#machine for making bricks

Text

May the colors of Holi ignite the flames of creativity and inspiration within you

SnPC Machines: Factory of bricks on wheel

Brick Making Vehicle Or Best Brick Making Company: Our Machines Are Designed To Be Mobile Or Portable Units And Can Be Easily Transported To The Site Where The Clay Bricks Are Required We Have A Assembly Plant In India. Our Mobile Brick Making Machines Are Viral And Trending In The Name Of SnPC Clay Mobile Brick Making Machines India, SnPC Clay Mobile Brick Making Machines Nepal, SnPC Clay Brick Making Machines In Bangladesh, Clay Brick Making Machine In Afghanistan, SnPC Brick Making Machine India, SnPC Red Brick Making Machine In Tamilnadu, SnPC Brick Making Machine In Tamilnadu, SnPC Brick Making Machine In Assam, SnPC Brick Making Machine Utterpradesh, SnPC Brick Making Machine Rajasthan, SnPC Brick Making Machine Punjab, SnPC Brick Making Machine Uttarakhand, SnPC Brick Making Machine Haryana, SnPC Brick Making Machine Bihar, SnPC Brick Making Machine Karnataka, SnPC Brick Making Machine Andhra Pradesh, SnPC Brick Making Machine Telangana, SnPC Brick Making Machine Odisha, SnPC Brick Making Machine Maharashtra, SnPC Brick Making Machine Gujarat, Clay Brick Making Machine In Uzbekistan, Clay Brick Making Machine In Kyrgyzstan, Clay Brick Making Machine In Kazakhstan,SnPC Brick Making Machine In UP, SnPC Mobile Clay Brick Making Machine In Saudi Arabia And Clay Brick Making Machine With Dryer.

#snpc machines#brick making machine#Holi wishes#Machine for making bricks#Innovation in brick making#BMM160#SBM180#BMM310#BMM410#BMM400

3 notes

·

View notes

Text

working on more old wips. i spent so long on this one i really should finish it, messing around with rough colors. idk how i want to color this one yet.

#wip#think this brush is too grainy though. i should use something smoother since the lines are so fine and low res#sleep anxiety is still making my brain feel like a washing machine with a brick in it so i cant promise when this will be done#but it will be done#paladin danse

179 notes

·

View notes

Text

Hello I offer you this once in a lifetime WIP and then I go back to the abyss

If you would like to see more bloody Akaza doodles, stick around

#akaza#kny akaza#akaza kimetsu no yaiba#akaza fanart#kny#I need to make him all bloody all the time#my little pookie bear#my little meow meow#my little messy eater#need to throw bricks at him and grab him by the hair and yank him around#I need to put him in a washing machine and watch him swirl and spin around#hopey’s doodles

18 notes

·

View notes

Text

the fact that bucky barnes, internationally wanted fugitive, was canonically- canonically -a scrapbooker

#bucky barnes#looks like a harley-riding brick shithouse of a rocker but is actually a soft pastel cottagecore hipster.#cacw#😩#bucky meta#meta#mcu#mcu meta#hydra: we are going to turn this man into a terrifying killing machine#actual disney princess bucky in his prison cell: [bonding with the rats growing teeny mushrooms from the wall moss]#hydra: ...we are going to start by throwing out his whole personality#bucky: this entire apartment is laid out tactically so I can destroy anyone who breaks in...#also bucky: ...except for that corner. that's my crafting corner.#*ed: he can fight using the contents of his crafting corner too; he'll just be super mad about it#He makes super-suit suggestions. He goes to market to buy plums. He scrapbooks. He runs a small goat farm(?) in Wakanda.

250 notes

·

View notes

Text

I may or may not have started a project that will probably overwhelming me...

#by the time that copper tower completely ages i should have prepared everything...#the tall pallete is for the fantasy towers i will build on a windswept mountain next to my base#the small pallete is for the entire village#i dont get why most minecraft players hate the new bamboo blocks.. they're pretty!!#a bit biased because I use bamboo for my little Filipino hut as a main base#but really there's so much to bamboo people are probably missing on... it works well with cherry. blackstone. warped and crimson. mud bricks#and there's so much variety you get from crafting bamboo blocks as well...#BUT YEAH this is my first minecraft project and tbh i am scared 😂 but ey... been wanting to do this for the longest time...#my last village didn't quite do well... now im determined to make this work...#this is gonna be a big task as i cant build redstone machines... it'll kill my phone 😂😂😭😭😭... no automation all manual...#that's enough rambling from me... have a good day! ✨#wyn talks :)#minecroof

14 notes

·

View notes

Text

Durable Clay brick making machine

SnPC Machines: Clay brick making machine manufacturers in India

SnPC Machines India Is A Leading Manufacturer Of Brick Making Machines Specially The Mobile Brick Making Machines Bmm160, Bmm310, Bmm400, Bmm404 And Sbm180 All The Models Can Be Tailored As Per The Customers Requirements For Both Indian And Overseas Customers.

#SnPC Machines#clay brick making machine#machine for making brick#red clay brick machine#BMM310#best clay brick machine in India#innovation in brick machine#red soil brick machine#brick machine India#brick machine Gujarat

2 notes

·

View notes

Text

sewing shed time tomorrow, finally gonna make that apron for work and the black hoodie inspired by Maya from the newest Silent Hill game 👀🙏

#willing it into existence tbh#idk how i'll feel after stripping down the walls of my room to the brick#i just wanna CREATE!!!!!!!!! AUGHHHHH!!!!!#also just wanna see how i'll fare with the apron at work. if it'll keep me safe from all the popcorn and nacho crumbs#and the splashback from the soda fountain and the slushie machine#alsooooo oversized sporty hoodie!!!!! with big pockets and long sleeves with thumbholes to make sweater paws!!!!!!

3 notes

·

View notes

Text

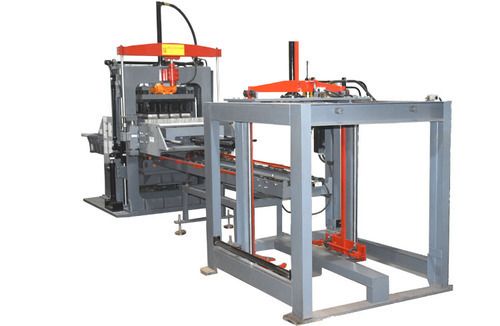

A Comprehensive Guide to Hydraulic Paver Block Making Machine

Welcome to "A Comprehensive Guide to Hydraulic Paver Block Making Machine." In the ever-evolving world of construction and infrastructure development, the significance of efficient and eco-friendly building materials cannot be overstated. Paver blocks have emerged as a popular choice due to their durability, versatility, and aesthetic appeal. At the heart of this revolution lies the Hydraulic Paver Block Making Machine – a game-changing technology that has transformed the production of paver blocks.

This article aims to delve into the intricacies of Hydraulic Paver Block Making Machine, providing a detailed exploration of their working principles, key components, and various types available in the market. We will uncover tips and some troubleshooting steps.

Moreover,we will highlight essential considerations for selecting the right machine that aligns with specific project requirements. Whether you are an industry professional seeking to optimize production processes or an enthusiast eager to grasp the mechanics behind paver block manufacturing, this guide will equip you with invaluable insights.

Understanding Hydraulic Paver Block Machine Specifications

When it comes to hydraulic paver block machines, understanding their specifications is crucial for making informed decisions. These machines are essential for producing high-quality, durable, and aesthetically pleasing paver blocks used in various construction projects.

Hydraulic paver block machine specifications encompass a range of key features. The capacity, which determines the number of blocks produced per hour, directly impacts productivity. The molding area size affects the dimensions and shapes of the blocks. Additionally, the power and pressure rating influence the machine's efficiency and performance.

Moreover, it's essential to consider the automation level and control system, as advanced automation ensures precision and ease of operation. The type of molds compatible with the machine allows for versatility in block design. Understanding these specifications empowers buyers to select the ideal hydraulic paver block machine that aligns with their specific project requirements, resulting in cost-effective and successful paving solutions.

Choosing the Right Paver Type: Interlocking vs. Non-interlocking

When it comes to selecting the right paver type for your project, the choice between interlocking and non-interlocking pavers plays a crucial role in determining the overall outcome. Here are some key points to consider for each option:

Interlocking Pavers:

Interlocking pavers are designed to fit tightly together, creating a durable and stable surface.

They offer excellent load-bearing capabilities, making them ideal for driveways, walkways, and high-traffic areas.

The interlocking design provides flexibility, allowing them to withstand ground movement without cracking.

These pavers come in various shapes, colors, and patterns, enabling versatile and visually appealing designs.

Installation is relatively easier due to the interlocking system, reducing labor time and costs.

Repairs are simple, as individual pavers can be replaced without affecting the entire surface.

Non-Interlocking Pavers:

Non-interlocking pavers are more affordable compared to their interlocking counterparts.

They are suitable for light to moderate traffic areas like patios, garden pathways, and decorative landscape elements.

Installation may require more precision and skill as they do not have the interlocking mechanism.

Although repairs are possible, they might be more labor-intensive and could involve replacing larger sections.

Pro Tips for Maintaining Your Paver Block Making Machine

Regular Cleaning: Clean the machine daily to remove any residual concrete and debris that can cause blockages or malfunctions.

Lubrication: Keep all moving parts well-lubricated to reduce friction and prevent wear and tear.

Inspection: Conduct routine inspections to identify and address any signs of wear, damage, or misalignment promptly.

Tighten Bolts: Check and tighten all bolts and nuts regularly to maintain stability and prevent vibrations.

Replace Worn Parts: Replace worn-out parts immediately to prevent further damage and ensure optimal performance.

Calibration: Calibrate the machine regularly to ensure accurate and consistent block dimensions.

Electrical Connections: Inspect and secure electrical connections to prevent electrical issues.

Professional Maintenance: Schedule periodic maintenance by qualified technicians to address complex servicing and extend the machine's lifespan.

Operating Guidelines: Train operators on proper machine operation and safety protocols to prevent mishandling or accidents.

Store in Shelter: Store the machine in a sheltered area to protect it from weather conditions and extend its longevity.

Troubleshooting Hydraulic Paver Block Making Machine

Low Block Quality: Adjust the hydraulic pressure and ensure proper alignment of molds to improve block quality.

Block Disintegration: Check the mix proportions of raw materials and the curing process for better block strength.

Oil Leaks: Inspect hydraulic hoses and connections, repair or replace damaged parts, and refill hydraulic oil as needed.

Excessive Noise/Vibrations: Tighten loose components and bolts, and ensure proper leveling of the machine.

Uneven Block Height: Verify uniform material distribution in the mold and calibrate the machine for consistent block height.

Machine Not Starting: Check power supply, fuses, and safety switches; repair or replace faulty electrical components.

Insufficient Block Production: Clean and maintain the machine regularly, and optimize the production process for efficiency.

Irregular Block Shapes: Inspect mold condition, ensure proper vibration, and adjust mold settings to achieve uniform shapes.

Safety Hazards: Implement strict safety protocols, provide training to operators, and display safety guidelines prominently.

Seek Professional Help: If issues persist, consult experienced technicians or manufacturers for advanced troubleshooting and repairs.

Conclusion

A Comprehensive Guide to Hydraulic Paver Block Making Machine highlights the indispensable role of perfect hydraulic machines in revolutionizing paver block production. The detailed exploration of working principles, types, and maintenance underscores their efficiency and eco-friendly advantages. By embracing these cutting-edge technologies, the construction industry gains a competitive edge in creating durable and visually appealing infrastructure. As Perfect Hydraulic Machines continue to shape the future of paver block manufacturing, their impact on sustainable construction practices remains unparalleled.

#Hydraulic Paver Block Making Machine#perfect hydraulic machines#hydraulic machines#Fly Ash Brick Machine

2 notes

·

View notes

Text

https://karanengineering.com/

Fly Ash Brick Making Machine manufacturers

2 notes

·

View notes

Text

I am finding that the more I learn about and understand and even like myself, the less palatable I become.

It’s very hard. To know what to do.

I am making sense to myself for the first time in years. I am proud of who I am finding out I am. I am relieved to be making peace and headway. But even when I find relief in acceptance of something I was ashamed of before, I cannot un-hide it from the world. It was buried for a reason.

I am not afraid of the other parts of me, or ashamed of them. I’m glad they’re with me. I am not ashamed of being them, but I am afraid of what other people will think and do if they know. I cannot make them feel the way I do.

I like the parts of me I am discovering and making peace with, healing.

But they were broken for a reason.

The more of them I fix and find, the less of myself I can share with anyone.

It’s hard.

To be more okay and more awake. To dig up parts you buried. And then brick them up in the walls.

#I think you can’t understand this if it’s not what you are. and it’s not always the same. sexuality and romance were not as hard for me#because they weren’t something at play every second of every day of my life. they’re part of me. big parts. but they aren’t /me/.#I think trans people do get it. certain mental illnesses. personality disorders. things that are never gone. always you always there always#screaming to be known and acknowledged and let out. you can’t imagine how hard that is#how it is not to want to hide something or be ashamed of it. to want it to be known and grown and loved. and have to hide it in the walls of#your head so it doesn’t discomfort the people you love. so they’re not sad. or too worried. or disappointed. or because you’re scared. of#all the new ways people from laws to loved ones could and would hurt you as soon as they caught wind#for every choice to talk even a little to be a balancing act potentially with the rest of your life.#you cannot begin to know the rage and the pain and the hopelessness of that and knowing the situation will /never/ change#it’s not sometimes it’s always. always you want you you like and know to be known and loved and supported and helped to heal and grow. to#get to just /be/ at all. to get to be alive instead of always hiding in the shadows jumping at noise#and having no hope you will ever get there at all. even with just ten people for the rest of your life#to have pieces click into place for the first time in decades and the machine starts and you are proud and relieved and joyful#but you have to hide it for the rest of your life because it would be too painful for people who love you and it’s selfish to cause pain#why? it’s not fair. it shouldn’t cause pain. I’m not ashamed or scared. people who love me shouldn’t be either. why is it wrong to openly#be who I am to people who love me? why is it right to brick myself up again? why doesn’t anyone say ‘no you’re wrong#don’t brick it up.’ why can’t I either? I know the situation. I know you have to put survival first#that does not. make it fair#poetry#痛い痛い痛い痛い痛い#don’t ask me what this is about. if I can’t talk to my own family I sure as hell am not going to talk to a stranger about it

6 notes

·

View notes

Text

My overall thoughts on BATDR:

Honestly, Even with some of the flaws to the game- and how some characters were underused, n how they fucked over Sammy- I really did love the game. Story wise I thought it was? Not bad! I actually, really liked it d:] Biting and Attacking Wilson- I was super surprised when Nathan- wasn’t ‘bad’- Was absolutely expecting him to be cruel, and wicked- and take control over the ink machine himself. Surprised to learn it was his SON- The Janitor of his own studio who did.

The whole thing w Joey- I also rly Liked. I had a FEELING that Audrey would be related to Joey in the end- Really love the idea of just, Him creating her from the machine and raising her- The bit of Allison coming into his life and making him sort of, change his ways, and give ‘Henry’ his own angel was nice d:]

SPEAKING OF HENRY. I LOVE HIM. I was so worried what his design would look like- and I love it sm. Sweet old man- I’m giving him a kiss. The bit w him in his cell made me scream- the moment I heard him speak i lost it JKJLG,K.FDSHJG He sounded so defeated and just. Accepting of what the ‘cycle’ became n that being his new reality- it made me so sad. Dude is just TIRED let him REST. PLEASE!!!!!!!!!!!!!!!!

The ending like chapter 5 of batim was a lil jumbled, but I did love that Audrey has sort of- taken up the role of control on the story now. Hopefully she’s able to give everyone a happier ending- AND. THE IDEA OF THEM BEING ABLE 2 CROSS INTO OUR WORLD NOW!!!!!!!! A. Means they can finally escape the studio n maybe? try and live- semi ‘normal’ lives w Audrey.

Overall this game has: made me love n Cherish Bendy even more- fuck Wilson, and the keepers- I’m mauling them for HURTING MY BOY-!

But yea. I rly liked it d:) Excited to see if we get

anything else- like a dlc, or something.

#Cade.Txts#this is not agt all coherent i just kinda rambled.#BATDR Spoilers#batim spoilers#spoilers#also do not understand why people r so suprised at gent not being 'normal' or 'bad' because like.#wbhat sort of construction company or brick laying company can make something like the ink machine- given what it Does-#to me its pretty obvious they were NEVER normal- clearly they've HAD alternative motives.#excited to see if we learn More aout that or not d:0

6 notes

·

View notes

Text

Stand by machine, SBM-180 dispatched to Gujarat, India

SnPC Machines: Factory on brick on wheel

Stand by brick making machine, SBM-180 dispatched to Gujarat, India by SnPC Machines. SnPC Machines is supplying fully automatic brick making machine all across the world and bringing a great revolution in construction industry.

instagram

#SnPC Machines#brick making machine#clay brick machine#top quality bricks#brick machine India#brick machine Delhi#brick machine Haryana#Team SnPC#machine for making bricks#BMM410#BMM310#BMM160#Instagram

4 notes

·

View notes

Text

it was too much i had to make my own post

line cook here. ACCURATE

if you don't get the hate, here's what you don't understand.

it takes up to 2 hours to close down the kitchen.

The last 60-90 minutes before closing time you do almost no cooking because the restaurant doesn't have many people in it and you've already cooked most of their diners.

So if someone walks in during, like, the last hour, the cook is in the middle of an industrial deep clean of the kitchen.

(these numbers can vary quite a bit from place to place but i have worked several restaurants with these actual times and the concept remains the same)

Say the place closes at 10. If you wait til the restaurant is already closed to start all your cleaning duties, you'll be there until at least midnight.

More than that your boss knows that on an average night you can start your clean up as soon as the last rush ends and get out of there around 10:45, even 10:15 on a slow night if you get lucky. That means there are plenty of restaurants where if you do take until midnight the manager is going to come up to you at some point that week and ask you what went wrong that night, and you'd better have an answer.

So this example restaurant closes at 10 pm. The dinner rush ends around 8:30, and shortly after that the cook is going to start getting every single dish possible over to the dishwasher because the dishwasher always gets hit hard and late, and the machine runs for 2 full minutes and only holds so many dishes, so the way that works out is if you wait an extra 30 minutes to give the dishwasher all your stuff it can mean adding like 60 minutes to the end of his shift. And you're gonna KEEP finding shit to send to the dishpit right up until you leave probably.

all these little square and rectangle containers in this cold table have to be pulled out and changed over into new containers, replaced by new full ones, or in some cases filled from larger containers in the back, which can result in even more empty containers to send to the dishwasher.

while it's all pulled apart to do this, you have to clean up all the spilled food and sauce and juices and stuff from the joints and ledges and shelves and drip trays

Once you get your line changed over in this way, and fully stocked, anytime someone orders something that makes use of a bunch of that stuff, you have to restock and re-clean it some. It might already be covered in plastic. Some of it might already be stuck in the back to make room to take apart your cutting board counter to clean. To cook a dish isn't TOO much of a problem at this point, but you're really hoping for zero orders because you still have so much other cleaning to do.

Meanwhile the salad bar and appetizer section and server station and everybody are all doing the same thing. Even the bartenders are stocking olives and lemons and sending back whisks and stir spoons and shakers and empty 4quart storage containers that used to hold the back-up lemons and olives and things. Every section is dumping their must-be-cleaneds to the dishpit as fast as possible because early and fast is the only thing they can do to to help that dishpit not absolutely drown into overtime.

The poor dishwasher is always the last to clock out, soaking wet and exhausted.

Around this time you probably scrub the flat top, which has turned black from cooked on grease and is still about 500 degrees. Line cooks are divided in opinion on water-based or oil based cleaning methods for this, but they all involve scrubbing with (usually) a brick of pumice stone using every ounce of your strength while you try not to burn yourself

you scrub it from fully blackened to gleaming silver and now if somebody orders something that needs the flat top to cook, you can either fuck up your cleaning job or fake it in a couple frying pans and pass that tiny fuck you down to your dishwasher (who usually understands, especially if you help them take the garbage out or clean your own floor drain later)

If there's deep fried stuff on the menu then the fryers have to be cleaned out, which includes straining the oil out into enormous and super-heavy pots full of oil so hot that if you spill on yourself then it's probably a hospital visit and if you slip and fall face first into it it'll be the last thing you ever do.

Then you gotta scrub out the fryer. Like you gotta take the (hot) screen out and reach your arm down into the weird rounded pipes and curved areas (so hot, burn you if you brush against them hot) and scrub off whatever is down there

Depending on your kitchen you might have to do up to four of these. Then you'll have to pour the (dangerously hot) oil back in

oh, and if you didn't dry the pipes and get ALL the water out of the trap and tank?

water reacts with hot oil in a sort of mentos and coke way that can send a tidal wave of oil past the open flame of the pilot light ...HUGE dangerous mess and/or burn down the kitchen if the oil lights up.

Unless! If the oil has been used too hard and needs to be changed, it's time to carry those open topped super heavy pots full of will-kill-you-hot oil and dump them in the barrel outside by the dumpsters so you can put room temp fresh oil in the fryers. whew!

The clean up is not just some light wiping down that can be easily interrupted, is what i'm saying.

You might have to do some kind of walk-in duty (moving around 50lb cases of lettuce and 50lb bags of onions to get to the stacks of five gallon buckets full of salad dressings and sauces to move so you can reach the giant metal pots and bus tubs full of prep and get it all organized and make sure it's all labeled and i have to stop now i'm having flashbacks)

THE POINT IS

by 15 or however many minutes to close, the line cook is doing an intense deep clean and probably has the whole stove taken apart to detail.

For some industrial stoves this means lifting off large cast iron plates that weigh like 20 lbs each and are still quite hot. Whatever metal burners are on there, you gotta take off and clean, you can see here the lines that indicate the large thick cast iron rectangles that sit on top of the burners to allow heavy pots to rest on. Those five (each has one front burner hole and one back burner hole, see?) have to be lifted off and cleaned with soap and a wire brush usually, and then the underneath area also has to be cleaned because a lot of shit falls through the burner holes on a busy night.

if you didn't do it when you did the flat top you have to do the grease trap (which can be like a full five minutes and is always disgusting).. You gotta clean out all the little gas jets in each burner with a wire or something so the burners all flame evenly, and sometimes you have to remove some of the natural gas piping that connects the burners to access where you have to clean.

you gotta clean out the bottom of the oven and the wire racks, and, oh gods, you gotta take down the filter vents from the hood fans above the stove.

See all the lined parts along the top of the wall?

those are hood vents, and as they pull air up they also pull a lot of grease and they have to be taken down and cleaned, then you gotta climb up there and scrub where they go before you put them back...

And then there's the mopping and floor drains and...

Anyway, that's what the line cook is doing when you walk in fifteen minutes before closing and order something that needs to be cooked on that stove. They are doing an entire industrial cleaning of a professional kitchen.

In some restaurants maybe one or two of these jobs will be every other night or even only twice a week, but in many, possibly most kitchens, ALL of these things happen EVERY night. You don't want to leave any food mess that might attract insects or rodents for one thing, so a really good kitchen is as close to brand new as you can get it every night.

IF YOU ABSOLUTELY HAVE TO ORDER SOMETHING ANYWAY, HERE IS WHAT TO DO

open with an apology and ask the server to go ask what the cook would prefer you to order.

Any good server will already know what the cook is hoping for and what will make their line cook go into the walk in and scream. If it's significantly less than an hour to close and they say some variant of "oh anything is fine" they are either telling the lie their boss wants them to say, or they actually do not know what their line cook wants, and you can either use human connection and a conspiratorial just-between-us tone to get them to drop the customer-is-always-right act, or get them to actually go ask the cook.

It might be as specific as "the lasagna is easiest on the kitchen" or it might be a simple guideline like "nothing that requires the flat top" or "any of the sautés are easy" but a good line cook will probably have a system for if they have to make a couple of the most popular items after they start their close, so the answer is likely to include something most people like and you should be good to order that.

but for the love of all that's holy, please only do so at great need. Leave that last 30-60 minutes to the truly desperate and the crew's duties.

#long post#sorry#i just have a lot of DO PEOPLE UNDERSTAND feelings left over from all my years in restaurants#restaurants#line cook#service industry

27K notes

·

View notes

Text

“If buying isn’t owning, piracy isn’t stealing”

20 years ago, I got in a (friendly) public spat with Chris Anderson, who was then the editor in chief of Wired. I'd publicly noted my disappointment with glowing Wired reviews of DRM-encumbered digital devices, prompting Anderson to call me unrealistic for expecting the magazine to condemn gadgets for their DRM:

https://longtail.typepad.com/the_long_tail/2004/12/is_drm_evil.html

I replied in public, telling him that he'd misunderstood. This wasn't an issue of ideological purity – it was about good reviewing practice. Wired was telling readers to buy a product because it had features x, y and z, but at any time in the future, without warning, without recourse, the vendor could switch off any of those features:

https://memex.craphound.com/2004/12/29/cory-responds-to-wired-editor-on-drm/

I proposed that all Wired endorsements for DRM-encumbered products should come with this disclaimer:

WARNING: THIS DEVICE’S FEATURES ARE SUBJECT TO REVOCATION WITHOUT NOTICE, ACCORDING TO TERMS SET OUT IN SECRET NEGOTIATIONS. YOUR INVESTMENT IS CONTINGENT ON THE GOODWILL OF THE WORLD’S MOST PARANOID, TECHNOPHOBIC ENTERTAINMENT EXECS. THIS DEVICE AND DEVICES LIKE IT ARE TYPICALLY USED TO CHARGE YOU FOR THINGS YOU USED TO GET FOR FREE — BE SURE TO FACTOR IN THE PRICE OF BUYING ALL YOUR MEDIA OVER AND OVER AGAIN. AT NO TIME IN HISTORY HAS ANY ENTERTAINMENT COMPANY GOTTEN A SWEET DEAL LIKE THIS FROM THE ELECTRONICS PEOPLE, BUT THIS TIME THEY’RE GETTING A TOTAL WALK. HERE, PUT THIS IN YOUR MOUTH, IT’LL MUFFLE YOUR WHIMPERS.

Wired didn't take me up on this suggestion.

But I was right. The ability to change features, prices, and availability of things you've already paid for is a powerful temptation to corporations. Inkjet printers were always a sleazy business, but once these printers got directly connected to the internet, companies like HP started pushing out "security updates" that modified your printer to make it reject the third-party ink you'd paid for:

https://www.eff.org/deeplinks/2020/11/ink-stained-wretches-battle-soul-digital-freedom-taking-place-inside-your-printer

Now, this scam wouldn't work if you could just put things back the way they were before the "update," which is where the DRM comes in. A thicket of IP laws make reverse-engineering DRM-encumbered products into a felony. Combine always-on network access with indiscriminate criminalization of user modification, and the enshittification will follow, as surely as night follows day.

This is the root of all the right to repair shenanigans. Sure, companies withhold access to diagnostic codes and parts, but codes can be extracted and parts can be cloned. The real teeth in blocking repair comes from the law, not the tech. The company that makes McDonald's wildly unreliable McFlurry machines makes a fortune charging franchisees to fix these eternally broken appliances. When a third party threatened this racket by reverse-engineering the DRM that blocked independent repair, they got buried in legal threats:

https://pluralistic.net/2021/04/20/euthanize-rentier-enablers/#cold-war

Everybody loves this racket. In Poland, a team of security researchers at the OhMyHack conference just presented their teardown of the anti-repair features in NEWAG Impuls locomotives. NEWAG boobytrapped their trains to try and detect if they've been independently serviced, and to respond to any unauthorized repairs by bricking themselves:

https://mamot.fr/@[email protected]/111528162905209453

Poland is part of the EU, meaning that they are required to uphold the provisions of the 2001 EU Copyright Directive, including Article 6, which bans this kind of reverse-engineering. The researchers are planning to present their work again at the Chaos Communications Congress in Hamburg this month – Germany is also a party to the EUCD. The threat to researchers from presenting this work is real – but so is the threat to conferences that host them:

https://www.cnet.com/tech/services-and-software/researchers-face-legal-threats-over-sdmi-hack/

20 years ago, Chris Anderson told me that it was unrealistic to expect tech companies to refuse demands for DRM from the entertainment companies whose media they hoped to play. My argument – then and now – was that any tech company that sells you a gadget that can have its features revoked is defrauding you. You're paying for x, y and z – and if they are contractually required to remove x and y on demand, they are selling you something that you can't rely on, without making that clear to you.

But it's worse than that. When a tech company designs a device for remote, irreversible, nonconsensual downgrades, they invite both external and internal parties to demand those downgrades. Like Pavel Chekov says, a phaser on the bridge in Act I is going to go off by Act III. Selling a product that can be remotely, irreversibly, nonconsensually downgraded inevitably results in the worst person at the product-planning meeting proposing to do so. The fact that there are no penalties for doing so makes it impossible for the better people in that meeting to win the ensuing argument, leading to the moral injury of seeing a product you care about reduced to a pile of shit:

https://pluralistic.net/2023/11/25/moral-injury/#enshittification

But even if everyone at that table is a swell egg who wouldn't dream of enshittifying the product, the existence of a remote, irreversible, nonconsensual downgrade feature makes the product vulnerable to external actors who will demand that it be used. Back in 2022, Adobe informed its customers that it had lost its deal to include Pantone colors in Photoshop, Illustrator and other "software as a service" packages. As a result, users would now have to start paying a monthly fee to see their own, completed images. Fail to pay the fee and all the Pantone-coded pixels in your artwork would just show up as black:

https://pluralistic.net/2022/10/28/fade-to-black/#trust-the-process

Adobe blamed this on Pantone, and there was lots of speculation about what had happened. Had Pantone jacked up its price to Adobe, so Adobe passed the price on to its users in the hopes of embarrassing Pantone? Who knows? Who can know? That's the point: you invested in Photoshop, you spent money and time creating images with it, but you have no way to know whether or how you'll be able to access those images in the future. Those terms can change at any time, and if you don't like it, you can go fuck yourself.

These companies are all run by CEOs who got their MBAs at Darth Vader University, where the first lesson is "I have altered the deal, pray I don't alter it further." Adobe chose to design its software so it would be vulnerable to this kind of demand, and then its customers paid for that choice. Sure, Pantone are dicks, but this is Adobe's fault. They stuck a KICK ME sign to your back, and Pantone obliged.

This keeps happening and it's gonna keep happening. Last week, Playstation owners who'd bought (or "bought") Warner TV shows got messages telling them that Warner had walked away from its deal to sell videos through the Playstation store, and so all the videos they'd paid for were going to be deleted forever. They wouldn't even get refunds (to be clear, refunds would also be bullshit – when I was a bookseller, I didn't get to break into your house and steal the books I'd sold you, not even if I left some cash on your kitchen table).

Sure, Warner is an unbelievably shitty company run by the single most guillotineable executive in all of Southern California, the loathsome David Zaslav, who oversaw the merger of Warner with Discovery. Zaslav is the creep who figured out that he could make more money cancelling completed movies and TV shows and taking a tax writeoff than he stood to make by releasing them:

https://aftermath.site/there-is-no-piracy-without-ownership

Imagine putting years of your life into making a program – showing up on set at 5AM and leaving your kids to get their own breakfast, performing stunts that could maim or kill you, working 16-hour days during the acute phase of the covid pandemic and driving home in the night, only to have this absolute turd of a man delete the program before anyone could see it, forever, to get a minor tax advantage. Talk about moral injury!

But without Sony's complicity in designing a remote, irreversible, nonconsensual downgrade feature into the Playstation, Zaslav's war on art and creative workers would be limited to material that hadn't been released yet. Thanks to Sony's awful choices, David Zaslav can break into your house, steal your movies – and he doesn't even have to leave a twenty on your kitchen table.

The point here – the point I made 20 years ago to Chris Anderson – is that this is the foreseeable, inevitable result of designing devices for remote, irreversible, nonconsensual downgrades. Anyone who was paying attention should have figured that out in the GW Bush administration. Anyone who does this today? Absolute flaming garbage.

Sure, Zaslav deserves to be staked out over an anthill and slathered in high-fructose corn syrup. But save the next anthill for the Sony exec who shipped a product that would let Zaslav come into your home and rob you. That piece of shit knew what they were doing and they did it anyway. Fuck them. Sideways. With a brick.

Meanwhile, the studios keep making the case for stealing movies rather than paying for them. As Tyler James Hill wrote: "If buying isn't owning, piracy isn't stealing":

https://bsky.app/profile/tylerjameshill.bsky.social/post/3kflw2lvam42n

If you'd like an essay-formatted version of this post to read or share, here's a link to it on pluralistic.net, my surveillance-free, ad-free, tracker-free blog:

https://pluralistic.net/2023/12/08/playstationed/#tyler-james-hill

Image:

Alan Levine (modified)

https://pxhere.com/en/photo/218986

CC BY 2.0

https://creativecommons.org/licenses/by/2.0/

#pluralistic#playstation#sony#copyright#copyfight#drm#monopoly#enshittification#batgirl#road runner#financiazation#the end of ownership#ip

23K notes

·

View notes

Text

Things you must know about the Fly Ash Brick Making Machine

I would like to sketch a fly ash brick making machine as a new revelation because it makes the construction easier. This disruptive technology converts industrial waste into structurally sound and aesthetically appealing bricks that can replace traditional clay ones.

The most notable fact is that fly ash bricks are an important element of environmentally friendly construction. They may assist in easing the pressure exerted on raw materials, and they also contribute to the conservation of carbon emissions in construction. This brick making machine makes bricks that eliminate the buildup of waste in landfills and reduce the use of clay and destroy topsoil.

The method of making fly ash bricks is more energy efficient than the normal methods of brick making. These machines are gaining acceptance globally due to their high productivity, low cost of production and enhanced quality of the bricks. The need for brick making machine in India is still on the rise and there is no doubt that they will be part of the future construction industry.

Composition of Fly Ash Bricks

Fly ash bricks are made of fly ash (50–70%), cement (10–20%), sand or stone dust (10–20%), or other materials. The specific proportion may slightly differ but the outcome is a brick that is light in weight, high strength and sustainable. The fly ash brick making machine compels and shapes these materials to develop bricks of superior quality.

Environmental Benefits

Another advantage of fly ash bricks is the reduction of waste products that affect the environment in industries. Another positive impact of fly ash bricks on the environment is that fly ash is considered industrial waste and using it in the production of bricks helps minimize waste. These bricks aid in the handling of waste from coal fired power plants by using fly ash in the production of the building bricks. The fly ash brick manufacturing process also needs less energy than other bricks as it does not involve high temperatures like kilns for baking clay bricks.

How Fly Ash Brick Making Machines Work

Fly ash brick making machine work on a closed cycle system with its essential components to mix and mold the bricks from raw materials.

Hopper: This component stores the raw material requirements used in the production such as fly ash, gypsum and sand.

Mixer: The mixer plays a key role in the whole process of producing the final product as it helps in mixing all the raw materials in the proper manner.

Conveyor: This is initiated by a conveyor belt that takes the mixed material to the brick mold.

Brick Mold: This is the final step whereby the resultant mixture is shaped into the required brick forming through high pressure.

Step-by-Step Process:

Feeding: Materials have to be supplied to the hopper, which is the entry point into the mill.

Mixing: They move to the mixer to be well blended with the other materials.

Conveying: The blended mixture then goes through the inclined conveyor to the brick mold.

Molding: The produce is compacted into the brick mold to produce bricks.

Curing: Molded bricks are then cured with water or steam so as to gain the required strength of the bricks.

Types of Fly Ash Brick Making Machines

Manual Brick Making Machine:

Pros: Affordable, easy to use, and efficient for small scale production.

Cons: Slow production, requires many workers, bricks are not of uniform quality and have less production capability.

Semi-Automatic Brick Making Machine:

Pros: Sustained cost, enhanced productivity, and more uniformity in the quality of bricks produced.

Cons: Needs manual effort, suitable for moderate volumes of production.

Fully automatic brick making machine:

Pros: Large production capacity, low dependence on labor, high degree of uniformity of bricks, numerous features.

Cons: Higher initial cost involved, need for skilled personnel for running and controlling the machinery.

Which Fly Ash Brick Making Machine is best for your business?

Scale: First of all, you need to define the scale of production you want to achieve. Do you intend to carry out a small project or a big project that requires industrial-level infrastructure? Semi-automatic machines may help with small-scale operations while fully automatic machines would serve large-scale production purposes with better accuracy and productivity.

Features: Now that we have already discussed some types of brick making machine, it is now for us to determine the special features that we require for the machine. Some of the common types of bricks to produce include hollow bricks, solid bricks and interlocking bricks. It is advisable to look for machines that have variable mold characteristics and those that make it easier to operate and maintain the machine. Based on the operational capacity or labor availability, automation types like manual, semi-automated or automated should also be incorporated.

Budget: First of all, estimate the initial cost that might be required for starting the business. It is a well-known fact that fully automatic machines are generally costlier than partially automatic ones, but in the long run, it saves money on labor as well as time. Compare the prices of various machines to one another and factor in how much you could save in the future.

Consider possible methods of funding the purchase like loans, leasing or installment purchases. Most suppliers provide payment options that allow you to make a functioning initial installment. This will also help in discovering the return on investment (ROI) which will indicate the time it will take for the machine to start generating its own value in terms of efficiency and the reduction of costs.

Supplier Reputation: It is vital that one conducts research on the potential suppliers to make sure that they are okay in the market. Search for opinions on the specific topic, the number of stars given to the product or service and other people’s experiences that they may have written about on a blog, social media, etc.

Brick Machinery is popular for being a recognized company, producing standard machines, and good customer service. We want you to get the most out of your purchase which is why we offer a good after-sales service such as installation support, training for your staff and we are always ready to offer our assistance in case of a technical hitch.

Why choose brick machinery?

Brick Machinery is among the best companies in the market and has made a name for itself in the market. Brick Machinery aims to provide the best quality products with advanced technologies in its machinery. We have provided excellent quality of our products in the form of fly ash brick making machine that can be witnessed from the above specifications.

Technologically, our machines utilize advanced automation in the process of producing bricks, thereby decreasing human intervention. We provide client-oriented solutions to satisfy all project characteristics and provide you with the ideal machine.

How Brick Machinery Plans to Stay Ahead in the Industry

Brick Machinery is striving continually to be at the forefront of brick making technologies and products. Brick Machinery aims at directing resources to advanced research and development to bring in new high technology fly ash brick making machine that offer the best quality and competence in the market. They work with the market, customer feedback, and other industry players. They make sure that their machines are fit for the current demand.

Further, it has a social responsibility towards the environment, that it is involved in the establishment of fly ash bricks also in the practice of eco-friendly manufacturing techniques. The technological advancements and laid down policies on sustainable development put brick machinery in the right place to lead the market in the future in terms of Brick Making Machine both nationally and internationally.

Are you ready for a change and to bring the best brick making technology to your construction projects? You can also read more about our products and their specifications in the brick making machine portal of our website.

#fly ash brick making machine in gujarat#fly ash brick plant#fly ash brick making machine#brick making machine#brick making machine in India

0 notes

Text

Fly Ash Brick Making Machine Manufacturer in India

Indian Trade Bird provides these machines, which utilize fly ash, a by-product of coal combustion, to create eco-friendly and cost-effective bricks . As the world strives for sustainable building practices, Fly Ash Brick Making Machines offer an innovative solution. By utilizing fly ash waste, these machines reduce dependence on conventional brick production methods, which can have a negative environmental impact . Fly ash is a readily available and inexpensive material, leading to significant cost savings in brick production compared to traditional methods. Fly ash bricks are known for their strength, dimensional accuracy, and fire resistance, making them ideal for various construction applications.

For more details clicks here - https://www.indiantradebird.com/product/fly-ash-brick-making-machine

0 notes