#multimeter tutorial

Explore tagged Tumblr posts

Text

my dryer is broken……so i’ve been trying to dry the clothes by hanging them in the bathroom and pointing a pedestal fan at them for the last 9 hours. works okay for shirts but does NOT work for towels 🙃

#need to get husband to go buy multimeter tomorrow and actually watch the tutorial and see if we can figure what’s wrong with it#cause if not i’m just straight up buying a new one bro this is ridiculous#(obvs not a new one but one off marketplace i mean)

6 notes

·

View notes

Text

Mosfet Testing......

#working #mobile #repair #mobilephone #mobilerepair #mobiles #mosfet #mobilephonerepairspecialist #MOSFET #mobicationhub #mobicationhub9509959090 #testing #mobilerepairtools #iPhone #androidrepair

#mosfet testing#mosfet#how to test mosfet#mosfet transistor#mosfet testing with multimeter#how to check mosfet#how to check mosfet with multimeter#easy method of testing mosfet#how to test mosfet using multimeter#n channel mosfet#smd mosfet testing#how to test mosfet with multimeter#how to test a mosfet#test mosfet#n channel mosfet testing#mosfets#mosfet test#mosfet explained#easy way to test mosfet#p channel mosfet testing#mosfet tutorial

0 notes

Text

DIY: CC1101 Module for Flipper Zero

Your Flipper Zero comes with an internal CC1101 module for SubGhz functionality, but if you want to increase the range, you can build an external module quite easily.

The CC1101 module I used above cost around USD3, and the AMS1117 5v to 3.3v step down power supply buck is around USD0.5. You will also need some male and female headers, prototype board and wires. You can find all these parts in Amazon, Aliexpress, etc.

There are several different CC1101 modules, so please refer to this page for the wiring schematics for the module you are using. The only difference with my design is that I am using an AMS1117 step down power supply buck to convert Flipper Zero 5v to 3.3v so that this module can be smaller since everything sits over the GPIO 1-8 of Flipper Zero, and it also makes this module hot swappable.

My wiring connections and modules are as follows:

First, we cut the prototype board and headers to the required size.

Next, we solder the male and female headers, and the AMS1117 module in place and connect them accordingly. It would be a good idea to use a multimeter to double check that you have all the connections wired correctly and nothing is accidentally touching each other when they shouldn’t.

Now we can insert the CC1101 module and connect it to Flipper Zero, and run some tests. Open SubGHz > Radio Settings > Module and select “External”. Now you can use it like how you normally use the SubGhz functions.

That’s it! Now we can move on to designing a case for this. I used TinkerCAD and printed it on my Snapmaker 2. My 3D files are over here, but you might need to modify it to your needs.

Here is the final result.

Hope you found this tutorial useful. Happy making!

5 notes

·

View notes

Text

From Circuits to Solutions: Practical Projects to Elevate Your EE Skills

From Breadboards to Breakthroughs” encapsulates the journey of an aspiring electrical engineer as they evolve from basic circuit experiments to advanced, real-world engineering projects. Hands-on projects are essential for building practical skills, reinforcing theoretical knowledge, and preparing for professional challenges. Below is a guide to project-based learning that can help you improve your electrical engineering (EE) skills at every stage.

Beginner Projects: Building Foundations

Simple LED Circuit

What you learn: Basic circuit design, current and voltage concepts, use of resistors and LEDs.

Tools: Breadboard, jumper wires, resistors, LEDs, battery.

Battery Tester

What you learn: Measuring voltage and current, basic instrumentation, and safety practices.

Water Level Indicator

What you learn: Sensor integration, simple logic circuits, and practical applications.

Logic Gates and Digital Circuits

What you learn: Boolean logic, digital circuit fundamentals, and troubleshooting.

DIY Switch Circuits

What you learn: Circuit switching, input/output devices, and practical wiring.

Intermediate Projects: Expanding Your Skills

Infrared Security System

What you learn: Sensor-based security, signal processing, and system integration.

Digital Voltmeter

What you learn: Instrumentation, analog-to-digital conversion, and measurement accuracy.

Solar Charger

What you learn: Renewable energy concepts, power management, and circuit protection.

Motor Control Circuits

What you learn: Driving motors, pulse-width modulation (PWM), and power electronics.

Heart Rate Monitor

What you learn: Biomedical instrumentation, sensor interfacing, and signal filtering.

Advanced Projects: Real-World Breakthroughs

Smart Home Automation System

What you learn: IoT, wireless communication (Bluetooth, Wi-Fi), and system integration.

Wireless Power Transfer System

What you learn: Inductive coupling, resonant circuits, and energy efficiency.

Dual Axis Solar Power Tracker

What you learn: Mechatronics, sensor feedback, and renewable energy optimization.

Smart Energy Meter

What you learn: Real-time data monitoring, wireless communication, and energy management.

DIY Quadcopter or Drone

What you learn: Embedded systems, motor control, wireless communication, and robotics.

Why Hands-On Projects Matter

Resume Building: Practical projects demonstrate your skills to potential employers and can help you land internships or jobs

Theory Application: Projects bridge the gap between classroom learning and real-world engineering challenges.

Skill Discovery: Experimenting with different projects helps you identify your interests and strengths.

How to Get Started

Gather Basic Tools: Invest in a quality breadboard, jumper wires, resistors, capacitors, LEDs, and a multimeter.

Start Simple: Begin with basic circuits and gradually tackle more complex projects as your confidence grows.

Use Online Resources: Take advantage of tutorials, simulation tools, and open-source project guides.

Join Maker Communities: Engage with online forums, local maker spaces, and engineering clubs for support and inspiration.

Document Your Work: Keep a project journal, take photos, and share your progress on platforms like GitHub or LinkedIn.

Conclusion

Arya College of Engineering & I.T. is one of the best colleges of Jaipur, which is progressing from breadboard experiments to advanced engineering projects is a transformative process that builds both technical expertise and problem-solving confidence. By systematically advancing through beginner, intermediate, and advanced projects, you will develop a robust skill set that prepares you for the challenges and opportunities of a career in electrical engineering.

1 note

·

View note

Text

From Breadboards to Breakthroughs: Hands-On Projects to Improve Your EE Skills

From Breadboards to Breakthroughs” encapsulates the journey of an aspiring electrical engineer as they evolve from basic circuit experiments to advanced, real-world engineering projects. Hands-on projects are essential for building practical skills, reinforcing theoretical knowledge, and preparing for professional challenges. Below is a guide to project-based learning that can help you improve your electrical engineering (EE) skills at every stage.

Beginner Projects: Building Foundations

Simple LED Circuit

What you learn: Basic circuit design, current and voltage concepts, use of resistors and LEDs.

Tools: Breadboard, jumper wires, resistors, LEDs, battery.

Battery Tester:

· What you learn: Measuring voltage and current, basic instrumentation, and safety practices.

Water Level Indicator

What you learn: Sensor integration, simple logic circuits, and practical applications.

Logic Gates and Digital Circuits: What you learn: Boolean logic, digital circuit fundamentals, and troubleshooting.

DIY Switch Circuits: What you learn: Circuit switching, input/output devices, and practical wiring.

Intermediate Projects: Expanding Your Skills

Infrared Security System: What you learn: Sensor-based security, signal processing, and system integration.

Digital Voltmeter: What you learn: Instrumentation, analog-to-digital conversion, and measurement accuracy.

Solar Charger: What you learn: Renewable energy concepts, power management, and circuit protection.

Motor Control Circuits

What you learn: Driving motors, pulse-width modulation (PWM), and power electronics.

Heart Rate Monitor: What you learn: Biomedical instrumentation, sensor interfacing, and signal filtering.

Advanced Projects: Real-World Breakthroughs

Smart Home Automation System: What you learn: IoT, wireless communication (Bluetooth, Wi-Fi), and system integration.

Wireless Power Transfer System: What you learn: Inductive coupling, resonant circuits, and energy efficiency.

Dual Axis Solar Power Tracker: What you learn: Mechatronics, sensor feedback, and renewable energy optimization.

Smart Energy Meter: What you learn: Real-time data monitoring, wireless communication, and energy management.

DIY Quadcopter or Drone: What you learn: Embedded systems, motor control, wireless communication, and robotics.

Why Hands-On Projects Matter

Resume Building: Practical projects demonstrate your skills to potential employers and can help you land internships or jobs

Theory Application: Projects bridge the gap between classroom learning and real-world engineering challenges.

Skill Discovery: Experimenting with different projects helps you identify your interests and strengths.

How to Get Started

Gather Basic Tools: Invest in a quality breadboard, jumper wires, resistors, capacitors, LEDs, and a multimeter.

Start Simple: Begin with basic circuits and gradually tackle more complex projects as your confidence grows.

Use Online Resources: Take advantage of tutorials, simulation tools, and open-source project guides.

Join Maker Communities: Engage with online forums, local maker spaces, and engineering clubs for support and inspiration.

Document Your Work: Keep a project journal, take photos, and share your progress on platforms like GitHub or LinkedIn.

Conclusion

Arya College of Engineering & I.T. is one of the best engineeering college in Jaipur, which is progressing from breadboard experiments to advanced engineering projects is a transformative process that builds both technical expertise and problem-solving confidence. By systematically advancing through beginner, intermediate, and advanced projects, you will develop a robust skill set that prepares you for the challenges and opportunities of a career in electrical engineering.

Source: Click Here

#best btech college in jaipur#top engineering college in jaipur#best private engineering college in jaipur#best engineering college in rajasthan#best btech college in rajasthan#best engineering college in jaipur

0 notes

Text

3 weeks ago my dryer stopped working.

I watched repair tutorials, looked up reddit threads of common issues, I got out my dad's multimeter and measured all the electrical parts I could reach inside after removing panels!

I finally ordered 2 parts off ebay and replaced them.

Dryer works!

Except now it makes a low humming noise when plugged in but not actively running.

And is warm like the heating element isn't shutting off when the switch is set to off.

So it DRIES clothes, which is what we want.

But in order to not burn my house down, I flip the breaker off after using the dryer. Which is working for now.

Except I really want to go to bed, it's past midnight, and my load of jeans still isn't dry after 1 cycle so I put it on longer and I have to stay up to flip the breaker when the clothes finally dry.

0 notes

Text

EZ Battery Reconditioning

EZ Battery Reconditioning is an online guide that shows you a simple, step-by-step method to repair and recharge various types of batteries, helping you save money while keeping your devices running.

This program offers detailed, easy-to-follow manuals filled with expert tips, taking you through the entire process from start to finish.

Each manual is tailored to a specific battery type, making it quick and straightforward to find and fix the battery you need.

What is EZ Battery Reconditioning?

Replacing worn-out, drained, or deteriorating batteries can be costly, especially when they power valuable items like cars, laptops, or premium electronics. However, most batteries are not beyond salvation—they can be restored, recharged, and reused.

EZ Battery Reconditioning offers a user-friendly online guide that unveils an easy, step-by-step process to breathe life back into numerous types of batteries, allowing you to save money while keeping your devices energized.

This extensive program brims with expert insights and advice, all carefully compiled into a collection of practical manuals. Each manual is tailored to a specific battery type, enabling you to swiftly identify and repair the battery you need.

Within the comprehensive EZ Battery Reconditioning resources, you'll discover in-depth explanations, testing techniques, straightforward instructions, and hands-on tutorials.

These features empower anyone to revive old batteries, even without technical skills or experience. Better still, there’s no need for pricey equipment—the majority of tasks can be accomplished using basic household tools you likely already own.

How Does EZ Battery Reconditioning Work?

The process of revitalizing a battery with the EZ Battery Reconditioning program is not only straightforward but also highly effective, allowing anyone to restore batteries that would otherwise be discarded.

The first essential step is evaluating whether the battery is a good candidate for reconditioning. Not all batteries can be brought back to life, and this critical assessment ensures you’re not wasting time and resources on an unsuitable battery.

The program guides you through various tests and methods to determine the battery's health, making it easier to decide whether it’s worth the effort.

Once you've determined the battery's potential for reconditioning, the next step is gathering the necessary tools. While some people may feel daunted by the idea of using specialized equipment, the truth is, the tools required for this process are quite basic and accessible.

A multimeter, for instance, is used to measure the battery’s voltage and check for any irregularities, which helps you identify whether it needs a recharge or if further steps are required.

Additionally, a reliable battery charger is a must-have to ensure the battery is brought to full charge. Protective gear, including gloves and goggles, ensures that you stay safe during the reconditioning process, as batteries contain chemicals that can be harmful if mishandled.

The EZ Battery Reconditioning program is comprehensive, covering a wide array of batteries that are commonly used in everyday life. Car batteries, laptop batteries, and even small rechargeable batteries are all addressed in detail. Each type of battery has its own unique set of reconditioning techniques, and the program breaks down these processes step by step.

Whether you’re working with a car battery that’s lost its charge or a laptop battery that no longer holds power, you’ll be provided with detailed instructions on how to safely and effectively restore their functionality. This ensures that no matter the type of battery you’re working with, you'll have the knowledge and confidence to bring it back to life.

By following the carefully crafted steps and methods provided in the program, you can extend the lifespan of your batteries, saving money while also contributing to a more sustainable way of living. The knowledge gained from this program not only empowers you to recondition batteries but also opens up opportunities for reducing waste and relying less on costly replacements.

To Read More Visit Here

#ezbatteryreconditioning#ezbatteryreconditioningreview#EZBatteryReconditioningofficialwebsite#BatteryRepair#SaveMoney#RechargeBatteries#DIYBatteryFix#BatteryMaintenance#EcoFriendly#SustainableLiving#BatteryLife#StepByStepGuide#ExpertAdvice#BatteryRecycling#GadgetRepair#MoneySavingTips#BatterySolutions#OnlineGuide#DeviceCare#GreenEnergy

0 notes

Text

Surgery On A Game Gear #1

I decided recently to start blogging the stuff I do as like a diary in order to keep track of the stuff I do. I can't always make YouTube videos on my interests because posting too frequently is bad for a channel. But also because my interests don't always make for good videos. I bought a Game Gear a few years ago and I finally decided to try and fix it. I found a soldering iron and multimeter in my apartment left behind by the prior tenants. They're both functioning still. I looked up a bunch of tutorials for all kinds of repairs on gaming hardware in addition to working on game gears. It seems like this might be easier than I thought, I previously worked in tech on iPhone, Tablet, & Laptop repair. Mostly as diagnosis so I have some useful experience already.

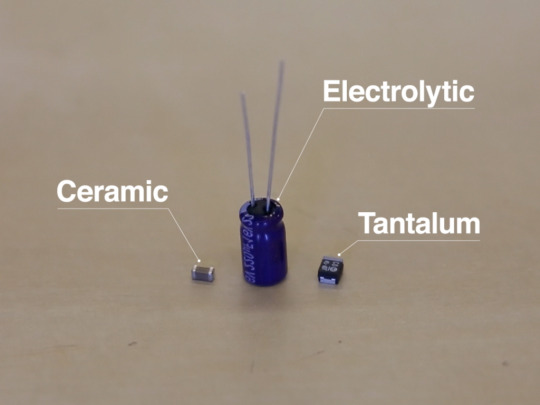

Turns out a lot of video game repairs tend to be pretty easy things, polarizer replacements for Wonderswans, Capacitor replacement for Game Gears, and things like that. Seems like every major console has 1 major failure point and fixing that lets them live up to another couple of decades. Thanks to Ceramic Capacitors made for the Game Gear replacing the electrolytic capacitors with them means capacitors that will never need to be changed again. Awesome. So currently I'm awaiting on the arrival of a ceramic capacitor kit which should be here Tuesday. I heard this is a harder replacement than electrolytic capacitors but ceramic is cheaper and better. Besides, I heard you can't really mess up a device beyond repair with solder. You can always remelt, clean, and try again. So I have the opportunity for plenty of practice.

Above is a picture of the inside of my actual Game Gear. I'm not 100% sure if it's a capacitor issue because the interior is surprising clean and the screens randomly fail on these. I've seen a lot of videos where the electrolytic capacitors were leaking. That's because inside of them is a liquid. Since these fail frequently I'll be replacing them anyway. But it's weird to me that they aren't leaking. If replacment fixes it I'll be replacing only the shell to a custom one, if it doesn't fix them then I'll need to buy a screen replacement which costs around 70 USD.

You're probably wondering where the capacitors are. If you've seen a capacitor before they look like little batteries with legs. I marked them in the red circles in the picture above. The capacitors inside a game gear are encased in a black plastic housing. They might have done this because they knew the capacitors would be an issue and the plastic was to prevent leakage or maybe it was just extra protecting. But after nearly 30 years this plastic has become very brittle and isn't protecting anything. Weirdly they also glued them down and the plastic has begun to fuse to the board. So removing them means sometimes the plastic will break leaving bits of glued plastic to the board. These will then have to be melted off with a soldering iron. Thankfully I only had a couple like that.

I'm guessing my game gear was lightly used, which makes sense as it only came with 4 games. I got it from an older woman selling off some old video game stuff to a local games store. I also picked up an Atari 2600 and about 30 games from her.

Removing them is pretty easy, first I used forceps to lift them. If they were stubborn I used flush cutters to lift them. I tried to avoid using the flush cutters as they might snip the plastic housing. On the bottol left one you can see a bit got stuck to the board. You can leave the plastic, it won't get in the way of a ceramic capacitor because they're much smaller. The ceramic capacitor won't need to be bent to lay down.

After lifting removal is easy. You use forceps to hold the capacitor then push the soldering iron against the solder to melt it. This will free the capacitor's little metal legs and it'll come right off. I had my iron set to 400 Celsius if someone sees this and tries it in the future. For removing the plastic I used a wedge tip and gently rubbed the area until the plastic was gone.

Overall, this was a pretty easy thing to do. But once the ceramic capacitors come in I'll have to put those in and this a little bit smaller and don't have legs. I've heard it's a pretty challenging solder and I've only soldered once before and that was 2 days ago to fix the contacts on a Genesis' power port. But if this is the majority of what I'll be doing in repairing these old devices then I think I can handle it. I've already ordered some extra dead gaming devices, Wonderswans, to repair. Hopefully I can increase the number of working retro electronics in the world. It'd be a shame to see these go in a dump where they can't be played.

I'll see you all again in a few days when the capacitors come in. Hopefully this all turns out well so I can get that custom case. I'll eventually replace the screen regardless as the screens are pretty bad but I'd like to avoid having to drop 130 usd on both at once. When a damaged Wonderswan goes for 10 bucks that money could be better spent fixing those.

1 note

·

View note

Text

Essential Tools and Kits for Mobile and Laptop Repair Enthusiasts

In today's fast-paced world, our mobile phones and laptops are indispensable. When they break or malfunction, it can be incredibly frustrating. For those who love a good DIY project or just want to save on repair costs, having the right tools and kits for mobile and laptop repairs is essential. This guide will help you understand which tools are crucial for tackling common issues and why having a well-equipped toolkit is a game-changer for repair enthusiasts.

Basic Tools for Mobile and Laptop Repair

1. Precision Screwdrivers

Precision screwdrivers are a must-have for any repair enthusiast. Most electronic devices use small screws that require special screwdrivers to remove. Invest in a set that includes various types of heads such as Phillips, flat, Torx, and Pentalobe, which are commonly found in smartphones and laptops.

2. Pry Tools

Pry tools, also known as spudgers, are used to open devices without damaging their delicate components. These tools come in plastic or metal and help you safely pry apart phone or laptop casings.

3. Tweezers

Tweezers are essential for handling small components and connectors inside your devices. ESD (Electrostatic Discharge) safe tweezers are particularly important to prevent static electricity from damaging sensitive parts.

4. Suction Cups

Suction cups are used to lift screens off mobile phones and tablets without causing damage. They provide a secure grip and make it easier to remove screens, especially on devices with adhesive seals.

5. Spare Screws and Adhesives

Having a collection of spare screws and adhesives can save you a lot of hassle. Screws are easy to lose, and having the right adhesive can ensure that parts like screens stay securely in place after repairs.

Advanced Tools for Professional-Level Repairs

1. Multimeter

A multimeter is an essential tool for diagnosing electrical issues. It can measure voltage, current, and resistance, helping you identify faulty components and connections.

2. Heat Gun

A heat gun is used to soften adhesives and solder joints, making it easier to remove and replace components. It's particularly useful for screen replacements and soldering tasks.

3. Soldering Iron and Solder

For more advanced repairs, such as fixing broken connections or replacing small components, a soldering iron and solder are indispensable. Look for a temperature-controlled soldering iron for more precise work.

4. Magnifying Glass or Microscope

Working with tiny components can strain your eyes. A magnifying glass or a microscope can help you see what you're doing more clearly, ensuring more accurate repairs.

5. ESD Mat and Wrist Strap

Electrostatic discharge can damage sensitive electronic components. An ESD mat and wrist strap are essential to ground yourself and protect the device from static electricity during repairs.

Recommended Kits for Mobile and Laptop Repairs

1. iFixit Pro Tech Toolkit

The iFixit Pro Tech Toolkit is highly recommended for both beginners and professionals. It includes a wide range of precision tools, spudgers, tweezers, and a magnetic mat to keep screws organized. iFixit also provides detailed repair guides for various devices.

2. Kaisi 136 in 1 Precision Screwdriver Set

This comprehensive set includes 136 pieces, featuring various precision screwdrivers, spudgers, tweezers, and other essential tools. It's a great option for those who want an all-in-one solution for mobile and laptop repairs.

3. XOOL 80 in 1 Precision Set

The XOOL 80 in 1 Precision Set offers a good balance of quality and affordability. It includes a variety of precision tools, pry tools, and a handy carrying case to keep everything organized.

Tips for Successful Repairs

Research Beforehand: Before attempting any repair, research your specific device and the problem. Watch tutorial videos or read guides to understand the steps involved.

Organize Your Workspace: Keep your tools and parts organized to avoid losing small screws and components. A magnetic mat can be particularly helpful.

Take Your Time: Rushing can lead to mistakes. Take your time to ensure each step is done correctly.

Practice on Old Devices: If you're new to repairs, practice on old or broken devices to build your confidence and skills.

Conclusion

Having the right tools and kits can make all the difference in successfully repairing your mobile phone or laptop. Whether you're a novice or a seasoned repair enthusiast, investing in quality tools will not only make the process smoother but also more enjoyable. Remember, while DIY repairs can be rewarding, some issues may still require professional assistance.

For those times when a repair feels beyond your skill level or you simply prefer expert help, consider reaching out to GoFix, a reliable mobile repair service known for its quality work and excellent customer service. With GoFix, you can trust that your device is in good hands and will be repaired promptly and professionally.

0 notes

Text

Mastering Multimeters: Essential Principles for Manufacturing & Automation Technicians

Dive into the essential principles of using multimeters in manufacturing and automation with our comprehensive video tutorial. From understanding basic functions to advanced troubleshooting techniques, this video equips technicians with the knowledge needed to excel in their field. Join us as we explore voltage, current, resistance measurements, and more, tailored specifically for Manufacturing and Automation Technicians. This video is brought to you by the Philadelphia Technician Training Institute, where our program prepares technicians for success in today's rapidly evolving industry.

#automation programs in philadelphia#automation tech institute in philadelphia#automation certification programs in philadelphia#automation trade schools degree in philadelphia#automation certification classes in philadelphia#automation certification courses in philadelphia#automation college in philadelphia#school automation in philadelphia#Electrical programs in philadelphia#Electrical tech institute in philadelphia

0 notes

Text

Demystifying Electrical Measuring Instruments: A User's Guide

Introduction

In the intricate realm of industrial operations, electrical measuring instruments play a pivotal role in ensuring precision, accuracy, and reliability. At PowerTech, the commitment to demystifying these instruments becomes a cornerstone in empowering users. This article serves as a comprehensive user's guide, unraveling the complexities and intricacies of electrical measuring instruments.

The Landscape of Electrical Measuring Instruments

The article begins by painting a panoramic view of the diverse landscape of electrical measuring instruments. From multimeters to oscilloscopes, readers are introduced to the array of instruments that form the backbone of electrical measurements. PowerTech's role as a guide through this landscape is established.

Understanding Measurement Parameters

A key aspect of demystification lies in understanding the parameters these instruments measure. The article delves into voltage, current, resistance, frequency, and other crucial parameters. PowerTech's commitment to providing instruments that cater to a spectrum of measurement needs is highlighted.

Navigating Instrument Features

Demystification extends to the features embedded in electrical measuring instruments. Readers are guided through the functionalities such as auto-ranging, data logging, and connectivity options. PowerTech's emphasis on user-friendly designs that enhance operational efficiency is showcased.

Practical Applications and Use Cases

The article takes a practical turn by illustrating real-world applications and use cases of electrical measuring instruments. From troubleshooting electrical circuits to validating equipment performance, readers gain insights into how these instruments become indispensable tools in diverse industrial scenarios.

PowerTech's Commitment to User Education

The demystification journey is aligned with PowerTech's commitment to user education. The article highlights educational resources, tutorials, and support avenues provided by PowerTech to empower users in harnessing the full potential of electrical measuring instruments.

Calibration and Maintenance Essentials

Demystification is incomplete without addressing the importance of calibration and maintenance. The article explores PowerTech's approach to ensuring that electrical measuring instruments deliver accurate and reliable results over time. Calibration services and preventive maintenance become integral components of the user experience.

User-Friendly Interfaces

Navigating the user interface is a crucial aspect of demystification. The article details how PowerTech's electrical measuring instruments are designed with user-friendly interfaces, ensuring that users, regardless of expertise levels, can seamlessly operate and interpret results.

PowerTech: Your Partner in Demystifying Electrical Measurements

The article concludes by positioning PowerTech as a trusted partner in demystifying electrical measurements. Whether for seasoned professionals or those new to the field, PowerTech's instruments and educational initiatives stand as pillars supporting users on their journey of mastering electrical measurements.

Conclusion

"Demystifying Electrical Measuring Instruments: A User's Guide" closes with an invitation for readers to explore the vast world of electrical measurements with confidence. The article encourages industries to partner with PowerTech for instruments that not only deliver accurate results but also empower users through knowledge and demystification.

0 notes

Text

Technical educational equipment Manufacturer, Suppliers and Exporter in India

Technical educational equipment is a broad term that encompasses a wide range of tools and devices used to teach and train students in technical fields. These tools can be used to teach a variety of subjects, including engineering, computer science, and vocational trades. Some common types of technical educational equipment include: Laboratory equipment: This type of equipment is used to conduct experiments and collect data. It can include items such as microscopes, balances, and spectrometers. Training simulators: These simulators provide students with hands-on experience with real-world equipment and processes. They can be used to train students in a variety of skills, such as welding, operating machinery, and flying airplanes. Software and instructional materials: These materials provide students with the information they need to learn about technical topics. They can include textbooks, online tutorials, and interactive simulations. Technical educational equipment can be a valuable asset for schools and training institutions. It can help students to develop the skills and knowledge they need to succeed in technical careers. When choosing technical educational equipment, it is important to consider the needs of the students and the curriculum being taught. The equipment should be safe, reliable, and easy to use. It should also be up-to-date with the latest technology. Technical educational equipment can be expensive, but it is a worthwhile investment. It can help students to develop the skills they need to succeed in the workforce. Here is a list of common technical educational equipment used in school and college laboratories: 1. Microscopes: Compound Microscope Stereo Microscope 2. Laboratory Glassware: Beakers Flasks Test Tubes Graduated Cylinders 3. Chemistry Apparatus: Bunsen Burners Pipettes Centrifuges 4. Physics Instruments: Vernier Calipers Spectrometers Oscilloscopes 5. Biology Equipment: Petri Dishes Incubators 6. Environmental Science Instruments: pH Meters Conductivity Meters Water Quality Testing Kits 7. Engineering Tools: Digital Multimeters Power Supplies Soldering Stations 8.Computer Science Equipment: Desktop Computers Laptops Raspberry Pi Kits 9.Mathematics Tools: Graphing Calculators Geometry Kits Compass and Protractor Sets 10.Electronics Kits: Breadboards Resistors Capacitors 11. Robotics Components: Motors Sensors Microcontrollers 12. Geology Instruments: Rock and Mineral Kits Geological Hammers Compass Clinometers 13. Astronomy Equipment: Telescopes Star Charts Solar Filters 14. Material Science Tools: Spectrophotometers Tensile Testing Machines 15. Safety Equipment: Lab Coats Safety Goggles Fire Extinguishers 16. Audio-Visual Equipment: Projectors Interactive Whiteboards Educational Software 17.3D Printers and Scanners: 3D Printers 3D Scanners 18. Virtual Reality (VR) Systems: VR Headsets VR Simulators 19. Renewable Energy Kits: Solar Panels Wind Turbine Kits 20. Math and Science Software: Simulation Software Data Analysis Tools

0 notes

Text

DIY: ESP32 Cam + ESP8266 Combo Flipper Zero Module

Here is my project for this weekend, a Flipper Zero module with both ESP32 CAM and ESP8266 D1 Mini combined. This allows me to use it for Marauder, Deauther, WiFi Scanner, Camera, Morse Flash, etc. in a single module. I did consider doing a Mayhem board with NRF24/CC1101, but I find myself rarely using them and Flipper has CC1101 built in anyway (just with shorter range).

The steps to build it is relatively simple. It just combines the two separate modules and some switches to switch between between the two. Below is a quick guide on how I build it. Note that this is not meant to be a detailed step by step tutorial. If you have some experience with building electronic projects, you should be able to follow along.

Build Steps

Start by cutting the prototype board to the required size and the header pins to the correct lengths (8 & 10 pins). Adjust the position of the plastic thingy holding the male header pins, then bend the pins.

After that, we solder all the header pins to the prototype board and also start soldering the required wires. See the references at the end of this post for all the wiring you need to do to connect the necessary pins.

I used four DPDT switches to switch between the 2 modules. All the required connections from Flipper goes to the switches, then from the 2 poles of the switches to the 2 modules. The same with the antenna as well, as I didn’t want to have 2 separate antennas.

Now is a good time to use a multimeter to check all the connections are good and that there no shorts.

Lastly, we use hot glue to hold the antenna cables securely to the prototype board. Here’s what the completed module looks like.

Now we just need to attach the antennas and insert the ESP32 Cam and ESP8266 modules. Oh, and if you have not mod your D1 Mini to use an external antenna, read this. Flash all the required firmware and test!

Next project, designing and 3D printing a case for this module.

Useful Reference

esp8266_deauther

Flipper Tutorial ESP8266 Deauther v2

ESP32Marauder

flipperzero-mayhem

Flipper Zero ESP32 CAM Camera Module

Flipper-Zero-Camera-Suite

1 note

·

View note

Text

The Ultimate Guide to Defy Appliance Repairs

When it comes to household appliances, Defy has established itself as a trusted and reliable brand. However, like any other appliances, Defy appliances can also encounter issues over time. This is where knowing how to handle Defy appliance repairs comes in handy. Whether it's your Defy refrigerator, washing machine, or oven, understanding the basics of troubleshooting and repair can save you time and money.

Defy Appliance Repairs: A DIY Approach

Diagnosing the Problem: The first step in tackling Defy appliance repairs is identifying the problem. Is your Defy refrigerator not cooling as it should? Is your washing machine making strange noises? Is the oven temperature not accurate? Clearly pinpointing the issue will help you narrow down your repair efforts.

Gathering the Tools: Before you begin any repair, make sure you have the necessary tools at hand. Wrenches, screwdrivers, multimeters – these can be essential in fixing the problem correctly. Having the right tools ensures that your repair work goes smoothly without causing further damage.

Keyword: Defy Appliance Repairs: Throughout your repair process, keep the keyword "Defy appliance repairs" in mind. This will remind you of the brand and the specific focus of your repair task. Repeat this keyword to reinforce the brand and the purpose of your efforts.

Finding Resources: In the age of the internet, finding resources for Defy appliance repairs is easier than ever. Look for official Defy troubleshooting guides, online forums where users discuss similar issues, and even video tutorials. These resources can provide step-by-step guidance and visual aids for a more effective repair.

Safety First: Before you start tinkering with your Defy appliance, remember to prioritize safety. Unplug the appliance from the power source to avoid any electrical mishaps. If the repair involves gas connections, exercise caution and consider seeking professional help.

Taking Professional Help: While some minor Defy appliance repairs can be done by yourself, there are times when it's best to call in the professionals. Complex issues, intricate parts, or situations where you're not confident can warrant the expertise of a repair technician. This ensures that the appliance is fixed properly and reduces the risk of further problems.

Preventive Measures: Once you've successfully completed your Defy appliance repairs, consider implementing preventive measures. Regular cleaning, maintenance, and following manufacturer guidelines can extend the lifespan of your Defy appliances and minimize the need for frequent repairs.

Well, understanding how to handle Defy appliance repairs can be a valuable skill for any homeowner. From diagnosing the problem to gathering the right tools and resources, a DIY approach can often save you time and money. However, always prioritize safety and know when it's best to seek professional assistance. By keeping the keyword "Defy appliance repairs" in mind, you'll stay focused on the brand and its specific repair requirements throughout the process.

0 notes

Text

GODIAG GT108 Super OBDI-OBDII Conversion Adapter Use Tutorial

Godiag GT108 Super OBDI-OBDII Universal Conversion Adapter is specially designed for cars, SUVs, trucks, tractors, mining vehicles, generators, boats, motorcycles, and individual ECU control units, etc. It can convert the OBDI diagnostic interface into standard OBDII diagnostic interface through DIY wiring interface, and connect to OBDII diagnostic programming equipment to read data streams, diagnose fault codes, program, activate and code... for the car maintenance personnel conveniently.

Godiag GT108 Converter features:

1.DIY wiring, it can be converted to OBDII according to the car diagnostic interface.

Because the definitions of diagnostic interfaces in different regions are inconsistent, the popular conversion cables and adapters in the market cannot use different definitions of diagnostic interfaces. GODIAG GT108 Super OBDI-OBDII Adapter can be used by maintenance engineers to connect according to their own needs.

2.The device has reverse connection protection.

If the power supply is connected wrong, the device will not burn out, and it will not cause harm to the OBDII diagnostic programming device.

3.Independent GND4, GND5

It is more suitable for judging the problem of poor grounding of some control units.

4.Analog IGN switch.

Press the IGN switch, the corresponding port outputs ING VCC

5.Power indicator, GND4, GND5 switching indicator, IGN switching indicator.

6.DIY the way to lock the wire.

Equipped with different diagnostic interface cables, ECU cables, and locking screwdrivers.

7.Truck & Car Diagnostic Interface Connection Jumper Kit

Different configurations of wiring kits are different, please purchase according to maintenance needs.

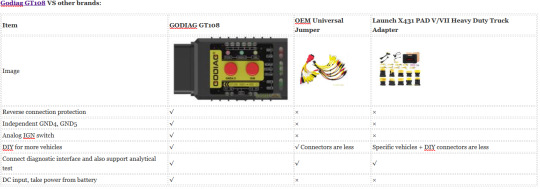

Godiag GT108 VS other brands:

Godiag GT108 Connection Diagram:

Some vehicles’ definition:

Audi VW Skoda Seat/ BMW/ Ford/ Mazda PIN

Mercedes- Benz 38 PIN

Godiag GT108+ diagnostic tool (i.e. Autel MK808)+ Car Connection:

Gogidag GT108+ Delphi DS150+ Truck Connection:

Gogidag GT108+ Godiag GT106 + Truck Connection:

Gogidag GT108+ OBDSTAR MS70+ Motorcycle Connection:

Gogidag GT108+ Delphi DS150+ Mine Vehicles, Tractors, Boats and Generators Connection:

Gogidag GT108+ ECU Connection:

How to use Godiag GT108 Conversion Adapter?

1.Find the definition of the diagnostic interface

Find the maintenance manual of your own vehicle, or search online.), or see the definition diagram of the corresponding diagnostic interface of the GT108 manual.

2.According to the interface definition, find out the connection line needed by your car, and connect to the GT108 adapter according to the definition. (Use a screwdriver to lock the terminal.)

3.Connect the connected diagnostic cable to the vehicle OBD1 diagnostic interface according to the definition.

Connect GND 4 or GND5 first, and then connect BAT+.

If the power cable is connected correctly, the POW light of the GT108 host will light up.

If the vehicle diagnostic interface does not have power, please connect the car battery to the DC power connector of GT108 with the battery cable.

If the vehicle needs the ignition signal, connect the O-IGN line, and press the IGN switch, the corresponding IGN light will light up, and the O-IGN line will output the ignition power signal.

4.Connect the communication line CAN or K-line to the diagnostic interface.

Note: If it is the truck diagnostic software added by the car diagnostic equipment, you need to buy a GT106 24V to 12V adapter.

5.Connect the diagnostic device to start diagnosing the vehicle.

NOTE:

If you cannot find the definition for your own vehicle diagnostic interface, you can first find out the power supply of the diagnostic interface. First use the black battery clip on the battery connection cable to connect the negative pole of the battery, and then use the BAT+ line to connect to the diagnostic interface to find the power supply. You can also use a multimeter to find the diagnostic interface power supply. The definition of the diagnostic interface can also be judged by the GT101 PIRT Electric Circuit Tester device.

Godiag GT108 OBDI-OBDII Conversion Adapter has A, B, C three configurations. A & B configurations are at the same price, and the C configuration is more expensive as it supports the vehicles covering A & B.

A Configuration is for Cars, SUVs, Pickup Trucks, and Motorcycles

(Item No. SO669-C, Price: €48)

B Configuration is for Trucks, Tractors, Mining Vehicles, Generators, and Boats

(Item No. SO669-B, Price: €48)

C Configuration includes both A and B configuration.

(Item No. SO669, Price: €57)

0 notes

Text

Vancouver's Top Appliance Repair Technicians at Your Service

Understanding the sequential procedures required in Appliance repair can be extremely valuable. You may save time and money by learning how to repair your appliances without difficulty. The first step is to identify the problem. Is there insufficient cooling in your refrigerator? Is your washing machine refusing to empty? After determining the issue, you can move on to the next stage, which is research. Spend some time researching common causes and solutions for the problem you're experiencing. This will help you understand what has to be done on a deeper level. Then, gather all of the necessary equipment and supplies. To avoid aggravation and unnecessary delays, make sure you have everything you need before starting the repair. Now is the time to get your hands dirty! Refer to the thorough directions in tutorials or repair manuals for your specific type of equipment. Take your time and carefully follow each guideline to ensure a proper repair. Finally, once the repair is complete, test your appliance to confirm it is working properly again.

Learning the Fundamentals of Appliance Repair

Appliance maintenance is a necessary skill in today's fast-paced, technologically-driven environment. Understanding the fundamentals of appliance repair, whether it's a broken dishwasher or a broken refrigerator, can save you time, money, and stress. Identifying the problem is the first step in undertaking any repair project. This can be accomplished by scrutinizing the appliance thoroughly and listening for any unexpected sounds or noises. After you've diagnosed the problem, gather the appropriate equipment and materials before trying any repairs. Having the correct equipment on hand, from screwdrivers to multimeters, is critical. It's now time to begin the repair process. This could include repairing a broken part, clearing clogged filters, or rewiring electrical connections. If you are unsure about any procedure, always consult the appliance's instructions or get professional assistance. Finally, once the repair is completed, it is critical to test the appliance to confirm appropriate operation. By learning the fundamentals of appliance repair, you may become a more self-sufficient homeowner and save the trouble of calling in a professional for every minor problem. So roll up your sleeves and prepare to take on your next appliance repair assignment!

Common Appliance Troubleshooting

It is critical to have a clear grasp of the problem at hand when troubleshooting typical appliance issues. Begin by identifying the individual device that is creating problems and determining the nature of the problem. Is it a broken refrigerator that isn't chilling properly? Maybe a dishwasher that isn't draining properly? After you've found the issue, you may start troubleshooting. This typically requires inspecting for obvious signs of wear or damage, such as frayed wires or leaky hoses. In addition, look for any pertinent error codes or troubleshooting advice in the appliance's user handbook. Sometimes the issue is as simple as a blown fuse or clogged filter, which can be easily repaired. If you're unsure how to proceed or if the problem persists, consult with a professional Vancouver appliance repair provider. They are qualified and experienced to detect the problem and resolve it safely and effectively.

Methodical Repair Procedures for a Wide Range of Appliances

When repairing various pieces of equipment, it's critical to follow a step-by-step approach to ensure a successful and rapid repair. The first step is to properly diagnose the problem by analyzing the appliance and establishing the root cause. After determining the problem, the next step is to obtain the necessary tools and supplies for the repair. Replacement components, screwdrivers, and other specialized equipment may be included. The repair process can now commence with the tools in hand. It is critical to disassemble the appliance carefully, noting the order and placement of each component. Once the damaged component has been located, it can be replaced or fixed as needed. After the repair is finished, the appliance should be carefully reassembled, making sure that all components are properly aligned and linked. Finally, before declaring the repair process complete, the appliance must be tested to confirm appropriate functionality. Even the most complex appliance repairs can be completed effectively by following this step-by-step procedure.

Conclusion:

Finally, it is clear that the use of renewable energy sources is critical to the long-term viability of our planet. The evidence is strong that fossil fuels are diminishing at an alarming rate and inflicting irreparable environmental damage. Furthermore, by creating new jobs, renewable energy not only reduces carbon emissions but also supports economic growth. Switching to renewable energy will clearly benefit both present and future generations, in addition to being necessary. However, it is critical to realize the challenges that this change offers, specifically the upfront high costs and the need for infrastructure construction. Despite these challenges, the long-term benefits of renewable energy much surpass the short-term costs. Thus, in order to reduce climate change and secure a sustainable future, companies, individuals, and governments must all take action and prioritize the use of renewable energy sources.

0 notes