#materialstesting

Text

Non-Destructive Testing: Trends, Challenges, and Future Outlook of the Global Market

The global non-destructive testing market size is anticipated to reach USD 34,148.1 million by 2030, registering a CAGR of 7.9% from 2023 to 2030, according to a new report by Grand View Research, Inc. The market is expected to experience substantial growth during the forecast period. This growth can be attributed to the increasing manufacturing activities in both developing and developed nations.

Non-destructive Testing Market Report Highlights

The market is expected to exhibit a CAGR of 7.9% over the next eight years owing to a rise in manufacturing-related activities, globally

The services segment accounted for the largest revenue share of over 75.0% in 2022. The high upfront cost of non-destructive equipment coupled with technical complexities involved in their deployment/installation is the major reason influencing end-users to outsource their non-destructive testing operations

Rapid industrialization, especially in developing economies has significantly contributed to the growth of the market

The manufacturing vertical segment was the dominant segment in 2022 and is expected to witness a healthy CAGR of 9.3% over the forecast period owing to the increased manufacturing activities primarily in Asia Pacific.

North America dominated the market in 2022 and accounted for the largest revenue share of more than 36.0%, owing to the extensive adoption of NDT techniques in the region

For More Details or Sample Copy please visit link @: Non-destructive Testing Market Report

The application of non-destructive testing (NDT) plays a crucial role in precise fault detection, effectively reducing the probability of product/component failures and associated repair costs. NDT also accelerates the manufacturing process by eliminating potential faults beforehand. The market is expected to be driven by the advancements in non-destructive testing methods, as these technological improvements ensure accurate fault detection and significantly reduce the complexity of testing procedures.

The ultrasonic testing segment is projected to experience substantial growth, which can be attributed to factors such as the equipment's user-friendly nature, the presence of skilled technicians, and the precise detection of faults. Furthermore, the manufacturing segment is anticipated to extensively adopt NDT techniques during the forecast period due to the growing awareness of their benefits and applications.

#NonDestructiveTesting#NDT#StructuralSafety#TestingTechnologies#IndustrialInspection#DefectDetection#MaterialsTesting#UltrasonicTesting#RadiographicTesting#VisualInspection#NDTMethods#NDTEquipment#NDTServices#SafetyStandards#RiskAssessment#QualityControl#NDTIndustry

0 notes

Photo

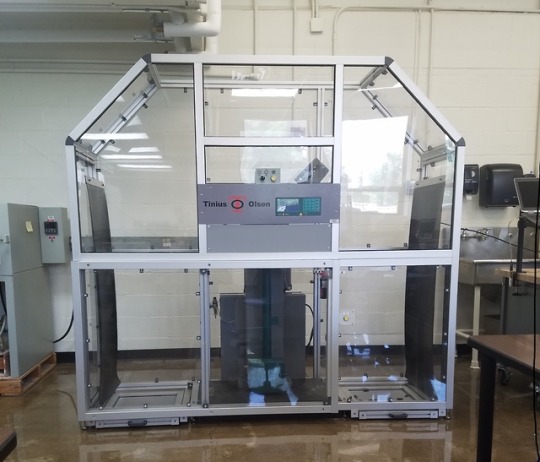

Cincinnati State Technical College, a Tinius Olsen Success Story

Tinius Olsen has helped one of the leading Technical Colleges in America, the Cincinnati State Technical and Community College, to up-grade and further develop its materials testing laboratory.

This is the culmination of a partnership between the two organisations that goes back to the establishment of the College in 1969, as Mike DeVore, Professor & Program Chair of the Mechanical Engineering Technology & Welding Technology Dept explains:

“I started teaching at Cincinnati State 29 years ago and at that time we had a very old Tinius Olsen tensile test machine that still worked extremely well on a day to day basis.”

“Our testing lab had been in operation since almost the establishment of the school so we decided to update our lab in 1993 and, due to the reliability and generally good history that we had with the old machine, I decided to purchase another from Tinius Olsen.”

“I visited the factory in Pennsylvania and was very impressed with the quality of work and professionalism of the employees at the company, so we purchased our second Tinius Olsen machine, a 60L Super L Tensile Tester. Again we enjoyed great service with the machine until the controls unfortunately failed last year.”

“Fortunately, we had obtained funding to upgrade our materials test lab with all new equipment and it was a relatively easy decision to once again look to Tinius Olsen, thanks in the main to the great experience we have had with the company over the years. It was also important to me to try to purchase American made equipment, whenever possible.”

The machines installed at the Colleges’ testing lab are a 10,000 In/lb Bench Top Torsion Tester, a Model IT406 Pendulum Impact tester, four Rockwell and one Brinnel Hardness Testing machines, as well as retro-fitting the 60L Super L. This has resulted in a substantial investment by the College into their state of the art testing laboratory, which should see at least another 30 years problem free use.

“The new equipment is used in several courses within our Mechanical Engineering Technology, Welding Technology, and Civil Engineering Technology programs. The primary use is in our MET 140 Engineering Materials course where our students spend the semester doing destructive testing.”

“Between the three programs we have over 500 hundred students - all of which will use this lab at some point in their curriculum. The tests we currently perform within the lab include Tensile, Bend, Hardness, Torsion and Impact testing as well as Heat treating.”

Cincinnati State Technical and Community College, which is celebrating its 50th anniversary this year, provides student-focused, accessible, high-quality technical and general education, academic transfer, experiential and cooperative education and workforce development.

The College offers more than 130 associate degree and certificate programs through its four academic divisions and the Workforce Development Center.

“We have a long history with Tinius Olsen. We have used their material testing equipment for nearly 50 years here at Cincinnati State and intend to keep the relationship intact for years to come. They are a great American company and we are proud to use their equipment to educate our students,” continued Mr DeVore.

“Through the use of our Tinius Olsen equipment we are able to prepare our students to go out into industry with a thorough knowledge of material testing. Tinius Olsen test equipment is used by many of our employers and they appreciate the fact that our students are learning to use industry standard equipment.”

#testing#education#cincinnati#commitment#support#cincinnatistatecollege#materialstesting#students#programs#hardnesstesting#tensile testing#torsion#engineering#technology#impacttest#degree#courses#curriculum#equipment#madeinusa#prepare#employers#industry#standards#teaching#testing labs#reliable#relaibility#rockwell#brinell

1 note

·

View note

Text

Material Analysis Laboratory

Material Testing Laboratory is an important step in understanding how your materials will perform or react under a wide variety of stresses. The element can assist you in evaluating and understanding your material properties like tensile strength of thermal analysis and much more

The benefits of understanding material properties affect every stage of an application. Material properties testing can assist in R&D projects, prevent failures in the final product, and anticipate issues before they arise.

The component offers a broad range of material properties testing services, specializing in metals, advanced composites, polymers, ceramic composites, and many more. The component can provide valuable insight into virtually any material characteristic and any material type. We have experience in providing testing for many sectors and handle projects large and small in relation to material testing. With a global network of labs and resources, we perform everything from routine tensile testing to custom fatigue programs.

Conducting materials testing for customers for over four decades, we are your ideal partner to provide the independent and industry-leading services you require. Our material testing laboratory covers infrastructure, rubber, and automotive components, metals, composites, polymers, construction materials, and more.

Our material analysis lab can fulfill all your requirements with a state-of-the-art facility.

#materialtestinglaboratory#materialtest#textiletestinglaboratory#materialtestingservices#materialtestinglab#rubberhardnesstester#materialtestinglaboratories#materialstesting#Materialtestinglaboratories#cellularfoamandsponges#plasticmaterialtestinglab

0 notes

Text

Hasbro Games Trivial Pursuit Family Edition (Amazon Exclusive)

Hasbro Games Trivial Pursuit Family Edition (Amazon Exclusive)

Price: (as of – Details)

Trivial Pursuit Family Edition Game. High quality toys for children all agesMade using safe materialsTested for quality and durabilityTrivial Pursuit Family Edition game has questions for kids and for adults1,200 questionsQuicker pacePlay individually or in teams

View On WordPress

0 notes

Photo

Trying out #supersculpy for the first time, and I've got to say, It's way better than the cheapo stuff I was using before. I can work additively, carve and handle the sculpt without too much deformation. Highly recommended. #wip #polymerclay #sculpture #creature #sculpt #materialstest #nathandrawsdaily

0 notes

Photo

Trying out #supersculpy for the first time, and I've got to say, It's way better than the cheapo stuff I was using before. I can work additively, carve and handle the sculpt without too much deformation. Highly recommended. #wip #polymerclay #sculpture #creature #sculpt #materialstest #nathandrawsdaily http://ift.tt/2f2Ll56

0 notes

Photo

Materials testing today in strengths 👷🏻♀️ #strengthsofmaterials #strengthofmaterials #materialstesting #tension #tensilestrength #tensilestrengthtest #civilengineering #engineering #engineeringstudent (at Oregon Tech)

#strengthofmaterials#materialstesting#tension#civilengineering#tensilestrength#engineering#tensilestrengthtest#engineeringstudent#strengthsofmaterials

1 note

·

View note

Photo

Back in July last year two laboratory test technicians were sent to jail in Hong Kong for falsifying compression test results on concrete cubes at the contract test lab Jacobs. At the time of discovering the issue 19 lab techs were arrested. See more...

And now a NASA investigation has sighted “Altered test results” behind the failure of a clamshell structure that encapsulates satellites as they travel through the atmosphere as being responsible for the failure of its Taurus XL Orbiting Carbon Observatory (OCO) and Glory missions in 2009 and 2011, respectively. See more ...

The issue of stakeholders falsifying results or editing reports in the materials or device manufacture and test verification supply chain is not new, way back in 2000’s the medical industry was hit by the problem initially identified in India’s drug and medical device industry, then found in Germany’s and on and on, this contributed to the USA FDA’s work in 2000’s and finally the issue of 21 CFR Part 11 the Code of Federal Regulations that establishes the United States Food and Drug Administration regulations on electronic records and electronic signatures (ERES). Part 11, as it is commonly called, defines the criteria under which electronic records and electronic signatures are considered trustworthy, reliable and equivalent to paper records.

Our Tinius Olsen materials testing platform “Horizon” under which materials tests are controlled, results calculated, reported and saved is CFR21 Part 11 capable. But more and more I believe this capability and the functionality which enables compliance is of use beyond the medical industry, in fact in any industry where the testing of materials, components and devices is of significance. The key to Horizon’s capability is not just indelible digital record keeping but the functions and ever-present cloak of compliance it maintains as a deterrent. If an operator changes a test parameter, performs an edit or a delete Horizon can be configured to place an alert on screen, transmit notifications and require digital 3rd party sign off before the operator can proceed. This level of monitoring in no way effects a user’s productivity, I would go as far as to say it improves productivity because of the implicit move away from paper recording and or operators tapping data into the system for batches and tests. At Tinius Olsen we are pleased to have partnered with compliance specialists Xybion to offer a total solution enabling users to underpin their test results and product compliance status.

And better still the capability can be added to existing Tinius systems, be they testing metals, composites, concrete, packaging systems, toys, baby soothers, in fact any raw material or device or component strength and performance testing system.

#nasa#rocket#horizon#testinglaboratory#satellite#tinius#olsen#space news#space#medical#industry#medical devices#international#materialstesting#electronic#compliance#components#performance#productivity#improve#partnership#capability#testingsystem#metals#composites#concrete#rubber#plastics

1 note

·

View note

Photo

Resilience of a rubber compound is a measurement of how elastic it is when exposed to various stresses. Tinius Olsen rubber testing systems are built to exacting mechanical standards, with the latest measurement technology

https://www.tiniusolsen.com/tinius-olsen-products

1 note

·

View note

Text

Material Testing

Material Testing Laboratory is an important step in understanding how your materials will perform or react under a wide variety of stresses. The element can assist you in evaluating and understanding your material properties like tensile strength of thermal analysis and much more

The benefits of understanding material properties affect every stage of an application. Material properties testing can assist in R&D projects, prevent failures in the final product, and anticipate issues before they arise.

The component offers a broad range of material properties testing services, specializing in metals, advanced composites, polymers, ceramic composites, and many more. The component can provide valuable insight into virtually any material characteristic and any material type. We have experience in providing testing for many sectors and handle projects large and small in relation to material testing. With a global network of labs and resources, we perform everything from routine tensile testing to custom fatigue programs.

Conducting materials testing for customers for over four decades, we are your ideal partner to provide the independent and industry-leading services you require. Our material testing laboratory covers infrastructure, rubber, and automotive components, metals, composites, polymers, construction materials, and more.

Our material analysis lab can fulfill all your requirements with a state-of-the-art facility.

#textiletestinglaboratory#materialtestingservices#materialtestinglab#materialtestinglaboratory#rubberhardnesstester#materialtestinglaboratories#materialstesting#Materialtestinglaboratories#cellularfoamandsponges#plasticmaterialtestinglab

0 notes

Photo

Tinius Olsen plays a crucial role in ensuring safety-critical fasteners for wind turbines.

Tinius Olsen plays a crucial role in ensuring safety-critical fasteners for wind turbines reach the marketplace at the highest quality possible.

Global manufacturers Cooper & Turner, who have established operations in the UK, China and USA, have been a vital part of the renewable energy industry for over two decades, producing bolts and fixings for the entire wind turbine structure. This includes towers in some remote and challenging environments, such as offshore wind farms.

“We started servicing the wind turbine market more than 25 years ago, long before it became an integral part of the global energy supply,” says David Briggs, Head of Global Quality and Technical Information at the Cooper and Turner Group.

“The manufacture and provision of high quality, safety-critical fasteners, with the ability to operate in some of the most hostile environments in the world, has gained us an unrivalled reputation in the wind turbine marketplace.

”Quality control and safety is where Tinius Olsen has been an integral part of the production process. Cooper & Turner have been using a Tinius Olsen Super L Universal Testing Machine for over 10 years, and it has proved to be one of the most reliable machines within the production process.

“The Tinius Olsen Super L is utilised multiple times per day, with its maximum capacity of 3000kN ensuring the testing of each of our safety-critical fasteners meet all international standards and beyond.”

“We currently supply to all aspects of wind turbine construction including Foundation, Tower Construction, Blade to Hub, Nacelles and Off-shore Transition Pieces. All have their specific tolerances due to the different stresses generated by the motion dynamics throughout the structure.”

With this in mind, all steel is purchased to Cooper &Turner’s own internal specifications, which have been developed over the years to ensure the right tensile strength while still maintaining good ductility. Because these products are used for both onshore and offshore turbines, they must also be extremely robust.

“Bolts have diameters ranging from M16 right up to M80, are generally made of alloy steel, and are heat treated to meet the mechanical properties of ISO898-1 property class 8.8 and 10.9.

“Most fasteners within a turbine are installed by Torque so we have to ensure the product we supply hits the target preload and a determined Torque. The Tinius Olsen machine is capable of applying a torque of 60,000Nm and measuring loads of up to 5000kN.

”The company have their own in-house testing facility, specialising in destructive and non-destructive metal testing and are one of the few within the industry capable of testing large bolts full size.

Other in-house testing includes salt spray testing, tensile testing, as well as Charpy, Rockwell and Micro hardness.

“Over the last 10 years the Tinius Olsen Super L has enabled us to stand out from our peers. Our customers are able to relax knowing that because of this excellent machine, we are able to test our critical products to the maximum safety requirements.”

For further information contact Richard Coombs on [email protected]

#testing#windenergy#industry#greenenergy#manufacturing#materialstesting#engineering#sustainableenergy#tiniusolsen

0 notes

Photo

Video Extensometry

Improvements in both video technology and computer software has a new generation of non-contact extensometers coming to the fore; the video extensometer.

Video extensometers have many advantages. They give users greater flexibility and the best available accuracy across a broad range of applications.

“A video extensometer is a non-contact strain measurement device that has no contributing influence on the specimen being tested,” says Shawn Byrd, Technical Manager at Tinius Olsen

“A VE works by measuring the strain on material samples. Specimens are often provided with lines, dots or various patterns of black-and-white marks. The sensors and software algorithms within the video extensometer detect the motion of these marks and thus the change in length/displacement during the test.”

“Brittle or thin materials benefit particularly from this non-contact solution, as well as samples that release energy at failure, such as a boost at break with cables, ropes or belts. Measurements inside a thermal cabinet or environmental test chamber are also included.”

The Epsilon One is a perfect example of a modern video extensometer and one easily applied to all Tinius Olsen machines. It is inclusive of hydraulic and electro-mechanical platforms, with the ability to be configured for R&D as well as commercial and academic laboratories. It is capable of achieving ASTM E83 class B-1, and ISO 9513 class 0.5 accuracy levels. The system also has a laser assist alignment feature that speeds sample placement and it is designed for fast repetitive testing.

“It has numerous material applications, including metals, plastics, composites, elastomers. It also has ease of mounting, laser alignment as well as always on and real time analysis. The technology also works well for tests where elongation and variation of section measurement are needed, as well as tests where transverse elongation and r & n values are required for ISO 10113 and ISO 10275. In addition, various high strain, small sample geometry is a great candidate for a video extensometer.”

Recent improvements in video technology and image analysis software, such as Tinius Olsen’s own Horizon product, has seen materials testing system manufacturers focus on video extensometers (VE) to provide accurate measurement for a number of specific applications. They are especially effective where contact extensometers might have an adverse impact on test results or accuracy.

“Video Extensometers have been around since the early 1990’s, with the latest VE technology instruments an attractive replacement for mechanical extensometers, laser-scanning systems and strain gauges.”

“They offer many benefits and provide a number of advantages compared with traditional contacting devices This includes no influence on the test specimen, negating errors due to worn or damaged parts or inertia from moving parts and no damage as a result of energy release at failure.”

VE technology’s greatest advantage, however, is its versatility. It is simple and easy to use. One camera can be utilised for both longitudinal and transverse strain measurement, with only a simple adjustment and alignment, with respect to the test axis, being required. The technology permits multiple fields of view as well as multiple strain and material tests and real-time viewing and analysis.

Also, as no load is introduced into a sample, break and slippage due to knife edge engagement is a non-issue.

Application

VE lends itself to a wide range of applications. The technology is especially well suited for rigid materials such as metals and composites, plus a wide range of other materials lend themselves to non-contact tensile strain measurement, such as plastics, textiles, paper, thin sheets, foils and wires.

“The technology is appropriate for conducting a variety of test procedures such as the measurement of material properties and true strain controlled tensile tests. It also includes exploration of cracks, investigation of strain behaviour on dynamic tensile tests, dynamic and high-speed tests and vibration analysis.”

As an example, an R&D lab performs tension and compression tests on a variety of materials ranging from metal and wood to elastomers and plastics. In addition, it has several different traction machines with different interfaces and multiple gauges that utilise different ranges and technologies.

“Of all the available extensometer solutions, only VE offers the versatility and adaptability to meet all of the testing laboratory’s needs. It enables the lab to conduct tests that measure only a few millimetres with an accuracy of 0.1µm, up to 100 millimetres, with only two focal lengths. With its digital and analog interfaces, VE is compatible with all of the lab’s tensile test machines.”

“VE also solves many of the problems that can occur when a specimen has relatively soft edges like a thermoplastic or has features that can rupture or break, causing damage to a clip on extensometer. Overall, VE provides users with a high-performance, high-accuracy and reliable solution for a host of test and measurement applications.”

Operation

Video extensometry incorporates a high-resolution digital camera with advanced real-time image processing to make highly precise strain measurements of a variety of specimen types. The video camera captures the image, which is transferred via an IEEE 1394 (Firewire) interface to a PC or laptop computer.

Longitudinal strain is determined by measuring the change in distance between two line markers that are applied to the test specimen with a colour marker, sticker or clamp. A variety of optional marking pens and target applicators are available.

The video extensometer determines the position of the markers through changes in the brightness of the light/dark edges of the markers. The camera digitises the image, and image analysis algorithms measure the change in grayscale along one image line on the specimen surface. These algorithms allow the instrument to measure edge positions with sub-pixel accuracy.

The transverse deformation is calculated from the measured change in the width of the specimen. Gauge length is automatically measured at the beginning of each test and used for strain calculation, eliminating errors due to inaccurate specimen marking.

The measured values are transferred from the video extensometer to a tensile test machine through a digital or analog interface. The tensile testing machine can then record and post process every measurement in the same way as other strain sensors or gauges. Typically the E-modulus and Poisson’s ration are calculated.

Features and Capabilities

The current generation of VE equipment feature modern, configurable and intuitive user interfaces as well as a wide range of options for data communications, management and export. Its multithread-analysis-kernel supports multi-core processors to achieve low processor load.

A variety of templates are available for different measurement tasks. Connecting a video extensometer to a tensile testing machine also allows for fully automatic operation.

Depending on the type of camera (high-accuracy versus high-speed), VE is capable of significantly different accuracy and sampling rates. With a high-accuracy, 2-megapixel camera, accuracy is 0.002% strain (1µm@100mmFow) and the sampling rate is 50Hz, while the fast version camera offers VGA resolution, a 0.02% strain (10µm @ 100mmFow) and a 4000Hz sampling rate.

“Of all the available extensometer solutions, only VE offers the versatility and adaptability to meet all of the laboratory’s needs. With it, the lab can conduct tests that measure only a few millimetres with an accuracy of 0.1µm up to 100 millimetres, with only two focal lengths. With its digital and analog interfaces, VE is compatible with all of the lab’s tensile test machines.”

“VE also solves many of the problems that can occur when a specimen has relatively soft edges like a thermoplastic or has features that can rupture or break and cause damage to a clip on extensometer. Overall, VE provides users with a high-performance, high-accuracy and reliable solution for a host of test and measurement applications.”

“The best choice for a particular material or application might not be the right choice for another. Keeping that mind, given recent improvements in both hardware and software, extensometer users need to seriously consider video extensometers based on their flexibility, versatility, reliability and cost-effectiveness over a wide range of materials and applications.”

Shawn Byrd is technical manager at Tinius Olsen, and his primary focus is on materials testing and the application of various standards to different testing platforms that help evaluate materials and products.

He is a member of ASTM Committees C09 on Concrete and Concrete Aggregates, D30 on Composite Materials, E28 on Mechanical Testing, and F16 on Fasteners. Involved with independent testing labs in the United States, China, India, and Singapore, he has also completed numerous Nadcap, American Association for Laboratory Accreditation, and ISO audits.

#metrology#precision#accuracy#astm#extensometry#tiniusolsen#flexibility#computersoftware#epsilon#video#materialstesting#technology#analysis

0 notes

Photo

Creating high performing and safer aircraft and components, capable of sustaining many hours in flight, saving energy as well as guaranteeing a contained environmental impact is key in today's competitive aerospace industry

https://www.tiniusolsen.com

#testing#aerospace#safetyfirst#machinetools#materialstesting#precision#machines#metals#automated#manufacturing#automotive#quality#plastics#capacity#packaging#hydraulics#materials#safety#designed

0 notes

Photo

Results acquired by the Tinius Olsen automated materials testing systems are reported in accordance with the relevant test standard be it ISO, ASTM, JIS, GB or GOST standards

https://www.tiniusolsen.com/tinius-olsen-products/automated-system

#testing#automation#software#calibration#materialstesting#hydraulic#robot#systems#machine#machines#test#metals#manufacturing#performancetesting#tests#automotive#quality

0 notes

Photo

The SL series features patented dual-pressure hydraulic loading system in a rugged four-column construction. Our Horizon materials testing software allows various basic and comprehensive tests

https://www.tiniusolsen.com/tinius-olsen-products/tensile-compression-tinius-olsen/sl-series-material-test-machine

#testing#software#design#hydraulic#materialstesting#machinetools#tests#precision#hydraulics#manufacturing#aerospace#loadtesting#automotive#performancetesting#materials

0 notes

Photo

Strength of materials is an important component of automotive safety, with international standards in place to ensure performance of these materials. Tinius Olsen's materials testing experience is a vital cog within this global wheel

https://www.tiniusolsen.com

#automotive#safety#materialstesting#machinetools#hydraulic#precision#materials#metals#manufacturing#aerospace#systems#testing#automation#plastics#productivity#medicaldevices#quality

0 notes