#industries india

Video

undefined

tumblr

He didn’t invent anything

#tiktok#bill gates#technology history#technology#tech bros#tech billionaires#philanthropy#billionaire#taxes#it industry#india#wages and salaries#wages#outsourcing

14K notes

·

View notes

Text

Endangered Indian sandalwood. British war to control the forests. Tallying every single tree in the kingdom. European companies claim the ecosystem. Spices and fragrances. Failure of the plantation. Until the twentieth century, the Empire couldn't figure out how to cultivate sandalwood because they didn't understand that the plant is actually a partial root parasite. French perfumes and the creation of "the Sandalwood City".

---

Selling at about $147,000 per metric ton, the aromatic heartwood of Indian sandalwood (S. album) is arguably [among] the most expensive wood in the world. Globally, 90 per cent of the world’s S. album comes from India [...]. And within India, around 70 per cent of S. album comes from the state of Karnataka [...] [and] the erstwhile Kingdom of Mysore. [...] [T]he species came to the brink of extinction. [...] [O]verexploitation led to the sandal tree's critical endangerment in 1974. [...]

---

Francis Buchanan’s 1807 A Journey from Madras through the Countries of Mysore, Canara and Malabar is one of the few European sources to offer insight into pre-colonial forest utilisation in the region. [...] Buchanan records [...] [the] tradition of only harvesting sandalwood once every dozen years may have been an effective local pre-colonial conservation measure. [...] Starting in 1786, Tipu Sultan [ruler of Mysore] stopped trading pepper, sandalwood and cardamom with the British. As a result, trade prospects for the company [East India Company] were looking so bleak that by November 1788, Lord Cornwallis suggested abandoning Tellicherry on the Malabar Coast and reducing Bombay’s status from a presidency to a factory. [...] One way to understand these wars is [...] [that] [t]hey were about economic conquest as much as any other kind of expansion, and sandalwood was one of Mysore’s most prized commodities. In 1799, at the Battle of Srirangapatna, Tipu Sultan was defeated. The kingdom of Mysore became a princely state within British India [...]. [T]he East India Company also immediately started paying the [new rulers] for the right to trade sandalwood.

British control over South Asia’s natural resources was reaching its peak and a sophisticated new imperial forest administration was being developed that sought to solidify state control of the sandalwood trade. In 1864, the extraction and disposal of sandalwood came under the jurisdiction of the Forest Department. [...] Colonial anxiety to maximise profits from sandalwood meant that a government agency was established specifically to oversee the sandalwood trade [...] and so began the government sandalwood depot or koti system. [...]

From the 1860s the [British] government briefly experimented with a survey tallying every sandal tree standing in Mysore [...].

Instead, an intricate system of classification was developed in an effort to maximise profits. By 1898, an 18-tiered sandalwood classification system was instituted, up from a 10-tier system a decade earlier; it seems this led to much confusion and was eventually reduced back to 12 tiers [...].

---

Meanwhile, private European companies also made significant inroads into Mysore territory at this time. By convincing the government to classify forests as ‘wastelands’, and arguing that Europeans would improves these tracts from their ‘semi-savage state’, starting in the 1860s vast areas were taken from local inhabitants and converted into private plantations for the ‘production of cardamom, pepper, coffee and sandalwood’.

---

Yet attempts to cultivate sandalwood on both forest department and privately owned plantations proved to be a dismal failure. There were [...] major problems facing sandalwood supply in the period before the twentieth century besides overexploitation and European monopoly. [...] Before the first quarter of the twentieth century European foresters simply could not figure out how to grow sandalwood trees effectively.

The main reason for this is that sandal is what is now known as a semi-parasite or root parasite; besides a main taproot that absorbs nutrients from the earth, the sandal tree grows parasitical roots (or haustoria) that derive sustenance from neighbouring brush and trees. [...] Dietrich Brandis, the man often regaled as the father of Indian forestry, reported being unaware of the [sole significant English-language scientific paper on sandalwood root parasitism] when he worked at Kew Gardens in London on South Asian ‘forest flora’ in 1872–73. Thus it was not until 1902 that the issue started to receive attention in the scientific community, when C.A. Barber, a government botanist in Madras [...] himself pointed out, 'no one seems to be at all sure whether the sandalwood is or is not a true parasite'.

Well into the early decades of twentieth century, silviculture of sandal proved a complete failure. The problem was the typical monoculture approach of tree farming in which all other species were removed and so the tree could not survive. [...]

The long wait time until maturity of the tree must also be considered. Only sandal heartwood and roots develop fragrance, and trees only begin developing fragrance in significant quantities after about thirty years. Not only did traders, who were typically just sailing through, not have the botanical know-how to replant the tree, but they almost certainly would not be there to see a return on their investments if they did. [...]

---

The main problem facing the sustainable harvest and continued survival of sandalwood in India [...] came from the advent of the sandalwood oil industry at the beginning of the twentieth century. During World War I, vast amounts of sandal were stockpiled in Mysore because perfumeries in France had stopped production and it had become illegal to export to German perfumeries. In 1915, a Government Sandalwood Oil Factory was built in Mysore. In 1917, it began distilling. [...] [S]andalwood production now ramped up immensely. It was at this time that Mysore came to be known as ‘the Sandalwood City’.

---

Text above by: Ezra Rashkow. "Perfumed the axe that laid it low: The endangerment of sandalwood in southern India." Indian Economic and Social History Review 51, no. 1, pages 41-70. March 2014. [Bold emphasis and some paragraph breaks/contractions added by me. Italicized first paragraph/heading in this post added by me. Presented here for commentary, teaching, criticism purposes.]

#a lot more in full article specifically about#postindependence indian nationstates industrial extraction continues trend established by british imperial forestry management#and ALSO good stuff looking at infamous local extinctions of other endemic species of sandalwood in south pacific#that compares and contrasts why sandalwood survived in india while going extinct in south pacific almost immediately after european conques#abolition#ecology#imperial#colonial#landscape#indigenous#multispecies#tiger#tidalectics#archipelagic thinking#intimacies of four continents#carceral geography#geographic imaginaries#haunted

220 notes

·

View notes

Text

A Fast-Paced New Commercial by Early Man Film Celebrates the Cultural Rhythms of India

89 notes

·

View notes

Text

Imagine Studio at the Trees, Mumbai - Studio Lotus

#Studio Lotus#architecture#design#building#modern architecture#interiors#contemporary architecture#adaptive reuse#renovation#industrial#factory#studio#offices#artists#steel#copper#mumbai#indian architecture#india#cool architecture

70 notes

·

View notes

Text

The standard legend of India’s Green Revolution centers on two propositions. First, India faced a food crisis, with farms mired in tradition and unable to feed an exploding population; and second, Borlaug’s wheat seeds led to record harvests from 1968 on, replacing import dependence with food self-sufficiency.

Recent research shows that both claims are false.

India was importing wheat in the 1960s because of policy decisions, not overpopulation. After the nation achieved independence in 1947, Prime Minister Jawaharlal Nehru prioritized developing heavy industry. U.S. advisers encouraged this strategy and offered to provide India with surplus grain, which India accepted as cheap food for urban workers.

Meanwhile, the government urged Indian farmers to grow nonfood export crops to earn foreign currency. They switched millions of acres from rice to jute production, and by the mid-1960s India was exporting agricultural products.

Borlaug’s miracle seeds were not inherently more productive than many Indian wheat varieties. Rather, they just responded more effectively to high doses of chemical fertilizer. But while India had abundant manure from its cows, it produced almost no chemical fertilizer. It had to start spending heavily to import and subsidize fertilizer.

India did see a wheat boom after 1967, but there is evidence that this expensive new input-intensive approach was not the main cause. Rather, the Indian government established a new policy of paying higher prices for wheat. Unsurprisingly, Indian farmers planted more wheat and less of other crops.

Once India’s 1965-67 drought ended and the Green Revolution began, wheat production sped up, while production trends in other crops like rice, maize and pulses slowed down. Net food grain production, which was much more crucial than wheat production alone, actually resumed at the same growth rate as before.

But grain production became more erratic, forcing India to resume importing food by the mid-1970s. India also became dramatically more dependent on chemical fertilizer.

According to data from Indian economic and agricultural organizations, on the eve of the Green Revolution in 1965, Indian farmers needed 17 pounds (8 kilograms) of fertilizer to grow an average ton of food. By 1980, it took 96 pounds (44 kilograms). So, India replaced imports of wheat, which were virtually free food aid, with imports of fossil fuel-based fertilizer, paid for with precious international currency.

Today, India remains the world’s second-highest fertilizer importer, spending US$17.3 billion in 2022. Perversely, Green Revolution boosters call this extreme and expensive dependence “self-sufficiency.”

106 notes

·

View notes

Text

I fucking hate this post. 'no matter the genre or setting it's probably from hollywood' the rest of the world (and non-mainstream american creators) make tv and film and write stories too and you'd probably know that if you bothered to pull your head put of your ass and look outside your little mainstream bubble you fucking idiot.

#honestly yeah a lot of my film and tv is american too but this post pisses me off so bad bc it's just assuming that american#tv and movies are univsersa#'no matter the genre' show me an american wuxia film then.#actually im looking at my letterboxd and that might not even be true#even in the english language sphere the british film industry is huge ntm japan korea france mexico china india....#egypt! palestine! russia! kenya! broaden your fucking horizons! I'm in despair#oh australia. even independent us filmmakers! and films from indigenous creators!#cor.txt

11 notes

·

View notes

Text

Industrial Arts Impact Wrench Hazy Triple IPA (Picked up at Circle Liquor in Somers Point, NJ). A 4 of 4. As you'd expect, this is just bursting with tropical fruit and orange citrus and varied other hop notes in the nose. The body is incredibly well balanced despite it being 10% -- there's a lot of juicy sweetness but also some grain notes behind it, and a firm bitterness alongside the booze towards the finish.

#industrial arts#impact wrench#hazy triple ipa#hazy ipa#triple ipa#ipa#india pale ale#beer#circle liquors#Somers point#nj#pa#4

10 notes

·

View notes

Text

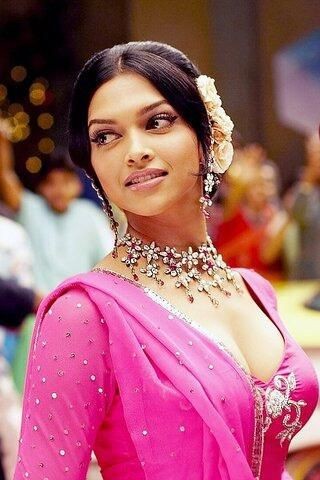

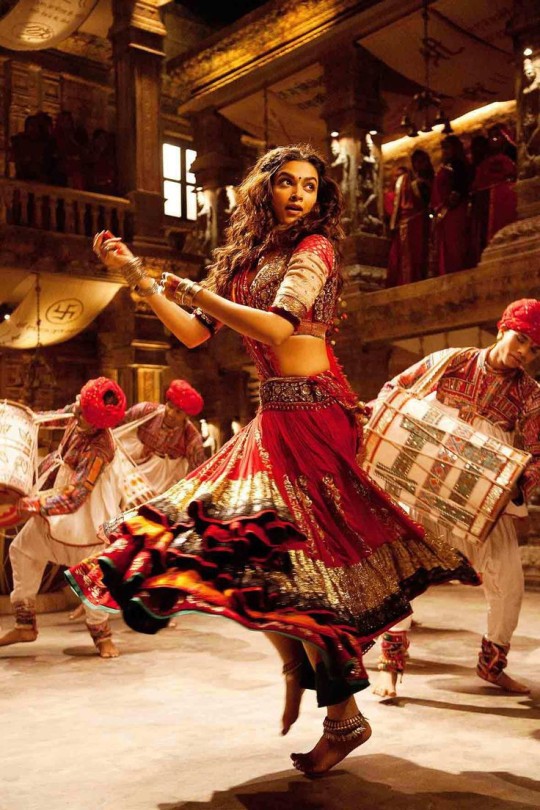

Indian Cinema💗

#happy birthday#birthday#desi teen#desi things#growing up desi#desi aesthetic#desi memes#desi dark academia#desi humor#desi shit posting#india#indian aesthetic#bollywood#movie quotes#indian celebrities#indian cinema#music industry#deepikapadukone#ranbir kapoor#srk#acting#aesthetic vibes#aestheitcs#aesthetic

229 notes

·

View notes

Text

charging the basic oxygen furnace, Tata Steel

92 notes

·

View notes

Text

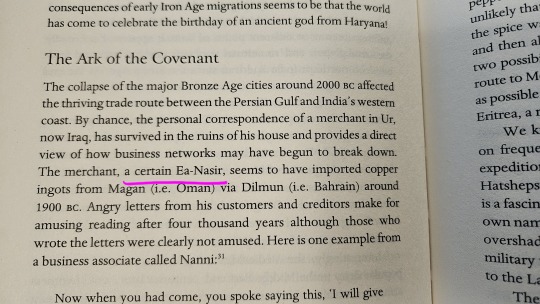

A wild Ea-Nasir appeared!

#the book is#The Ocean of Churn#by Sanjeev Sanyal#very readable history of the Indian Ocean trade#this section is kind of hilarious because Ea-Nasir doesn't really have anything to do with anything?#it's just background 'yeah there used to be a massive copper industry in Oman'#and the section is more about how we know that egypt traded with india and oman#because of peppercorns and frankincense#and they probably came through ethiopia/eritrea#it really seemed to me like it was just irresistible to throw one of the best preserved and funniest merchants of the area in there#ea-nasir#tumblr's favorite copper merchant

18 notes

·

View notes

Text

#reminded me of a lecture in college on 19th century victorian literature. mill on the floss i think. the professor spoke of how#agrarian society was in tune with temporal cycle of nature. seasons religious days tides etc. with the first industrial revolution saw a#dramatic shift in the human experience of time with clocks and timekeeping mostly for the time labourers spent toiling in factories#mentioned how time was now 'spent' rather than 'passed'; leisure was taken completely out of daily life. things became task-oriented which#kept on increasing. the factories would tamper with the clock to keep increasing the time labourers worked on the floor.#you can't tamper with the sun and moon now can you?#anyway this also brings to mind the demand for separate timezones in india#also brings to mind the concept of timesheets and how freelancers charge by the hour.#also brings to mind max weber's protestant ethic and the spirit of capitalism for some reason#i side with the luddites

23 notes

·

View notes

Text

In India, where many rural women still plaster the walls and build stoves using a composite of mud and cow dung, they sometimes add hairs to bind and strengthen the mixture. What is remarkable is just how many of these apparently ‘folk uses’ of hair are today being taken up by designers and engineers interested in developing sustainable technologies. Recent experiments by geoscientists and engineers in Australia and India suggest that human hair, owing to its high tensile strength, is highly effective for reinforcing asphalt in roads and for blocking the development of microscopic cracks in concrete when mixed in the right proportions.

4 notes

·

View notes

Text

Fiery Flavour: The Art and Science of Crafting Jalapeno Sauce in India

Jalapeno sauce is a culinary delight that adds a fiery kick to dishes, tantalizing taste buds with its bold flavor profile. In recent years, this spicy condiment has gained popularity not only in India but also across the globe, including in the United Arab Emirates (UAE). As a leading manufacturer in India, Modern Food Products is dedicated to mastering the art and science of crafting premium Jalapeno sauce that satisfies the cravings of spice enthusiasts everywhere. In this blog post, we shall delve into the intricate process of producing Jalapeno sauce, explore its growing demand in the UAE market, and highlight the private labelling services offered by Modern Food Products to cater to diverse customer needs.

The Essence of Jalapeno Sauce

Jalapeno sauce is more than just a condiment; it is a culinary experience that combines heat, flavor, and versatility. At Modern Food Products, we understand the importance of capturing the essence of fresh Jalapeno peppers to create a sauce that excites the palate. Our Jalapeno sauce is crafted using premium-quality Jalapeno peppers sourced from trusted growers, ensuring optimal flavor and heat levels that elevate any dish.

The Art of Crafting Jalapeno Sauce

Crafting the perfect Jalapeno sauce requires a delicate balance of ingredients and meticulous attention to detail. Here is a glimpse into the artistry behind our Jalapeno sauce production process:

1. Ingredient Selection: We start by hand-selecting the finest Jalapeno peppers, ensuring they are ripe, firm, and bursting with flavor. Alongside Jalapenos, we carefully choose complementary ingredients such as vinegar, garlic, onions, and spices to enhance the sauce's depth and complexity.

2. Roasting and Blending: To unlock the full flavor potential of Jalapeno peppers, we roast them to perfection, imparting a smoky undertone to the sauce. The roasted Jalapenos are then blended with other ingredients to achieve a smooth and consistent texture, ensuring every bite delivers a burst of fiery flavor.

3. Cooking and Seasoning: The blended ingredients are cooked down to intensify the flavors and achieve the desired consistency. Throughout the cooking process, we meticulously season the sauce with the perfect balance of salt, sugar, and spices, ensuring a harmonious flavor profile that leaves a lasting impression.

4. Packaging: Once the Jalapeno sauce reaches its optimal flavor and texture, it is carefully packaged in jars or bottles designed to preserve freshness and extend shelf life. Our packaging solutions are not only functional but also visually appealing, reflecting the premium quality of our Jalapeno sauce.

Jalapeno Sauce: A Spicy Sensation in the UAE Market

The UAE market has a growing appetite for bold and flavorful condiments, making Jalapeno sauce a popular choice among consumers. As a leading Jalapeno sauce manufacturer in India, Modern Food Products is proud to serve the UAE market with our premium-quality products. Whether used as a dipping sauce, marinade, or flavor enhancer, our Jalapeno sauce adds an irresistible zing to a wide range of dishes, from sandwiches and tacos to grilled meats and seafood.

Private Labelling Services for Custom Solutions

At Modern Food Products, we understand that every customer has unique preferences and requirements. That is why we offer comprehensive private labelling services to cater to diverse needs and preferences. Whether you are a retailer, distributor, or foodservice provider in the UAE looking to offer Jalapeno sauce under your own brand, we can collaborate with you to create custom solutions that align with your brand identity and specifications.

Our private labelling services encompass:

Custom Formulation: We work closely with clients to develop custom formulations tailored to their desired flavor profile, heat level, and packaging preferences. Whether you prefer a mild, medium, or hot Jalapeno sauce, we can adjust the recipe to meet your specifications.

Branding and Packaging: Our team of graphic designers can assist you in designing eye-catching labels and packaging that showcase your brand identity and appeal to your target audience. From label design to bottle customization, we ensure that your private label Jalapeno sauce stands out on the shelves.

Quality Assurance: As a trusted Jalapeno sauce manufacturer, we adhere to strict quality control measures throughout the production process to ensure consistency, safety, and compliance with regulatory standards. With our private labelling services, you can rest assured that your branded Jalapeno sauce meets the highest quality standards.

Conclusion

In conclusion, Jalapeno sauce is a spicy sensation that has captured the hearts and taste buds of consumers in India and the UAE alike. At Modern Food Products, we take pride in our expertise in crafting premium Jalapeno sauce that delivers unparalleled flavor and quality. Whether you are a consumer seeking an authentic Jalapeno sauce experience or a business looking to launch your own private label Jalapeno sauce, we have the resources and capabilities to meet your needs. Contact us today to explore our range of Jalapeno sauce products and private labelling services, and elevate your culinary creations with a touch of fiery flavor.

#Jalapeno sauce suppliers in UAE#Jalapeno sauce manufacturing industries in UAE#Jalapeno sauce manufacturer in UAE#Private labelling services in India#extracts#flavor#hot sauce#ketchup#canned foods#bottled items#Kitchen#condiments#restaurants#Hotels#fast food#sauces#UAE#India

7 notes

·

View notes

Text

Preserving Assets: The Role of Corrosion Inhibitors in Industrial Maintenance

Corrosion is a persistent threat to industrial assets, causing billions of dollars in damages annually across various sectors. From oil and gas facilities to manufacturing plants, the impact of corrosion can be devastating, leading to equipment failures, production downtime, and costly repairs. However, with the right preventive measures in place, such as corrosion inhibitors, industrial facilities can effectively mitigate the risk of corrosion and prolong the lifespan of their assets. As a leading chemical company in Vadodara, Imperial Oilfield Chemicals Pvt. Ltd. (ICPL) understands the critical role of corrosion inhibitors in industrial maintenance. In this blog post, we'll explore the importance of corrosion inhibitors, their applications, and the expertise of ICPL as a corrosion inhibitor manufacturer and exporter in India.

Understanding Corrosion Inhibitors

Corrosion inhibitors are chemical compounds designed to protect metal surfaces from the damaging effects of corrosion. By forming a protective barrier on the metal surface or altering the corrosion process, inhibitors prevent or slow down the oxidation and deterioration of metals in corrosive environments. Corrosion inhibitors are widely used in various industries, including oil and gas, petrochemicals, power generation, water treatment, and manufacturing, to safeguard critical assets and infrastructure from corrosion-related failures.

The Importance of Corrosion Inhibitors in Industrial Maintenance

1. Asset Protection: Industrial facilities rely heavily on equipment and infrastructure made of metal, such as pipelines, tanks, vessels, and machinery. Corrosion inhibitors play a crucial role in protecting these assets from corrosion, extending their service life and reducing the need for frequent repairs or replacements.

2. Cost Savings: Corrosion-related failures can result in significant financial losses due to equipment downtime, production disruptions, and repair expenses. By incorporating corrosion inhibitors into maintenance programs, industries can minimize the risk of corrosion-related failures and realize substantial cost savings in the long run.

3. Safety and Reliability: Corrosion compromises the structural integrity of industrial assets, posing safety hazards to personnel and the surrounding environment. Corrosion inhibitors help maintain the reliability and safety of critical infrastructure, reducing the likelihood of accidents, spills, and environmental contamination.

4. Environmental Protection: Corrosion-related leaks and spills can have detrimental environmental consequences, polluting soil, water bodies, and ecosystems. By preventing corrosion and minimizing the risk of leaks and spills, corrosion inhibitors contribute to environmental protection and sustainability efforts.

Applications of Corrosion Inhibitors

Corrosion inhibitors find applications across various industrial sectors, where metal components are exposed to corrosive environments. Some common applications of corrosion inhibitors include:

Oil and Gas Production: In the oil and gas industry, corrosion inhibitors are used to protect pipelines, well casings, and production equipment from corrosion caused by corrosive fluids, gases, and environmental conditions.

Water Treatment: Corrosion inhibitors are added to cooling water systems, boilers, and wastewater treatment facilities to prevent metal corrosion caused by dissolved oxygen, scale formation, and aggressive ions.

Manufacturing: In manufacturing processes involving metal components, such as automotive, aerospace, and electronics manufacturing, corrosion inhibitors are used to protect parts, components, and machinery from corrosion during production, storage, and transportation.

Marine and Offshore Structures: Corrosion inhibitors are applied to marine vessels, offshore platforms, and coastal structures to protect against corrosion in seawater environments.

ICPL: Your Trusted Corrosion Inhibitor Manufacturer and Exporter in India

As the best chemical company in Vadodara, ICPL is dedicated to delivering high-quality corrosion inhibitors tailored to the specific needs of industrial clients. Here's why ICPL is the preferred choice for corrosion inhibitors in India:

Expertise and Experience: With decades of experience in the chemical industry, ICPL possesses the expertise and technical know-how to develop and manufacture corrosion inhibitors that meet the highest quality standards and regulatory requirements.

State-of-the-Art Facilities: ICPL operates state-of-the-art manufacturing facilities equipped with advanced technologies and production processes to ensure the consistent quality and performance of its corrosion inhibitors.

Customized Solutions: ICPL offers customized corrosion inhibitor formulations tailored to the unique requirements and operating conditions of industrial applications. Our team of experts works closely with clients to develop solutions that address specific corrosion challenges and performance objectives.

Global Reach: As a corrosion inhibitor exporter in India, ICPL serves clients worldwide, exporting its products to diverse markets across Asia, Africa, the Middle East, and beyond. With a strong global presence and distribution network, ICPL delivers reliable corrosion protection solutions to industries around the globe.

Conclusion

In conclusion, corrosion inhibitors play a crucial role in industrial maintenance by protecting metal assets from the damaging effects of corrosion. As a leading corrosion inhibitor manufacturer and exporter in India, ICPL is committed to providing high-quality corrosion inhibitors that safeguard critical infrastructure, ensure operational reliability, and promote cost-effective maintenance practices. With ICPL's expertise, customized solutions, and global reach, industries can effectively mitigate the risk of corrosion and preserve the integrity of their assets for years to come. Contact ICPL today to learn more about our corrosion inhibitor products and solutions.

#Corrosion inhibitor Vadodara#Best chemical company in Vadodara#Corrosion Inhibitor exporter in India#Corrosion inhibitors manufacturer in India#Oxygen scavenger Chemical in Vadodara#Oxygen scavenger Chemical supplier in Gujarat#Oxygen scavenger Chemical Manufacture India#Oxygen scavenger Chemical exporter in Gujarat#Oil and gas industry#Oil and gas companies#Oil and gas pipelines#leading Oilfield Chemicals manufacturer and exporter in India

7 notes

·

View notes

Text

Boosting Efficiency: The Role of ERP Software in Modern Manufacturing Operations

In today's fast-paced manufacturing landscape, efficiency is not just a desirable trait; it's a necessity. To stay competitive and meet the demands of the market, manufacturers must streamline their processes, optimize resource utilization, and enhance decision-making capabilities. This is where Enterprise Resource Planning (ERP) software steps in as a game-changer. In this article, we'll delve into the pivotal role of ERP systems in revolutionizing manufacturing operations, particularly in India's thriving industrial sector.

Understanding ERP for Manufacturing Industry

ERP systems for manufacturing are comprehensive software solutions designed to integrate and automate core business processes such as production planning, inventory management, supply chain logistics, financial management, and human resources. By consolidating data and operations into a unified platform, ERP empowers manufacturers with real-time insights, facilitates collaboration across departments, and enables informed decision-making.

Streamlining Operations with ERP Solutions

In the dynamic environment of manufacturing, where every minute counts, efficiency gains translate directly into cost savings and competitive advantages. ERP software for manufacturing offers a multitude of features that streamline operations and drive efficiency:

1. Enhanced Production Planning: ERP systems enable manufacturers to create accurate production schedules based on demand forecasts, resource availability, and production capacity. By optimizing production timelines and minimizing idle time, manufacturers can fulfill orders promptly and reduce lead times.

2. Inventory Management: Efficient inventory management is crucial for balancing supply and demand while minimizing holding costs. ERP software provides real-time visibility into inventory levels, automates reorder points, and facilitates inventory optimization to prevent stockouts and overstock situations.

3. Supply Chain Optimization: ERP solutions for manufacturing integrate supply chain processes from procurement to distribution, enabling seamless coordination with suppliers and distributors. By optimizing procurement cycles, minimizing transportation costs, and reducing lead times, manufacturers can enhance supply chain resilience and responsiveness.

4. Quality Control: Maintaining product quality is paramount in manufacturing to uphold brand reputation and customer satisfaction. ERP systems offer quality management modules that streamline inspection processes, track product defects, and facilitate corrective actions to ensure adherence to quality standards.

5. Financial Management: Effective financial management is essential for sustaining manufacturing operations and driving profitability. ERP software provides robust accounting modules that automate financial transactions, streamline budgeting and forecasting, and generate comprehensive financial reports for informed decision-making.

6. Human Resource Management: People are the cornerstone of manufacturing operations, and managing workforce efficiently is critical for productivity and employee satisfaction. ERP systems for manufacturing include HR modules that automate payroll processing, manage employee records, and facilitate workforce planning to align staffing levels with production demands.

The Advantages of ERP for Manufacturing Companies in India

India's manufacturing sector is undergoing rapid transformation, fueled by factors such as government initiatives like "Make in India," technological advancements, and globalization. In this dynamic landscape, ERP software plays a pivotal role in empowering manufacturing companies to thrive and remain competitive:

1. Scalability: ERP solutions for manufacturing are scalable, making them suitable for companies of all sizes – from small and medium enterprises (SMEs) to large conglomerates. Whether a company is expanding its operations or diversifying its product portfolio, ERP systems can adapt to evolving business needs and support growth.

2. Compliance: Regulatory compliance is a significant concern for manufacturing companies in India, given the complex regulatory environment. ERP software incorporates compliance features that ensure adherence to industry regulations, tax laws, and reporting requirements, minimizing the risk of non-compliance penalties.

3. Localization: ERP vendors catering to the Indian manufacturing sector offer localized solutions tailored to the unique requirements of the Indian market. From multi-currency support to GST compliance features, these ERP systems are equipped with functionalities that address the specific challenges faced by Indian manufacturers.

4. Cost Efficiency: Implementing ERP software for manufacturing entails upfront investment, but the long-term benefits far outweigh the costs. By streamlining processes, optimizing resource utilization, and reducing operational inefficiencies, ERP systems drive cost savings and improve overall profitability.

5. Competitive Edge: In a fiercely competitive market, manufacturing companies in India must differentiate themselves through operational excellence and agility. ERP software equips companies with the tools and insights needed to outperform competitors, adapt to market dynamics, and capitalize on emerging opportunities.

Choosing the Right ERP Software for Manufacturing

Selecting the right ERP solution is crucial for maximizing the benefits and ensuring a smooth implementation process. When evaluating ERP software for manufacturing, companies should consider the following factors:

1. Industry-specific functionality: Choose an ERP system that offers industry-specific features and functionalities tailored to the unique requirements of manufacturing operations.

2. Scalability and flexibility: Ensure that the ERP software can scale with your business and accommodate future growth and expansion.

3. Ease of integration: Look for ERP systems that seamlessly integrate with existing software applications, such as CRM systems, MES solutions, and IoT devices, to create a cohesive technology ecosystem.

4. User-friendliness: A user-friendly interface and intuitive navigation are essential for ensuring widespread adoption and maximizing user productivity.

5. Vendor support and expertise: Select a reputable ERP vendor with a proven track record of success in the manufacturing industry and robust customer support services.

Conclusion

In conclusion, ERP software has emerged as a cornerstone of modern manufacturing operations, empowering companies to enhance efficiency, drive growth, and maintain a competitive edge in the global market. For manufacturing companies in India, where agility, scalability, and compliance are paramount, implementing the right ERP solution can be a transformative investment that paves the way for sustainable success. By harnessing the power of ERP, manufacturers can optimize processes, streamline operations, and unlock new opportunities for innovation and growth in the dynamic landscape of the manufacturing industry.

#ERP software providers in India#Manufacturing enterprise resource planning#ERP systems for manufacturing companies#ERP system for manufacturing industry#ERP for manufacturing companies#ERP software for engineering company#ERP software for engineering companies in India#ERP software for engineering companies in Mumbai#ERP solution providers in India#ERP for manufacturing industry#ERP systems for manufacturing#ERP solutions for manufacturing#ERP software manufacturing industry#ERP for manufacturing company in India#India

7 notes

·

View notes

Text

youtube

Every week, Eco India brings you stories that inspire you to build a cleaner, greener and better tomorrow.

Dye-infused effluent worsens India's water crisis. A fabric workshop and chemical firm in Gujarat have some ideas — from harvesting rainwater to bio-remediation via canna — and using sustainable pigments.

***********

Credits

Supervising Producer: Nooshin Mowla

Field Producer & Script: Aadya Baoni

Video Editor: Richard Kujur Associate Producer: Ipsita Basu

Director of Photography: Paul Varghese

DoP Asst: Vivek Bhaya

Production Assistant & Script: Aakriti Thatal

Executive Producer: Sannuta Raghu

#Scroll.in#eco india#solarpunk#dye#fabric#textile#textile industry#water#water crisis#fabric workshop#Gujarat#india#rainwater#rainwater harvesting#bio-remediation#canna#pigments#sustainable pigments#Youtube

11 notes

·

View notes