#manufacturing innovations

Text

"Unlocking Industry Insights: EIIR Trend Industry Reports"

Dive into the heart of global industries with EIIR Trend Industry Reports. Our platform curates' in-depth analyses, trends, and data across diverse sectors, offering a panoramic view of industrial landscapes. From manufacturing advancements to market trends, EIIR Trend Industry provides comprehensive insights for enterprises, professionals, and investors. Stay informed, stay strategic with EIIR Trend Industry Reports.

0 notes

Text

i know its silly to keep harping on that basketball pump IV needle person but their "survival is survival" statement pisses me off so bad. its such a misinformed concept of even just the mechanics of basic animal survival. humans are not a solitary predator species. humans are social apes and survival is something we do collectively. thats how come we humans are so good at "survival" via things like sanitation and proper tool use and standarized methods for treating illness and injury. making iv needles by sharpening a basketball pump on a rock is a good example of survivalist innovation in a specific moment but it is NOT a basis for a functioning society that effectively nurtures and protects its injured, elderly, and vulnerable members to the fullest extent it can.

#i truly cant stand anprim and social darwinist types i really cant#survival of the fittest is about the forces that drive evolution over thousands of years idiot not a basis for social ideology#and as others have said on that post basing your materials for emergency surgery on mass manufactured items is so#lmfao#(tosses aside hundreds of years worth of medical science and innovation) We'll Just Figure It Out In the Moment

10 notes

·

View notes

Text

Swiss researchers develop robotic additive manufacturing method that uses earth-based materials—and not cement

Researchers at ETH Zurich, a university in Switzerland, have developed a new robotic additive manufacturing method to help make the construction industry more sustainable. Unlike concrete 3D printing, the process does not require cement.

According to a press statement from ETH Zurich, the robotic printing process, called impact printing, uses cheap, abundant, and low-carbon earth-based materials such as clay or excavated earth. Currently, the robotic additive manufacturing method uses a mix of excavated materials, silt, and clay. Most of the custom material is common waste product sourced locally from Eberhard Unternehmungen, a Swiss construction company. In the future, the process could use other materials.

With ETH Zurich’s method, a robot deposits material from above, gradually building a wall. On impact, the pieces of material bond together, with minimal additives. Whereas concrete 3D printing creates layers, ETH Zurich’s method extrudes and drops the material one bit at a time at velocities of up to 10 meters per second. The fast speed allows the material to bond quickly.

youtube

ETH Zurich’s process can build full-scale, freeform structures, including one- or two-story walls and columns. The printing tool has been used to build structures as tall as almost 10 feet. The process results in walls with a bumpy texture, but robotic surface finishing methods can achieve a smoother finish.

The custom printing tool can be integrated with multiple robotic platforms. As a result, the tool can build walls in both offsite facilities and onsite construction projects. At ETH Zurich’s Robotic Fabrication Laboratory, the tool has been integrated with a high-payload gantry system. The hardware can be mounted on an autonomous legged excavator to build walls on sites with variable terrain.

ETH Zurich says it aims to increase the cost competitiveness of sustainable building materials through efficient and automated production.

#solarpunk#solarpunk business#solarpunk business models#solar punk#solarpunk innovation#earth based construction#switzerland#3D printing#additive manufacturing#Youtube

7 notes

·

View notes

Text

Abrasion Resistance Plate

Abrasion resistance plates, often referred to as wear plates, are specialized steel components designed to withstand the severe wear and tear encountered in various industrial applications.

Abrasion resistance plates are engineered to withstand severe wear and tear from friction and impact, making them ideal for high-demand environments where durability is essential. These plates are commonly made from high-carbon steel alloys, which are heat-treated to enhance hardness and improve their resistance to abrasion. The most common grades include AR400, AR500, and AR600, each offering progressively higher levels of hardness and wear resistance. Overall, abrasion resistance plates are a critical component in industries that require robust solutions to withstand abrasive environments.

Top Industry Applications

In the construction industry, Abrasion-Proof Plate play a significant role in safeguarding machinery and infrastructure subjected to heavy loads and abrasive conditions. These plates are used in various applications, including the construction of crushers, aggregate screens, and wear liners for earth-moving equipment.

These plates are primarily used in industries such as mining, construction, and material handling, where the ability to withstand abrasive environments is crucial. For example, in mining operations, Heavy-Duty Abrasion Plate are employed in the linings of chutes, hoppers, and conveyor systems to protect the underlying steel structures from the continuous impact and friction of transported materials.

To read more about our product you can visit our website.

https://www.wearplates.co.in/abrasion-resistant-plates-sheets.html

7 notes

·

View notes

Text

Carbon Pipe Fittings : Astm A234 WPB Pipe Fittings Manufacturers

Introduction:

ASTM A234 WPB pipe fittings, also known as carbon steel pipe fittings, have largely become standard parts in many industries. The fitting elements will be used to adapt straight pipe or tubing sections, to maintain different size or shape, and to control the rate of flow of liquids.

Always resistant to strength and versatile, ASTM A234 WPB fittings play a critical role in industries dealing with oil, gas, petrochemicals, and power generation.

What are ASTM A234 WPB Pipe Fittings?

They are used to connect pipes in shapes such as elbows, tees, reducers, and caps. The prime factors that make the use of these fittings highly prevalent are their excellent mechanical properties, like high tensile strength and resistance to corrosion. They are very important in ensuring the integrity and efficiency of piping systems across industries.

Manilaxmi Industrial also supplies Carbon ASTM Pipe Fittings around the globe.

Real-Time Advancements in Industries

Ranging from new manufacturing technologies and materials science to improved performance and reliability, these fittings have carved out a niche in use. Applications of the ASTM A234 WPB carbon steel pipe fitting have greatly improved in the industrial sector.For example, refined heat treatment processes leave behind fittings that are easier to manipulate and work under higher pressure and temperature conditions.

Besides, numerous coating and lining innovations provide improved corrosion resistance and give extended life expectancy.

Manilaxmi Industrial the Indian manufacturers, suppliers, and exporters have been among the most active adopters of these developments to ensure that the country is retained as a main supplier of quality pipe fittings in the global market.

Technology and Need in Various Countries

Demands for ASTM A234 WPB carbon steel pipe fittings are ever-increasing in the global scenario. This demand has been hastened further by the requirement of strong, efficient piping systems in the developing countries and renovated or rejuvenated ones in the developed nations.

Such as setting up power plants and oil refineries. In contrast, developed nations always require update works and servicing of already existing facilities. Equipped with state-of-the-art technology in the manufacturing process, these fittings comply with strict standards that make them very important and cardinal for maintaining efficiency and safety during industrial operations.

Conclusion

In conclusion, ASTM A234 WPB pipe fittings are the most essential material in the industrial market, possessing qualities of high durability, adaptability, and tolerance toward extreme situations. With relentless development in the manufacturing technologies, further improvements are made in their performances, making them trustworthy for different applications.

#innovation#management#technology#metalfabrication#metalwork#supplychain#manufacturers#exporters#suppliers

9 notes

·

View notes

Text

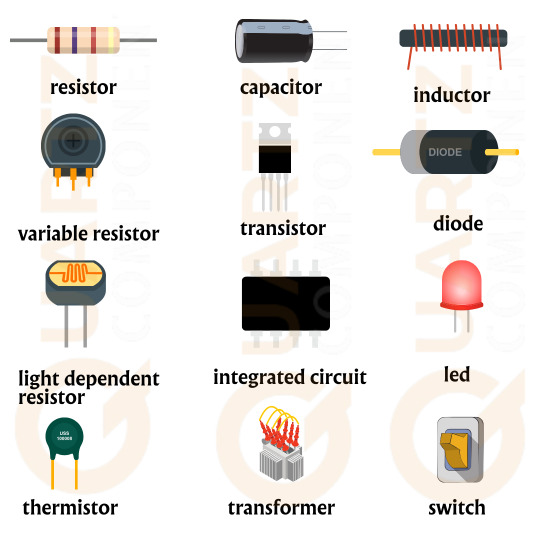

Electronics Components

#components #electronics #engineering #electrical #arduino #electronic #innovation #design #robotics #electroniccomponents #raspberry #technology #manufacturing #industrial #gaming #school #learningbydoing #solar #bahrain #pc #pcb #budaiya #muhharaq #manama #engineeringforkids #saar #riffa #makersgonnamake #isatown #summerprogram

#Electronics Components#components#electronics#engineering#electrical#arduino#electronic#innovation#design#robotics#electroniccomponents#raspberry#technology#manufacturing#industrial#gaming#school#learningbydoing#solar#bahrain#pc#pcb#budaiya#muhharaq#manama#engineeringforkids#saar#riffa#makersgonnamake#isatown

10 notes

·

View notes

Text

Making open-source electronics in NYC, USA @adafruit

Some factory footage!

#adafruit#electronics#opensource#manufacturing#opensourcehardware#nyc#technology#innovation#pcb#retro

17 notes

·

View notes

Text

Mastering Neural Networks: A Deep Dive into Combining Technologies

How Can Two Trained Neural Networks Be Combined?

Introduction

In the ever-evolving world of artificial intelligence (AI), neural networks have emerged as a cornerstone technology, driving advancements across various fields. But have you ever wondered how combining two trained neural networks can enhance their performance and capabilities? Let’s dive deep into the fascinating world of neural networks and explore how combining them can open new horizons in AI.

Basics of Neural Networks

What is a Neural Network?

Neural networks, inspired by the human brain, consist of interconnected nodes or "neurons" that work together to process and analyze data. These networks can identify patterns, recognize images, understand speech, and even generate human-like text. Think of them as a complex web of connections where each neuron contributes to the overall decision-making process.

How Neural Networks Work

Neural networks function by receiving inputs, processing them through hidden layers, and producing outputs. They learn from data by adjusting the weights of connections between neurons, thus improving their ability to predict or classify new data. Imagine a neural network as a black box that continuously refines its understanding based on the information it processes.

Types of Neural Networks

From simple feedforward networks to complex convolutional and recurrent networks, neural networks come in various forms, each designed for specific tasks. Feedforward networks are great for straightforward tasks, while convolutional neural networks (CNNs) excel in image recognition, and recurrent neural networks (RNNs) are ideal for sequential data like text or speech.

Why Combine Neural Networks?

Advantages of Combining Neural Networks

Combining neural networks can significantly enhance their performance, accuracy, and generalization capabilities. By leveraging the strengths of different networks, we can create a more robust and versatile model. Think of it as assembling a team where each member brings unique skills to tackle complex problems.

Applications in Real-World Scenarios

In real-world applications, combining neural networks can lead to breakthroughs in fields like healthcare, finance, and autonomous systems. For example, in medical diagnostics, combining networks can improve the accuracy of disease detection, while in finance, it can enhance the prediction of stock market trends.

Methods of Combining Neural Networks

Ensemble Learning

Ensemble learning involves training multiple neural networks and combining their predictions to improve accuracy. This approach reduces the risk of overfitting and enhances the model's generalization capabilities.

Bagging

Bagging, or Bootstrap Aggregating, trains multiple versions of a model on different subsets of the data and combines their predictions. This method is simple yet effective in reducing variance and improving model stability.

Boosting

Boosting focuses on training sequential models, where each model attempts to correct the errors of its predecessor. This iterative process leads to a powerful combined model that performs well even on difficult tasks.

Stacking

Stacking involves training multiple models and using a "meta-learner" to combine their outputs. This technique leverages the strengths of different models, resulting in superior overall performance.

Transfer Learning

Transfer learning is a method where a pre-trained neural network is fine-tuned on a new task. This approach is particularly useful when data is scarce, allowing us to leverage the knowledge acquired from previous tasks.

Concept of Transfer Learning

In transfer learning, a model trained on a large dataset is adapted to a smaller, related task. For instance, a model trained on millions of images can be fine-tuned to recognize specific objects in a new dataset.

How to Implement Transfer Learning

To implement transfer learning, we start with a pretrained model, freeze some layers to retain their knowledge, and fine-tune the remaining layers on the new task. This method saves time and computational resources while achieving impressive results.

Advantages of Transfer Learning

Transfer learning enables quicker training times and improved performance, especially when dealing with limited data. It’s like standing on the shoulders of giants, leveraging the vast knowledge accumulated from previous tasks.

Neural Network Fusion

Neural network fusion involves merging multiple networks into a single, unified model. This method combines the strengths of different architectures to create a more powerful and versatile network.

Definition of Neural Network Fusion

Neural network fusion integrates different networks at various stages, such as combining their outputs or merging their internal layers. This approach can enhance the model's ability to handle diverse tasks and data types.

Types of Neural Network Fusion

There are several types of neural network fusion, including early fusion, where networks are combined at the input level, and late fusion, where their outputs are merged. Each type has its own advantages depending on the task at hand.

Implementing Fusion Techniques

To implement neural network fusion, we can combine the outputs of different networks using techniques like averaging, weighted voting, or more sophisticated methods like learning a fusion model. The choice of technique depends on the specific requirements of the task.

Cascade Network

Cascade networks involve feeding the output of one neural network as input to another. This approach creates a layered structure where each network focuses on different aspects of the task.

What is a Cascade Network?

A cascade network is a hierarchical structure where multiple networks are connected in series. Each network refines the outputs of the previous one, leading to progressively better performance.

Advantages and Applications of Cascade Networks

Cascade networks are particularly useful in complex tasks where different stages of processing are required. For example, in image processing, a cascade network can progressively enhance image quality, leading to more accurate recognition.

Practical Examples

Image Recognition

In image recognition, combining CNNs with ensemble methods can improve accuracy and robustness. For instance, a network trained on general image data can be combined with a network fine-tuned for specific object recognition, leading to superior performance.

Natural Language Processing

In natural language processing (NLP), combining RNNs with transfer learning can enhance the understanding of text. A pre-trained language model can be fine-tuned for specific tasks like sentiment analysis or text generation, resulting in more accurate and nuanced outputs.

Predictive Analytics

In predictive analytics, combining different types of networks can improve the accuracy of predictions. For example, a network trained on historical data can be combined with a network that analyzes real-time data, leading to more accurate forecasts.

Challenges and Solutions

Technical Challenges

Combining neural networks can be technically challenging, requiring careful tuning and integration. Ensuring compatibility between different networks and avoiding overfitting are critical considerations.

Data Challenges

Data-related challenges include ensuring the availability of diverse and high-quality data for training. Managing data complexity and avoiding biases are essential for achieving accurate and reliable results.

Possible Solutions

To overcome these challenges, it’s crucial to adopt a systematic approach to model integration, including careful preprocessing of data and rigorous validation of models. Utilizing advanced tools and frameworks can also facilitate the process.

Tools and Frameworks

Popular Tools for Combining Neural Networks

Tools like TensorFlow, PyTorch, and Keras provide extensive support for combining neural networks. These platforms offer a wide range of functionalities and ease of use, making them ideal for both beginners and experts.

Frameworks to Use

Frameworks like Scikit-learn, Apache MXNet, and Microsoft Cognitive Toolkit offer specialized support for ensemble learning, transfer learning, and neural network fusion. These frameworks provide robust tools for developing and deploying combined neural network models.

Future of Combining Neural Networks

Emerging Trends

Emerging trends in combining neural networks include the use of advanced ensemble techniques, the integration of neural networks with other AI models, and the development of more sophisticated fusion methods.

Potential Developments

Future developments may include the creation of more powerful and efficient neural network architectures, enhanced transfer learning techniques, and the integration of neural networks with other technologies like quantum computing.

Case Studies

Successful Examples in Industry

In healthcare, combining neural networks has led to significant improvements in disease diagnosis and treatment recommendations. For example, combining CNNs with RNNs has enhanced the accuracy of medical image analysis and patient monitoring.

Lessons Learned from Case Studies

Key lessons from successful case studies include the importance of data quality, the need for careful model tuning, and the benefits of leveraging diverse neural network architectures to address complex problems.

Online Course

I have came across over many online courses. But finally found something very great platform to save your time and money.

1.Prag Robotics_ TBridge

2.Coursera

Best Practices

Strategies for Effective Combination

Effective strategies for combining neural networks include using ensemble methods to enhance performance, leveraging transfer learning to save time and resources, and adopting a systematic approach to model integration.

Avoiding Common Pitfalls

Common pitfalls to avoid include overfitting, ignoring data quality, and underestimating the complexity of model integration. By being aware of these challenges, we can develop more robust and effective combined neural network models.

Conclusion

Combining two trained neural networks can significantly enhance their capabilities, leading to more accurate and versatile AI models. Whether through ensemble learning, transfer learning, or neural network fusion, the potential benefits are immense. By adopting the right strategies and tools, we can unlock new possibilities in AI and drive advancements across various fields.

FAQs

What is the easiest method to combine neural networks?

The easiest method is ensemble learning, where multiple models are combined to improve performance and accuracy.

Can different types of neural networks be combined?

Yes, different types of neural networks, such as CNNs and RNNs, can be combined to leverage their unique strengths.

What are the typical challenges in combining neural networks?

Challenges include technical integration, data quality, and avoiding overfitting. Careful planning and validation are essential.

How does combining neural networks enhance performance?

Combining neural networks enhances performance by leveraging diverse models, reducing errors, and improving generalization.

Is combining neural networks beneficial for small datasets?

Yes, combining neural networks can be beneficial for small datasets, especially when using techniques like transfer learning to leverage knowledge from larger datasets.

#artificialintelligence#coding#raspberrypi#iot#stem#programming#science#arduinoproject#engineer#electricalengineering#robotic#robotica#machinelearning#electrical#diy#arduinouno#education#manufacturing#stemeducation#robotics#robot#technology#engineering#robots#arduino#electronics#automation#tech#innovation#ai

3 notes

·

View notes

Text

Ultimate Guide to PCB Testing Methods: Ensuring Quality and Reliability in Your Circuits

In the electronics sector, Printed Circuit Boards (PCBs) are the life-lines of virtually all gadgets that are in use in the modern society. From humble home appliances to gigantic industrial equipment, PCBs are the skeletal framework of hardware organization and connection of circuit elements. It is vital to guarantee the quality and dependability of these fundamental parts – thus enters PCB testing methods. It is our hope that this extensive hand will help identify the most suitable test strategies for PCB testing, why these techniques matter, and how to maximize your circuits’ functionality.

Introduction

Firstly, an increase in the capability of different electronic devices leads to higher necessary requirements to the PCBs used in their production. Performing tests on the PCBs is an essential step in the manufacturing process done to confirm that a given board performs as a unit to the expected levels. This guide aims at explaining various techniques of PCB testing with a view of having a better understanding on how to achieve quality and reliability on the circuits.

Why PCB Testing is Crucial

PCB Testing When it comes to the potential defects on PCBs, there are shorts, opens, and some component placements. They can cause device failure, decline in performance level, and sometimes also pose safety issues. Through high-quality testing regimes, it becomes easier to address problems before they reach the customer, and thus manufacturers will have reliable and efficient products. Key reasons for PCB testing include:

Detecting Manufacturing Defects: Solder bridges, missing and placed in wrong position components, all can be detected in the initial stages easily.

Ensuring Functionality: Ensuring that the PCB does what is wanted and needed when it is in use, and under several conditions.

Quality Assurance: Ensuring that the business meets industry standards, and what clients require of them.

Cost Efficiency: Decreasing the likelihood of rework and recall by identifying possible defects before they get to the customer.

Types of PCB Testing Methods

These are the types of PCB Testing Methods:

Visual Inspection

Technique one as also referred to as the VI or visual inspection is the simplest and basic type of testing done on PCBs. The technique entails inspecting the board with naked eyes for some of the common faults including solder bridges, missing parts, and misalignment issues.

Automated Optical Inspection (AOI)

AOI employs cameras and software algorithms to check PCBs for defects and performs the inspections singly. This method of inspection is far more efficient than the manual inspection and simultaneously versatile enough to identify numerous problems.

X-ray Inspection

Some functions which include examination of features of BPCs that could not be easily inspected include solder joints under components through x-ray inspection. It is especially effective in inspecting defects in BGA (Ball Grid Array) and other various packages as well.

In-Circuit Testing (ICT)

ICT entails applying different voltage across the PCB to checks on the electrical characteristics of the needy part and connections. The use of this method is highly recommended for the identification of functional problems and verification of the circuit’s goodness.

Functional Testing (FCT)

Functional testing evaluates the effectiveness of the PCB pointing to the fact that it can be tested when placed in use. This method enables the certification of that the PCB works as expected under actual environment.

Flying Probe Testing

In flying probe testing, the probes are moved around to test the electrical properties of the created PCB. Lower to medium volume production runs can be made easily by using this technique; hence it is advantageous in this regard.

Boundary Scan Testing

Boundary scan testing also called as JTAG testing extends test circuitry into all the components for testing the connections between them. Although, this method is very efficient for identifying connection problems and faults.

Burn-In Testing

Burn-in testing puts the PCB in a state of operational stress for a long time to capture early-life failures. This aspect makes the method reliable for the long term since it is likely to identify problems that may occur when the equipment is in use for a long time.

Detailed Analysis of Each Testing Method works

These are the detailed analysis of each testing method works:

Visual Inspection

Pros:

Simple and low-cost

Determined to be a system for the reporting of noticeable defects as soon as they are observed.

Cons:

Time-consuming for complex boards

Limited to visible defects

Automated Optical Inspection (AOI)

Pros:

Fast and accurate

Is capable of detecting various kinds of defects.

Non-destructive

Cons:

High initial setup cost

May need to have better settings optimized for specific boards.

X-ray Inspection

Pros:

Examines hidden features

Ideal for complex packages

Cons:

Expensive equipment

Requires skilled operators

In-Circuit Testing (ICT)

Pros:

Thorough electrical testing

High fault coverage

Cons:

Requires custom fixtures

Not for all the boards or servers that you wish to build.

Functional Testing (FCT)

Pros:

Ensures real-world performance

Detects system-level issues

Cons:

Time-consuming

The mathematical test object can involve complex arrangements of test configurations.

Flying Probe Testing

Pros:

Flexible and adaptable

Cost-effective for small batches

Cons:

Slower than ICT for big volumes

Applicable only when the board is specially designed

Boundary Scan Testing

Pros:

Interconnections have high fault coverage.

Said; No need to have physical access to the test points

Cons:

Requires boundary scan-enabled components

Complex setup

Burn-In Testing

Pros:

Identifies early-life failures

Ensures long-term reliability

Cons:

Time-consuming and costly

Perhaps stressful to the board

Choosing the Right Testing Method

The choice of the appropriate method of PCB testing can be influenced by several factors such as the level of complexity of the PCB and the numbers of boards to be tested as well as the actual costs of the testing process and other features. Consider the following when choosing a testing method:

Board Complexity: Great board densities or component placement can be a determinant as to whether one needs AOI or X-ray inspection.

Production Volume: Applications that are characterized by high volumes can be easily facilitated by ICT while the low to medium volume applications may require flying probe testing.

Budget: Both manual inspection and AOI are favorable for various production volumes, while X-ray and ICT are more expensive at the beginning.

Specific Requirements: There are two types of the test, namely Functional Test and Burn-In Test that should be made so as to attain the long term reliability in applications that are critical.

Best Practices for PCB Testing

Using the best techniques in testing PCBs increases the quality and reliability of the circuits that you are working on. Here are some key practices to follow:

Early Testing: It is recommended to carry out the tests when the product is still in its design and manufacturing phase so that problems can be noted earlier before they reach a very catastrophic level.

Automate Where Possible: Use method such as automation to reduce the time and improve on the quality of the testing.

Regular Calibration: It is necessary to check if all the testing equipment used for calibration are accurate.

Comprehensive Coverage: This way, you will be able to ensure that there are no defects that are not tested as the best testing approach combines all types of testing methods.

Document Everything: Ensure that you keep records of the tests performed, the results obtained, as well as any measures taken to correct the breaches.

Common Challenges and How to Overcome Them

These are the common challenges and how to overcome them:

False Positives/Negatives

Automated testing methods maybe good some times, they give you the results that are either positive or negative and this will lead to unnecessary rework or more alarming leaving critical defects unfound. In order to avoid this, make sure that testing algorithms and testing equipment are updated and fine-tuned from time to time.

Component Access

Some of the testing techniques involve handling parts of the circuit and with high density board this can be very difficult. Some of the ways in which testbench implementation can be avoided are as follows Boundary scan testing and X-ray inspection.

High Costs

Some form of testing such as X-ray and ICT testing is often very costly. The effectiveness must come with reasonable prices; try to combine some of the mentioned approaches to cover all the aspects without spending too much money.

Future Trends in PCB Testing

About the future, it can be stated that its trends will be in fact linked to the tendencies in technologies and expectations towards ever higher quality and quantity of tested PCBs. Key trends to watch include:

AI and Machine Learning: Using of intelligence algorithms and machine learning in testing algorithms to enhance the efficiency and the minimization of false negative or false positives.

IoT and Smart Manufacturing: Higher testing flexibility and opportunities for the continuous test process supervision.

Advanced Imaging Techniques: The need for better techniques that would enhance the detection of defects within a printed circuit.

Environmental Stress Testing: More focus in the testing of PCBs under different environmental pressures in order to improve on its longevity.

Conclusion

Quality and reliability of packaged circuits have to be maintained to contribute positively in any electronic equipment. This paper seeks to explain the common testing techniques for PCB so that PCB manufacturers are able to test and see if they are free from defects and if they are functional. This ultimate guide will give you a full insight on the available options in PCB testing that will enable you make the best decision that will give you perfect circuits.

The aim is to help you understand how to attain the best quality of PCBs, what methods are worth following, and what trends drive future improvements, thus contributing to the quality of the final electronic products and, consequently, consumer satisfaction.

#PCBTesting#Electronics#CircuitBoard#QualityControl#Engineering#Technology#Manufacturing#IndustrialDesign#Tech#Innovation

2 notes

·

View notes

Text

Medium voltage support insulator manufacturers in India | radiantenterprises

Elevate your electrical solutions with Radiant Enterprises, a top name among customised insulator manufacturers in India. Specializing in high-quality epoxy insulators, we cater to the specific needs of your projects with precision and expertise. As leading medium voltage support insulator manufacturers in India, we provide durable and reliable products that meet the highest industry standards.

Trust Radiant Enterprises for innovative and customized insulator solutions designed to enhance the performance and safety of your electrical systems.

#Epoxy insulator#Customised insulator manufacturers in India#Medium voltage support insulator manufacturers in India#epoxy bushing#epoxy insulator#epoxy resin#electrical company#electrical engineering#electrical industry#fuse cutouts#smart grid sensor#rail insulator#railway technology companies#train operating companies#locomotive#tramways#metro systems#traffic infrastructure#third rail#cable connector#innovative insulators#export quality

4 notes

·

View notes

Text

Unlocking the potential of tomorrow's innovations, Design and Automation Services' reverse engineering solutions redefine progress in design and manufacturing.

With over a decade of expertise, we specialize in: - Precision 3D scanning and modeling 📐 - Rapid prototyping for seamless product development 🚀 - Restoring obsolete designs to fuel innovation 🔧 - Collaborative solutions for competitive advantage 💡 Our dedication to excellence ensures your ideas evolve into tangible successes, shaping a smarter, more efficient future.

Contact Design and Automation Services today to transform your vision into reality. 🌟

Call us on 📞 +91 9574 024 279

or

Visit: https://www.designautomations.com/

#DesignAndAutomationServices#Innovation#ReverseEngineering#ProductDevelopment#PrecisionEngineering#FutureTech#CollaborativeSolutions#Manufacturing#TransformativeIdeas

2 notes

·

View notes

Text

youtube

#industrial ar#augmented reality#Virtual reality#VR#immersive#innovation#edtech#fintech#artificial intelligence#VR travel#MR for manufacturing#Youtube

2 notes

·

View notes

Text

instagram

#メカニカルエンジニアリング#ロボット#製造#自動車工学#革新#テクノロジー#エンジニア#機械設計#エンジン#サイエンスフィクション#mechanicalengineering#robot#manufacturing#automobileengineering#innovation#technology#engineer#mechanicaldesign#engine#scifi#Instagram#dystopian#dystopia#cyberpunk#sciencefiction#bookstagram#postapocalyptic#dystopianfiction#books#art

4 notes

·

View notes

Text

Are you looking for a reliable and precise low-volume manufacturing service?

Look no further! 🌟

At ProtoTech Machining, we are not just a manufacturer; we innovate with precision.🛠️

Our company specializes in top-notch low-volume manufacturing services that are tailored to various industry needs such as aerospace, medical, automotive, robotics, and many other sectors. From CNC machining to Rapid prototyping and Sheet Metal Fabrication, our expert team can leverage cutting-edge technologies to turn complex designs into reality. 🚀

Plus, whether you need 3D printing, 5-axis, or Swiss CNC machining, we have the best capabilities to provide innovative and cost-effective solutions without compromising quality. ✨

So don’t wait any longer! Contact us now and let us be your partner in all your manufacturing needs. 📞

Browse https://prototech-machining.com/low-volume-manufacturing/ to learn more.

#prototechmachining#3dprinting#cncmachining#technologies#swisscncmachining#manufacturing#innovative#metalfabrication#aerospace#medical#automative#robotics

2 notes

·

View notes

Text

Zero Friction Coatings Market: Charting the Course for Enhanced Performance and Sustainable Solutions

The global zero friction coatings market size is estimated to reach USD 1,346.00 million by 2030 according to a new report by Grand View Research, Inc. The market is expected to expand at a CAGR of 5.6% from 2022 to 2030. Growth can be attributed to the fact that these coatings reduce friction and wear resulting in low fuel consumption and less heat generation. According to the European Automobile Manufacturers' Association, 79.1 million motor vehicles were produced across the globe in 2021 which was up by 1.3% as compared to 2020. Zero friction coatings can extend the time between component maintenance and replacement, especially for machine parts that are expensive to manufacture.

Zero Friction Coatings Market Report Highlights

In 2021, molybdenum disulfide emerged as the dominant type segment by contributing around 50% of the revenue share. This is attributed to its properties such as low coefficient of friction at high loads, electrical insulation, and wide temperature range

The automobile & transportation was the dominating end-use segment accounting for a revenue share of more than 35% in 2021 due to the rapid growth of the automotive industry across the globe

The energy end-use segment is anticipated to grow at a CAGR of 5.7% in terms of revenue by 2030, owing to the excessive wear on the drill stem assembly and the well casing during the drilling operations in the oil and gas sector

In Asia Pacific, the market is projected to witness the highest CAGR of 5.8% over the predicted years owing to the presence of car manufacturing industries in the countries such as Japan, South Korea, and China

For More Details or Sample Copy please visit link @: Zero Friction Coatings Market Report

Several applications in the automobile industry use wear-resistant plastic seals that require zero tolerance for failure and lifetime service confidence. Increasing demand for the product from the automotive industry across the globe for various applications including fuel pumps, automatic transmissions, oil pumps, braking systems, and others is expected to drive its demand over the forecast period.

Low friction coatings can be used in extreme environments comprising high pressure, temperatures, and vacuums. These coatings can provide improved service life and performance thereby eliminating the need for wet lubricants in environments that require chemicals, heat, or clean room conditions. The product containing molybdenum disulfide (MoS2) are suitable for reinforced plastics while those free from MoS2 are suitable for non-reinforced plastics.

Zero friction coatings are paint-like products containing submicron-sized particles of solid lubricants dispersed through resin blends and solvents. The product can be applied using conventional painting techniques such as dipping, spraying, or brushing. The thickness of the film has a considerable influence on the anti-corrosion properties, coefficient of friction, and service life of the product. Its thickness should be greater than the surface roughness of the mating surfaces.

ZeroFrictionCoatingsMarket #FrictionlessTechnology #CoatingInnovations #IndustrialEfficiency #ZeroFrictionSolutions #AdvancedMaterials #SurfaceCoatings #ManufacturingAdvancements #GlobalIndustryTrends #InnovativeCoatings #PerformanceOptimization #MechanicalSystems #SustainableTechnology #IndustrialApplications #FutureTech #InnovationInMaterials #EfficiencySolutions #ZeroFrictionMarket #TechnologyInnovation #EngineeringMaterials

#Zero Friction Coatings Market#Frictionless Technology#Coating Innovations#Industrial Efficiency#Zero Friction Solutions#Advanced Materials#Surface Coatings#Manufacturing Advancements#Global Industry Trends#Innovative Coatings#Performance Optimization#Mechanical Systems#Sustainable Technology#Industrial Applications#Future Tech#Innovation In Materials#Efficiency Solutions#Zero Friction Market#Technology Innovation#Engineering Materials

2 notes

·

View notes

Text

Exporters of Stainless Steel 304 Pipes & Tubes: Global Supply

@manilaxmiindustrial : Manilaxmi Industrial

Explore the features, applications of Stainless Steel 304 Pipes & Tubes. This guide highlights their importance in various industries, emphasizing durability and corrosion resistance.

Stainless Steel 304 Pipes, Stainless Steel 304 Tubes, SS 304 Pipes, SS 304 Tubes, Stainless Steel, Pipes, Tubes, Industrial Materials

Stainless Steel 304 is one of the most widely used and versatile types of stainless steel in the industry. Known for its exceptional corrosion resistance, durability, and aesthetic appeal, Stainless Steel 304 Pipes and Tubes are vital components in a variety of applications, spanning across multiple industries.

What is Stainless Steel 304?

Stainless Steel 304 belongs to the austenitic family of stainless steel, which is composed of 18-20% chromium and 8-10.5% nickel, along with other elements such as carbon, manganese, and silicon.

The high chromium content provides excellent corrosion resistance, while the nickel enhances its strength and toughness.

This combination makes Stainless Steel 304 a popular choice for pipes and tubes, particularly in environments where corrosion resistance is a critical factor.

Applications of Stainless Steel 304 Pipes & Tubes

Stainless Steel 304 Pipes and Tubes are used in a wide array of industries due to their adaptability. Some of the most common applications include:

Food and Beverage Industry: The hygienic properties of Stainless Steel 304 make it ideal for food processing, storage, and transportation. It is resistant to corrosion from food products, cleaning agents, and the wide range of temperatures involved in food production.

Chemical and Petrochemical Industries: Stainless Steel 304 can withstand harsh chemicals, making it a preferred material for chemical processing equipment and pipelines. Its resistance to acidic and alkaline solutions ensures longevity in these demanding environments.

Construction Industry: Stainless Steel 304 Pipes and Tubes are frequently used in architectural structures, particularly in areas where aesthetics and durability are important. Its resistance to weathering and corrosion makes it a suitable material for both interior and exterior applications.

Automotive Industry: The durability and strength of Stainless Steel 304 make it an excellent choice for automotive exhaust systems, fuel lines, and other components that require resistance to high temperatures and corrosion.

Pharmaceutical Industry: In environments where cleanliness is paramount, Stainless Steel 304 shines. Its non-reactive properties and ease of cleaning make it ideal for the pharmaceutical industry, especially in the manufacturing of medicines and medical equipment.

#Manilaxmi Industrial#manufacturers#exporters#suppliers#industrial#innovation#pipeaccessories#manilaxmiindustrial

3 notes

·

View notes