#BLIIoT Applications

Explore tagged Tumblr posts

Text

BLIIoT 4G SMS Remote Monitoring Alarm Controller S272 for Aquaculture Monitoring

Foreword

Aquaculture is an important agricultural industry, and real-time monitoring of water quality parameters is critical to the success of farming

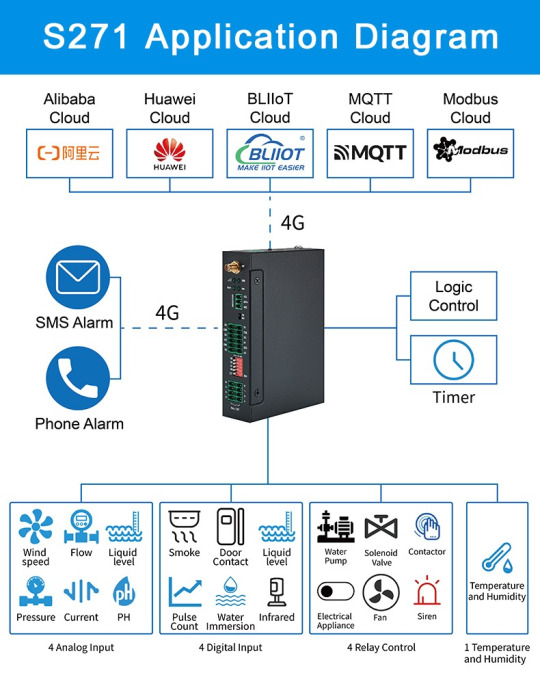

Remote Monitoring RTU 271 Functions

Remote Monitoring RTU 271 have 8 digital inputs, 6 analog or PT100 resistance temperature detector (RTD) inputs, 4 relay outputs, 1 environmental sensor input for monitoring site temperature and humidity, and an RS485 serial port. It can automatically monitor and operate I/O ports through SMS, cloud platform, web server, Internet, timer and programmed interlocking events.

Solution Requirements

Real-time monitoring of water quality parameters such as PH value and conductivity of water bodies. Users can remotely see the water quality conditions in real time through mobile phones and computers. When PH value, conductivity, dissolved oxygen and other parameters exceed the limits, users will be notified through SMS, phone calls, WeChat, emails, etc.

Solution Introduction

Remote Monitoring RTU S272 transmits data to the cloud for data processing through a wired connection with the PH sensor. The cloud feeds the data back to the cloud platform. Users can obtain PH value, conductivity, redox potential, and dissolved oxygen through the mobile APP computer web page. and other status; when the relevant parameters of water quality exceed the limit, the alarm information will be notified to the personnel on duty through text messages, phone calls, WeChat, etc. When necessary, equipment such as acid adding pumps or alkali adding pumps can be directly controlled through the cloud platform

Solution Advantages

1. Data Collection and Analysis

Remote Monitoring RTU S272 supports 4G transmission without distance restrictions, can monitor water quality parameters in real time, record data, perform historical data analysis, and provide visual reports so that farmers can better understand water quality conditions.

2.Real-time Monitoring

Monitor on-site water quality status 24 hours a day through mobile phones and computers; provide a solution for real-time monitoring of water quality parameters, remote access and alarm notification for the aquaculture industry

3. Alarm and Notification System

The system can set thresholds for water quality parameters. Once the parameters exceed the limits, users will be notified through multiple notification channels (SMS, phone calls, WeChat, and emails) so that they can take timely measures.

4. Remote Access and Control

Through mobile phones, computers and other devices, users can remotely access monitoring data at any time and even perform remote control to adjust water conditions.

5. Results and Benefits

By using Remote Monitoring RTU S272, the aquaculture industry can monitor water quality parameters in real time, obtain timely alerts and remote control, improve breeding efficiency, reduce losses, and achieve greater economic benefits.

Summarize

Remote Monitoring RTU S272 brings innovative solutions to the aquaculture industry, helping farmers achieve real-time water quality monitoring, alarm notification and remote control, thereby improving the efficiency of aquaculture, ensuring the healthy growth of organisms, and creating greater value.

More information about BLIIoT 4G SMS Remote Monitoring Alarm Controller S272: https://www.bliiot.com/m2m-rtu-p00174p1.html

#iot#iotsolution#smartaquaculture#remotemonitoring#remotecontrol#alarm#controller#rtu#gateway#iomodule#sms#4g#rs485#modbus#mqtt#scada#alibabacloud#huaweicloud#BLIIoT#BLIIoT Applications

0 notes

Text

BLIIoT|New Version BE115 IEC104 OPC UA Modbus MQTT BACnet PLC Protocols Air Conditioning Protocols Multi-protocol Integration Gateway

Introduction

Many industrial systems and devices use different communication protocols based on their specific requirements and legacy systems. Multi-protocol integration allows these systems to communicate with each other regardless of the protocols they support, ensuring seamless interoperability.

Multi-protocol integration involving IEC 104, OPC UA, Modbus, MQTT, DL/T645, PLC protocols, and BACnet requires a comprehensive approach to ensure seamless communication between diverse industrial systems.

Multi-protocol integration enables centralized monitoring and control of diverse systems from a single interface. This unified approach simplifies management, reduces complexity, and enhances operational efficiency by providing a comprehensive view of the entire industrial ecosystem.

Product Description

BE115 supports a wide range of industrial protocols, including IEC 104, OPC UA, Modbus, MQTT, PLC protocols, and BACnet, to ensure compatibility with diverse industrial systems and devices.

BE115 supports bi-directional communication, allowing data to flow seamlessly between devices and systems using different protocols. This includes both read and write operations for data exchange.

It offers robust management and monitoring capabilities to configure, monitor, and manage the gateway and connected devices efficiently. This includes remote management, configuration backup, firmware updates, and real-time monitoring of device status and performance.

Product features

Supports DL/T645, IEC104, Modbus RTU, Modbus TCP, MQTT, OPC UA, BACnet/IP, BACnet MS/TP, PLC protocols, air conditioning protocols.

Supports connection to up to 50 devices and collection of 4,000 data points.

Supports 6 RS232/RS485 optional inputs.

It adopts embedded ARM MCU and is a product developed based on Linux OS system.

2 Ethernet ports (WAN port and LAN port).

Support 4G, WiFi, GPS.

Support OpenVPN, SNMPV1/V2.

It supports routing functions and cascade switch data collection to facilitate the collection of more industrial equipment data. The software has complete functions and covers most common application scenarios.

It integrates the humanized configuration interface that BLIIoT adheres to, as well as remote configuration, remote firmware upgrade and other functions. Users only need to make simple settings.

It adopts a fastening structure and has a power supply design with anti-reverse connection protection.

It adopts BLIIoT's patented rail buckle technology and supports standard DIN35 rail installation and wall-mounted installation.

0 notes

Text

BLIIoT Water Meter Pulse Counting Gateway S271

Background

No matter where you live, water and electric meters are an absolute must. Water meters record how much water you use and how much you pay for it. Water meters help monitor data, conserve water, and lower water bills.

Pulse Counting Gateway

Pulse Counting Gateway S271 is designed to count the number of pulses from electricity meters, water meters or general meters as well as machinery and equipment with pulse outputs. Quickly and cost-effectively transform your traditional water meter into a smart water meter, monitoring data in real time.

Solution

Pulse Counting Gateway S271 can be used in different applications such as agricultural irrigation, smart building meter reading and industrial water use. The device can be connected to a pulse water meter, and then collect water use data and upload the data to the IoT cloud platform via 4G for further visualization. Users can check the status of the water meter and perform monitoring and control at any time. The pulse counter can provide remote monitoring and visual intelligent data management to achieve water conservation.

More information about Water Meter Pulse Counting Gateway S271: https://www.bliiot.com/m2m-rtu-p00175p1.html

0 notes

Text

BLIIoT OPC UA Distributed Ethernet IO Module BL205 Helps Digital Factory

Introduction

The digital factory is an important concept in today's industry, and it represents the future of manufacturing. In the realization of the digital factory, the collection, transmission and analysis of data become crucial. In this process, the OPC UA distributed IO module plays a key role, providing strong support and flexibility for the digital factory.

OPC UA is closely related to the digital factory because it can be used as a bridge connecting various components in the digital factory to realize real-time data transmission and sharing.

Introduction to OPC UA

OPC UA (Open Platform Communications Unified Architecture) is a communication protocol designed to enable data exchange and communication across different devices and systems. It provides a standardized method for connecting and managing devices and applications in industrial automation systems. Key advantages of OPC UA include cross-platform compatibility, high security and scalability.

OPC UA is closely related to the digital factory because it can be used as a bridge connecting various components in the digital factory to realize real-time data transmission and sharing.

Industrial Internet of Things Transformation

One of the challenges of IIoT transformation is how to seamlessly integrate existing OT systems into new IT systems.

OPC UA I/O to SCADA without gateway

Traditionally, most solutions utilize protocol gateways to convert remote I/O data to OPC UA, which requires additional configuration, and the software installed in the gateway's operating system increases the risk of the system being attacked by malware. To solve this problem, OPC UA Distributed Ethernet IO Module BL205 communicates directly via SCADA and OPC UA cloud without additional gateway, saving additional cost and integration work.

Application of OPC UA Distributed Ethernet IO Module BL205 in Digital Factory

Real-time data collection and transmission

A digital factory requires real-time production data in order to monitor the production process in real time and make timely decisions. OPC UA Distributed Ethernet IO Module BL205 can effectively collect data from sensors and devices and transmit it to a central database or cloud platform for use by factory managers and engineers.

Remote Monitoring and Control

The existence of OPC UA Distributed Ethernet IO Module BL205 makes remote monitoring and control possible. Factory managers can access production data from anywhere and remotely control it as needed, increasing work flexibility and efficiency.

Troubleshooting and Predictive Maintenance

Through real-time data analysis, digital factories can realize fault diagnosis and predictive maintenance. OPC UA Distributed Ethernet IO Module BL205 can collect health status data of equipment and help engineers predict when equipment needs to be maintained or replaced, thereby reducing downtime and maintenance costs.

Data analysis and optimization of production

A digital factory is not just about data collection, but also data analysis and optimizing production. OPC UA Distributed Ethernet IO Module BL205 provides real-time data, which can be used for optimization and improvement of the production process to improve production efficiency and quality.

Cost-effective: High I/O density and daisy-chain solutions save costs

With high I/O density and support for daisy chain connection, OPC UA Distributed Ethernet IO Module BL205 series is the most cost-effective solution to meet diverse needs. Users benefit from cost savings in I/O modules, switches, amount of wiring and space savings in the control cabinet.

In conclusion

OPC UA distributed IO modules are a key component of digital factories. They provide factories with real-time data and remote control capabilities, helping factories achieve higher production efficiency, quality and maintainability. With the development of the digital factory, we can expect to see more innovations and improvements to meet the changing needs of the manufacturing industry and push industrial production to new heights.

More information about the OPC UA Distributed Ethernet IO Module BL205 :https://www.bliiot.com/opc-ua-io-controller-opc-ua-i-o-controller-opc-ua-io-module-p00347p1.html

#iot#iotsolutions#digitalfactory#industrialautomation#smartfactory#industria40#opcua#ethernetio#scada#BLIIoT#BLIIoT Applications

0 notes

Text

BLIIoT OPC UA Distributed Remote Ethernet IO Module BL205 to SCADA

Traditionally, most solutions utilize protocol gateways to convert remote I/O data to OPC UA, which requires additional configuration, and the software installed in the gateway's operating system increases the risk of the system being attacked by malware. To solve this problem, OPC UA Distributed Ethernet IO Module BL205 communicates directly via SCADA and OPC UA cloud without additional gateway, saving additional cost and integration work.

#iot#digitalfactory#industrialautomation#smartwater#opcua#ethernet#iomodule#scada#remotemonitoring#datacollection#BLIIoT#BLIIoT Applications

0 notes

Text

Siemens S7-200SMART PLC Extend BLIIoT ProfiNet Distributed IO Module BL201

Siemens S7-200SMART and BL201

1. Prepare IO modules: Coupler BL201, digital output module M2082, digital input M1081, analog input module M3401, analog output M4043. Module assembly and wiring Installation, Device connection.

2. BL201, S7-200SMART, and PC need the same LAN. Power on BL201 and S7-200SMART, and open Siemens STEP 7-MicroWIN SMART software. Click GSDML management, in the pop-up window, click Browse to find the GSD file of BL201 and click Open, click Open to complete the installation of the GSD file.

3. Click Tools, click Find PROFINET Devices, click Find Devices, find BL201, and the name of the BL201 coupler is bl200pns. (The found coupler name must be consistent with this name during configuration.)

4. Click Tools, click PROFINET. Select the controller and click Next.

5. Find BL201 in the hardware catalog, click Add, add it to the device list, modify the name of the coupler to bl200pns (communication key parameters), and assign the IP address of 192.168.5.10 to the coupler. The IP address assigned to the coupler must be in the same LAN as the IP address of the PLC. You can also modify the IP address of the PLC on this interface. After the modification is complete, click Next.

6. Configure the IO module connected with the BL201. Click Generate. Add modules in the order of the IO modules hung behind the BL201. Power supply modules, extended power supply modules, and terminal modules do not need to be configured and do not participate in the sorting.

M2082 corresponds to address QW128, M1081 corresponds to address IW128, M3401 corresponds to address IW129-IW136, and M4043 corresponds to address QW129-QW136.

7. Click PLC, click Download, search for PLC in the pop-up window, and click OK. click to download.

After the download is successful, open the status chart and monitor the channel value of the IO module.

Refer to Process Data Definition. When the range is 4-20mA, the theoretical value input of AI first channel IW129 is: 22958/65535*16+4=9.60507 mA. When the range is 0-5V, the output of the first AO QW129 is: 65535/65535*5=5V.

Process Data Definition

BL201 does not support the data collected by the serial port module temporarily, the data point address of the I/O module is determined by the Profinet master, and the data of AI and AO are mapped to 0-65535.

For example: Requires analog output 3V, the issued value is: When the range is 0-5V, 3*65535/5=39321. When the range is 0-10V, 3*65535/10=19660.5, since AO is an integer, 19660 will be issued.

For example: The AI value in the master is 56789, then when the range is 0-20mA, the theoretical value of AI is: 56789/65535/20=17.33089mA. When the range is 4-20mA, the theoretical value of AI is: 56789/65535*16+4=17.86471mA.

More information about BLIIoT ProfiNet Ethernet Distributed Edge IO Module BL201: https://www.bliiot.com/profinet-io-system-p00348p1.html

#iot#smartfactory#industrialautomation#smartcities#io#profinet#siemens#s7#edgecomputing#ethernet#BLIIoT#BLIIoT Applications

0 notes

Text

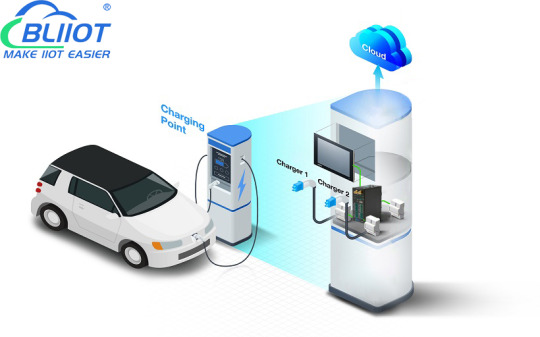

Application of Embedded ARM Industrial Edge Computer in EV Charging Pile Control System

Foreword

With the popularity of electric vehicles, charging piles play an important role as the infrastructure for charging electric vehicles. However, traditional charging piles have some problems and challenges in terms of energy management and user experience. In order to solve these problems, the concept of electric charging pile came into being, which incorporates advanced technology to provide smarter, more efficient and more convenient charging services. In the process of realizing the EV charging pile, the excellent performance and characteristics of the BLIIoT Embedded ARM Industrial Edge Computer BL302 provide a strong support for it.

Demands and Challenges of EV Charging Piles

The number of charging piles is huge, the installation locations are scattered, the environment is harsh, management is not easy, and the cost of equipment maintenance is often very high.

The EV charging pile industry protocol is not unified and standardized, and the protocols used by various manufacturers of EV charging pile equipment are quite different, which has caused certain difficulties for the management of the monitoring center and is not convenient for data statistics.

Most of the EV charging stations are in the outdoor environment, which has extremely high requirements on the performance of the equipment, and must be above industrial-grade standards.

For the operation and maintenance of traditional charging stations, the charging piles still need to be inspected and inspected by means of manual inspection on the station and on-site investigation, and remote management must be used to save operation and maintenance costs.

Introduction to Application Scenarios

EV charging piles are generally composed of BLIIoT Embedded ARM Industrial Edge Computer BL302, power controller, power module, interface module, interface management system and other parts.

With the BLIIoT Embedded ARM Industrial Edge Computer BL302 as the core, build a safe operation system for electric vehicle charging piles. BLIIoT Embedded ARM Industrial Edge Computer BL302 can realize the functions of electric vehicle charging pile teaching and data networking, remote monitoring, communication, system fault diagnosis, parameter adjustment, safety monitoring, etc., to meet the needs of users in multi-scenario applications, and to facilitate management personnel to monitor anytime and anywhere The charging pile improves the charging efficiency and user experience of the user. The algorithm decoding performance of the electric vehicle charging station is improved by more than 75% on the original basis, and the power consumption is reduced by nearly 2/3.

Functional Requirements

Charging status monitoring

BLIIoT Embedded ARM Industrial Edge Computer BL302 can collect the operating status data of EV charging piles, collect voltage, current, temperature, etc. through sensors or instruments, and judge the operating status of EV charging piles based on these data, thereby realizing charging status monitoring and unmanned intelligent operation. Optimize maintenance and operation, and improve the utilization rate of charging piles.

Environmental monitoring

BLIIoT Embedded ARM Industrial Edge Computer BL302 has an IO module applied to EV charging piles, which can be used in conjunction with sensors to collect surrounding environmental parameter data, such as temperature, humidity, air pressure, etc., and judge the charging environment based on the data. These data can realize environmental monitoring and ensure the safe operation of electric vehicle charging piles.

Security monitoring

BLIIoT Embedded ARM Industrial Edge Computer BL302 applied to EV charging piles can collect the voltage, current, temperature, humidity, air pressure and other parameter data of EV charging piles by installing sensors, and judge the charging operation based on these data. In this way, the safety monitoring of EV charging piles can be realized. In addition, BLIIoT Embedded ARM Industrial Edge Computer BL302 can also collect leakage information of EV charging piles and issue an alarm in time to detect potential safety hazards in the entire area of the charging station and ensure the safety of the entire area of the charging station.

If you feel fire hazards, artificial charging dangerous behaviors, abnormal equipment temperature, etc., immediately start the sound and light system alarm and SMS phone notification to remind the charging user to leave, and immediately feed back to the staff for processing. If no one responds within a certain period of time, the charged equipment will be controlled to shut down the entire charging station to ensure safe operation and maintenance.

Mobile payment

BLIIoT Embedded ARM Industrial Edge Computer BL302 can not only realize 24-hour unmanned charging service, but also realize the payment function of EV charging piles by accessing the payment system, and supports credit card payment, QR code payment and other payment methods.

Advantages of BLIIoT Embedded ARM Industrial Edge Computer BL302

Fanless design, with the characteristics of stability, firmness, reliability, etc., can conveniently realize free charging operation, and can collect various charging parameters on site in real time.

Support CAN bus interface communication, which can meet the needs of more industrial application fields.

4*RS232/RS485 interface, 1*CAN port, 2*Ethernet port, 2*PWM port output, 1*USB interface, 1*Power input/output interface, 1*HDMI video display interface, which can meet various applications Scenario function expansion requirements can support users to plug and play, speeding up project implementation.

2*DI port, which can be flexibly connected to card readers, printers, watt-hour meters and other equipment, so that users can freely operate the EV charging pile.The chassis is made of aluminum alloy, which has the characteristics of firmness, good shock resistance, fast heat dissipation, dust-proof and splash-proof, and does not absorb heat in the sun to prevent the internal temperature from escaping in summer.

BLIIoT Embedded ARM Industrial Edge Computer BL302 wide temperature operation (-40~80℃, 5%~95% RH), wide voltage design and ESD protection up to EC standard can perfectly protect the system from the harsh environment and operation problems of the charging station. Many problems such as overvoltage and overcurrent during charging.

In addition, the 8 reasons for choosing the BLIIoT Embedded ARM Industrial Edge Computer BL302 have advantages that are incomparable to similar products of the same industry in the application of EV charging piles.

BLIIoT Embedded ARM Industrial Edge Computer BL302 uses NXP high-performance processor I.MX6ULL with a running speed of up to 800MHz, and is equipped with 8G Flash space and 512M RAM. It can run LINUX, Ubuntu, Debian and other OS compatible Node-Red, QT, Python, C++ and other applications. Support MySQL, InfluxDB, SQLite and other databases.

With the continuous development of the EV charging pile industry, the application of industrial computer in the charging industry is getting more and more in-depth. At present, the edge computing based on the ARM architecture, which is a leading technology, provides EV charging pile industry users with its stable quality and high cost performance. A cost-effective solution. It can also be applied to vertical EV charging piles, mobile charging cars, and power exchange cabinets.

In Conclusion

In the realization of the EV charging pile, the BLIIoT Embedded ARM Industrial Edge Computer BL302 plays an indispensable role. Its high performance, stability, diverse hardware interfaces and smart energy management functions enable EV charging piles to provide more efficient and smart charging services and promote the sustainable development of the electric vehicle industry.

More information about BLIIoT Embedded ARM Industrial Edge Computer BL302 : https://www.bliiot.com/edge-computing-gateway-p00359p1.html

#iot#iotsolutions#smartcities#smartcharging#evchargingpile#industrialcomputer#edgecomputing#nodered#linux#ubantu#debian#ethernet#wifi#4g#BLIIoT#BLIIoT Applications

0 notes

Text

BLIIoT Remote Monitoring Gateway RTU S271 Collects the Refrigerator Temperature in Real Time through the Cloud

BLIIoT Remote Monitoring Gateway RTU S271 provides 4 digital inputs, 4 analog or PT100 Resistance Temperature Detector (RTD) inputs, 4 relay outputs, 1 ambient sensor input for monitoring onsite temperature and humidity. It can monitoring and operates the I/O ports by SMS, APP, Web Server, internet, timers and programmed inter-lock events automatica

#iot#iotsolution#smartcities#remotemonitoring#remotecontrol#modbus#mqtt#scada#4g#sms#cloud#temperaturemonitoring#BLIIoT#BLIIoT Applications

0 notes

Text

BLIIoT Modbus to MQTT Gateway BL100 is used in Chemical Plants to Collect Gas Sensor Data

BL100 is a cost-effective industrial IOT gateway based on cellular network. It supports Modbus RTU, Modbus TCP, MQTT, Alibaba Cloud, HUAWEI Cloud, BLIIoT Cloud, custom platform and transparent data transmission. Users can connect it to third-party server, cloud platform and SCADA easily.

#iot#iotsolution#smartfactory#iotgateway#remotemonitoring#datacollection#modbus#mqtt#huaweicloud#alibabacloud#scada#BLIIoT#BLIIoT Applications

0 notes

Text

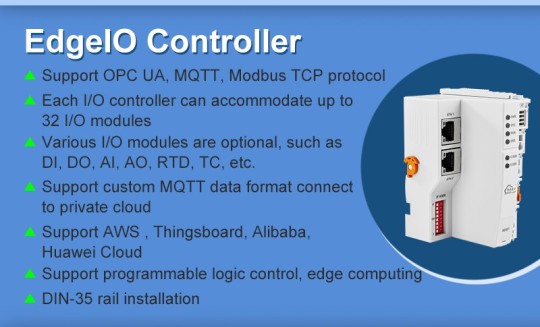

BLIIoT Remote Ethernet Modbus TCP Distributed Edge I/O Module BL200

Distributed Modbus TCP I/O Module BL200 is a new type of I/O system that supports Modbus TCP protocol, built-in programmable logic control, edge computing, customized applications. it suitable for Industrial Automation. BL200 Modbus TCP Distributed Edge I/O Module BL201 ProfiNet Distributed Edge I/O Module BL202 EtherCAT Distributed Edge I/O Module BL203 Ethernet/IP Distributed Edge I/O Module BL205 OPC UA Distributed Edge I/O Module BL206 MQTT Distributed Edge I/O Module BL206Pro Modbus TCP, MQTT, OPC UA Distributed Edge I/O Module BL207 BACnet Distributed Edge I/O Module

#iot#Iomodule#industrialautomation#smartfactory#modbus#mqtt#opcua#profinet#ethercat#ethernetip#bacnet#ethernet#edgecomputing#BLIIoT#BLIIoT Applications

0 notes

Text

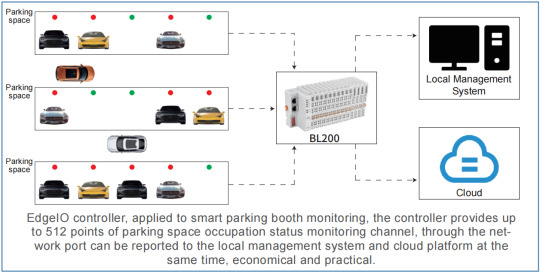

BLIIoT Ethernet Distributed Edge I/O System applied to Smart Parking Lot

With the continuous acceleration of the urbanization process, parking difficulties have become a problem faced by many cities. With the vigorous development of the national and local governments in recent years, it is expected that there will be more and more overall smart parking projects in the future, and the industrial scale is expected to reach hundreds of billions or even trillions. This article will introduce the application case of BLIIoT Ethernet Distributed Edge I/O System applied to Smart Parking Lot.

1. Case Background

At present, the parking space detection technology includes magnetoelectric technology, ultrasonic technology, infrared technology, and image recognition parking space technology. Considering the influence of environmental factors such as electromagnetic interference and signal interference, it is usually carried out in combination, such as using different sensors and applying different protocols, in order to improve the accuracy and real-time performance of parking space detection.

For the data collected by these sensors, data analysis and uploading are required. Usually, the parking lot needs a transmission distance of more than 100 meters, so the traditional wired transmission will face the challenge of transmission distance and the cost of ground installation, which may lead to difficulties in maintenance of communication interruption or failure. Major smart parking integration solution providers are urgently paying attention to the development of the industry!

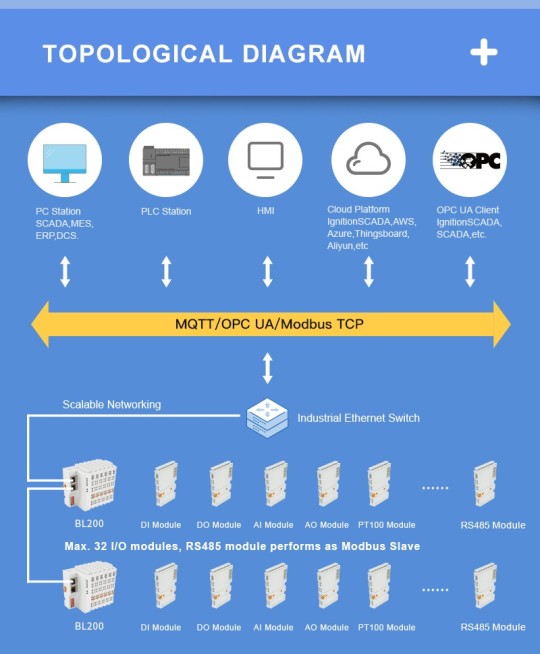

2. What is BLIIoT Ethernet Distributed Edge I/O System?

The BLIIoT Ethernet Distributed Edge I/O System consists of couplers and I/O modules. It is responsible for collecting and transmitting various signal data. It supports up to 32 I/O modules and 512 signal collections. It is an I/O controller with edge computing for collection control. Compared with the traditional wired transmission method, the distributed I/O system reduces the data transmission time between devices and improves the efficiency of data collection. It has the characteristics of strong scalability, good flexibility, high reliability and easy management.

3. BLIIoT Ethernet Distributed Edge I/O System Solution

Selection of hardware equipment

In order to ensure the accuracy and real-time performance of data collection, high-quality IO modules need to be selected. After comparison, the customer chose the I/O module developed by barium-rhenium technology.

Data collection and processing

The I/O board supports various types of input/output signal acquisition, such as digital input, digital output, analog input, analog output, PT100, PT1000, thermocouple, pulse input, pulse output, RS485 and other I/O signals. Users can configure each interface of the node according to their needs.

In terms of data processing, among the collected signals, the distributed I/O controller has built-in edge computing functions, which can realize data processing and logic linkage without relying on the cloud and the host computer, and realize cloud-side collaboration.

In terms of data aggregation, the distributed I/O module can seamlessly integrate information from multiple data collection points, aggregate and transmit the information to the coupler for further analysis and processing.

Immediate response: Distributed I/O modules can quickly collect and process data, and there is a very short delay time from signal input to output, making on-site operation and maintenance and system real-time control more convenient.

Remote monitoring: Remote real-time monitoring and control of signal acquisition and data processing functions of distributed I/O modules. Through the Internet of Things platform or internal system platform, administrators can keep abreast of the data status of each node, equipment failure alarms, and avoid danger or damage.

Storage and transmission

After the data is collected and transmitted, it needs to be stored and analyzed. For data storage in smart parking lots, the following factors need to be considered: reliability, storage and processing speed, confidentiality and privacy, and cost. Considering the above factors, you can choose some well-known cloud platforms, such as Alibaba Cloud, Huawei Cloud, AWS Cloud, and ThingsBoard.

4. Application Topology Diagram of Distributed I/O System

Distributed I/O module is a hardware device for decentralized and distributed data acquisition and control, with the following features:

Support large-scale expansion: Distributed I/O modules can support massive input/output, and both digital and analog signals can be adapted, which makes it more flexible when expanding nodes.

Network communication interface: connect to the remote master device or sensing node through different network communication interfaces, and support two-way transmission of signals, so as to realize open interconnection and intercommunication.

Technical standardization: Distributed I/O modules often adopt standardized technical solutions, such as industrial network protocols such as Modbus TCP/MQTT/OPC UA/Modbus TCP/ProfiNet/EtherCAT/EtherNet/IP, etc., making the interconnection with other industrial automation equipment easier.

Unified management: The acquisition and control system based on I/O modules can also be managed in a unified manner, and the supervision and configuration of each node device can be realized on the cloud management platform.

Data processing capability: Compared with other smart devices, the distributed I/O module has more advantages in data processing, because it has built-in edge functions, and can realize the linkage control of local I/O signals without the need for the upper computer and cloud platform or PLC, which greatly improves the response speed of the site and relieves the pressure of data processing on the cloud upper computer.

More information about BLIIoT Ethernet Distributed Edge I/O System:

https://www.bliiot.com/edgeio-io-controllers-p00334p1.html

#iot#iotsolutions#smartparking#lot#remotemanagement#datacollection#modbus#mqtt#opcua#iomodule#ethernetswitch#edgecomputing#BLIIoT#BLIIoT Applications

0 notes

Text

BLIIoT SMS/4G Remote Monitoring RTU Gateway S275 applied to Smart Environment Monitoring

1. Foreword

Environmental pollution has a huge impact on human health and ecosystems, so environmental monitoring is particularly important. This article will introduce the application of BLIIoT SMS/4G Remote Monitoring RTU Gateway S275 in smart environmental monitoring. By connecting various sensors and realizing remote data transmission and control, the device can monitor, manage and control environmental pollution sources in real time, providing reliable data support for environmental protection.

2. Importance of Environmental Pollution Monitoring

Environmental pollution poses a serious threat to human health and ecosystems, so the importance of environmental monitoring is self-evident. Through real-time monitoring and control of pollution sources in the environment, we can take timely measures to protect the environment, reduce pollutant emissions, and provide reliable data support for environmental protection decisions.

3. What is BLIIoT SMS/4G Remote Monitoring RTU Gateway S275?

BLIIoT SMS/4G Remote Monitoring RTU Gateway S275 is an industrial class, high reliability, high stability, and programmable Remote Terminal Unit (RTU). It embedded 32-Bit High Performance Microprocessor MCU, inbuilt industrial Cellular module. It provides 8 digital inputs, 6 analog or PT100 Resistance Temperature Detector (RTD) inputs, 4 relay outputs, 1 ambient sensor input for monitoring onsite temperature and humidity, and RS485 serial port, supports extending 320 I/O tags via Modbus RTU protocol. It can monitoring and operates the I/O ports by SMS, APP, Web Server, internet, timers and programmed inter-lock events automatically.

4. Application scenarios in Smart Environment Monitoring

Pollution source monitoring

The process of systematically monitoring and evaluating emissions from specific sources of pollution. Its purpose is to determine the emission of pollution sources, assess its impact on the environment and human health, and provide data support for taking corresponding pollution prevention and control measures.

Exhaust gas monitoring

The process of monitoring and analyzing the waste gas generated in industrial production, transportation, energy utilization and other activities. Its main purpose is to assess and monitor the impact of exhaust emissions on the environment and human health to ensure compliance with relevant environmental regulations and standards.

Wastewater Monitoring

The process of monitoring and evaluating wastewater discharge and treatment systems. It aims to ensure that sewage discharge complies with relevant environmental regulations and standards to protect the environment and human health.

Noise Monitoring

The process of monitoring and evaluating noise levels in an environment. Its purpose is to assess the extent to which noise affects human health, the quality of life of residents and the environment, and to ensure compliance with relevant noise regulations and standards.

BLIIoT SMS/4G Remote Monitoring RTU Gateway S275 is the core device of the pollution source automatic monitoring system, which supports the connection of various sensing devices, including air pollution sources, such as sulfur dioxide, hydrocarbons, particles, carbon dioxide, hydrogen chloride, VOCs, etc., and waste water pollution sources, such as COD, nitrogen , total, PH, etc., BLIIoT SMS/4G Remote Monitoring RTU Gateway S275 via 4G uploads data to the cloud platform/server to realize real-time monitoring, collection, analysis and upload of all elements of pollution sources.

5. Data real-time monitoring and remote control

BLIIoT SMS/4G Remote Monitoring RTU Gateway S275 connects various pollution sensors through DIN/DO/AIN/RS485, collects data and uploads it to the cloud platform or server to realize centralized management and analysis of real-time data monitoring. At the same time, it also supports remote control of the operating status and alarm functions of related equipment to ensure the safe operation of the equipment.

6. Summarize

BLIIoT SMS/4G Remote Monitoring RTU Gateway S275 plays an important role in environmental pollution monitoring. It has a wide range of application scenarios, covering pollution source monitoring, waste gas monitoring, sewage monitoring, noise monitoring and other fields. Through real-time monitoring, remote control and data management, it can provide accurate data and decision support for environmental protection. In the future, with the continuous development of IoT technology, 4G RTU terminals will play a more important role in environmental pollution monitoring.

More information about BLIIoT SMS/4G Remote Monitoring RTU Gateway S275 : https://www.bliiot.com/cellular-iot-modbus-rtu-8din6ain-pt1004relay1thusbrs485320-extend-i-o-tags-p00175p1.html

#iot#iotsolutions#smartcities#enviornment#remotemonitoring#remotecontrol#modbus#mqtt#4glte#sms#gateway#io#rtu#BLIIoT#BLIIoT Applications

0 notes

Text

How to use BLIIoT S275 SMS/4G RTU gateway for Chicken house monitoring?

1. Foreword

Chicken house is a large-scale farming. The traditional breeding program is to feed and adjust the temperature according to the experience of the farmers. However, the traditional breeding method cannot know all the environmental conditions of the Chicken house in real time. Whenever the environmental conditions are not suitable, the chickens will be stressed and die, resulting in major economic losses.

Moreover, the temperature, humidity and other environmental conditions required for each stage of chicken growth are different, so a good breeding environment is the key to successful breeding. The role of the chicken house breeding environmental control system is to provide accurate monitoring information and quickly adjust the breeding environment. Optimizing the breeding plan can better understand the actual situation of the chicken house and protect the interests of farmers.

2. IoT monitoring solution

Chicken house environmental monitoring is the specific application of Internet of Things technology in animal husbandry production, operation, management and service. Various sensors are used to extensively collect parameters including temperature, humidity, noise, light, harmful gases (ammonia, hydrogen sulfide, carbon dioxide), etc. Collect sensor data through the Internet of Things monitoring equipment, and upload the data to the server/cloud platform, and also perform real-time monitoring through the SMS app to achieve comprehensive monitoring and control of the chicken house environment.

Front-end: collect temperature, humidity, ammonia, carbon dioxide concentration, light intensity, oxygen concentration data.

BLIIoT SMS 4g Wireless Remote Monitoring RTU S275: which can collect data and carry out monitoring control and power failure alarm, monitor the real-time environmental data of the chicken house and judge the growth and development environment of the chicken.

The trigger function can be linked to equipment control, such as turning on the fan to cool down when the temperature in the house is too high, or turning on the heating device when the temperature in the house is too low. The system is very practical and can be used for remote control of livestock companies as well as for analyzing data and analysis.

Backend: It can connect to cloud platform or server through Modbus and MQTT protocol for remote real-time monitoring, and notify farmers or ranchers through network and mobile APP, WeChat, webpage, SMS and timely phone calls.

3. What is BLIIoT SMS 4g Wireless Remote Monitoring RTU S275?

BLIIoT SMS 4g Wireless Remote Monitoring RTU S275 is an industrial class, high reliability, high stability, and programmable Remote Terminal Unit (RTU). It embedded 32-Bit High Performance Microprocessor MCU, inbuilt industrial Cellular module. It provides 8 digital inputs, 6 analog or PT100 Resistance Temperature Detector (RTD) inputs, 4 relay outputs, 1 ambient sensor input for monitoring onsite temperature and humidity, and RS485 serial port, supports extending 320 I/O tags via Modbus RTU protocol. It can monitoring and operates the I/O ports by SMS, APP, Web Server, internet, timers and programmed inter-lock events automatically.

The Cellular IoT Modbus RTU inbuilt TCP/IP protocol stack make it suitable for internet of things (IoT) applications, it can be easily to operate by the provided cloud, app, and web server, or integrated to you IoT applications according to the TCP/UDP protocol, or integrated to SCADA systems by standard Modbus TCP protocol, too. This is very useful if you need remote control onsite devices with low cost solution.

4. IoT Monitoring Advantages

Real-time environmental data collection and monitoring

The intelligent livestock monitoring system uses BLIIoT SMS 4G Wireless Remote Monitoring RTU S275 equipment to realize the comprehensive collection and monitoring of chicken house environmental data. Through sensors to collect multiple key indicators such as temperature, humidity, ammonia, carbon dioxide concentration, light intensity, and oxygen concentration, the system can understand the environmental conditions inside the chicken house in real time.

Remote control and linkage equipment

The intelligent livestock monitoring system has a powerful remote control function, and can precisely control the chicken house environment by linking other equipment. For example, when the temperature in the chicken house is too high, the system can automatically turn on the fan to cool down; when the temperature is too low, the system will turn on the heating device for heating. In this way, it can be ensured that the environmental parameters such as temperature and humidity inside the chicken house are always maintained in a suitable range, and good environmental conditions are provided for the growth of chickens.

Remote real-time monitoring and alarm notification

Through the connection with the cloud platform or server, the intelligent livestock monitoring system can realize remote real-time monitoring. Farmers or ranchers can view chicken house environmental data and monitoring results anytime, anywhere through the Internet, mobile APP, WeChat, web pages and other methods. At the same time, the system can send short messages, phone calls or other notifications in time to send alarm messages to farmers or ranchers, reminding them to pay attention to abnormal changes in the chicken house environment, so as to take timely measures.

Data analysis and optimization decision

The intelligent livestock monitoring system can not only monitor environmental data in real time, but also store and analyze the collected data. Through the statistics and analysis of a large amount of data, farmers or ranchers can understand the changing trends and laws of the chicken house environment, formulate more scientific and reasonable decision-making plans, and improve the efficiency of livestock and poultry farming.

5. Conclusion:

The application of BLIIoT SMS 4G Wireless Remote Monitoring RTU S275 in the smart chicken house monitoring system has brought a huge impetus to the development of animal husbandry with its real-time environmental data collection and remote control functions. It can monitor the environmental conditions of the chicken house in real time, link other equipment for precise control, and provide a good growth and development environment. At the same time, through remote real-time monitoring and alarm notification, the system enables farmers or ranchers to know the situation of the chicken coop in time and take corresponding measures. In addition, the function of data analysis also provides more scientific and reasonable decision-making basis for farmers or ranchers. With the continuous development of intelligent technology, intelligent animal husbandry monitoring system will play an increasingly important role in animal husbandry, providing strong support for the sustainable development of the industry.

More information about BLIIoT SMS 4G Wireless Remote Monitoring RTU S275:

#iot#iotsolutions#smartfarming#rtu#gateway#io#4glte#sms#alarmsystem#controller#remotemonitoring#remotecontrol#modbus#mqtt#scada#alibabacloud#huaweicloud#BLIIoT#BLIIoT Applications

0 notes

Text

BLIIoT 8TH+2Relay 4G SMS Temperature Data Logger Alarm System S266 Used in Rail Temperature Monitoring

S266 It is designed as a cost effective, low power consumption, self-contained data logger. It has 8 temperature sensor inputs with embedded GSM/GPRS/3G/4G module, providing an all-in-one instrument for data logging, remote data acquisition, alarm and control.

#iot#iotsolutions#datalogger#alarmsystem#rtu#controller#temperaturemonitoring#4glte#sms#remotemonitoring#remotecontrol#BLIIoT#BLIIoT Applications

0 notes

Text

BLIIoT 4G Wireless Ethernet Sensor to MQTT Weather Monitoring RTU Gateway S475 Applied to Small Weather Station Monitoring

Front end: wet and dry bulb temperature sensor, rain gauge, wind speed sensor, light sensor, humidity sensor, etc. Equipment: weather monitoring RTU gateway S475 Backend: cloud, server, SMS, etc.

#iot#iotgateway#iotsolutions#smartweather#remotemonitoring#4g#ethernet#sms#modbus#mqtt#alarm#controller#datacollection#cloud#server#BLIIoT#BLIIoT Applications

1 note

·

View note

Text

How to monitor boiler status remotely through BLIIoT Industrial PLC Gateway BL102

1. Project background

Boilers are indispensable power equipment in industrial production such as chemical industry, oil refining, and power generation. With the continuous expansion of industrial production scale and continuous innovation of production equipment, the boiler as the power and heat source of the whole plant is also developing towards large capacity, high parameters and high efficiency. Due to the current level of boiler automation control is not high, boilers are mainly inspected manually, but the location of the boiler equipment is scattered, if the inspection and maintenance require the presence of maintenance personnel, it is not only time-consuming and labor-intensive, but also the cost of operation and maintenance is huge. The staff on duty only knew about the failure and reported it by phone, resulting in a delay in dealing with the problem. In order to ensure safe and stable production, the Internet of Things monitoring solution is adopted. Through the Internet of Things, the online real-time monitoring of boilers can realize the remote online collection, monitoring, statistics, analysis and intelligent decision-making of energy saving and emission reduction of boiler operating data, and establish a comprehensive twenty-four for boilers. Hourly monitoring is particularly important.

2. Situation Analysis

Boilers are relatively independent, decentralized, and inconvenient to manage

With the large-scale expansion of industrialization, boiler installations are also increasing, but the equipment is relatively vertical, geographically scattered, and even has a large space span, which is not convenient for managers to quickly and effectively monitor and manage each site.

Boiler operation and maintenance service costs are high, and labor costs are large

Offline operation and maintenance services, high travel costs, and high time costs: the reuse rate of equipment service technology is low, no one records and maintains the knowledge of work order operation and maintenance, and cannot view summary reports for repairs, repairs, and inspection records. Unable to objectively assess operation and maintenance personnel.

Unable to understand the operating status of boiler equipment in real time

The state of boiler equipment is uncontrollable to a certain extent, and it is impossible to know the internal operating state of the equipment and the thermal efficiency of the boiler at any time only through manual inspection.

Without remote video monitoring, on-site faults cannot be fed back and dealt with in a timely manner

When the equipment fails, on-site maintenance personnel are required to actively discover the equipment failure, but the automation of the boiler is not high, so the alarm cannot be received in time, and the problem cannot be checked in time, which is time-consuming and laborious.

There is no complete system monitoring data support, lack of scientific analysis and statistical means

Manual alone cannot record a large amount of data in real time, and cannot understand the historical conditions and data of boiler operation.

3. IoT Boiler Monitoring Significance

IoT boiler remote monitoring adopts industrial-grade network transmission and storage technology, real-time acquisition and edge calculation of boiler online operating parameters. It can not only ensure the safe and stable operation of the boiler, reduce the labor intensity of operators, but also improve thermal efficiency, reduce coal and electricity consumption, realize economical operation, and achieve the purpose of easy operation and production management.

4. Design principles

The system design takes into account the following principles:

Applicability: Fully research and analyze customer needs, and combine the current status of equipment and customers' long-term planning to realize system functions under the concept of long-term, reliable, advanced and energy-saving

Advancement: Apply the Internet of Things system, advanced control hardware and network technology to optimize and improve the design of the remote control system

Economy: use the most reasonable software and hardware configuration to achieve high performance-price ratio

Reliable and safe: In the system design, the hardware and software are fully considered, the isolation of faults and the weakening of the scope of influence are carried out according to the standard during installation and debugging

Execution: The system design, software and hardware configuration, network and communication protocol, database, etc. all meet the relevant international and domestic standards. Interfaces are reserved during system design, making hardware and software functional modules easy to maintain, expansion, and upgrades can be completed in a short period of time.

5. Framework

The boiler remote control system consists of three parts, 1. Front-end sensors, boiler equipment 2. BLIIoT Industrial PLC Gateway BL102 3. IoT cloud platform/Server

The BLIIoT Industrial PLC Gateway BL102 collects the data of the boiler equipment at the lower end and uploads the data to the cloud platform, and provides functions such as equipment networking and edge computing. The cloud platform is the operation platform of the solution, and relevant equipment teaching data, report information, and operating parameters are all on the cloud platform. Summarize and display on the Internet to provide users with analysis and decision-making basis. At the same time, the user's management and control of the device is also operated on the cloud platform.

6. Scheme detailed design

Hardware design

The silver furnace remote monitoring system consists of two parts, silver furnace equipment, gateway acquisition equipment, cloud platform/mobile phone monitoring center. The gateway collection equipment is connected to the furnace equipment, and the gateway uploads the collected boiler data to the cloud platform/server through 4G/Ethernet. Since Internet transmission is not limited by distance, multiple terminal devices can be connected to one monitoring center at the same time, so one monitoring center can monitor multiple boiler equipment. The monitoring center is mainly responsible for processing the data sent by each terminal, and displaying and saving the historical data in real time on the computer. At the same time, the monitoring center can also give a real-time alarm to the dangerous data that appears.

Platform monitoring

Remote monitoring of equipment: All parameters of the boiler can be monitored in real time through the web page or mobile APP, including the operating status of the boiler, and the collection of PLC data is supported to make message exchange faster and more convenient, and the same monitoring screen as the scene can be quickly built. Remotely monitor the status of the boiler as if you were on site, which can solve the problems of difficult equipment maintenance, high travel costs, and delays in obtaining information.

Fault alarm and remote diagnosis: set different thresholds for boiler steam pressure, temperature, flow rate, furnace door temperature, main body exhaust gas temperature, water level and other parameters. If a fault occurs, it will be sent through WeChat message, APP message, and telephone voice at the first time , SMS and other notifications to the management personnel. Real-time understanding of boiler operation through the cloud platform, so that faults can be quickly located and resolved without going to the site.

Statistical analysis of historical reports: the platform can realize the data summary calculation of multiple boiler equipment, and can carry out intermediate summary variable storage and statistics on boiler furnace pressure, primary return water pressure, outlet water pressure, total steam flow and other data, so as to achieve historical There are traces of data. High-quality reports can make the basic situation of the boiler more transparent and help managers make decisions that are conducive to improving production efficiency.

Rich user permissions: For convenience, system functions need to be customized according to different users, adding roles with different permissions. Set up different roles to view different menus, add different accounts to view user operation log information, and facilitate the fine-grained management of personnel.

Operation and maintenance management: users can make equipment inspection plans, and realize equipment repair, maintenance inspection records and other operations on the mobile phone. It can manage the whole life cycle of consumable and core components of the burner, effectively improving the efficiency of after-sales work. Realize that maintenance problems can be checked back and traced to compact operation and maintenance responsibilities.

Data summary large screen: display the operating status and work data of boiler equipment scattered in different locations in the form of charts, which can be monitored uniformly through computers, mobile phones and large screens. The data display in the form of graphics is more three-dimensional, Can be seen at a glance. Moreover, the graphical display can clearly see the dynamic changes at the first time.

7. Solution advantage

Wide compatibility: All serial devices with Moubus protocol can be connected to the IoT cloud platform with simple configuration, plug and play. The gateway adopts an independent interface module, so there is no need to modify boilers, water pumps and other equipment.

Efficient operation: The data center adopts a modular and matrix design, and each functional module can process large amounts of data in a timely manner, and multiple connections can also run smoothly.

Diversified display: Users can remotely view the operating status of the equipment through mobile APP, computer webpage, and mobile webpage.

Reliable and stable performance: It has provided wireless monitoring solutions for many customers, and has specialized processing for equipment management, data display, disaster prevention backup and other functions to ensure reliable and stable operation of the system for a long time

Low cost: no need to build a network, no need to install a server, and no need to hire professional engineers, just connect the gateway to the device to be monitored, enter the platform for simple configuration,

7x24 hours of safe operation and maintenance:the gateway acts as a device manager for 24-hour comprehensive inspection of equipment, and implements unified monitoring access and intelligent alarms for all servers under the platform

Data transmission security: the gateway supports TSL, SSL and OPENVPN functions to ensure data security.

More information about the BLIIoT Industrial 4G PLC Gateway BL102: https://www.bliiot.com/plc-gateway-p00306p1.html

#iot#iotsolutions#industrialautomation#industria40#smartfactory#iotgateway#boiler#plc#modbus#mqtt#opcua#remotemonitoring#datacollection#cloud#BLIIoT#BLIIoT Applications

1 note

·

View note