#techno automation

Explore tagged Tumblr posts

Text

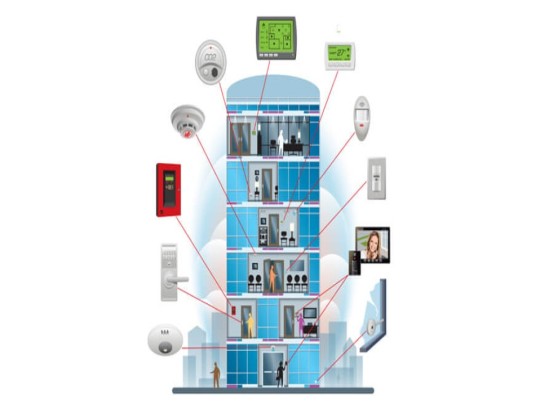

Office and Shopping Malls Automation Solution

From Bangladesh's perspective, Energy Saving is very important due to the scarcity of fuel, and an office's security is also crucial. Our Automation Solution aims to improve the quality of your office experience by increasing security and comfort while at the same time-saving energy. In this case, our Automation solution is not only applied in shopping malls but also in individual shops. We can also provide a similar type of solution for Chain Stores

Lighting Control

Heating-Cooling Control

Shutter-Blind Control

Presence/Movement Detection

Daylight Detection

BMS Integration

for more information visit: https://www.technoapogee.com/en/product-and-service/bms/office-and-shopping-malls-automation-solution

#fire safety#electrical safety#technology#business#home & lifestyle#home decor#architecture#audit#techno apogee#apogee engineering#office#officeautomation#techno automation#buildings#shopping#shopping mall#shoppingmalsautomation#automation#security#development#building automation system#automationmalls

1 note

·

View note

Text

Beats, Bytes & The Future Sound: AI Meets Electronic Music

Electronic music has always been about pushing boundaries, breaking rules, and bending sound into new dimensions. Now, artificial intelligence is stepping into the booth, reshaping how beats are built, melodies emerge, and tracks come to life. This isn’t about robots replacing producers—it’s about a new creative partnership, where human intuition meets machine-driven possibilities.The Evolution…

#AI and sound design#AI beat generation#AI for producers#AI in electronic music#AI in music production#AI mixing and mastering#AI music algorithms#AI music collaboration#AI music creation#AI music technology#AI music trends.#AI rhythm generation#AI-driven sound synthesis#AI-generated beats#AI-powered music software#artificial intelligence in techno#artificial intelligence music production#automated music production#creative AI music#digital music production#electronic music and AI#electronic music tools#future of music production#machine learning music#music composition AI#music innovation AI#music production AI tools#music production tools#neural networks in music#sound design AI

0 notes

Text

Local Control Stations: An Essential Component in Industrial Automation

In the world of industrial automation, Local Control Stations (LCS) play a critical role in enhancing operational efficiency and safety. These devices, strategically located near machinery or equipment, provide operators with direct control over specific processes without needing to interact with a central control system. Their importance lies in offering real-time control and emergency shutdown options, making them indispensable in sectors like oil and gas, manufacturing, chemical processing, and power generation.

What is a Local Control Station?

A Local Control Station is an industrial control panel equipped with switches, push buttons, indicators, and other interface devices that allow operators to control equipment directly at the location of the process. These stations are usually enclosed in durable housings, often made of materials such as stainless steel or cast aluminum, ensuring they can withstand harsh environmental conditions like high temperatures, dust, moisture, and potential chemical exposure.

Local Control Stations can be custom-designed to suit the specific requirements of the application, including the number and type of buttons, lights, and other control components. They typically include:

Start/Stop switches: For basic operational control.

Emergency stop buttons: To instantly halt machinery in case of an emergency.

Indicator lights: Providing visual feedback on system status (e.g., power on, running, or fault conditions).

Selector switches: To toggle between operational modes (e.g., manual, automatic, maintenance).

These stations allow for localized manual control over equipment, which is essential in situations where central control systems might not be practical or fast enough to respond to immediate safety concerns.

The Role of Local Control Stations in Industrial Operations

Local Control Stations are designed to enhance the safety and efficiency of industrial operations. By placing control capabilities near the equipment, operators can quickly intervene when necessary, reducing the risk of delays in responding to machinery malfunctions or safety hazards. This proximity to equipment enables swift action, reducing downtime and potentially preventing costly accidents.

In addition to safety, LCS also contributes to process efficiency by offering real-time, localized control, meaning operators can fine-tune processes based on immediate feedback. This localized control is particularly useful in industries where process precision is vital, such as pharmaceuticals, chemical production, and food and beverage manufacturing.

Types of Local Control Stations

Depending on the industry and application, there are different types of Local Control Stations. Some of the most common types include:

Basic Push Button Stations: The simplest form of control stations, featuring start/stop buttons and emergency stops. These are often used in smaller installations or for straightforward operations.

Hazardous Area Control Stations: Designed to be explosion-proof or intrinsically safe, these stations are used in industries like oil and gas, where hazardous atmospheres may be present. These control stations are engineered to prevent ignition sources from causing explosions.

Multi-Function Control Stations: These stations feature multiple controls, including push buttons, switches, and indicators, all within one enclosure. They offer greater versatility and are often found in complex machinery or systems that require more comprehensive control.

Customized Local Control Stations: Many manufacturers offer customization options, enabling companies to tailor LCS solutions to their specific process needs. These stations can include any combination of control features and are often designed to integrate with existing automation systems.

Advantages of Using Local Control Stations

The use of Local Control Stations offers several key advantages to industrial operations:

Enhanced Safety: By allowing operators to control equipment directly at the site, LCS enables quick responses to emergency situations. The presence of emergency stop buttons is especially critical in high-risk environments, where immediate shutdowns can prevent accidents or equipment damage.

Operational Efficiency: LCS allows operators to make quick adjustments and real-time decisions without having to return to a central control room. This immediate interaction can optimize workflow and reduce the likelihood of production delays.

Flexibility and Customization: Local Control Stations can be configured to suit specific operational needs. Whether the requirements are for a simple start/stop function or more complex control options, LCS provides versatile solutions.

Durability in Harsh Environments: Built to withstand extreme temperatures, corrosive substances, and high-pressure environments, these control stations are well-suited for industries where conditions are less than ideal. Their robust design ensures reliable performance, even in challenging conditions.

Localized Control in Remote Areas: For industries such as oil and gas, where equipment is often spread out over large geographical areas, LCS serves as a practical solution for on-site control. This is particularly important in remote operations, where access to a central control room may be limited.

Key Industries Utilizing Local Control Stations

Several industries rely heavily on Local Control Stations for efficient and safe operations. These include:

Oil and Gas: In hazardous environments like offshore rigs or refineries, LCS provides immediate control over pumps, valves, and safety equipment, ensuring operational safety.

Manufacturing: LCS is used to control machinery in production lines, offering real-time feedback and control for efficiency and safety.

Chemical Processing: In plants where sensitive chemical reactions occur, LCS offers operators the ability to quickly adjust processes or shut down equipment to prevent accidents.

Power Generation: Local Control Stations are integral in controlling turbines, generators, and other equipment in power plants, allowing for quick adjustments to optimize output and maintain safety.

Conclusion

As industries continue to emphasize automation and safety, Local Control Stations remain a vital component of modern industrial setups. By providing operators with localized, real-time control over equipment, they ensure that processes run smoothly and safely. Whether for starting machinery, stopping operations during emergencies, or monitoring equipment status, LCS offers the reliability and control necessary in high-demand industries.

For businesses seeking robust and reliable Local Control Stations, Freture Techno Pvt. Ltd. offers a range of high-quality, customizable solutions designed to meet the specific needs of various industries. Buy Local Control Station from Freture Techno Pvt. Ltd. today to ensure efficient and safe industrial operations.

0 notes

Text

The Silent Guardians: Unveiling the Role of Valve Automation in Modern Industry

The intricate network of pipes that snake through industrial facilities plays a vital role in keeping processes running smoothly. But the true unsung heroes of this network are the industrial valves – the silent guardians that control the flow of fluids and gases. Traditionally, these valves were operated manually, requiring constant human intervention. However, with advancements in technology, industrial valve automation has emerged as a game-changer, transforming the way these guardians operate and unlocking a multitude of benefits for modern industry.

Industrial Valves: The Backbone of Process Control

Industrial valves come in various types, each designed for a specific function. From regulating pressure and flow rates to completely isolating sections of piping, valves ensure the smooth and efficient operation of various processes. However, manual operation can be time-consuming, labor-intensive, and prone to human error.

Valve Automation: A Symphony of Efficiency and Control

Valve automation replaces manual operation with a combination of actuators and control systems. Actuators, powered by sources like compressed air, electricity, or hydraulics, provide the physical force to open, close, or adjust the position of the valve. Control systems, ranging from simple timers to sophisticated computer-based systems, provide the brains of the operation, sending signals to the actuators based on pre-programmed parameters or real-time process data.

The Symphony's Benefits: How Valve Automation Enhances Industry

The integration of valve automation offers a multitude of advantages:

Enhanced Process Control: Automated valves ensure precise and consistent control over flow rates and pressure, leading to improved product quality and process efficiency.

Improved Safety: Automated systems can react faster to process deviations or emergencies, minimizing safety risks associated with manual intervention.

Reduced Operational Costs: Valve automation minimizes labor requirements for valve operation and allows for remote monitoring, leading to reduced manpower needs and improved overall operational efficiency.

Optimized Production: Automated valves enable faster response times and precise control, leading to optimized production cycles and increased output.

Data-Driven Decision Making: Advanced control systems can collect and analyze data from automated valves, providing valuable insights for process optimization and predictive maintenance.

The Future of Valve Automation: A Glimpse into a Smarter Industrial Landscape

The future of valve automation is brimming with possibilities. The integration of smart technologies like sensors and communication capabilities is paving the way for "smart" valve actuators. These actuators provide real-time feedback on valve position, performance parameters, and potential issues, enabling predictive maintenance and remote monitoring within the framework of the Industrial Internet of Things (IIoT).

Freture Techno: Your Partner in Industrial Valve Automation

Freture Techno, a leading manufacturer of industrial valves and automation solutions in Mumbai, India, understands the critical role of valve automation in modern industry. They offer a comprehensive range of high-quality industrial valves, actuators, and control systems to cater to diverse industrial needs. Their commitment to innovation ensures that their solutions are reliable, efficient, and integrate seamlessly with modern automation technologies.

Embrace the Silent Guardians of Efficiency:

By partnering with Freture Techno, you can leverage the power of valve automation to unlock a new era of process control, safety, and efficiency in your industrial operations. Consider Freture Techno as your trusted partner for all your industrial valve automation needs, and experience the silent symphony of enhanced performance in your industry.

0 notes

Text

Unleash the power of Innovation

#cybersecurity#techie#techno#engineer#ai#marketing#tecnologia#future#startup#robotics#computerscience#artificialintelligence#oneplus#it#d#developer#love#digital#india#s#gaming#python#programmer#iot#photography#internet#automation#covid#google#entrepreneur

0 notes

Text

Samsung, a renowned global technology leader, has recently introduced an impressive advancement in biometric security with its Biometric Card IC. In this article, we will delve into the Samsung Biometric Card IC, exploring its features, working principle, potential applications, and the future impact it could have on the security landscape. Click the link to know more.!

0 notes

Text

The Toshiba A8A-44 (4A4B) Control Relay offers reliable performance for your electrical needs. With a 220V-3A and 440V-1A capacity, this relay ensures efficient operation in various applications. Designed for durability and efficiency, the Toshiba A8A-44 provides robust control in both industrial and commercial settings. Its compact design and high-quality materials guarantee long-lasting use and minimal maintenance. Ideal for controlling electrical circuits, this relay enhances safety and performance. Choose the Toshiba A8A-44 (4A4B) Control Relay for dependable, high-quality electrical control solutions.

#automation#industrial equipment#industrial#industrial spare parts#industrialautomation#industrial and marine automation#relays#industrialinnovation#industrial techno

0 notes

Text

ROBOT ID PACK

NAMES ︰ aerobot. agatha. ai. alan. alethea. alexia. algernon. alistair. alpha. amaryllis. ambrose. androbot. androic. andromeda. angelica. antenna. arabella. araminta. arcade. auto. automaton. axel. axis. badnik. bionel. bolt. byte. care. celline. cello. chip. chipique. clank. cloniste. clonoid. cobot. codelle. cole. curiosity. cy. cyber. cybette. cybion. cypher. data. dell. della. delpha. delta. digi. dot. droid. droidess. droidis. dronette. echo. elektra. euna. eva. eve. fritz. giga. gizmo. glitch. grey. gynoid. helix. holo. holodir. hydra. ida. jet. kaput. kinect. krudzu. linion. mac. mace. machibella. machina. mal. malware. mation. mech. mecha. mechael. mechan.ace. metal. metalia. metalish. micro. motherboard. motor. nano. neo. nucleus. nyquist. orbit. parallel. pip. pixel. prime. primus. proto. quantum. radar. radius. ram. ray. reflect. reflectette. robo. robonaut. rusty. satellite. scrappy. selsyn. sentiex. servo. shard. siri. solar. sonar. spark. sparkie. sparky. sputnik. steele. sterling. stochastic. synchro. synie. synthett. talus. terra. tin. tink. tobor. ultramarine. ultron. unimate. unit. virus. waldo. zip.

PRONOUNS︰ ai/ai. algo/algorithm. android/android. app/app. auto/auto. auto/automated. auto/automaton. axis/axi. beep/boop. bio/bionic. bio/bioplastic. blast/blast. bo/bot. bolt/bolt. bot/bot. buffer/buffer. byte/byte. cell/cell. chaos/chaos. chi/chip. click/click. clo/clone. code/code. coil/recoil. command/command. compute/computer. core/core. cyb/cyborg. cyber/cyber. data/data. dev/device. device/device. dig/digital. digi/digital. droi/droid. droid/droid. e/exe. electric/electric. entry/entries. exo/exoskeleton. gear/gear. gli/glitch. glitch/glitch. hack/hack. ho/holo. holo/holo. hologram/hologram. in/install. intra/intranet. link/link. machi/machine. mal/malfunction. mal/malware. mech/mech. mecha/mechanical. mechanic/mechanic. metal/metal. metro/metro. motor/motor. neo/neo. neon/neon. nuclear/nuclear. propeller/propeller. radar/radar. retro/retro. robo/robo. robo/robot. robot/robot. rubber/rubber. satellite/satellite. sca/scan. shard/shard. shine/shiny. signal/signal. solar/solar. steel/steel. stem/stem. swi/switch. syn/synth. syn/synthetic. tech/tech. techno/techno. test/test. text/text. turing/turing. vi/viru. web/site. web/web. whirr/whirr. wi/wifi. wire/wire. wired/wired. ⚙️/⚙️. 🔧/🔧. 🔩/🔩. 🛠//🛠. 🤖/🤖.

#pupsmail︰id packs#id pack#npt#name suggestions#name ideas#name list#pronoun suggestions#pronoun ideas#pronoun list#neopronouns#nounself#emojiself#robotkin#machinekin#androidkin#robotcore

1K notes

·

View notes

Text

Frederick Sinclair is a really interesting foil to Mr. House. I mean you start digging into this and it's just parallel after parallel after parallel. Start at the high level. House sinks inordinate amounts of resources into saving the city of Las Vegas - not the people, but the city- from nuclear destruction; as long as the stage endures, he can get anyone to wear the costumes. Sinclair sets up an entirely new "community" totally off-the-grid for the sake of protecting one woman, plasters that place with her likeness. House is a visionary with a 200-year action plan to rebuild society in his image, bootstrap space exploration, and construct an interplanetary empire; Sinclair sank everything he had into building the most secure facility possible for a woman who he knew was terminally ill anyway, just to ensure that her last few years lived in the aftermath of the nuclear apocalypse would be as comfortable as possible- there's a fundamental pessimism baked into what he was doing. Both House and Sinclair relied heavily on automated defensive systems and cutting-edge, esoteric technologies to accomplish their ends, but House built his power base on proprietary robotics and computing technology, much of which he personally designed- an outgrowth of his policy of never widening his circle any more than he absolutely has to. Sinclair, in his naive techno-optimism, outsourced his utopia, grabbing flashy third-party technologies like a kid in a candy store- opening a backdoor for the Think Tank to poison his city and ultimately getting everyone at the Gala Event killed when the holograms malfunctioned and went berserk.

Their management styles are inverse. House allows countless abuses to occur under his aegis because he subscribes to a libertarian-when-convenient philosophy where he doesn't much care what the little people do as long as he gets his cut and they don't rock the boat too much- a hands-off approach that fosters resentment amongst his subordinates, lets the White Gloves and Omertas get up to untold levels of fuckery while Freeside languishes and Benny conspires against him. Sinclair, by contrast, had a sincerely-held utopian-straight-edge safety-first micromanagement approach built into the very bones of the casino, he appeared to genuinely give a shit about the safety of the construction crew on the villa, and he was well-liked by nearly everyone who had any direct contact with him- and yet untold horrors also went down under his aegis, because his myopic focus on building the vault for Vera let Dean Domino and the Think Tank run circles around him, good intentions be damned. Their respective interpersonal dispassion and obsession are on display in how they react to betrayal. House's tone never rises above exasperation when it comes time to clean house of Benny, the Omerta Leadership and the White gloves; he treats them as problems to be solved, gears that are slightly out of alignment; By contrast, when Sinclair learns that Dean and Vera have been playing him, he channels the monomaniacal energy he previously directed towards protecting Vera towards the goal of building the perfect poetic-ironic death trap for her and Dean.

There are some other parallels in their personal lives. For one thing they both trusted a pastiche of a 40s lounge singer a lot more than they should have. They both tried to digitize, immortalize their girlfriends- and the discrepancy in how they went about it is telling. House's recreation of Jane isn't terribly robust, and in terms of House's overall project she's an afterthought. She's more a sock-puppet than a person, a sanded-down copy of a woman who died forever-and-a-half ago, forever agreeable, never saying no. Convenient. Only the most superficial visual elements preserved- an illustration of her face on a robotic chassis. Sinclair was obsessive in recreating Vera, preserving her likeness. It's all over the villa, her hologram is everywhere, her voice is everywhere. The terminal in the lightwave lab in Old World Blues reveals that he was still obsessed with getting her hologram right even after the love curdled into hate. All of it a monument to the real woman, and yet in all of it the real woman is still lost, buried under the mythologized projection. He didn't respect the real person enough to let her know that she was dying. A total failure of preservation from the opposite direction. (Except in the suites, where you can hear her very authentic dying pleas.)

You find both of them in their basements. House only looks a little better than Sinclair, but he's got much more of a voice in the narrative. He took steps to make sure he'd be around to tell you what he thinks about everything, fine-tuned the voice with which he speaks to the world, the face he presents. It matters to him that he gets to tell his own story. We find out a lot about House, from House; but for the kind of figure that he is, a shocking amount of what we learn about Sinclair comes from other people, people who knew him or wrote about him. The only image of him you can find is a downplayed element of a larger mosaic. The two documents you find that're written from his perspective have been buried for 200 years, and they're yards from his corpse. And the more recent of the two is an apology. I mean admittedly at the point where he wrote that apology Sinclair was personally turbofucked regardless. If the cloud didn't get him the holograms would have, or the radiation, or, or, or. You can read some level of ego into what he did in the face of that. But however futile it was, he died in the specific way that he did because he recognized that he'd done something awful, and he was trying everything he could think of to correct it. Somehow I find it very hard to imagine House doing either of those things- admitting fault or putting skin of his own in the game to make it right.

#fallout#fallout new vegas#fnv#mr house#frederick sinclair#meta#vera keyes#fallout jane#dead money#thoughts#fallout: new vegas#robert house#effortpost

825 notes

·

View notes

Text

Hotel & Hospital Solutions

We provide a Guest Room Management System (GRMS) for star rating Hotels from EAE Technology, Turkey. It is designed to ensure a mind-blowing experience for your guests. Our intelligent solutions are based on interactive technology that compliments the exceptional experience you want for your guests in all areas, such as restaurants, ballrooms, meeting rooms, and gym & fitness clubs. Implementing an Automation System in a hospital helps improve overall hospital management, enhance staff’s working efficiency, save operating costs, and create a safe and efficient healthcare environment

Detection of the presence of border without cardholder

Lighting Control

Heating-Cooling Control

Shutter-Blind Control

Shutter-Blind Control

Nursing Call System Integration

BMS Integration

For more information visit: https://www.technoapogee.com/en/product-and-service/bms/hotel-hospital-solutions

#home & lifestyle#home decor#interiors#homestuck#fire safety#electrical safety#business#technology#home automation#hotel#hotel automation#resort#travels#travel#techno apogee#techno automation

1 note

·

View note

Text

Beats, Bytes & The Future Sound: AI Meets Electronic Music

Electronic music has always been about pushing boundaries, breaking rules, and bending sound into new dimensions. Now, artificial intelligence is stepping into the booth, reshaping how beats are built, melodies emerge, and tracks come to life. This isn’t about robots replacing producers—it’s about a new creative partnership, where human intuition meets machine-driven possibilities.The Evolution…

#AI and sound design#AI beat generation#AI for producers#AI in electronic music#AI in music production#AI mixing and mastering#AI music algorithms#AI music collaboration#AI music creation#AI music technology#AI music trends.#AI rhythm generation#AI-driven sound synthesis#AI-generated beats#AI-powered music software#artificial intelligence in techno#artificial intelligence music production#automated music production#creative AI music#digital music production#electronic music and AI#electronic music tools#future of music production#machine learning music#music composition AI#music innovation AI#music production AI tools#music production tools#neural networks in music#sound design AI

0 notes

Text

Every time I go back and watch Vampire Hunter D: Bloodlust, I’m amazed all over again by the panoply of genres this movie and the VHD setting in general indulges in.

The story is set in “the distant future, where vampires rule the night but their numbers are dwindling”. It sort of plays like a weird techno-gothic post-apocalyptic sci-fi western? Over the course of Bloodlust, we start out in a cross-bedecked gothic city, head to a meeting in a ruined church straight out of western, complete with rifle-armed cowboys on guard, go full fucking Dune in the middle with D riding his biomechanical horse across the back of field-sized sand manta rays migrating across a massive duned desert, head to a small canyon town that's a hideout for various yokai, stop off at a roman ruin in a lake and a massive science fiction stronghold with a mirror-cloaked exterior and automated defense lasers, before heading to the final showdown in the massive crimson techno-gothic castle of Carmilla the vampire queen, which doubles as a spaceship. Because the vampire D has been pursuing this whole time wants to go to the endless night of space to be with his love.

The team of hunters competing with D are armed with, variously, a massive fucking hammer, an absolutely ridiculous arm-mounted crossbow that launches roughly 2000 silver arrows a second, a singularity shooting pistol, and an astral self that flies around the battlefield like an angry sparkly ghost that shoots lasers.

Conveyances include said already-mentioned biomechanical horse, a horse-drawn carriage drawn by similar horses, a full-on motorbike, a massive armoured motor truck-slash-tank, and also said previously-mentioned spaceship.

Let’s just say the aesthetic is simultaneously all over the place, and weirdly unified. It’s a far flung dystopic future run by gothic creatures of the night, after the slow apocalypse that has led to their dwindling. So you have futuristic technology and gothic medieval sensibilities in bizarre but functional post-apocalyptic union. It’s really cool.

Possibly helped by the fact, mind you, that this movie is just stupidly beautiful and so gorgeously animated that you’ll forgive it a lot of sins. But it isn’t actually committing too many. The weird genre blend makes sense, and the vibe is cool and coherent enough that you’ll roll with it.

#vampire hunter d bloodlust#vampire hunter d#vhd#genre#so many genres#this setting is something i'm telling ya what

117 notes

·

View notes

Text

The Power of Rotation: A Comprehensive Look at Rotary Actuators

Transform Pneumatic, Hydraulic, or Electric Energy to Mechanical Rotation

In the realm of industrial automation, precise control over movement is paramount. Rotary actuators play a vital role in achieving this control, converting various forms of energy into rotary motion to power a wide range of applications. From the delicate movements of robotic arms to the powerful operation of valves and gates, rotary actuators offer a versatile and efficient solution for driving rotational tasks. This article delves into the world of rotary actuators, exploring their types, working principles, functionalities, and their diverse applications across various industries.

Understanding Rotary Actuators:

At their core, rotary actuators are mechanical devices that translate energy into rotary motion, or torque, around a specific axis. This energy source can be electric, pneumatic, hydraulic, or even manual. By converting this energy, rotary actuators enable precise control of angular displacement and rotational force, making them ideal for applications requiring positioning, opening, closing, or rotating various mechanisms.

Types of Rotary Actuators:

The diverse world of rotary actuators encompasses various types, each catering to specific needs and applications:

Electric Rotary Actuators: Powered by electric motors, these actuators offer precise control and are well-suited for automated applications. They come in various configurations, including stepper motors, servo motors, and DC gear motors, each offering distinct torque and speed characteristics.

Pneumatic Rotary Actuators: Utilizing compressed air as the energy source, these actuators are known for their speed and force output. They are commonly used in applications requiring high-speed actuation or limited space availability. Rack and pinion and vane types are two common configurations of pneumatic rotary actuators.

Hydraulic Rotary Actuators: These actuators rely on hydraulic fluid for power, offering exceptional force and torque capabilities. They are ideal for heavy-duty applications requiring high power output, such as operating large valves or manipulating massive machinery components.

Working Principles of Rotary Actuators:

The specific working principle of a rotary actuator depends on its type. Here's a simplified breakdown of the primary types:

Electric Rotary Actuators: An electric motor converts electrical energy into rotational motion of the motor shaft. This rotation can be geared down or up to achieve the desired output speed and torque. In stepper motors, the rotation occurs in discrete steps, offering precise positioning control. Servo motors provide continuous rotation with precise control over speed and position based on feedback signals.

Pneumatic Rotary Actuators: Compressed air enters the actuator body, pushing against a piston or vane, causing it to rotate. The direction of rotation is controlled by valves that direct the compressed air flow. Rack and pinion actuators convert the linear motion of the piston or vane into rotary motion using a gear rack and pinion gear. Vane actuators utilize the direct rotation of the vane within the actuator body.

Hydraulic Rotary Actuators: Hydraulic fluid, pressurized by a pump, enters the actuator body and exerts force on a piston or vane. The resulting linear motion is converted into rotary motion through a gear mechanism similar to pneumatic rotary actuators.

Functionalities of Rotary Actuators:

Rotary actuators perform a wide range of functions in various applications. Some key functionalities include:

Positioning: Rotary actuators can precisely position mechanical components or robotic arms to specific angles.

Opening and Closing: They can be used to open and close valves, gates, dampers, and other mechanisms requiring rotational movement.

Mixing and Stirring: Rotary actuators can power mixing blades or stirrers in various industrial processes.

Indexing and Material Handling: They can be used for precise indexing of materials in automated production lines or material handling equipment.

Clamping and Gripping: Rotary actuators can be used to clamp or grip objects in robotic applications or assembly lines.

Selection Considerations for Rotary Actuators:

Choosing the right rotary actuator for your application requires careful consideration of several factors:

Torque and Speed Requirements: The actuator's torque output and speed capabilities need to match the application's specific demands.

Power Source: Electric, pneumatic, or hydraulic power sources should be chosen based on available resources and desired control characteristics.

Duty Cycle: The frequency and duration of operation for the actuator must be considered to ensure proper sizing and prevent overheating.

Accuracy and Repeatability: The level of precision required for positioning or control should be factored in when selecting the actuator type.

Environmental Conditions: The operating environment, including temperature, humidity, and potential exposure to dust or liquids, should be considered to ensure proper material selection and protection for the actuator.

Applications of Rotary Actuators (Continued):

Building upon the previous section, here's a detailed look at some key industry applications of rotary actuators:

Oil & Gas: Rotary actuators are crucial in the oil & gas industry for:

Valve operation: Opening and closing valves for flow control in pipelines, refining processes, and wellheads.

Actuating blowout preventers (BOPs): Ensuring safety by closing wellbores in case of emergencies.

Positioning drilling equipment: Providing precise control over drilling heads and other downhole tools.

Power Generation: Rotary actuators are used in power plants for:

Valve actuation: Regulating fluid flow in cooling systems, boiler operations, and steam turbines.

Damper control: Adjusting air intake and exhaust dampers for combustion efficiency.

Positioning solar tracker systems: Optimizing the angle of solar panels to maximize sun exposure.

Food & Beverage: Rotary actuators contribute to automation in food processing by:

Operating valves for ingredient mixing, filling lines, and sterilization processes.

Positioning robotic arms for food handling, packaging, and palletizing.

Controlling conveyor belts for product movement within the production line.

Automotive Industry: Rotary actuators play a role in:

Robotic welding and painting applications: Precise movement of robotic arms for welding and painting car bodies.

Assembly line automation: Positioning and manipulation of components during vehicle assembly.

Climate control systems: Adjusting air flow dampers for heating, ventilation, and air conditioning within vehicles.

Aerospace & Defense: Rotary actuators find application in:

Aircraft control surfaces: Moving rudders, ailerons, and flaps for aircraft maneuverability.

Landing gear deployment and retraction: Precise actuation of landing gear mechanisms.

Radar positioning: Controlling the movement of radar antennae for target detection and tracking.

Construction: Rotary actuators contribute to automation in construction by:

Operating valves in concrete mixing trucks and other heavy machinery.

Positioning robotic arms for automated welding and material handling.

Controlling the movement of construction equipment attachments like excavator buckets and bulldozer blades.

Beyond these specific examples, rotary actuators are present in countless other applications across diverse industries. Their versatility, reliability, and ability to convert various energy sources into precise rotational motion make them a cornerstone of industrial automation.

Freture Techno: Your Partner in Rotary Actuator Solutions

Freture Techno Pvt. Ltd., a leading manufacturer of rotary actuators in Mumbai, India, offers a comprehensive range of high-quality electric, pneumatic, and hydraulic rotary actuators. With a commitment to innovation and engineering excellence, Freture Techno caters to diverse industry needs. Their team of experts can assist you in selecting the optimal rotary actuator for your specific application, ensuring optimal performance, reliability, and efficiency. Visit their website today to explore their product portfolio and discover how Freture Techno can be your trusted partner in rotary actuator solutions.

#valves#automation#Pneumatic#Hydraulic#Electric#Rotary Actuators#Freture Techno#Manufacturer#Mumbai#India

0 notes

Text

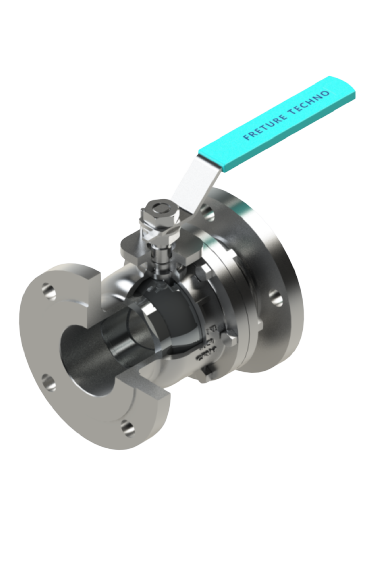

In Control: Comparing Manual and Automated Ball Valve Actuation Systems

In the world of fluid control and regulation, ball valves stand out as essential components, facilitating the smooth operation of various industrial processes. What sets them apart is their actuation system, the mechanism responsible for opening and closing the valve. In this article, we delve into the fascinating realm of ball valve actuation, comparing the merits and nuances of manual and automated systems.

Manual Ball Valve Actuation:

Manual ball valve actuation has been the tried-and-true method for decades. It involves a simple, hand-operated lever or wheel that turns the valve stem, controlling the flow of fluids. This traditional approach offers a tactile and direct connection for operators, allowing them to respond quickly to changes in the system. It's cost-effective, straightforward, and reliable, making it a popular choice for applications where simplicity is paramount.

Advantages of Manual Actuation:

Cost-Effectiveness: Manual ball valves are generally more affordable than their automated counterparts, making them an attractive option for budget-conscious projects.

Reliability: With fewer components and less complexity, manual systems often boast higher reliability, requiring minimal maintenance.

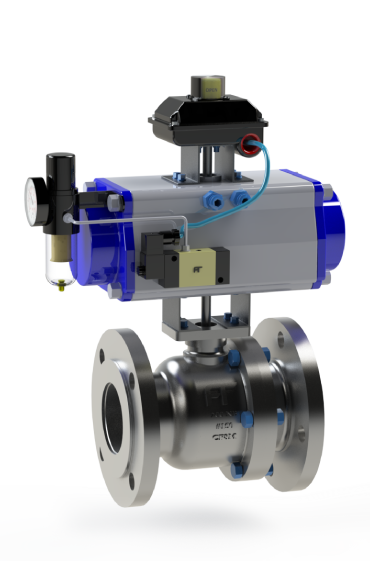

Automated Ball Valve Actuation:

As industries evolve, the demand for increased efficiency and precision has given rise to automated ball valve actuation systems. These systems utilize electric, pneumatic, or hydraulic power to control valve movements. Automation introduces a new level of sophistication, allowing for remote operation, precise control, and integration with complex industrial processes.

Advantages of Automated Actuation:

Precision and Control: Automated systems provide precise control over the valve's position, flow rates, and timing, enhancing overall process efficiency.

Remote Operation: With automated systems, valves can be operated remotely, reducing the need for manual intervention in hazardous or hard-to-reach environments.

Integration with Control Systems: Automated ball valves seamlessly integrate with modern control systems, facilitating a more interconnected and responsive industrial setup.

Comparative Analysis:

Response Time: Manual systems offer quick response times, but automation excels in applications where rapid and precise adjustments are critical.

Complexity: While manual systems are simpler, automated systems add complexity. The choice depends on the specific requirements of the application.

Cost vs. Performance: Manual systems are cost-effective and reliable, but automated systems justify their higher cost through enhanced precision, remote operation, and integration capabilities.

Conclusion:

In the dynamic landscape of industrial processes, the choice between manual and automated ball valve actuation systems hinges on the specific needs of each application. Both systems have their merits, offering a spectrum of options for engineers and operators to tailor their choices based on factors such as cost, simplicity, precision, and the level of automation required. As industries continue to advance, the ball valve actuation landscape will undoubtedly see further innovations, providing even more choices for those seeking optimal fluid control solutions.

#ball valve manufacturer#ball valve suppliers#ball valve#manufacturers#freture techno#mumbai#india#valve automation

0 notes