#nickel alloys

Text

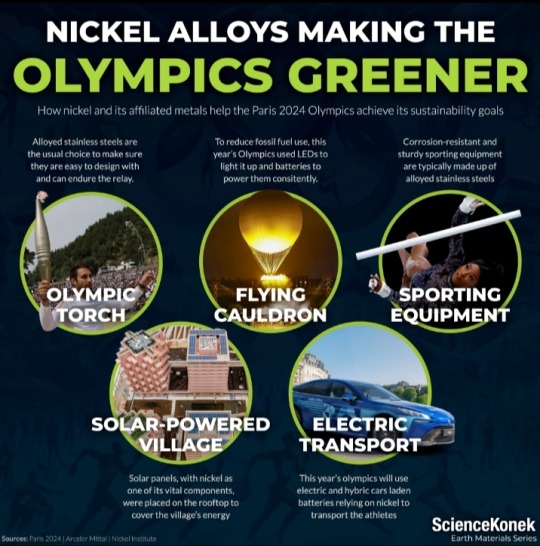

𝗧𝗢𝗪𝗔𝗥𝗗𝗦 𝗚𝗥𝗘𝗘𝗡𝗘𝗥 𝗢𝗟𝗬𝗠𝗣𝗜𝗖𝗦! 🏟️

Achieving greener Olympic games is not an overnight feat nor a simple design.

It involves a lot of materials from the Earth, such as nickel alloys, to make the Paris 2024 Olympics a sustainable event! 🔎

#2024 Paris Olympics#2024 Summer Olympics#Paris 2024#Olympic Games#Olympics#nickel alloys#sustainability#flying cauldron#solar power#electric vehicles#olympic village

4 notes

·

View notes

Text

Nickel Alloys Stockist in Mumbai

At MV Super Alloys, we are a leading stockist, importer, and trader of nickel alloys,including nickel-copper alloys, nickel-based super alloys, iron-nickel alloys, nickel-iron alloys, nickel-chromium alloys, and other high nickel alloys, in Mumbai, Hyderabad, India.

0 notes

Text

Exploring the World of Nickel Alloys: What You Need to Know

Welcome to the fascinating world of nickel alloys! If you've ever wondered about the shiny, versatile metals used in various industries worldwide, then this blog post is for you. These alloys are not only durable and corrosion-resistant but also play a crucial role in modern technology and innovation. Let's dive into what makes nickel alloys so special and why they're essential materials in today's industrial landscape.

Advantages and Applications of Nickel Alloys

When it comes to using this alloy, there are numerous advantages that make them a popular choice in various industries. One of the main benefits is their exceptional resistance to corrosion and high temperatures, making them ideal for applications where strength and durability are essential.

This alloys are widely used in the aerospace industry for components such as turbine engines and aircraft structures. Their ability to withstand extreme conditions makes them crucial for ensuring safety and reliability in aviation.

In the medical field, this alloy play a vital role in manufacturing surgical instruments, implants, and medical devices due to their biocompatibility and resistance to bodily fluids.

The oil and gas industry also heavily relies on nickel alloys for equipment exposed to harsh environments like offshore drilling rigs. Their corrosion resistance helps prolong the lifespan of critical components in this sector.

The versatility of this alloy makes them indispensable across a wide range of industries where performance under demanding conditions is non-negotiable.

Common Types of Nickel Alloys

When it comes to nickel alloys, there are several common types that are widely used in various industries. One of the most popular ones is Nickel 200, known for its excellent resistance to corrosion and high thermal and electrical conductivity.

Another common type is Nickel 201, a low-carbon variant of Nickel 200 that offers similar properties but with improved ductility and lower carbon content.

Inconel alloys are also commonly used, offering outstanding oxidation resistance at high temperatures and excellent mechanical strength. Inconel 600, Inconel 625, and Inconel 718 are some well-known variations.

Monel alloys, such as Monel 400 and Monel K-500, are highly resistant to corrosion by acids and alkalis. These alloys find applications in marine engineering due to their exceptional strength.

Hastelloy alloys like Hastelloy C-276 exhibit great resistance to a wide range of chemical process environments including strong oxidizers. These versatile nickel-based superalloys are favoured in harsh industrial settings for their reliability.

Factors to Consider Before Choosing a Nickel Alloy

When selecting a nickel alloy for your project, there are several factors to consider. Think about the specific environment in which the alloy will be used. Will it be exposed to high temperatures, corrosive chemicals, or extreme pressures? Understanding the conditions will help you choose the right nickel alloy that can withstand these challenges.

Another crucial factor is the desired properties of the final product. Different nickel alloys offer varying levels of strength, ductility, and resistance to heat and corrosion. Assessing these requirements will guide you towards selecting an alloy that best suits your needs.

Cost is also a significant consideration when choosing a this alloy. While some alloys may offer superior performance, they might come at a higher price point. Balancing quality with affordability is key in making an informed decision.

Don't forget about availability and support from a reputable alloy’s supplier. Ensure that you can easily source the required materials and receive any necessary technical assistance throughout your project's lifespan.

Maintenance and Care for Nickel Alloys

Maintenance and care for these alloys are essential to ensure their longevity and performance. Regular cleaning with a mild detergent and water can help remove dirt and grime without causing damage to the alloy's surface. Avoid using abrasive cleaners or harsh chemicals that can scratch or corrode the nickel alloy.

To prevent tarnishing, it is recommended to dry the nickel alloy thoroughly after cleaning. Applying a coat of metal polish specifically designed for nickel alloys can help maintain its luster and protect it from oxidation. Inspecting the alloy periodically for any signs of wear or corrosion is also important in preventing further damage.

Storing these alloys in a cool, dry place away from direct sunlight can help preserve their appearance and structural integrity. Additionally, avoiding exposure to extreme temperatures or humidity levels can prevent potential degradation of the alloy over time. Regular maintenance routines will not only keep your nickel alloys looking great but also extend their lifespan significantly.

Innovative Uses of Nickel Alloys in Various Industries

This alloy have found innovative applications across a wide range of industries, thanks to their exceptional properties and versatility. In the aerospace industry, nickel alloys are used in aircraft engines due to their high temperature resistance and corrosion protection. These alloys help enhance engine performance and durability while withstanding extreme conditions.

In the medical field, nickel-based materials are utilized for orthopaedic implants and surgical instruments. Their biocompatibility and strength make them ideal for long-term use within the human body. Additionally, in the automotive sector, nickel alloys play a crucial role in manufacturing components that require excellent heat resistance and mechanical strength.

Furthermore, the oil and gas industry rely on this alloy for equipment subjected to harsh environments such as deep-sea drilling operations. The outstanding resistance to corrosion makes these materials essential for ensuring safety and efficiency in extracting resources from challenging locations.

Conclusion: The Future of Nickel Alloys in Technology and Beyond

Nickel alloys have proven to be versatile and reliable materials with a wide range of applications across various industries. As technology continues to advance, the demand for nickel alloys is expected to grow even further. With their exceptional properties and capabilities, nickel alloys are poised to play a crucial role in shaping the future of technology and beyond.

As we look ahead, it is clear that nickel alloys will remain at the forefront of material science, providing essential support for advancements in technology, sustainability efforts, and beyond. By staying informed about the latest developments in this field and working closely with reputable suppliers of these alloys, industries can harness the full potential of these remarkable materials for a brighter future.

0 notes

Text

Exploring the Diversity of Nickel Alloys: A Guide by Apex Metal India

Nickel alloys are the unsung heroes of the materials world, offering a unique blend of strength, corrosion resistance, and versatility. At Apex Metal India, we take pride in being a Leading Importer, Supplier, and Stockist of these diverse nickel alloys, sourced from reputable European mills with valid certificates. In this guide, we'll delve into the different types of nickel alloys and their unique characteristics, shedding light on how they empower various industries.

1. Inconel Alloys - Inconel alloys are the high-temperature champions. They offer superb resistance to extreme temperatures and corrosion, making them indispensable in aerospace and gas turbine components. Apex Metal India provides various grades, including Inconel 600 and Inconel 718,and many more ensuring top-notch quality for your projects.

2. Hastelloy Alloys- Hastelloy alloys are renowned for their exceptional corrosion resistance, especially in highly aggressive chemical environments. Industries such as chemical processing and oil and gas rely on Hastelloy alloys like Hastelloy C4, C-276, etc for their critical applications.

3. Incoloy Alloys- Incoloy alloys are valued for their unique combination of strength and corrosion resistance. They find use in diverse applications, ranging from marine environments to nuclear reactors. Apex Metal India offers a range of Incoloy alloys, ensuring that you have access to materials tailored to your specific requirements.

4. Monel Alloys- Monel alloys are celebrated for their exceptional corrosion resistance, making them ideal for applications in marine and acidic environments. One of the most widely used grades is Monel 400, but Apex Metal India goes further by providing options like Monel K-500 and Monel R405, ensuring you have the right Monel alloy for your specific needs.

5. Nickel-Copper Alloys Nickel-copper alloys offer a balanced blend of strength and corrosion resistance, making them highly suitable for applications in chemical processing and marine industries. Apex Metal India provides Nickel-Copper alloys like Alloy 825 and Alloy 925, ensuring that you have access to materials that can withstand the toughest challenges.

Your Partner for Nickel Alloys

With our extensive range of nickel alloys, you gain the power to choose the perfect material tailored to your specific needs. Whether you're soaring in the Aerospace Industry, working in corrosive Chemical Environments, or Power and Energy Generation, Apex Metal India is here to provide you with the finest nickel alloys available.

Reach out today and unlock the potential of nickel alloys for your projects. Contact us now for expert guidance and top-notch materials!

0 notes

Text

Nickel Alloys Fastener Supplier - Fasteners LLP

Fasteners LLP is a leading supplier of nickel alloys fasteners, including nickel alloy 200 and nickel alloy 201 fasteners. We offer a wide range of nickel alloys fasteners in a variety of sizes and finishes to meet the needs of our customers. Our nickel alloys fasteners are known for their durability, corrosion resistance, and high temperature performance.

0 notes

Text

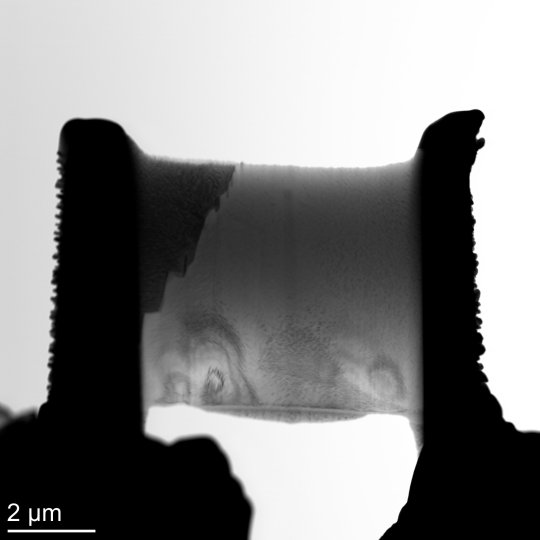

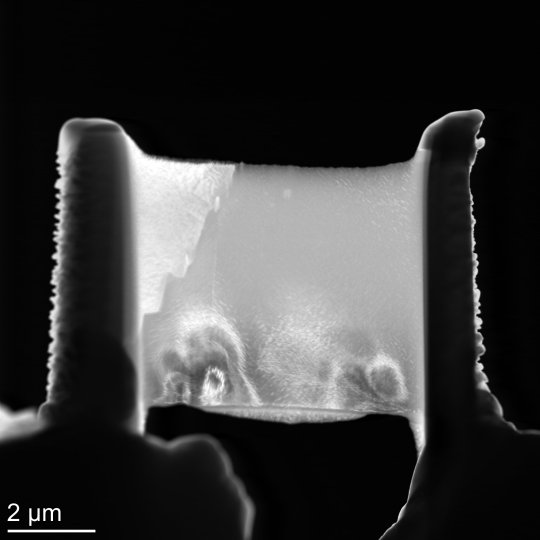

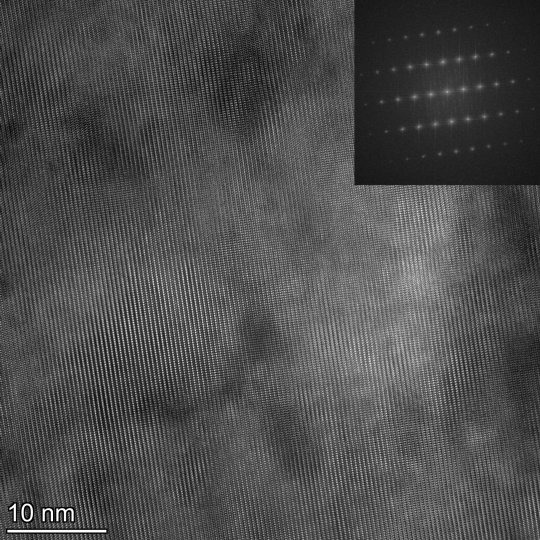

Some alloys don't change size when heated, and we now know why

Nearly every material, whether it is solid, liquid, or gas, expands when its temperature goes up and contracts when its temperature goes down. This property, called thermal expansion, makes a hot air balloon float, and the phenomenon has been harnessed to create thermostats that automatically turn a home furnace on and off. Railroads, bridges, and buildings are designed with this property in mind, and they are given room to expand without buckling or breaking on a hot day.

Thermal expansion occurs because a material's atoms vibrate more as its temperature increases. The more its atoms vibrate, the more they push away from their neighboring atoms. As the space between the atoms increases, the density of the material decreases and its overall size increases.

There are a few exceptions, but by and large, materials conform strictly to this principle. There is, however, a class of metal alloys called Invars (think "invariable"), that stubbornly refuse to change in size and density over a large range of temperatures.

Read more.

70 notes

·

View notes

Text

Carbon SS weld fittings / How to Choose the Right Carbon Steel Socket Weld Fittings

Introduction

Ganpat Metal Industries, Mumbai, India, is involved in the manufacture, supply, and export of Carbon Steel Socketweld Fittings at par with global quality standards. It is fabricated to cater to all the rigid industry standards, giving reliability and durability to their customers across different industrial applications., we will delve into the intricacies of carbon steel socketweld fittings, covering their product overview, specifications, benefits, applications, and provide a call to action for those seeking top-quality fittings.

Product Overview

Carbon steel socketweld fittings are designed for high-pressure applications and are extensively used in industries such as oil and gas, petrochemicals, power generation, and more. These fittings are engineered to provide a strong, leak-proof connection between pipes, ensuring the integrity of the piping system. The socketweld design involves inserting the pipe into a recessed area of the fitting and then applying a fillet weld around the joint. This method provides a secure and permanent bond, making it ideal for critical applications.

To read more about the product you can website our website :

#carbon steel socketweld fittings manufacturers#high nickel alloy socketweld fittings stockists#carbon steel socketweld fittings suppliers#high nickel alloy socketweld fittings suppliers#tumblr#aesthetic#love#like#tumblrgirl#follow#instagram#instagood#photography#likeforlikes#s#art#likes#tumblrboy#frasi#grunge#girl#o#cute#fashion#sad#photooftheday#photo#frases#followforfollowback#frasitumblr

8 notes

·

View notes

Note

Some dragonkin: i'm a third generation western scaleback from a temperate deciduous forest, my scales are 37% copper and 60% nickel alloy, my diet consisted of ground dwelling marsupials

Me: hehe im purple

LMAO yeah I feel that

#copper nickel alloy scales sound cool as hell but also heavy as hell sjshdbdjg#rani talks#asked and answered#anonymous

65 notes

·

View notes

Text

*documentary narrator* acids and rare extracts this thirteen year is slapping on their face could have bought a court alchemist another ten years of life, were they to have access to them nine hundred years ago

#releasing a pack of ravenous alchemists into the Claire’s and seeing if they can devise an elixir of life#with cheap face masks and nickel alloys

3 notes

·

View notes

Text

Need to get some clothing accessories. Genuinely wondering if I should start looking for non-commercial sources? Like, say you want to buy a belt. Is it ethically better to ask in your communities if anyone knows someone who does leather working commissions, and if so commission them to make it? It'd probably be $20 at nordstrom rack, but if I actually desire to minimize harms while consuming is this a local minima selection or a balance-of-utility directive? I can construct equally viable and absurd arguments every which way, but the long and short of it is if you have to take someone's word it's ethically made either way why not get the most direct relative gradient?

#Fashion ethics#Ethics of consumption#This is literal no one asked bullshit#I just was looking for a new collar (mine's showing signs of wear) and remembered I keep meaning to find a belt that fits#Made me start thinking about how they're basically the same thing#Leather band with a metal fixing mechanism (buckle not made of nickel copper or an alloy thereof) on one end#And centrally placed holes at regular intervals at the other end to control how tight it is#If I wanted to pick up the hobby or even learn the skill this is what I could use to justify it#Unfortunately lacking the time space or attention span to do so - there must be other people who have#If you have or know someone who accepts leather working commissions let me know?#I'm in the market

3 notes

·

View notes

Text

i really love these but silver 925 is super likely to give me an allergic reaction (nickel in the alloy.... rip). but look at them.

#they're even blue!!!#maybe i could very carefully snip off the piercing part and replace it with another material? not much of a problem w anything just touchin#the regular outside skin but the moment i put a nickel alloy in a piercing i will experience trouble#kind a risky experiment for 85 + shipping tho

5 notes

·

View notes

Text

China Alloy Steel, Alloy Steel, wholesale Alloy Steel, Alloy Steel manufacturers stainless steel manufacturers, stainless steel suppliers, stainless steel factory, China stainless steel price, Chinese suppliers https://superbmaterials.com/

#630 stainless steel#631 stainless steel#stainless steel forging#stainless steel alloys#alloy steel china#carbon steel china#nickel alloys china#stainless steel china#copper producers china#heat resistant alloys#china#united states#Shanghai#Pudong#suppliers#stainless#Alloy Steel#Alloy#Steel#Chinese#factory#manufacturers#kitchen

2 notes

·

View notes

Text

Pipes and Tubes Manufacturers in India

Searching for pipes and tube manufacturers in India. Call MV Super Alloys for nickel alloys, plates, and stainless steel. It is the best stockist and supplier in Mumbai. Visit the website today!

0 notes

Photo

Harry Bertoia

Sonambient, 1970s

Nickel alloy with bronze base

52 × 11 3/4 × 11 3/4 in

5 notes

·

View notes

Text

DUPLEX STEEL & ENGINEERING -

Duplex steel and engg. Co. Pvt. Ltd is one of the leading manufacturer of Duplex Steel 2205, Super duplex 2507, pipe, Tube, sheet, plates, flanges, fasteners in India.

DUPLEX STEEL 2205 / UNS S31803PLATES / SHEETS / COIL

Request the latest Duplex Steel 2205 Plates / Sheets / Coil Price List. Please Call +91 98691 88888 or Send an Email to [email protected] for Duplex Steel UNS S31803, 1.4462 Pipe Plates / Sheets / Coil Ready stock information and updated price list.

https://www.unisteelsengg.com

#Duplex Steel 2205 Sheet#Super duplex 2507 Plate#Stainless Steel Pipe#SS Tubes#duplex 2205 pipe#duplex 2205 tube#316 Stainless steel Sheet#Inconel 200 Flanges#Monel 400 Tube Fittings#Nickel Alloy 20 Sheet#Titanium Grade 2 Round Bar#Hastelloy C22 Angle Bar Supplier#Alloy 20 Butt weld Fittings Dealer#Inconel 600 Flanges Exporter in India

2 notes

·

View notes