#scada applications

Explore tagged Tumblr posts

Text

customized scada applications

1 note

·

View note

Text

Industrial Alarm Management Application

#industrial reporting solution#industrial reporting software#industrial reports development company#reporting tool for industrial automation#reporting software for industrial automation#Scada reporting software#report generation in Scada#best reporting software#Scada report generation#best reporting tools#industrial automation reporting tool#reporting tool for Scada#web based reporting tools#web based reporting software#automated reporting and data analysis software#Batch Reporting Application#Data Log Reporting Application#MKT Analysis#MKT Analysis reports development#Market Analysis application#Alarm Reporting Application

0 notes

Text

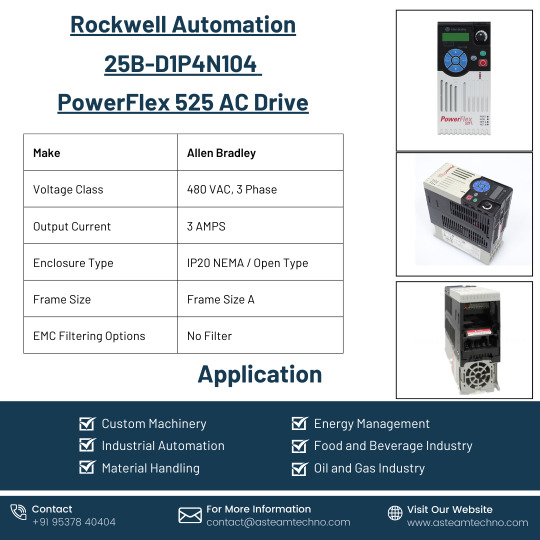

Rockwell Automation 25B-D1P4N104

The Rockwell Automation 25B-D1P4N104 is a part number for a specific variable frequency drive (VFD) within the Allen-Bradley PowerFlex 525 series. The PowerFlex 525 is a compact, versatile, and cost-effective drive designed to control motors in a wide range of industrial applications.

#automation#trending#tumblr trends#viralpost#viral#bestdeals#trendingnow#allen bradley#rockwell automation#plc#SCADA#HMI#powerflex525#application#technical#development#engineering#programs

1 note

·

View note

Text

Looking for the Best Automation Solution In Zirakpur. Our company stands as a leading project expert in Electrical, IoT, SCADA, Artificial Intelligence, Automation Solution, and Instrumentation. We specialize in delivering cutting-edge, customized automation solutions to optimize business operations. With a commitment to innovation and excellence, we provide the best automation systems in Zirakpur, ensuring efficiency, scalability, and long-term success for our clients.

1 note

·

View note

Text

BLIIoT 4G SMS Remote Monitoring Alarm Controller S272 for Aquaculture Monitoring

Foreword

Aquaculture is an important agricultural industry, and real-time monitoring of water quality parameters is critical to the success of farming

Remote Monitoring RTU 271 Functions

Remote Monitoring RTU 271 have 8 digital inputs, 6 analog or PT100 resistance temperature detector (RTD) inputs, 4 relay outputs, 1 environmental sensor input for monitoring site temperature and humidity, and an RS485 serial port. It can automatically monitor and operate I/O ports through SMS, cloud platform, web server, Internet, timer and programmed interlocking events.

Solution Requirements

Real-time monitoring of water quality parameters such as PH value and conductivity of water bodies. Users can remotely see the water quality conditions in real time through mobile phones and computers. When PH value, conductivity, dissolved oxygen and other parameters exceed the limits, users will be notified through SMS, phone calls, WeChat, emails, etc.

Solution Introduction

Remote Monitoring RTU S272 transmits data to the cloud for data processing through a wired connection with the PH sensor. The cloud feeds the data back to the cloud platform. Users can obtain PH value, conductivity, redox potential, and dissolved oxygen through the mobile APP computer web page. and other status; when the relevant parameters of water quality exceed the limit, the alarm information will be notified to the personnel on duty through text messages, phone calls, WeChat, etc. When necessary, equipment such as acid adding pumps or alkali adding pumps can be directly controlled through the cloud platform

Solution Advantages

1. Data Collection and Analysis

Remote Monitoring RTU S272 supports 4G transmission without distance restrictions, can monitor water quality parameters in real time, record data, perform historical data analysis, and provide visual reports so that farmers can better understand water quality conditions.

2.Real-time Monitoring

Monitor on-site water quality status 24 hours a day through mobile phones and computers; provide a solution for real-time monitoring of water quality parameters, remote access and alarm notification for the aquaculture industry

3. Alarm and Notification System

The system can set thresholds for water quality parameters. Once the parameters exceed the limits, users will be notified through multiple notification channels (SMS, phone calls, WeChat, and emails) so that they can take timely measures.

4. Remote Access and Control

Through mobile phones, computers and other devices, users can remotely access monitoring data at any time and even perform remote control to adjust water conditions.

5. Results and Benefits

By using Remote Monitoring RTU S272, the aquaculture industry can monitor water quality parameters in real time, obtain timely alerts and remote control, improve breeding efficiency, reduce losses, and achieve greater economic benefits.

Summarize

Remote Monitoring RTU S272 brings innovative solutions to the aquaculture industry, helping farmers achieve real-time water quality monitoring, alarm notification and remote control, thereby improving the efficiency of aquaculture, ensuring the healthy growth of organisms, and creating greater value.

More information about BLIIoT 4G SMS Remote Monitoring Alarm Controller S272: https://www.bliiot.com/m2m-rtu-p00174p1.html

#iot#iotsolution#smartaquaculture#remotemonitoring#remotecontrol#alarm#controller#rtu#gateway#iomodule#sms#4g#rs485#modbus#mqtt#scada#alibabacloud#huaweicloud#BLIIoT#BLIIoT Applications

0 notes

Text

Battery-operated Remote Terminal Units Market Research, Size, Share, Analysis, Overview and Regional Outlook Study 2017 – 2032

The market for Remote Terminal Units (RTUs) that are battery-operated allows them to function in isolated or off-grid regions where access to a reliable power supply is restricted. RTUs are electronic devices used to monitor and manage remote equipment and processes in many different industries, such as oil and gas, water and wastewater management, power distribution, and telecommunications. Here is a summary of the market for battery-operated RTUs, including information on demand:

Market Overview: Due to a number of circumstances, the market for battery-operated RTUs has been expanding. The need for battery-operated RTUs has been fueled by the necessity for remote monitoring and control capabilities in various industries, particularly in places with weak power infrastructure. These devices enable efficient monitoring and control of remote assets without the requirement for a continual external power source thanks to their dependable and autonomous operation.

Demand Drivers:

1. Real-time monitoring and control of assets: situated in remote or isolating locations are necessary in many businesses. Without the requirement for a sizable power infrastructure or reliance on cable connections, battery-operated RTUs allow for effective data gathering, monitoring, and control of these assets.

2. Applications Off-Grid: In off-grid applications where access to a dependable power supply is restricted or nonexistent, battery-operated RTUs are widely used. Examples include remote water pumping stations in rural areas, environmental monitoring stations, remote weather monitoring stations, and remote oil and gas wellheads.

3. Emergency and Temporary Installations: Whereas immediate deployment is necessary, battery-powered RTUs are also used in emergency and temporary installations. When catastrophe recovery, building projects, or temporary infrastructure installations are taking place, these machines can instantly provide remote monitoring and control capabilities.

4. Environmental Monitoring: Data collection from remote weather stations, air quality sensors, and water quality sensors are all important aspects of environmental monitoring that battery-operated RTUs play a key role in. Continuous monitoring is made possible in remote or environmentally delicate locations by these equipment.

5. IoT Connectivity: The need for battery-operated RTUs has increased as the Internet of Things (IoT) is becoming more widely used in a variety of businesses. These devices are essential parts of IoT networks because they provide seamless data transmission, communication, and control between remote assets and central management systems.

Here are some of the key benefits for Stakeholders:

Remote Monitoring and Control

Flexibility and Mobility

Cost-Effective Deployment

Resilience to Power Outages

Integration with IoT and Smart Grids

Increased Data Accessibility

Environmental Monitoring and Compliance

Rapid Deployment for Emergency Response

Redundancy and Reliability

Scalability and Future-Proofing

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/battery-operated-remote-terminal-units-market/10333/

Market Segmentations:

Global Battery-operated Remote Terminal Units Market: By Company • SIEMENS • SENECA • Omniflex • King Pigeon Communication Co.,Limited • Servelec Group • TEKBOX • Micro Sensor Co., Ltd. • Hitachi Group • Remsdaq Ltd Global Battery-operated Remote Terminal Units Market: By Type • GPRS • GSM • Modular • Others Global Battery-operated Remote Terminal Units Market: By Application • Power Industry • Government and Utilities • Industrial Global Battery-operated Remote Terminal Units Market: Regional Analysis The regional analysis of the global Battery-operated Remote Terminal Units market provides insights into the market's performance across different regions of the world. The analysis is based on recent and future trends and includes market forecast for the prediction period. The countries covered in the regional analysis of the Battery-operated Remote Terminal Units market report are as follows: North America: The North America region includes the U.S., Canada, and Mexico. The U.S. is the largest market for Battery-operated Remote Terminal Units in this region, followed by Canada and Mexico. The market growth in this region is primarily driven by the presence of key market players and the increasing demand for the product. Europe: The Europe region includes Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe. Germany is the largest market for Battery-operated Remote Terminal Units in this region, followed by the U.K. and France. The market growth in this region is driven by the increasing demand for the product in the automotive and aerospace sectors. Asia-Pacific: TheAsia-Pacific region includes Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, and Rest of Asia-Pacific. China is the largest market for Battery-operated Remote Terminal Units in this region, followed by Japan and India. The market growth in this region is driven by the increasing adoption of the product in various end-use industries, such as automotive, aerospace, and construction. Middle East and Africa: The Middle East and Africa region includes Saudi Arabia, U.A.E, South Africa, Egypt, Israel, and Rest of Middle East and Africa. The market growth in this region is driven by the increasing demand for the product in the aerospace and defense sectors. South America: The South America region includes Argentina, Brazil, and Rest of South America. Brazil is the largest market for Battery-operated Remote Terminal Units in this region, followed by Argentina. The market growth in this region is primarily driven by the increasing demand for the product in the automotive sector.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/battery-operated-remote-terminal-units-market/10333/

Reasons to Purchase Battery-operated Remote Terminal Units Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Battery-operated Remote Terminal Units#RTU Market#Remote Monitoring#Wireless RTU#Industrial Automation#Battery-powered RTU#IoT (Internet of Things)#Energy Efficiency#Data Collection#Telemetry#Remote Control#Battery-powered Sensors#SCADA (Supervisory Control and Data Acquisition)#Energy Management#Off-grid Applications#Renewable Energy#Battery Technology#Remote Sensing#Communication Protocols#Edge Computing#Connectivity Solutions#Remote Data Acquisition#Condition Monitoring#Asset Management.

0 notes

Text

The Difference Between Low, Medium, and High Voltage Switchgear

Switchgear plays a critical role in the generation, transmission, and distribution of electrical power. It ensures safe and efficient operation by controlling, protecting, and isolating electrical circuits and equipment. But not all switchgear is created equal — low, medium, and high voltage switchgear are designed for different voltage levels and applications.

Understanding the differences between these types is crucial for electrical engineers, electricians, project managers, and anyone involved in power systems. In this article, we break down what sets them apart in terms of voltage range, components, applications, design, and safety considerations.

What is Switchgear?

Before diving into the differences, let’s clarify what switchgear is.

Switchgear refers to the combination of electrical disconnect switches, fuses, or circuit breakers used to control, protect, and isolate electrical equipment. It is essential for de-energizing equipment for maintenance and for clearing faults in the power system.

Classification by Voltage Level

Low Voltage Switchgear (LV)

Voltage Range:

Up to 1,000V AC (typically 400V/690V in 3-phase systems)

Key Components:

Miniature Circuit Breakers (MCBs)

Molded Case Circuit Breakers (MCCBs)

Residual Current Devices (RCDs)

Contactors and relays

Busbars, metering, control panels

Applications:

Residential and commercial buildings

Data centers and office spaces

Light industrial automation

Control panels and motor control centers (MCCs)

Characteristics:

Compact and easy to install

High frequency of operation

Relatively simple maintenance

Often enclosed in modular panels

Standards:

IEC 61439

NEC (National Electrical Code)

Medium Voltage Switchgear (MV)

Voltage Range:

1kV to 36kV (sometimes up to 72.5kV)

Key Components:

Vacuum circuit breakers (VCBs)

SF₆ (sulfur hexafluoride) insulated switchgear

Current and voltage transformers (CTs, VTs)

Protective relays

Grounding switches

Applications:

Electrical substations

Large factories and industrial plants

Railways and airports

Renewable energy farms (wind/solar)

Characteristics:

Higher insulation and safety requirements

More robust protection systems

Often installed indoors or in compact outdoor enclosures

May use gas-insulated or air-insulated designs

Standards:

IEC 62271–200

IEEE C37 series

High Voltage Switchgear (HV)

Voltage Range:

Above 36kV (commonly 66kV, 132kV, 220kV, up to 765kV)

Key Components:

SF₆ circuit breakers

Air blast or oil circuit breakers (older systems)

Gas-insulated switchgear (GIS)

Disconnectors and earthing switches

High-end protection relays and SCADA integration

Applications:

National and regional power transmission networks

Power generation plants

Interconnecting large substations

Critical infrastructure (e.g., large data centers, airports)

Characteristics:

Complex installation and high-cost infrastructure

Requires rigorous safety procedures and specialized training

Often installed outdoors or in GIS (Gas Insulated Switchgear) format

Includes extensive monitoring and automation

Standards:

IEC 62271–100 (HV circuit breakers)

IEEE C37.06

ANSI C37 series

Safety Considerations

Always follow local electrical codes, use personal protective equipment (PPE), and conduct routine maintenance regardless of switchgear type.

Conclusion

Choosing the right switchgear type is critical for ensuring safe and efficient power distribution. Whether you’re designing a residential panel or a high-voltage substation, knowing the difference between low, medium, and high voltage switchgear helps you make informed decisions about equipment, safety, and performance.

Mastering this knowledge isn’t just good practice — it’s essential for anyone serious about a career in the electrical field.

4 notes

·

View notes

Text

A Comprehensive Guide to Power Systems Protection for Engineers

Introduction:

Power systems protection is a critical aspect of electrical engineering that focuses on safeguarding electrical equipment, personnel, and the power grid from faults, failures, and abnormal operating conditions. This comprehensive guide aims to provide engineers with valuable insights into key principles, techniques, and best practices in power systems protection.

1. Understanding System Operation and Fault Types:

Before delving into protection strategies, it is essential to have a solid understanding of how power systems operates and the various types of faults that can occur. This includes studying system components, such as generators, transformers, transmission lines, circuit breakers, relays, and protective devices. Familiarity with fault types like short circuits, open circuits, ground faults, and transient overvoltages is crucial as a foundation.

2. Principles of Protection Coordination:

Effective power systems protection requires proper coordination among protective devices. Engineers must understand the concept of selectivity to ensure that only the device closest to a fault operates, minimizing disruption to the rest of the system. Proper coordination involves selecting appropriate current settings, time delays, and coordination curves for relays and circuit breakers.

3. Relay Device Fundamentals:

Relays are an integral part of power systems protection, serving as the first line of defense against electrical faults. Engineers should have a thorough knowledge of different relay types, including overcurrent relays, differential relays, distance relays, and directional relays. Understanding their operating principles, features, and limitations aids in choosing the most suitable relays for specific applications.

4. Protective Device Coordination:

Coordinating protective devices within a system is critical to maintaining stability and preventing cascading failures during faults. Engineers must carefully analyze and design protection schemes that consider factors such as fault impedance, fault currents, relay response characteristics, and coordination margins. Advanced techniques like time grading and impedance grading can be employed to achieve optimal coordination.

5. Fault Analysis and System Modeling:

Performing fault analysis and system modeling helps engineers gain insights into power flow, fault currents, voltage profiles, and system stability. Engineers must be proficient in using software tools like ETAP, PSCAD, and DSA Tools to accurately simulate fault scenarios and assess the performance of protection schemes. Detailed knowledge of system modeling techniques enables engineers to make informed decisions regarding relay settings and coordination.

6. Communication-Based Protection:

With the increasing complexity of modern power systems, communication-based protection plays a crucial role in maintaining reliability. Knowledge of communication protocols such as IEC 61850, GOOSE (Generic Object-Oriented Substation Event), and SCADA (Supervisory Control and Data Acquisition) systems is essential for engineers to design and implement advanced protection solutions that utilize real-time data exchange between substations and control centers.

7. Integration of Automation and Control Systems:

Incorporating automation and control systems into power systems protection enhances operational efficiency and reduces response time during faults. Engineers need to understand concepts like remote terminal units (RTUs), programmable logic controllers (PLCs), and human-machine interfaces (HMIs). Familiarity with protocols like Modbus, DNP3 (Distributed Network Protocol), and OPC (OLE for Process Control) enables seamless integration of protection systems with wider control infrastructure.

8. Commissioning, Testing, and Maintenance:

Implementing effective protection strategies requires thorough commissioning, testing, and maintenance procedures. Engineers should be well-versed in practices like primary injection testing, secondary injection testing, relay calibration, fault simulation, and periodic inspections. Adhering to manufacturer guidelines, industry standards, and safety protocols ensures equipment reliability and optimal performance.

9. Access to Resources and Industry Awareness:

Staying connected with organizations like the IEEE (Institute of Electrical and Electronics Engineers) and IET (Institution of Engineering and Technology) is crucial for access to valuable resources. Engineers should actively seek research papers, technical articles, conferences, and networking opportunities. Staying informed about relay technology advancements from prominent manufacturers aids in adopting the latest protection techniques.

10. Software Applications for Enhanced Protection:

Utilizing software applications is vital in power systems protection. Advanced tools like ETAP, PSCAD, and DSA Tools aid in relay coordination analysis, fault simulation, and system modeling. Acquiring proficiency in these common industry software packages enables engineers to design and optimize protection schemes effectively.

11. Compliance with Local National Codes:

Adhering to local national codes and regulations is paramount in power systems protection. Understanding and implementing specific electrical codes and standards relevant to the country of operation is crucial. Compliance ensures safe and reliable system design, installation, and operation aligned with legal requirements and best practices.

Conclusion:

By encompassing the principles, techniques, and best practices discussed in this guide, engineers pursuing careers in power systems protection can develop a strong foundation. Continuous learning, staying updated on industry advancements, and compliance with local national codes will ensure engineers can design, implement, and maintain robust and reliable protection schemes for the power grid and its critical assets.

The Author Biography: Qusi Alqarqaz

Qusi Alqarqaz is an experienced professional in power system protection, specializing in sharing knowledge and guiding young engineers. With a career spanning utility and oil and gas industries in Texas, New Mexico, and Qatar, he has amassed extensive industry experience.

Collaborating with leading manufacturers such as SEL, ABB, Siemens, Schneider, among others, Qusi has gained proficiency in a range of protective relays. He actively pursues continuing education, completing professional development courses with software providers including ETAP and Milsoft, enabling him to utilize advanced tools for power system analysis and protection design.

Qusi's dedication to staying up-to-date with industry advancements led him to pursue additional training. He completed professional development courses at Wisconsin University, equipping him with specialized knowledge crucial for working with high-voltage power systems. He also studied power generation extensively at Strathclyde University in the UK.

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals. Through his posts, he aims to offer guidance and mentorship for young engineers in power system protection. His practical advice and personal experiences will empower the next generation of experts in this field.

Contact the Author:

Qusi actively shares his knowledge through collaborating on large-scale projects and providing training sessions for professionals.

Qusi Alqarqaz

9 notes

·

View notes

Text

The Benefits of Using Modular Switchgear Systems

Why Modern Industries Are Choosing Modular Solutions for Electrical Infrastructure

In today’s fast-paced industrial and commercial environments, electrical safety, efficiency, and scalability are more important than ever. That’s where modular switchgear systems come into play. Designed to meet the evolving needs of various sectors — such as manufacturing, commercial buildings, power utilities, and data centers — modular switchgear offers flexibility, safety, and long-term value.

In this article, we’ll explore the key benefits of using modular switchgear systems, and why they are becoming the preferred choice over traditional switchgear configurations.

What Is a Modular Switchgear System?

A modular switchgear system is a type of switchgear that is built from interchangeable modules or sections. Each module contains electrical components such as circuit breakers, busbars, relays, isolators, and fuses. These modules are pre-engineered and can be easily configured, added, or replaced based on the specific requirements of a facility.

Modular switchgear is used for the protection, control, and isolation of electrical equipment. It is typically found in low voltage (LV) and medium voltage (MV) power distribution systems.

Top Benefits of Modular Switchgear Systems

1. Flexibility and Scalability

One of the most significant advantages of modular switchgear is its flexible design. Whether you’re expanding an existing facility or starting from scratch, modular systems allow you to add or remove units without interrupting the entire system.

· Ideal for facilities expecting future expansion

· Easy to customize layout based on project demands

· Supports phased development in infrastructure projects

2. Enhanced Safety and Reliability

Modern modular switchgear systems are designed with advanced safety features. Segregated compartments, arc fault containment, and reliable insulation materials ensure operator safety and system reliability.

· Reduces risk of electrical faults and arc flashes

· Complies with IEC and ANSI safety standards

· Minimizes downtime during maintenance or upgrades

3. Ease of Installation and Maintenance

Thanks to its pre-fabricated modules, modular switchgear is faster and easier to install compared to conventional systems. It also simplifies troubleshooting and routine maintenance.

· Less on-site wiring and civil work required

· Individual modules can be isolated for servicing

· Reduces maintenance costs and system downtime

4. Compact and Space-Saving Design

With limited space in modern industrial setups, compactness is crucial. Modular switchgear systems are designed for space optimization, making them perfect for high-density environments.

· Vertical and horizontal expansion possible

· Reduced footprint compared to traditional gear

· Neat and organized layout improves cable management

5. Future-Proof and Upgrade-Friendly

Industries evolve, and so should your electrical infrastructure. Modular switchgear supports easy integration of new technologies, such as remote monitoring, IoT-enabled control systems, and energy management solutions.

· Supports integration with SCADA and BMS systems

· Accommodates evolving energy needs

· Long lifecycle with upgrade options

6. Cost-Effective Over the Long Term

Though the initial investment may be higher than conventional switchgear, the long-term benefits of modular systems — including reduced downtime, lower maintenance costs, and scalability — make them a cost-effective solution.

· Lower total cost of ownership (TCO)

· Reduced operational expenses

· Optimized energy efficiency

Applications of Modular Switchgear Systems

Modular switchgear is suitable for a wide range of applications, including:

🏢 Commercial buildings

🏭 Industrial plants

⚡ Power generation and distribution

🖥 Data centers

🏥 Hospitals

🏗 Infrastructure projects and smart cities

Conclusion

If you’re looking for a smart, scalable, and reliable solution for your electrical distribution system, modular switchgear systems are a worthy investment. With benefits ranging from safety and efficiency to cost savings and future readiness, they offer a significant upgrade over traditional switchgear models.

0 notes

Text

IYYM is a leading provider of industrial automation and pump solutions in the UAE. We specialize in engine-driven pumps, centrifugal and positive displacement pumps, VFD panels, electric motors, and complete control panel systems. Whether it’s water treatment, petroleum storage, or oil & gas applications, our advanced, low-maintenance systems ensure efficiency and reliability. As a trusted fuel system dealer and VFD panel manufacturer, IYYM also delivers SCADA, PLC, and metering systems for precise flow control. From custom skid packages to fuel management systems, we support every step – from design to after-sales. Visit https://www.iyym.com to learn more.

0 notes

Text

Best Panel Meters Manufacturer in Ahmedabad

Panel meters are essential instruments used across various industries to display measurements such as voltage, current, frequency, and temperature. They come in two primary types: analog and digital. Analog panel meters utilize a needle and dial to represent values, offering a quick visual reference, especially useful for monitoring trends or fluctuations. Digital panel meters, on the other hand, provide precise numerical readings, making them ideal for applications requiring exact measurements. Modern digital meters often feature additional functionalities like alarms, data logging, and communication interfaces, enhancing their utility in complex systems. The versatility of panel meters extends to their applications. In industrial settings, they monitor machinery performance, ensuring operations remain within specified parameters. In power distribution, they track electrical loads, aiding in energy management and preventing overloads. Specialized panel meters, such as energy meters, measure consumption over time, facilitating accurate billing and energy audits. Temperature panel meters are crucial in processes where thermal conditions must be maintained, like in HVAC systems or manufacturing processes Selecting the appropriate panel meter involves considering factors like the type of measurement, required accuracy, display preferences, and additional features. For instance, applications needing high precision might favor digital meters with advanced features, while those requiring simple trend monitoring might opt for analog meters. Furthermore, integration capabilities with other systems, such as SCADA or PLCs, can influence the choice, ensuring seamless data communication and control within larger automation frameworks

For More Details Click here: https://www.indiantradebird.com/product/panel-meters

0 notes

Text

Aluminum Homogenizing Furnace: Optimizing Microstructure for Superior Performance

In the aluminum processing industry, achieving uniform material properties is essential to ensure performance, durability, and machinability. One critical process used to enhance the internal structure of aluminum billets and ingots is homogenization. At the core of this process is the Aluminum Homogenizing Furnace, a specialized heat treatment system designed to improve alloy distribution and prepare aluminum for further processing.

What is an Aluminum Homogenizing Furnace?

An Aluminum Homogenizing Furnace is an industrial furnace used to heat aluminum castings (mainly billets or ingots) to high, controlled temperatures and then allow them to cool at a specific rate. This thermal cycle helps eliminate chemical segregation that occurs during solidification and redistributes alloying elements such as magnesium, silicon, or copper more uniformly across the billet structure.

The result is a more consistent microstructure that enhances mechanical properties and minimizes defects during extrusion or rolling.

Purpose of Homogenization

During casting, aluminum billets solidify unevenly, causing segregation of alloying elements between the center and the outer regions. This non-uniformity can lead to:

Poor mechanical strength

Uneven extrusion behavior

Cracks or surface defects

Homogenization eliminates these issues by:

Reducing segregation of alloying elements

Softening the billet for easier deformation

Enhancing dimensional accuracy during forming

Improving surface finish and tool life

Typical Homogenizing Cycle

Heating Phase: The billets are heated slowly to a homogenizing temperature, typically between 500°C to 600°C, depending on the alloy.

Soaking Phase: The material is held at this temperature for several hours to allow diffusion and alloy redistribution.

Cooling Phase: Controlled cooling (air, furnace, or forced convection) helps prevent internal stresses and maintain the improved structure.

Key Features of an Aluminum Homogenizing Furnace

Uniform Temperature Distribution: Ensures that all billets or ingots receive equal thermal treatment.

High-Performance Insulation: Minimizes heat loss and improves energy efficiency.

Precision Controls: Advanced PLC or SCADA systems manage temperature ramping, soak times, and cooling cycles.

Custom Tray and Racking Systems: Designed to hold large loads of billets while ensuring airflow and uniform treatment.

Cooling Chambers: Integrated or standalone cooling zones for controlled cooling processes.

Types of Aluminum Homogenizing Furnaces

Batch Homogenizing Furnace: Ideal for small-to-medium production quantities with flexibility in alloy types.

Continuous Homogenizing Furnace: Designed for large-scale, automated production with high throughput.

Combination Systems: Integrated with cooling tunnels or quenching chambers to streamline the process.

Applications Across Industries

Extrusion Plants: Homogenized billets lead to smoother extrusion with minimal die wear.

Automotive Sector: Ensures uniform strength and surface finish in vehicle components.

Aerospace Industry: Demands high structural integrity and alloy consistency for critical parts.

Building & Construction: Supplies reliable aluminum profiles for windows, doors, and facades.

Conclusion

The Aluminum Homogenizing Furnace is a vital tool for modern aluminum manufacturers seeking to optimize the performance of their billets or ingots before downstream processing. By enhancing internal consistency and reducing material defects, this furnace ensures that the aluminum products meet the highest standards of quality and reliability.

Investing in a high-efficiency, precision-controlled homogenizing furnace can significantly boost productivity, reduce scrap rates, and improve final product quality in any aluminum processing facility.

0 notes

Text

Alarm Management Software

#Alarm Management Application#Alarm Management Software#Industrial Alarm Management Application#Industrial Alarm by SMS#OPC Alarm by SMS#OPC alarm notification software#MSSQL Backup Utility#SQL Server Backup#SQL Backup and Restore Utility#MSSQL Data Truncate#Data Backup and Restore#Database Backup#Database Backup and Restore Utility#opc alarms by SMS applications Alarms by SMS#sql alarms by SMS application#Digital Alarms by SMS#digital alarms by SMS application#Analog Alarms by SMS#analog alarms by SMS application#SMS Alarm SCADA#SMS Alarm SCADA system

0 notes

Text

AVEVA (Wonderware) System Platform

SCADA, HMI, MES, and IIoT applications, AVEVA System Platform (previously Wonderware System Platform) is a unified operations center solution that offers an open, adaptable, and scalable architecture. In manufacturing and infrastructure operations, it provides a common basis for supervisory control, data collection, and real-time display.

Key Features of AVEVA System Platform

Object-Oriented Architecture

Scalability and Flexibility

Centralized Configuration and Deployment

Real-Time Data Handling

Integrated Historian

Security and User Management

Common Use Cases

Supervisory control and monitoring for manufacturing plants.

Energy and utilities operations management.

Water and wastewater facility control.

Oil & gas SCADA systems.

Smart buildings and infrastructure monitoring.

#automation#technology#tech#plc automation#aveva#scadatraining#scada systems#software programing#software#PLC#VFD#automotive

2 notes

·

View notes

Text

Diesel Flow Meter Manufacturers

Introduction

Fuel usage is the heartbeat of any operation that runs on diesel — whether it’s a truck fleet, a mining site, or a fuel station. Accurate diesel measurement isn't just about keeping records — it’s about saving money, reducing waste, and keeping operations efficient. That’s why Fluidyne’s diesel flow meter manufacturer are trusted across industries.

Introduction to Fluidyne

Overview of Fluidyne Control Systems

Fluidyne is a pioneering Indian manufacturer of high-precision fluid management systems. From flow meters to fuel automation, their solutions are engineered for industries that demand performance, durability, and accuracy.

Core Expertise in Fluid Measurement Technology

Backed by decades of experience, Fluidyne focuses on flow metering and dispensing systems for diesel, petrol, AdBlue, and other industrial fluids — catering to both small operators and large enterprises.

What is a Diesel Flow Meter?

A diesel flow meter is a device that measures the volume of diesel fuel passing through it, typically in liters or gallons. It's essential for accurate billing, inventory control, and efficiency monitoring.

Industries That Use Diesel Flow Meters

Transportation & Logistics

Mining & Construction

Oil & Gas

Agriculture & Marine

Why Choose Fluidyne Diesel Flow Meters?

Precision Engineering

Fluidyne meters offer ±0.5% or better accuracy, ensuring you measure every drop of diesel accurately — critical when dealing with high-value fuel.

Trusted by Major Sectors

Used by government utilities, transport fleets, and private oil retailers, Fluidyne's meters are built to meet industrial-grade standards.

Proven Track Record

With installations across India, Africa, and the Middle East, their meters have stood the test of time and terrain.

Types of Diesel Flow Meters by Fluidyne

Mechanical Diesel Flow Meters

Classic, reliable, and low-maintenance — these are ideal for remote areas and manual operations.

Digital Diesel Flow Meters

With backlit displays, real-time monitoring, and preset volume dispensing, these are suited for automated fueling stations.

Oval Gear Diesel Flow Meters

For high-viscosity diesel and accurate batching, oval gear meters deliver top-notch precision.

Electromagnetic Flow Meters

Though uncommon for diesel, Fluidyne also offers specialized magnetic meters for niche applications.

Comparison of Flow Meter Types

TypeAccuracyIdeal ForMaintenanceMechanical±1%Rural, Manual SitesLowDigital±0.5%Retail, IndustrialModerateOval Gear±0.2%Precision RefuelingLowElectromagnetic±0.3%Special FluidsModerate

Key Features of Fluidyne Diesel Flow Meters

Robust Metallic Construction for outdoor and harsh environments

LCD or LED Displays with totalizer and batch readings

Real-Time Data Integration with SCADA or ERP

Customizable Calibration Settings

Explosion-Proof Options Available

Applications Across Industries

Transport and Logistics

Manage every liter dispensed to trucks, reducing fuel theft and improving record accuracy.

Construction and Mining

Diesel usage in excavators and loaders is huge — Fluidyne meters help track it in real-time.

Fuel Depots and Retail Stations

Ensure regulatory compliance and accurate billing with commercial-grade meters.

Marine and Defense

From patrol boats to coastguard ships, accurate diesel metering is a mission-critical task.

Technological Innovations by Fluidyne

IoT Integration

Fluidyne meters can transmit data via cloud-based monitoring systems, allowing centralized fuel tracking.

Remote Monitoring via GSM/GPRS

Stay updated with SMS or web dashboards about diesel consumption and meter health.

Smart Dispensing Systems

Pre-program diesel volume to auto-shutoff after dispensing — ideal for fuel depots and bunkering stations.

Manufacturing Excellence

In-House Design and Calibration

All meters are designed and tested in-house using master calibrators and gravimetric testing systems.

ISO Certifications and Quality Assurance

Fluidyne adheres to ISO 9001 standards, ensuring consistency in quality and performance.

Custom Solutions

From dual-line outputs to multi-nozzle systems, Fluidyne designs solutions around your needs.

How to Select the Right Diesel Flow Meter

Determine Flow Rate – Choose a meter that suits your pump capacity.

Fuel Type and Viscosity – Diesel is medium-viscosity; choose suitable materials.

Installation Space – Inline, vertical, or wall-mounted options available.

Automation Needs – Go digital if you need data integration.

Maintenance and Support

Simple Cleaning and Calibration

Annual Service Contracts Available

24/7 Technical Support via phone or onsite visits

Quick Access to Spares and Accessories

Competitive Advantages

Designed & Made in India

Global Export Standards

Cost-effective Compared to Imports

Strong After-Sales Network

Real-World Use Case

A major logistics fleet operator in Maharashtra installed Fluidyne diesel meters across their depots. Result?

30% drop in unaccounted diesel

15% savings on overall fuel budget

Instant access to reports for fleet managers

Comparison with Other Diesel Flow Meter Brands

BrandAccuracyCostSupportCountryFluidyne±0.5%$$India-WideIndiaTCS±0.2%$$$$LimitedUSAPIUSI±1.0%$$$ModerateItalyFill-Rite±1.0%$$$LowUSA

Fluidyne strikes the perfect balance between performance, price, and local support.

Conclusion

When it comes to diesel flow measurement, accuracy isn't optional — it’s essential. With Fluidyne’s advanced diesel flow meters, you're not just measuring fuel — you're measuring efficiency, savings, and control. Whether you manage a fleet, run a construction site, or operate a fuel depot, Fluidyne is your go-to partner for dependable, high-performance flow metering.

FAQs

1. Are Fluidyne diesel flow meters explosion-proof? Yes, models with ATEX and flameproof ratings are available for hazardous zones.

2. Can they handle high flow diesel pumps? Absolutely. Fluidyne meters are available for flows up to 300 LPM or more.

3. Are they approved for commercial fuel dispensing? Yes, they comply with Weights & Measures Department standards where applicable.

4. What is the warranty period? Typically, 12 months, with extended warranty plans available.

5. Can I get a digital + mechanical combo? Yes, Fluidyne offers hybrid models with mechanical totalizers and digital readouts.

0 notes

Text

Key Benefits of Using Siemens SCADA and WinCC in Automation

The ever-increasing demand for real-time monitoring, control, and data-driven decision-making in the industrial world has reached an all-time high. Hence, this is where Siemens SCADA solutions are applied. Siemens SCADA systems try to enhance operational visibility and efficiency by providing robust and scalable automation control in various industries.

Explore the Complete range of Siemens SCADA PC Systems designed for efficient industrial automation.

What is Siemens SCADA?

Siemens SCADA (Supervisory Control and Data Acquisition) is a command center that supervises, controls, and analyzes industrial processes. It provides centralized monitoring and real-time data visualization across distributed automation setups. From small manufacturing plants to large process ones, Siemens SCADA allows for control, less downtime, and increased productivity.

Advanced SIMATIC WinCC platform is the backbone of the SCADA solutions offered by Siemens.

SIMATIC WinCC-The Heart of WinCC SCADA System

SIMATIC WinCC is Siemens’ flagship SCADA platform, applied widely in industrial automation applications. It provides a seamless and flexible environment for engineering and runtime tasks. The integrated suite allows the user to handle operation, monitoring, history data archiving, and advanced analytics.

WinCC SCADA always performs uniformly and intuitively, whether you have a single-machine setup or a network of connected production lines. Other highlights include:

Real-Time Visualization: Allowing for the viewing of critical process data and system state by plant operators in real-time.

Alarm Management: Notifying its users of any deviations or faults from the system on time.

Data Logging & Archiving: Collecting and storing for historical analysis and regulatory compliance.

Remote Access: Authorized personnel can watch and control systems from anywhere.

With its above features, Siemens SCADA Software is widely accepted in industries like automotive, food processing, pharmaceutical, and energy.

Why Choose Siemens SCADA software?

Siemens SCADA software is more than mere monitoring; it is an entire industrial intelligence system that brings together Siemens PLCs, HMIs, and drives under a unified and efficient sun of automation. Its open architecture supports third-party integrations, endowing it with high levels of flexibility to adapt to existing infrastructures.

Some of the advantages include:

Scalability: Works on any kind of project, ranging from the simplest machine-level control to plant-wide operations.

Cybersecurity: Built-in cyber-safety features ensure the protection of the system against unauthorized access and cyber threats.

User-Friendly Interface: An easy operation for engineers and operators.

Industry 4.0 ready: Enables connectivity with IoT platforms, cloud services, and AI-based analytics.

Conclusion

Selecting the correct SCADA system is cardinal in achieving operational excellence. With Siemens SCADA, powered by SIMATIC WinCC, industries unlock real-time insights, process optimizations, and smarter decisions across their entire production facility.

Naksh Technology Solutions LLP takes pride in offering comprehensive customer support and the supply of Siemens SCADA solutions. Naksh Technology is your partner in excellence within the automation space-from consultation and integration to after-sales support.

0 notes