#water parameter testing equipment

Text

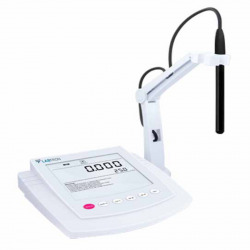

Benchtop Ion Meter

Benchtop Ion meter for F comes with (F) fluoride ion selective electrode for fluoride ion concentration measurement. This Ion meter comes with ± 0.5 % F.S. measurement accuracy. The direct ion concentration readout helps in the elaborate measurement process. The system menu allows setting the 8 parameters like calibration points, stability condition, etc. It can measure concentration in ppm, mg / L, and mol / L. The mV measurement is used to check the performance of ion selective electrodes.

#scientific equipment#water testing equipment#laboratory equipment#equipment#analytical equipment#benchtopion meter#water parameter testing equipment#Waste water testing equipment

0 notes

Text

#water quality monitor#water Analyzer#water quality analyzer#water Analyzers#turbidity analyzer#water analysis equipment#tss meter#TSS meter#water hardness meter#water hardness test meter#multi-parameter water quality meter#cod analyzer#COD analyzer#ph meter#PH meter#water distiller equipment#water particle tester#auto titration meter#auto titration equipment#dew point meter#Puc monitor#puc device#puc monitor#vehicle emission#emission control

0 notes

Note

I'm a bit shy asking this so I'll stick to anon for the time being. I visited a pet store today and they had the cutest little fish roaming at the bottom of one of their tanks gulping and spitting out sand. I couldn't find the species on the side with the names and tried to do some research and I think it may be a Sand Sifting Goby? All I saw was that they require salt water and that it seemed to feed off whatever was in that sand. I'm genuinely obsessed with this little guy and took plenty of videos, but I don't want to make bad decisions and get one without proper knowledge and research. I was curious to know if you had any facts or tips to help me out? Thank you 🩷

Sounds adorable!! Sand sifting gobies are a whole group of species that come in a variety of colours, all of them looking quite sweet! No doubt the fish was captivating to look at doing its little sand sifting :D

You say you do not wish to make a bad decision and simply impulse buy one without research, which is a good mindset to start from. Fish are not a monolith of animals, they're a large and diverse group of species, each one having their own specific criteria for keeping. I don't know if you've kept fish before or not anon, but I will be giving a general explanation that lets a person who hasn't get started: fish require specific water parameters (temperature, pH, general hardness and calcium carbonate concentration, salinity, etc.), substrate (thickness at the bottom, colour, roughness), plants (density of plants, real or fake, etc.), decor (will the decor scratch or accidentally harm the fish, do they like to hide, etc.), tankmates (of their own species or of different species, or lack thereof), food (specific dietary preferences and restrictions), lighting (harsh or dimmed, amount of light a day), so many things! Freshwater and saltwater aquariums are also different and require different equipment.

The very first thing I recommend you do is go to the pet store (or contact them through social media or email) and ask them what species the goby is. This way you can do research on the specific species instead of sifting through general information about all sand sifting gobies, which may be completely different from our dear little friend at the pet store! That's actually the crux of obtaining a fish or another aquatic life companion: RESEARCH! Soooo much research. You must research your finned friend so much it's starting to feel ridiculous and your family is asking you if you're "still planning on that fish or..?". Look up care guides and fish forums, watch YouTube videos, gather up all the information you get. Some of it contradicts itself, which is why it's important to look to many many sources. Try seeing the newest ones and see what parameters and suggestions are most common. That's only the beginning, though: if you've never owned a fish before, you need to learn about all these aquarium-keeping terms and how to maintain an aquarium, what you need for an aquarium, how to cycle it, etc.. Actually, that's probably best to do before you look up care guides, now that I think about it... Or do both at the same time, that's what I did when I was planning my shrimp tank. See beginner's guides to saltwater fishkeeping, on several sites, move onto more advanced guides and learn the terminology. Learn why these parameters matter so much, or why and how to cycle your tank. Weigh the pros and cons of having plants or some plant species, research different substrates, see what tanks and lights and filters are smartest for you, learn about aquarium pests. Try to find a good middle ground for what's sensible for you and what's the best for your pet; we keep animals for our enjoyment, but we also want to make sure they're having their best time too! Make a list for all the items you need, see how much different options cost, make a budget. Research the water parameters of your city or town, or test the water yourself. See what needs to be done to it so it's suitable for your animal. I've never kept a saltwater tank so I don't know the specifics of it myself, but if you wish to be a saltwater aquarium keeper you must learn! It's a lengthy process, but I went through seven months of preparation before I got my dwarf shrimps. This included my research (I don't have an estimate for how many articles and forums I looked through but my "Shrimps" playlist I made in preparation has 52 videos of just cherry shrimp and aquarium-keeping educational videos), shopping for equipment and plants and setting everything up, and cycling my aquarium. Dear folks in my notes also informed me that saltwater tanks and setups tend to be more expensive than freshwater setups!

Maybe at some point you find that the setup and equipment are simply too expensive, or incompatible with your lifestyle or living situation, or you change your mind for another reason during the preparation process. And that's valid and okay! You took the time to learn and what you learned was just that: it wasn't meant to be. It's much better than getting an animal without preparing and only finding out afterwards that you're incompatible in some way. Learning about these things won't be for "nothing" either, as now you have the valuable knowledge of how to keep fish and an aquarium! It may prove useful later in life if you eventually do obtain an aquarium, or you can become the resident fish knower (very rewarding). You may also decide to look into freshwater gobies, as they are gobies all the same but easier to care for! Please take a look at the folks in the notes and their lovely info.

Hope this helps anon! Perhaps you were wishing for a fish facts -format post, but my measly one-to-four sentence daily fish facts do not a species expert make. Instead I want to give out a guide on how to get started on your goby-keeping journey. I hope it works out for you, I wish you good luck! :)

52 notes

·

View notes

Text

i think there's the idea that fishtanks are really expensive and hard to take care of but there are lots of ways to set up tanks that aren't like that- even if you often kill things or have difficulty remembering to care for them ! and im bored right now so im just gonna, write about how you can do that

what you'd need:

a glass or acrylic tank

dirt & sand

rocks, driftwood, & other decor (optional)

heater, filter, light

plants

testing equipment

you can get a tank for really cheap off facebook marketplace or craigslist or ebay! and you can use just about any dirt, as long as it doesn't have pesticides/herbicides (unfertilized organic garden soil is great). sand is easy to find at pet stores, but it's expensive--you can get silicate play sand or pool filter sand for cheaper (just make sure it doesn't have calcium in it). you can test rocks you find on the ground for tank safety with vinegar- if it bubbles, then it'll leach calcium (undesirable, messes with water parameters) and if it doesn't, it's fine to use ! (if you're worried about Things on them, you can boil them for a few minutes.)

heaters, filters, and lights tend to be cheap if you just go for rudimentary adjustable ones. you can get shop lights and an outlet timer at any department store. plus if you know an aquarium hobbyist, chances are they'll have extras

same thing with plants, too ! if there's an aquarium hobby group near you then that's a great way to get free stuff. tanks are like little gardens so there's usually lots of plant clippings that would otherwise get thrown out. plus, free creatures that hitchhike on them !!!

another super cool way to get rocks, sand, dirt, wood, leaves, plants etc is to just ! go to a stream or lake ! preferably one that's distanced from roads and you know isn't super polluted. i picked up some water cress off the side of a hiking trail and now i have a really cute sprawling thing growing that i got FOR FREE!!!!!

testing equipment is gonna be expensive, but it's often a one-time purchase. liquid tests are more time consuming than paper strips, but more accurate. you might also need dechlorinator (more-so if your tap is treated with chloramine; chlorine evaporates but chloramine doesn't) (you can find that out by looking up your local water treatment report). other small items that r helpful: plastic tubes/hoses for siphoning water in/out, pipettes, tweezers, tiny scissors, buckets, and (depending on ur tank) liquid fertilizer, root tabs, and mineral mixes.

what's cool about this: setting up a tank with a layer of dirt covered by sand (you can do 1 inch dirt + 2 inches sand or 1.5 inches dirt + 1 inch sand) and then adding a bunch of plants will make a tank that needs less maintenance !! if you get the water parameters stable and have a good amount of plants and tiny creatures (worms crustaceans etc), then lots of fish (not all though) will be healthy and can mind their own better !! it's a balance ofc but once you strike it suddenly you can go a month without looking at it and nothing changes. life is beautiful

anyway thats!!! it. i love you <3

#fuck this is a lot of words#fishblr#fishkeeping#beginner fishkeeping#i could talk about this literally all day so if anyone wants me to elaborate: hiiiiiiii

47 notes

·

View notes

Note

Got it in one!

I was just thinking about how Lapis first communicated with Steven when she was still in the mirror

and I started stringing together like

What if, after the flare, Desmond ended up not in the Grey as the Reader

but like, in the mesh of POEs connecting them to the Grey

Which, exists somewhat out of the flow of time

and that in that mesh, he registered not as a user, existing where he shouldn't, or as a target, but as another piece of the machinery

Essentially, there's no inherent intelligences to the Apples

they could store and project ideas, orders, knowledge

but they don't *decide* things

they don't withhold information or toy with their users

there needs to be a mind to do that

Often in human history, that mind was Juno

but now, it's Desmond.

Desmond wasn't made for this. He's not Isu; the only POE he's used were modified to work specifically for him. Not to mention he *died* right before this, so he's not in the best shape when he gets tangled in the Eden network, not in the position to be making decisions. The network scans him in as equipment and makes use of him as such.

The Apples aren't made to make decisions? Well, now they are. There's a conveniently delivered brain pattern to use for interpreting questions and what relevant information to deliver. The brain is half fried and doesn't want to be doing this? Too bad.

Desmond's not even really conscious at first. Not really *Desmond.* And when he is...it's like being a long way under dark water. He can feel his legs kicking, his arms thrashing. But he can't see a surface. He can feels waves rolling him one direction and then another, but he doesn't know which way is up.

Until one day, like a shaft of sunlight piercing the depths, showing him the shape of his cage, Desmond hears a voice he recognizes: Altaïr.

Continuation of the ask:

....I don't know if I built it up right but.

Yeah Desmond gets brought up, more conscious, more aware when his ancestors interact with the Apples.

But the trouble is, even though he's more aware, he's still part of the Eden mesh. He's part of the machinery, the network, boxed in by operation parameters that he doesn't know how to break out of. Altaïr asks the Apple for knowledge, and he can feel the machinery at work, his brain co-opted for processing, sorting information to spit back out. It's overwhelming, burning, it hurts, he's left spinning and nauseous except he hasn't got a body, he doesn't even have the relief of letting it out.

It costs him more than he can say, to impose his will on the Apple. He knows what the target--Altaïr, not the target, it's Altaïr--is asking, knows which answers the use--*not* the user, Juno is not using him to influence his ancestors, he won't let her--wants him to give, to influence and entice. And giving something else leaves him reeling with pain, sends him back into that dark ocean for who knows how long.

But he claws his way back up. And he does it again, and again, and again, trying to to help, trying to tell Altaïr what he really needs to know (trying to say I'm here, I'm here, please, PLEASE)

And it took a while, too long as far as Desmond was concerned, before he could feel that Altaïr had noticed something.

And it had started so small that even Desmond didn’t realize it at first.

Altaïr’s voice had grown softer when he ordered the Apple to show him something. His question had become vaguer, giving Desmond more leeway on how to interpret the question, and lessen the pain he goes thru as he adds more than what Altaïr requested.

They cannot truly communicate with one another and Altaïr was cautious, understanding that the artifact in his hand had a hand in Al Mualim’s fall from grace (or perhaps it had simply shown the truth that Altaïr had not seen… had not wanted to see) so there was always this worry that this was simply another way for the artifact to get a hold of him.

He started testing his theory, asking vague questions to see how the Apple would react to it.

That was how he heard it.

The same voice he thought he had imagined back when Abbas had used the Apple during Al Mualim’s wake.

The same voice he had tried to reason was part of the mob back in Cyprus.

The voice that kept telling him, “I’m here, I’m here, please… please…”

Altaïr was sure it had come from the Apple itself.

The question was if the voice itself was truly begging for help or was this another one of the Apple’s tricks, trying to appeal to him.

He kept it a secret, both because he did not want to worry anyone and also because there was something inside him that could not help but wish to not share this.

A desire to find out the truth all on his own.

It was a selfish one, perhaps, but it was a desire so deep that he dared not go against it.

Not yet, anyway.

So he started to study the Apple more.

Questions such as “who are you?” seemed to hurt it for some reason, the Apple vibrating and heating in his hands until he could no longer hold it in fear of burning his palms. It would always show a vaguely humanoid shape created with golden dust that would scatter and fall if Altaïr attempt to touch it.

Altaïr noted them as the forbidden questions and tried to stir clear from them.

Vague questions work best.

“What should I focus on for now?” would show him a glimpse of an armor for a moment before it would shake, as if someone was trying to pull it away. That someone… would always take the same humanoid shape made of golden dust.

Someone Altaïr could only see from the corner of his eyes.

After that, he would receive a new vision, sometimes quite blurry that Altaïr wasn’t sure what he was supposed to be seeing. Sometimes, clear enough that Altaïr would be left frozen for just a moment because…

Because they were always warnings.

Abbas’ growing hatred and jealousy, fueled by the truth Altaïr had given him that he did not wish to believe and twisted by the tantalizing power he had as he held the Apple for a few moments all those years back…

Rauf’s future illness that would take his life decades from now. One that needed a specific medicine that was not available during this time yet could be created, Altaïr had the time and the procedures to make it now…

A sword glowing the same golden light as the Apple in the hands of a dangerous man he does not know yet…

Altaïr noticed the Apple tend to focus on Abbas a lot whenever he asked “What should I be worried about?” or “What should I be careful of” and a part of him, that part that was young and childish and still believed that their friendship could be fixed, wanted to believe that the Apple simply did not wish to have Abbas as its master once more.

But… he could sense it.

After being in the presence of the voice that continues to beg him to acknowledge his existence, he could hear the urgency and fear.

Not for itself…

But for Altaïr.

For his family.

So when it had shown him a… memory? A vision?

A possible future?

To see his face marred with wrinkles and greying hair…

To hear his own voice speak of Sef’s death in the hands of Abbas’ men…

He could not dismiss it.

So he asks the Apple…

“How… how can I save my son?”

And the Apple shuddered.

No.

It was vibrating.

It grew hot.

It was happening once more.

Altaïr had asked a forbidden question.

Yet, he held the Apple.

The burning pain was bearable if it meant he could save Sef.

He could feel it traveling across his right arm, enveloping it in heat that threatened to burn him from the inside.

Until finally…

Everything went dark.

At first, Altaïr had assumed he had lost consciousness.

Then he saw the golden dust by his feet, forming a trail that Altaïr knew he must follow.

So he follows.

Deeper and deeper into the darkness…

No.

It was no longer the darkness.

It had turned grey.

And the ground he was walking on began to play…

Memories?

Visions?

Altaïr wasn’t sure how he knew but he was sure…

They were visions of the future…

Of men and women who followed the Creed just as him, brothers and sisters who fought to defend mankind and free will.

So he continued to follow it…

Until he reached what might be the end.

Or perhaps the beginning.

Maybe even the middle of this endless grey.

A tree made of gears and golden metal, forever turning and moving as its very roots stretched all over.

And, in the middle of this machine…

Was a man with eyes glowing like the sun…

Surrounded by gears threatening to envelop him whole.

As Altaïr watched, he could see the way the gears continue to dig to his flesh, pushing him deeper and deeper into the metallic golden tree.

Altaïr wasn’t sure if he was making the right choice.

He wasn’t even sure if he should do such a thing.

The man wasn’t moving, his face still like a sculpture with eyes vacant and without life.

Yet, Altaïr swore he heard him even though his mouth remained close.

“Altaïr…”

His name…

Spoken in the same voice as the one he had been hearing from the Apple for so long.

So he grabbed him and pulled.

The gears began to dig into his skin as well and Altaïr gritted his teeth as he felt the power of countless artifacts just like his Apple begin to assault his senses.

Ordering him to stop.

Or to join the man.

But Altaïr was nothing if not stubborn.

A persistent stubborn idiot as Malik would sometimes call him if he believed Altaïr was doing something futile.

And, every time Malik believed it would be futile, Altaïr would still find a way to succeed.

And this…

This would be no different.

He is, after all…

A persistent stubborn idiot.

When he comes to, he is back in his office, laying on his back on the floor. His entire body aches and he felt stinging pain from where he remembered the gears have dug into his skin.

He could not feel any gears though which he would count as a good thing.

He could still feel the burning pain on his right arm though but it was now a pleasant warmth.

The warmth of a person’s hand entwined with his.

Altaïr blinked.

Then he turned his head to look to his right…

And he saw the man in his vision lying next to him, eyes closed but breathing.

Oh.

……… How was he supposed to explain this to Maria and Malik?

#short fic#i guess?#i didn’t specify sef’s age#so you can pick which year this is happening#(aka do you want young dilf!altaïr or sugar daddy vibes older altaïr)#i’m unsure if the plan is to keep desmond stuck#but you gave me altaïr and my otp heart immediately went#altdes#is it altdes time?#it’s altdes time!#to be fair#this could be generic#but it’s me#soooo#no usual tags#ask and answer

38 notes

·

View notes

Text

Studying combustion and fire safety

Research on the International Space Station is helping scientists to understand how fire spreads and behaves in different environments and learn how to prevent and extinguish fires in space.

Combustion investigations contribute to the safety of crew members, equipment, and spacecraft by guiding selection of spacecraft cabin materials, improving understanding of fire growth, and identifying optimal fire suppression techniques. This research also contributes to fire safety on Earth and some studies improve our understanding of combustion for uses such as producing electricity and powering vehicles on the ground.

Microgravity dramatically influences flames and provides a unique environment for studying combustion. For example, on Earth, hot gases from a flame rise and gravity pulls cooler, denser air to the bottom of a flame, creating the classic shape and flickering effect. In microgravity, this flow doesn't occur and on the space station, low-momentum flames tend to be rounded or even spherical. By removing the effects of buoyancy, microgravity provides researchers a better understanding of specific flame behaviors.

The Combustion Integrated Rack (CIR), developed and operated by NASA's Glenn Research Center, provides a secure and safe environment for a wide range of combustion experiments. Different chamber inserts that enable a variety of investigations include the Multi-user Droplet Combustion Apparatus, which supported FLame Extinguishment Experiments (FLEX), the Advanced Combustion via Microgravity Experiments (ACME) insert, and the Solid Fuel Ignition and Extinction—Growth and Extinction Limit (SoFIE) chamber.

FLEX, which analyzed the effectiveness of fire suppressants, led to the discovery of a type of cool flame, where the fuel continued "burning" under certain conditions after extinction of the visible flame. Typical flames produce carbon dioxide and water, but cool flames produce carbon monoxide and formaldehyde. Learning more about the behavior of these chemically different flames could lead to the development of more-efficient, less-polluting vehicles. Cool flames produced on Earth quickly flicker out. Since they burn longer in microgravity, scientists have the opportunity to study them.

FLEX-2 looked at how quickly fuel droplets burn, the conditions required for soot to form, and how mixtures of liquid fuels evaporate before burning. Results could help make future spacecraft safer and increase fuel efficiency for engines using liquid fuel on Earth.

ACME is a set of six independent studies using the CIR to examine fuel efficiency and pollutant production in combustion on Earth. The series also looked at improving spacecraft fire prevention through a better understanding of materials flammability.

One ACME investigation, Flame Design, studied the quantity of soot produced under different flame conditions. Soot, the carbon residue left when carbon-containing material does not fully burn, causes environmental and health issues but is desirable for some purposes. Results could enable the design of flames with more or less soot, depending on the specific need, and may help create more efficient and less polluting designs for burning fuel.

ACME's Burning Rate Emulator (BRE) simulated the flammability of solid and liquid materials by burning gaseous fuels under specific conditions. Analysis of 59 BRE burn tests provided data on heat flow, flame size, effects of fuel mixture flow, and other important parameters. Results could improve the fundamental understanding of materials flammability and assess whether existing methods for testing flammability are effective in microgravity.

Burning and Suppression of Solids (BASS) was one of the first investigations to examine how to extinguish fuels burning in microgravity. Putting out fires in space must consider flame geometry, characteristics of the materials, and methods used to extinguish it, because methods used on the ground could be ineffective or even make the flame worse.

BASS-II examined the characteristics of a variety of fuel samples to see whether materials burn as well in microgravity as in normal gravity, given the right conditions. Several papers have reported results from BASS-II, with findings including the differences between flame spread and fuel regression and comparison of flame spread rates.

SoFIE-GEL analyzes how the temperature of a fuel affects material flammability. Researchers report that experiment observations agree with trends predicted by the models. This investigation, the first in a series, tested various fuels including flat sheets, thick slabs, cylinders, and spheres.

Saffire is a series of experiments conducted aboard uncrewed Cygnus cargo spacecraft after they depart the station, which makes it possible to test larger fires without putting crew members at risk. Results on flame spread in microgravity can be used to establish the rate of heat release in a spacecraft and show that reducing pressure slows down that spread.

Confined Combustion, sponsored by the ISS National Lab, examines flame spread in confined spaces of different shapes. Confinement affects fire characteristics and hazards. Researchers report specifics on interactions between a flame and its surrounding walls and the fate of the flame, such as growth or extinction. These results provide guidance for the design of structures, fire safety codes, and response in space and on Earth. Other results suggest that confinement can increase or decrease solid fuel flammability depending on conditions.

FLARE, an investigation sponsored by JAXA (Japan Aerospace Exploration Agency), also tests the flammability of materials in microgravity. Results could significantly improve fire safety on future missions.

Flame studies help keep crews in space safe. This research also could lead to more efficient combustion that reduces pollutants and produces more efficient flames for uses on Earth such as heating and transportation.

TOP IMAGE....Image of a flame burning one of the BASS tests on extinguishing burning fuels. Credit: NASA

LOWER IMAGE....A sample of fabric burns inside an uncrewed Cygnus cargo spacecraft for the Saffire-IV experiment. Credit: NASA

2 notes

·

View notes

Text

Mounting Press Machine (metallographic specimen mounting press)

Our automatic metallographic specimen mounting press, equipped with in-out water cooling system. These products are expertly developed using top-quality materials & contemporary techniques in accordance with the set norms of the industry. It is suitable for heat mounting thermo hardening & thermoplastic materials. After the parameters such as heating temperature, heat preserving time and applied force etc. are set up, put the mounting material into the machine, close the cover and press the start button, then the machine will finish the job automatically. The operator can change 4 specification patterns according to the difficult specimens. It can make 2 specimens at one time.

#manufacture#industrial equipment#manufacturer#metallurgical#metallographicequipments#specimen mounting machine#specimen mounting press#mounting press machine#mounting press#mounting#mounting machine manufacture in uttar pradesh#mounting machine specification#mounting press machine specification#specimen mounting machine supplier#specimen mounting machine manufacture#mounting machine supplier#mounting machine manufacture#mounting machine supplier in delhi#mounting machine manufacture in delhi#mounting machine supplier in india#mounting machine manufacture in india

1 note

·

View note

Text

Design and Application of the Automatic Instrument in Sewage Treatment

Reading guide: In the new era, water pollution is becoming more and more serious, especially urban and industrial sewage discharge continues to increase, leading to water pollution gradually serious. Our government pays more and more attention to the protection of water resources and takes a series of measures to strengthen the treatment of urban and industrial sewage, promote the sewage treatment process to achieve the best treatment effect, and the treatment equipment can operate normally and stably, thus putting forward higher requirements for automatic instruments in sewage treatment, and relevant enterprises must pay high attention.

Relevant personnel shall monitor the impurities and content parameters in the sewage and take corresponding measures to deal with the problem. At present, in the actual monitoring, because the impurity content of sewage has various and complex characteristics, the manual measurement method not only increases the work amount but also is difficult to achieve the goal of material composition measurement. The automatic instrument design can automatically measure sewage materials, provide accurate sewage material cost, and has been widely used in sewage treatment.

Importance of automatic instruments in sewage treatment

The continuity of sewage treatment is strong, the process is complex, the equipment is numerous, and the management is difficult. In order to achieve the safe and long-term operation of sewage treatment equipment and treatment process, it is necessary to scientifically manage the entire production process of sewage treatment. The important value of automatic control of sewage treatment in today's society is gradually emerging. In the whole process of modern sewage treatment, no matter what method is used, Many parameters of these processes need to be tested.

At this stage, many large-scale process sewage and domestic sewage treatment plants are equipped with automatic instruments such as online total phosphorus, online ammonia nitrogen, online COD, online BOD, redox potential, temperature, pH value, and liquid level difference. Through the use of these automatic instruments, various process parameters are detected, and they are transmitted to the DCS system and other upper computers. Through the upper computer, different process equipment in the process construction is scientifically and effectively controlled, Coordinate the relationship between sewage treatment processes, supply, and demand, and promotes the full and reasonable utilization of different facilities and equipment. At the same time, some important process parameters in the design and application of automatic instruments, such as the measurement accuracy of aeration rate and dissolved oxygen value, are the preconditions for ensuring automatic control.

The measured values of these instruments can automatically control and adjust the process equipment and effectively guide the sewage treatment process. In addition, the automation instrument and DCS system, and other upper computers, can alarm the process in real-time to ensure the safety of equipment and production. It can be seen that the automation instrument plays a very important role in the sewage treatment process.

Importance of automatic instruments in sewage treatment

Specific applications of automatic instruments in sewage treatment

Application of temperature instrument in sewage treatment

Generally, an anaerobic digestion process is required in the process of sewage treatment. This process requires dynamic monitoring with temperature instruments and pressure instruments. The purpose is to facilitate the staff to properly adjust the anaerobic digestion conditions in combination with their dynamics, so as to obtain the best effect. In the application process of temperature instruments, the most commonly used thermal element is a platinum thermistor. However, considering the small number of temperature control points of the platinum thermistor, it is usually necessary to use it together with the temperature transmitter. Through the comprehensive application of the two, the thermal signal can be converted into an electrical signal of 4~20mA, and then connected to the analog module of the electrical signal, so that the data can be extracted and the entire processing process can be simplified.

Application of flow meter in sewage treatment

In sewage treatment, flow meters play a very important role, mainly in the detection of sewage volume, sewage return flow, aeration volume, and other parameters, providing a detailed and reliable basis for the control of sewage treatment operating conditions. At the same time, the flow meter can also reasonably judge the operation of the equipment in sewage treatment. At present, the flow meters in sewage treatment mainly include ultrasonic flowmeters, differential pressure flowmeters, and electromagnetic flowmeters. In the design stage, the most appropriate one should be selected according to the actual needs of the user to ensure the effectiveness of sewage treatment.

The flow meter used by a certain unit is an electromagnetic flowmeter. The working principle of the electromagnetic flowmeter is the electromagnetic induction principle. It measures the flow of the conductive fluid according to the induction electric magnetic field generated by the conductive fluid when the external magnetic field is applied. The characteristics of the flowmeter are that it is not affected by the change in fluid density, temperature, viscosity, and conductivity, and the induced electrical signal of the sensor has a linear relationship with the average flow rate. The measurement has high accuracy, and it is suitable for measuring the fluid with small particles in sewage treatment.

Application of flow meter in sewage treatment

Application of COD analyzer in sewage treatment

Chemical oxygen demand (COD) refers to the amount of strong oxidant required for sewage treatment per unit volume under certain conditions. It is an important part of the indicator system for measuring sewage treatment effects. It can also be used to measure the organic content in sewage. The greater the COD, the higher the organic content in sewage, and the more serious the water pollution. COD measuring instruments are divided into two types: spectrophotometry and electrochemical measurement.

The working principle of spectrophotometry for COD measurement is that when the mixed solution of the water sample, potassium dichromate, catalyst, and concentrated sulfuric acid is put into the digestion tank and heated to a certain temperature, the chromium ion is reduced from tetravalent to trivalent and the color of the liquid changes. The degree of discoloration is opposite to the organic content of the water sample, The instrument changes the COD value by comparing colors and changing colors. In addition, the COD analyzer is a kind of analytical instrument with high precision. Foreign countries are more mature in research, production, production, and technology. To ensure the accuracy of measurement, especially in the case of high process requirements, foreign products should be preferred.

When sewage treatment is carried out, it is necessary to strengthen the determination of the COD index, so as to continuously optimize the sewage treatment process and continuously improve the sewage treatment effect.

Application of ammonia nitrogen online monitor

At present, the methods commonly used for ammonia nitrogen online monitor monitoring in China are spectrophotometry and ammonia gas sensitive electrode method. The spectrophotometry is to mix ammonia in a water sample with potassium iodide and mercury iodide to form an alkaline mixed solution, produce a reddish brown colloidal solution through a chemical reaction, and measure it within the wavelength range of 410~424nm. At the same time, the main interference factor in the process of monitoring is the chemical substances that produce chromaticity and turbidity. In application, most ammonia nitrogen monitors use the ammonia gas-sensitive electrode method.

Application of dissolved oxygen meter in sewage treatment

Dissolved oxygen is closely related to the partial pressure of oxygen in the air, atmospheric pressure, and water temperature. If the dissolved oxygen in pure water is about 9mg/L at 20 ℃ and 100kPa, under the action of aerobic bacteria, the biodegradation of some organic compounds requires the consumption of dissolved oxygen in the water. It is calculated by organic carbon. According to the formula of C+O2=CO2, 12g carbon requires 32g oxygen. In addition, if the dissolved oxygen value in the water drops to 5mg/L, some fish will have difficulty breathing. Generally, there are two sources of dissolved oxygen: first, when the dissolved oxygen in water is not saturated, the oxygen in the atmosphere will seep into the water; Second, plants in water release oxygen through photosynthesis, and the dissolved oxygen in the water will be continuously supplemented with the oxygen dissolved in the air and the photosynthesis of green aquatic plants. However, if the water body is polluted by organic matter, the oxygen consumption is serious, and the dissolved oxygen cannot be supplemented in time, the anaerobic bacteria in the water body will be rapidly propagated, and the organic matter will cause the water body to become black and stinky due to corruption.

At the current stage, the three most widely used methods in sewage treatment are aerobic anaerobic microbial treatment, activated sludge treatment, and biofilm treatment. The content of dissolved oxygen in water plays a decisive role in whether microorganisms can survive in water. Therefore, it is necessary to ensure that there is enough dissolved oxygen in the water to support the activity of microorganisms. The dissolved oxygen meter plays a very important role in dissolution monitoring, The aeration rate can be well adjusted, and the problem of sludge filament bulking in the application of the activated sludge method can also be effectively avoided. Generally, a dissolved oxygen meter is composed of a sensor and a transmitter. Dissolved oxygen sensor includes two types of sensors: coated electrode and filmless electrode, which are both composed of a cathode, anode, and electrolyte. In the specific application, the relevant staff should scientifically and effectively set the installation position of the dissolved oxygen meter according to the actual situation of the sewage and the construction site to effectively avoid electrode scaling and pollution, so as to give full play to the use effect of the dissolved oxygen meter.

Application of dissolved oxygen meter in sewage treatment

Matters need attention in the design of the sewage treatment automation instrument

In the process of applying automatic instruments to sewage treatment, it is very easy to attach some impurities contained in sewage to the surface of the automatic instruments. If this is not handled in the long run, it will have a serious impact on the operation stability of the automatic instruments, thus damaging the accuracy of the instrument detection and measurement data. In the process of automatic instrument design, the problem of instrument cleaning must be solved. First of all, set the automation instrument at a position convenient for disassembly, and the staff can adjust the instrument according to the actual situation. Secondly, scientific and reasonable maintenance measures shall be formulated in combination with the working place and working environment of the automation instrument to make it operate stably for a long time.

Conclusion

To sum up, the automatic instrument plays a crucial role in the sewage treatment process. It is the basic part of the computer and automatic control, which can greatly reduce the workload and improve production efficiency. Relevant enterprises shall select appropriate automation instruments based on the actual situation and design automation instrument systems more perfectly to ensure their reasonable application.

Recourses from https://www.supmeaflow.com/

2 notes

·

View notes

Text

All about SUBSEA insulation or wet thermal insulation

The petroleum industry produces hydrocarbon, which becomes difficult to develop by the use of an offshore platform, through the subsea production system (SPS). SPS is known to be an economical way to bring hydrocarbons to the surface.

What is the petroleum industry?

The petroleum industry is known to be one of the largest industries in the world, where oil and gas are the primary products produced by the industry. The industry has divided into several sectors, the upstream, i.e. E & P sectors are responsible for the exploration and production of oil and gas.

Oil companies use sophisticated techniques and/or discover the latest technologies to find the oil reserves continuously to expand and grow their oil and gas production. For the search for new oil reservoirs, the E & P sector is shifting to ultra-deep water for its operation which explores the reservoirs at more depth and with higher pressures and temperatures than before.

Where the Underwater or Subsea Insulation is used?

To resist such a high pressure and temperature the industry has developed the wet thermal insulation system, which in time, increased its demand. The wet insulation insulates equipment from high pressure and/or high temperature and the architectures used in the subsea production system, include;

PLET

FLET

PLEMs

Flowlines

Risers

Umbilical

The purpose of insulation in the subsea

The purpose of using the subsea or underwater insulation system is one or more of the following:

Reduce the rate of heat transfer in the pipeline

Maintain the temperature

Assure the flow of fluid from the reservoir to land

Help in preserving the production system’s operational integrity

Who carries out the wet insulation work

Subsea insulation has many parameters and requirements that differentiate them from a normal conventional insulation system. The insulation system requires sophisticated machines and tools and a skilled workforce to carry out the activities like insulation application, inspection, and quality control.

There are subcontractors (or application contractors) who have specialized tools and trained/experienced workforces to carry out the application of the wet thermal insulation system. Oil companies often hire such a contractor for their subsea projects to apply insulation to piping and equipment.

Inspection and testing requirements

The subsea insulation work is carried out at multiple stages and every stage requires inspection and quality control to ensure specification compliance, the oil companies assign a quality controller or quality control inspector to witness the inspection and quality control activities carried out by the application contractor.

The down part here is that there are only a few inspectors who received the subsea insulation training and/or are familiar with the application requirements, inspection parameters, acceptance criteria, and the like.

If the assigned inspector is not skilled enough with the subsea insulation systems there is the possibility that the application contractor does the malpractice and the assigned inspector on behalf of the client accept the work blindly which could lead to an undesirable result or poor quality work.

The catastrophic issues that are associated with an item that was poorly insulated are wax deposition and wax gelation which blocks the pipeline and makes it unusable.

Insulation Inspector Courses Available

A quality control inspector with IOGS Level 3 Insulation Inspector qualification performs inspection and quality control tasks professionally and independently, inspect, monitor, and evaluate insulation work at every stage to ensure compliance with the applicable standard and specification, and collect all valuable data to report systematically to a higher authority.

Due to the current pandemic scenario, and the trends, we are now offering the IOGS level 3 course virtually that allows you to complete it from your work or home. For more details about the Insulation inspector IOGS level 3 course, you can visit www.iogs.org or click the link below.

Offshore — Subsea Work — How to Apply GSPU Thermal Insulation on SUBSEA Pipeline

#quality control#inspection#online courses#onlinetraining#quality#quality inspector#skilldevelopment#skills#training#courses#qualification#safety#quality of life#qc#qaqc#refinery#fireproofing#fire protection#oil and gas refining#oil&gas#oil and gas industry#oil industry#oil and gas#insulation#thermal insulation#zoom#jobposting#jobhunt#knowledge#heat transfer

2 notes

·

View notes

Text

Tanker Truck Guide: Mastering Operations and Logistics

The versatility of DEF tankers

Diesel exhaust fluid (DEF) tanks are a key part of the modern transportation environment, especially with increasing environmental regulations. DEF, a non-toxic solution composed of urea and deionized water, is used to reduce harmful emissions from diesel engines. DEF tankers are designed to safely transport this sensitive liquid while maintaining its purity and efficiency.

Custom Propane Carts: Safety and Efficiency

Propane, a widely used fuel source for heating, cooking and even as a vehicle fuel, requires specialized transportation due to its flammability. Custom propane tankers are designed with strict safety features for handling this volatile substance. These trucks are equipped with robust safety mechanisms, including pressure relief valves, emergency shut-off systems, and high-strength materials that withstand the pressures of compressed gas transportation.

Customization options for propane trucks include different tank sizes, configurations, and delivery systems. For example, some custom propane trucks are equipped with metering systems that allow accurate measurement of fuel dispensed and ensure accuracy of delivery and billing.

The importance of customization in tanker trucks

Customization for tanker trucks goes beyond simply meeting regulatory standards; it is about increasing operational efficiency, safety and reliability. Each industry has specific needs that cannot be fully met by commonly supplied solutions. Custom tankers are designed with the end user in mind, taking into account factors such as load capacity, terrain, climate and the nature of the substance being transported.

For example, a DEF tank operating in a cold climate may need advanced heating systems to prevent the liquid from freezing, while a propane truck in a hot environment may require special insulation to maintain safety. Customization ensures that these carts not only fit, but are optimized to perform in their specific roles.

Creating custom tanks involves a collaborative process between manufacturers and clients. It starts with understanding the specific needs and challenges the client faces. This may include site visits, consultations and detailed discussions about the operating environment, regulatory requirements and required functionality.

Once the requirements are clear, teams of designers and engineers get to work creating detailed plans and models of the custom tank. Advanced computer-aided design (CAD) software is often used to simulate various aspects of tank performance and ensure that the final product will meet all specifications and standards.

The manufacturing process involves precision engineering and high-quality materials for the construction of the tank. Whether it’s a DEF tank truck or a custom propane truck, the emphasis is on durability, safety, and functionality. Rigorous testing is performed to ensure that the tank can withstand the demands of its intended use, including pressure tests, leak tests and performance evaluations under various conditions.

As the industry evolves and new challenges arise, the demand for more advanced and specialized tankers is expected to grow. Innovations in materials are likely to increase the efficiency and durability of these trucks. Additionally, advances in automation and smart technologies could lead to more sophisticated monitoring and control systems that would improve safety and operational efficiency.

For example, the integration of IoT (Internet of Things) technologies into custom tanks could provide real-time data on various parameters such as pressure, temperature and liquid levels. This can help operators monitor and manage tanks more effectively, reduce the risk of accidents and improve overall efficiency.

Conclusion

Custom tankers, including DEF tanks and custom propane trucks, play a vital role in a variety of industries by providing customized solutions for the transportation and storage of liquids and gasses. The customization process ensures that these tanks meet specific needs, increasing safety, efficiency and reliability. As technology advances, the future of custom tankers looks promising, with innovations to further improve their performance and capabilities. Whether for DEF, propane or other substances, custom tanker trucks will continue to be an indispensable asset in the logistics and transportation industries.

0 notes

Text

How To Build A Concrete Batch Plant Step By Step

Want to know how to build a concrete batch plant, we need to understand the whole process first, including what formalities are required, what is the process of building the concrete batch plant, what matters need to be paid attention to, what are the requirements, and what is the overall investment cost. These are the early understanding of the how to build a concrete batch plant, but also some of the questions that users often ask.

The whole process of how to build a concrete batch plant, including site selection, planning, construction, equipment purchase and other aspects, the following is a basic process:

1, Pre-planning and design:

Determine the size of the mixing plant, capacity, equipment selection, etc..

According to the site selection for site planning and layout, including site leveling, road paving, drainage system, power system, etc..

Design the production flow of the concrete mixing plant, including feeding, batching, mixing, discharging, etc.

2, Equipment procurement and installation:

Procure the core equipment of the concrete batching plant, such as mixing host, material weighing system, material conveying system, water supply system, etc.

According to the size and weight of the equipment, formulate an installation plan, use car cranes and other equipment to lift the pillars, main engine, cement tanks, belts and other components to ensure that each piece of equipment is installed in place.

3, Infrastructure construction:

Carry out foundation excavation according to the planning requirements, reinforce the foundation, and carry out bearing capacity test and inspection to ensure the stability of the foundation.

The foundation of the mixing machine is discharged, reinforcing bars are made, formwork is installed, concrete is poured, and ground bolts are pre-buried, and other processes are carried out.

After completion of pouring, carry out maintenance to ensure that the concrete reaches the design strength before dismantling the mold.

4, Equipment commissioning and test run:

After the equipment installation is completed, carry out debugging and trial operation to ensure that the equipment operates normally and the systems work in a coordinated manner.

During the commissioning process, pay attention to checking the parameters such as metering precision and mixing time to ensure that the process requirements are met.

5, Environmental protection and safety measures:

Install dust removal equipment to collect and dispose of the dust generated during the mixing process to protect the environment.

Equipped with necessary safety facilities, such as guardrails, warning signs, etc., to ensure safety in the production process.

6, Personnel training and operation:

Train the operators to familiarize them with the operation, maintenance and repair methods of the equipment.

Formulate operation regulations and safety production system to ensure standardized operation and safe production in the production process.

7, Operation and Maintenance:

During the operation of the concrete batch plant, regular maintenance and repair of the equipment is carried out to ensure the normal operation of the equipment.

Regular inspection and maintenance of equipment, timely detection and treatment of equipment failure.

8, Optimization and improvement:

According to the actual situation in the production process, optimize and improve the concrete batch plant to improve production efficiency and product quality.

Introduce new technology and new equipment to improve the automation level and intelligentization level of the mixing plant.

The above are the basic steps of how to build a concrete batch plant, and the specific steps may vary according to the actual situation. In actual operation, it should be adjusted and optimized according to the specific situation.

This resource is from http://www.batchingplantng.com/haomei-news/how-to-build-a-concrete-batch-plant.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes

Text

The Ultimate Guide to Hanna Salinity Meters: Working and Benefits of Use

Salinity is a critical parameter in various fields, including aquaculture, environmental monitoring, and water treatment. Accurate measurement of salinity is essential for maintaining the health of aquatic organisms and ensuring the quality of water. The Hanna Salinity Meter, a product of Hanna Instruments, provides precise and reliable salinity measurements. In this blog, we will explore how the Hanna Salinity Meter works and the benefits it offers.

What is a Hanna Salinity Meter?

The Hanna Salinity Meter is an advanced instrument designed to measure the salt concentration in a solution. Known for its precision and ease of use, this device is widely used in laboratories, aquariums, and industrial applications. Hanna Instruments, the manufacturer, is renowned for producing high-quality scientific instruments, and their salinity meter are no exception.

How Does a Hanna Salinity Meter Work?

Understanding the working mechanism of a Hanna Salinity Meter can help users make the most of this sophisticated device. Here’s a step-by-step explanation of how it operates:

Calibration: To ensure accuracy, the Hanna Salinity Meter needs to be calibrated using a standard solution. This step is crucial for obtaining reliable readings.

Immersion of Probe: The probe of the salinity meter is immersed in the solution to be tested. The probe is sensitive to the electrical conductivity of the solution, which is directly related to its salinity.

Measurement: The meter measures the electrical conductivity of the solution. Since salt ions in the water conduct electricity, the conductivity measurement can be converted into a salinity reading.

Temperature Compensation: Hanna Salinity Meters are equipped with automatic temperature compensation. This feature adjusts the salinity reading based on the temperature of the solution, ensuring accurate results.

Display of Results: The salinity value is displayed on the meter’s digital screen, providing a clear and easy-to-read measurement.

Benefits of Using a Hanna Salinity Meter

Investing in a Hanna Salinity Meter comes with several advantages that make it a valuable tool for professionals and hobbyists alike:

High Accuracy: Hanna Instruments salinity meters are known for their precision. They provide accurate and consistent readings, which are crucial for maintaining optimal conditions in various applications.

Durability and Reliability: These meters are built to last. Their robust design ensures they can withstand rigorous use in different environments without compromising accuracy.

Ease of Use: The user-friendly interface and straightforward calibration process make these meters accessible to both professionals and beginners. The clear digital display simplifies the reading process.

Versatility: Hanna Salinity Meters are suitable for a wide range of applications. Whether you are monitoring salinity in an aquarium, conducting environmental research, or managing water treatment processes, these meters deliver consistent performance.

Cost-Effective: Considering their features and durability, Hanna Salinity Meter prices are competitive. They offer great value for money, making them a cost-effective solution for salinity measurement needs.

Applications of Hanna Salinity Meters

Hanna Salinity Meters are utilized in various industries and applications due to their versatility and reliability:

Aquaculture: Maintaining the right salinity levels is crucial for the health of aquatic organisms. Hanna Salinity Meters help in ensuring optimal conditions in fish farms and aquariums.

Environmental Monitoring: Scientists use these meters to monitor salinity levels in natural water bodies, aiding in environmental conservation efforts.

Water Treatment: In water treatment facilities, accurate salinity measurement is essential for ensuring water quality and compliance with standards.

Food and Beverage: Salinity is a critical parameter in the production of certain food and beverage products. Hanna Salinity Meters help in maintaining quality and safety standards.

Education: These meters are excellent educational tools, allowing students to conduct experiments and learn about salinity measurement.

Conclusion

The Hanna Salinity Meter is an indispensable tool for anyone needing accurate salinity measurements. Its reliability, ease of use, and versatility make it a preferred choice across various fields. Whether you are concerned with the salinity of water in aquaculture, environmental monitoring, or industrial applications, investing in a Hanna Salinity Meter ensures that you have a precise and dependable instrument at your disposal.

By understanding how a Hanna Salinity Meter works and recognizing its benefits, you can better appreciate its role in your specific applications. So, if you are in the market for a salinity meter, consider the trusted quality of Hanna Instruments.

0 notes

Text

Unleashing the Dominance of CFR's F1/F2 Octane Rating Unit

The CFR® F1/F2 Octane Rating Unit revolutionizes fuel testing, setting benchmarks for precision, dependability, and simplicity. Since the first CFR octane rating engines in 1929, this standard has become vital for the automotive and petroleum sectors. Explore the features and benefits that position CFR's Octane Rating Unit as a leader in fuel testing.

Setting the Standard: CFR F1/F2 Octane Rating Engines

CFR F1/F2 octane rating engines serve as benchmarks for testing fuels according to ASTM D2699, D2700, IP 236, and IP 237. These engines have delivered reliable data for research octane number and motor octane number assessments for decades.

Confidence in a Fully Integrated Fuel Testing System

A complete CFR octane fuel testing system includes the Engine Air Control System, the F1/F2 octane rating engine, XCP™ Technology, and a CFR® exhaust surge tank. This system ensures control over critical parameters, allowing users to focus on their work without system distractions.

Data Integrity with XCP Technology

XCP Technology enhances data integrity by automatically capturing essential information for each rating. The XCP Digital Control Panel generates user-friendly Excel-based reports, reducing manual recording errors. These reports include KI values, Octane Numbers, environmental data, and KI vs. fuel level curves. The XCP integrates seamlessly into a Laboratory Information Management System (LIMS), ensuring accurate data capture and processing.

Reliability of Proven Design

Since 1929, CFR Engines Inc. products have proven reliable for thousands of users. Continuous upgrades, like the robust engine crankcase and cylinder/head, ensure long operating life. With routine maintenance, CFR octane rating engines meet the rigorous demands of modern fuel testing.

Precision through Modern Instrument Control

The CFR F1/F2 Octane Rating Unit, equipped with XCP Technology, uses digital instrumentation to record and process critical aspects of operation and performance. On-board barometric pressure adjustments, increased automation, a broad octane meter range, and precise control of engine intake air enhance overall precision.

Cost Savings with One System Flexibility

The CFR F1/F2 Octane Rating System offers unmatched flexibility and cost savings. Users can switch between any of the four test procedures in ASTM Methods D2699 or D2700 with simple component changes and push-button control. This versatility optimizes resources, speeds test transitions, reduces operator training, and enhances repeatability.

Other Important Features that Set CFR Apart

XCP integrated safety monitoring system: Provides shutdown protection in case of power loss, low oil pressure, overheating, or electrical overload.

User-friendly touch-screen HMI panel: Simplifies unit operation and octane rating tests.

Built-in prompts: Guide operators through test procedures, ensuring consistency.

Thermal siphon cooling condenser: Maintains constant cylinder jacket water temperature.

Digital knock meter: Displays actual knock intensity value, eliminating visual interpretation.

Electronic maintenance log: Documents vital maintenance information.

Non-contact laser sensor: Accurately measures cylinder height.

Synchronous/reluctance motor: Provides power for starting and absorbs engine output.

Electronic on-board barometer: Automatically corrects cylinder height for barometric pressure changes.

Environmentally friendly RTDs: Manage critical temperature variables.

Built-in diagnostic feature: Allows troubleshooting of the octane rating unit.

On-screen operations and maintenance manuals: Ensure easy access to essential information.

Experience the Future of Fuel Testing

CFR commits to innovation and excellence in fuel testing and development. Ongoing research and development ensure our products evolve to meet the changing needs of the automotive and petroleum industries.

Unmatched Support and Service

Choosing CFR means accessing a world-class support and service network. Our team of experts assists with installation, training, maintenance, and technical inquiries, ensuring your success.

Join the CFR Revolution

Join industry leaders who trust CFR for their octane rating needs. The F1/F2 Octane Rating Unit with XCP Technology is a game-changer. Experience precision, reliability, and ease of use like never before.

Contact CFR Today

Elevate your fuel testing capabilities. Contact CFR to learn more about our products, request a demonstration, or get a quote. Together, we drive the future of automotive excellence.

0 notes

Text

A water testing lab in Dubai plays a crucial role in ensuring the safety and quality of water for residential, commercial, and industrial use. These labs are equipped with state-of-the-art technology to analyze various water parameters, including chemical composition, microbiological contaminants, and physical properties.

0 notes

Text

Why HVAC Testing, Adjusting & Balancing is Crucial for Your Building's Health

A well-functioning HVAC system is vital for maintaining a comfortable and healthy indoor environment. However, even the most advanced HVAC system can operate inefficiently if not properly tested, adjusted, and balanced (TAB). Regular HVAC testing adjusting and balancing by qualified professionals like HVAC consultants or companies offering HVAC air balancing & water balancing services is an investment that pays off in numerous ways.

What is HVAC Testing, Adjusting & Balancing (TAB)?

HVAC TAB is a systematic process that ensures your HVAC system performs at its peak efficiency. Here's a breakdown of the key steps:

Testing: Specialized instruments are used to measure various parameters like air flow rates, temperatures, pressures, and vibration levels. This data provides a clear picture of the system's current performance.

Adjusting: Based on the test results, technicians meticulously adjust components like dampers, valves, and fan speeds. This fine-tuning optimizes airflow and ensures proper delivery of conditioned air throughout the building.

Balancing: The final stage involves meticulously balancing the system to achieve uniform air and water flow across all conditioned spaces. This ensures everyone in the building experiences optimal comfort levels.

Benefits of Regular HVAC TAB:

Investing in regular HVAC TAB offers a multitude of benefits for building owners and occupants:

Enhanced Comfort: A balanced system delivers consistent temperatures throughout the building, eliminating hot and cold spots. This translates to a more comfortable and productive environment for occupants.

Improved Indoor Air Quality: Proper airflow helps prevent stagnant air and promotes better distribution of fresh air. This can significantly enhance indoor air quality and reduce the risk of respiratory problems.

Reduced Energy Consumption: An unbalanced system can overwork to compensate for inefficiencies, leading to higher energy bills. Regular TAB ensures optimal performance, minimizing energy consumption and lowering operational costs.

Extended Equipment Life: Balanced operation reduces stress on HVAC components, leading to extended equipment life and minimizing the need for costly repairs and replacements.

Reduced Maintenance Costs: A well-maintained and balanced system requires less frequent maintenance, saving money on technician visits and parts replacement.

Who Should Perform HVAC TAB?

HVAC TAB is a specialized task best left to qualified professionals. Look for experienced HVAC consultants or companies offering dedicated HVAC air balancing & water balancing services. These professionals possess the necessary expertise, equipment, and certifications to conduct thorough TAB procedures.

When to Schedule HVAC TAB:

There are several instances when HVAC TAB is crucial:

New Construction or Major Renovations: After installation, a new HVAC system requires TAB to ensure it functions as per design specifications.

Existing Buildings: Regular TAB (typically every 1-3 years) is essential to maintain optimal performance and identify potential issues before they escalate.

Reduced Comfort Levels or Uneven Temperatures: If occupants experience discomfort or inconsistent temperatures, TAB can diagnose and rectify airflow imbalances.

Increased Energy Bills: A sudden spike in energy consumption could indicate an unbalanced system. TAB can help identify the cause and improve efficiency.

For comprehensive HVAC testing adjusting and balancing services, consider a reputable company like Aerosys HVAC Solutions. With their team of experienced technicians and cutting-edge equipment, Aerosys can ensure your HVAC system operates efficiently and delivers optimal comfort for years to come. Regular TAB not only saves money but also promotes a healthier and more productive environment for everyone in your building.

So, breathe easy and schedule your HVAC TAB appointment today!

#chiller plant optimization companies in india#hvac consultants in india#hvac system audit companies in india#aerosys hvac

0 notes

Text

Modern Tomato Paste Manufacturing Company is Ready to Supply Tomato Paste That Carries Authentic Flavor of Tomatoes!

Tomatoes are one of the favorite fruits of people from around the world and scientifically known as solanum lycopersicum. This fruit originating from South America, has journeyed through the history to become a staple in the world of cuisines. These fruits come in a wide range of sizes, colors and shapes. The versatility of it is unmatched in kitchens; tomatoes are used in many ways such as salads, soups and sauces. The fruit have benefits in health ranging from promoting heart health to reducing the risk of certain cancers. In addition to the culinary and nutritional significance, they hold a symbolic and cultural importance in many societies.

Uses automated system and high end equipments

Modern tomato paste manufacturing company plays a vital role in the food supply chain. They serve as an essential and a versatile ingredient that enriches the taste and nutrition of countless dishes around the world. The company continues to shape the future of food production and consumption through sustainability, quality and innovation. The modern manufacturing company employs state of the art equipment such as evaporators, pulpers and heat exchangers to streamline the process of production and to maximize the efficiency. With the help of automated systems various parameters are monitored such as pH levels, viscosity and temperature and this helps to ensure quality and consistency in the final product.

Modern Tomato Paste Manufacturing Company

Quality comes first for them

Quality control is the top priority of the company, with rigorous testing that are conducted at every stage of the production to maintain product safety and integrity. Tomato paste factory China uses samples and is analyzed for texture, color, flavor and microbial content to meet stringent food safety standards and regulatory requirements. The factory also focuses on sustainability by implementing eco friendly practices such as water recycling systems and waste reduction to minimize environmental impact. With the help international distributors and logistics providers they ensure timely delivery to retail stores and industrial clients across the globe.

#Modern Tomato Paste Manufacturing Company#Tomato Paste Factory China#Good Quality Canned Tomatoes#Tomato Hot Pot Base#Tomato Paste in Sachet

0 notes