industry

The Soft Magnetic Composite Market is Valued at USD 5.4 billion in 2024 and is projected to reach USD 8.8 billion by 2030, growing at a CAGR of 7.3% During the Forecast period of 2024–2032.

Introduction:

Soft magnetic composites (SMCs) are innovative materials designed to enhance the performance of electrical and magnetic components. Comprised of ferromagnetic powders insulated with a dielectric binder, SMCs exhibit superior magnetic properties, including high permeability, low eddy current losses, and excellent thermal stability. These characteristics make them ideal for applications in the automotive, industrial, and consumer electronics sectors, driving the demand for SMCs in various modern technological advancements.

Download a Free Sample Copy of the Report: https://www.marketdigits.com/request/sample/4081

Major Vendors in the Global Soft Magnetic Composite Market:

➲ Arnold Magnetic Technologies.,

➲ Dexter Magnetic Technologies, Inc.,

➲ Electron Energy Corporation,

➲ Elna Magnetics.,

➲ Hitachi Metals Ltd.,

➲ MMG Canada Limited,

➲ PROTERIAL, Ltd.,

➲ Rio Tinto, Steward Advanced Materials LLC,

➲ Sumitomo Electric Industries, Ltd.,

➲ and Others.

Research Methodology:

Our research methodology involves a blend of primary and secondary research to ensure the accuracy and reliability of the data. Primary research includes interviews with industry experts, surveys, and observations of the market dynamics. Secondary research involves the analysis of industry reports, company publications, and authoritative databases. This comprehensive approach provides a well-rounded view of the market, ensuring that the findings are both credible and actionable.

The Report Offers:

❖ Market Overview: An in-depth look at the market dynamics, including drivers, restraints, opportunities, and challenges.

❖ Segmentation Analysis: Detailed analysis of the market by material type, application, end-user, and geography.

❖ Competitive Landscape: Profiles of leading players, their market share, product portfolio, and strategic initiatives.

❖ Technological Advancements: Insights into the latest technological innovations and their impact on the market.

❖ Market Forecasts: Projections for market growth and trends over the next five to ten years.

Inquire Before Buying at — https://www.marketdigits.com/request/enquiry-before-buying/4081

Segmentations Analysis of Soft Magnetic Composite Market: -

By Materials Type

➲ Electronic Iron

➲ Si-Steel

➲ Soft Ferrite

➲ Others

By Grade

➲ 1P

➲ 3P

➲ 5P

➲ Others

By Application

➲ Generators

➲ Transformers

➲ Switching Circuits

➲ Inductors

➲ Sensors

➲ Motor

➲ Others

Mostly Asked Questions:

❖ What are the key factors driving the growth of the Soft Magnetic Composite Market?

❖ How is the market segmented, and which segment is expected to witness the highest growth?

❖ Who are the major players in the market, and what are their strategies?

❖ What are the latest technological advancements in the soft magnetic composite industry?

❖ What are the prospects and market forecasts for the next five years?

Click to Request Free 10% Customization on this Report @ https://www.marketdigits.com/request/customization/4081

Conclusion:

The Soft Magnetic Composite Market is poised for significant growth, driven by advancements in technology and increasing demand across various sectors. This comprehensive report provides valuable insights and data to help businesses navigate the evolving market landscape, identify new opportunities, and make strategic decisions to achieve sustained growth. Access this report to stay informed and gain a competitive edge in the dynamic world of soft magnetic composites.

0 notes

Text

Magnetic Particle Inspection Services by Integrated NDE Solution in Pune

Magnetic Particle Inspection (MPI) is a highly effective non-destructive testing method used to identify surface and subsurface flaws in ferromagnetic materials. Utilizing magnetic fields and fine iron particles, MPI can reveal cracks, inclusions, and other defects that might compromise the integrity of a component. This technique is vital across various industries, including aerospace, automotive, and construction, where safety and reliability are paramount.

How MPI Works

The process begins with the magnetization of the test object. This can be achieved through direct or indirect methods, depending on the object's shape and material properties. Once magnetized, fine iron particles, either in dry powder form or suspended in a liquid, are applied to the surface. These particles are attracted to areas of flux leakage, which occur where there are discontinuities such as cracks or voids. The particles cluster around these areas, forming visible indications that can be further analyzed.

Advantages of MPI

High Sensitivity: MPI is capable of detecting very small surface and slightly subsurface defects.

Immediate Results: The process allows for real-time inspection and analysis, facilitating quick decision-making.

Cost-Effective: Compared to other non-destructive testing methods, MPI is relatively inexpensive and easy to perform.

Applications of MPI

MPI is utilized extensively in various fields:

Aerospace: Ensures the structural integrity of critical components like turbine blades and landing gear.

Automotive: Used to inspect engine blocks, crankshafts, and other vital parts.

Petrochemical: Monitors pipelines and storage tanks for potential leaks or weaknesses.

Construction: Verifies the quality of welds and steel structures to prevent failures.

Integrated NDE’s MPI Services

Integrated NDE offers comprehensive MPI services, both on-site and in-house. Their team of highly skilled Level 2 and Level 3 qualified professionals use advanced equipment and techniques to provide reliable and accurate inspections. By adhering to stringent industry standards, they ensure the highest level of quality and safety for their clients.

For more detailed information on their Magnetic Particle Inspection services, visit Integrated NDE's MPI page.

#magnetic particle inspection service#magnetic particle inspection#non destructive testing#ndt testing#destructive testing#Positive Material Identification#"non destructive inspection#ndt inspection services#ultrasonic testing ndt#non destructive weld testing#ndt inspection#non destructive testing services

0 notes

Text

A Magnetic Core is a device used for storing and transforming electromagnetic energy. Made primarily of iron or other magnetic materials, it is widely used in power converters, electric motors, inductors, and other electronic devices, serving to enhance energy efficiency and stabilize current.

Specific Information for Magnetic Core

Magnetic cores are an integral part of many inductor designs, as they help enhance the inductance and magnetic field strength. Here is some specific information about magnetic cores:

Types of Magnetic Cores: There are various types of magnetic cores used in inductors, including ferrite cores, powdered iron cores, laminated cores, and toroidal cores. Each type has its own unique properties and is suitable for different applications.

Ferrite Cores: Ferrite cores are made from a ceramic material composed of iron oxide and other metal oxides. They have high magnetic permeability and are commonly used in high-frequency applications due to their low losses and excellent magnetic properties at high frequencies.

Powdered Iron Cores: Powdered iron cores are made by compressing iron powder into a desired shape. They have high magnetic permeability and are often used in power applications due to their ability to handle high currents and high magnetic flux densities.

Laminated Cores: Laminated cores are made by stacking thin layers of magnetic material, such as silicon steel, to reduce eddy current losses. They are commonly used in low-frequency applications where low core losses are important.

Toroidal Cores: Toroidal cores are ring-shaped cores with a hole in the center. They provide a closed magnetic circuit, resulting in low magnetic leakage and high inductance. Toroidal cores are often used in applications where compact size and high efficiency are required.

Core Materials: The choice of core material depends on factors such as frequency range, power handling capacity, and desired performance characteristics. Different core materials have different saturation levels, temperature stability, and frequency response.

Core Losses: Magnetic cores can experience losses due to hysteresis and eddy currents. Hysteresis losses occur when the magnetic field is repeatedly reversed, while eddy current losses occur due to circulating currents induced in the core material. Minimizing core losses is important to improve the efficiency and performance of the inductor.

Core Selection: Selecting the right magnetic core involves considering factors such as the required inductance value, operating frequency, current handling capacity, temperature stability, and size constraints. Manufacturers provide datasheets and application notes to assist in selecting the appropriate core for a specific inductor design.

High-Frequency Magnetic Ring Series

Our High-Frequency Magnetic Rings are designed for superior performance in high-frequency applications. They offer excellent magnetic properties, high saturation magnetic induction, and low core loss. Ideal for use in power supplies, inverters, and other high-frequency electronic equipment.

Ferrite Magnetic Ring Series

Our Ferrite Magnetic Rings are made from high-quality ferrite materials, offering excellent magnetic conductivity and high resistance to demagnetization. They are perfect for use in a wide range of applications, including EMI suppression, inductors, transformers, and more.

0 notes

Text

Unlocking the Secrets of Quasicrystal Magnetism: Revealing a Novel Magnetic Phase Diagram - Technology Org

New Post has been published on https://thedigitalinsider.com/unlocking-the-secrets-of-quasicrystal-magnetism-revealing-a-novel-magnetic-phase-diagram-technology-org/

Unlocking the Secrets of Quasicrystal Magnetism: Revealing a Novel Magnetic Phase Diagram - Technology Org

Quasicrystals are intermetallic materials that have garnered significant attention from researchers aiming to advance understanding of condensed matter physics. Unlike normal crystals, in which atoms are arranged in an ordered repeating pattern, quasicrystals have non-repeating ordered patterns of atoms. Their unique structure leads to many exotic and interesting properties, which are particularly useful for practical applications in spintronics and magnetic refrigeration.

A unique quasicrystal variant, known as the Tsai-type icosahedral quasicrystal (iQC), and its cubic approximant crystals (ACs) display intriguing characteristics. These include long-range ferromagnetic (FM) and anti-ferromagnetic (AFM) orders, as well as unconventional quantum critical phenomena, to name a few. Through precise compositional adjustments, these materials can also exhibit intriguing features like ageing, memory, and rejuvenation, making them suitable for developing next-generation magnetic storage devices. Despite their potential, however, the magnetic phase diagram of these materials remains largely unexplored.

To uncover more, a team of researchers, led by Professor Ryuji Tamura from the Department of Materials Science and Technology at Tokyo University of Science (TUS) in collaboration with researchers from Tohoku University recently conducted magnetization and powder neutron diffraction (PND) experiments on the non-Heisenberg Tsai-type 1/1 gold-gallium-terbium AC.

“For the first time, the phase diagrams of the non-Heisenberg Tsai-type AC have been unravelled. This will boost applied physics research on magnetic refrigeration and spintronics,” remarks Professor Tamura.

Their findings were published in the journal Materials Today Physics.

Through several experiments, the researchers developed the first comprehensive magnetic phase diagram of the non-Heisenberg Tsai-type AC, covering a broad range of electron-per-atom (e/a) ratios (a parameter crucial for understanding the fundamental nature of QCs). Additionally, measurements using the powder neutron diffraction (PND) revealed the presence of a noncoplanar whirling AFM order at an e/a ratio of 1.72 and a noncoplanar whirling FM order at the e/a ratio of 1.80. The team further elucidated the ferromagnetic and anti-ferromagnetic phase selection rule of magnetic interactions by analyzing the relative orientation of magnetic moments between nearest-neighbour and next-nearest neighbour sites.

Image title: Magnetic phase diagram of the systems uncovered in this study

Image caption: A magnetic phase diagram of the Au-Ga-Tb 1/1 ACs showing e/a dependence of TC, TN, or Tf (red markers). The yellow, cyan, and dark blue background colours represent whirling AFM, whirling FM, and spin-glass regimes, respectively. The corresponding magnetic structures of the whirling AFM and FM orders are shown on top.

Image credit: Farid Labib from Tokyo University of Science

Professor Tamura adds that their findings open up new doors for the future of condensed matter physics. “These results offer important insights into the intricate interplay between magnetic interactions in non-Heisenberg Tsai-type ACs. They lay the foundation for understanding the intriguing properties of non-Heisenberg ACs and non-Heisenberg iQCs that are yet to be discovered.”

In summary, the present breakthrough propels condensed matter physics and quasicrystal research into uncharted territories, paving the way for advanced electronic devices and next-generation refrigeration technologies!

Source: Tokyo University of Science

You can offer your link to a page which is relevant to the topic of this post.

#applications#atom#atoms#attention#background#Blue#Collaboration#colours#comprehensive#condensed matter#crystals#Dark#devices#display#electron#electronic#electronic devices#Features#FM#Foundation#Fundamental#Fundamental physics news#Future#Gallium#gold#insights#LED#Link#magnetism#materials

0 notes

Text

Magnetic Drawer

The magnetic drawer is mainly used to remove ferromagnetic impurities from raw materials such as powder, flakes, granules, etc. It is widely used in ceramic, electric power, mining, plastic, chemical, rubber, pharmaceutical, food, environmental protection, pigment, dye, electronics, metallurgy and other industries.

About Magnetic drawer

The magnetic drawers effectively remove ferrous fractions and fines from free-flowing material. They are designed to separate ferrous metals in various powder processing applications in the food industry and the chemical industry.

◆ The internal strong magnetic filter bars are capable of extracting unwanted ferrous metals. The housing can be a frame with one, two or more layers of high strength drawers.

◆ To facilitate cleaning, the operator pulls two handles to the front of the housing to remove the magnetic drawer from the product stream. When the drawer is pulled out, the metal accumulated on the bar can be wiped off and placed in the catch box.

Magnetic Drawer Features and Characteristics

Material

Souwest magnetech offers products with high quality 304 and 316 stainless steel for the external frame and rare earth permanent magnets for the internal magnetic filter bars.

Cleaning

The easy-clean version grate magnets in housing are designed to simplify the cleaning process to encourage frequent and quick removal of collected metal.

Magnetic circuit

The well-designed magnetic circuit distribution of the magnetic filter bar maximizes the magnetic field strength in the gaps between the bars, so that when the material falls vertically from the top through the area of the bars, the iron impurities inside will be magnetized and thus firmly adsorbed on the bars.

Self-cleaning Magnetic Drawer

Self-cleaning magnetic drawer with a scraperboard is the ideal solution for removing ferrous metals from plastic

granules and easily cleaning the ferrous from magnetic bars with a special scraper design, and room working.

temperature. Magnetic strength is as follows:

□8000GS □10000GS □12000GS.

0 notes

Text

Development Status Analysis of China's Ferrite Permanent Magnet Industry

Development Status Analysis of China’s Ferrite Permanent Magnet Industry

1. Output

In terms of output, according to statistics, from 2017 to 2021, the output of permanent magnet ferrite in my country will remain above 500,000 tons, and the overall trend will be to rise first and then fall. Among them, the output in 2018 reached the peak of this period, with an output of 545,400 tons. tons, and…

View On WordPress

#ceramic ferrite magnets#Ferrite#Ferrite magnet#ferrite magnetic materials#Ferrite Magnets#ferrite permanent magnets#ferrite permanent magnet#ferromagnetic#Lamination steels#magnet composition#Magnet Maker#Magnetic alloy#magnetic field#magnetic fields#magnetic force#magnetic material#Magnetic Metals#magnetic properties#magnetic structures#Magnetic powder#Magnetism#paramagnetic materials#Permanent Magnet#Rare Earth Magnets#Sintered NdFeB Magnets#sintered soft magnetic materials

0 notes

Text

Quality Magnetic Products & Solutions

Magnets and magnets assemblies have to meet increasingly complex requirements.

Advantage of Bonded Magnetic Compounds

As a new type of magnetic material, bonded magnetic compounds have been widely used in the field of motors, sensors, electromagnetic shielding, etc, and providing a more cost-effective and reliable composite material for home appliances, automobiles, and office supplies industries. Our products are also being used in some new areas, such as cosmetics, toys and so on. By combining the good processing and mechanical properties of the plastic with the magnetic properties of the magnetic powder, the bonded magnets have gained incomparable advantages over traditional sintered magnetic materials. In addition to bonded magnetic compounds, economical and environment-friendly functional composite material, such as high-density compounds and metal bonded plastic, hard ferromagnetic materials may also provide new ideas for your design.

l Adjustable magnetic properties to meet your customized application requirements.

l Flexible shape design and magnetization orientation bring high cost-effective products.

l High precision and uniform magnetic field distribution bring high stability.

Hard Magnetic Bonded Compounds

Hard Magnetic Bonded Compounds are manufactured by embedding hard magnetic powder into the thermoplastic resin, and then can be directly injected into the required product by injection molding as same as ordinary plastic particles. One of the advantages of hard magnetic bonded compounds lies in the ability to produce magnetic compound with the complex shape or thin-wall structure, it also can be used to produce magnetic compound with inserts such as axles, stainless steel bushings, rings and so on, which is suitable for mass production and can reduce the assembly cost. Meanwhile, it is possible to magnetize magnets in a variety of patterns (axial, radial, multipole, etc) by applying a magnetic field in the injection mold.

Hard-Ferrite Bonded Magnetic Compounds

Bonded Neodymium Magnetic Compounds

Hybrid Bonded Magnetic Compounds

Bonded SmFeN Magnetic Compounds

Soft Magnetic Bonded Compounds

Soft magnetic bonded magnets produced by injection molding are also increasingly widely used in the fields of communication and electronic components, such as wireless charging, electromagnetic shielding, transformer skeleton, etc. The advantages of relatively high permeability, low loss, easy molding, and high-cost effectiveness make it play an increasingly important role in those fields. The electromagnetic compatibility and shielding characteristics of the components can be improved effectively through the different structural design. Moreover, soft magnetic bonded magnets also play an important role in the miniaturization and lightweight of devices.

Other Functional Composite Materials

High density and metal bonded plastic products with complex and delicate structures can also be prepared by the injection molding process. Density can be adjusted as required from 2-13 g/cm3, which can replace some traditional aluminum alloy, zinc alloy, stainless steel, and other materials with metallic texture. Its environmental advantage and shielding function of high-energy ray (X-ray, etc) make it suitable to replace the traditional lead metal alloy. It has high dimensional precision and excellent mechanical properties, which is suitable for processes such as turning, milling, drilling, and so on.

High-Density Compounds

Metal Bonded Plastic

Magnet Solutions

More than 20 years of research on the plastic and magnetic industry has made us a comprehensive technology company involving the development and production of

kinds of magnetic materials, injection mold development, magnetic field questions and solutions, and so on. We have in-depth cooperation with many famous companies in the fields of automobiles, home appliances, and power tools, etc. Extensive project development experience has created a group of professional technical talents who can quickly transform customers' ideas into products.

Make Maglastics Magenet Your Projects

Automotive

Industrial Supplies

Home Appliances

Office Supplies

Daily Use

Why Choose Maglastics

Maglastic is a leading manufacturer and provider of bonded magnetic compounds, we serve a variety of markets and our magnetic compounds are used in high-efficiency motors, generators, sensors and more. We have expanded overseas business and established strong relationships with our customers.

Research & Development

Professional R&D conditions for basic research and pilot-scale manufacturing of products.

Raw Material Technology

Powder refining, optimizing the particle size distribution and surface treatment technology.

Automatic Production

Owner-managed factory with scientific quality management system and automatic production equipment.

Tool Making

We can provide customized mold design scheme to accelerate the project.

https://www.maglastic.com/products/

1 note

·

View note

Text

Magnetic Materials

All types of materials and substances posses some kind of magnetic properties which are listed further down in this article. But normally the word “magnetic materials” is used only for ferromagnetic materials ( description below), however, materials can be classified into following categories based on the Paramagnetic materials

The materials which are not strongly attracted to a magnet are known as paramagnetic material. For example: aluminium, tin magnesium etc. Their relative permeability is small but positive. For example: the permeability of aluminium is: 1.00000065. Such materials are magnetized only when placed on a super strong magnetic field and act in the direction of the magnetic field.

Paramagnetic materials have individual atomic dipoles oriented in a random fashion as shown below:

Magnetic Domains in Paramagnetic Materials

The resultant magnetic force is therefore zero. When a strong external magnetic field is applied , the permanent magnetic dipoles orient them self parallel to the applied magnetic field and give rise to a positive magnetization. Since, the orientation of the dipoles parallel to the applied magnetic field is not complete , the magnetization is very small.

Magnetic field through a paramagnetic material

2. Diamagnetic materials

The materials which are repelled by a magnet such as zinc. mercury, lead, sulfur, copper, silver, bismuth, wood etc., are known as diamagnetic materials. Their permeability is slightly less than one. For example the relative permeability of bismuth is 0.00083, copper is 0.000005 and wood is 0.9999995. They are slightly magnetized when placed in a very string magnetic field and act in the direction opposite to that of applied magnetic field.

In diamagnetic materials , the two relatively weak magnetic fields caused due to the orbital revolution and and axial rotation of electrons around nucleus are in opposite directions and cancel each other. Permanent magnetic dipoles are absent in them, Diamegnetic materials have very little to no applications in electrical engineering.

Magnetic field through a diamagnetic material

3. Ferromagnetic materials

The materials which are strongly attracted by a magnetic field or magnet is known as ferromagnetic material for eg: iron, steel , nickel, cobalt etc. The permeability off these materials is very very high ( ranging up to several hundred or thousand).

The opposite magnetic effects of electron orbital motion and electron spin do not eliminate each other in an atom of such a material. There is a relatively large contribution from each atom which aids in the establishment of an internal magnetic field, so that when the material is placed in a magnetic field, it’s value is increased many times thee value that was present in the free space before the material was placed there.

For the purpose of electrical engineering it will suffice to classify the materials as simply ferromagnetic and and non-ferromagnetic materials. The latter includes material of relative permeability practically equal to unity while the former have relative permeability many times greater than unity. Paramagnetic and diamagnetic material falls in the non-ferromagnetic materials.

Soft Ferromagnetic materials

They have high relative permeability, low coercive force, easily magnetized and demagnetized and have extremely small hysteresis. Soft ferromagnetic materials are iron and it’s various alloys with materials like nickel, cobalt, tungsten and aluminium . ease of magnetization and demagnetization makes them highly suitable for applications involving changing magnetic flux as in electromagnets, electric motors, generators, transformers, inductors, telephone receivers, relays etc. They are also useful for magnetic screening. Their properties may be greatly enhanced through careful manufacturing and and by heating and slow annealing so as to achieve a high degree of crystal purity. Large magnetic moment at room temperate makes soft ferromagnetic materials extremely useful for magnetic circuits but ferromagnetics are very good conductors and suffer energy loss from eddy current produced within them. There is additional energy loss due to the fact that magnetization does not proceed smoothly but in minute jumps. This loss is called magnetic residual loss and it depends purely on the frequency of the changing flux density and not on it’s magnitude.

b. Hard Ferromagnetic materials

They have relatively low permeability, and very high coercive force. These are difficult o magnetize and demagnetize. Typical hard ferromagnetic materials include cobalt steel and various ferromagnetic alloys of cobalt, aluminium and nickel. They retain high percentage of their magnetization and have relatively high hysteresis loss. They are highly suited for use as permanent magnet as speakers, measuring instruments etc.

4. Ferrites

Ferrites are a special group of ferromagnetic materials that occupy an intermediate position between ferromagnetic and non-ferromagnetic materials. They consist of extremely fine particles of a ferromagnetic material possessing high permeability , and are held together with a binding resin. The magnetization produced in ferrites is large enough to be of commercial value but their magnetic saturation are not as high as those of ferromagnetic materials. As in the case of ferromagnetics, ferrites may be soft or hard ferrites.

a. Soft Ferrites

Ceramic magnets also called ferromagnetic ceramics, are made of an iron oxide, Fe2O3, with one or more divalent oxide such as NiO , MnO or ZnO. These magnets have a square hysteresis loop and high resistance and demagnetization are valued for magnets for computing machines where a high resistance is desired. The great advantage of ferrites is their high resistivity. Commercial magnets have resistivity as high as 10^9 ohm-cm. Eddy currents resulting from an alternating fields are therefore, reduced to minimum, and the range of application of these magnetic materials is extended to high frequencies , even to microwaves . Ferrites are carefully made by mixing powdered oxides, compacting and sintering at high temperature. High-frequency transformers in televisions and frequency modulated receivers are almost always made with ferrite cores.

b. Hard Ferrites

These are ceramic permanent magnetic materials. The most important family of hard ferrites has the basic composition of MO.Fe2O3 where M is barium(Ba) ion or strontium (Sr) ion. These materials have a hexagonal structure and low in cost and density. Hard ferrites are used in generators, relays and motors. Electronic applications include magnets for loud speakers, telephone ringers and receivers. They are also used in holding devices for door closer, seals, latches and in several toy designs.

1 note

·

View note

Text

New Metal Alloy

As a leading manufacturer, Cheeven has rich experience in producing new metal alloys which are suitable for electronics, aviation, transportation, semiconductor integrated circuits, optical discs, flat panel displays, etc.

NEW METAL ALLOY TYPES

High Damping Copper Alloy

Damping material has high internal damping and a large elastic modulus. Attached to the vibrating body, different types of copper alloys can effectively suppress the vibration and reduce the noise radiation. As a leading company, Cheeven makes them by adding the right amount of plasticizer, fillers, and additives to well-performing adhesives.

High-strength and High-elasticity Copper-nickel-manganese Alloy

High strength and high elasticity copper alloy is a copper alloy with high strength and high elasticity, as one of copper nickel alloy suppliers, Cheeven provides many kinds of alloy made of copper manganese nickel.

High-strength and High-conductivity Copper-silver Alloy

High-conductivity and high-strength copper alloys have high strength and plasticity, good thermal conductivity, corrosion resistance, and no ferromagnetism.

Copper Nickel Indium Powder

Copper-nickel-indium powder is a superalloy powder with excellent powder properties, low oxygen content, high sphericity and good flow properties.

High Purity Titanium Target

The company can produce more than 99.99% high-purity titanium targets. It is used in semiconductor integrated circuits, optical discs, flat panel displays and other fields.

Products

FSW Products

Carbon Nanotubes Products

Electric Heating Radiator

Die Casting Products

New Metal Alloy

High Damping Copper Alloy

High-strength and High-elasticity Copper-nickel-manganese Alloy

High-strength and High-conductivity Copper-silver Alloy

Copper Nickel Indium Powder

High Purity Titanium Target

New Metal Alloy Introduction

NEW METAL ALLOY INTRODUCTION

There are many kinds of new metal alloys, such as copper alloy, copper nickel manganese alloy, and copper-silver alloy.

This kind of new metal alloy is a high-strength and high-conductivity Cu alloy material developed by the company. The material has high tensile strength, excellent electrical conductivity, and good stress relaxation resistance. New metal alloy will not produce sparks when it is impacted. You can easily find new metal alloys be widely used in mobile communication, aerospace, automotive industry and other fields: lead frame materials in various circuit boards, integrated circuits and other electronic systems; high-strength conductor materials; elastic components in electrical appliances, shrapnel, pins, elastic contacts, etc. At present, the company's main products are rods, rods, plates, strips and so on.

0 notes

Text

SEAMLESS STEEL PIPES COMMONLY NDT METHODS

1. seamless steel tube magnetic particle testing (MT) or magnetic flux leakage testing (EMI)

The detection principle is based on the ferromagnetic material is magnetized in a magnetic field, the discontinuity of the materials or products (defect), magnetic flux leakage, magnet powder adsorption (or detected by detector) was revealed (or displayed on the instrument). This method can only be used for ferromagnetic materials or surface or near-surface defects testing of products.

2. seamless steel tube penetration test (PT)

Includes fluorescent, colored in two ways. Because of its simple, convenient operation, is for lack of magnetic particle inspection test effective methods for surface defects. It is mainly used for inspection of surface defects of non-magnetic material.

Principles of fluoroscopy are checked products will be immersed in a fluorescent liquid, due to capillary phenomenon of seamless steel tubes, filled with fluorescent liquid in the defect, get rid of the liquid on the surface, due to light-induced effects, liquid fluorescent under ultraviolet light revealed defects.

Dye penetrant inspection of the theory and principles of fluoroscopy is similar. Is no need for special equipment, just use defects Imaging powder adsorption in liquid coloring in manifest suction surface defects.

3. seamless steel pipe ultrasonic testing (UT)

This method is the use of ultrasonic vibration to find materials or parts inside (or surface) defects. Depending on the ultrasonic vibration method can be divided into CW and pulsed wave; according to the different modes of vibration and propagation can be divided into p-wave and s-wave and surface waves and lamb waves 4 form in the workpiece spread; according to the different sound transmission and reception conditions, and can be divided into single probe and probe.

4. seamless steel tube for Eddy current testing (ET)

Eddy current detection of alternating magnetic field produces the same frequency of the Eddy current in the metal, using the Eddy-current the size relationship between the resistivity of metallic materials and to detect defects. When surface defects (cracks), the resistivity will increase the presence of defects, associated with Eddy-current is reduced accordingly, small change after enlargement of the Eddy current instruments indicated, will be able to show the existence and size of defects.

5. seamless steel tube radiographic testing (RT)

One of the earliest methods of non-destructive testing, is widely used in metal and non-metal materials and products for internal defects testing, at least more than 50-year history. It has incomparable advantages, namely test defects, reliability and intuitiveness, radiographic and will be used for defect analysis and as a quality document archive. But this way there are more complex, higher-cost disadvantage, and should pay attention to radiation protection

Cangzhou shenlong pipe pipe manufacture is a premier worldwide source for carbon steel pipes, stainless steel tube, seamless pipes, welded pipe, galvanized tubes, casing pipes and steel fittings.

0 notes

Text

Magnetic Core Market Investment Opportunities,Industry Share & Trend Analysis Report to 2026

Magnetic Core Market: Overview

Magnetic core is a magnetic material with good magnetic quality that is used to enclose and guide magnetic fields in electromechanical, electrical, or magnetic devices such as electric motors, electromagnets, transformers, inductors, generators, and magnetic recording heads. Magnetic cores are made of ferromagnetic metals such as iron or ferrimagnetic composites such as ferrites. The magnetic field is generated by a current conducting coil of wire surrounding the core. Magnetic core can increase the strength of a magnetic field in an electromagnetic coil.

Read report Overview-

https://www.transparencymarketresearch.com/magnetic-core-market.html

Magnetic cores are created form three basic materials: bulk metals, powdered materials, and ferrite materials. Bulk metals are processed into ingots from furnaces. They are is then put into the process of cold and hot rolling. As the powder core processing starts, ingots go through multiple steps of grinding unless the powder is of proper consistency for the required performance. Usually, machining of powder cores is not carried out after processing. Ferrite materials consist of ceramic materials of iron oxide, carbonate of manganese or alloyed with oxides, nickel, cobalt, magnesium, or zinc. Magnetic core material can be either solid metal, soft iron, laminated silicon steel, special alloy, vitreous metal, or powdered metal iron.

Get Brochure of the Report @

Magnetic Core Market: Key Segments

Magnetic cores can be segmented based on structure and end-use. In terms of structure the magnetic core can be segmented into straight cylinder rod, single “I” core, “C” or “U” core, “E” core, “E”& “I “core, planer core, pot core and toroidal core. Straight cylindrical rod is mostly made of powered iron and ferrite. It is used in radios for tuning the inductor. Single “I” core is square shaped and is rarely used. It is likely to be found in car ignition coils. “U” and “C” shaped cores are used to make square closed cores. Windings can be installed on single or both legs of the core. “E” shaped cores are used where a closed magnetic system is required. In most of “E” shaped cores, the cross-sectional area of center leg is more compared to individual section of outer legs. Therefore, the electrical circuit is placed around the center leg. In case of 3-phase transformer, all the three legs of “E” shaped core are of the same size and all legs are wound.

Enquiry before buying :

The “E” and “I” shaped core are stacked together to form a closed system. The “I” is stacked with the open end “E” to form three legged structure. The “E” and “I” cores are widely used in autotransformers, power transformer and inductors. The pot core is internally hollow and completely encloses the coil. It is round in shape. This design helps reduce electromagnetic interference and prevents radiations. The toroid core has a shape of a doughnut. The coil is wound around the circumference of the core. It is widely used in high frequency audio amplifiers. Based on end-use, the magnetic core market can be divided into automotive components, electrical components, and energy transfer equipment.

Magnetic Core Market: Regional Outlook

In terms of region, the global magnetic core market can be segregated into North America, Europe, Asia Pacific, Latin America, and Middle East & Africa. Asia Pacific is projected to lead the global magnetic core market during the forecast period, followed by North America and Europe. China and India account for key share of the magnetic core market in Asia Pacific, as the electrical vehicle industry is expected to expand significantly in the near future. Latin America and Middle East & Africa are likely to constitute moderate share of the magnetic core market during the forecast period.

More Trending Report by Transparency Market Research –

https://www.prnewswire.com/news-releases/glycerol-market-to-advance-at-cagr-of-6-3-during-20212031–asserts-tmr-study-301500966.html

Magnetic Core Market: Key Players

Key players operating in the magnetic core market include Hitachi Metals, Ltd., TDK Corporation, MAGNETICS, Advanced Technology & Materials Co., Ltd, MH&W International Corp., DMEGC, POCO Holding Co. Ltd, Zhaojing Incorporated Company, and TOSHIBA ELECTRONIC DEVICES & STORAGE CORPORATION.

About Us:

Transparency Market Research is a global market intelligence company, providing global business information reports and services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insight for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants, use proprietary data sources and various tools and techniques to gather, and analyse information. Now avail flexible Research Subscriptions, and access Research multi-format through downloadable databooks, infographics, charts, interactive playbook for data visualization and full reports through MarketNgage, the unified market intelligence engine. Sign Up for a 7 day free trial!

Contact

Rohit Bhisey

Transparency Market Research,

90 State Street, Suite 700,

Albany, NY 12207

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Email: [email protected]

Website: https://www.transparencymarketresearch.com

0 notes