#rootcauseanalysis

Explore tagged Tumblr posts

Text

How to Keep Your Check Sheet in 7 QC Tools Current and Move It Forward

In the world of quality control and continuous improvement, the 7 QC tools are the foundation for solving problems and enhancing processes. Among these tools, the Check Sheet in 7 QC tools is one of the simplest yet most powerful methods for collecting real-time data in a structured, visual format.

However, just creating a check sheet once isn’t enough. To keep it valuable and relevant, you must update, improve, and align it with your changing process needs. In this blog, we’ll explore how to keep your Check Sheet current and how to enhance its effectiveness over time.

✅ Why Check Sheets Matter in Quality Control

A Check Sheet helps collect data at the source—during inspections, operations, or even customer service. It’s a tool to track:

Defects and error types

Equipment failures

Downtime causes

Frequencies of events

Inspection results

Used correctly, it helps teams spot trends, make decisions based on evidence, and take corrective actions. But if the format is outdated or misaligned with current operations, it loses effectiveness.

✅ Steps to Keep Your Check Sheet Current and Effective

1. Revisit Your Quality Objectives

Begin by asking: What are we trying to measure or control?

As business priorities shift—new product lines, new machines, or different customer complaints—your Check Sheet must reflect those changes. Update your data categories, frequencies, and timeframes to match your current quality goals.

2. Validate the Categories and Data Points

Are you still tracking the right issues? A Check Sheet created months ago may be collecting data that’s no longer useful.

✔ Eliminate outdated categories ✔ Add new defect types or failure modes ✔ Clarify ambiguous terms ✔ Ensure frontline operators understand each category

3. Keep the Format Simple and Clear

A cluttered or confusing Check Sheet leads to inconsistent data collection. Stick to these principles:

Use plain language

Keep columns/rows organized

Avoid excessive detail

Use tick marks or symbols for faster recording

Consider using digital versions (spreadsheets or apps) for efficiency

4. Align Check Sheets with Process Changes

Have you changed tools, materials, or workflows recently?

Update your Check Sheet to reflect these adjustments. For example, if you’ve introduced automation, you might need to track machine error codes instead of manual defects.

5. Standardize Across Shifts and Teams

Inconsistent data ruins trend analysis. Make sure everyone uses the Check Sheet the same way by:

Providing short training or refresher sessions

Using standardized formats across shifts and departments

Clarifying who fills it out and when

Reviewing entries regularly for completeness

6. Review Data Trends and Take Action

A Check Sheet isn’t valuable unless you do something with the data.

Summarize data weekly or monthly

Identify defect patterns, peak times, or recurring failures

Share findings with relevant teams

Link data to corrective actions, Kaizen events, or root cause analysis

7. Digitize for Better Insights

While paper-based Check Sheets are still useful, digital versions offer advantages like:

Real-time data capture

Easy filtering and analysis

Automatic charts and graphs

Remote sharing with quality teams

Consider using tools like Excel, Google Sheets, or quality management software.

✅ When to Revise or Replace Your Check Sheet

Your Check Sheet may need a revamp if:

The same issues have been solved and no longer occur

New types of defects are emerging

Operators complain it’s too complicated

The data collected isn’t helping decisions

The process being monitored has changed

Don’t be afraid to revise or rebuild your Check Sheet—it’s a living tool.

✅ Benefits of Keeping Your Check Sheet Updated

Ensures accurate, real-time data collection

Helps identify trends before they become major issues

Supports faster problem-solving

Increases operator engagement and ownership

Provides valuable input for other QC tools like Pareto Charts or Control Charts

✅ Conclusion

A Check Sheet may look simple—but when updated and used effectively, it becomes a powerful tool for improving quality. By regularly reviewing and refining it, you ensure it continues to support real-time decision-making, reduce defects, and drive continuous improvement.

Remember, in the spirit of the 7 QC tools, quality is not a one-time act—it’s a habit.

#7QCTools#CheckSheet#QualityControl#ContinuousImprovement#ProcessImprovement#QualityManagement#DataDriven#ManufacturingExcellence#QualityAssurance#RootCauseAnalysis

0 notes

Text

Fixing the problem is good. Understanding why it happened is better. Too often, we stop at surface-level fixes—treating symptoms while the real cause keeps hiding below. That’s where Root Cause Analysis (RCA) steps in: not just to ask what happened, but to dig deeper and ask why… until the real answer is found. If you don’t get to the root, the problem will grow back. Watch the reel, rethink your approach to incidents, and take a step closer to true prevention.

#RootCauseAnalysis#WorkplaceSafety#IncidentPrevention#EHS#ContinuousImprovement#ThinkBeyondFixes#COREEHS#ZeroHarm

0 notes

Text

Top Forensic Engineering Services in Amherst | RSH Experts

We offer expert forensic engineering service in Amherst for structural assessments, failure analysis, and legal cases. Trusted. Precise. Professional. Call Now- (469) 290-2585.

0 notes

Text

How to Handle Customer Complaints with Process Confirmation TCards?

Discover effective strategies to resolve customer complaints using process confirmation tools like TCards. Improve quality, compliance, and satisfaction effortlessly

For more details read our blog :

#CustomerComplaints#Handlingcomplaints#Complaintresolutionprocess#Rootcauseanalysis#Processcompliance#Improvingcustomerexperience#TCards#Customercomplainttracking#ustomersatisfactionimprovement#Complaintpreventionstrategies#Standardoperatingprocedures#Effectivecustomercommunication#Processconfirmation#Customersatisfaction#Qualityassurance#Processimprovement#Processauditchecklist#Complaintmanagementtools#Workflowmanagement#Correctiveactions#Visualtasktracking#Businessprocessimprovementtools#Taskmonitoringtools#Rootcauseanalysistools

0 notes

Link

���� Nissan's Fall from the Top: What Really Happened (2010–2025)

Once a global leader in innovation and performance, Nissan is now a cautionary tale in the auto world. From the dramatic downfall of Carlos Ghosn to aging product lines, failed pickups, and missed EV opportunities—this in-depth article breaks down the root causes behind Nissan’s decline.

🔎 Inside you'll find: ✔️ Real financial & sales data (2010–2025) ✔️ Governance breakdowns & alliance struggles ✔️ Missed market trends & tech stagnation ✔️ Actionable insights for auto industry watchers

If you're into automotive strategy, corporate shakeups, or just curious how a brand can rise and fall—this is a must-read.

📖 Read the full story now

#Nissan#AutoIndustry#BusinessFailure#EVShift#NissanCrisis#TumblrReads#AutoTrends#CorporateStrategy#RootCauseAnalysis#CarlosGhosn

0 notes

Text

🔍 Fixing Symptoms vs Solving Problems in IT: The Power of RCA in ServiceNow

In the world of IT operations, quick fixes are tempting—but they lead to recurring issues and wasted resources.

This blog breaks down: ✔️ The difference between symptoms and root problems ✔️ How ServiceNow enables structured RCA ✔️ Real examples of MTTR reduction ✔️ How AI transforms incident resolution ✔️ Step-by-step RCA implementation in ServiceNow

🎯 Whether you're an IT leader, developer, or service manager, mastering RCA is key to proactive, scalable IT operations.

👉 Read the full post: https://mjbtech.com/blog_pages/Fixing-Symptoms-vs-Solving-Problems-How-RCA-in-ServiceNow-Transforms%20-Your-IT-Strategy.html

#RootCauseAnalysis#ServiceNow#MTTR#ITOperations#DigitalTransformation#IncidentManagement#AIinIT#ProblemManagement#TechBlog#MJBTechnologies

1 note

·

View note

Text

youtube

Struggling with Quality Issues in Manufacturing? QRQC Could Be Your Game Changer! In today’s fast-paced manufacturing world, defects, delays, and inefficiencies can drastically impact your bottom line. That’s where Quick Response Quality Control (QRQC) comes in! Learn how this powerful problem-solving methodology helps you detect, analyze, and resolve quality issues quickly, ensuring smoother production and happier customers.

Why Watch This Reel? * Save time and money with QRQC strategies. * Learn when and how to implement QRQC for maximum impact. * Discover real-world examples of QRQC applications in action!

When Do You Need QRQC? * High defect rates or product recalls * Customer complaints piling up * Scrap and rework skyrocketing * Unplanned production stoppages * New product launches or process deviations

Want to improve efficiency and eliminate defects in your manufacturing process? 🚀 QRQC is the solutions!

#QRQC#QualityControl#ManufacturingExcellence#RootCauseAnalysis#EfficiencyBoost#ProcessImprovement#Compliance#VegasConsulting#ProblemSolving#QualityMatters#Youtube

1 note

·

View note

Text

#ProjectManagement#RiskManagement#ProjectRisks#RiskIdentification#ProjectPlanning#ProactiveManagement#ProjectSuccess#RiskMitigation#ManagementTips#BusinessStrategy#ProjectLeadership#SWOTAnalysis#ScenarioPlanning#ExpertAdvice#Brainstorming#RootCauseAnalysis#DelphiTechnique#LessonsLearned#ProjectStrategy#RiskAssessment

0 notes

Text

Proactive Problem Management: A Strategic Approach to Elevating IT Service Excellence

In the ever-evolving landscape of IT service management, organizations are recognizing the critical role of proactive problem management in maintaining a robust and efficient IT infrastructure. In this blog post, we delve into the significance of proactive problem management, shedding light on how it contributes to preventing issues, reducing downtime, and ultimately enhancing overall IT service delivery.

Understanding Proactive Problem Management:

Proactive Problem Management Defined Proactive problem management is a strategic and preemptive approach aimed at identifying and resolving potential IT issues before they escalate into critical problems. Unlike reactive measures, which address issues after they occur, proactive problem management involves continuous analysis, prediction, and preventive actions.

The Importance of Proactive Problem Management:

Preventing Issues Before They Occur:

Proactive problem management enables IT teams to identify potential issues in their early stages, allowing for preventive measures to be implemented before they can impact operations.

Reducing Downtime and Service Disruptions:

By addressing problems proactively, organizations can significantly reduce the occurrence of downtime. This not only minimizes disruptions to business operations but also enhances overall productivity.

Enhancing IT Service Delivery:

A proactive approach to problem management contributes to the overall improvement of IT service delivery. Timely identification and resolution of issues lead to a smoother and more reliable service experience for end-users.

Optimizing Resource Utilization:

Proactive problem management helps organizations optimize the utilization of IT resources. By addressing issues before they escalate, teams can allocate resources more efficiently, ensuring that critical tasks receive the attention they require.

Boosting User Satisfaction:

When IT systems operate smoothly without frequent disruptions, end-users experience higher satisfaction levels. Proactive problem management directly contributes to a positive user experience by minimizing the impact of potential issues.

Strategies for Effective Proactive Problem Management:

Addressing Challenges with Freshservice:

Early Detection Through Robust Monitoring:

Freshservice's Monitoring Capabilities: The platform offers comprehensive monitoring tools that provide real-time insights into IT system performance. By continuously tracking key metrics, potential issues are identified at an early stage.

Root Cause Analysis Made Efficient:

Integrated Root Cause Analysis in Freshservice: Conducting root cause analyses is streamlined with Freshservice's integrated tools. The platform assists IT teams in dissecting past incidents, understanding underlying causes, and applying this knowledge to proactively address potential problems.

Automation and Predictive Insights:

Leveraging Automation in Freshservice: Freshservice incorporates advanced automation features that go beyond routine tasks. Automation can be utilized for predictive insights, allowing the platform to anticipate issues based on historical data and patterns.

Collaboration and Knowledge Sharing:

Freshservice's Collaborative Environment: Foster collaboration within IT teams through Freshservice's collaborative tools. The platform promotes knowledge sharing, enabling teams to collectively identify and resolve potential problems based on shared insights.

Benefits of Using Freshservice for Proactive Problem Management:

Streamlined Workflows for Quick Intervention:

Efficient Ticketing System: Freshservice's ticketing system ensures that potential problems are swiftly converted into actionable tickets, streamlining workflows for quick intervention and resolution.

Centralized Information Repository:

Knowledge Base in Freshservice: The platform's knowledge base serves as a centralized repository, facilitating the sharing of insights and best practices. This knowledge-sharing culture contributes to proactive problem management.

Enhanced User Satisfaction:

Improved User Experience: With reduced downtime and proactive issue resolution, Freshservice enhances the overall user experience. Users benefit from a more reliable and efficient IT service delivery, leading to increased satisfaction.

Optimized Resource Allocation:

Smart Resource Allocation Features: Freshservice's features for smart resource allocation ensure that IT teams optimize their resources effectively, focusing on critical tasks and potential problem areas.

Conclusion: By leveraging Freshservice's suite of tools and features, organizations can transform their approach to proactive problem management. The platform empowers IT teams to detect issues early, conduct efficient root cause analyses, and foster a collaborative environment for knowledge sharing. In doing so, Freshservice becomes a key ally in elevating IT service excellence and ensuring a proactive and forward-thinking IT culture within the organization.

#FutureOfIT#ServiceDelivery#ITLeadership#TechSolutions#ProactiveIT#ITServiceExcellence#FreshserviceSolutions#ITSMPlatform#AutomationTools#RootCauseAnalysis#UserExperience#DigitalTransformation#ITleadership

1 note

·

View note

Text

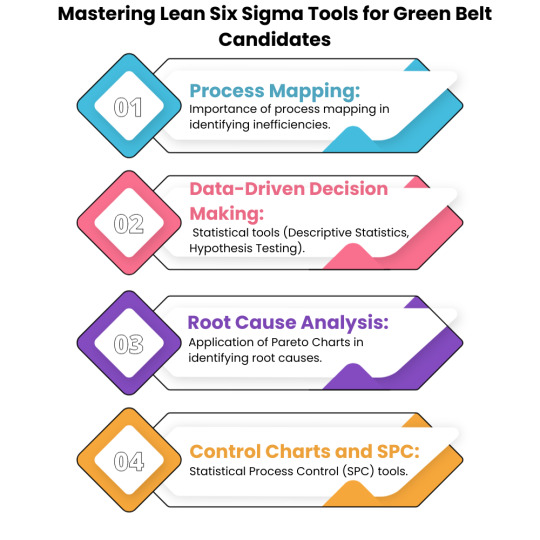

Mastering Lean Six Sigma Tools: A Deep Dive for Green Belt Certification Candidates

Introduction:

Lean Six Sigma, a well-known methodology for streamlining processes and increasing organizational productivity, empowers management with complex tools The mastery of these tools is critical to Greenbelt candidates who want to have more influence in their organizations. This blog will begin an in-depth analysis of the most important Lean Six Sigma tools. We will provide practical insights and guidance for Lean Six Green Belt candidates targeted to navigate their roles successfully.

1. Understanding DMAIC: The Foundation of Lean Six Sigma

At the core of Lean Six Sigma is the DMAIC process—Define, Learn, Evaluate, Improve, and Control. Each stage represents an important step in the journey of process improvement. We will break down the challenges in each category and shed light on their associated key objectives, strategies, and tools. With a better understanding of DMAIC, Greenbelt candidates can establish a structured and systematic approach to their development projects.

2. Process Mapping: Visualizing the Journey to Improvement

Process mapping is a key tool in the Lean Six Sigma arsenal. Through techniques such as flowcharts and value stream maps, Greenbelt candidates gain a visual understanding of existing processes. We explore how these maps not only identify inefficiencies but also foster collaboration among cooperatives. Deeper involvement in process mapping provides Greenbelts with the visual tools needed for effective problem-solving.

3. Data-Driven Decision Making: Statistical Tools for Green Belts

Statistical tools form the backbone of data-driven decision-making in Lean Six Sigma Green Belt candidates will benefit from descriptive statistical analysis, hypothesis testing, and regression analysis. Real-world examples will demonstrate how these tools enable data analytics, allowing for more informed and effective decision-making throughout the project lifecycle

4. Root Cause Analysis: Uncovering the Source of Problems

Identifying the root causes of problems is an important part of Lean Six Sigma Certification. Tools like the 5 Whys, fish skeleton diagrams, and Pareto charts make comprehensive root analysis easier. Through practical insights, Green Belt applicants will learn how to use these tools effectively, solving key problems that hinder implementation success.

5. Continuous Improvement with Kaizen Events

Kaizen processes are powerful tools for rapid, focused improvement. By organizing and facilitating Kaizen meetings, Greenbelt champions can drive change in their organizations. Success stories will demonstrate how these events can lead to significant improvements in processes, and foster a culture of continuous improvement.

6. Control Charts and SPC: Ensuring Sustainable Gains

Long-term sustainable improvement is a key consideration in Lean Six Sigma. Control charts and Statistical Process Control (SPC) provide tools to effectively monitor and control processes. Prospective Greenbelt developers will gain insight into the use of these tools to ensure that the gains made during the renovation are sustainable over the long term.

Conclusion: Empowering Green Belt Candidates for Impact

Mastery of Lean Six Sigma tools is not just a prerequisite for Green Belt certification; Being a problem solver and a system improvement expert is a journey. As Greenbelt candidates embrace the complexities of DMAIC, process mapping, statistical analysis, neuroanalysis, Kaizen events, control charts, and more, they position themselves as catalysts for innovation and efficiency This knowledge not only contributes to accurate certification but also Greenbelt continuous improvement in their organizations Also positioning themselves as cultural champions The ongoing journey to master these tools continues, marked by growth, learning, and commitment to positive change.

#LeanSixSigma#GreenBelt#ProcessImprovement#DMAICFramework#DataDrivenDecisionMaking#ContinuousImprovement#RootCauseAnalysis

0 notes

Text

Our comprehensive guide on how to become a Six Sigma Black Belt will set you on the path to professional excellence. Dive into the DMAIC methodology, delve into key concepts from 'The Certified Six Sigma Black Belt Handbook, Third Edition,' and create an eye-catching resume. Improve your skills, pass the certification exam, and advance your career in process improvement and organizational efficiency.

https://rawkashish004.wixsite.com/professionalcourses/post/mastering-six-sigma-a-comprehensive-guide-of-how-to-be-six-sigma-black-belt-certified

#DMAIC#SixSigma#ProcessImprovement#ContinuousImprovement#QualityManagement#ProblemSolving#DataAnalysis#RootCauseAnalysis#ProcessOptimization#QualityControl#LeanSixSigma

0 notes

Text

Preventing accidents starts with identifying hazards and understanding their root causes. Our expert team excels in performing thorough root-cause analyses, paving the way for accident-free environments.

Call +91 93247 30856 / 022 27672890

email [email protected]

Visit: www.anil-engineering.com

#rootcauseanalysis#preventaccidents#preventhazards#anilengineering#goldstandardofengineering#goldstandard#engineeringexcellence#achievingsuccess

0 notes

Text

"Mastering Excellence: Navigating the Lean Six Sigma Green Belt Certification Journey"

Embark on a transformative journey of operational mastery with our blog, "Mastering Excellence: Navigating the Lean Six Sigma Green Belt Certification Journey." Explore the essential concepts covered in Green Belt training, from the foundational DMAIC methodology to statistical tools, root cause analysis, and the philosophy of continuous improvement.

#LeanSixSigma#ProcessImprovement#GreenBeltCertification#ContinuousImprovement#DMAIC#DataAnalysis#RootCauseAnalysis

0 notes

Text

Top Forensic Engineering Services in Lott | RSH Experts

We offer expert forensic engineering service in Lott for structural assessments, failure analysis, and legal cases. Trusted. Precise. Professional. Call Now- (469) 290-2585.

0 notes

Text

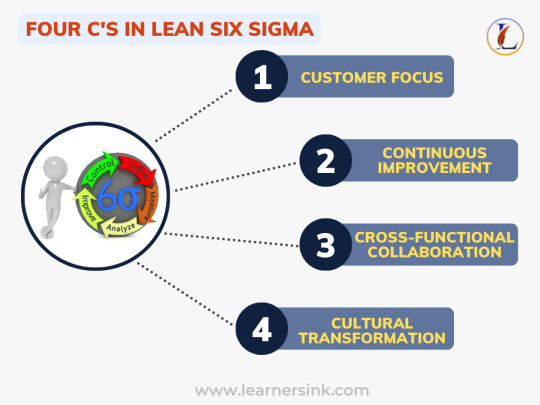

Mastering the Four C's of Lean Six Sigma: Clarity, Collaboration, Customer Focus, and Continuous Improvement.

Learn more >>

#LeanSixSigma#QualityManagement#ProcessImprovement#DataAnalysis#Efficiency#ProblemSolving#ContinuousImprovement#BusinessExcellence#LeanThinking#CustomerFocus#Collaboration#ProcessOptimization#PerformanceMetrics#RootCauseAnalysis#QualityControl#OperationalExcellence#StreamliningProcesses#SixSigmaMethodology#WasteReduction#DataDrivenDecisions#project management#pmpcertifiction

1 note

·

View note

Text

youtube

Embark on an empowering journey with Douglas Vandergraph as he shares invaluable insights on realizing your dreams and goals. Dive into the transformative '5 Whys' Technique, derived from Japan's renowned factory system, in this captivating video. By repeatedly asking 'Why?' five times, you uncover the root cause of any problem, enabling effective resolution. Douglas exemplifies seizing opportunities, daily growth, and making a positive impact. Let Douglas inspire you to achieve your aspirations. Join his heartfelt endeavor to assist individuals in their pursuit of success. Watch now for actionable guidance and motivation.

#DreamRealization #GoalAchievement #5WhysTechnique #PersonalGrowth #SuccessInspiration

#5whystechnique#rootcause#rootcauseanalysis#youtube#motivation#success#success story#successful#successstories#motivationalspeaker#motivationalstory#inspirationalstory#motivateyourself

0 notes