#low carbon airship

Text

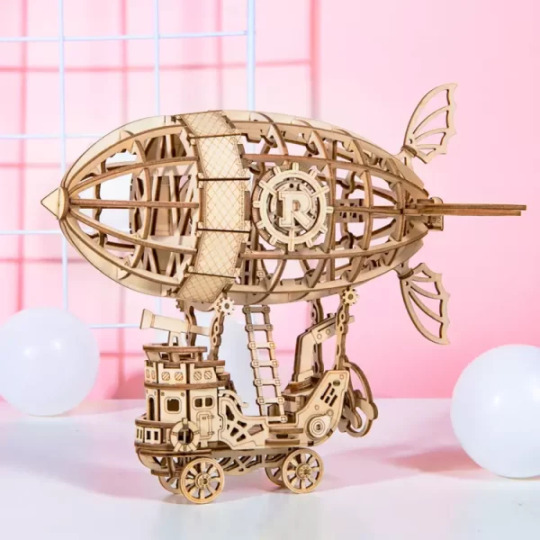

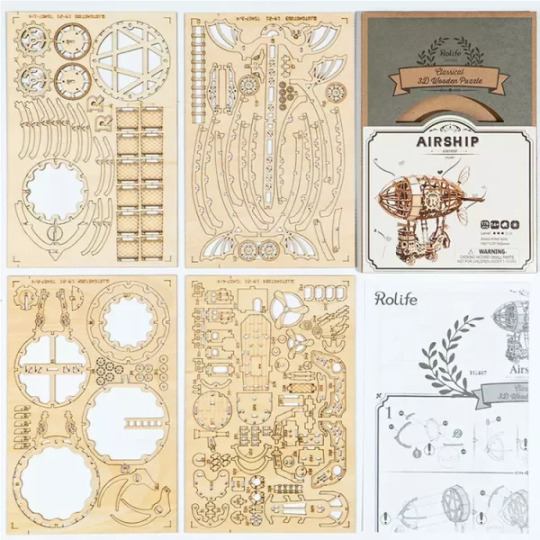

Airship DIY Puzzle 3D Wooden Puzzle is made of high-quality materials and first-class laser cutting technology. The design is novel and unique, which distinguishes it from other 3D wooden toys. There are detailed instructions in the packing box, easy to understand and ensure an easy and smooth assembly process.

#puzzle#airship#diy#airships#the airship#among us airship#3d puzzle diy#diy 3d puzzle#airship map#3d puzzle#riddler trophy stagg airship beta puzzle#airship glitch#batman arkham knight puzzle - titl airship#airship among us#zeppelin airship#low carbon airship#the airship release date#airship map release date#among us airship map#wooden puzzle#airship among us release date#3d wooden puzzle#among us airship map release date#robotime

3 notes

·

View notes

Note

78. Trapped Together, please! Surprise me :eyes:

Disclaimer: This is an AU between my character Eve and my partner's character, Flynt! He, unfortunately, dislikes being perceived™ so I can't link you to his stuff.

Also this whole thing is very unserious because they're very unserious and I love them.

Evelyn Rivers was overdue for a no-good, terrible day.

Arguably, any day with another person's company and a lack of good whisky was a no-good, terrible day, but this was an exceptionally bad no-good, terrible day.

And it all began the moment his face flashed into her peripheral.

"RHALGAR'S TITS, COCK AND ASS!" The low tong of wrench hitting pipe resonated through the cramped entanglement of metal and wires, narrowly missing the blonde hair of his ear... and the little fucker did absolutely nothing. He looked down at her, the space between them nary and inch, and grinned.

"Hi."

"Th' fuck you mean hi?" Eve tried to hiss, though it exited more like a wheeze.

"Hi," Flynt repeated, like that was a sufficient answer, "I'm stuck."

This was a problem. Right up to and including this moment, the mechanic had been lying on her back, meticulously rejigging the wires of her deathtrap airship, The Junker. Because it was a hodgepodge of rubber, iron and hammered-on scraps of carbon-fibre, she wasn't particularly big. Enough for one person, to be sure; two was pushing the luck. But her engine, while deep, was certainly not enough for two people to linger comfortably — less so when the other looked like stashed cables at the back of her wardrobe, kept for the never-occurring 'later on'.

"You're not stuck, Flynt —" Eve paused.

Flynt didn't lie, that was the issue at hand. He might obfuscate, he might withhold information. But as far as a direct question to answer ratio, the viera did not lie. "—Are you actually stuck?"

"Without a doubt." She was going to kill the cheery motherfucker. "I fell in."

"How did — YOU KNOW WHERE THIS IS?" The question was rhetorical. She swiped at him with the wrench and missed atrociously, further enraged by his blind luck. He let out an 'Oops!' and began to comically scramble, freeing himself by pushing a pipe completely out of alignment as she chased him and nearly smacked her clean in the face with it.

"STOP! RUINING! MY! FUCKIN'! SHIP!"

Bang, bang, bang! The chorus of her tools hitting steel rather than bone.

"That was choked for ages!" He claimed, grabbing hold of whatever would take him as he clamoured out. "I'm helping!"

"YOU NO' DOING SHIT —" She bellowed, even as SERS lit up from the pilot console above and began to speak in a pleasant tone.

"Designation Evelyn, it is my pleasure to inform you that, due to your efforts, our fuel efficiency has been increased by twenty percent!"

"SHUT TH' FUCK UP, SERS."

13 notes

·

View notes

Text

The Magbox Christmas Speech (or something like it)

So it's been a little over a month since anybody new showed up in the system. If there is anyone else to find, now is obviously not the time to find them... so for all intents and purposes, this may as well be it.

Putting this under a cut because it's long. But if you want to know what life has been like as a system since we discovered ourselves 6 months ago, go on ahead.

I've seen things happen in our inner world that you wouldn't believe. The ways our mind acts out the struggles between parts, the struggle to redefine ourselves, to try and find meaning in something that's been suppressed for 35 years? We don't just tell ourselves a story, we live through it. We drink deep from the well of our subconscious, we feel the arms of our loved ones around us as much as we feel every blow in a fight. I've tried to fight it and our brain won't let me. It just makes things more and more real; taking away control over things like my in-system ability to change size, and feeding me dizzying sensations of rising and falling in our body until I get pulled "out of front" abruptly. And I know, once I'm no longer looking through the eyes but stuck in that far-too-real dream, that I'm either too big to touch our "control desk" or I'm too small to reach it.

It's not all bad, though. We've learned to co-operate with the whims of the subconscious and reap the rewards, finding sanctuary, finding community, finding wonders we've never lived but often dreamed of. I've eaten fruit that tastes like chocolate pudding, dived into streams and caught fish with my teeth, dug up sweet potatoes with my hands and roasted them on a bonfire. I've danced in a moonlit field, on the deck of an airship, and at a spiraling rave in another dimension. I've jumped into a carbonated lake in a volcano, been on a low-gravity spacewalk, and flown through the clouds of what we call Dreamscape. I've seen the magenta moon rise for the first time over the Village Green like a flag of victory, and the Deepwoods so full of glowing flowers - how our system interprets hope - that it looked like it was on fire. We have a pub, a park, a cafe, an arcade, a ballroom for celebrations, we have an adult-size "funhouse" full of things to climb and ballpits to fall into. We've dined under a sky full of stars and seen it light up with fireworks. Our world is equal parts magic and mundane.

But I've also held the parts of us that never got to grow up, as they cried and screamed and revealed horrors we'd long forgotten. I've felt one of our own try to jump on my back and control my actions like a puppet, because they were the one keeping the system suppressed, and they were convinced everything had gone to hell because of me. I've felt the sheer existential terror of a deeply blurry front, where everything you know gets lost in the fog, and you suddenly realize you don't know who you are. I've seen alters try to tear each other apart with teeth and claws, try to ruin our realspace life by hurting other people, try to hurt our shared body because it feels like there's no way out. I've wept over what happened to us and what we never had, knowing that the ones who made us this way would never believe us, never mind apologize for what they did.

And I've enacted Operation Kaiju; a contingency plan we hoped we'd never have to use. I've grown to a huge size, and faced down the giant amalgamation of every bit of trauma that didn't get to form an alter over those three and a half decades, that was so big it could only manifest as a place inside our head - The Red Forest. Full of eerie silence, an endless layer of fallen leaves on the ground, trees with white bark like stripped bones, always cold but devoid of wind or snow. And after it trapped one of us inside it, the first thing that alter said on getting out, covered in cuts and scratches, was "don't go in there, it hates us". It hated us because how dare we do this, how dare we pull ourselves away from it so it becomes less and we become more. And I've shouted at it, screamed at it as it rose up out of the world and tried to claw at us, told it no, you can't have them back. They are mine. I don't want to fight you but I will not let you take them from me. And I've put my hand on the wall that kept it separate from us; comforted it, listened to it, until it was finally ready to lay down peacefully and let itself die in order to become the rest of us.

I've known joy and I've known fear, and so has everybody else. I've seen the paths between our domains crumble from stress and cut us off from each other for weeks. And the system raised its voice in song, as one, to tell me they're okay, because we will never be alone again and that is a promise. There is no going back.

And now, at the end of the year, we're here. Who knows what our system will look like in a year, or in 10 years. Over the course of the rest of our shared life. We've desperately searched for our missing parts together over the past six months, and now that search could very well be coming to an end. Our total headcount, 39, doesn't seem like it'll go up but might actually go down. This has already happened three times; Roxxy fused with Rosie and gave us Roxanne, Rakugaki and Charlie became Anarchy, Yvonne and Harvey created Nocturne. Maybe more will happen, maybe they won't, but whatever their choice is we know that nobody will ever go dormant again if we can help it. There will never be a time where someone faces such overwhelming despair, they go to sleep and hope they never wake up again.

But here's to the start of a new chapter. Here's to moving forward as one and as many at the same time. We're done digging in the depths for whatever hurt might lie in there, and we don't need to just survive any more. We don't need to keep settling for something to kill more and more time, feeling neither highs nor lows, expecting nothing and never being disappointed. We can do better. We have to start figuring out how to thrive.

Happy Holidays, from all of us to all of you.

- Terry & The Alters Of The Magbox System

6 notes

·

View notes

Text

Halloween: Basement, bedroom:

half-overcast sky, windows somewhat alight with sun

an alive white Stove rolls in: Its burners lift and drift to its low sides,

mount, uncoil and re-wrap to make four wheel-rims.

Rain on a skylight glass: the wet window is a scalp

Gypsum boxes and corners are the walls of a skull.

Wheelstove: I miss cooking you lunch,

your basement was our rib cage

….my hands feel useless…

I can’t find our lungs.

A clothing rack on tank treads drives in. It stops, and speaks:

“You never want to wear the gifts I get you”

A microwave turns into a gondola on a burlap airship. It hovers and replies:

“I made him dinner; he won’t even touch one plate of what’s leftover….

So ungrateful.”

Hallway more brightly lit;

new knowing of losses+Time’s flight

Thinking forwards from the dirt diamond by a gas station

craftsman siding is the skin on timber cheekbones.

Wheelstove: Make my longing travel:

from low in the angry left corner, toward far up as a balloon fish in the top right sky.

As for now;

I just was, and will again be alone,

cooking a memory in our rib cage.

A disk of dim sunlight on my Autumn;

the cloudcast sky; a gray crystal dome

is a VTOL craft with a gantry

and two large parenthesis for clamps

and it floats over the proscenium arch,

its steel propellers turning through noonlight rain:

That’s the Sunlightfog arriving.

Bed frame is the rib bones; window drapes the torso skin

The fogged window is an unclean jacket

Wheelstove: soul + pictures encased are

shot out the bell of a glass musket into ↑ orbit ←

That for them. But for me? Should I, that? should I even think

that I in the Heavens should forgiven be? I look out the window—

Sunlightfog: I’m ease of mind. I’m peace which drifts foreverywhere

Wheelstove: One who can’t be killed?

***

Seven years back, one side of the mattress burned

and the burnt leftovers froze.

Now three ungloved hands pick up

pieces; of the crumblechank of ice + crumble of roasted wool

,and unload them in a trough of carbon fluid, at downstage middle;

brown flurry, slowly drips through a factory.

Now the stove acts by remembering:

one cold hand flips a toggle on the console of the Anatomy-Arranger:

Sheetfoam+ash+springs melt, flow, harden into beams

and are welded bolted and wrenched together as bones, with muscle,

and drinking-straw tendons.

***

A robotic duck with a chainsaw head walks in and fells an oak tree,

The tree trunk is stripped barkless, halved, and carved into a duo of legs that stomp on the porch.

A soda can opens like a barnacle, and tapemeasure-tendrils wave out.

Clotherack:

“that was the last drink, I am so thirsty, you couldn’t save some for me?”

A suitcase opens like a clam. A tongue made out of an exercise band ejects a greasy steel block which goes high to the left, and impacts the airship: Now the Airship bursts and crashes to the floor.

Microwareship:

“I am….popped”

Car Keys+Diploma+Portrait+Toolbox+Keycard+Tombstone

personal items are all melted/mixed→crumpled→flooded with Sunlight,

poured in a bubble-shell which is then released to swim upward; so

records of identity become a jellyfish big as the day sky

over the big stage floor: ↓

Rusted Keys+ID photo+Birth Certificate+Razor+Backpack+Shoes ↓

Rustad Keyis ID Phorta Binth Certofecate Razop Bapacker Shoesar ↓

Ruystald Keyris g’ID Phortans bingth Cero’fecalle ba’padder Sho-seart ↓

cruystald kteynris ogi-Ortans Bwingths cepro’fepelle bar-pudder s-Hseart ↓

cruystal k-Tenrils oi-orgtans Wingths ePro’fepeller baRudder H’seart

Crystal Tendril Organs Wings Propeller Rudder Heart

↓

This Soul-Shield/Heaven-Enterer is now

Shot through a green glass pistol from the past, through Earth’s present orbit, then past Time itself.

3 notes

·

View notes

Text

Vein Finder Market: Dissecting the Factors Steering Growth and Potential Risks

Vein Finder Market provides in-depth analysis of the market state of Vein Finder manufacturers, including best facts and figures, overview, definition, SWOT analysis, expert opinions, and the most current global developments. The research also calculates market size, price, revenue, cost structure, gross margin, sales, and market share, as well as forecasts and growth rates. The report assists in determining the revenue earned by the selling of this report and technology across different application areas.

Geographically, this report is segmented into several key regions, with sales, revenue, market share and growth Rate of Vein Finder in these regions till the forecast period

North America

Middle East and Africa

Asia-Pacific

South America

Europe

Key Attentions of Vein Finder Market Report:

The report offers a comprehensive and broad perspective on the global Vein Finder Market.

The market statistics represented in different Vein Finder segments offers complete industry picture.

Market growth drivers, challenges affecting the development of Vein Finder are analyzed in detail.

The report will help in the analysis of major competitive market scenario, market dynamics of Vein Finder.

Major stakeholders, key companies Vein Finder, investment feasibility and new market entrants study is offered.

Development scope of Vein Finder in each market segment is covered in this report. The macro and micro-economic factors affecting the Vein Finder Market

Advancement is elaborated in this report. The upstream and downstream components of Vein Finder and a comprehensive value chain are explained.

Browse More Details On This Report at @https://www.globalgrowthinsights.com/market-reports/vein-finder-market-101448

Global Growth Insights

Web: https://www.globalgrowthinsights.com

Our Other Reports:

Vein Finder Market Growth

Low-Power Geolocation Market

Global Serial EEPROM Market Size

Global Airship Market Growth

Organic Cheese Market Forecast

Global Augmented Reality and Virtual Reality (AR and VR) Market Share

Embedded Processors Market Growth Rate

Indoor Unmanned Delivery Robot Market Size

Intragastric Balloons Market Share

Fast Food and Quick Service Restaurant Market Analysis

Monoclonal Antibody Therapeutics Market

Drone Identification Systems Market Growth

Global Personalized Hydration Solutions Market Growth

Global Machine Vision and Vision Guided Robotics Market Size

Global Kubernetes Solutions Market Share

Cryogen Free Dilution Refrigerators Market Forecast

Dental Ultrasonic Scaler Market Size

Water Hardness Removal Market Growth Rate

Gantry or Cartesian Robots Market Analysis

DTH Drill Rig Market Share

Polyhydroxyalkanoates (Pha) Market Growth

Cable Cleats Market

Global Digital Twin Market Size

Global Essential Oil & Aromatherapy Market Growth

Antibody Testing Market Forecast

Global Carbon Fiber Geogrid Market Share

RF-over-Fiber (RFoF) Solutions Market Growth Rate

Frameless Brushless DC Motors Market Size

Request for Proposal (RFP) Software Market Share

Automotive Steering Systems Market Analysis

Pipeline Monitoring System Market

Luxury Safari Tourism Market Growth

Global Virtual Power Plant Market Growth

Global Epidural Anesthesia Sets Market Size

Global Left Ventricular Assist Device (LVAD) Market Share

Sauna and Spa Market Forecast

Automotive Vehicle To Everything (V2X) Communications Market Size

Capillary Blood Collection Tubes Market Growth Rate

Global Floating Production System Market Size

Global Molecular Diagnostics(MDx) Market Share

#Vein Finder Market Size#Vein Finder Market Share#Vein Finder Market Trends#Vein Finder Market Industry#Vein Finder Market Growth

0 notes

Text

New Oil and Gas News

The United States energy industry has been an important source of employment, energy, and fuels for millions of Americans. But the sector is undergoing a major shift from one that mainly focused on fossil fuels to a clean, renewable energy-based industry. As such, it is critical that the oil and gas industry remain on top of this transition, especially in light of recent calls for reduced greenhouse gas (GHG) emissions.

The oil and gas industry is being called out for not spending enough on clean alternatives. But while the oil and gas industry is facing a variety of supply disruptions, there are a number of new developments that are increasing its chances of success in this area.

Oil and gas companies are investing in carbon capture, a process that can reduce greenhouse gas emissions by capturing and storing carbon dioxide. Several companies have announced plans to implement these technologies in the coming years. Some projects are in the construction phase, and more are expected to be announced in the future.

In addition, several major oil producers are buying companies that produce biogas, a cleaner, low-carbon alternative to gasoline. Biogas is a byproduct of landfills, and can be purified and shipped via pipelines like conventional gas. Moreover, it qualifies for tax credits under the Inflation Reduction Act.

Meanwhile, oil and gas companies are being urged by a growing grassroots movement to address climate change. Ceres, a non-profit group that focuses on promoting sustainable societies, is causing a shift in the industry's thinking. And while the impact will only become more severe over the coming years, the oil and gas industry can't afford to ignore these calls.

A technology company is launching an airship that can monitor emissions from the oil and gas industry. It also hopes to bring broadband to remote areas.

Meanwhile, a judge has halted the sale of a $192 million oil and gas lease in the Gulf of Mexico, citing future global warming emissions. This is the first legal roadblock for the industry since January.

There are a number of other developments in the sector, including an increase in seismic activity in the Permian Basin. In addition, the Environmental Protection Agency is preparing to finalize regulations on methane emissions from the oil and gas industry. While the government is projecting expansion in the sector by 124.8 percent in 2017, the industry is uncertain about its long-term plans.

As the demand for oil and gas continues to grow, the industry must continue to adapt to a rapidly changing environment. Its prospects are increasingly dependent on expanding clean air policies, expanding commitments to reducing carbon dioxide emissions, and the rapid evolution of clean energy technologies.

One key player in this arena is the American Petroleum Institute (API), which represents nearly 600 members of the oil and gas industry. They account for 12% of the country's reserves and 15% of its production. Among their priorities are a price on carbon dioxide and a promotion of low-emissions technology.

0 notes

Text

Airships Carbon Fiber Reinforced Polymer Market to Scale New Heights as Market Players Focus on Innovations 2022 – 2027

Latest business intelligence report released on Global Airships Carbon Fiber Reinforced Polymer Market, covers different industry elements and growth inclinations that helps in predicting market forecast. The report allows complete assessment of current and future scenario scaling top to bottom investigation about the market size, % share of key and emerging segment, major development, and technological advancements. Also, the statistical survey elaborates detailed commentary on changing market dynamics that includes market growth drivers, roadblocks and challenges, future opportunities, and influencing trends to better understand Airships Carbon Fiber Reinforced Polymer market outlook.

List of Key Players Profiled in the study includes market overview, business strategies, financials, Development activities, Market Share and SWOT analysis are Toray Industries, Inc. (Japan),Mitsubishi Chemical Holdings (Japan),Hexcel Corporation (United States),Teijin Limited (Japan),SGL Group (Germany),Solvay (Belgium),Hyosung (South Korea),AKSA (Turkey),Crosby Composites (United Kingdom),Cytec (United States)

Airships Carbon fibre reinforced polymers are composite materials that rely on carbon fibre for strength and stiffness, while the polymer acts as a cohesive matrix to protect and hold the fibres together, as well as providing some toughness. CFRP bars are produced with a variety of surface textures, which have a significant impact on their bond behaviour as NSM reinforcement. Their surface can be smoothed, sandblasted, sandcoated, or roughened with a peel-ply surface treatment. Round bars can also be spirally wound or ribbed with a fibre tow. Carbon fibre reinforced polymer (CFRP) composite materials are finding increased use in a variety of fields. They are strong and light, and are used in airships where high strength-to-weight ratios are required.

Key Market Trends: Airships are constructed with carbon fiber and aluminum frame inside skin of shiny mylar composite material

Opportunities: Reduction in the cost of carbon fiber

Potential opportunities in new applications

Growing demand from emerging markets

Market Growth Drivers: Government stimulus packages for aerospace and other industries for the COVID-19 crisis

Increase in demand for fuel-efficient vehicles

Increasing demand from the wind energy industry

Challenges: Maintaining uninterrupted supply chain and operating at full capacity

Development of technology to reduce cycle time

The Global Airships Carbon Fiber Reinforced Polymer Market segments and Market Data Break Down by Carbon Fibers (UHM (Ultra High Modulus), HM (High Modulus), IM (Intermediate Modulus), HT (High Tensile, Low Modulus), SHT (Super High Tensile)), Manufacturing Process (Lay-up, Resin Transfer Molding, Filament Winding, Compression Molding, Injection Molding, Pultrusion, Others), Source (Virgin, Recycled), Precursor Polymer (Polyacrylonitrile (PAN), Rayon, Petroleum Pitch)

Presented By

AMA Research & Media LLP

0 notes

Text

Airship to offer low-carbon flights with floor-to-ceiling windows

(CNN) — Growing awareness of the climate crisis means conscientious travelers are increasingly looking for alternatives to trips by airplane.

For many, that means traveling by high-speed train, but on Wednesday UK-based company Hybrid Air Vehicles (HAV) released the latest details of its airship, which boasts a far smaller carbon footprint than a conventional passenger plane.

The Airlander 10…

View On WordPress

0 notes

Text

A UK company is planning to bring airships back to the skies as a viable low-emissions alternative to internal flights or short hops across the border.

Hybrid Air Vehicles, which claims its blimp-style aircraft pump out 75% less carbon emissions than aeroplanes, said it was in talks with airlines who might operate routes such as Liverpool to Belfast and Seattle to Vancouver, with a fundraising underway to enable it to continue development.

#airship#airships#steampunk#futuristic#hybrid technology#electric#climate change#air travel#flight#blimp#global warming#travel#the uk

3 notes

·

View notes

Text

Some scientists are serious about resurrecting zeppelins for low-carbon travel

https://onezero.medium.com/planes-are-ruining-the-planet-new-mighty-airships-wont-d8eb39418acc

Comments

1 note

·

View note

Text

1 note

·

View note

Text

Cloud City

Over the past nearly 150 years Mars has dominated our minds. Ever since the discovery of “canals” on the Martian surface in 1877, science fiction writers have pushed the red planet into our collective consciousness. From the War of the Worlds first published in 1897 to the 2015 movie The Martian based on the book by the same name, we can’t get enough of it. So much that most major space agencies are planning trips to Mars in our lifetimes.

Why does Mars get all the attention though? It raises questions about our sister planet, Venus. What would colonization there look like?

source: https://sacd.larc.nasa.gov/smab/havoc/

The surface of Venus is comparable to the thermostat of Hell. Around 450 degrees Celcius (842 Fahrenheit) with surface pressure high enough to crush reinforced steel in a matter of hours, it hardly seems like a garden of Eden. However, it offers a few advantages Mars can’t compete with.

First of all, Venus is nearly the same size as Earth, which might not seem like a big deal, until you realize that means Venus also has nearly the same gravity as Earth (90 percent, Mars, by comparison, has less than half Earth’s gravity) which is good for long term colonization efforts. Astronauts on the ISS, most of whom spent 6 months to a year in low earth orbit, (read zero-g) lose bone mass at 10x the rate of someone with advanced osteoporosis. No one knows how Martian gravity would affect us feeble humans, but we know it wouldn’t be good.

The second advantage Venus has is it is between 14 and 140 million kilometers closer to Earth than Mars depending on what point it is in its orbit, making it much easier to transport supplies and humans. Remember, it’s a colony, we’ll have to bring everything ourselves. Venus also has a thick atmosphere that would protect us from UV radiation much better than Mars’ wispy atmosphere.

None of this matters if we can’t even land on the surface without bursting into flames, right? Not necessarily, Geoffrey Landis at NASA has proposed we instead colonize the skies. At about 50 kilometers (30 miles) above the surface, the ambient pressure drops to about one Earth atmosphere. and the temperature becomes a much more manageable 70 degrees C (160 F), while still offering all the advantages of gravity and UV protection.

The aptly named project HAVOC (High Altitude Venus Operational Concept) proposes that we send decked out zeppelins for astronauts to live and experiment in. The airships would primarily consist of an ascent vehicle, atmospheric habitat, and an envelope covered in solar panels and filled with an oxygen/nitrogen mix. Since both of these gases are lighter than the surrounding carbon dioxide/sulfur dioxide, the airship could float peacefully through the atmosphere. Well, except for the hurricane-like winds, but those wouldn’t have much of an effect on the blimp, in fact, it would reduce stress on the structure. Eventually, the blimps could lead to cloud cities miles above the surface.

sources:

https://sacd.larc.nasa.gov/smab/havoc/

https://www.youtube.com/watch?v=k2KX7QhKLME

https://www.youtube.com/watch?v=gJ5KV3rzuag

https://arc.aiaa.org/doi/pdf/10.2514/6.2011-7215

#nasa#astronomy#astrophysics#astronaut#space#mars#venus#project havoc#are these the right tags#running out of ideas

11 notes

·

View notes

Text

The aerospace market – Advanced Textiles Source

As NASA units a course for Mars and a return to the moon, and personal corporations interact in a new area race, textile corporations discover alternatives for high-performance fabrics and merchandise.

by Amy Goetzman

When does a single lemon value $2,000? When it’s in area. NASA stories that it prices about $10,000 in gasoline to launch one pound of payload into area—whether or not that payload is individuals, gear or supplies. Meaning the lemons astronaut Scott Kelly famously juggled on the Worldwide Area Station during his 2015−16 yr in area have been valued at about $2,000 each. Approaching it that method, it’s straightforward to see why supremely lightweight and powerful textiles play a important position in aerospace actions.

A vary of entities make the most of material technologies of their aerospace gear, including NASA, army organizations, airline and aerospace corporations, universities and research establishments, climate and science packages, and Google and datacom corporations. And the growing personal area exploration business, spurred by initiatives together with Elon Musk’s Area X, Jeff Bezos’s Blue Origin and Richard Branson’s Virgin Galactic, guarantees to create space journey accessible to (well-heeled) people who aren’t educated as astronauts. The area financial system is right here, with opportunities for corporations in the specialty materials business that can meet the necessities of utmost environments beyond the clouds.

NASA astronaut Robert Behnken installs ammonia line Multi-Layer Insulation (MLI) blankets, manufactured by Aerospace Fabrication & Supplies, on the Worldwide Area Station during a maintenance and development extravehicular activity session. Photograph: NASA.

Out-of-this-world materials

The people who make area fabrics noticed this coming. Composite Materials of America (CFA), Taylorsville, N.C., a subsidiary of the century-old weaving company Schneider Mills, has seen steadily growing demand for its carbon fiber textiles, notably Textral, a multidimensional carbon fiber weave. The company also produces custom materials and tapes using carbon, aramid, basalt, Innegra, fiberglass and polyethylene fibers, obtainable in unidirectional, bidirectional and hybrid weaves. CFA is certified to AS9100 Rev D., the worldwide management system normal for the Aircraft, Area and Defense (AS&D) business, as well as ISO9001.

“Carbon fiber is very strong and durable. It starts as a textile, but when it’s encapsulated in a resin and cured, it holds a shape, yet it is very lightweight. That makes it an excellent solution for aerospace use,” says David Shippee, CFA government director of sales. “We have perfected how to weave fibers to create high-tech fabrics, which perform well for our space customers. We can produce fabrics that have structural integrity, resist temperature changes, are strong and durable—basically, they are lighter, stronger, better. They save on fuel and deliver very high performance.”

The firm works intently with clients to develop textiles that go well with their design and performance necessities. While CFA’s merchandise have been perfected for use in area, many specialty Earth-bound corporations discover these high-performance supplies work nicely on the bottom.

“Some customers require technical fabrics for applications such as boats, extended solar arrays, barrier systems, vehicles, aircraft seat frames or sporting equipment,” says Shippee, noting that many luxurious and racing cars are integrating carbon fiber material into their designs. On Earth, carbon offers the same gasoline financial savings and durability it demonstrates in area.

“In many applications, if it’s made from plastic, it can be made better with carbon fiber fabrics,” he says.

Go well with up and wrap up

The fabrics produced by CFA and other specialty material suppliers that innovate for area find yourself in a variety of products. But perhaps none are as exciting as area suits. David Clark Co., based mostly in Worcester, Mass., is a pioneer within the subject, partnering with the Mayo Clinic in the 1940s to develop anti-G fits to protect Allied pilots from blacking out throughout high-G maneuvers.

“Some of David Clark’s early prototypes leveraged his ‘straightaway garment,’ which was essentially the Spanx® of the day,” says Shane Jacobs, softgoods design supervisor, Aerospace Life Help Methods, David Clark Co. Publish-war, the corporate continued to refine its go well with designs for rocket aircraft check pilots. As the area race ignited, this experience turned to multilayer full-pressure go well with development.

“We’ve been involved in every human space and high-altitude program since Gemini, including the Apollo Block 1 suits, the space shuttle program suits and the suits in development now for the Boeing CST-100 Starliner [Boeing’s next-generation space capsule that will take people to and from low-Earth orbit],” Jacobs says.

“Every suit we design is a little different. Requirements vary for suborbital versus orbital missions; the user might be suited for the duration of the flight or just for the launch. Some suits are lightweight and minimal complexity, such as the suit designed for the Starliner. Others are for longer duration missions to deep space, such as the suits for NASA’s Orion spacecraft. Those integrate complex systems, such as a feeding port, waste management and liquid cooling system. A consistent focus is always to design each suit to be low bulk, highly mobile and comfortable.”

Sample designers and engineers check go well with elements by way of CAD modeling and prototyping before manufacturing, Jacobs says. Suits are tested in quite a lot of environments, including underwater to simulate microgravity.

“Inside the suit, you are essentially in your own personal spacecraft,” he says. “It needs to be airtight yet selectively permeable to allow water vapor to escape. Other requirements are fire retardancy and high strength. We use low-elongation fabrics that will hold their shape while allowing people to move. You have to design the suit from the inside and understand what the user is feeling. If the suit isn’t optimally sized or is designed improperly, it can be pretty painful when it is pressurized.”

Naturally, he’s tried one on, although Jacobs hasn’t yet gone into orbit himself. However he says the company has an in depth eye on efforts to get shoppers into area, and he hopes to someday be a part of them. Within the meantime, the applied sciences the company has innovated for area are discovering a task in purposes on Earth, akin to Reebok’s Floatride Run Fast footwear, which advanced from an area boot design the corporate developed.

Much less glamorous than area suits, but no much less important are Multi-Layer Insulation (MLI) Blankets, similar to those designed by Aerospace Fabrication & Supplies LLC, Farmington, Minn. Comprised of a thin plastic film materials simply zero.00025 to zero.00033 inches (6 to 8 microns) thick and low conducting material spacers, these engineered thermal management blankets are used to insulate essential gear within the Area Shuttle Orbiter, the Worldwide Area Station, geospatial satellites, datacom satellites and cryogenic purposes.

“Think about it the way you’d look at insulation for your house; these blankets serve as a passive thermal control device for spacecraft,” says Brent Anderson, owner of Aerospace Fabrication. “They help protect and maintain instruments at room temperature inside.” In line with the essential have to maintain weight down in aerospace products, the blankets function an alternating layer development. “They are extremely lightweight. The internal layers are a loose-weave, almost bridal veil type fabric and metalized plastic film. Even though we use up to 20 layers, it only weighs a couple of ounces per square foot. On the outside, the material is coated with metals. That shiny surface reflects incoming thermal radiation off the surface.”

Anderson’s firm is all the time on the lookout for new materials or mixtures of fibers, he says. Along with weight, low conductivity and optical properties, the textiles used in these purposes must endure the tough surroundings of area. “We end up going out often to talk with the fabric industry to see what is new,” Anderson says. “For instance, 3D weaving is really taking off. We are watching that to see how we might incorporate it into our products.”

Whilst area purposes improve, the company faces a challenge that many producers in the aerospace market experience: relatively small demand. To keep a gentle backside line, the corporate additionally produces technical tapes and printed circuits and cables for the electronics business. “We want specialized materials that do extraordinary things, but we don’t tend to buy a lot of any one thing, so the price goes up for us,” Anderson says. “It doesn’t tend to be something most suppliers want to support, because the business ebbs and flows so much. Even as the need for space textiles increases, it’s still a small market compared to others.”

Raven Aerostar is the only provider to the NASA Balloon Program Office, offering both Zero Strain and Super Strain Balloons (SPB) for scientific missions. This flight’s objective was to check and validate the SPB know-how with the objective of long-duration flight (100+ days) at mid-latitudes. Photograph: NASA.

Nearer to house

Not all aerospace textiles make it to outer area. The stratosphere, the second layer of the Earth’s environment within the zone above the clouds, is turning into increasingly crowded with specialty high-tech balloons and airships. Textile-based purposes are perfect for this zone, which is characterized by thin air, limited weather events, exposure to the ozone layer and high levels of ultraviolet radiation from the solar. Raven Aerostar, Sioux Falls, S.D., has been innovating high-altitude textiles and stratospheric balloons because the 1950s.

“These are products that will fly two to five times as high as airplanes, so we need to make sure they meet extremely high quality standards,” says Joe Beck, Raven Aerostar plant manager and program manager. “The materials and the construction must be very robust to endure the external conditions, which can range in temperature from -50°C to -90°C [-60°F to -130°F]. These are typically filled with helium, so impermeability is a critical factor as well.”

Composed of “lighter-than-air” engineered polymer-based movies, Raven Aerostar’s stratospheric balloons look as delicate as a butterfly, but they will carry payloads up to 4 tons, acquire info used in scientific analysis, carry out army surveillance and help in GPS, radar and remote communications endeavors. As a division of Raven Industries, Raven Aerostar works intently with Raven Engineered Films, the division that develops the specialty polymer film and sheeting used in these purposes.

“We have our material design expertise right next door, so it’s easy to develop new materials for specific customer needs,” Beck says. “Our goal is always thinner, lighter and stronger.”

The rising area financial system may even create demand for textile merchandise that never depart Earth. Take the work of SLO Sail and Canvas of San Luis Obispo, Calif. The company focuses on marine fabrication, but army and aerospace organizations—together with Area X, California Polytechnic State University, the Nixus Challenge Glider and drone operators—have taken advantage of its design and fabrication know-how.

Applying its experience in versatile yet taut marine merchandise, the company has taken on tasks resembling crash nets for drones and specialty tarps which are put in around missiles and rockets on the launch pad or during development, says Karl Deardorff, SLO proprietor. The tarps are constructed from anti-static material, a essential requirement in an surroundings where a rocket booster is perhaps sitting on 100,000 kilos of rocket gasoline. Some jobs may want particular qualities, similar to polyester, carbon or conductive threads.

“The point is to protect people and equipment from FOD—foreign object debris,” Deardorff says. “A rocket that’s 230 feet high can have six to eight levels of scaffolding, and if something falls, that’s a problem. An anti-FOD tarp may only be 6 to 9 inches wide, but that is enough to avert damage or loss.”

Between NASA’s brief and long-range objectives, a new area race between deep-pocketed personal corporations, and some great benefits of high-tech textiles in area exploration, the aerospace market presents great potential for specialty material suppliers, designers and producers that wish to make their mark in excessive purposes.

“This is a growing area with lots of opportunity,” Deardorff says. “There is a lot of work for us all. We enjoy working closely with our customers on these unique projects, and we enjoy the excitement of designing for an industry with such big ambitions.”

Amy Goetzman is a freelance author based mostly in Maplewood, Minn.

The post The aerospace market – Advanced Textiles Source appeared first on Techno Crats Blog.

1 note

·

View note

Text

The aerospace market – Advanced Textiles Source

As NASA units a course for Mars and a return to the moon, and personal corporations interact in a new area race, textile corporations discover alternatives for high-performance fabrics and merchandise.

by Amy Goetzman

When does a single lemon value $2,000? When it’s in area. NASA stories that it prices about $10,000 in gasoline to launch one pound of payload into area—whether or not that payload is individuals, gear or supplies. Meaning the lemons astronaut Scott Kelly famously juggled on the Worldwide Area Station during his 2015−16 yr in area have been valued at about $2,000 each. Approaching it that method, it’s straightforward to see why supremely lightweight and powerful textiles play a important position in aerospace actions.

A vary of entities make the most of material technologies of their aerospace gear, including NASA, army organizations, airline and aerospace corporations, universities and research establishments, climate and science packages, and Google and datacom corporations. And the growing personal area exploration business, spurred by initiatives together with Elon Musk’s Area X, Jeff Bezos’s Blue Origin and Richard Branson’s Virgin Galactic, guarantees to create space journey accessible to (well-heeled) people who aren’t educated as astronauts. The area financial system is right here, with opportunities for corporations in the specialty materials business that can meet the necessities of utmost environments beyond the clouds.

NASA astronaut Robert Behnken installs ammonia line Multi-Layer Insulation (MLI) blankets, manufactured by Aerospace Fabrication & Supplies, on the Worldwide Area Station during a maintenance and development extravehicular activity session. Photograph: NASA.

Out-of-this-world materials

The people who make area fabrics noticed this coming. Composite Materials of America (CFA), Taylorsville, N.C., a subsidiary of the century-old weaving company Schneider Mills, has seen steadily growing demand for its carbon fiber textiles, notably Textral, a multidimensional carbon fiber weave. The company also produces custom materials and tapes using carbon, aramid, basalt, Innegra, fiberglass and polyethylene fibers, obtainable in unidirectional, bidirectional and hybrid weaves. CFA is certified to AS9100 Rev D., the worldwide management system normal for the Aircraft, Area and Defense (AS&D) business, as well as ISO9001.

“Carbon fiber is very strong and durable. It starts as a textile, but when it’s encapsulated in a resin and cured, it holds a shape, yet it is very lightweight. That makes it an excellent solution for aerospace use,” says David Shippee, CFA government director of sales. “We have perfected how to weave fibers to create high-tech fabrics, which perform well for our space customers. We can produce fabrics that have structural integrity, resist temperature changes, are strong and durable—basically, they are lighter, stronger, better. They save on fuel and deliver very high performance.”

The firm works intently with clients to develop textiles that go well with their design and performance necessities. While CFA’s merchandise have been perfected for use in area, many specialty Earth-bound corporations discover these high-performance supplies work nicely on the bottom.

“Some customers require technical fabrics for applications such as boats, extended solar arrays, barrier systems, vehicles, aircraft seat frames or sporting equipment,” says Shippee, noting that many luxurious and racing cars are integrating carbon fiber material into their designs. On Earth, carbon offers the same gasoline financial savings and durability it demonstrates in area.

“In many applications, if it’s made from plastic, it can be made better with carbon fiber fabrics,” he says.

Go well with up and wrap up

The fabrics produced by CFA and other specialty material suppliers that innovate for area find yourself in a variety of products. But perhaps none are as exciting as area suits. David Clark Co., based mostly in Worcester, Mass., is a pioneer within the subject, partnering with the Mayo Clinic in the 1940s to develop anti-G fits to protect Allied pilots from blacking out throughout high-G maneuvers.

“Some of David Clark’s early prototypes leveraged his ‘straightaway garment,’ which was essentially the Spanx® of the day,” says Shane Jacobs, softgoods design supervisor, Aerospace Life Help Methods, David Clark Co. Publish-war, the corporate continued to refine its go well with designs for rocket aircraft check pilots. As the area race ignited, this experience turned to multilayer full-pressure go well with development.

“We’ve been involved in every human space and high-altitude program since Gemini, including the Apollo Block 1 suits, the space shuttle program suits and the suits in development now for the Boeing CST-100 Starliner [Boeing’s next-generation space capsule that will take people to and from low-Earth orbit],” Jacobs says.

“Every suit we design is a little different. Requirements vary for suborbital versus orbital missions; the user might be suited for the duration of the flight or just for the launch. Some suits are lightweight and minimal complexity, such as the suit designed for the Starliner. Others are for longer duration missions to deep space, such as the suits for NASA’s Orion spacecraft. Those integrate complex systems, such as a feeding port, waste management and liquid cooling system. A consistent focus is always to design each suit to be low bulk, highly mobile and comfortable.”

Sample designers and engineers check go well with elements by way of CAD modeling and prototyping before manufacturing, Jacobs says. Suits are tested in quite a lot of environments, including underwater to simulate microgravity.

“Inside the suit, you are essentially in your own personal spacecraft,” he says. “It needs to be airtight yet selectively permeable to allow water vapor to escape. Other requirements are fire retardancy and high strength. We use low-elongation fabrics that will hold their shape while allowing people to move. You have to design the suit from the inside and understand what the user is feeling. If the suit isn’t optimally sized or is designed improperly, it can be pretty painful when it is pressurized.”

Naturally, he’s tried one on, although Jacobs hasn’t yet gone into orbit himself. However he says the company has an in depth eye on efforts to get shoppers into area, and he hopes to someday be a part of them. Within the meantime, the applied sciences the company has innovated for area are discovering a task in purposes on Earth, akin to Reebok’s Floatride Run Fast footwear, which advanced from an area boot design the corporate developed.

Much less glamorous than area suits, but no much less important are Multi-Layer Insulation (MLI) Blankets, similar to those designed by Aerospace Fabrication & Supplies LLC, Farmington, Minn. Comprised of a thin plastic film materials simply zero.00025 to zero.00033 inches (6 to 8 microns) thick and low conducting material spacers, these engineered thermal management blankets are used to insulate essential gear within the Area Shuttle Orbiter, the Worldwide Area Station, geospatial satellites, datacom satellites and cryogenic purposes.

“Think about it the way you’d look at insulation for your house; these blankets serve as a passive thermal control device for spacecraft,” says Brent Anderson, owner of Aerospace Fabrication. “They help protect and maintain instruments at room temperature inside.” In line with the essential have to maintain weight down in aerospace products, the blankets function an alternating layer development. “They are extremely lightweight. The internal layers are a loose-weave, almost bridal veil type fabric and metalized plastic film. Even though we use up to 20 layers, it only weighs a couple of ounces per square foot. On the outside, the material is coated with metals. That shiny surface reflects incoming thermal radiation off the surface.”

Anderson’s firm is all the time on the lookout for new materials or mixtures of fibers, he says. Along with weight, low conductivity and optical properties, the textiles used in these purposes must endure the tough surroundings of area. “We end up going out often to talk with the fabric industry to see what is new,” Anderson says. “For instance, 3D weaving is really taking off. We are watching that to see how we might incorporate it into our products.”

Whilst area purposes improve, the company faces a challenge that many producers in the aerospace market experience: relatively small demand. To keep a gentle backside line, the corporate additionally produces technical tapes and printed circuits and cables for the electronics business. “We want specialized materials that do extraordinary things, but we don’t tend to buy a lot of any one thing, so the price goes up for us,” Anderson says. “It doesn’t tend to be something most suppliers want to support, because the business ebbs and flows so much. Even as the need for space textiles increases, it’s still a small market compared to others.”

Raven Aerostar is the only provider to the NASA Balloon Program Office, offering both Zero Strain and Super Strain Balloons (SPB) for scientific missions. This flight’s objective was to check and validate the SPB know-how with the objective of long-duration flight (100+ days) at mid-latitudes. Photograph: NASA.

Nearer to house

Not all aerospace textiles make it to outer area. The stratosphere, the second layer of the Earth’s environment within the zone above the clouds, is turning into increasingly crowded with specialty high-tech balloons and airships. Textile-based purposes are perfect for this zone, which is characterized by thin air, limited weather events, exposure to the ozone layer and high levels of ultraviolet radiation from the solar. Raven Aerostar, Sioux Falls, S.D., has been innovating high-altitude textiles and stratospheric balloons because the 1950s.

“These are products that will fly two to five times as high as airplanes, so we need to make sure they meet extremely high quality standards,” says Joe Beck, Raven Aerostar plant manager and program manager. “The materials and the construction must be very robust to endure the external conditions, which can range in temperature from -50°C to -90°C [-60°F to -130°F]. These are typically filled with helium, so impermeability is a critical factor as well.”

Composed of “lighter-than-air” engineered polymer-based movies, Raven Aerostar’s stratospheric balloons look as delicate as a butterfly, but they will carry payloads up to 4 tons, acquire info used in scientific analysis, carry out army surveillance and help in GPS, radar and remote communications endeavors. As a division of Raven Industries, Raven Aerostar works intently with Raven Engineered Films, the division that develops the specialty polymer film and sheeting used in these purposes.

“We have our material design expertise right next door, so it’s easy to develop new materials for specific customer needs,” Beck says. “Our goal is always thinner, lighter and stronger.”

The rising area financial system may even create demand for textile merchandise that never depart Earth. Take the work of SLO Sail and Canvas of San Luis Obispo, Calif. The company focuses on marine fabrication, but army and aerospace organizations—together with Area X, California Polytechnic State University, the Nixus Challenge Glider and drone operators—have taken advantage of its design and fabrication know-how.

Applying its experience in versatile yet taut marine merchandise, the company has taken on tasks resembling crash nets for drones and specialty tarps which are put in around missiles and rockets on the launch pad or during development, says Karl Deardorff, SLO proprietor. The tarps are constructed from anti-static material, a essential requirement in an surroundings where a rocket booster is perhaps sitting on 100,000 kilos of rocket gasoline. Some jobs may want particular qualities, similar to polyester, carbon or conductive threads.

“The point is to protect people and equipment from FOD—foreign object debris,” Deardorff says. “A rocket that’s 230 feet high can have six to eight levels of scaffolding, and if something falls, that’s a problem. An anti-FOD tarp may only be 6 to 9 inches wide, but that is enough to avert damage or loss.”

Between NASA’s brief and long-range objectives, a new area race between deep-pocketed personal corporations, and some great benefits of high-tech textiles in area exploration, the aerospace market presents great potential for specialty material suppliers, designers and producers that wish to make their mark in excessive purposes.

“This is a growing area with lots of opportunity,” Deardorff says. “There is a lot of work for us all. We enjoy working closely with our customers on these unique projects, and we enjoy the excitement of designing for an industry with such big ambitions.”

Amy Goetzman is a freelance author based mostly in Maplewood, Minn.

The post The aerospace market – Advanced Textiles Source appeared first on Techno Crats Blog.

1 note

·

View note

Text

The aerospace market – Advanced Textiles Source

As NASA units a course for Mars and a return to the moon, and personal corporations interact in a new area race, textile corporations discover alternatives for high-performance fabrics and merchandise.

by Amy Goetzman

When does a single lemon value $2,000? When it’s in area. NASA stories that it prices about $10,000 in gasoline to launch one pound of payload into area—whether or not that payload is individuals, gear or supplies. Meaning the lemons astronaut Scott Kelly famously juggled on the Worldwide Area Station during his 2015−16 yr in area have been valued at about $2,000 each. Approaching it that method, it’s straightforward to see why supremely lightweight and powerful textiles play a important position in aerospace actions.

A vary of entities make the most of material technologies of their aerospace gear, including NASA, army organizations, airline and aerospace corporations, universities and research establishments, climate and science packages, and Google and datacom corporations. And the growing personal area exploration business, spurred by initiatives together with Elon Musk’s Area X, Jeff Bezos’s Blue Origin and Richard Branson’s Virgin Galactic, guarantees to create space journey accessible to (well-heeled) people who aren’t educated as astronauts. The area financial system is right here, with opportunities for corporations in the specialty materials business that can meet the necessities of utmost environments beyond the clouds.

NASA astronaut Robert Behnken installs ammonia line Multi-Layer Insulation (MLI) blankets, manufactured by Aerospace Fabrication & Supplies, on the Worldwide Area Station during a maintenance and development extravehicular activity session. Photograph: NASA.

Out-of-this-world materials

The people who make area fabrics noticed this coming. Composite Materials of America (CFA), Taylorsville, N.C., a subsidiary of the century-old weaving company Schneider Mills, has seen steadily growing demand for its carbon fiber textiles, notably Textral, a multidimensional carbon fiber weave. The company also produces custom materials and tapes using carbon, aramid, basalt, Innegra, fiberglass and polyethylene fibers, obtainable in unidirectional, bidirectional and hybrid weaves. CFA is certified to AS9100 Rev D., the worldwide management system normal for the Aircraft, Area and Defense (AS&D) business, as well as ISO9001.

“Carbon fiber is very strong and durable. It starts as a textile, but when it’s encapsulated in a resin and cured, it holds a shape, yet it is very lightweight. That makes it an excellent solution for aerospace use,” says David Shippee, CFA government director of sales. “We have perfected how to weave fibers to create high-tech fabrics, which perform well for our space customers. We can produce fabrics that have structural integrity, resist temperature changes, are strong and durable—basically, they are lighter, stronger, better. They save on fuel and deliver very high performance.”

The firm works intently with clients to develop textiles that go well with their design and performance necessities. While CFA’s merchandise have been perfected for use in area, many specialty Earth-bound corporations discover these high-performance supplies work nicely on the bottom.

“Some customers require technical fabrics for applications such as boats, extended solar arrays, barrier systems, vehicles, aircraft seat frames or sporting equipment,” says Shippee, noting that many luxurious and racing cars are integrating carbon fiber material into their designs. On Earth, carbon offers the same gasoline financial savings and durability it demonstrates in area.

“In many applications, if it’s made from plastic, it can be made better with carbon fiber fabrics,” he says.

Go well with up and wrap up

The fabrics produced by CFA and other specialty material suppliers that innovate for area find yourself in a variety of products. But perhaps none are as exciting as area suits. David Clark Co., based mostly in Worcester, Mass., is a pioneer within the subject, partnering with the Mayo Clinic in the 1940s to develop anti-G fits to protect Allied pilots from blacking out throughout high-G maneuvers.

“Some of David Clark’s early prototypes leveraged his ‘straightaway garment,’ which was essentially the Spanx® of the day,” says Shane Jacobs, softgoods design supervisor, Aerospace Life Help Methods, David Clark Co. Publish-war, the corporate continued to refine its go well with designs for rocket aircraft check pilots. As the area race ignited, this experience turned to multilayer full-pressure go well with development.

“We’ve been involved in every human space and high-altitude program since Gemini, including the Apollo Block 1 suits, the space shuttle program suits and the suits in development now for the Boeing CST-100 Starliner [Boeing’s next-generation space capsule that will take people to and from low-Earth orbit],” Jacobs says.

“Every suit we design is a little different. Requirements vary for suborbital versus orbital missions; the user might be suited for the duration of the flight or just for the launch. Some suits are lightweight and minimal complexity, such as the suit designed for the Starliner. Others are for longer duration missions to deep space, such as the suits for NASA’s Orion spacecraft. Those integrate complex systems, such as a feeding port, waste management and liquid cooling system. A consistent focus is always to design each suit to be low bulk, highly mobile and comfortable.”

Sample designers and engineers check go well with elements by way of CAD modeling and prototyping before manufacturing, Jacobs says. Suits are tested in quite a lot of environments, including underwater to simulate microgravity.

“Inside the suit, you are essentially in your own personal spacecraft,” he says. “It needs to be airtight yet selectively permeable to allow water vapor to escape. Other requirements are fire retardancy and high strength. We use low-elongation fabrics that will hold their shape while allowing people to move. You have to design the suit from the inside and understand what the user is feeling. If the suit isn’t optimally sized or is designed improperly, it can be pretty painful when it is pressurized.”

Naturally, he’s tried one on, although Jacobs hasn’t yet gone into orbit himself. However he says the company has an in depth eye on efforts to get shoppers into area, and he hopes to someday be a part of them. Within the meantime, the applied sciences the company has innovated for area are discovering a task in purposes on Earth, akin to Reebok’s Floatride Run Fast footwear, which advanced from an area boot design the corporate developed.

Much less glamorous than area suits, but no much less important are Multi-Layer Insulation (MLI) Blankets, similar to those designed by Aerospace Fabrication & Supplies LLC, Farmington, Minn. Comprised of a thin plastic film materials simply zero.00025 to zero.00033 inches (6 to 8 microns) thick and low conducting material spacers, these engineered thermal management blankets are used to insulate essential gear within the Area Shuttle Orbiter, the Worldwide Area Station, geospatial satellites, datacom satellites and cryogenic purposes.

“Think about it the way you’d look at insulation for your house; these blankets serve as a passive thermal control device for spacecraft,” says Brent Anderson, owner of Aerospace Fabrication. “They help protect and maintain instruments at room temperature inside.” In line with the essential have to maintain weight down in aerospace products, the blankets function an alternating layer development. “They are extremely lightweight. The internal layers are a loose-weave, almost bridal veil type fabric and metalized plastic film. Even though we use up to 20 layers, it only weighs a couple of ounces per square foot. On the outside, the material is coated with metals. That shiny surface reflects incoming thermal radiation off the surface.”

Anderson’s firm is all the time on the lookout for new materials or mixtures of fibers, he says. Along with weight, low conductivity and optical properties, the textiles used in these purposes must endure the tough surroundings of area. “We end up going out often to talk with the fabric industry to see what is new,” Anderson says. “For instance, 3D weaving is really taking off. We are watching that to see how we might incorporate it into our products.”

Whilst area purposes improve, the company faces a challenge that many producers in the aerospace market experience: relatively small demand. To keep a gentle backside line, the corporate additionally produces technical tapes and printed circuits and cables for the electronics business. “We want specialized materials that do extraordinary things, but we don’t tend to buy a lot of any one thing, so the price goes up for us,” Anderson says. “It doesn’t tend to be something most suppliers want to support, because the business ebbs and flows so much. Even as the need for space textiles increases, it’s still a small market compared to others.”

Raven Aerostar is the only provider to the NASA Balloon Program Office, offering both Zero Strain and Super Strain Balloons (SPB) for scientific missions. This flight’s objective was to check and validate the SPB know-how with the objective of long-duration flight (100+ days) at mid-latitudes. Photograph: NASA.

Nearer to house

Not all aerospace textiles make it to outer area. The stratosphere, the second layer of the Earth’s environment within the zone above the clouds, is turning into increasingly crowded with specialty high-tech balloons and airships. Textile-based purposes are perfect for this zone, which is characterized by thin air, limited weather events, exposure to the ozone layer and high levels of ultraviolet radiation from the solar. Raven Aerostar, Sioux Falls, S.D., has been innovating high-altitude textiles and stratospheric balloons because the 1950s.

“These are products that will fly two to five times as high as airplanes, so we need to make sure they meet extremely high quality standards,” says Joe Beck, Raven Aerostar plant manager and program manager. “The materials and the construction must be very robust to endure the external conditions, which can range in temperature from -50°C to -90°C [-60°F to -130°F]. These are typically filled with helium, so impermeability is a critical factor as well.”

Composed of “lighter-than-air” engineered polymer-based movies, Raven Aerostar’s stratospheric balloons look as delicate as a butterfly, but they will carry payloads up to 4 tons, acquire info used in scientific analysis, carry out army surveillance and help in GPS, radar and remote communications endeavors. As a division of Raven Industries, Raven Aerostar works intently with Raven Engineered Films, the division that develops the specialty polymer film and sheeting used in these purposes.

“We have our material design expertise right next door, so it’s easy to develop new materials for specific customer needs,” Beck says. “Our goal is always thinner, lighter and stronger.”

The rising area financial system may even create demand for textile merchandise that never depart Earth. Take the work of SLO Sail and Canvas of San Luis Obispo, Calif. The company focuses on marine fabrication, but army and aerospace organizations—together with Area X, California Polytechnic State University, the Nixus Challenge Glider and drone operators—have taken advantage of its design and fabrication know-how.

Applying its experience in versatile yet taut marine merchandise, the company has taken on tasks resembling crash nets for drones and specialty tarps which are put in around missiles and rockets on the launch pad or during development, says Karl Deardorff, SLO proprietor. The tarps are constructed from anti-static material, a essential requirement in an surroundings where a rocket booster is perhaps sitting on 100,000 kilos of rocket gasoline. Some jobs may want particular qualities, similar to polyester, carbon or conductive threads.

“The point is to protect people and equipment from FOD—foreign object debris,” Deardorff says. “A rocket that’s 230 feet high can have six to eight levels of scaffolding, and if something falls, that’s a problem. An anti-FOD tarp may only be 6 to 9 inches wide, but that is enough to avert damage or loss.”

Between NASA’s brief and long-range objectives, a new area race between deep-pocketed personal corporations, and some great benefits of high-tech textiles in area exploration, the aerospace market presents great potential for specialty material suppliers, designers and producers that wish to make their mark in excessive purposes.

“This is a growing area with lots of opportunity,” Deardorff says. “There is a lot of work for us all. We enjoy working closely with our customers on these unique projects, and we enjoy the excitement of designing for an industry with such big ambitions.”

Amy Goetzman is a freelance author based mostly in Maplewood, Minn.

The post The aerospace market – Advanced Textiles Source appeared first on Techno Crats Blog.

1 note

·

View note